Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

279results about How to "Normal production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface modified aramid fiber, surface modification method thereof and static sealing material

ActiveCN103194898AIncrease surface polarityImprove mechanical propertiesFibre typesMechanical propertyAramid

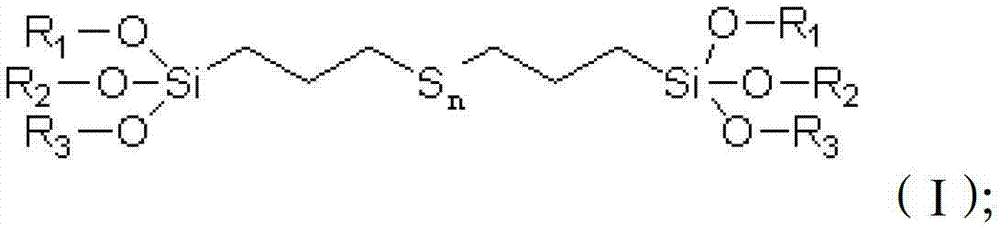

The invention provides a surface modified aramid fiber and a surface modification method of the surface modified aramid fiber. The surface modification method comprises the steps of coating silane coupling agent solution or a dispersion liquid on the surface of the aramid fiber and then drying the aramid fiber under the condition of being contacted with air, thus obtaining the surface modified aramid fiber, wherein a silane coupling agent has a structure in the formula (I) in the specification; n is 2 or 4; and R1, R2 and R3 are independently selected from alkyl with number of carbon atoms being 1-5. When being adopted to produce composite materials, the aramid fiber prepared by the surface modification method provided by the invention can prevent precipitation and deposition of base materials while improving the mechanical properties of the composite materials and is simple, easy and safe in production operation. The invention also provides a static sealing material. The static sealing material adopts the surface modified aramid fiber and has relatively good mechanical property, sealing property and other properties.

Owner:廊坊佰昂密封材料有限公司

Coproducing cement technological method of producing acid using phosphogypsum and sulfur

ActiveCN1948131AIncrease production intensitySimplify the heat transfer processSulfur-trioxide/sulfuric-acidExhaust gasSlag

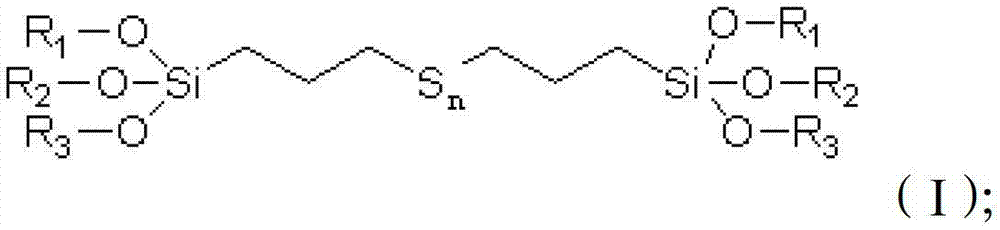

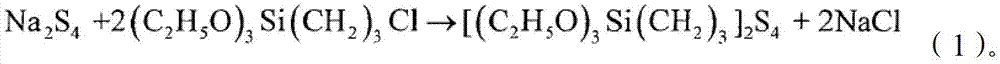

The present invention relates to a process capable of simultaneously preparing acid and producing cement by combining phosphogypsum with sulfur. It is characterized by utilizing waste slag phosphogypsum obtained by wet process phosphoric acid production to prepare acid and produce cement. In the concrete, the invented process includes the following steps: utilizing low-concentration SO2 gas discharged out from rotary kiln of phosphogypsum acid-making system and making said kiln gas undergo the processes of washing, cleaning and drying, then be mixed with high-concentration SO2 gas discharged from sulfur acid-making system to obtain the SO2 gas whose concentration is 8-9%; and adopting an advanced two-stage two-absorption acid-making process to prepare sulfuric acid; at the same time firing the phosphogypsum in the rotary kiln to obtain cement clinker, grinding and blending so as to obtain cement.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Method for culturing microalgae by utilizing aquaculture wastewater

InactiveCN107629961ADefense against microbial attackNo need for sterilization or disinfectionUnicellular algaeMicroorganism based processesEcologyCulture mediums

The invention relates to a method for culturing microalgae by utilizing aquaculture wastewater. The method comprises the following steps: 1) domesticating microalgae: inoculating microalgae into a culture medium for culturing, adding unsterilized aquaculture wastewater in a culture process and gradually increasing the adding rate of the aquaculture wastewater according to the growing number of themicroalgae; 2) activating the microalgae: adding the unsterilized aquaculture wastewater into the culture medium and then inoculating the domesticated microalgae into culture medium for performing amplification culture; and 3) culturing the microalgae: inoculating the activated microalgae into an unsterilized aquaculture wastewater solution and culturing under an outdoor condition, thereby realizing aquaculture wastewater purification and microalgae grease production. According to the method for culturing the microalgae by utilizing the aquaculture wastewater provided by the invention, the unsterilized aquaculture wastewater is adopted for culturing the microalgae under the outdoor condition, the aquaculture wastewater purification and the microalgae grease production can be realized at the same time and the method has the advantages of low cost and suitability for large-scale production.

