Patents

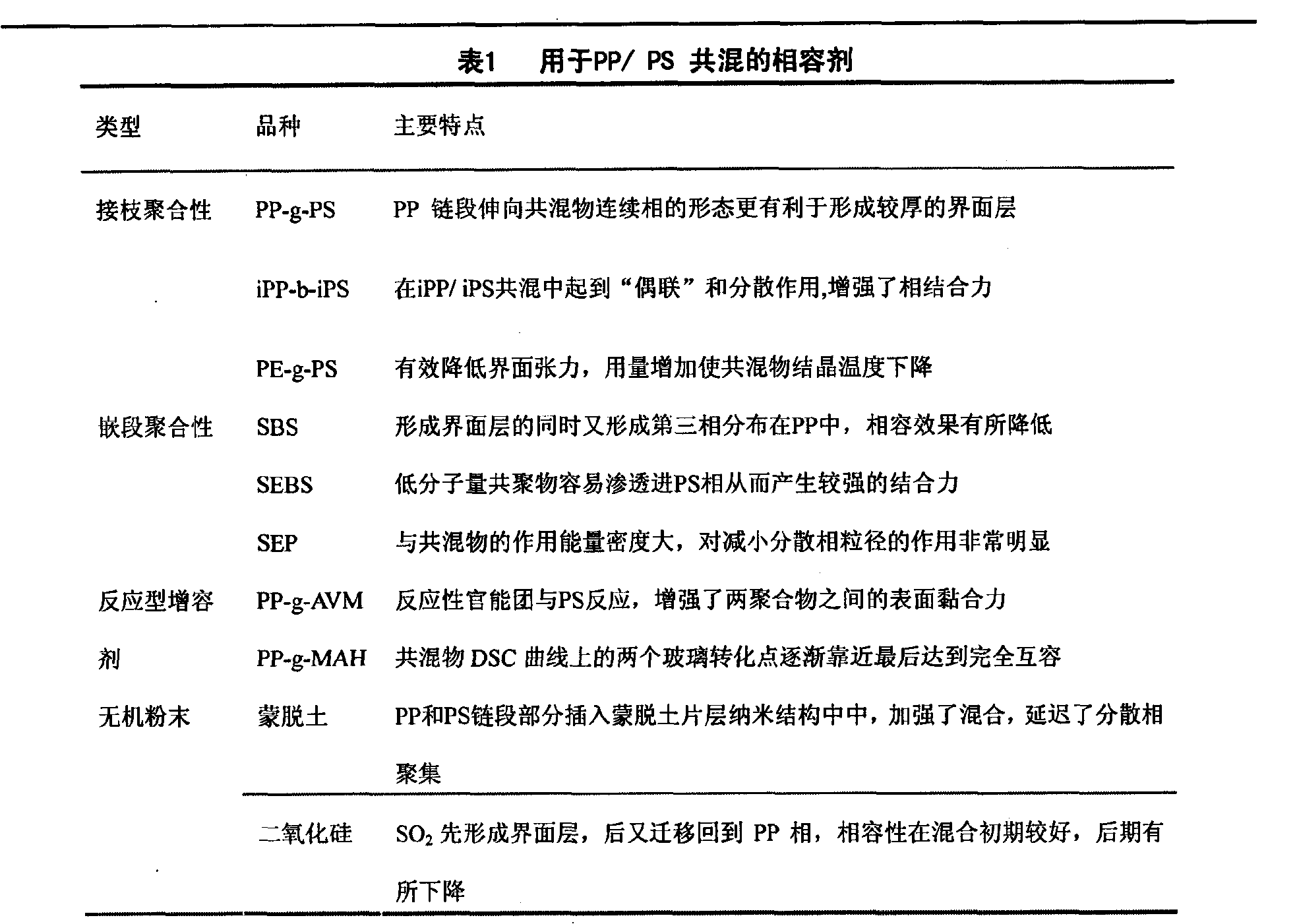

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

263results about How to "Increase surface polarity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

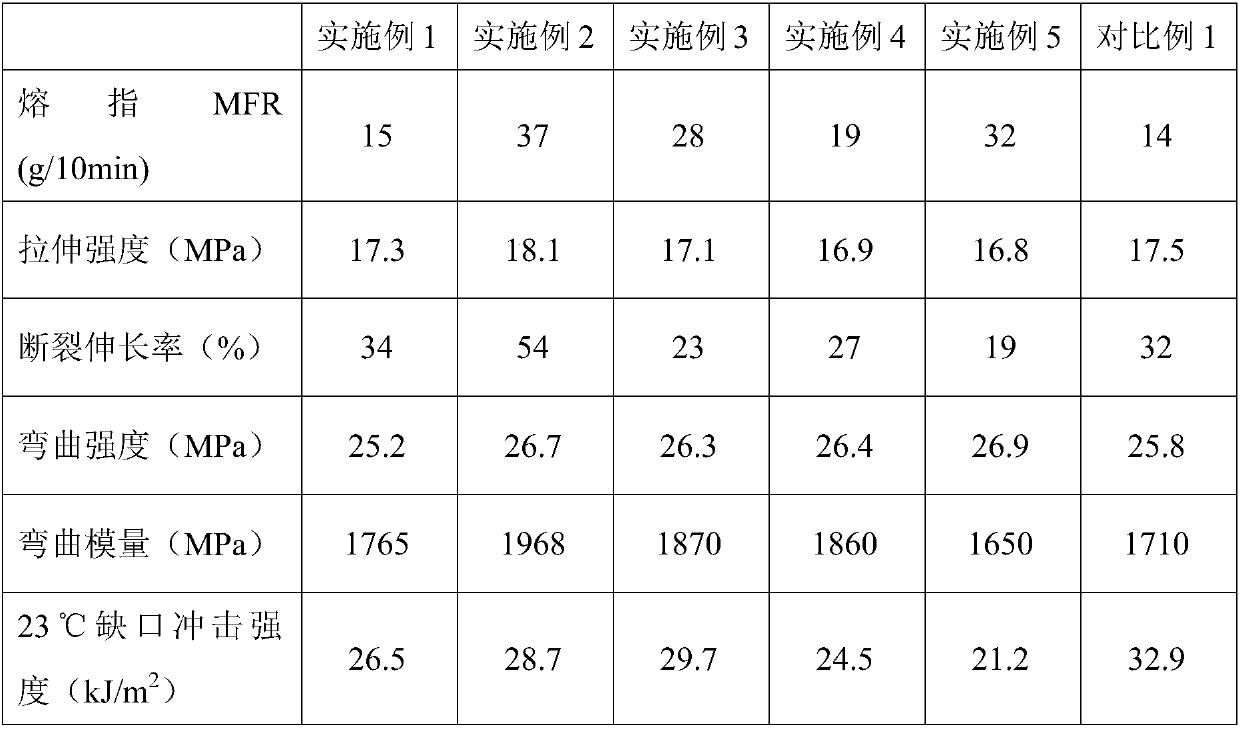

Filler masterbatch used for increasing polarity of polypropylene and preparation method thereof

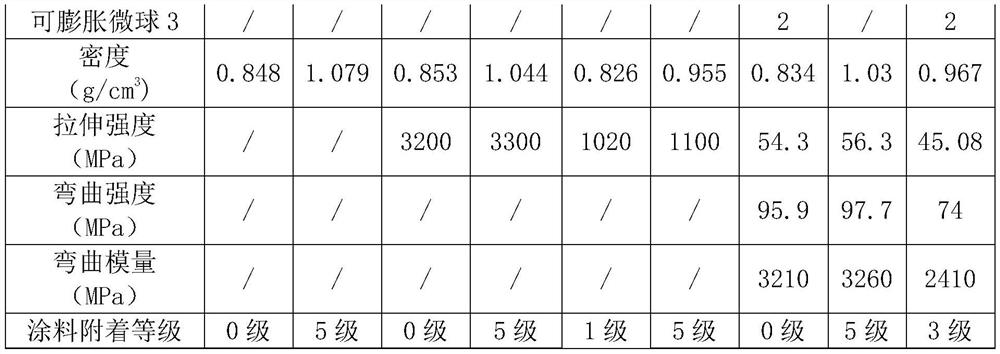

The invention discloses a filler masterbatch used for increasing the polarity of polypropylene and a preparation method thereof. The filler masterbatch is characterized by comprising the following components by weight percent: 50%-79% of inorganic filler, 15%-30% of carrier, 5%-17% of polar additive and 1%-3% of processing additive; and the polar additive is one or more of thermoplastic polyurethane resin (TPU), maleic anhydride grafted polypropylene, epoxy resin, ethylene acrylate, ethylene vinyl acetate, polyether amine and polybutylene polyol. In the preparation method of the invention, the added carrier can not improve the polarity of polypropylene, the inorganic filler is used to increase the rigidity of the material; the key is to introduce the polar additive with high unipolarity, thus the filler masterbatch used for increasing the polarity of polypropylene can be prepared; when the filler masterbatch is combined with the polypropylene material for production, the surface polarity of the filled and modified polypropylene material can be increased, the surface energy of the filled and modified polypropylene can be reduced, the dimension stability can be increased, the modified polypropylene material can have good paint adhesion and the material can be used to form exterior trimming parts such as bumpers and interior trimming parts such instrument panels.

Owner:KINGFA SCI & TECH CO LTD +3

Polar monomer graft-modified amorphous poly-alpha-olefin and preparation method thereof

The invention discloses a polar monomer graft-modified amorphous poly-alpha-olefin and a preparation method thereof. The polar monomer graft-modified amorphous poly-alpha-olefin is prepared by carrying out grafting reaction on amorphous poly-alpha-olefin, a peroxide initiator, a polar monomer and an auxiliary grafting agent under molten or dissolved conditions. The polar monomer graft-modified amorphous poly-alpha-olefin is prepared from the following raw materials: 100 parts of amorphous poly-alpha-olefin, peroxide initiator accounting for 0.1-1 wt% of the amorphous poly-alpha-olefin, polar monomer accounting for 0.5-10 wt% of the amorphous poly-alpha-olefin, auxiliary grafting agent accounting for 0.1-5 wt% of the amorphous poly-alpha-olefin, solvent accounting for 0-300 wt% of the amorphous poly-alpha-olefin, and antioxidant accounting for 0.05-2 wt% of the amorphous poly-alpha-olefin. The amorphous poly-alpha-olefin has the characteristics of high grafting ratio, light color, high polarity, favorable flowability, favorable storage capability and no risk in moisture crosslinking.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

