Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

177results about How to "Improve the level of automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for supervising clothing production based on radio frequency identification (RFID) technology

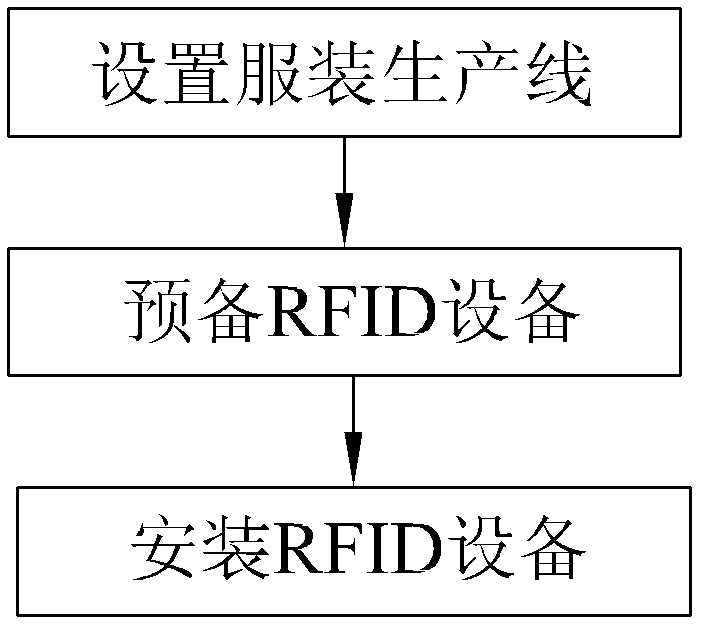

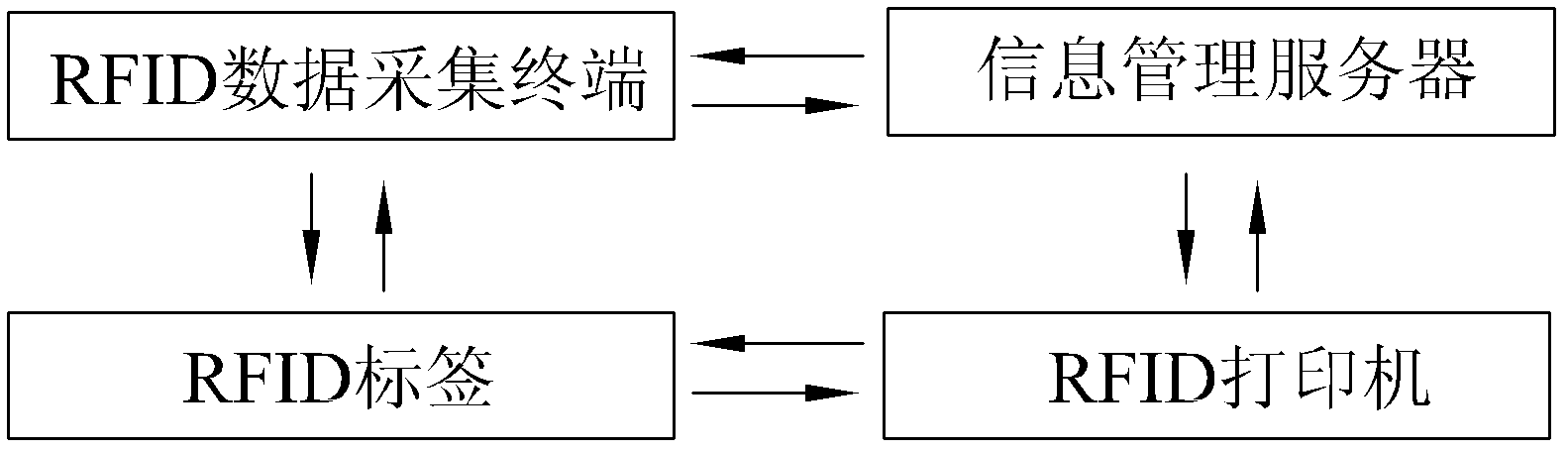

InactiveCN102254200AIncrease productivityRapid Manufacturing ManagementCo-operative working arrangementsClothes making applicancesProduction lineDecision management

The invention discloses a method for supervising clothing production based on a radio frequency identification (RFID) technology. The method comprises the following steps of: 1, setting a clothing production line; 2, preparing RFID equipment; and 3, installing the RFID equipment. The invention also discloses a system for implementing the method. By the method provided by the invention, clothing production operating information can be supervised quickly and accurately in real time. The system provided by the invention is simple in structure and smart in design. By adoption of the RFID technology, the conventional paper work ticket is replaced by an electronic RFID tag, and the RFID tag is arranged on each clothing product; every time when the clothing product finishes a process, an RFID data acquisition terminal in the corresponding process automatically sends the operating information of the process to an information management server; the production data of clothing in a certain process is collected in real time; an effect of supervising the clothing production is achieved; and the production efficiency and decision management capacity of an enterprise are effectively improved.