Owner:SHAOGUAN COLLEGE

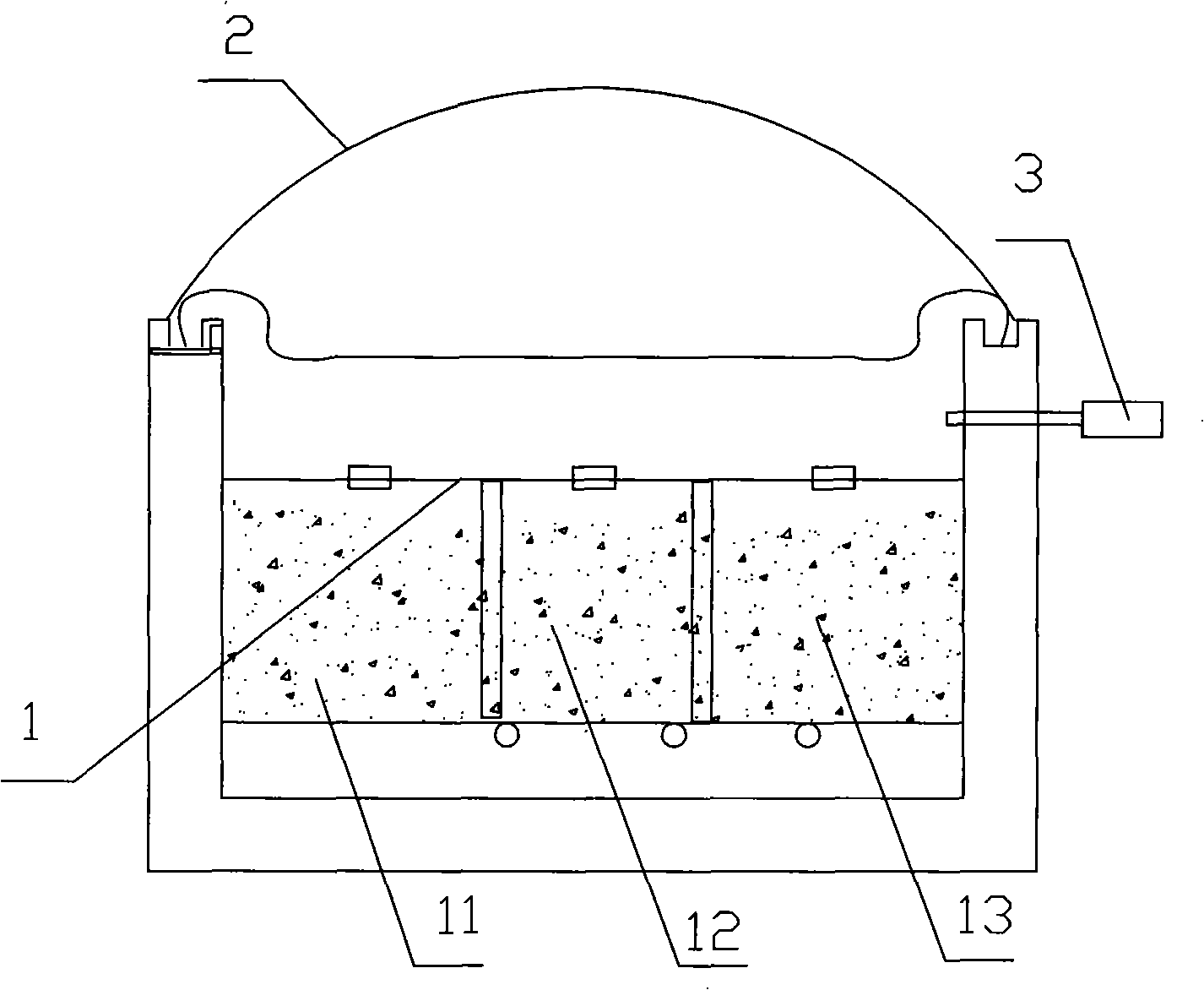

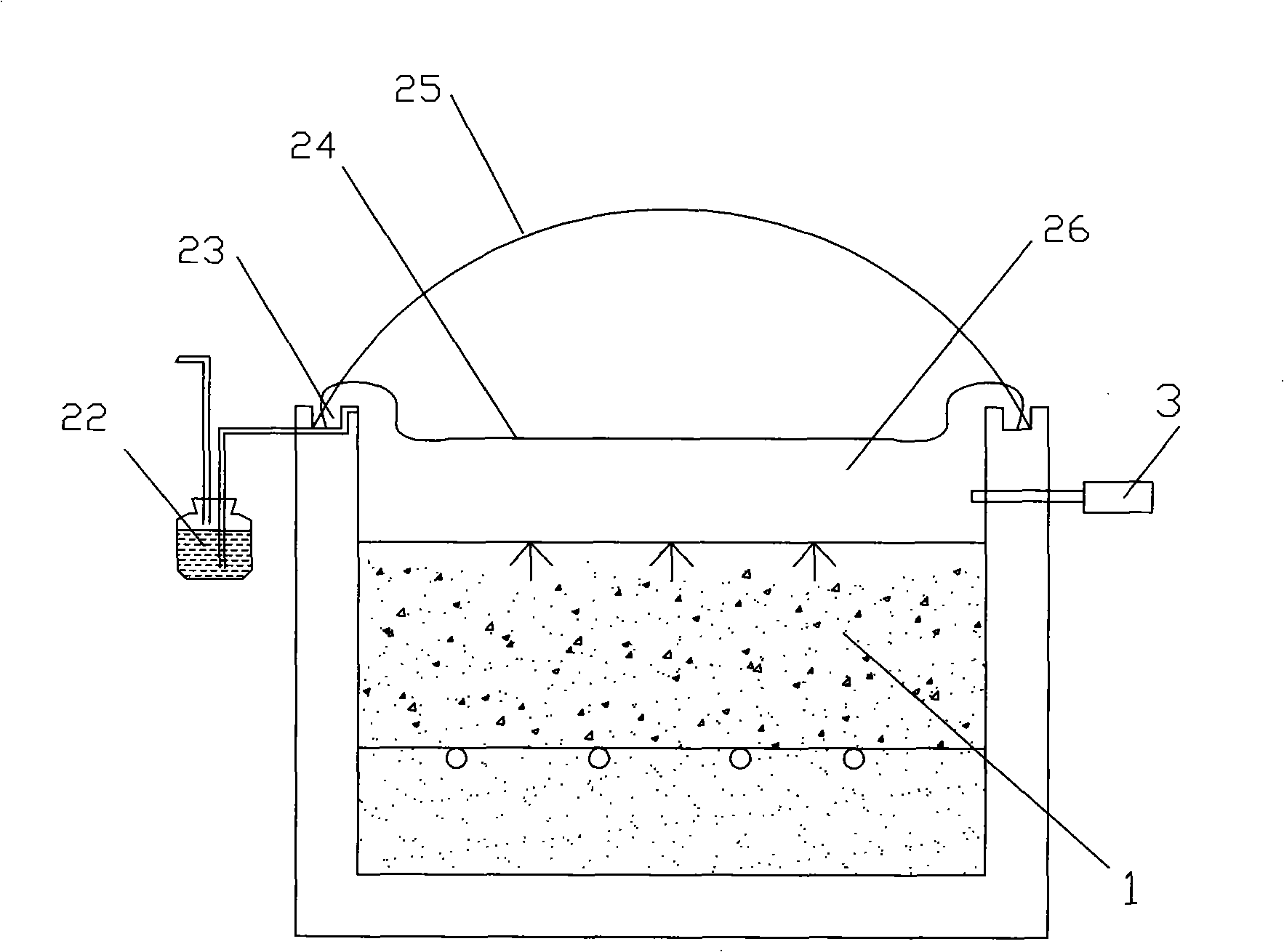

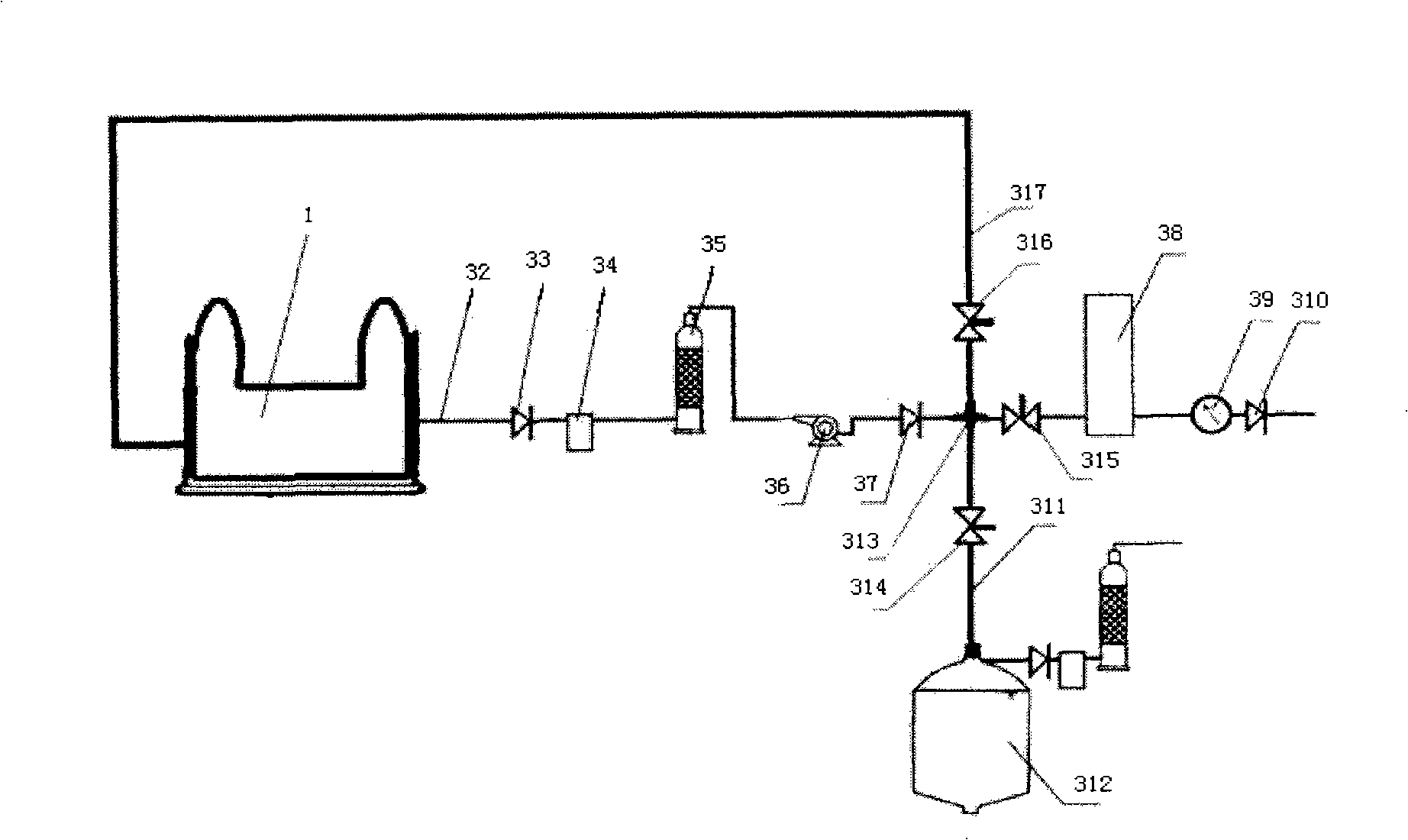

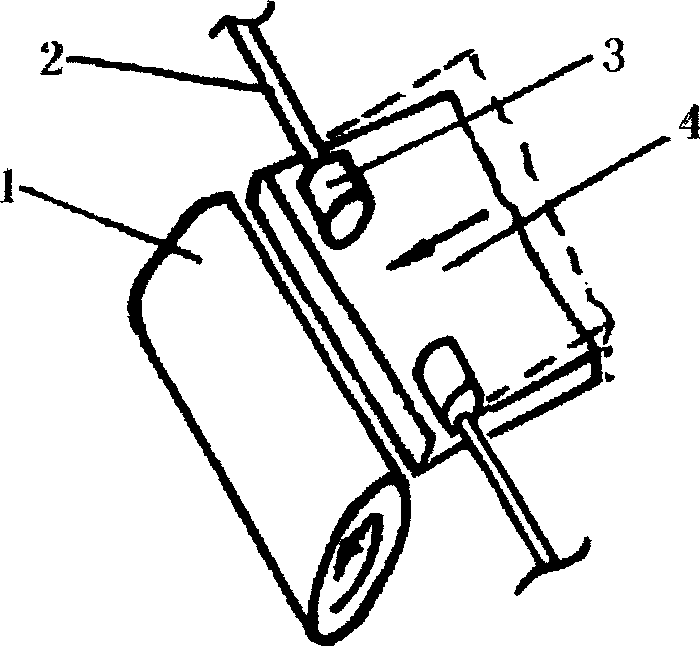

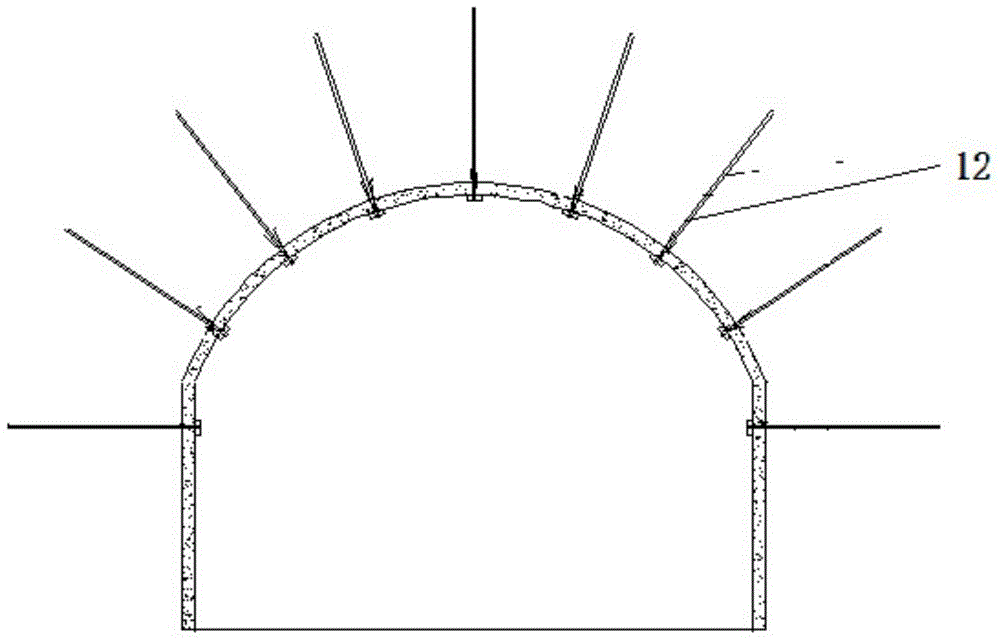

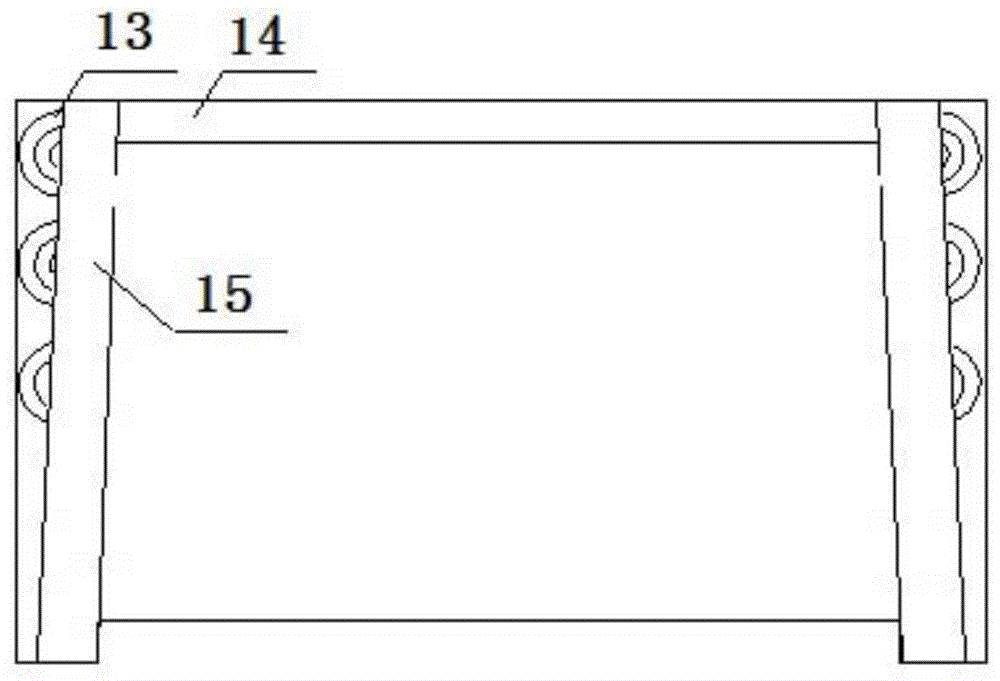

Large-sized open mouthed combined methane tank

InactiveCN101353623ALimited activity spaceFree from wear and tearBioreactor/fermenter combinationsBiological substance pretreatmentsCirculating pumpCharge and discharge

The invention discloses a large-scale open compound methane tank, including a fermenting tank (1), a gas collection and storage device (2), and an air feeder (3) connected with the fermenting tank, wherein, the fermenting tank includes a plurality of independent fermenting tanks which can be communicated or disconnected mutually. The methane tank also includes the gas collection and storage device, the air feeder, a solar warming device, a charging / discharging device and an anti-encrustation device of the methane tank. When in use, as the structure of the invention is provided with a plurality of independent fermenting tanks, the air can be fed continuously in the raw material renewal process; the charging / discharging device accelerates the material charging and discharging; the gas collection and storage device of the methane tank has low construction cost, a software cover can be opened or retracted according to gas production, a gas collection and storage chamber can be changed according to the methane quantity, the pressure in the gas collection and storage chamber can not be too high, and the solar warming device increases the temperature in the methane tank so as to lead the straw material to produce the methane under the suitable temperature in winter; and a circulating pump is used for spraying the methane fluid onto the straw material through a nozzle so as to avoid encrustation.

Owner:南阳市绿野循环农业研究所 +1

Phosphatizing liquid and preparation method thereof

InactiveCN101935831AReduce construction difficultyIncrease productivityMetallic material coating processesSodium fluoridePhosphoric acid

The invention discloses phosphatizing liquid. The phosphatizing liquid comprises the following components in percentage by weight: 7 percent of starter liquid, 0.38 to 0.4 percent of neutralizer, 0.2 to 0.6 percent of accelerator and the balance of water, wherein the starter liquid comprises the following components in percentage by weight: 30 to 36 percent of 85 percent phosphoric acid, 16 to 20 percent of 68 percent nitric acid, 15.6 to 18.4 percent of 99.7 percent zinc oxide, 0.4 to 0.6 percent of citric acid, 0.4 percent of sodium fluoride, 0.6 to 1 percent of nickel nitrate, 0.16 to 0.24 percent of ferric nitrate, 0.004 to 0.01 percent of copper nitrate and the balance of water.

Owner:景阳富

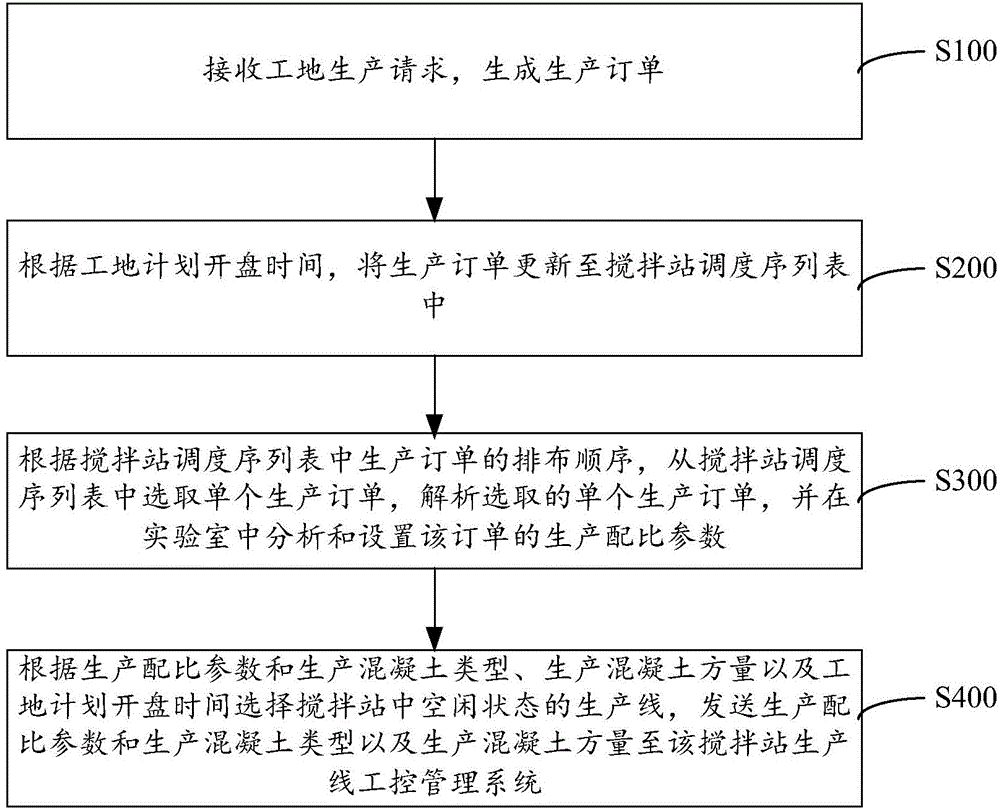

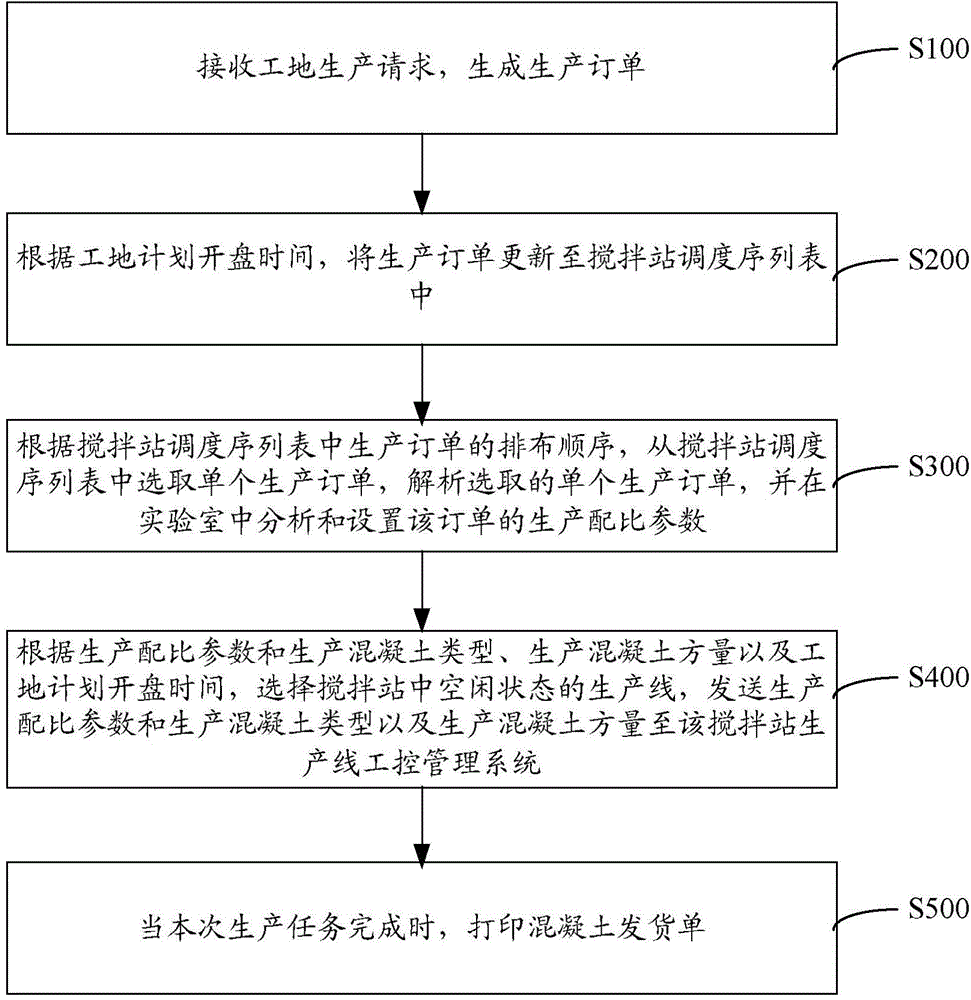

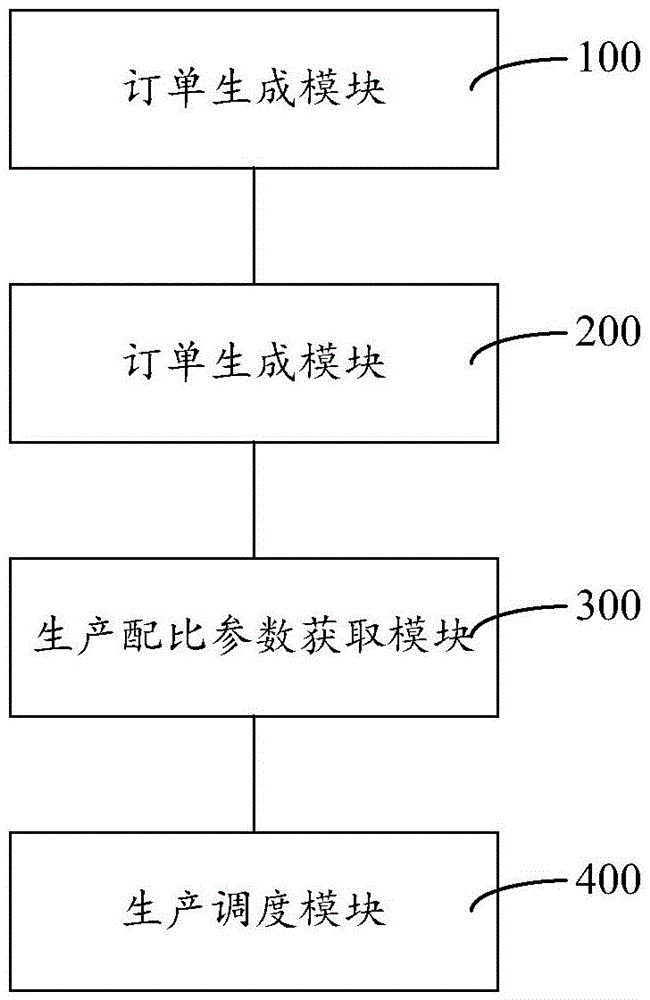

Production scheduling method and system for mixing plant

InactiveCN104573943ANormal productionProduction scheduling is normalResourcesTypes of concreteManagement system

The invention provides a production scheduling method and system for a mixing plant. According to the production scheduling method, production requests of construction sites are received, production orders are generated, and the production orders are updated in a scheduling list of the mixing plant according to planned opening time of the construction sites; a single production order is selected and analyzed, the production proportional parameters of the order are analyzed and set in a laboratory, the production proportional parameters, produced concrete type and produced concrete cubic meters are sent to a mixing plant industrial control management system, and a mixing plant production line for executing the production task is selected. In the production scheduling process in the whole mixing plant, the production orders can be received automatically without too many operators for control, coordination work with mixing plant industrial control management can be realized, the production line meeting the production task requirements is selected in the mixing plant for concrete production, good production scheduling of the mixing plant is realized, and normal and efficient production of the mixing plant is guaranteed.