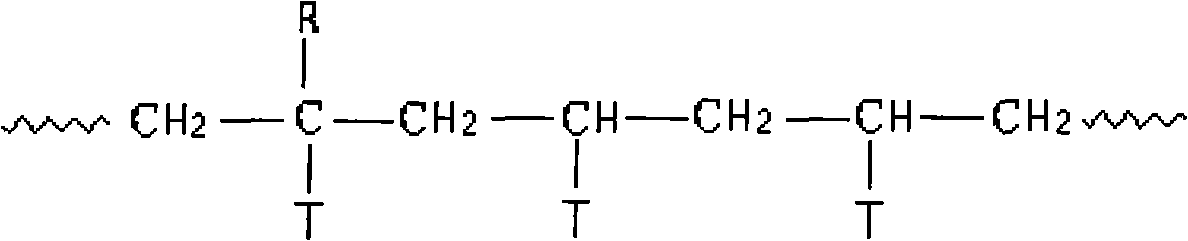

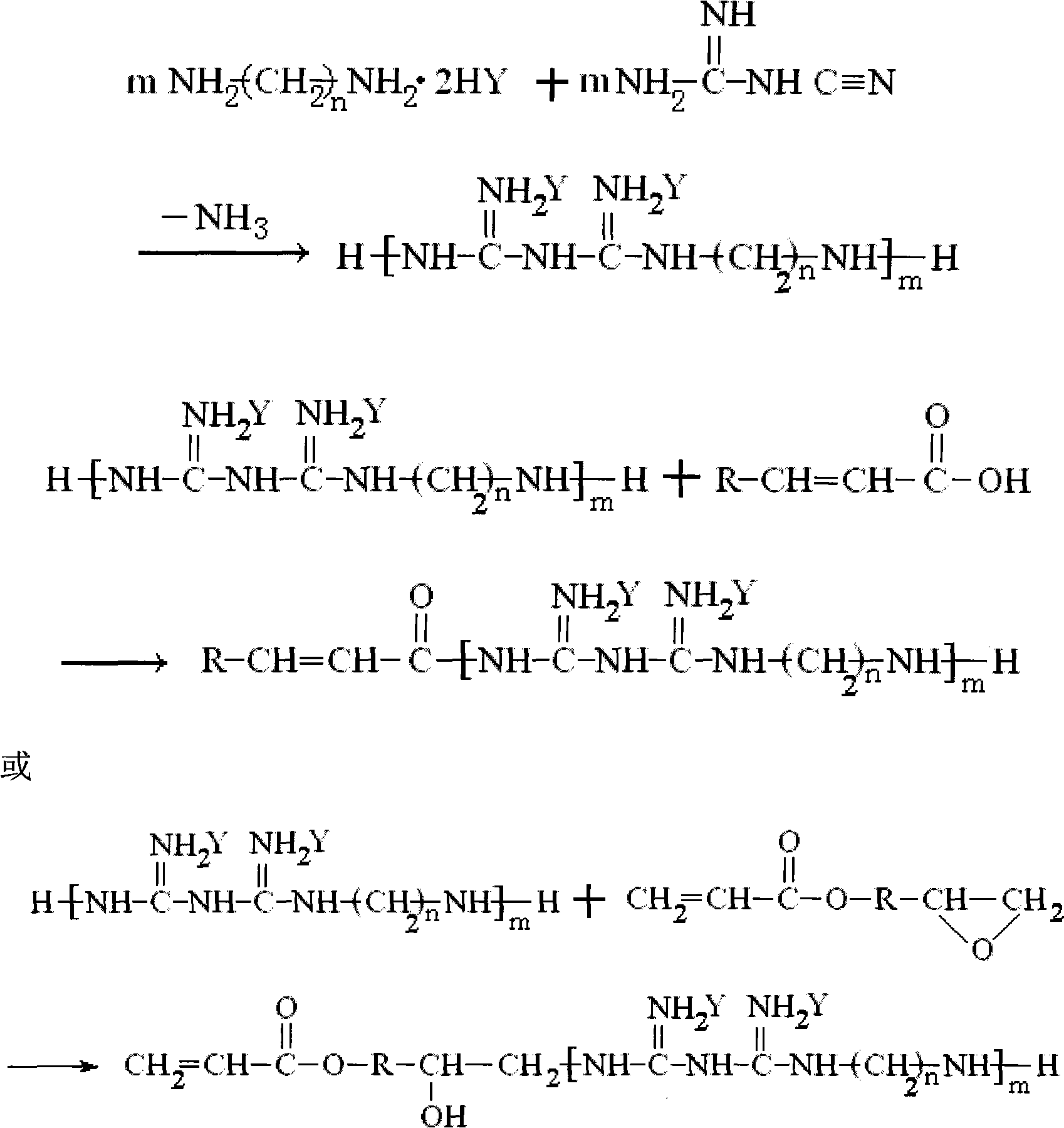

Polyolefin functional master batch, preparation method thereof and use thereof

ActiveCN101812160AAntibacterialAntistaticConjugated synthetic polymer artificial filamentsDisperse dyePolymer science

The invention relates to a polyolefin functional master batch, a preparation method thereof and use thereof. The functional master batch is prepared by blending a polyolefine resin, a guazatine oligomer, an olefin monomer, an initiator and the like and by a method of solvent graft, solid phase graft or melt graft and has a structural formula below, wherein in the formula, R represents the guazatine oligomer grafted to molecular chains of the polyolefin, and T may be hydrogen, chlorine, methyl, or phenyl. Compared with the prior art, by blending the functional master batch prepared by the invention with the corresponding polyolefin, various products, including fibers, thin films, water pipes and other plastic products, which have high antimicrobial performance and long-lasting effect and is safe and nontoxic to human bodies can be manufactured; and meanwhile, the acidic dye and disperse dye uptake of polyolefin fibers can be improved greatly, and the surface polarity, antistatic performance and paint film adhesion of polyolefin materials can be improved.

Owner:SHANGHAI FUYUAN PLASTICS SCI CO LTD

Polypropylene composite material with high paint adhesion and preparation method thereof

ActiveCN105440438AIncrease surface polarityGood compatibilityPolypropylene compositesCeramic materials

The invention provides a polypropylene composite material with high paint adhesion and a preparation method thereof. Through modification of surface polarity of a filler and introduction of a polypropylene modifier, the polarity of polypropylene and the filler is improved, compatibility between polypropylene and the filler is enhanced, and surface polarity of the polypropylene composite material is greatly improved; thus, the polypropylene composite material has excellent paint adhesion and can be applied to spraying and preparation of exterior decoration parts of an automobile. Moreover, the polypropylene composite material with high paint adhesion can be directly sprayed without spraying pre-treatment, so energy is saved and production cost is reduced.

Owner:ORINKO NEW MATERIAL CO LTD

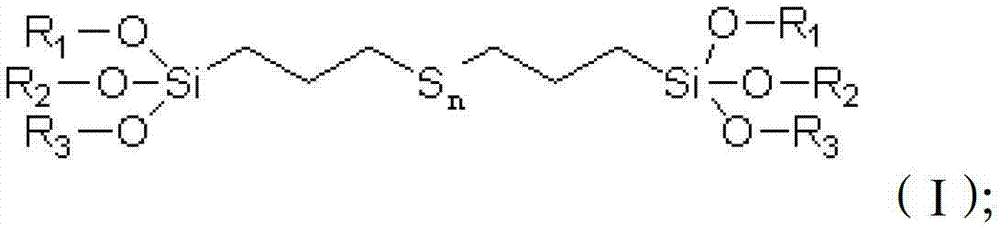

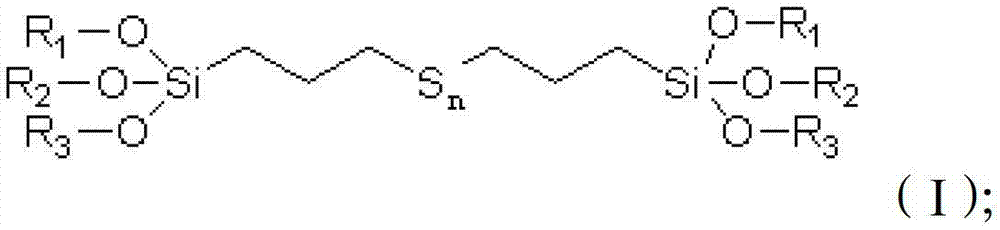

Surface modified aramid fiber, surface modification method thereof and static sealing material

ActiveCN103194898AIncrease surface polarityImprove mechanical propertiesFibre typesMechanical propertyAramid

The invention provides a surface modified aramid fiber and a surface modification method of the surface modified aramid fiber. The surface modification method comprises the steps of coating silane coupling agent solution or a dispersion liquid on the surface of the aramid fiber and then drying the aramid fiber under the condition of being contacted with air, thus obtaining the surface modified aramid fiber, wherein a silane coupling agent has a structure in the formula (I) in the specification; n is 2 or 4; and R1, R2 and R3 are independently selected from alkyl with number of carbon atoms being 1-5. When being adopted to produce composite materials, the aramid fiber prepared by the surface modification method provided by the invention can prevent precipitation and deposition of base materials while improving the mechanical properties of the composite materials and is simple, easy and safe in production operation. The invention also provides a static sealing material. The static sealing material adopts the surface modified aramid fiber and has relatively good mechanical property, sealing property and other properties.