Owner:DONGGUAN KEDA COMP SYST ENG

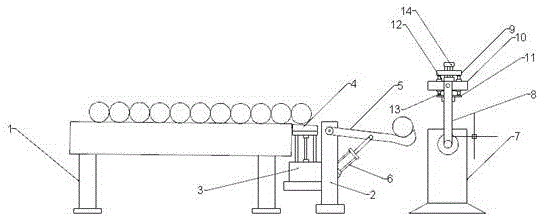

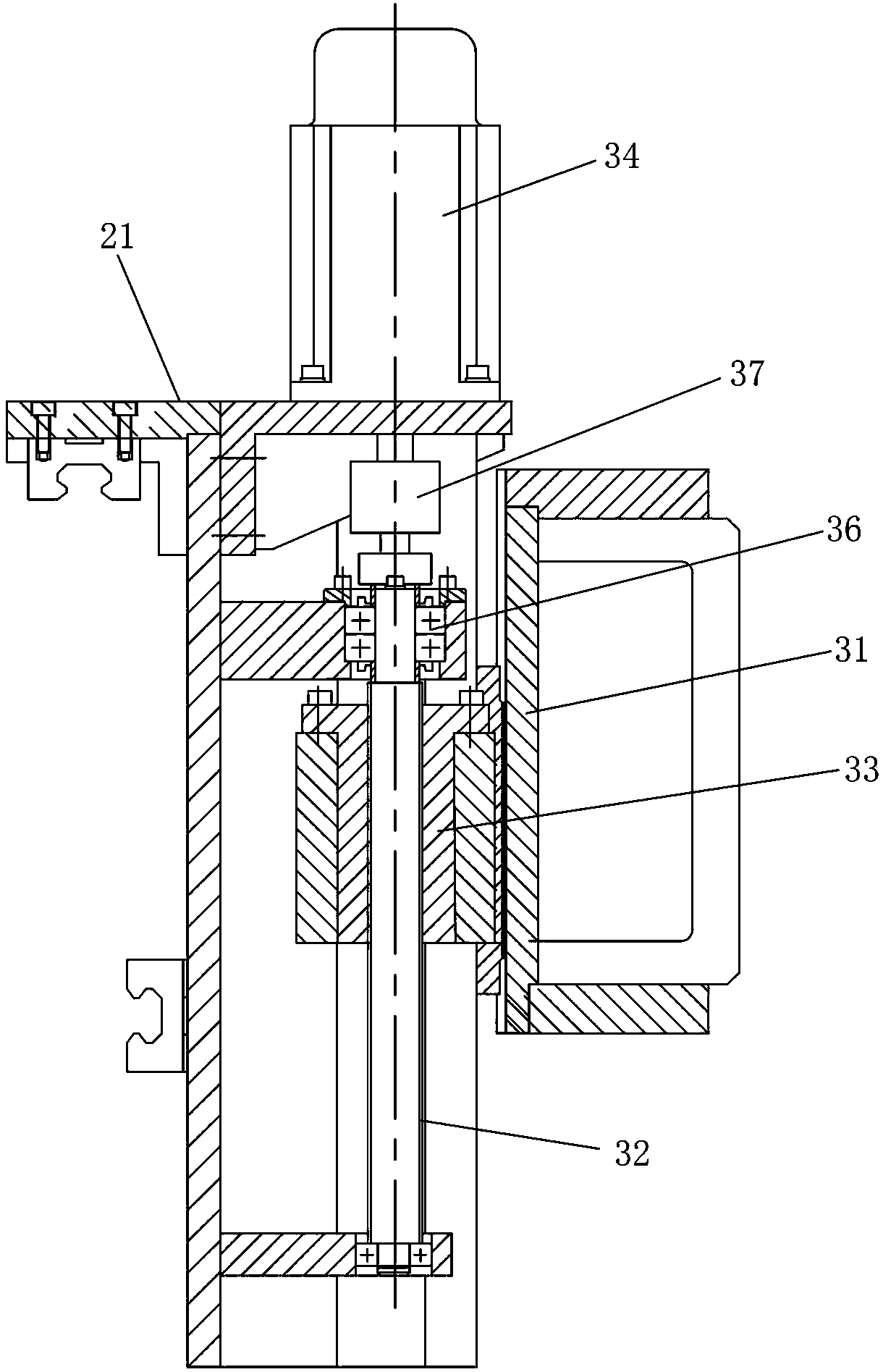

Slitting processing system of internal combustion engine cylinder sleeve

InactiveCN106141283AReduce labor intensityIncrease productivityTube shearing machinesShearing machine accessoriesEngineeringInternal combustion engine

The invention discloses a slitting processing system of an internal combustion engine cylinder sleeve. The slitting processing system comprises a feeding mechanism, a pipe cutting mechanism, a pipe clamping mechanism, a pipe feeding mechanism and a discharging mechanism which are sequentially arranged in the feeding direction; the pipe cutting mechanism comprises a machine tool, a pneumatic chuck arranged on the machine tool, and a first motor driving the pneumatic chuck to rotate; the back of the pneumatic chuck is connected with a connecting sleeve; the obverse side of the pneumatic chuck is connected with a sleeve chuck; the first motor drives the connecting sleeve to rotate through a belt pulley; the connecting sleeve drives the pneumatic chuck to rotate; and the pipe cutting mechanism is further provided with a tool bit and a feeding driver driving the tool bit to feed. Compared with the prior art, the slitting processing system has the following beneficial effects: automatic feeding and discharging are realized, the production efficiency and automatic production level are improved, and the labor intensity of workers is alleviated.

