Surface modified aramid fiber, surface modification method thereof and static sealing material

A technology of surface modification and aramid fiber, which is applied in the field of aramid fiber, can solve the problems affecting the performance of composite materials and the production cannot run normally, and achieve the effect of enhancing the effect, preventing precipitation, and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

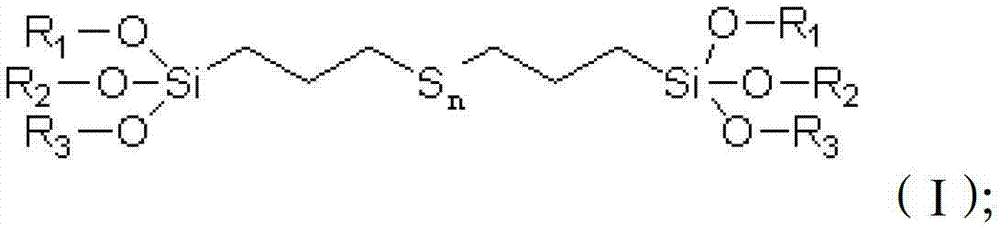

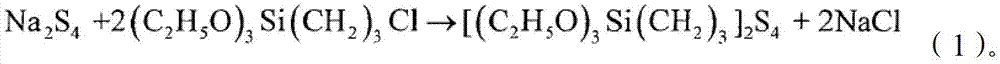

[0076] The silane coupling agent represented by formula (I) is dissolved in ethanol to obtain a silane coupling agent solution, wherein n is 2, R 1 , R 2 and R 3 Both are methyl groups; the mass concentration of the silane coupling agent is 1%.

[0077] The silane coupling agent solution is placed in the oiling machine, and under the conveyance of the constant pressure pump, the aramid fibers traveling on the production line are immersed online, and the travel speed of the aramid fibers is 3m / min, so that the silane coupling agent solution Evenly coated on the surface of aramid fiber.

[0078] The aramid fibers coated with the silane coupling agent solution were dried using a steam-heated drum dryer at a temperature of 60° C. and a drying time of 5 minutes under the condition of contacting air to obtain surface-modified aramid fibers.

[0079] Dry the fluororubber at 60°C for 24 hours.

[0080] 30wt% of dried fluorine rubber, 26wt% of surface-modified aramid fiber, 36wt% o...

Embodiment 2

[0092] The silane coupling agent represented by formula (I) (purchased from China Petroleum Corporation, Si69) was dissolved in n-propanol to obtain a silane coupling agent solution, wherein n was 4, R 1 , R 2 and R 3 are ethyl; the mass concentration of the silane coupling agent is 10%.

[0093] The silane coupling agent solution is placed in the oiling machine, and under the conveyance of the constant pressure pump, the aramid fibers traveling on the production line are immersed online, and the travel speed of the aramid fibers is 15m / min, so that the silane coupling agent solution Evenly coated on the surface of aramid fiber.

[0094] The aramid fibers coated with the silane coupling agent solution were dried using a steam-heated drum dryer under the condition of contacting air, the drying temperature was 100°C, and the drying time was 7 minutes to obtain surface-modified aramid fibers.

[0095] Dry the nitrile rubber at 50°C for 30 hours.

[0096] With 30wt% dried nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com