Owner:廊坊佰昂密封材料有限公司

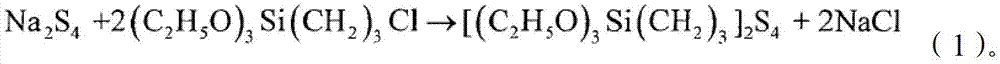

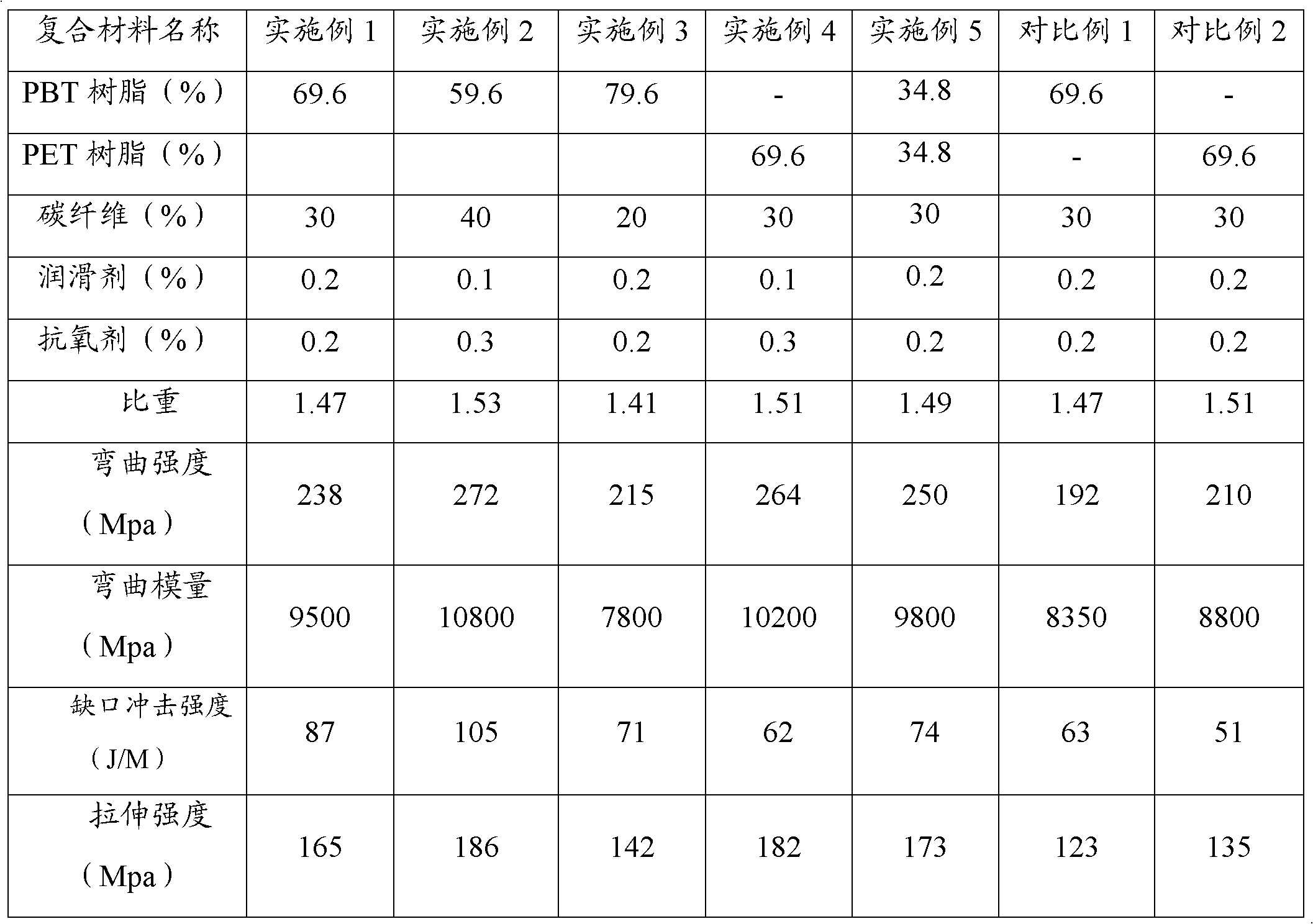

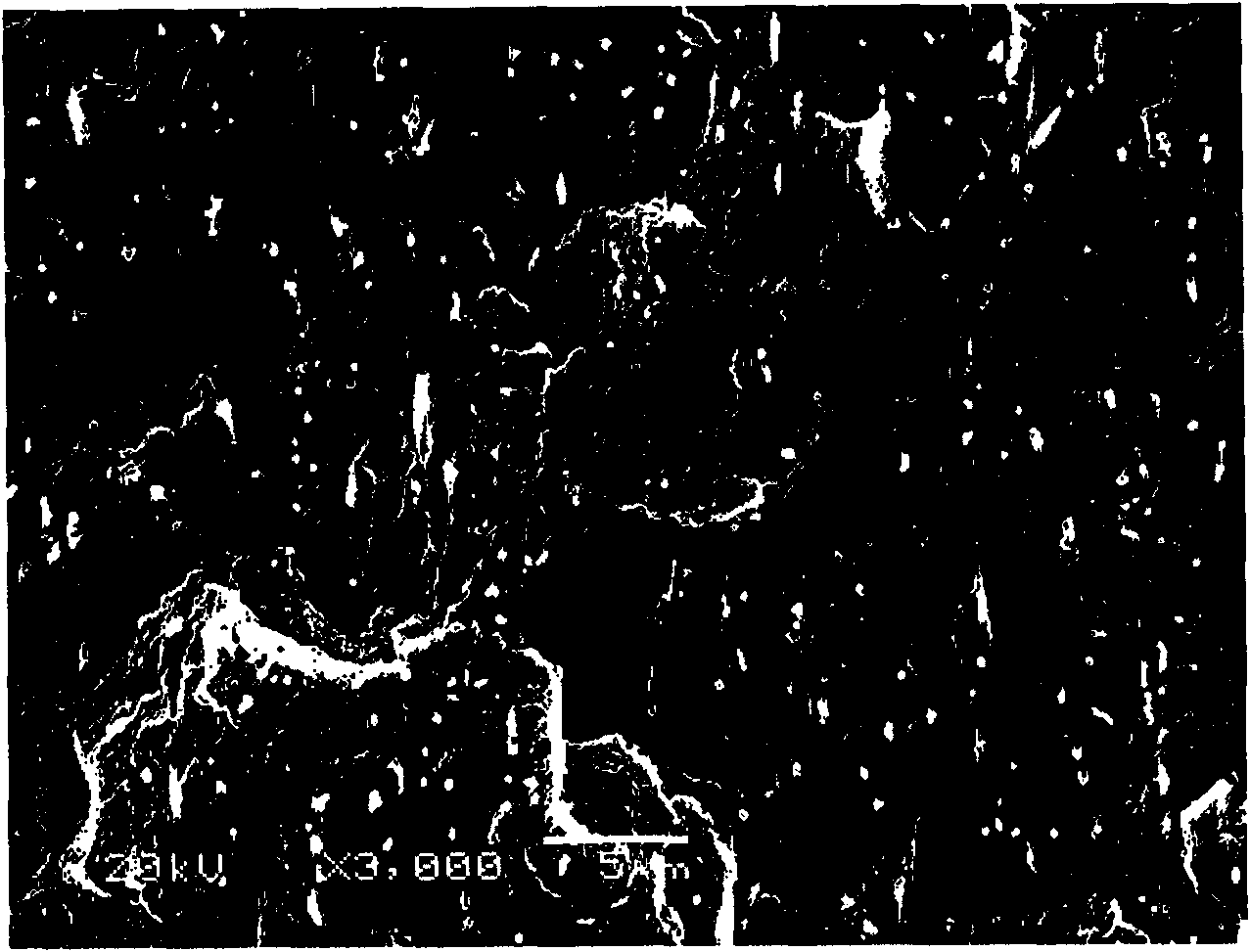

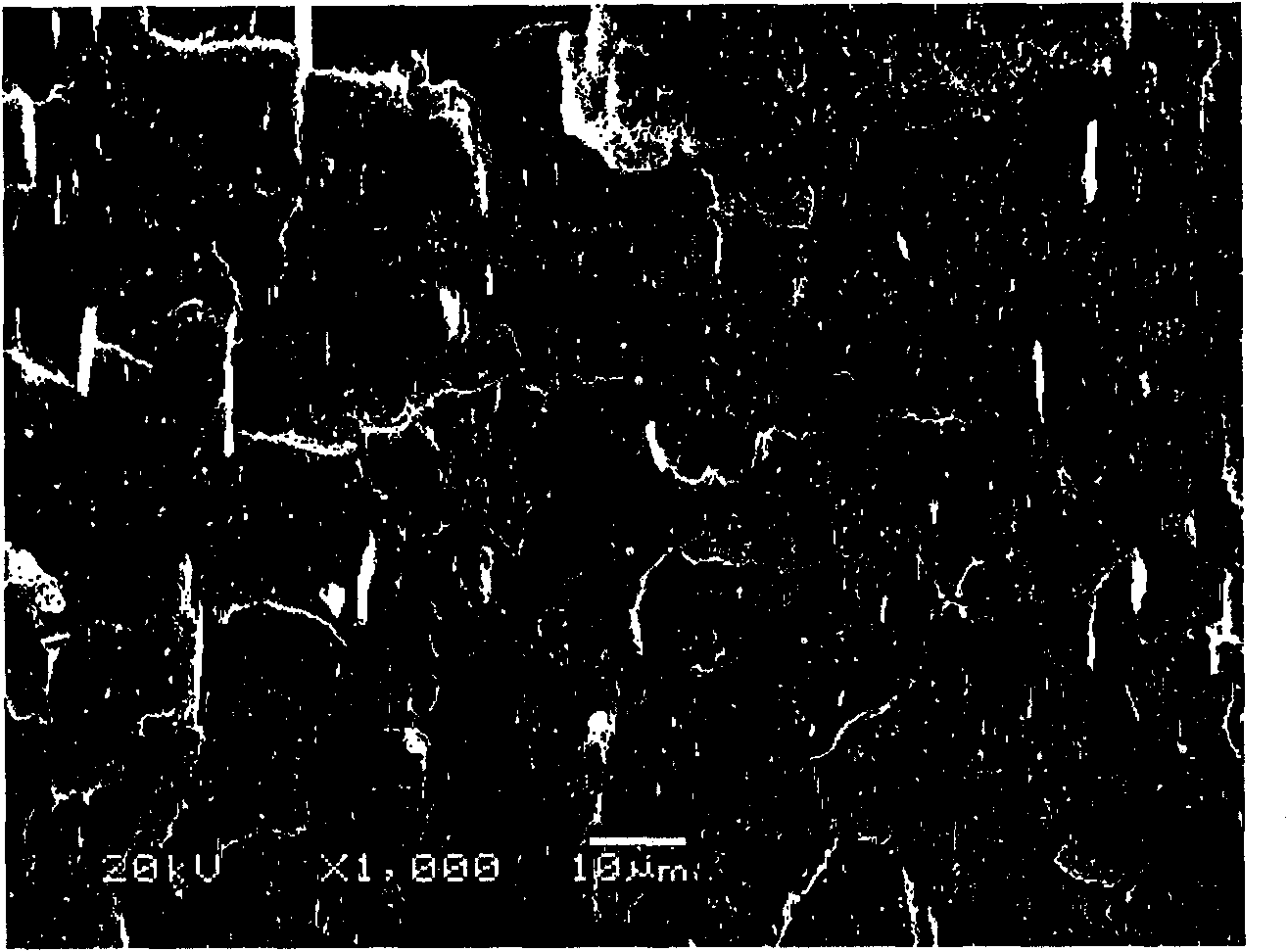

Carbon-fiber-reinforced polyester composite material and preparation method thereof

InactiveCN102311616AIncrease surface polarityGood bonding forceCarbon fibresCarbon fibersAntioxidant

The invention discloses a carbon-fiber-reinforced polyester composite material and a preparation method thereof. The composite material comprises the following components by weight percent (%): 60-80% of polyester, 0.1-0.3% of lubricating agent, 0.1-0.3% of antioxidant and 20-40% of carbon fiber. In the invention, surface treatment is carried out on the carbon fiber by virtue of liquid polyacrylonitrile so that the bonding performance between the carbon fiber and a polar polyester resin matrix is improved and mechanical properties of a material are enhanced. The invention has the advantages that: the surface polarity of the carbon fiber is improved; the bonding force between the carbon fiber and the resin matrix is improved; and the obtained carbon-fiber-reinforced polyester material has high strength, high toughness and simple production process and can be widely applied to a high-performance structural material for automobiles, military appliance and aviation.

Owner:SHENZHEN KEJU NEW MATERIAL

Antiskid EVA sole and preparation method thereof

ActiveCN104277316AImprove anti-slipExtended service lifeSolesDomestic footwearCross-linkWear resistant

The invention belongs to the technical field of an organic high-molecular compound, and particularly relates to an antiskid EVA sole and a preparation method thereof. The antiskid EVA sole is prepared from the following raw materials: EVA, liquid rubber, a thermoplastic elastomer, a tackifier, chlorinated polyethylene, hemp stem core superfine powder, an AC foaming agent, a cross-linking agent, nanozinc oxide, zinc stearate, stearic acid, a wear-resistant agent and inorganic fillers. The preparation method comprises the following steps: banbury-mixing and open-milling the raw materials, pelletizing to obtain antiskid EVA particles, and then performing heating foaming and secondary oil-pressure forming to the antiskid EVA particles, to obtain the antiskid EVA sole. The antiskid EVA sole has the characteristics of being light in mass, high in antiskid property, good in handfeel and size stability and the like, as well as excellent in tensile strength and tearing strength, is especially suitable for application on aspects of various shoe accessories, sole materials and the like, and is good in comfortableness and long in service life.

Owner:茂泰(福建)新材料科技有限公司

Lightweight high-elasticity EVA shoe sole and preparation method thereof

ActiveCN104804297ARaise the crystallization temperatureIncrease temperatureSolesCross-linkPolyolefin

The invention relates to the technical field of high-molecular compounds, and provides a lightweight high-elasticity EVA shoe sole and a preparation method thereof. The lightweight high-elasticity EVA shoe sole is prepared by the steps of performing internal mixing, open milling and pelleting on the materials of EVA, polyolefin segmented copolymer, ethylene propylene diene monomer, chlorinated polyethylene, a foaming agent, a cross-linking agent, zinc stearate, stearic acid, an abrasion-resistant agent and talcum powder, so as to obtain lightweight high-elasticity pellets, and performing injection molding at one time to obtain the lightweight high-elasticity EVA shoe sole. The lightweight high-elasticity EVA shoe sole provided by the invention has the characteristics that the resilience is high, the dimensional stability is high, the compression deformation rate is low, the surface is not easy to wrinkle, the weight is light, the comprehensive performance is good, the product percent of pass is high, and in addition, the EVA shoe sole is lighter in weight and is particularly suitable for production of top-grade EVA sport shoes and casual shoes.