Owner:ZYNP GRP ANHUI CO LTD

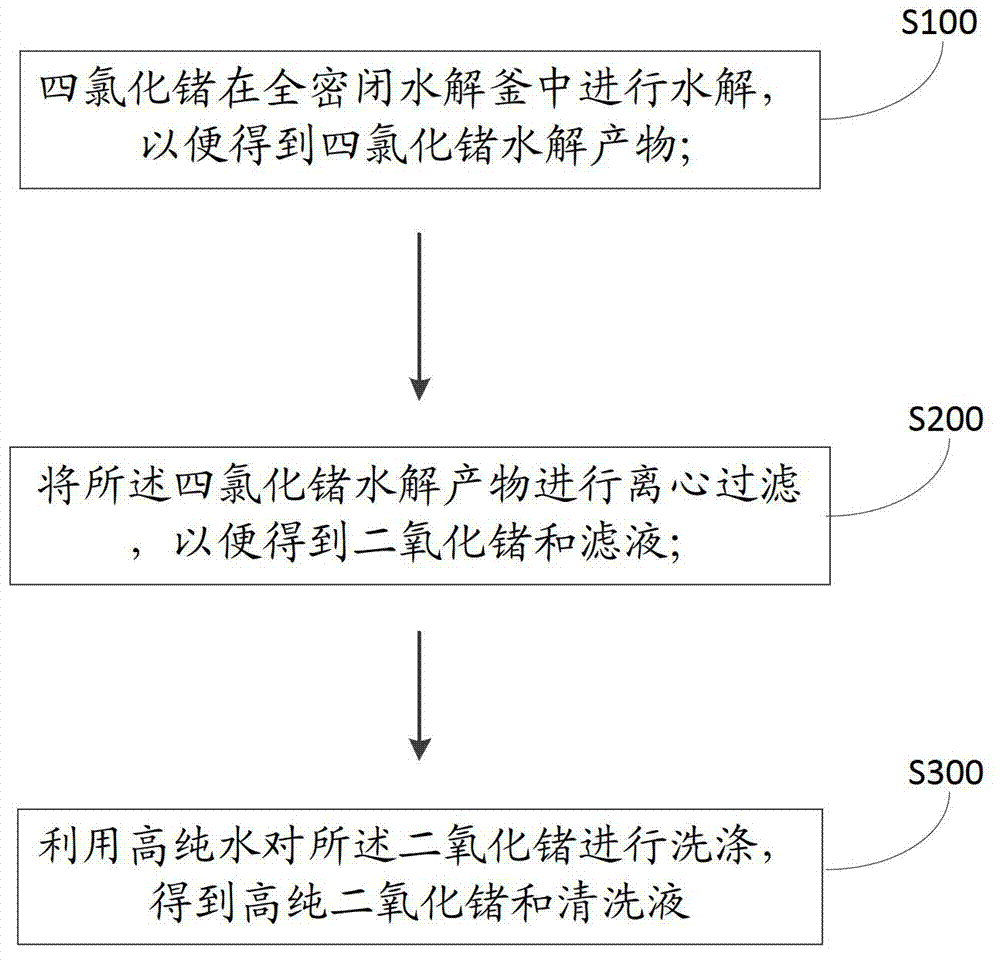

Novel process for preparing germanium dioxide (GeO2)

ActiveCN102774877AReduce lossesHigh degree of automationGermanium dioxideGermanium dioxideHydrolysis

The invention provides a method for preparing germanium dioxide (GeO2). According to the embodiment of the invention, the method comprises the following steps: hydrolyzing the germanium tetrachloride(GeCl4) in a fully-closed hydrolysis reactor to obtain the hydrolysis product of the GeCl4, centrifuging and filtering the hydrolysis product of the GeCl4 to obtain the GeO2 and the filtrate, and cleaning the GeO2 by high-purity water to obtain the high-purity GeO2 and the cleaning solution. According to the embodiment of the invention, the GeO2 hydrolyzing, filtrating and washing method and device have the advantages of high degree of automation, high GeO2 hydrolysis yield, good solid-liquid centrifugal separation effect, low production costs, less metal loss and environment friendliness.