Owner:HUNAN WANWU IND SOFTWARE

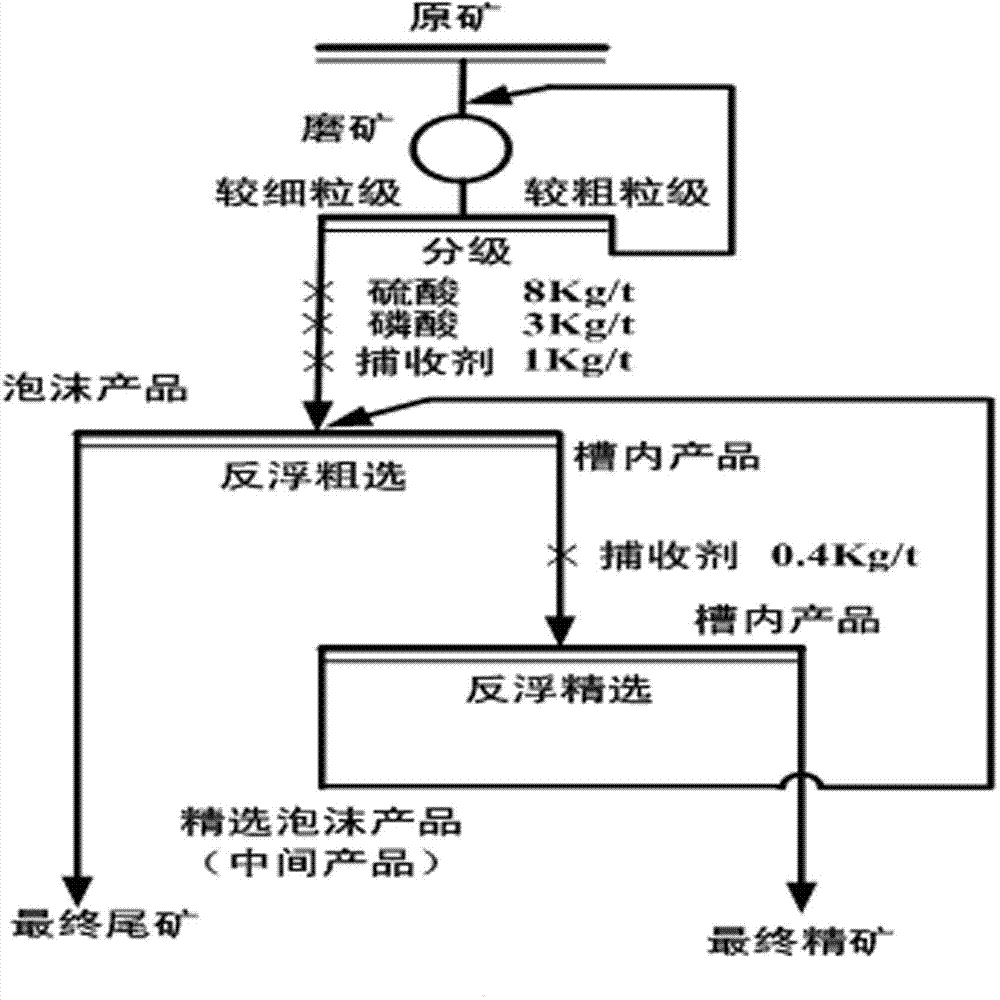

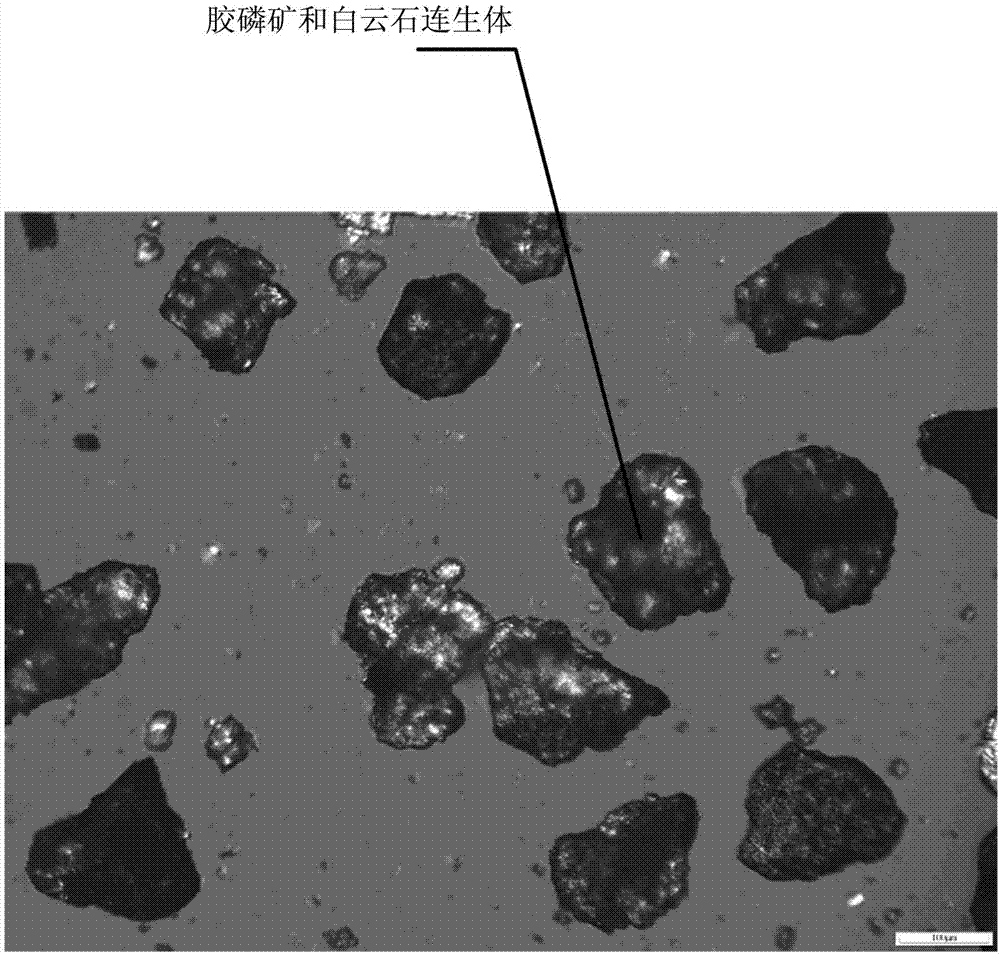

Process for reducing collophanite flotation tailing grade

ActiveCN104707734AHigh recovery rateReduce consumptionFlotationGrain treatmentsSocial benefitsPhosphorite

The invention discloses a process for reducing the collophanite flotation tailing grade. The process comprises the specific steps that firstly, mineral is ground, then the ground mineral products are graded, relatively coarse grained products obtained after grading are returned to a mill to be ground again, and the relatively fine grained products obtained after grading enter the flotation process to be subjected to reverse flotation operation; flotation foam products serve as final tailings, and products in a flotation cell are graded; relatively coarse grained products obtained after grading serve as intermediate products and are returned to the mill to be ground again, a closed-loop operation is formed, and relatively fine grained products obtained after grading serve as final fine mineral products. The high-magnesia collophanite is processed through the process, qualified phosphate concentrate with the MgO grade smaller than or equal to 0.8% is obtained, the recovery rate of concentrate is improved by 1-3%, and the tailing P2O5 grade is reduced by 1-2%. The stable collophanite flotation technical-economic indexes can be obtained through the process, the utilization rate of the phosphate rock resources is improved, the energy and chemical consumption of a whole flotation mill are reduced, the economic and social benefits of the flotation mill are improved, and the process has wide industrial popularization value.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

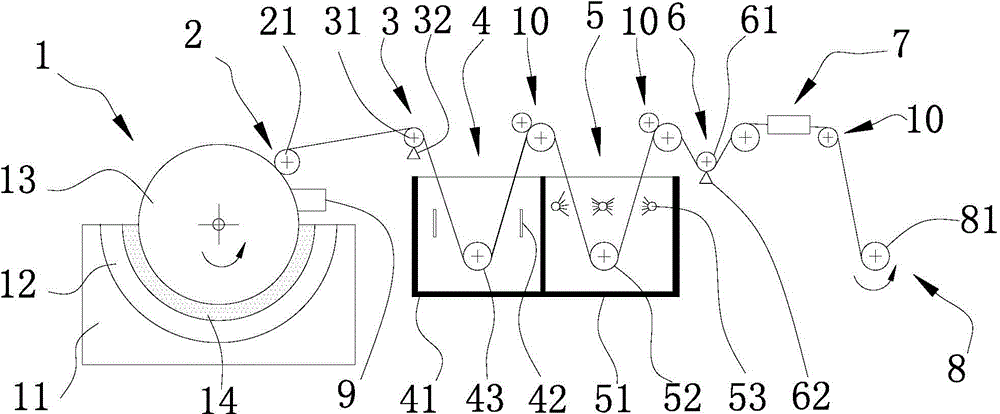

Method for maintaining position of thin belt

InactiveCN1413894ASlow down the speed of deviationControl deviationNon-mechanical conveyorsRollersEngineeringMagnet

An offset correcting method for thin driving belt has two approaches. One approach is used of magnetic attraction, that is, the permanent-magnet material is installed on the driving roller or the electromagnetic coil is installed in the driving roller and magnetic thin driving belt is used. Another approach is to arrange two pressing friction rollers at both ends of driving roller above the driving belt and regulating their pressure and tension can correct the offset of thin driving belt.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

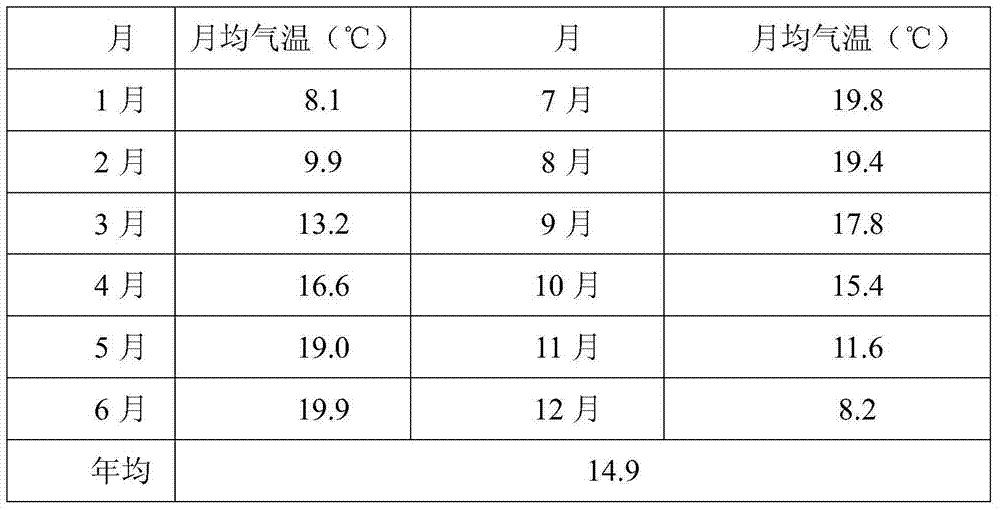

Method for producing short-day strawberry flowering seedlings in central region of Yunnan province

ActiveCN104115732AIncrease costImprove reproductive efficiencyCultivating equipmentsSoilless cultivationFragariaBEACH STRAWBERRY

The invention discloses a method for producing short-day strawberry flowering seedlings in the central region of Yunnan province. The method comprises the steps of variety selecting, stock plant field planting curing, seedling breeding and short-day flowering processing. The short-day strawberry variety with the properties that the number of flowers in simple inflorescence is more than 20, the flowering time of a single flower in the same inflorescence is scattered, and the flowering time of the simple inflorescence lasts for one or more months is selected; the stock plant field planting curing, the seedling breeding and short-day flowering processing are carried out in the central region of Yunnan province with the altitude ranging from 1,600 meters to 1,900 meters; a nutrient solution including 100-150 milligrams per liter of N, 20-25 milligrams per liter of P and 80-100 milligrams per liter of K is used for watering the seedlings during the stock plant curing period, the seedlings are processed for 10 hours in the short day and processed for 30-35 days under the natural temperature condition, and flower bud differentiation is achieved in more than 90 percent of seedlings. The flowering cost is low, the flowering seedling supply time is early, 30-40 seedlings can be harvested in each stock plant in the middle ten days of June, the fresh autumn short-day strawberries can be produced, and normal winter and spring fresh strawberry production can be guaranteed.

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI +1

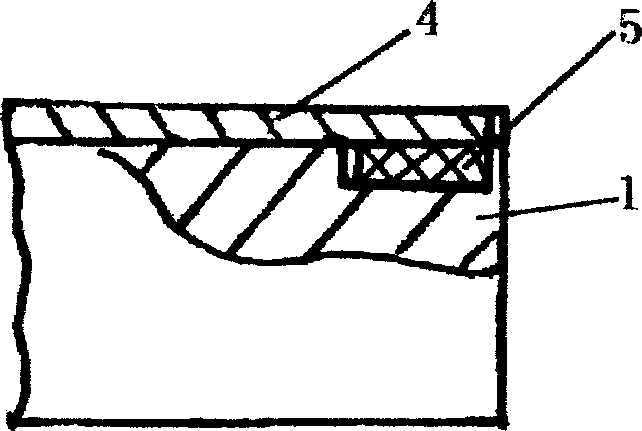

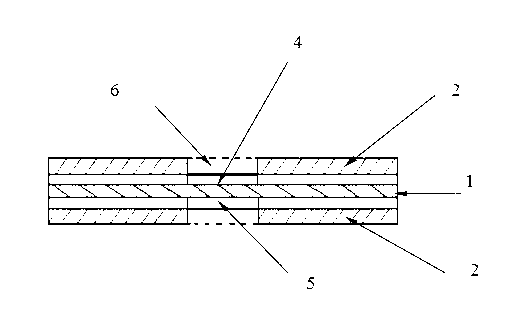

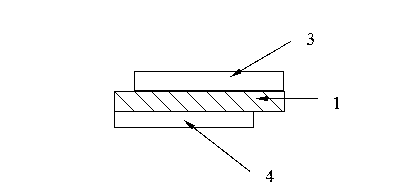

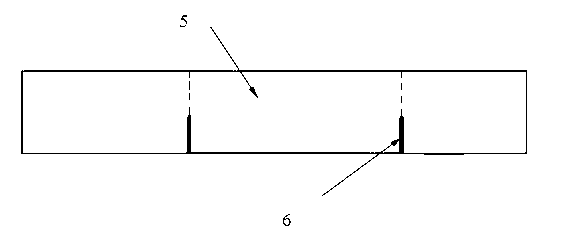

Flexibility and hardness combined circuit board and manufacturing method thereof

ActiveCN103298240AEliminate mechanical drillingSave PTH (copper oxide)Printed circuit assemblingPrinted circuit detailsEngineeringHardness

The invention provides a flexibility and hardness combined circuit board. The flexibility and hardness combined circuit board comprises a flexible board and a hard board, wherein the flexible board which is made of pure copper comprises an upper surface and a lower surface, the upper surface of the flexible board is attached with an upper protective film, and the lower surface of the flexible board is attached with a lower protective film, and the flexible board and the hard board are bonded through hot-pressing glue. The invention further provides a method for manufacturing the flexibility and hardness combined circuit board. The pure copper of the flexible board is used for replacing a double-faced board, production procedure is reduced, device investment is saved, production cost is reduced, production efficiency and product yield are improved, the hard board is precut, and the purpose of conducting normal circuit manufacturing of the flexibility and hardness combining circuit board can be realized by the utilization of a common film drying machine.