Owner:MAOTAI FUJIAN SOLES CO LTD

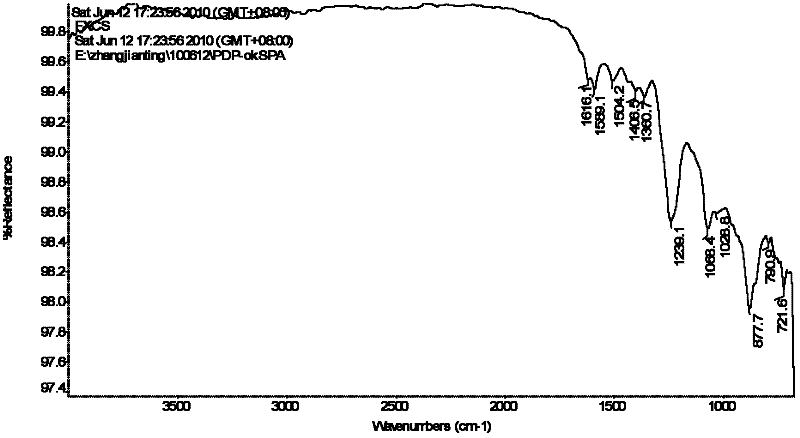

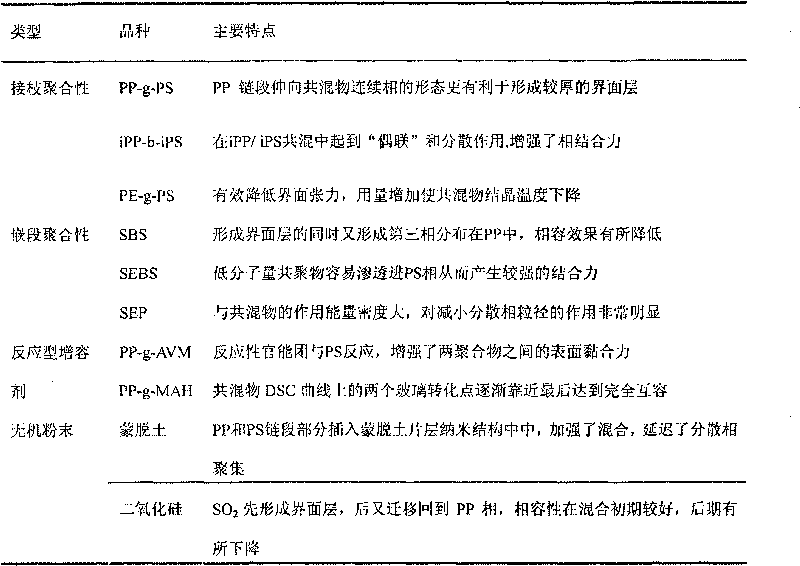

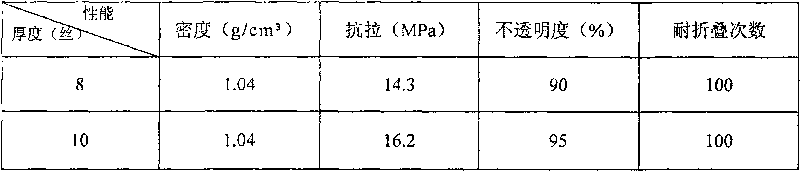

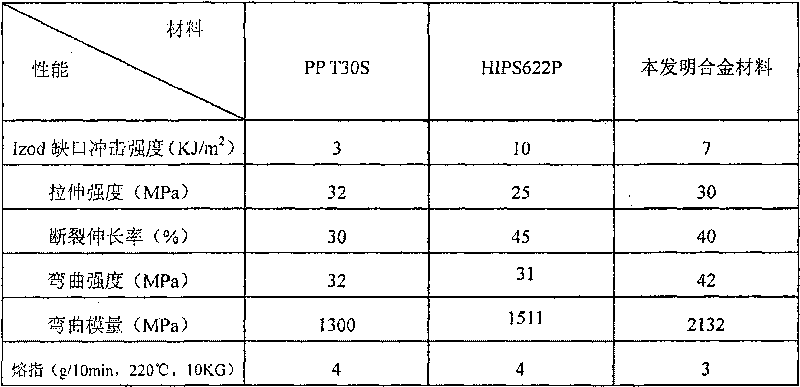

High-performance PS and PP alloy novel synthetic paper material

The invention provides a composition of a novel synthetic paper material and a preparation method. The invention comprises the following components in weight percent: 50-85% of polyolefin blend, 10% of inorganic mineral powder and 5-12% of auxiliary agent; then 0.1-1% of antioxidant calculated according to the total weight the above materials is added for pre-mixing; then a double-screw extruder is utilized for extrusion and pelletizing to manufacture into base resin with high steel and high toughness; and the comprehensive performances are all better than ordinary PP synthetic paper material,thus expanding the application range, and simultaneously by adding auxiliary agent (anti-static agent, antibacterial agent, aromatizing agent and the like), and by the processes of fusion, blending and even dispersion in the resin base body, different functional requirements can be satisfied. The paper manufactured from the high-performance PS and PP alloy novel synthetic paper material can be widely used in packaging, high-quality printed matters, tags, paper money, developing paper, tracing paper, express envelopes, paper fans, umbrellas and the like, can save a large amount of forest resource and water resource, and reduces sewage treatment pressure and energy consumption.

Owner:SICHUAN KINGFA TECH DEV

High-temperature resistant non-woven composite membrane for power lithium-ion battery and preparation method for high-temperature resistant non-woven composite membrane

ActiveCN103682217AImprove lyophilicityImprove cycle performanceCell seperators/membranes/diaphragms/spacersSecondary cellsHYDROSOLNonwoven fabric

The invention belongs to the field of lithium-ion battery membrane materials, and discloses a high-temperature resistant non-woven composite membrane for a power lithium-ion battery and a preparation method for the high-temperature resistant non-woven composite membrane. The non-woven composite membrane is prepared through the following steps: carrying out pre-treatment to non-woven cloth; introducing an active group containing hydrogen in non-woven surface and fiber holes, so as to obtain modified non-woven cloth; preparing sol by adopting a sol-gel method, coating the modified non-woven cloth with the sol, so as to obtain the non-woven composite membrane. The non-woven composite membrane prepared through the preparation method has excellent thermal stability, good air permeability and electrolyte wettability and high security, and has high potential for use in high-energy power lithium ion batteries. The preparation process is simple, equipment requirements are low, and achievement of industrialization is facilitated.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

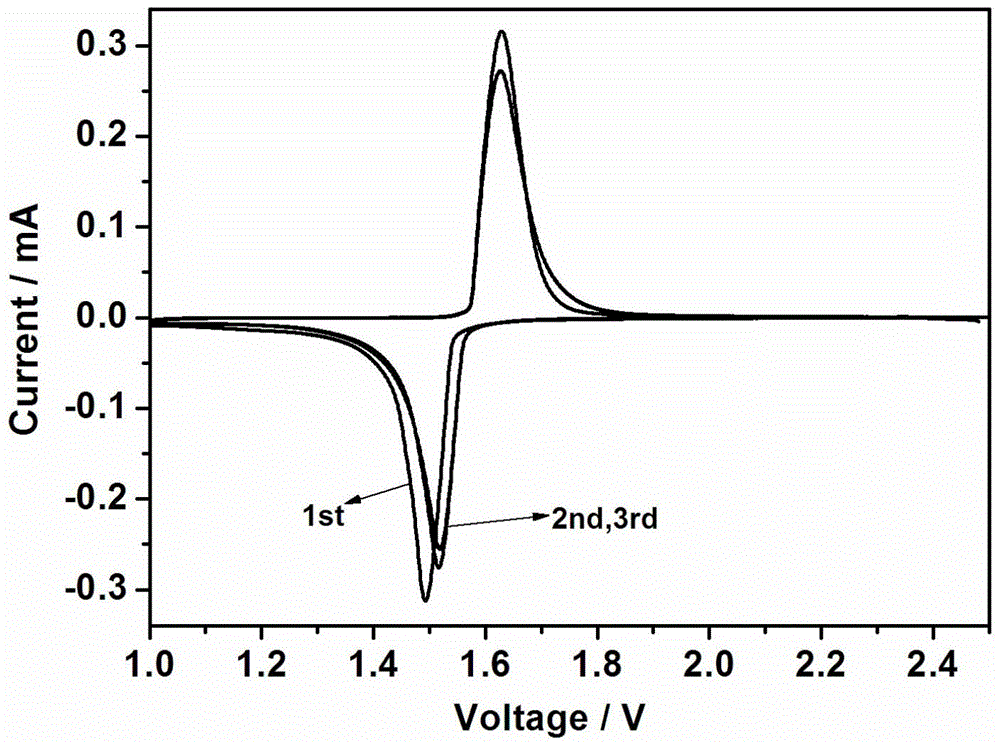

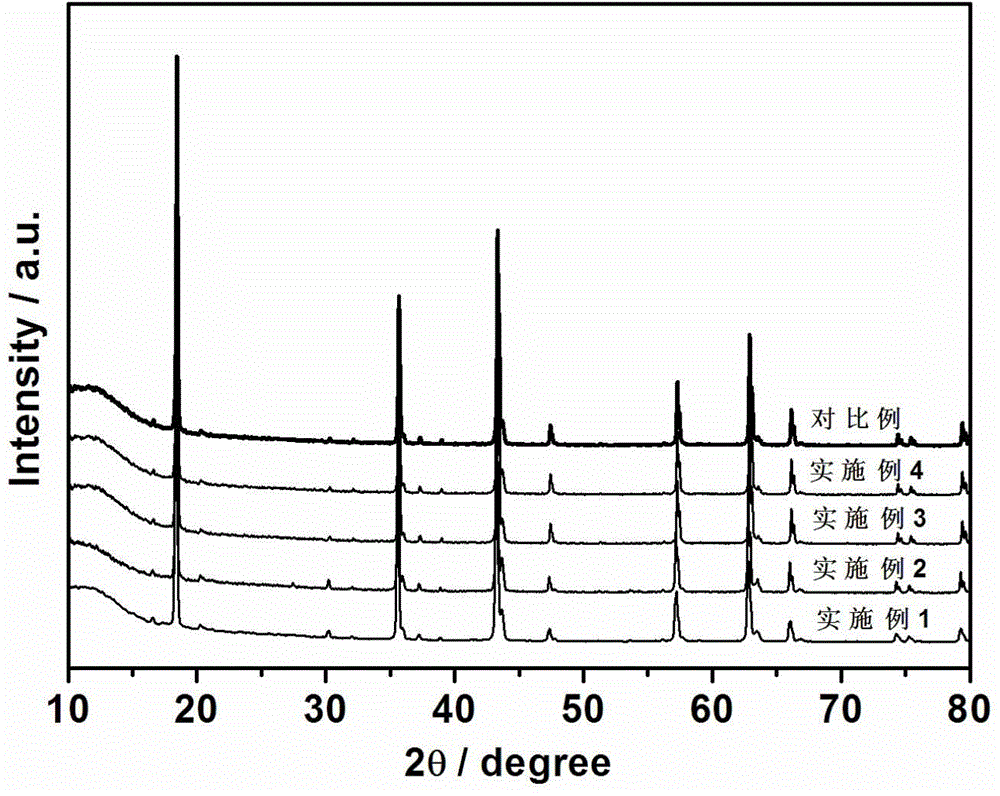

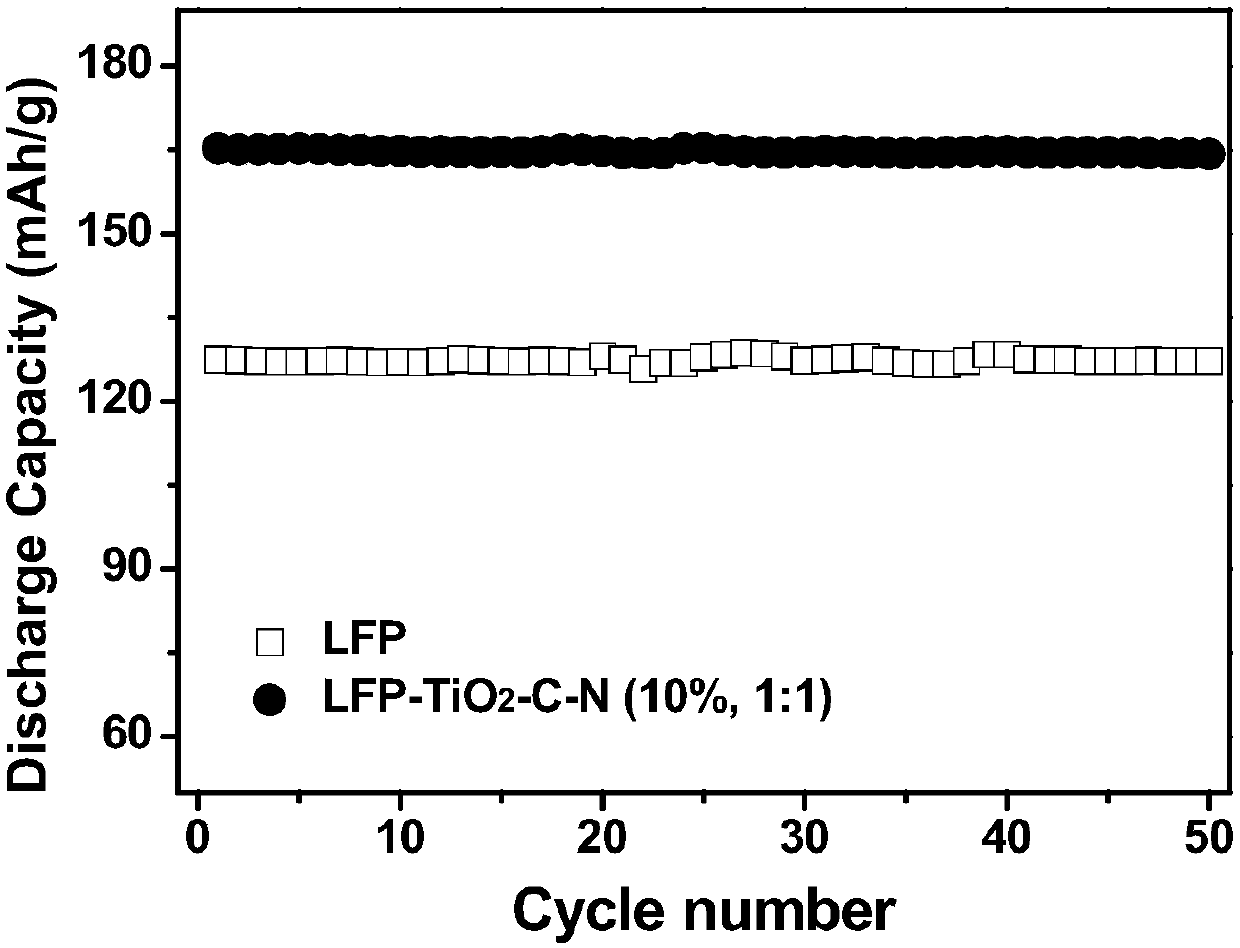

Preparation method of high-performance nitrogen-doped carbon-coated lithium titanate composite anode material of lithium ion battery

InactiveCN104409715AImprove charge and discharge efficiencyImprove conductivityCell electrodesSecondary cellsCarbon coatedBall mill

The invention relates to the technical field of preparation of electrode materials of lithium ion batteries and in particular discloses a preparation method of a high-performance nitrogen-doped carbon-coated lithium titanate composite anode material of a lithium ion battery. The method comprises the following steps: firstly adding a lithium source, nano titanium dioxide and tripolycyanamide into a ball according to a certain material ratio, taking absolute ethyl alcohol as a medium, ball milling and then spray drying, subsequently calcining the materials under the inert atmosphere condition, ball milling and screening to obtain a nitrogen-doped carbon-compounded lithium titanate material which is applied to the anode material of the lithium ion battery and is high in electrochemical performance. The preparation method of the high-performance nitrogen-doped carbon-coated lithium titanate composite anode material of the lithium ion battery is simple in process; the prepared anode material is high in reversible capacity and excellent in high-magnification cycle performance.