Owner:云南驰宏国际锗业有限公司

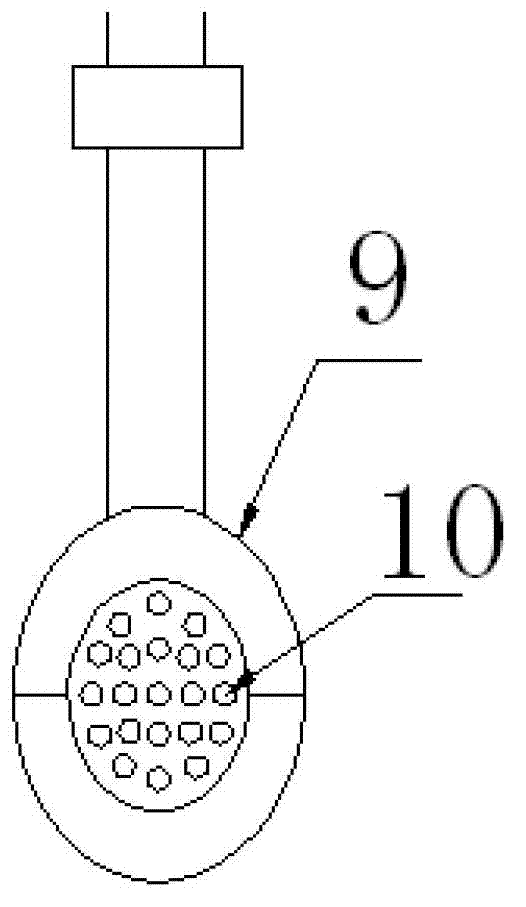

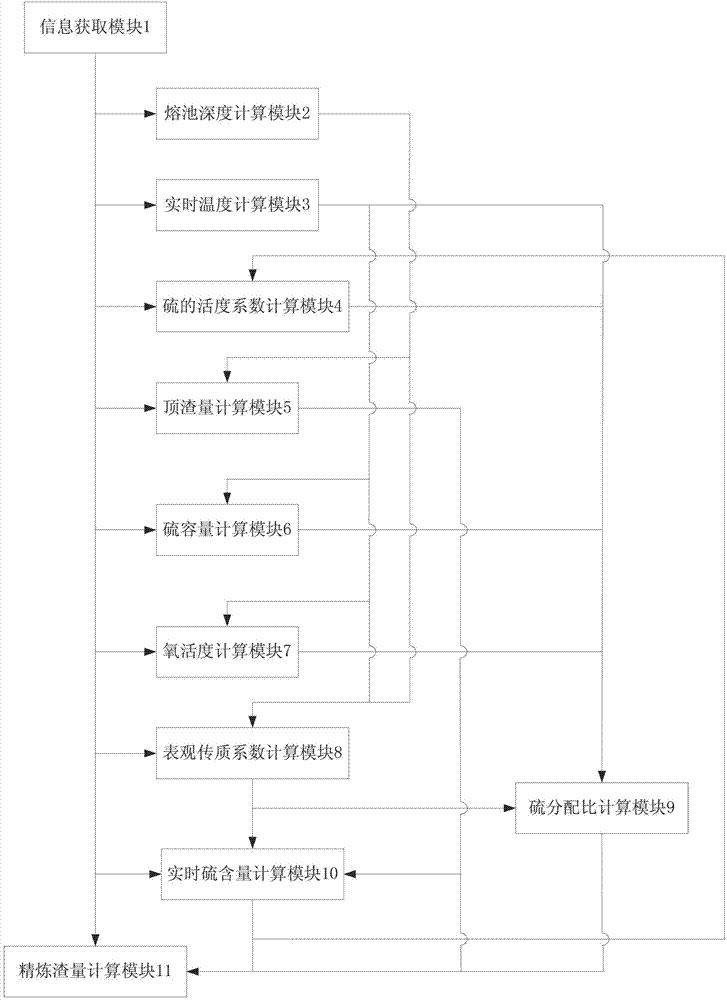

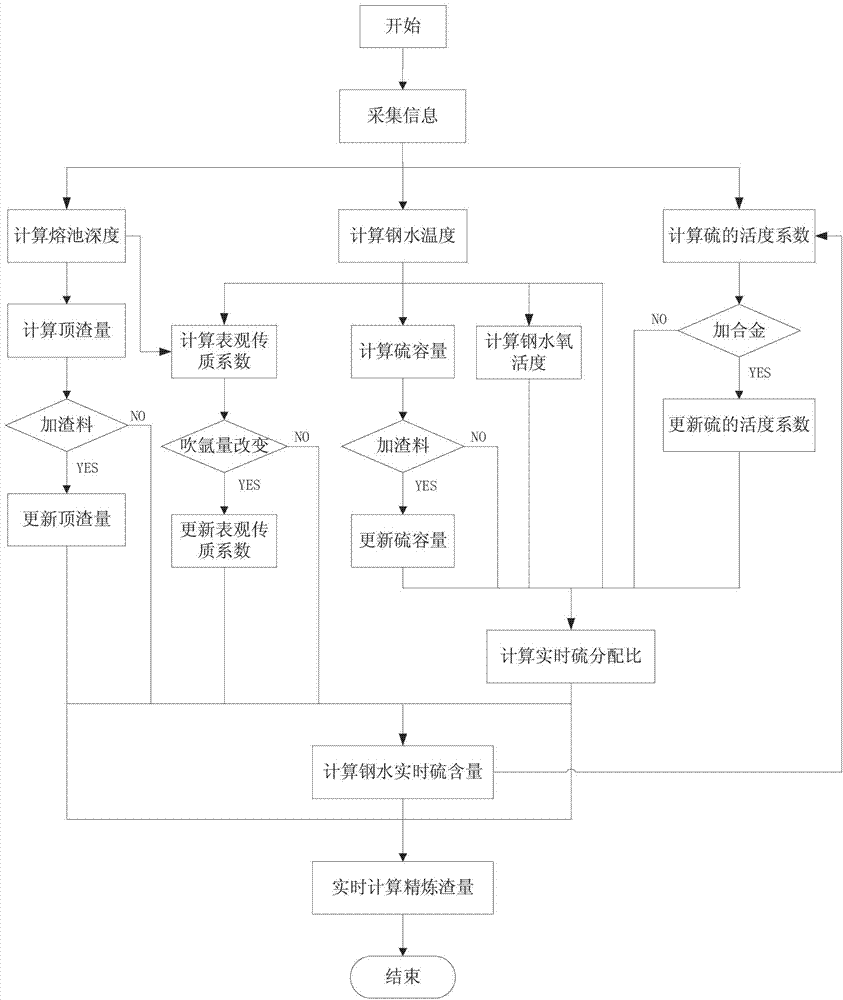

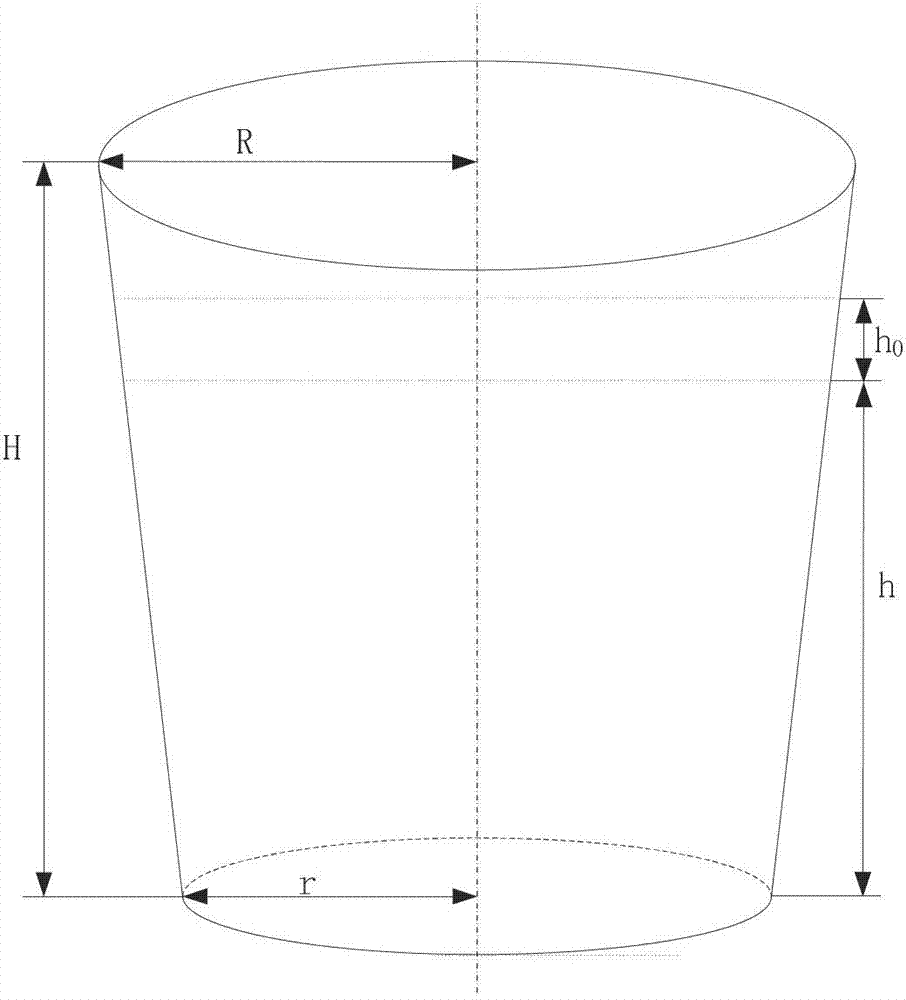

System and method for predicating amount of refining slag required during refining and desulfuration of LF (Ladle Furnace) on line

InactiveCN103397140AGuaranteed Reasonableness and AccuracyImprove the level of production automationProcess efficiency improvementSlagActivity coefficient

The invention provides a system and a method for predicating the amount of refining slag required during refining and desulfuration of an LF (Ladle Furnace) on line, belonging to the field of production and control of the metallurgical process. The system comprises an information acquiring module, a pool depth calculation module, a real-time temperature calculating module, a sulphur activity coefficient calculation module, a top slag quantity calculation module, a sulphur capacity calculation module, an oxygen activity calculation module, an apparent mass transfer coefficient calculation module, a sulphur distribution ratio calculation module, a real-time sulphur content calculation module and a refining slag amount calculation module. The method comprises the following steps of: respectively calculating the top slag quantity, the real-time sulphur distribution ratio, and the real-time sulphur content, and comprehensively calculating the amount of refining slag required in the desulfuration process according to the amount of molten steel, the initial sulphur content of the molten steel, the final sulphur content of the molten steel, the initial sulphur content in slag, and the final sulphur content in slag given by the initial information. According to the system and the method provided by the invention, the on-site production can be dynamically guided on line, and the defect that the refining amount can not be sufficiently and accurately calculated in real time in the prior art is overcome.