Owner:FLEX PLUS XIAMEN

Starch-based degradable garbage bag material and preparation process thereof

The invention discloses a starch-based degradable garbage bag material and a preparation process thereof. The garbage bag material is characterized by comprising the following components in parts by weight: 84-93 parts of heavy calcium carbonate, 18-23 parts of corn starch, 1-1.8 parts of surface treating agent, 4-9 parts of POE (Polyolefin Elastomer), 54-63 parts of HDPE (High-Density Polyethylene) and 1-3 parts of polyisobutene. The garbage bag material has the advantages of high dispersity, original longitudinal and transverse tensile force and good popularization value.

Owner:佛山市衡龙科技有限公司

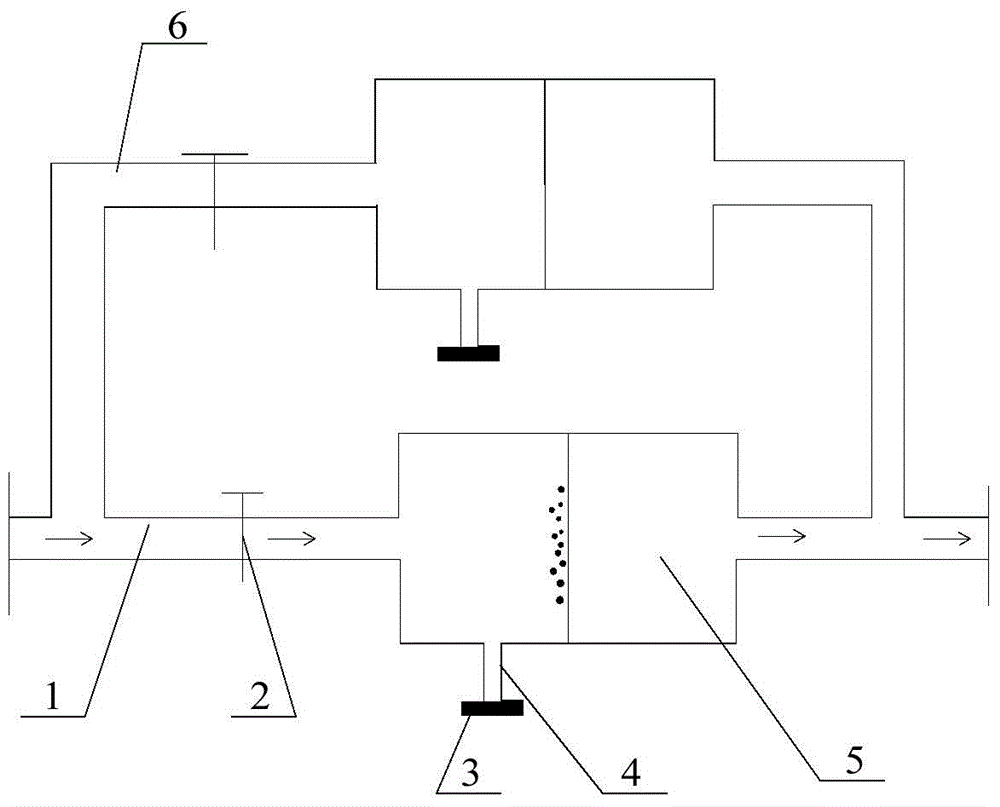

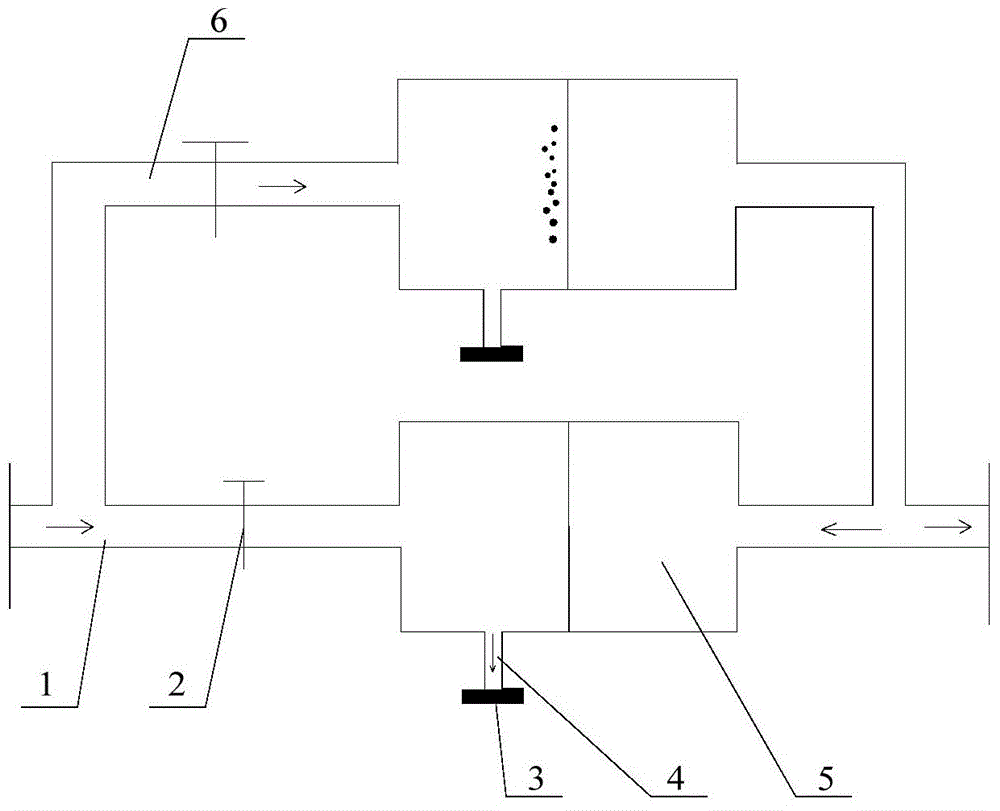

Backwash water quality filter system

ActiveCN104474771AGuaranteed filtering effectReduce maintenance frequencyFiltration separationFilter systemWater quality

The invention discloses a backwash water quality filter system. The backwash water quality filter system comprises a water supply branch and a backwash branch, which are connected with each other in parallel, wherein both the water supply branch and the backwash branch are respectively provided with a valve and a filter in serial connection in the direction from a water inlet to a water outlet, a filter element is arranged inside each filter to divide a chamber of a shell into a liquid inlet cavity and a liquid outlet cavity, the liquid inlet cavity is communicated with the water inlet through the valve, the liquid outlet cavity is communicated with the water outlet, and the filter on the water supply branch is provided with a sewage discharge pipe which can be opened and closed and through which the liquid inlet cavity is communicated with the exterior; in the application process, the backwash branch valve is closed, the water supply branch valve is opened, the backwash water quality filter system stays at a normal water supply state at the moment, and the impurities can be removed; after the backwash water quality filter system is used for a period of time, the water supply branch valve is closed, the backwash branch valve is opened, and the sewage discharge pipe on the water supply branch filter is opened to carry out the backwash. By adopting the structure, the maintenance frequency of the water quality filter system can be reduced; moreover, in the maintenance process, the filter for the supply water can be guaranteed, and the normal production can be guaranteed.

Owner:兖矿中科清洁能源科技有限公司

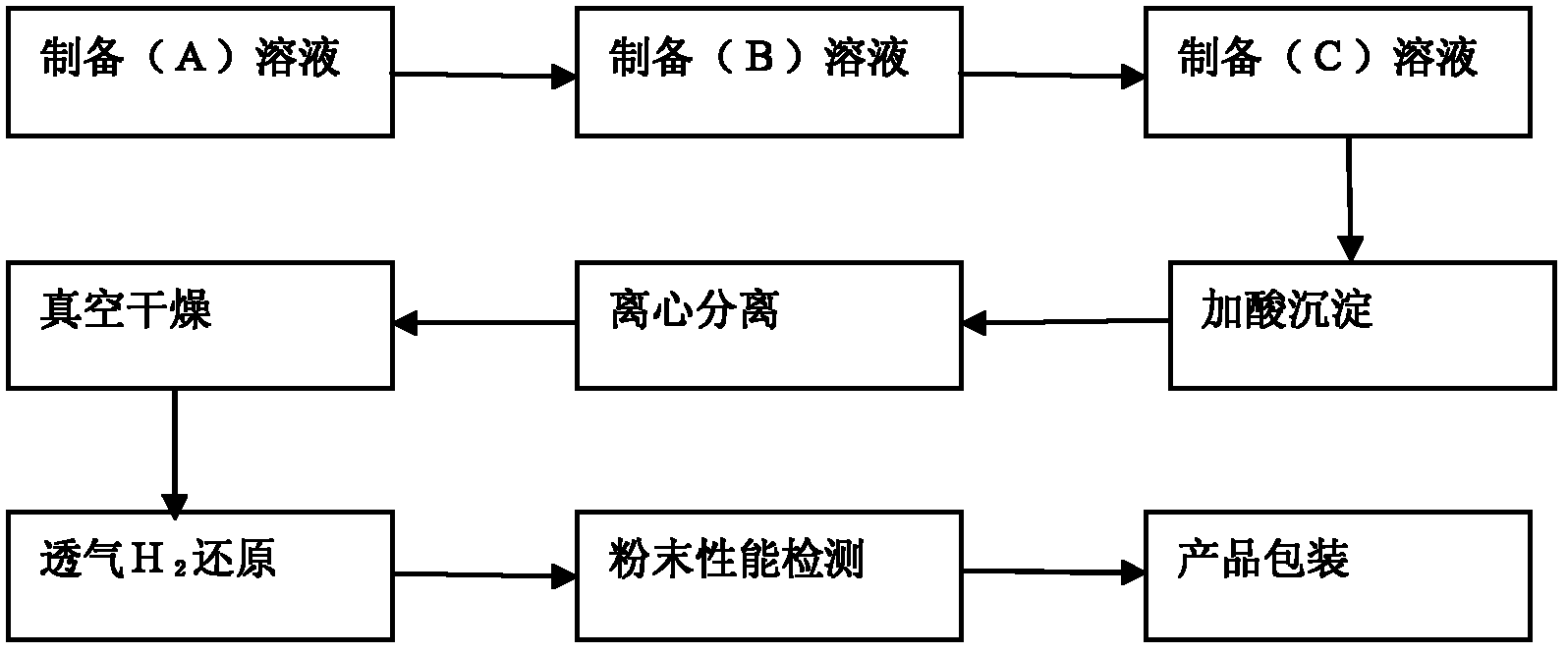

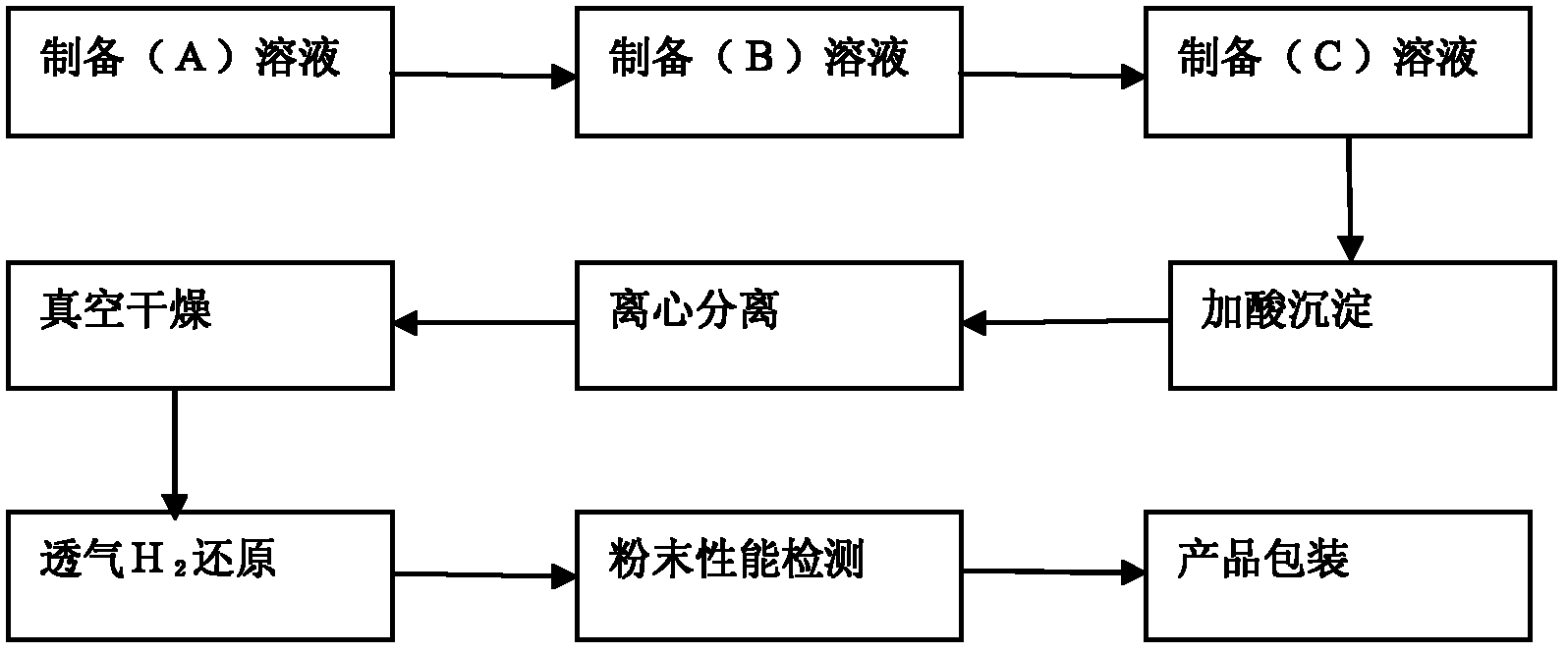

Method for preparing nano-tungsten powder by using sulfuric acid precipitation-H2 breathable reduction process

The invention belongs to the technical field of preparation of metal powder which belongs to a metal material, in particular to a method for preparing nano-tungsten powder by using a sulfuric acid precipitation-H2 breathable reduction process, which is suitable for large-scale industrial production of nano-tungsten powder. The method is characterized by comprising: performing a precipitation reaction under the common action of a separant and a dispersing agent by using diluted solution of ammonium tungstate and diluted aqueous solution of sulfuric acid to obtain nano particular tungstic acid precipitate, performing centrifugal separation at high speed, washing repeatedly, drying under vacuum, reducing in a continuous breathable H2 reduction furnace, and finally obtaining nano tungsten powder with an average particle size of less than or equal to 35 nano meters. The method has the advantages that: the cost is low; the production efficiency is high; the equipment is simple; the process is short; the investment is small; and continuous and automatic large-scale production can be realized easily.

Owner:UNIV OF SCI & TECH BEIJING

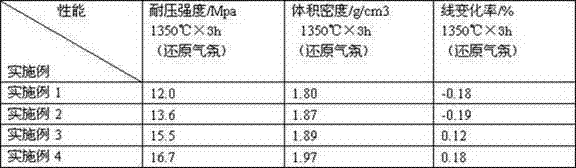

Novel blast furnace stemming

The invention discloses blast furnace stemming. The blast furnace stemming is characterized by comprising, by weight, 10-20 parts of gahnite, 5-15 parts of raw bauxite powder, 10-20 parts of gangue raw ores, 10-25 parts of gangue calcined clinker ores, 10-20 parts of composite clay, 10-33 parts of renewable graphite electrode powder, 8-18 parts of vanadium pentoxide, 3-8 parts of asphalt powder, 1.0-1.7 parts of Glydoln 2002, and 12-14.5 parts of extra binding agent. The novel blast furnace stemming is low in cost, capable of effectively maintaining chambering of tap holes, and is constant in using performance and operability after long-term storage.