Owner:HUBEI ENG UNIV

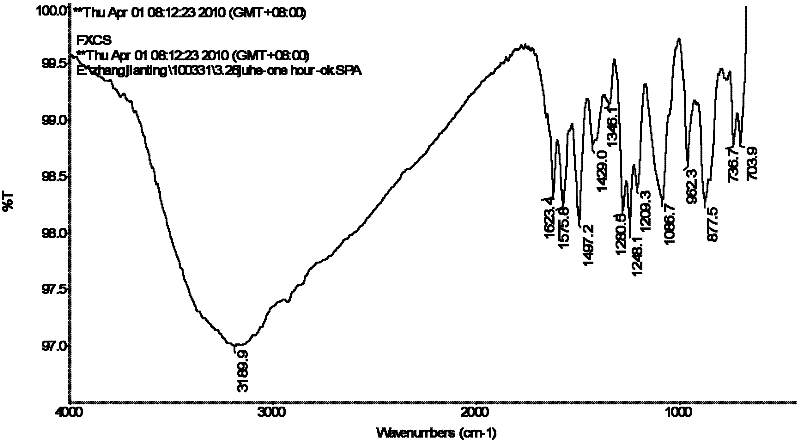

Preparation and application of hydroxyl modified poly-p-phenylene benzo imidazolinyl resin

ActiveCN102532546AHigh compressive strengthIncrease surface polarityMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention provides a preparation method of hydroxyl modified poly-p-phenylene benzo imidazolinyl resin and application of the resin in high performance fiber preparation. 1,2,4,5-tetraaminobenzene hydrochloride and two hydroxy terephthalic acid are utilized as raw materials, hydrogen chloride is desorbed from polyphosphoric acid, and the hydroxyl modified resin is prepared by temperature programming mixed with polycondensation. The resin can be applied to spinning processing and made into high performance fiber, particularly poly-1, 4-(2, 5-dyhydroxy) phenylene-2, 6-benzo diimidazole resin can directly utilize poly phosphoric acid liquid crystal basic solution when polymerization is finished to conduct manual wire drawing or dry-jet wet spinning to obtain poly-1, 4-(2, 5-dyhydroxy) phenylene-2, 6-benzo diimidazole fiber, compression and composite adhesive performance of the fiber are improved, and production cost is reduced. The preparation method and the application provide a new way for replacing PBO and M5 fiber to implement commercialization production of the high-performance fiber and developing research direction of high-technology materials.

Owner:ZHEJIANG UNIV OF TECH

PS (polystyrene) alloy synthetic paper and preparation thereof

The invention relates to novel PS (polystyrene) alloy synthetic paper which improves the stiffness, the surface polarity and the surface hardness and resists the chemical corrosion. The paper molded by using an extrusion tape casting method has white appearance and opacity, excellent physical property and superior price, can replace current commonly-used calendered paper, and replaces products of common paper PE (polyethylene) and common paper composite BOPP (biaxially-oriented polypropylene) membranes. The novel PS alloy synthetic paper is applied to common printing materials and processing materials by the characteristics of water prevention and tear resistance, applied to data needing permanent preservation by the characteristic of excellent weather resistance, and adapts to various labels of packages of drink bottles and cans. The invention does not produce the environment pollution during the manufacture and use, can save a great quantity of forest resources and water resources for country, lightens the sewage treatment pressure, and reduces the energy consumption.

Owner:SICHUAN KINGFA TECH DEV

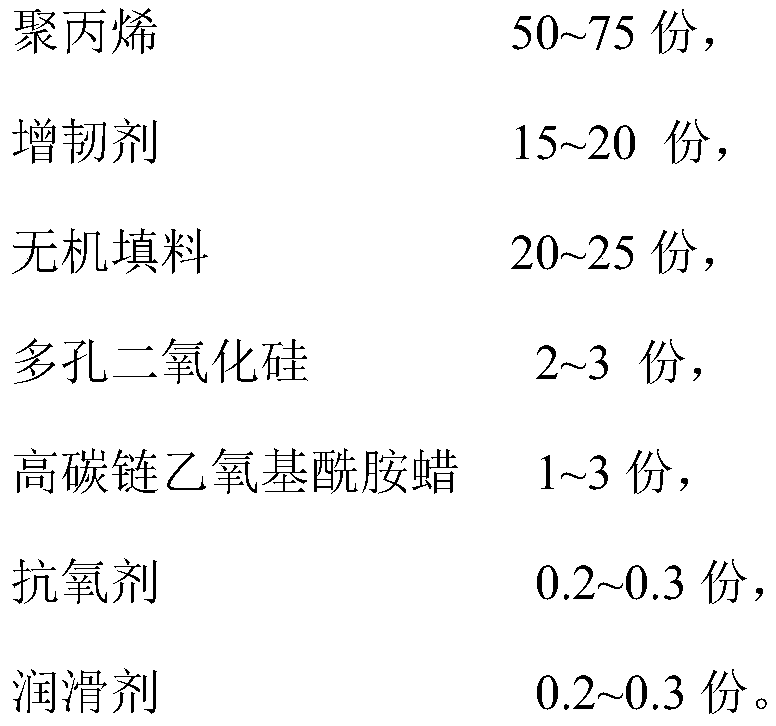

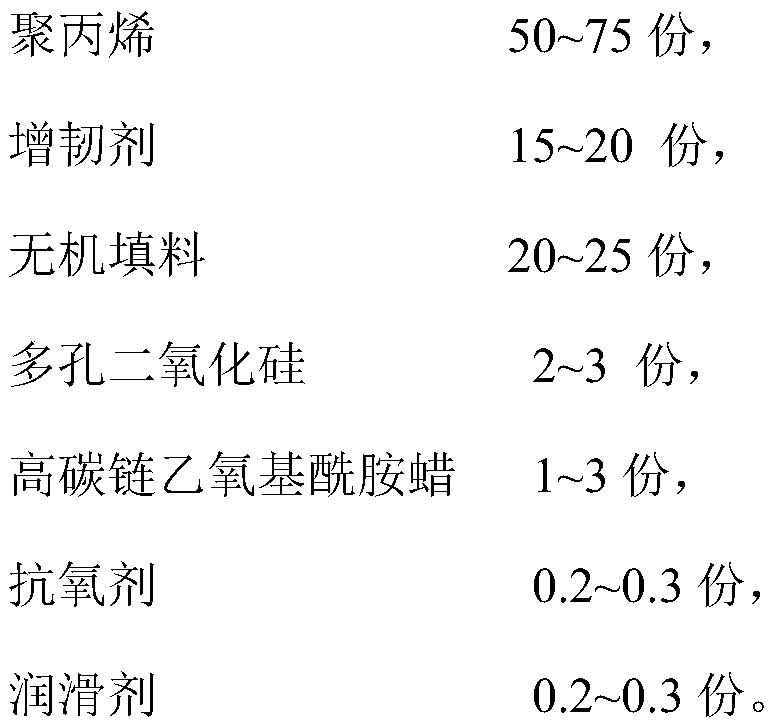

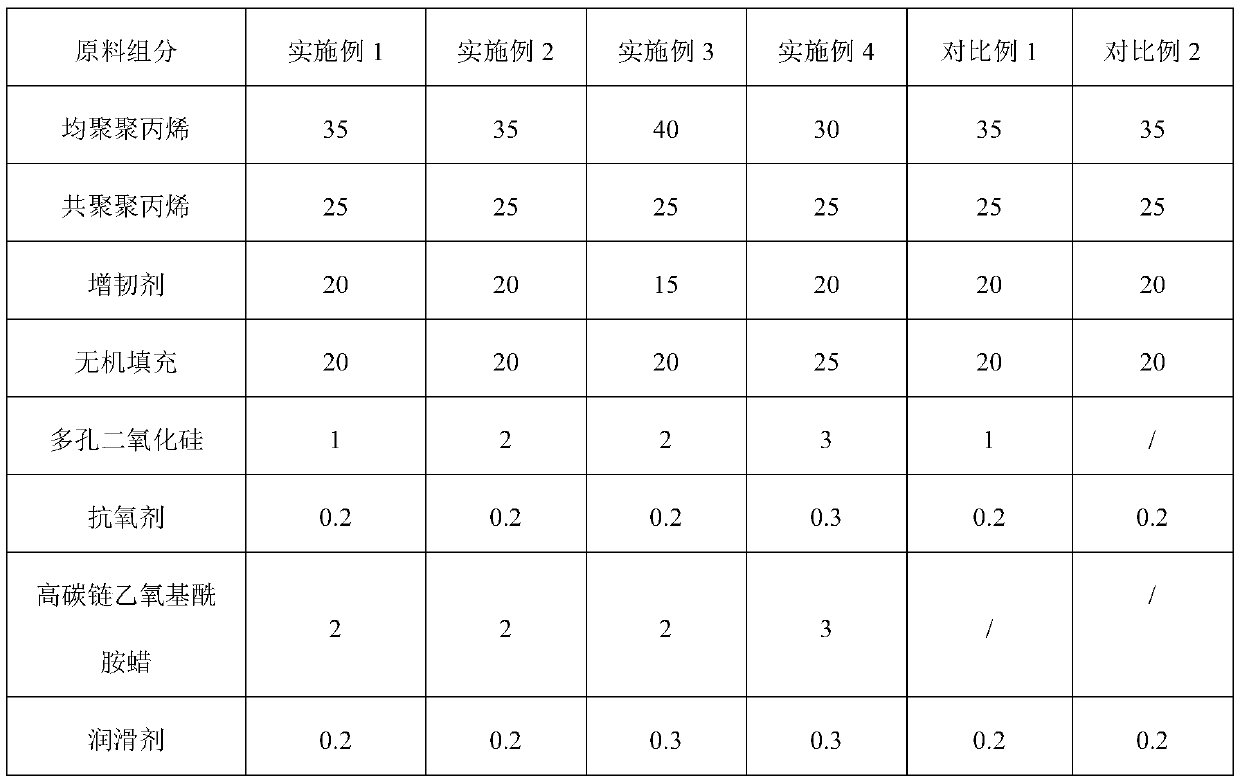

Modified polypropylene composite material for spraying and preparation method thereof

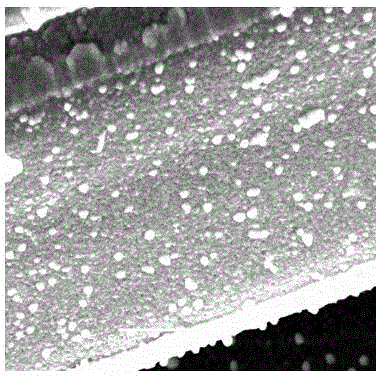

The invention discloses a modified polypropylene composite material for spraying and a preparation method thereof. The modified polypropylene composite material is prepared from the following components in parts by weight: 50-75 parts of polypropylene, 15-20 parts of a flexibilizer, 20-25 parts of an inorganic filler, 2-3 parts of porous silicon dioxide, 1-3 parts of high-carbon-chain ethoxy amidewax, 0.2-0.3 part of an antioxygen and 0.2-0.3 part of a lubricant. According to the modified polypropylene composite material, high polarity of the high-carbon-chain ethoxy amide wax is used for modifying the surface of a polypropylene composite material, surface polarity and surface tension of the material are significantly improved, flame-free treatment spraying of the material is achieved, and thus paint easily coat the composite material surface; and with the help of a microporous structure of the porous silica, the paint penetrates into the composite material surface more easily in thecoating process, cured paint resin and a composite material matrix maintain high bonding strength, and the requirements for long-period use of automotive exterior decoration spraying materials can bemet.

Owner:ORINKO NEW MATERIAL CO LTD

Preparation method of copper-zinc-iron ternary alloy chemical plating layer on surface of aramid fiber

InactiveCN104088138AHigh surface energyImprove wetting performancePhysical treatmentFibre typesChemical platingSurface modification

The invention discloses a preparation method of a copper-zinc-iron ternary alloy chemical plating layer on the surface of aramid fiber. The preparation method comprises the following steps: carrying out surface modification on aramid fiber; carrying out low-concentration colloid palladium treatment; and carrying out a copper-zinc-iron ternary alloy chemical plating process. The preparation method has the beneficial effects that an environment-friendly glyoxylic acid chemical plating process is used to realize co-deposition of a copper-zinc-iron ternary alloy; the plating layer is composed of following components in percentage by mass: 85%-90.5% of copper, 1.0%-3.0% of iron, 0.5%-1.5% of zinc and the balance of carbon and oxygen; through detection, the surface resistance of the plating layer keeps below 50m(omega) / sq; an adhesive tape method is used for determining the binding force between the plating layer and fabric fibers and the weight loss ratio is less than 0.1%; the plating layer is bright and a microstructure is uniform; the plating layer can resist atmosphere corrosion and meets the requirements of electric conduction, electromagnetic shielding, static electricity prevention and the like.