Owner:NORTHEASTERN UNIV +1

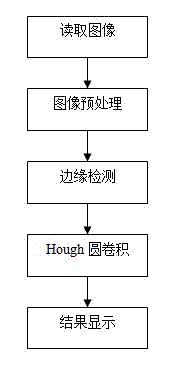

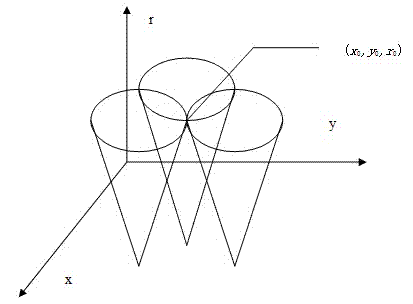

Hole set detection method and system based on Hough round convolution transformation algorithm

InactiveCN103925878AShort detection timeHigh measurement accuracyUsing optical meansComputation complexityTransformation algorithm

The invention provides a hole set detection method based on a Hough round convolution transformation algorithm. The hole set detection method includes the steps that noise in an image is filtered out, and the image is enhanced; the edge of the image is detected; the Hough round convolution transformation algorithm is adopted for processing the image: the two-dimensional image is mapped into three-dimensional space, Hough round convolution transformation is performed on the mapped image and an indicator function of a Hough circular cone, a three-dimensional Fourier transformation of the Hough circular cone is calculated in advance, then a Fourier transformation of the two-dimensional image is calculated, and then the two Fourier transformations are multiplied to obtain an Hough three-dimension Fourier transformation, and an Hough three-dimensional inverse Fourier transformation is calculated; coordinates and radius values of holes are obtained trough calculating peak points in the three-dimensional inverse Fourier transformation. The detection time is short, measuring precision is high, real-time performance is good, calculation complexity is reduced through the improvement in the algorithm, calculation efficiency is improved, and therefore production cost is reduced.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