Owner:HENAN POLYTECHNIC UNIV

Method for processing waste catalyst in production of pentafluoro ethane

InactiveCN1962064AEasy to recycleNormal productionAmino compound purification/separationCatalyst regeneration/reactivationPolymer scienceEther

The invention relates to a method for treating the waste catalyst in hydrofluoeic ether production, wherein it comprises: mixing catalyst, reacting with alkali, and distilling in distilling tower. The invention has low energy consumption and high quality, with low cost.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

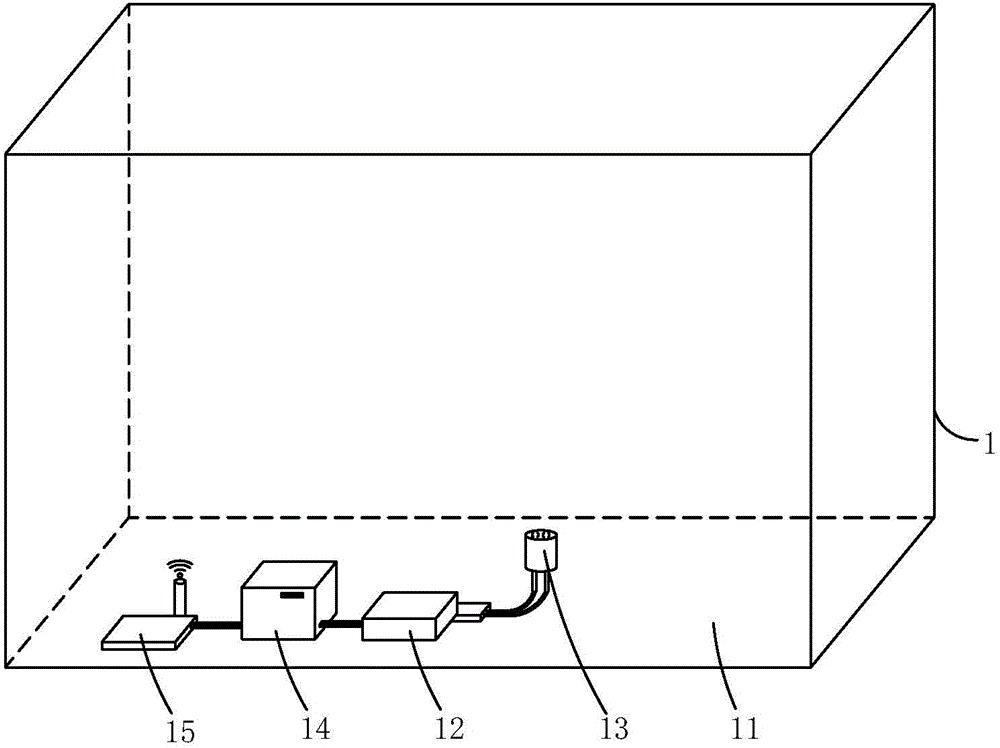

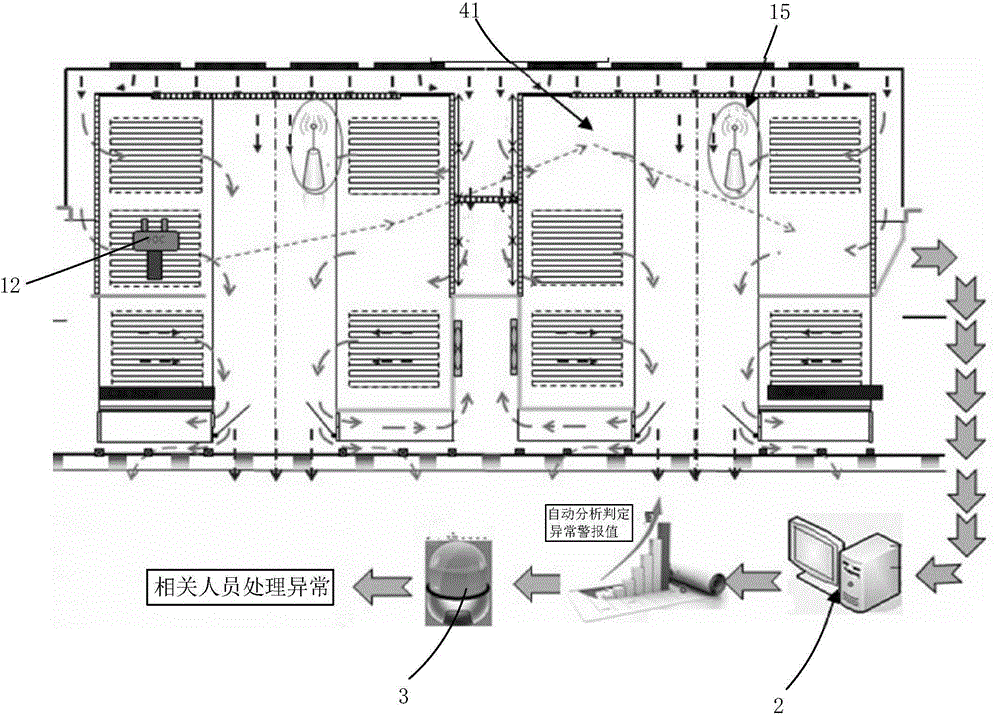

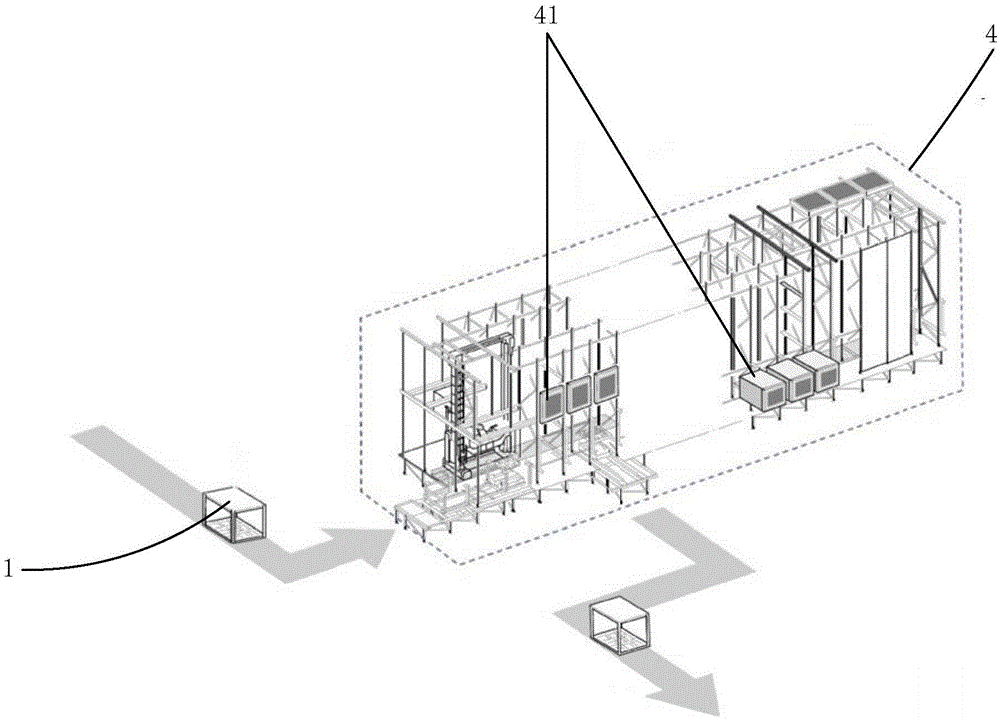

Automatic detection system and detection method for volatile organic compound

ActiveCN104792942AReduce warehouse downtimeEnsure normal productionMaterial analysisVolatile organic compoundAutonomation

The invention provides an automatic detection system and an automatic detection method for a volatile organic compound. The automatic detection system for the volatile organic compound comprises an automatic material handling system, a detection unit (1), a server (2) and a feedback unit (3), wherein the concentration of the volatile organic compound in the automatic material handling system can be automatically detected. The automatic detection method for the volatile organic compound comprises the following steps: setting a detection path of a detection unit (1) by virtue of a server (2), transporting the detection unit (1) through the automatic material handling system to detect the concentration of the volatile organic compound in the automatic material handling system, and simultaneously transmitting real-time detection data to the server (2); and automatically analyzing the detection data, judging an abnormal alarm value, and controlling the feedback unit (3) to send out an alarm to remind related personnel to process the abnormal condition. The manual measurement is replaced; the warehousing downtime is reduced; guarantee of normal production is facilitated; the measurement efficiency is improved; and the human cost is effectively reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Process for cleaning high-precision screen printing plates

The invention relates to a process for cleaning high-precision screen printing plates, which comprises the steps of: 1 rapidly taking down a screen printing plate in one minute after printing, and collecting residual silver paste on the screen printing plate in two minutes; 2 simultaneously wiping the front side and the back side of the screen printing plate with non-woven fabric wetted in a TM plate washing agent along the direction of mesh stretching angles; 3 after the both sides of the screen printing plate are cleaned by the TM washing agent, simultaneously wiping the front and the back sides of graphics fields with non-woven fabric wetted in a DM plate washing agent along the direction of mesh stretching angles, 4 checking graphs with lights, if partial graphs are invisible, simultaneously wiping the front and the back sides of the field with non-woven fabric wetted in the DM plate washing agent along the direction of mesh stretching angles, until the graphs are visible, wherein the whole wiping process is not more than ten minutes; and 5 after the screen plating plate is wiped clean, drying the screen printing plate with an ion blower gun. The process can rapidly clean the high-precision screen printing plates completely, and is quite effective to plates with high-precision screen printing silver paste that is difficult to be cleaned, has low cleaning cost, and guarantees the normal production.

Owner:TIANJIN ZHONGHUAN HI TECH

Blast furnace stemming

The invention discloses a blast furnace stemming, which is characterized by comprising the following components in parts by weight: 10-20 parts of waste stemming, 5-15 parts of waste alumina brick, 10-20 parts of gangue raw ore, 10-25 parts of gangue calcined processed ore, 10-25 parts of composite clay, 10-33 parts of regenerated graphite electrode powder, 8-18 parts of vanadium pentoxide, 3-8 parts of asphalt powder, 1.0-1.7 parts of Glydoln 2002, and 12-14.5 parts of bonding agent added in addition. The stemming has low cost, and can be used for maintaining a reamed hole at an iron outlet, and the usage and operation property are not lowered during long term of storage of the stemming.

Owner:山国强

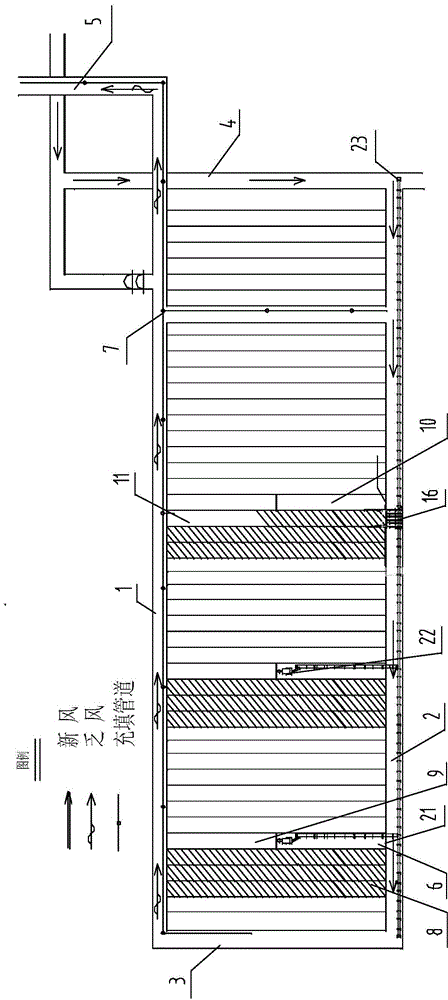

Coal mining and filling integrated method for coal mine

ActiveCN104675399AImprove fill rateFissure zone loweringUnderground miningSurface miningSocial benefitsEcological environment

The invention discloses a coal mining and filling integrated method for a coal mine. The method comprises the following steps: (1) digging out an air returning and filling pipeline lane, a boundary air lane and a transportation and air intaking lane of a mining region on a working surface of the mining region; (2) mining coal with a narrow strip channel in the working surface of the mining region, in which a ventilating system is formed, after coal mining in each narrow strip channel is finished, communicating the transportation and air intaking lane of the mining region with the air returning and filling pipeline lane of the mining region through narrow strip channels; (3) transporting coal mine cementing filling material slurry into a narrow strip channel excavating region formed after the coal mining in the narrow strip channels is finished for filling; and (4) mining the coal in the narrow strip channels while filling the narrow strip channel excavating region. The mechanical cementing, filling and milling method for the coal mining, disclosed by the invention, is beneficial to sufficiently developing underground coal resources, protecting the ecological environment and ground vegetation, releasing a large number of dull coal and prolonging the service life of a mine, and has remarkable economic benefits and social benefits.

Owner:内蒙古晨德建设工程有限公司

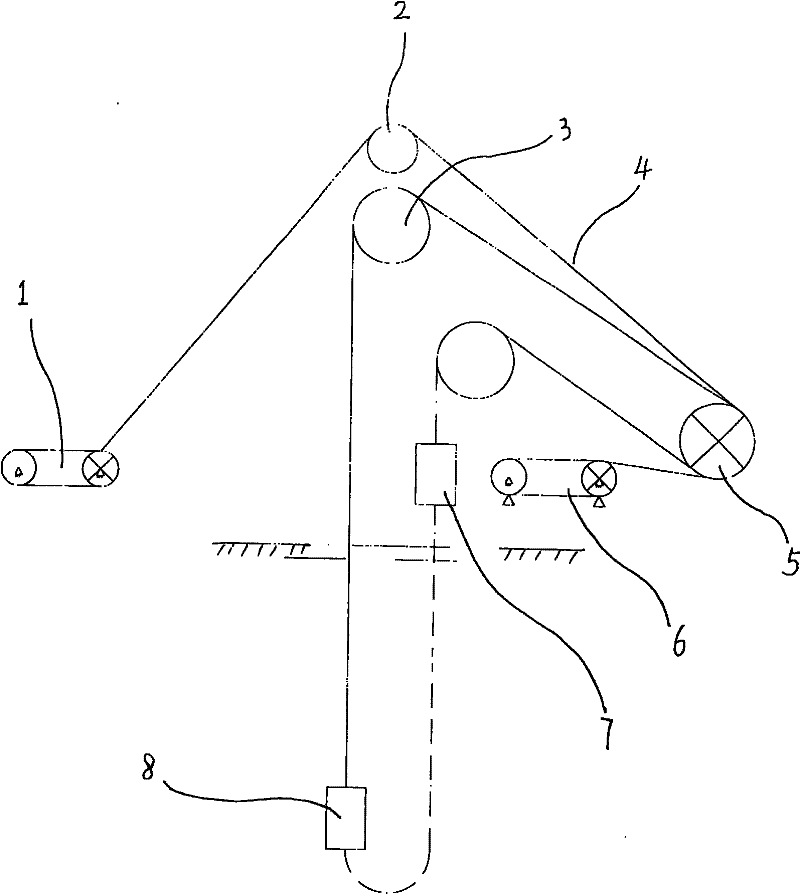

Method for replacing lifting ropes of multi-rope frictional geared winch

The invention discloses a method for replacing lifting ropes of a multi-rope frictional geared winch. A tensioner, a pulley block, a head sheave, the lifting ropes, the winch, a tractor, a container II and a container II are involved; and according to the characteristics of the multi-rope frictional geared winch, the ropes are replaced by effectively using the tensioner and the tractor, at least two ropes are always kept connected with the containers, the winch has enough traction to draw the containers in the rope replacement construction process, the lifting ropes keep enough intensity, themechanical operation level is improved, rope replacement time is reduced, the labor intensity of workers and high-attitude operation time at a wellhead are reduced, the aim of replacing the ropes safely is fulfilled and normal production is guaranteed.