Owner:SHANDONG JIANZHU UNIV

Elastic fluorocarbon paint and formula thereof

The invention relates to a formula of elastic fluorocarbon paint. The formula comprises the following ingredients: 40-50% of fluorocarbon resin, 15-20% of elastic resin, 0.3-0.5% of a wetting agent, 0.3-0.5% of a dispersant, 0.5-1% of a leveling agent, 15-20% of aluminium powder, 0.1-0.2% of an antifoaming agent, 0.1-0.5% of an anti-settling agent, 0-0.5% of a drier and 15-20% of a solvent. Long straight chain and low branched chain of a high-molecular elastic cross-linking agent react with a fluorine-containing polymer to form a highly-straight-chain and low-branched-chain polymer, the structure of which is jagged. The ultimate embodiment of properties is reflected in appropriate surface strength, excellent elasticity, telescopic springback function, high tensile strength and fracture resistance, low surface polarity and strong resistance to soiling and weatherability.

Owner:上海奥泽涂料有限公司

Novel special backing plate for photovoltaic diamond wire cutting

ActiveCN110317427AIncrease surface polarityImproved and stable bond strengthAdjuvantPhotovoltaic industry

The invention relates to the technical field of a special backing plate for diamond wire cutting silicon wafers in the photovoltaic industry, in particular to a novel special backing plate for photovoltaic diamond wire cutting. The backing plate is prepared from, by weight, 75-95 parts of ABS resin, 5-25 parts of PMMA resin, 5-15 parts of PC resin and / or PBT resin, 1-10 parts of a compatilizer, 1-10 parts of polyvinyl pyrrolidone, 1-10 parts of an adjuvant and 1-5 parts of an adhesion modifier. The backing plate has the advantages that the specific gravity is small, the consumption of manpoweris reduced, the production efficiency is improved, the backing plate does not adhere to diamond wires, the consumption of the diamond wires is reduced, and silicon materials and ABS / PMMA / PC plastic plates are conveniently recovered. By using the backing plate, obvious benefits of reducing the energy consumption and the cost and improving the production efficiency can be brought.

Owner:广西珀源新材料有限公司

Carbon fiber reinforced polyamide composite material and preparation method thereof

InactiveCN102311640AIncrease surface polarityGood bonding forceCarbon fibresCarbon fibersAntioxidant

The invention discloses a carbon fiber reinforced polyamide (PA) composite material and a preparation method thereof. The composite material consists of the following components in percentage by mass: 60 to 80 percent of polyamide, 0.1 to 0.3 percent of lubricant, 0.1 to 0.3 percent of antioxidant and 20 to 40 percent of carbon fibers. In the invention, the adhesive bonding property of the carbonfibers and a polarity polyamide resin matrix is improved and the mechanical property of the material is strengthened mainly by carrying out surface treatment on the carbon fibers by liquid polyacrylonitrile. The carbon fiber reinforced polyamide composite material has the advantages that the surface polarity of the carbon fibers is improved; the adhesive bonding property of the carbon fibers and the resin matrix is strengthened; and the obtained carbon fiber reinforced polyamide material has high strength, high toughness and simple production process and can be widely applied to a high-performance structural material for vehicles, military apparatus and aviation.

Owner:ANHUI KEJU NEW MATERIALS

Modified aramid fiber reinforced PA66 material and preparation method thereof

InactiveCN103709742AIncreased transverse tensile strengthHigh strengthRadio/micro wave fibre treatmentAbrasion resistant fibresRadiation DosagesRadiation frequency

The invention relate to a modified aramid fiber reinforced PA66 material and a preparation method thereof. The preparation method comprises the steps of modifying the aramid fibers by using microwave radiation, with radiation frequency being 0.5-5 GHZ, radiation dosage being 0.1-2 mW / cm<2> and radiation time being 1-240 s; and then processing the modified aramid fibers by using low temperature plasma, with a processing power being 10-400 W, a processing atmosphere being composed of 5-15% of hydrogen, 5-15% of fluorine and 70-90% of helium, a processing temperature being 0-150 DEG C and a processing time being 1-20 min. The surface layer and the core layer of the aramid fibers modified by the microwave radiation are crosslinked, so that transverse tensile strength of the fibers is increased; and after the low temperature plasma modification, the surfaces of the aramid fibers become rough and are rich in active free radicals and functional groups. The mechanical and wear resistant performances of the composite material prepared by blending and extruding the modified aramid fibers together with the PA66 resin through a double-screw extruder are increased by 15-20% than that of similar products at abroad, and can meet the requirements of the fields such as high speed railways and aerospace for high-performance wear-resistant components.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Nano mesoporous molecular sieve synergistic intumescent flame retardant flame-retardant polypropylene

InactiveCN102229719AUniform pore structureLarge specific surface areaPolypropylene compositesMolecular sieve

A nano mesoporous molecular sieve synergistic intumescent flame retardant flame-retardant polypropylene disclosed in the invention relates to a composite material of a nano mesoporous molecular sieve, an intumescent flame retardant (IFR) and a polypropylene (PP). The blend is compounded by carrying out extrusion granulation of 0.5-5wt% of the molecular sieve, 20-35wt% of the intumescent flame retardant (namely ammonium polyphosphate / pentaerythritol) and 60-80wt% of the polypropylene pellets to finally obtain the molecular sieve / intumescent flame retardant / polypropylene composite material with excellent mechanical and flame retardant property, wherein, the intumescent flame retardant is compounded by ammonium polyphosphate and pentaerythritol. According to the invention, by adding the nano mesoporous molecular sieve to carry out synergistic flame retardant, the flame retardant efficiency is improved obviously, the residual amount of carbon residue and the density of carbon bed are increased, the problem of the significant drop of the mechanical property caused by adding a large number of flame retardant is alleviated effectively, so that the wide application filed of the material is ensured.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Novel degradable composite plastic and preparation method thereof

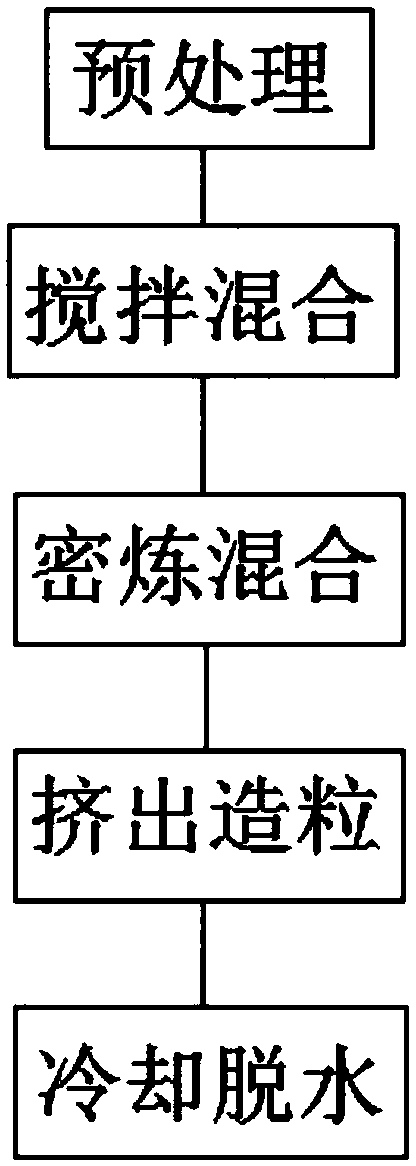

The invention relates to novel degradable composite plastic, comprising, by weight, 40-60 parts of polypropylene compound, 15-45 parts of micron plant short-staple, 5-15 parts of fillers, 3-7 parts ofcompatilizers, 0.4-0.6 part of antioxidant, 0.3-0.5 part of lubricant, 3-5 parts of antibacterial additives and 2-3 parts of biodegradable agents. Under cooperation of photocatalytic degradation andmicro-biological degradation, the composite plastic has excellent degradation performance, mechanic performance and mechanical property. A preparation method of the novel degradable composite plasticincludes pretreatment, mixing with stirring, mixing with a mixer, extrusion and granulation, cooling and dehydration, and the like. Components of the degradable composite plastic are mixed more dispersively By the preparation method, and thus, quality of the finished product is better.

Owner:广东力美新材料科技有限公司

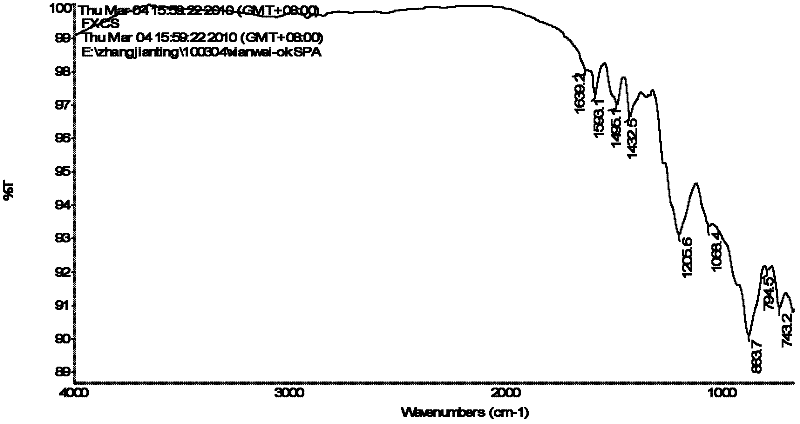

Polyhydroxy p-phenylene benzo bisoxazole polymer and preparation and application thereof

ActiveCN104119534AIncrease surface polarityImproves UV resistanceOrganic compound preparationMonocomponent synthetic polymer artificial filamentFiberPolymer science

The present invention discloses a polyhydroxy p-phenylene benzo bisoxazole polymer and preparation and application thereof. The polyhydroxy p-phenylene benzo bisoxazole polymer can be 3'-hydroxy-1', 4 '-phenylene-2, 6-benzo bisoxazole which is shown as formula I and has orderly distributed hydroxyl, or polyhydroxy-1', 4 '-phenylene-2, 6 benzo bisoxazole which is shown as formula II and has hydroxyl in random distribution. The polyhydroxy p-phenylene benzo bisoxazole polymer can be used for the preparation of hydroxyl modified PBO (cis-poly(p-phenylene-2,6-benzo bisoxazole) fiber, and comprises an AB type monomer shown as formula III used and a precursor shown as formula V, which are used for the ordered polymer, and a composite salt monomer shown as formula IV, which is used for the random polymer. The hydroxyl is introduced into the molecular chains of the PBO, can improve the fiber UV resistance performance, and has the advantages of outstanding mechanical properties, good heat resistance, light degradation resistance and flame resistance, good bonding property with a resin matrix, and the like.

Owner:宁夏瑞鼎科技有限公司

Polyolefin-based thermoplastic polymer composition

InactiveUS7834093B2Increase surface polarityGood paint adhesionBathing devicesLight therapyPolyolefinPolymer chemistry

Disclosed herein is a polyolefin-based thermoplastic polymer composition, in which an acrylate copolymer phase obtained by absorbing an alkyl acrylate monomer, an alkyl methacrylate monomer, a polar group-containing acrylate monomer and a polymerization initiator into a polyolefin matrix and then polymerizing the monomers is dispersed in a polyolefin phase. The thermoplastic polymer composition has excellent surface polarity leading to excellent paint adhesion.