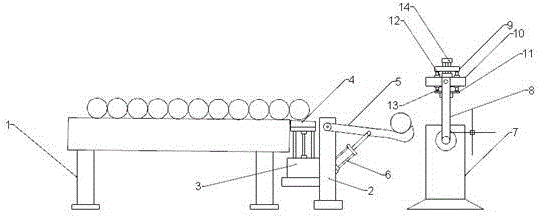

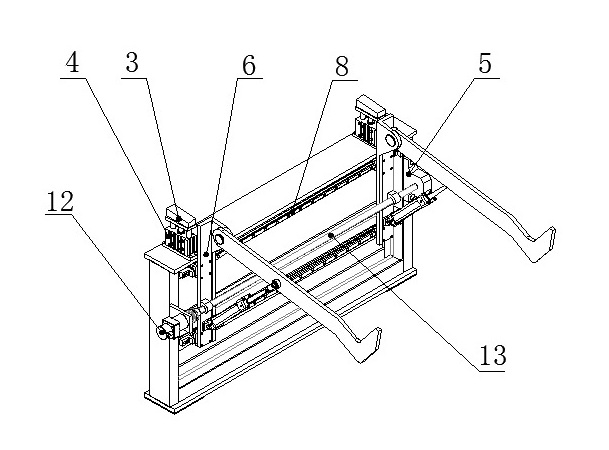

Pipe-cutting feeding device

InactiveCN102672523AReduce labor intensityIncrease productivityMetal working apparatusSteel tubeElectric machinery

The invention relates to a steel pipe-cutting feeding device. The steel pipe-cutting feeding device comprises a pipe storage rack and a feeding rack, wherein the feeding rack is provided with a pair of parallel supporting plates; the supporting plates is shaped like a rightward turned V; the bottoms of the supporting plates are connected with a cylinder; a lifting rollway is arranged on the side of the feeding rack and is connected with a guide rail; the guide rail is connected with a pair of parallel rollway supports; the rollway supports are connected with a screw rod; the feeding rack is connected with a motor; the motor drives the rollway supports to slide on the guide rail; the lifting rollway is provided with a lifting arm; a V-shaped bracket is arranged on the end part of the lifting arm; one end of the lifting arm is hinged with the rollway supports and the other end of the lifting arm is connected with a lifting cylinder; and the cylinder jacks one end of the lifting arm to rotate around the hinge end and realize lifting motion. The steel pipe-cutting feeding device can be applied to automatic feeding of a steel pipe cutter, has a compact structure, is simple to control, adapts to the pipes of different length and diameter, improves the production efficiency and reduces the labor intensity of workers.