Owner:张万忠

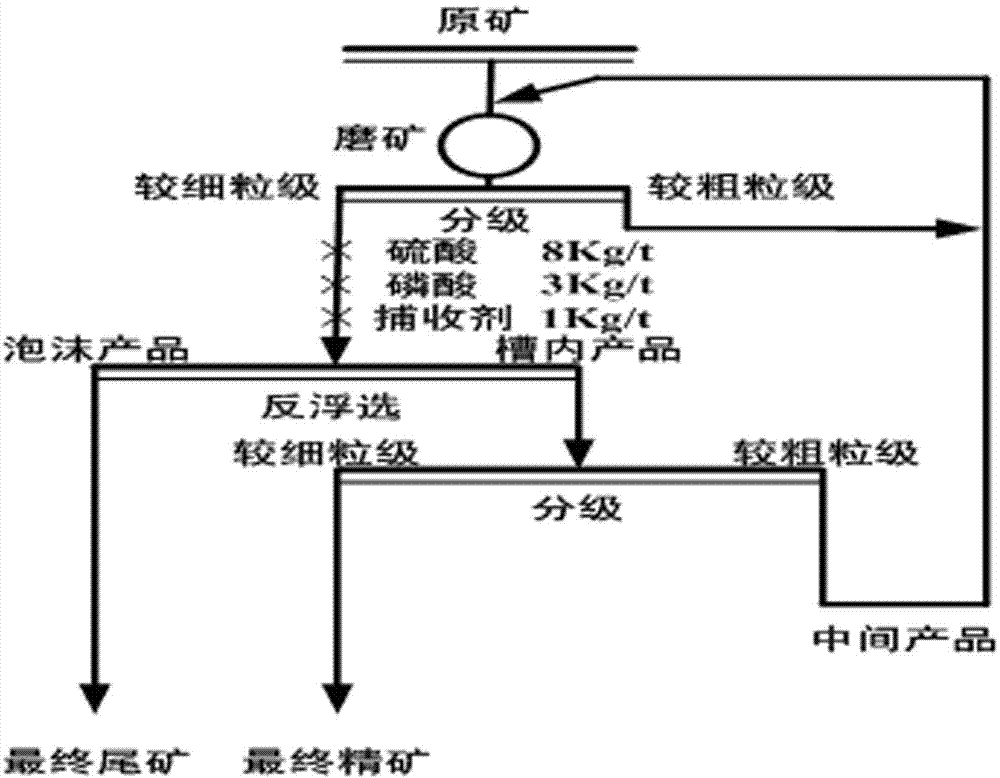

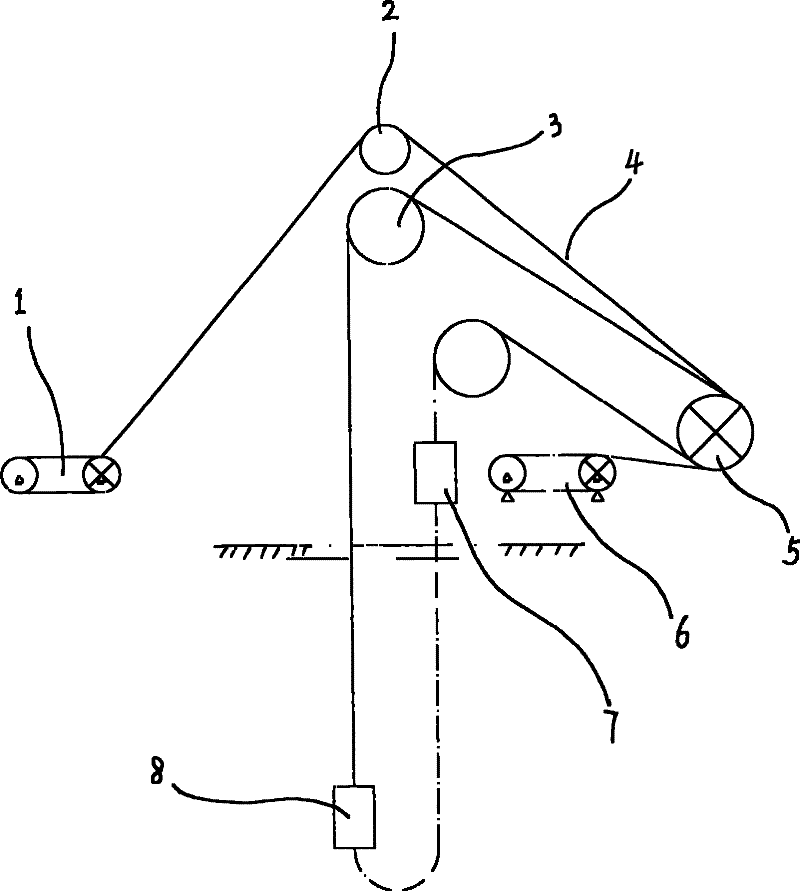

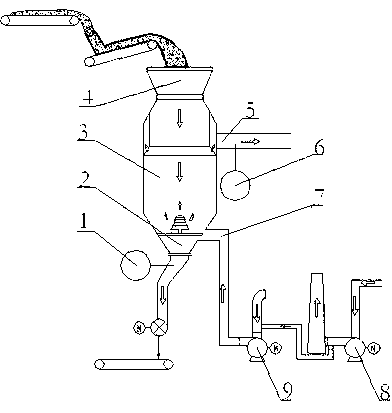

Weathered collophanite graded processing technique

ActiveCN102773151AStable productionNormal productionWet separationChemical industryResource utilization

The invention relates to a weathered collophanite graded processing technique, belonging to the technical field of chemical industry mineral processing. The weathered collophanite graded processing technique is one of techniques for implementing normal production and processing of weathered collophanite and enhancing phosphorus resource utilization ratio. The technique comprises steps as follows: weathered collophanite is crushed and subjected to primary grinding, the primary grinding product is firstly graded, the product with fine particle size is activated slime, the product with crude particle size is ore slurry and is subjected to secondary grinding, the secondary grinding product is subjected to comprehensive grading processing, the processed product which is easy for floatation is ore slurry with crush particle size and enters a floatation processing system to produce high-grade phosphorus concentrate, and the processed product which is hard for floatation is ore slurry with fine particle size and is directly used as low-grade phosphorus concentrate. The firstly graded activated slime can be directly sold as a low-efficiency fertilizer, the high-grade phosphorus concentrate and the low-grade phosphorus concentrate are mixed to form the final satisfactory mixed phosphorus concentrate product, and the floatation tailings of floatation processing directly enter a tailing house to be stored. The technique is especially suitable for processing weathered collophanite around the Dian Lake in Yunnan Province, implements normal and stable production of processing enterprises of weathered collophanite resources, enhances the utilization ratio of phosphorus resources of China, and has wide industrial popularization value.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

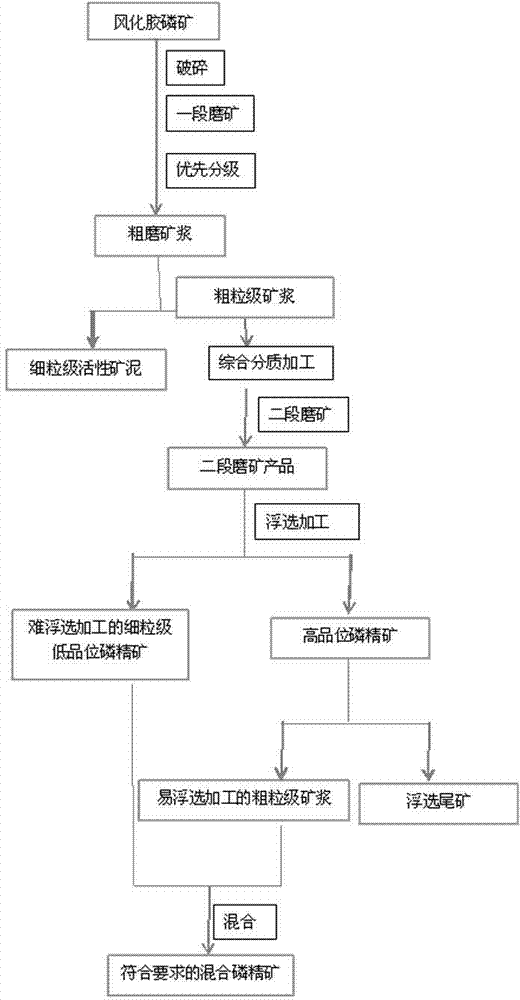

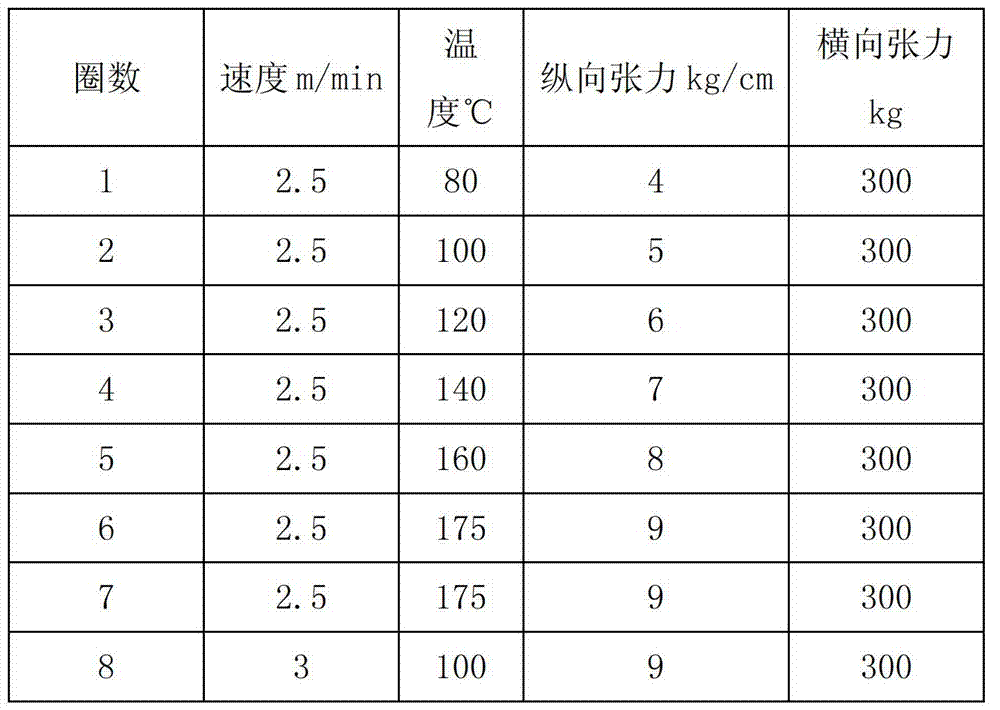

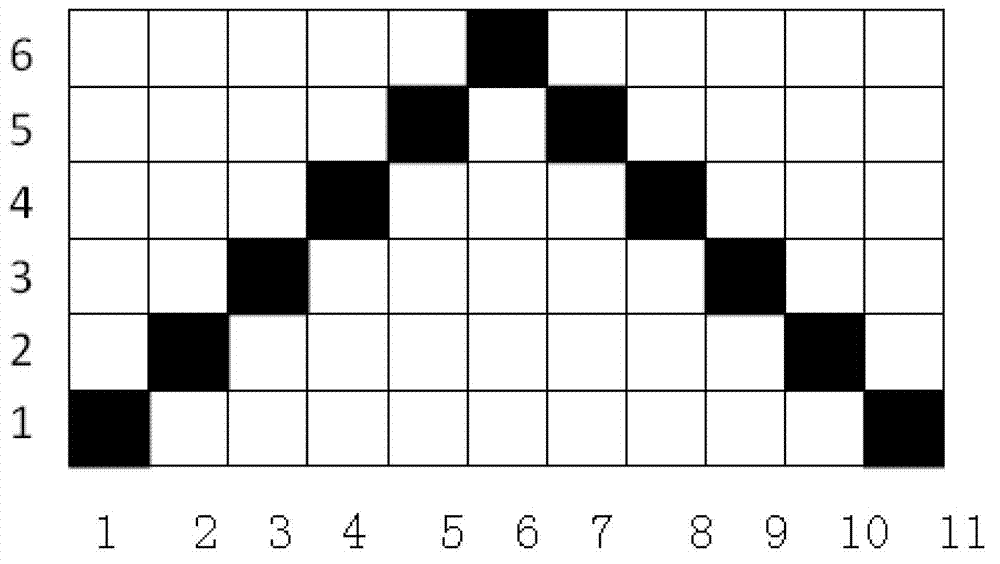

Process for producing polyester electric conduction filter strips

ActiveCN103088519AOrganizational stabilityHigh strengthFiltration separationOpen work fabricsPolyesterBiochemical engineering

The invention discloses a process for producing polyester electric conduction filter strips. The method comprises the following steps of: purchasing raw materials, checking wires, warping, delivering heads, weaving nets, checking the nets, shaping at one time, cutting the nets, manufacturing ports, checking finished products, packaging and putting in storage. According to the process, warp and weft wires are all Germany high-quality polyester single wires, and the innovative selection and application of black imported polyester electric conduction single wires guarantee the stability and the service life of products. By adjusting the process for producing the polyester electric conduction filter strips, normal production of all processes can be realized, and fabric products are stable in texture, flat in net surface, high in intensity, long in service life and excellent in performance.