Owner:AXIAMATERIALS

Polymer material and preparation method thereof

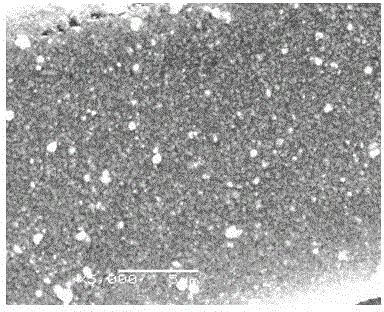

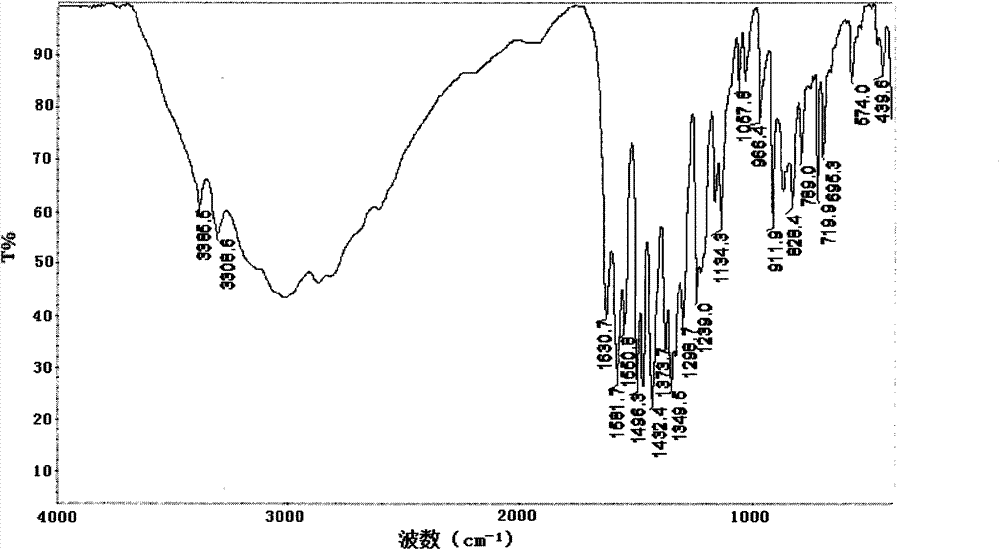

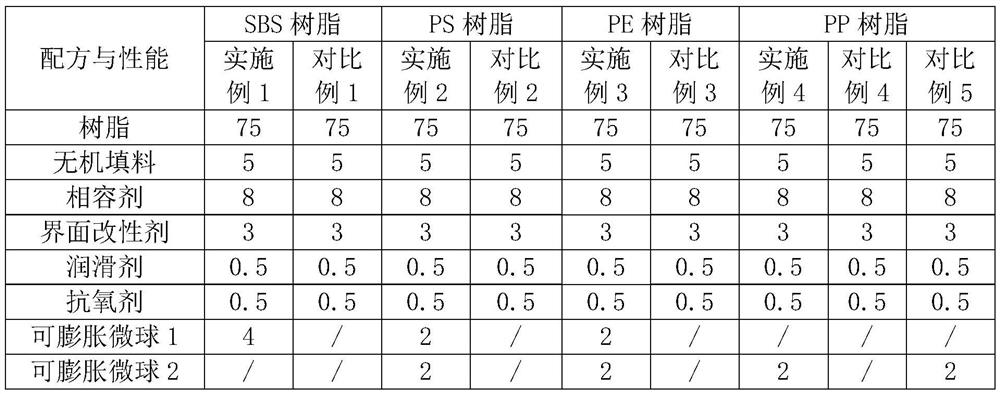

The invention discloses a polymer material and a preparation method thereof. The polymer material comprises polymer material particles, expandable microspheres, inorganic filler and the like. The preparation method comprises the following steps: uniformly mixing the polymer material particles, the inorganic filler, a compatilizer, ane interface modifier, a lubricant and an antioxidant in proportion, and extruding and bracing the mixture through a twin-screw extruder to obtain modified polymer master batch; and blending the modified polymer particles with expandable microspheres, and preparingthe low-density sprayable polymer composite material by using a single-screw injection molding machine. Under the condition of ensuring the strength of the polymer material, the buckling deformation and the density of the polymer material are effectively improved so that the surface of the material becomes rougher, the wetting ability is improved, and the sprayability is enhanced. More active groups exist on the surfaces of the expandable microspheres, and the hyperbranched interface modification aid is combined so that the surface polarity of the polymer is increased, and the sprayability ofthe polymer is improved.