Owner:SHENZHEN CEMCN

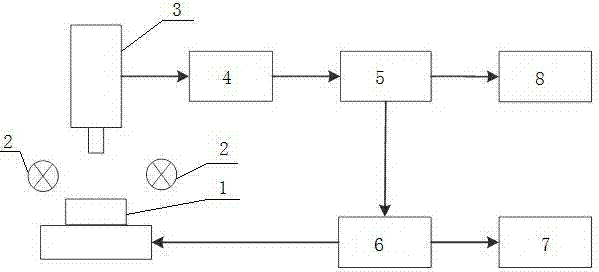

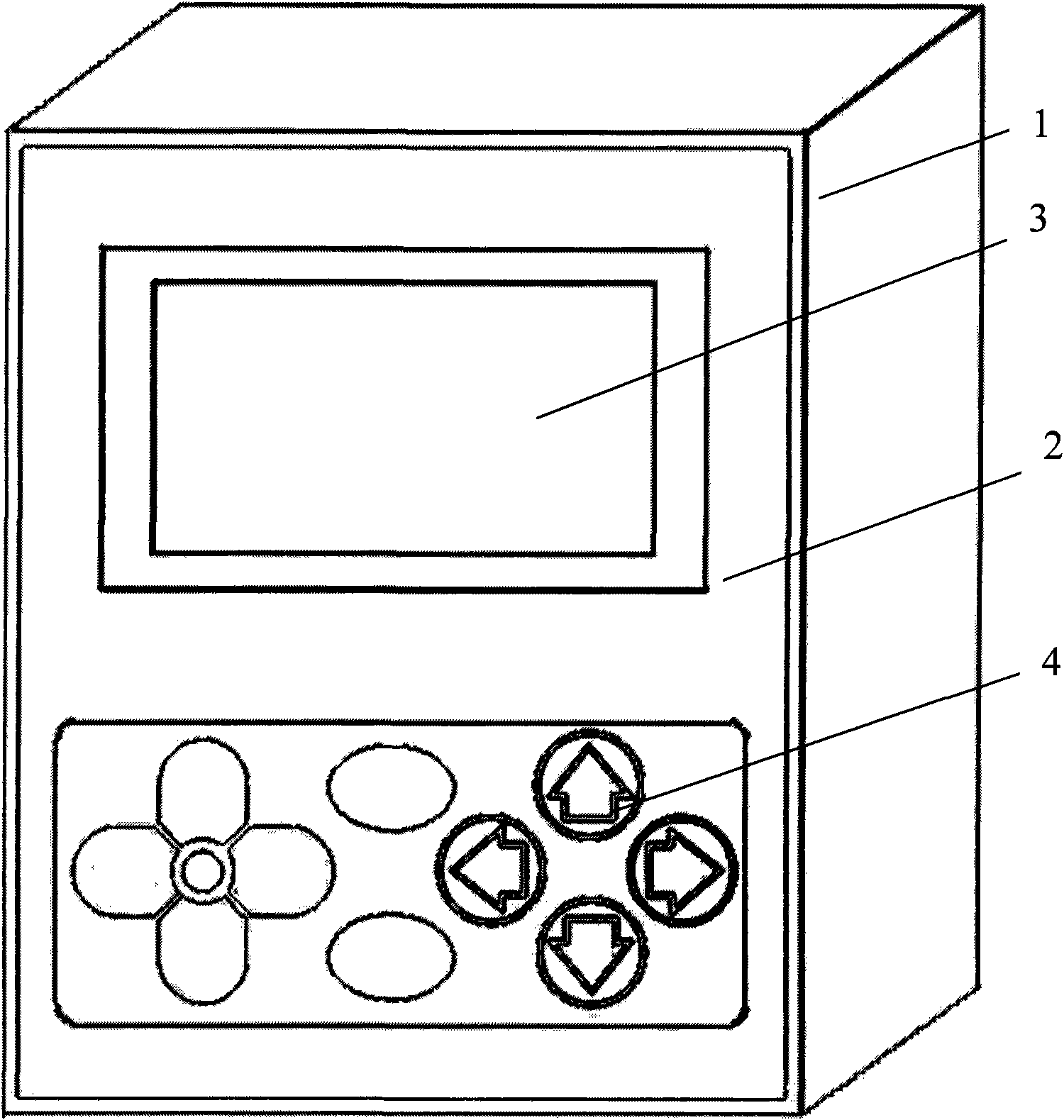

System and method for controlling continuous auto-packing machine

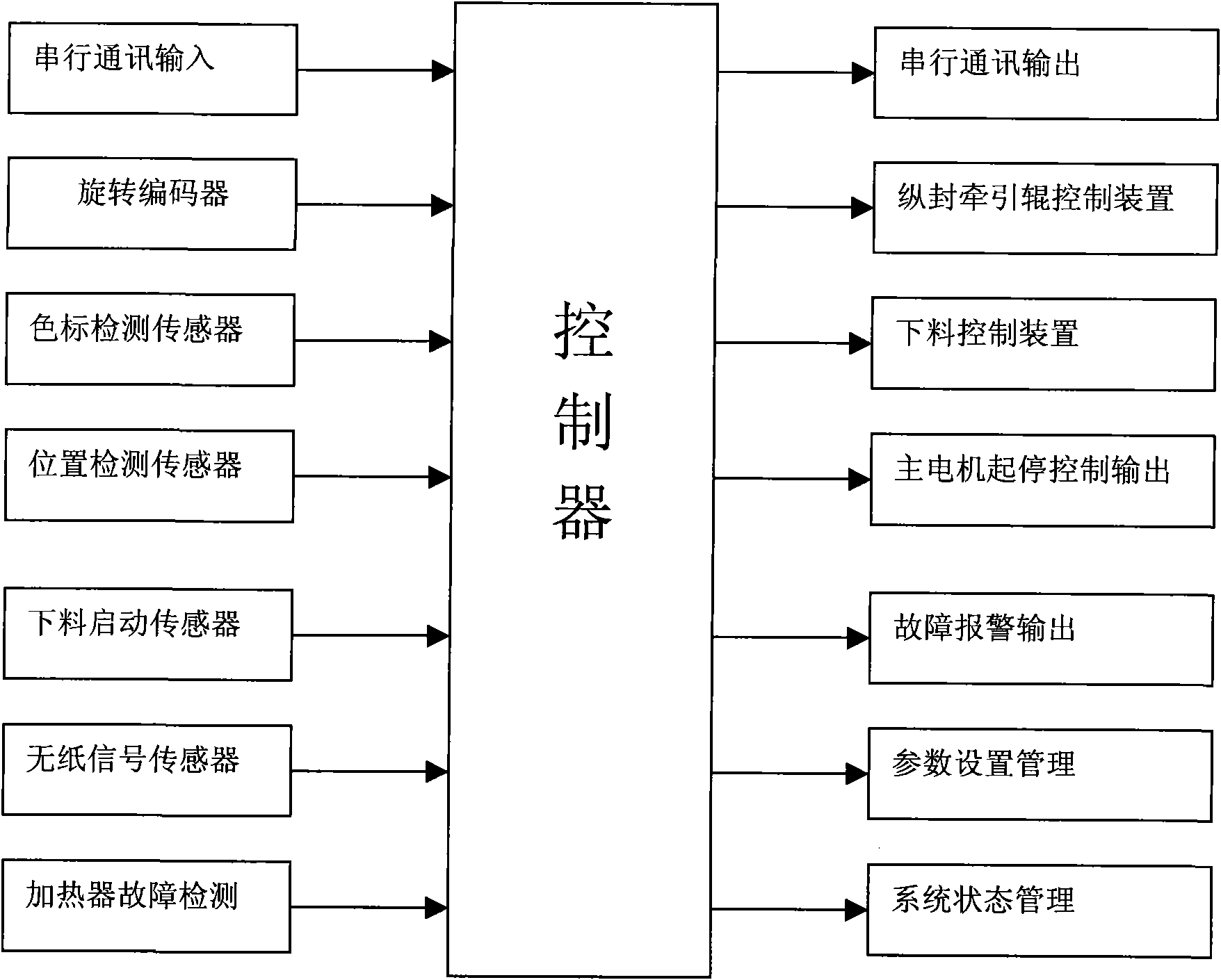

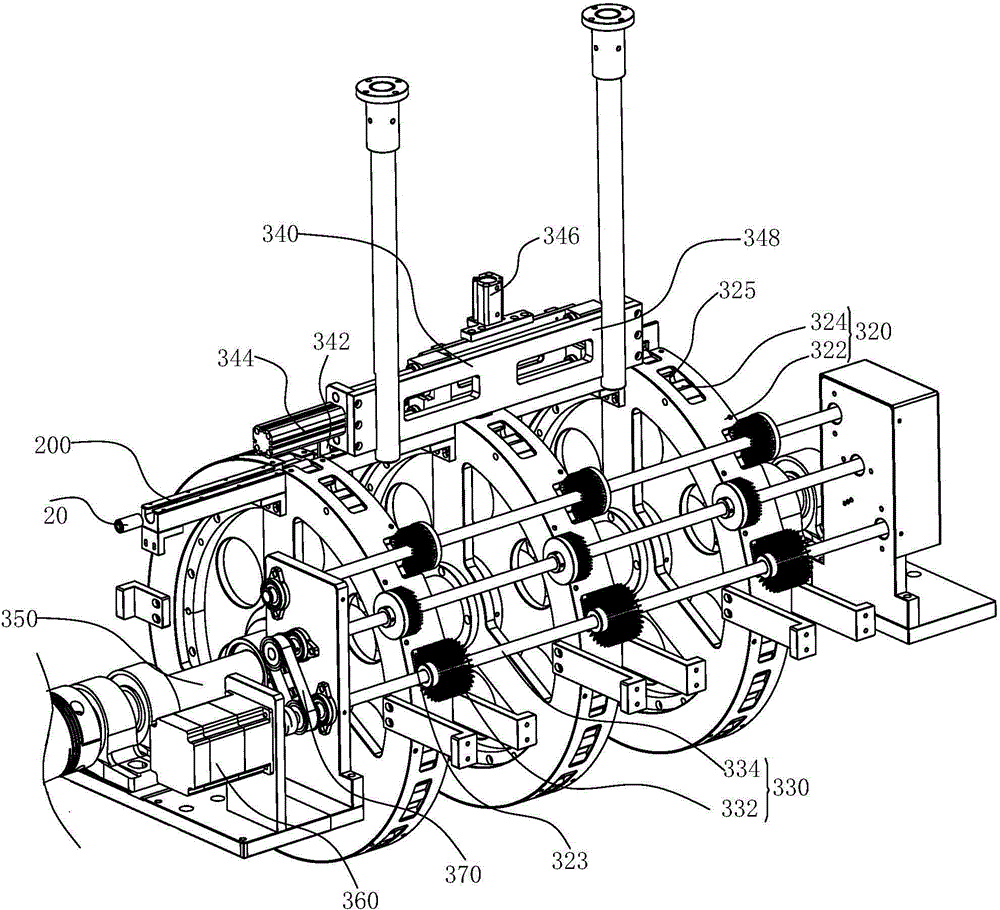

InactiveCN101559846AReasonable designSimple designPackaging automatic controlElectric programme controlColor ScaleLight touch

The invention relates to a system and a method for controlling a continuous auto-packing machine. The system comprises a rotary encoder, a position sensor, a color scale sensor, a vertical-seal drawing roller driver and a system controller; function parameters are input and stored into a memory of the system by corresponding function light touch keys of the system controller; a main motor of a packing machine runs; the system works; a vertical-seal drawing roller starts; and the