Owner:ANHUI PACIFIC SPECIALITY FABRIC

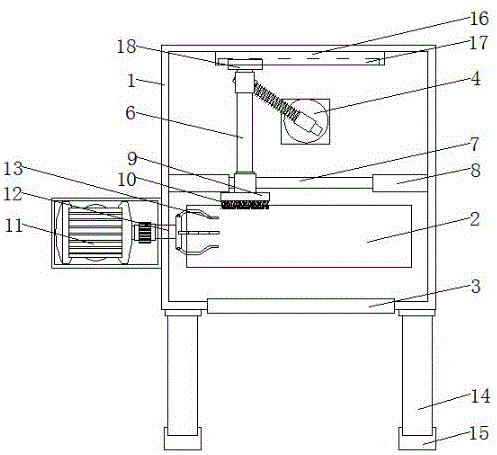

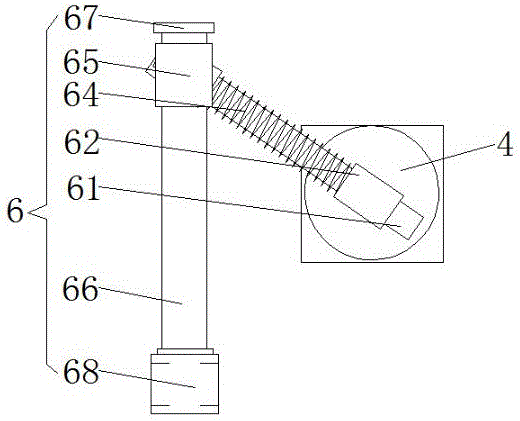

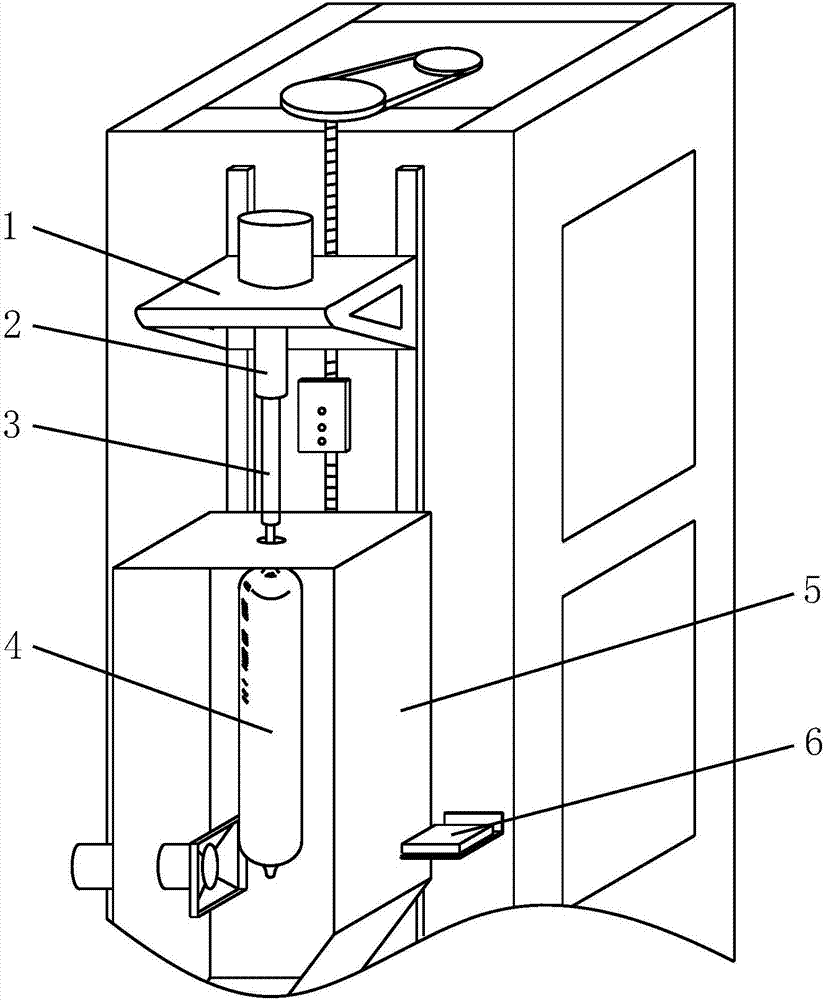

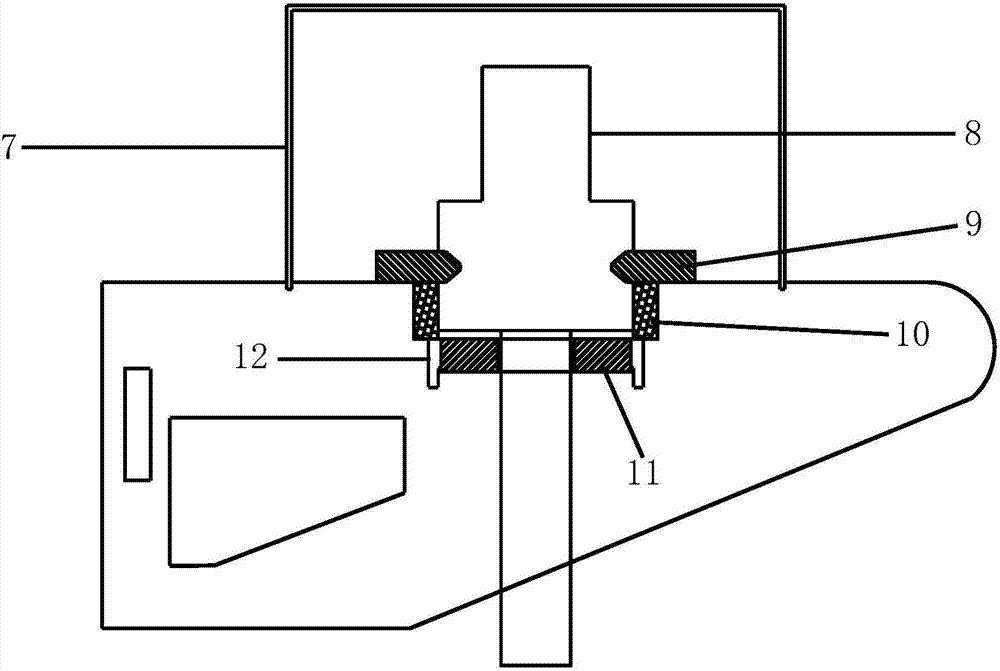

Surface grinding device for efficient energy-saving pump

ActiveCN105904315ASingle structureEasy to operateGrinding carriagesGrinding drivesCost (economic)Surface grinding

The invention discloses a surface grinding device for an efficient energy-saving pump. The surface grinding device for the efficient energy-saving pump comprises a housing; an opening is formed in the front side of the housing; a sundry outlet is formed in the bottom of the housing; a first motor is fixedly connected to the inner wall of the housing; a rotary shaft of the first motor is fixedly connected with a first connection rod through a coupler; one end, far away from the first motor, of the first connection rod is fixedly connected with a driving device; the top of the driving device is in sliding connection with the inner wall of the housing; a sliding rod is connected to the bottom of the driving device in a sleeved mode; the two ends of the sliding rod are fixedly connected with fixing rods correspondingly; and one end, far away from the sliding rod, of each fixing rod is fixedly connected with the inner wall of the housing. The surface grinding device for the efficient energy-saving pump has a single structure, is easy to operate and better facilitates usage of a user; the grinding effect is improved; later stage normal production and manufacturing of the efficient energy-saving pump are guaranteed; the working time is shortened; the economic cost expenditure is reduced; injuries to the user are prevented; and the safety problem is greatly solved.

Owner:JIANGSU WUXI HUISHAN PUMP IND

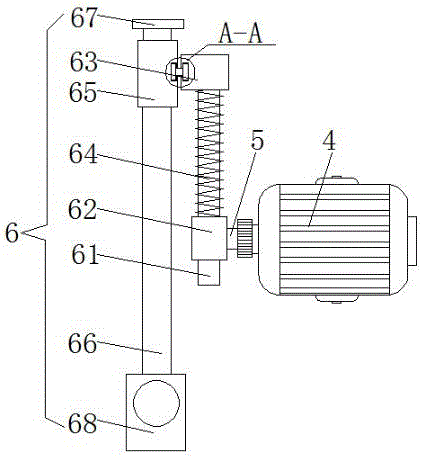

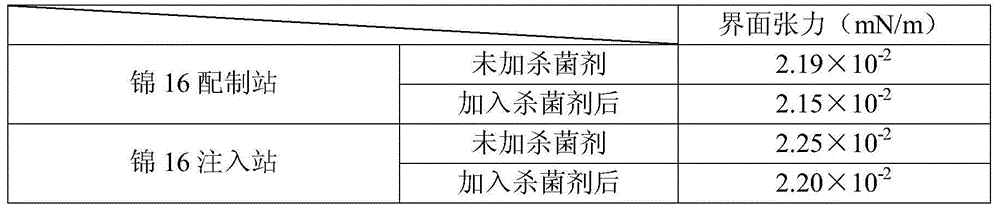

Bactericide for chemical flooding as well as preparation method and application of bactericide

InactiveCN104430494AGood application effect and application prospectIncrease productionBiocideDisinfectantsIron bacteriaSewage treatment

The invention provides a bactericide for chemical flooding as well as a preparation method and application of the bactericide. The bactericide is prepared from the following components in percentage by mass: 20-25 percent of tetrakis hydroxymethyl phosphonium sulfate, 0.3-0.5 percent of dithiocyano-methane, 3-5 percent of glutaraldehyde, 0.3-0.5 percent of xanthan gum, 0.3-0.5 percent of tween 80 and the balance of water. The preparation method of the bactericide comprises the following steps: adding water to mix tetrakis hydroxymethyl phosphonium sulfate and glutaraldehyde to obtain an insecticide A; adding water to mix dithiocyano-methane, xanthan gum and tween 80 to prepare an insecticide B; adding water to mix the insecticides A and B to prepare the bactericide. The invention further provides application of the bactericide in chemical flooding oilfield sewage treatment. The bactericide has good bacterium killing effect, can be used for completely killing sulfate reducing bacteria, iron bacteria and saprophytic bacteria without reducing viscosity of polymers or influencing the ultralow interfacial tension of the chemical blooding, and is a novel efficient bactericide for chemical flooding.

Owner:PETROCHINA CO LTD

Online loose body density measurement method and device

ActiveCN107255602AEnsure safetyTimely and accurate feedback of density dataSpecific gravity measurementWork periodMeasurement device

The invention discloses an online loose body density measurement method and device and relates to the field of VAD (vapor axial deposition) of optical fiber preform rods. The device comprises a weight measurement module, a volume measurement module and a density calculation module, wherein the weight measurement module is fixedly arranged onto the lifting platform of VAD equipment for measuring the weight of a preform rod loose body; the volume measurement module is fixedly arranged outside a deposition cavity for scanning and calculating the volume of a preform rod loose body. The online loose body density measurement device implements measurement in a state that deposition of the preform rod loose body is completed. Therefore, the online loose body density measurement device can ensure safety of production of the preform rod loose body, timely and accurately feed density data of the preform rod loose body back, avoid rejection of a furnace tube due to the fact that low-density optical fiber preform rod loose bodies fall into the furnace tube, save offline testing operation, significantly reduce the workload and the working time of operators and effectively improve the production efficiency.

Owner:WUHAN FIBERHOME RUITUO TECH CO LTD

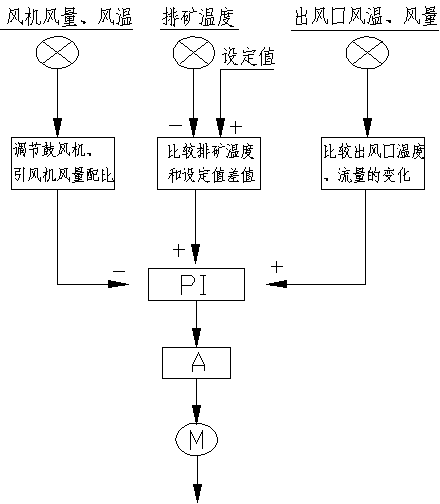

Automatic control method for cool-constant-temperature ore discharging of sinter ore furnace

ActiveCN103234366APrevent jump stopRealize safe and economical operationControl devices for furnacesAir volumeAutomatic control

An automatic control method for the cool-constant-temperature ore discharging of a sinter ore furnace comprises the steps of crushing sinter ore discharged from a sintering machine through a crushing device, screening the crushed sinter ore through a screening device, transporting the sinter ore into a cooling furnace through a sinter ore transportation device for cooling, and discharging the sinter ore outside the cooling furnace through a discharging device. When the sinter ore is cooled and discharged, a temperature detection device detects ore discharging temperature, and by adjusting the air quantity of an induced draft fan and a blowing fan, the ore discharging temperature is adjusted and stabilized at 90-200 DEG C. According to the automatic control method for the cool-constant-temperature ore discharging of the sinter ore furnace, the ventilation quantities and the air temperature of the fans can be adjusted according to the feedforward of the air temperature and the ore temperature of an air outlet, so that the ore discharging temperature, the waste heat air temperature and the waste heat air quantity can be controlled within certain ranges, the waste heat utilization system can be guaranteed to operate normally, and the normal ore discharging can be guaranteed; and overhigh or overlow ore discharging temperature can be prevented, the stable operation can be achieved, and the sinter ore quality can be enhanced.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Autologous epidermal melanin transplantation cell water survival method for treating vitiligo

InactiveCN107663512AAchieve rejectionNo rejectionCell dissociation methodsEpidermal cells/skin cellsCuticleTransplantation

The invention discloses a method for using vitiligo autologous epidermal melanin transplantation cells to divide and activate water, comprising the following steps: using a skin puncher to take a small amount of scalp containing hair follicles from the patient's head, separating and culturing the melanocytes in the hair follicles in vitro; The cultivation, cryopreservation and recovery of melanocytes; the cultivation and expansion of melanocytes; the biological identification of the morphology and function of melanocytes and the stability of genetic traits. In the present invention, a large number of autologous melanocytes are obtained by obtaining melanocytes in autologous scalp hair follicles, cultured and expanded in vitro, and these melanocytes have normal skin melanocyte functions and can normally produce skin melanin. The lack of melanocytes in the skin lesions, so as to achieve the purpose of treating vitiligo. This treatment method is different from the traditional treatment method, autologous cells will not appear rejection, and it does not need to be treated with drugs, and there is no potential risk.

Owner:长沙华研皮肤病医院有限公司

Production equipment of copper foil of negative current collector of ultra-thin lithium battery

InactiveCN104577133AQuality improvementReduce manufacturing costElectrode carriers/collectorsElectrolyte accumulators manufactureEngineeringCopper foil

The invention discloses production equipment of a copper foil of a negative current collector of an ultra-thin lithium battery. The production equipment comprises a control box and is characterized by also comprising an adhering device, a separating device, a first tension detecting device, an anti-oxidation device, a cleaning device, a second tension detecting device, a baking device and a receiving device, wherein the adhering device, the separating device, the first tension detecting device, the anti-oxidation device, the cleaning device, the second tension detecting device, the baking device and the receiving device are connected with the control box, are controlled by the control box and are arranged in sequence. The production equipment disclosed by the invention has the advantages that the design is reasonable, copper ions in copper sulfate are precipitated under the action of an electric field, are absorbed on a negative roll and are washed by a spraying device and the washed copper ions enter an anti-oxidation groove after bypassing a peeling roll and a detecting roll; after anti-oxidation treatment, the surface of the copper foil enters a washing groove to be subjected to bleaching, finally the bleached copper foil is dried by a drying oven after passing through the detecting roll and then is wound, and then the copper foil of the negative current collector of the ultra-thin lithium battery is prepared, so that the production procedure can be effectively shortened and the working efficiency can be improved.