Owner:CRERAX SCI & TECH CO LTD

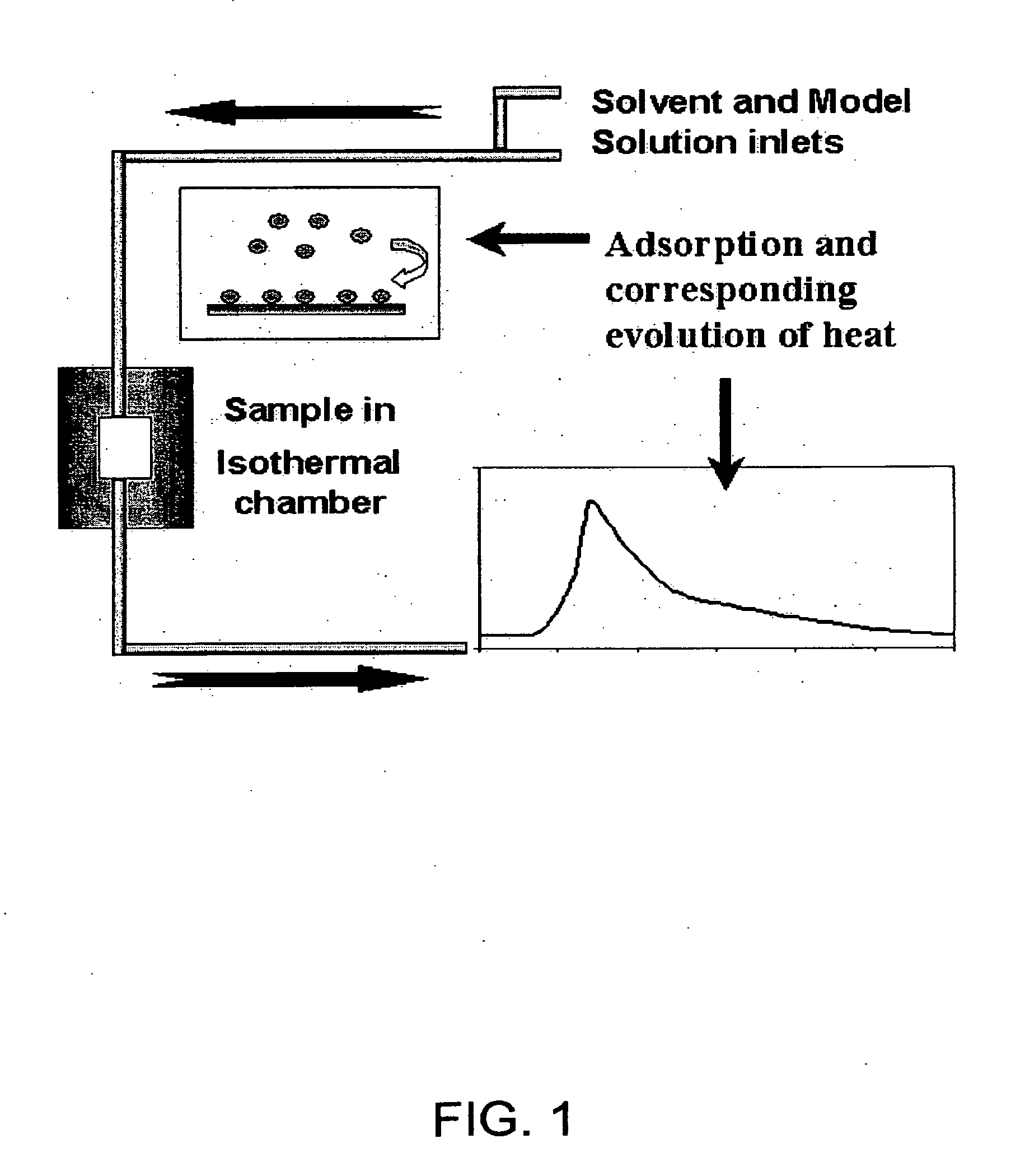

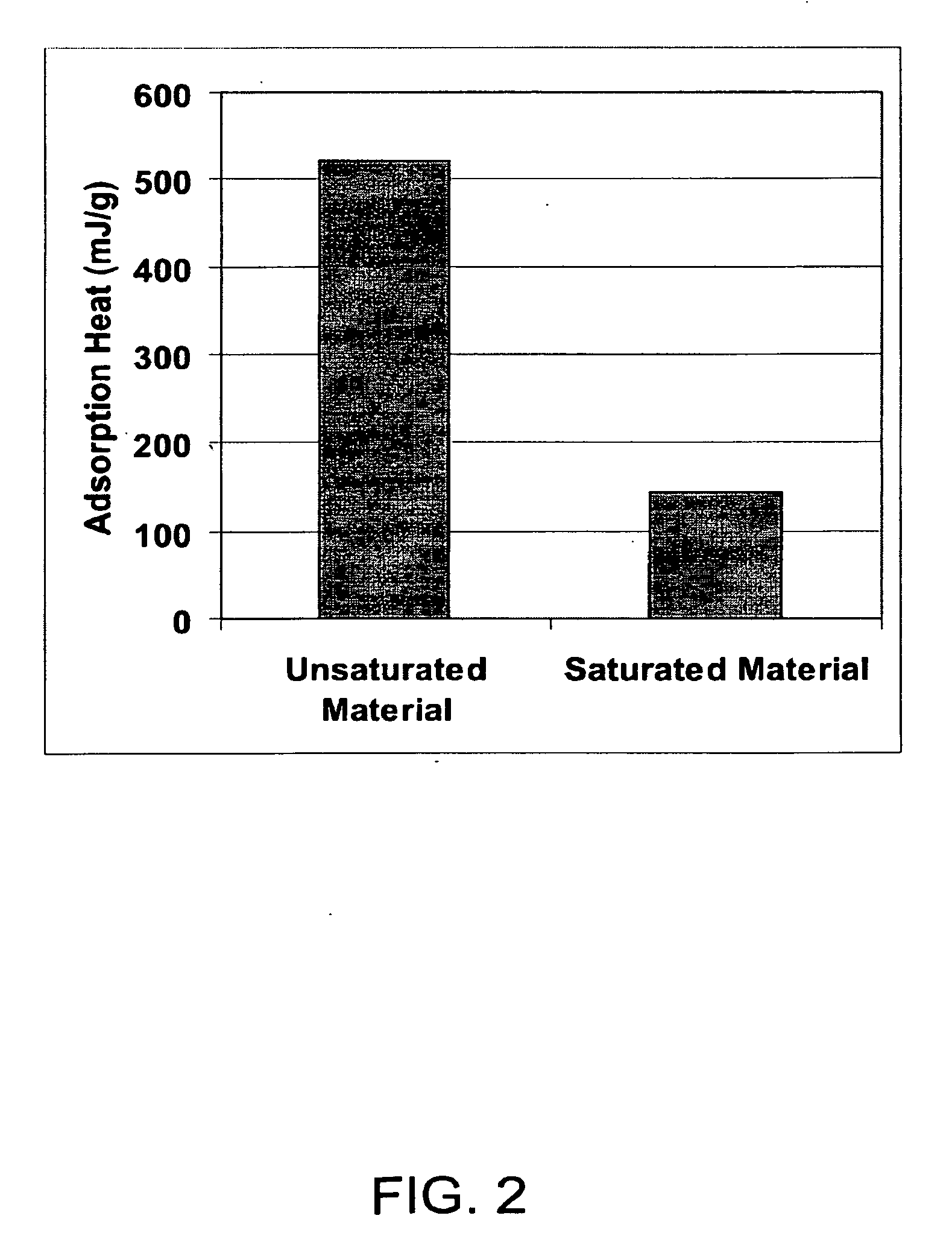

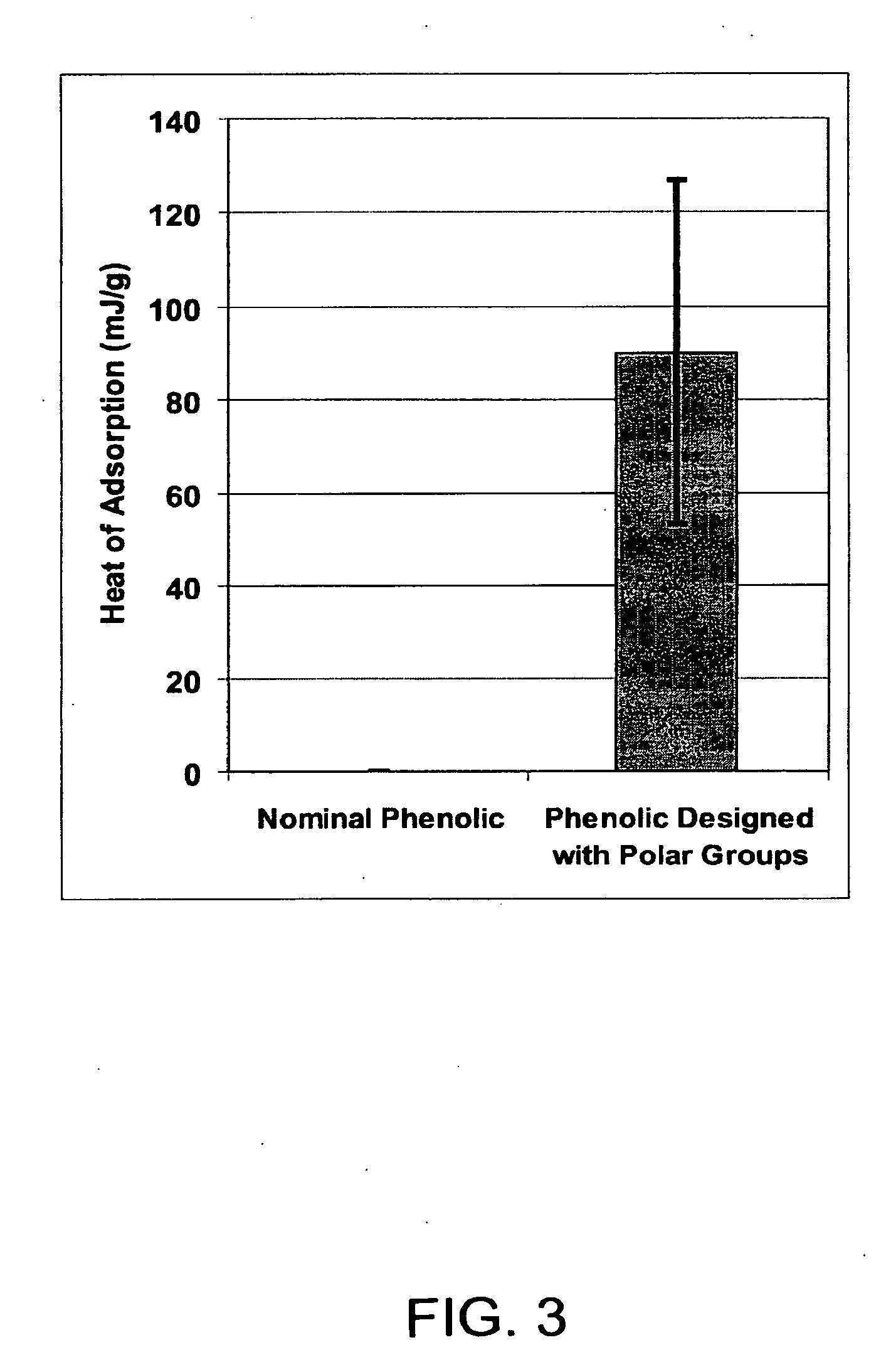

Friction Materials Made With Resins Containing Polar Functional Groups

InactiveUS20090048369A1Strong interactionImprove thermal stabilityOther chemical processesHeat resistant fibresInteraction energyElectrical polarity

A friction material that has a base material impregnated with at least one resin having at least one type of functional group that interacts with the additives in the lubricant. In the preferred embodiment, the resin is a hydroxyl or aldehyde modified phenolic. The heat of absorption, or the interaction energy, of the modified resins to friction modifier additives are larger than the heat of absorption of non-modified phenolic resins when compared to the same friction modifier additives or similar mimic compounds.

Owner:BORGWARNER INC

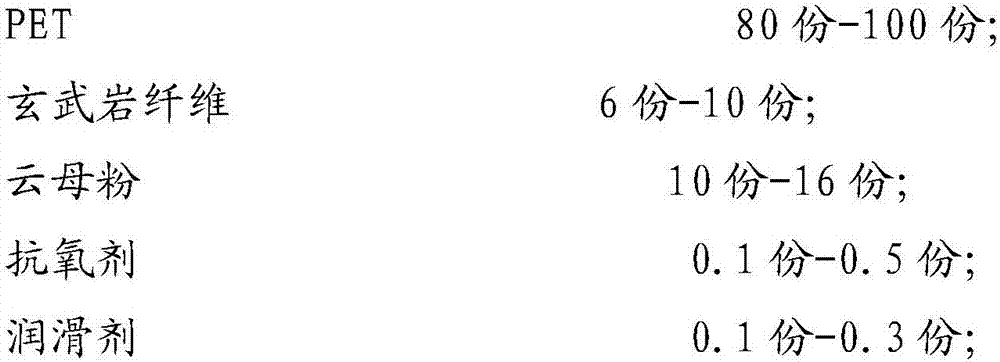

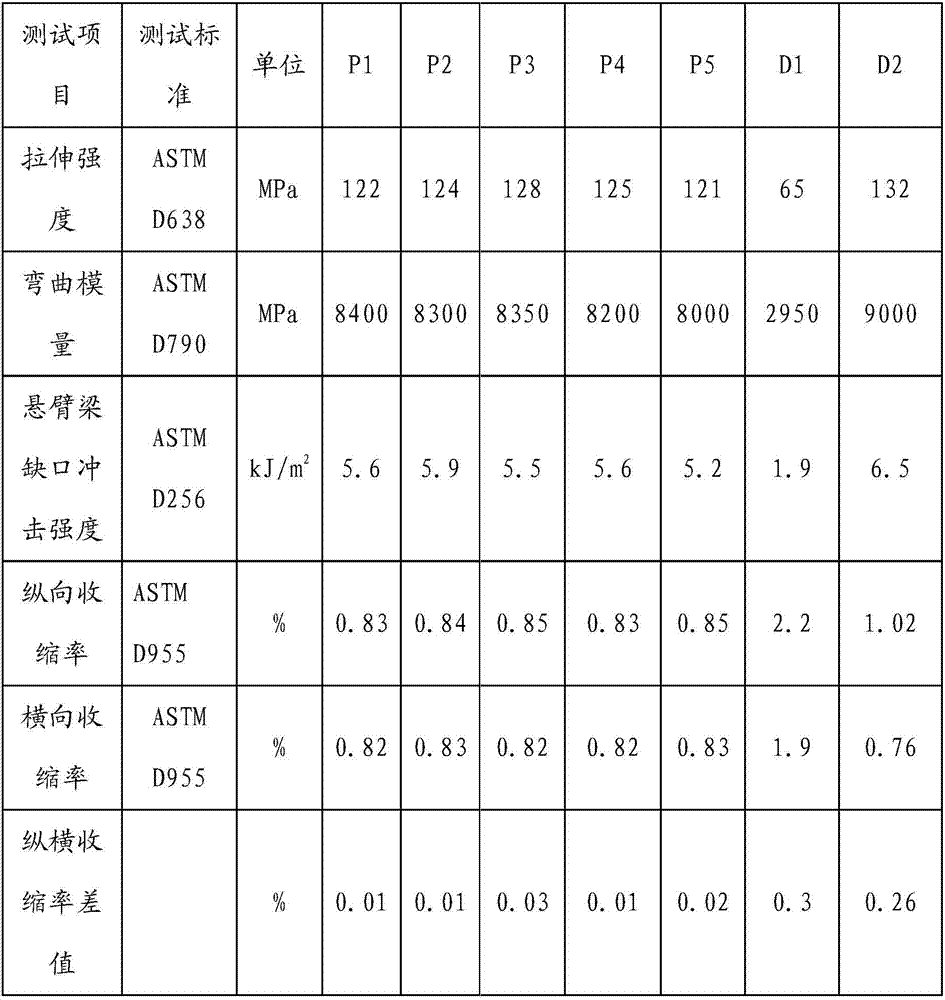

High-performance uniform-shrinkage-rate PET composite material and preparation method thereof

The invention relates to a high-performance uniform-shrinkage-rate PET composite material and a preparation method thereof. The PET composite material consists of the following components in parts by weigh as follows: 80-100 parts of PET, 6-10 parts of basalt fibers, 10-16 parts of mica powder, 0.1-0.5 part of an antioxidant and 0.1-0.3 part of a lubricant. According to the invention, the prepared PET composite material has excellent mechanical properties and uniform lateral and longitudinal shrinkage rates, ameliorates the problems that the impact property of PET composite materials is low and the shrinkage rate of the PET composite materials is not uniform. positive nitrogen ions N<+> are introduced to the surfaces of the basalt glass fibers through plasma processing, so that the active sites of the surfaces are increased, and the surface polarity is improved, and accordingly the attractive force and adhesive ability of the glass fiber surfaces are increased and the compatibility of the glass fibers and PET matrix is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Method for modification of rubber in crumb rubber concrete

InactiveCN105502986AImprove wettabilityIncrease surface polaritySolid waste managementPolymer sciencePotassium permanganate

The invention discloses a method for modification of rubber in crumb rubber concrete. The method comprises the steps of 1, preparing acidic potassium permanganate treating fluid, wherein the mass of potassium permanganate accounts for 0.5-3% of the total mass of the treating fluid, and nitric acid accounts for 0.5-6% of the total mass of the treating fluid; 2, soaking rubber particles in the acidic potassium permanganate treating fluid for 5-50 h, and filtering, cleaning and then drying the rubber particles. After being modified by means of the acidic potassium permanganate treating fluid, the wettability of the rubber particles is improved remarkably, the contact angle is reduced to 67.1 degrees from the original 80.3 degrees, and the surface polarity of the rubber particles is improved through the action between acidic potassium permanganate and the rubber particles; the peak intensity of the surface hydroxyl group or ether group of the modified rubber particles is improved remarkably, the carbanyl group or C=C bond in rubber can be partially oxidized into hydroxyl or carboxyl by potassium permanganate, and then the polarity of rubber macromolecules is improved; bonding force and mechanical engaging force between the modified rubber particles and cement paste are higher, and compressive strength and breaking strength are high.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Process for production of warp knitted silver-gilt undergarment lining

InactiveCN1570261AImprove structural deformationImprove uneven dyeingFibre treatmentSilver plateBiochemical engineering

This invention involves the warp knitting lining production technology, mainly is one silver-plating underwear lining production method. This method includes: A. Relaxes: Relaxes the fabric, causes the fabric full retraction, its internal tensity at the lowest condition; B. Laundering: Washes off on the fabric yarn preparation agent and the greasy dirt; C. Prearranging: Carries on prearranging to the fabric; Its characteristic lies in, d. Fabric calender: Causes the fabric to carry on in the rolling mill calender, improvement warp knitting needle structure distortion; E. Silver-plating: using vacuum ion film plating machine, carries on low temperature plasma processing to the lining to enhance the superficial polarity, this method which use vacuum ion plates continuously carries on the vacuum ion silver-plating to the fabric, enables the silver ion in the fabric surface even distribution, the entire technological process does not have the pollution. This invention provides the method may produce the upscale antibacterial health care warp knitting tension underwear lining, fully displays the silver-plating underwear to the human body health care function.

Owner:JIANGNAN UNIV

Preparation method for composite positive electrode material of lithium battery

InactiveCN107732186AImprove conductivityPromote circulationCell electrodesSecondary cellsHydrolysisLithium-ion battery

The invention specifically relates to a preparation method for a composite positive electrode material of a lithium battery, belonging to the technical field of preparation of positive electrode materials of lithium batteries. According to the invention, a nitrogen-containing carbon source is added in situ, so the carbon source containing a non-metal element is added during the preparation of a LiFePO4 material; and after heat treatment, a non-metal doped carbon-coated LiFePO4 composite material is formed. Hydrolysis and precipitation of a titanium source provide an alkaline environment for the polymerization of dopamine, avoid the use of a Tris buffer and prevent troubles caused by centrifugal separation after a reaction and product loss during the centrifugation of products. While polymerization of dopamine without Tris is realized, TiO2 nanoparticles are introduced onto the surface of LiFePO4, and the introduction of TiO2 into the system is beneficial for improving the stability ofthe composite material. The preparation method provided by the invention ensures excellent performance of the prepared material and is simple in preparation process, low in cost and free of product loss.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Polypropylene composite material for automobile sprayed exterior trimming parts and preparation method thereof

InactiveCN107641256AHigh-volume production featuresLow modification costPolypropylene compositesPolyolefin

The invention discloses a polypropylene composite material for automobile sprayed exterior trimming parts. The polypropylene composite material is prepared from the following raw materials in percentage by mass: 30 to 70 percent of high-impact-resistance co-polypropylene, 10 to 30 percent of high-melt-flow-index high-rigidity homo-polypropylene, 3 to 10 percent of metallocene polyolefin tougheningagent, 5 to 20 percent of talc powder and 2 to 10 percent of high-polarity graft. The invention further discloses a preparation method of the polypropylene composite material. According to the polypropylene composite material for automobile sprayed exterior trimming parts and the preparation method thereof disclosed by the invention, a high-polarity modified polymer is prepared through online melting chemical grafting; moreover, through a two-stage extruding granulator, secondary real-time melt blending of a high-activity and high-polarity modified polymer is realized, significant increase ofthe surface polarity of the obtained polypropylene composite material is ensured, and the adhesion and aging resistance of paint-coated parts are improved.

Owner:中广核俊尔(上海)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com