Preparation method for composite positive electrode material of lithium battery

A composite material and lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as inevitable product loss, achieve product loss, enhance conductivity and electrochemical reaction performance, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] A kind of TiO 2 LiFePO co-coated with nitrogen-doped carbon 4 The preparation method of composite lithium ion battery cathode material, the steps are as follows:

[0019] Step 1, the LiFePO 4 , tetrabutyl titanate, and dopamine were ultrasonically dispersed in isopropanol at a mass ratio of 9:0.5:0.5, and the reaction solution was stirred at room temperature for 6 hours.

[0020] Step 2, drying the product obtained in step 1 at room temperature overnight, grinding for 20 minutes, calcining at 600°C for 6 hours under an argon atmosphere, and then naturally cooling to room temperature to obtain the final product.

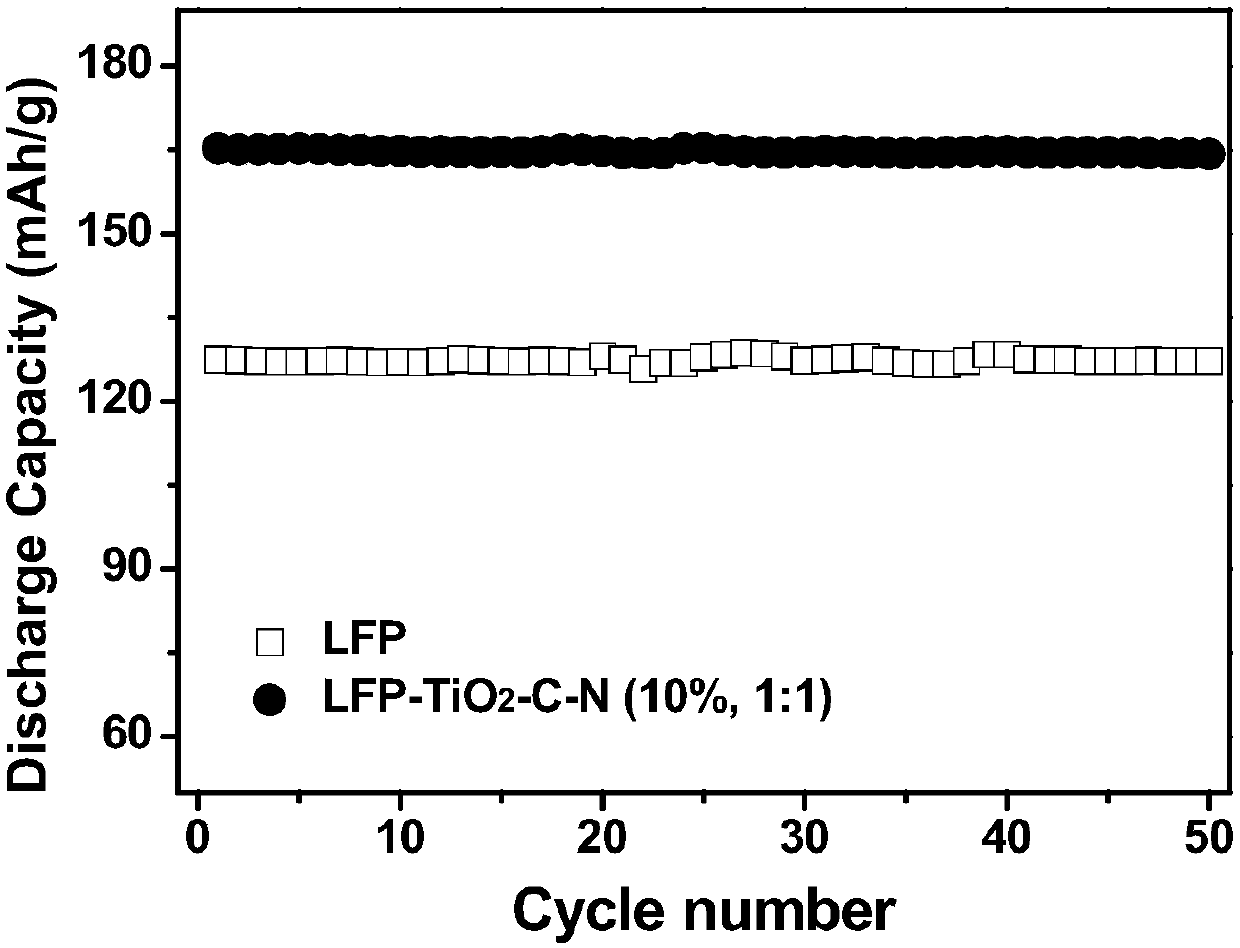

[0021] like figure 1 As shown, at 0.1C (17mA / g), LFP and LFP-TiO 2 The discharge specific capacity of -C-N is 127.4mAh·g respectively -1 and 165.3mAh·g -1 , corresponding to LiFePO 4 75% and 97% of theoretical specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com