Owner:陈浠

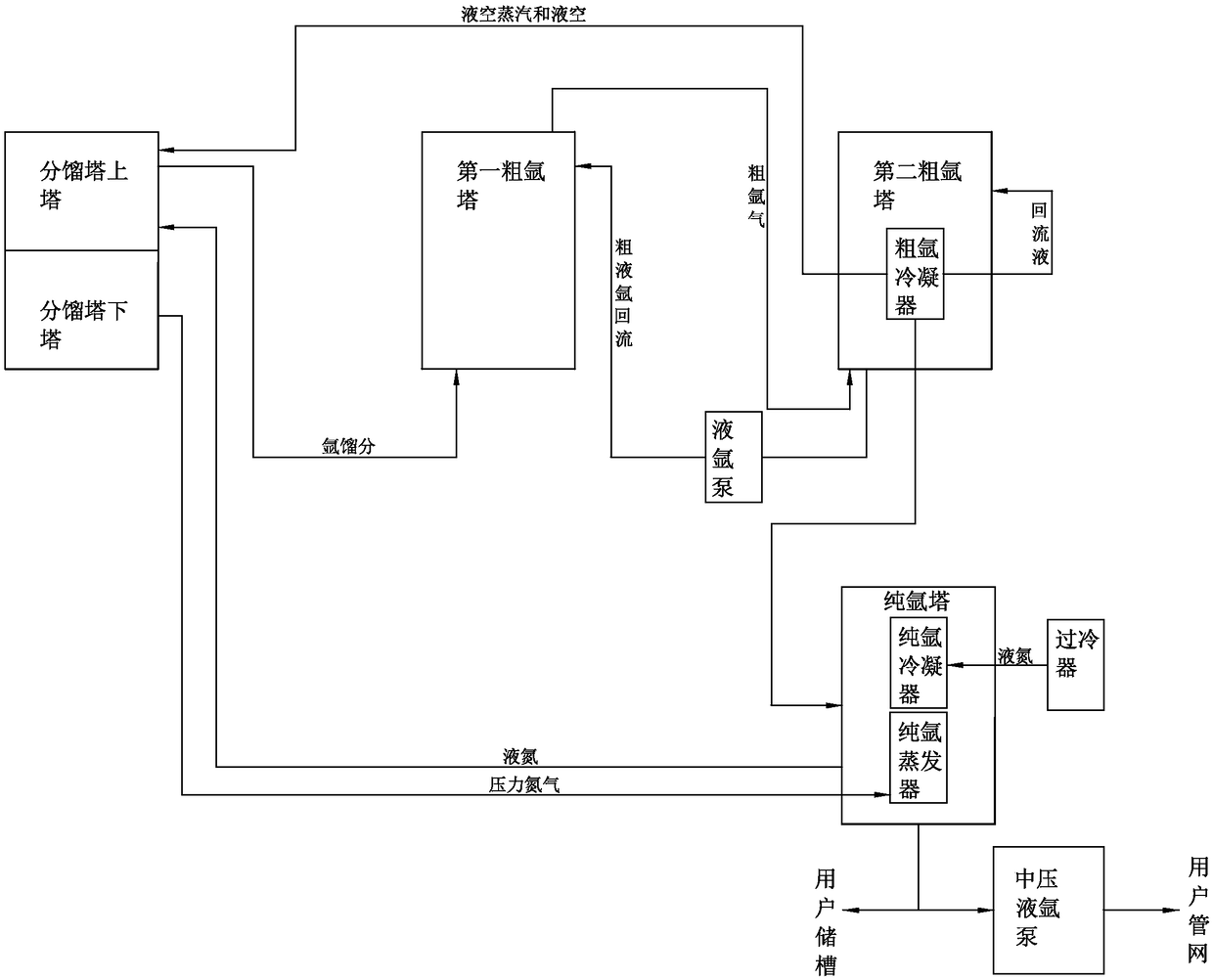

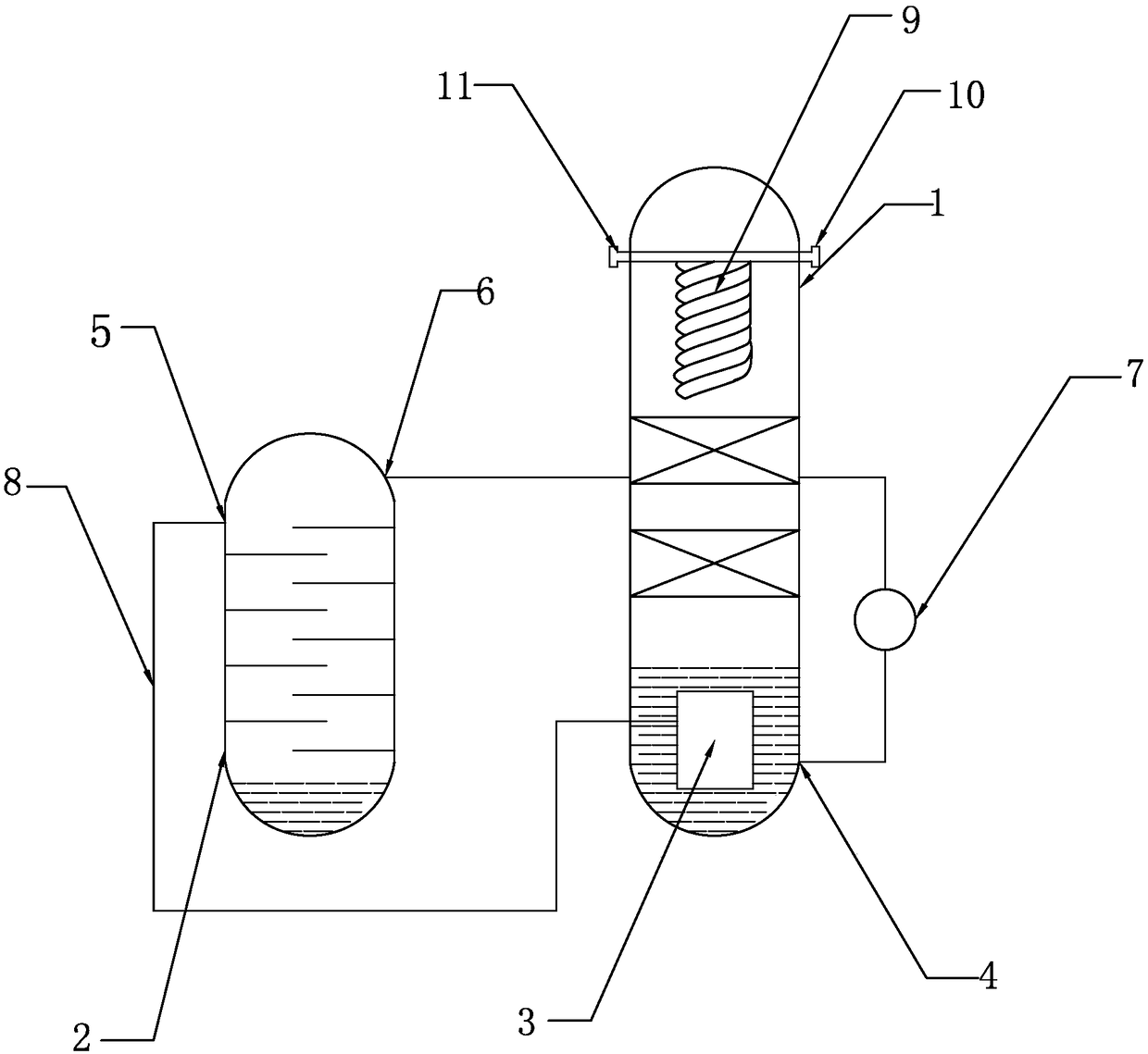

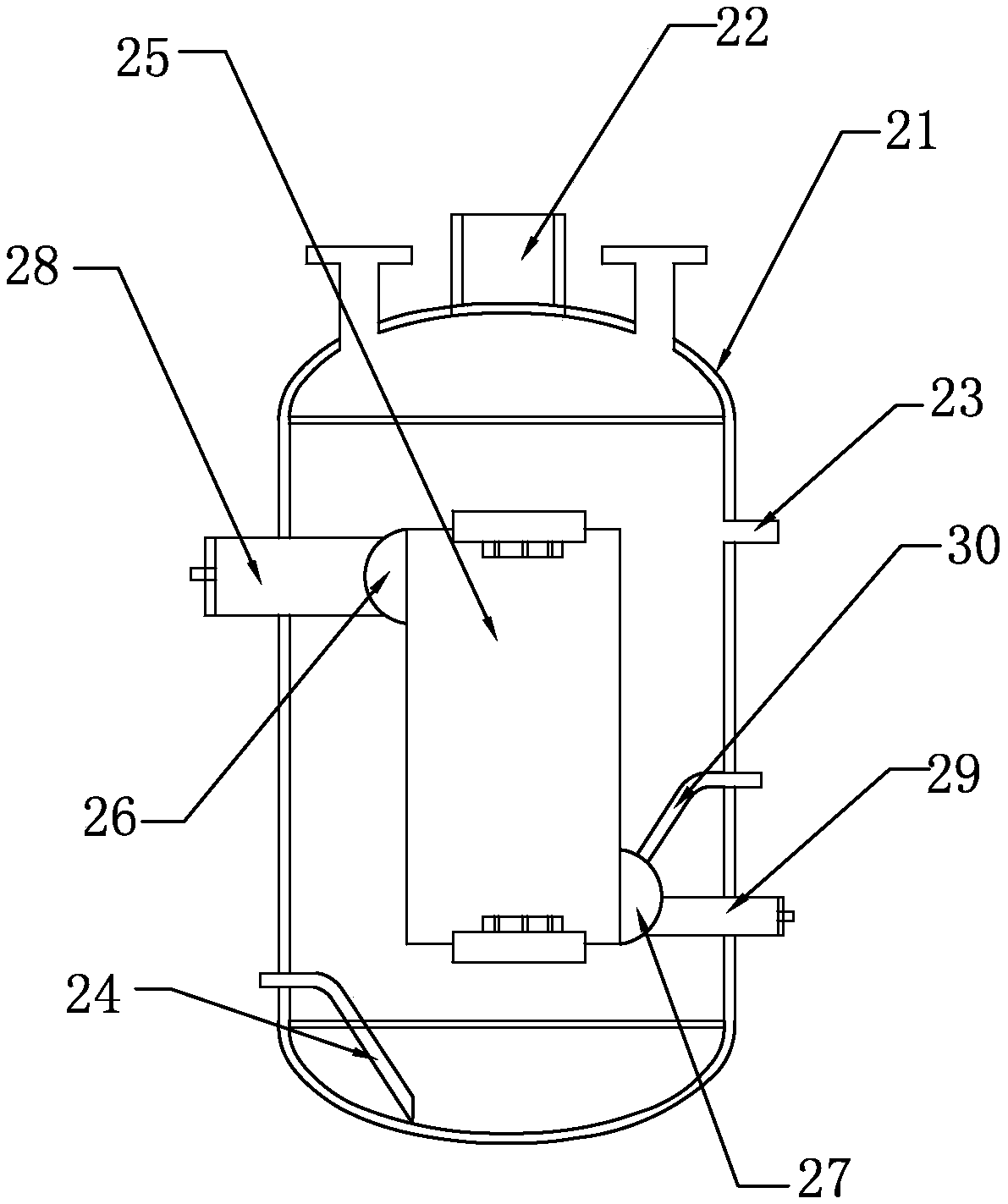

Argon production process and production line thereof

InactiveCN108731376AConveying low cooling lossReduce cold lossSolidificationLiquefactionPretreatment methodOxygen

The invention relates to an argon production process and a production line thereof. The process comprises the following steps: extracting argon fraction gas from a corresponding part of an upper towerof a fractionating tower; guiding the argon fraction gas from the bottom of a first crude argon column; taking coarse liquid argon discharged from the bottom of a second crude argon column on the upper part of the first crude argon column as a reflux liquid; leading coarse argon gas out from the top of the first crude argon column; feeding the coarse argon gas into a pure argon tower through thesecond crude argon column to obtain pure liquid argon in the bottom of the pure argon tower; and injecting a part of pure liquid argon in a liquid form into a user storage tank and pressurizing the other part of pure liquid argon in a cold box and feeding the same to a user pipe network. According to an industrial oxygen and nitrogen production process, the purity of a finished product of separated argon is relatively high through reasonable equipment arrangement, a pretreatment method and equipment as well as a reasonable process parameter design, the production efficiency is increased, and the production demand on high purity argon is fully met.

Owner:衢州杭氧气体有限公司

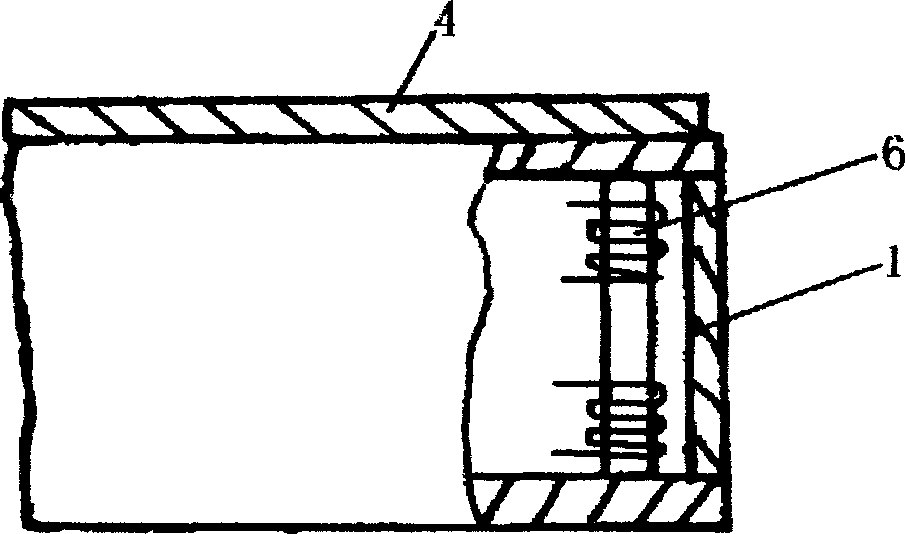

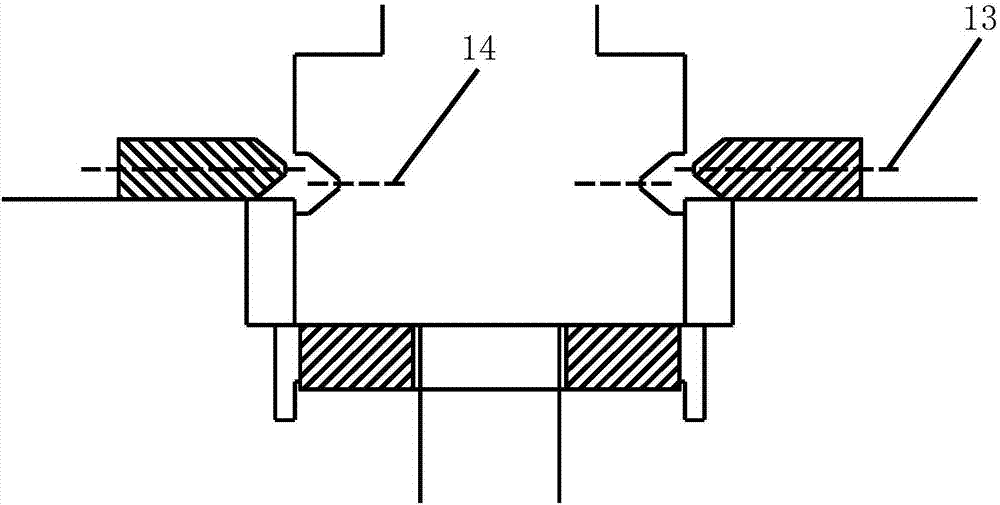

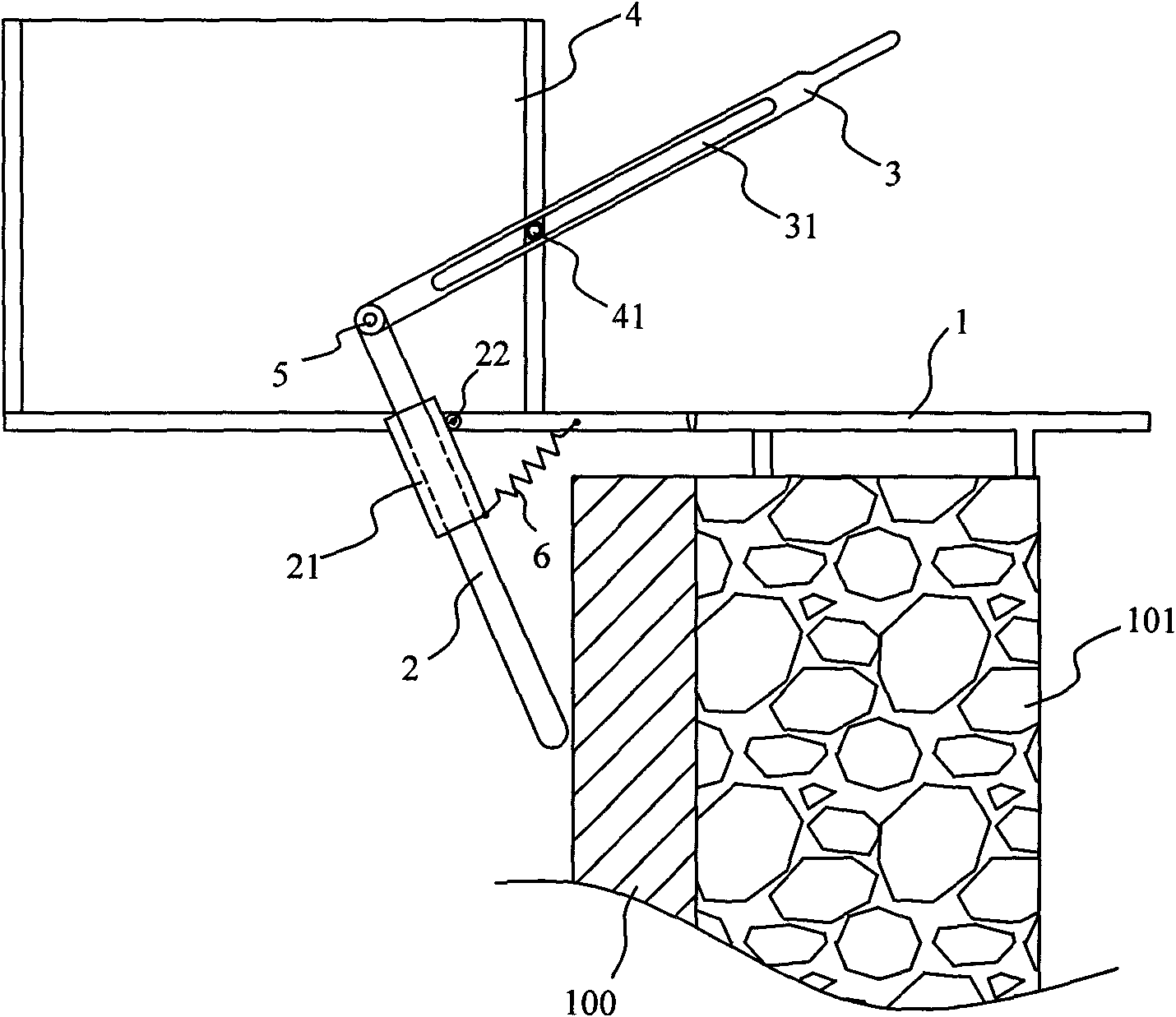

Blast-furnace iron tap channel side wall thickness detection device and method thereof

InactiveCN101963485ASimple structureEasy to useMechanical thickness measurementsArchitectural engineeringBlast furnace

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com