speed of the vertical-seal drawing roller and the speed of the main motor are synchronous, so as to finish the operations, such as packing, paper letting-off, bag length, size and speed setting, pictorial trade mark positioning, automatic system controlling, error compensating, and the like. As a horizontal-seal roller eccentric mechanism is eliminated, the system has the advantages of reasonable mechanical structure, simple control arrangement and convenient system operation. When the bag length is different, only the corresponding length dimension needs to be reset, therefore, other structures of the packing machine are not required to be adjusted. The system is applicable for the control to the bag making, the cursor tracking and the cutting operations of the continuous auto-packing machine.

Owner:天津电子信息职业技术学院 +5

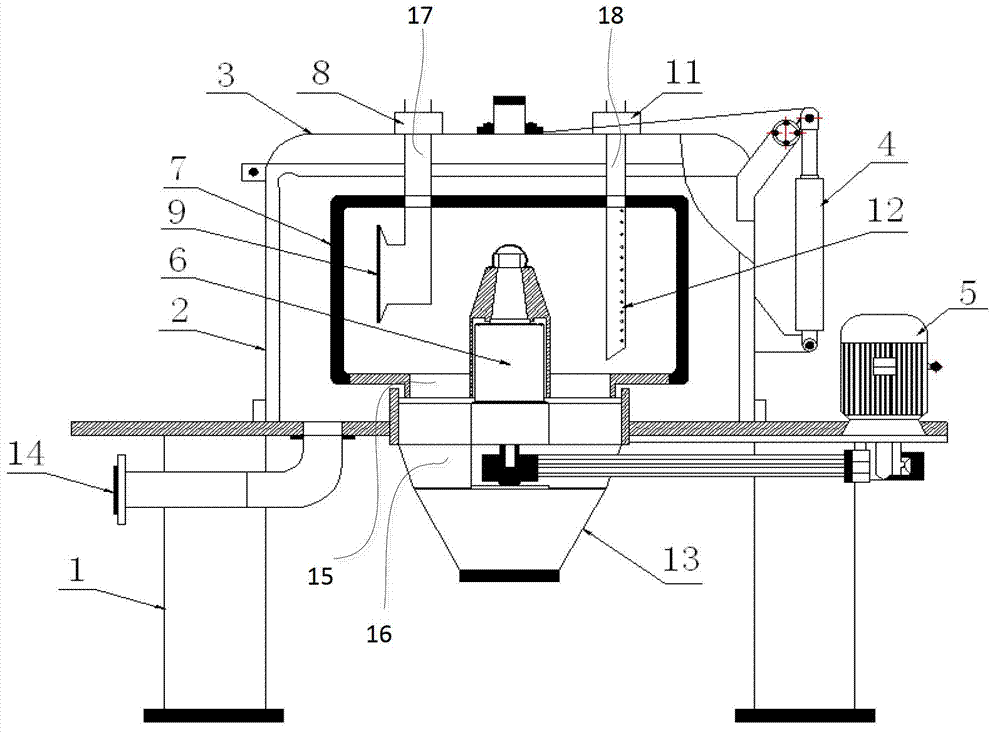

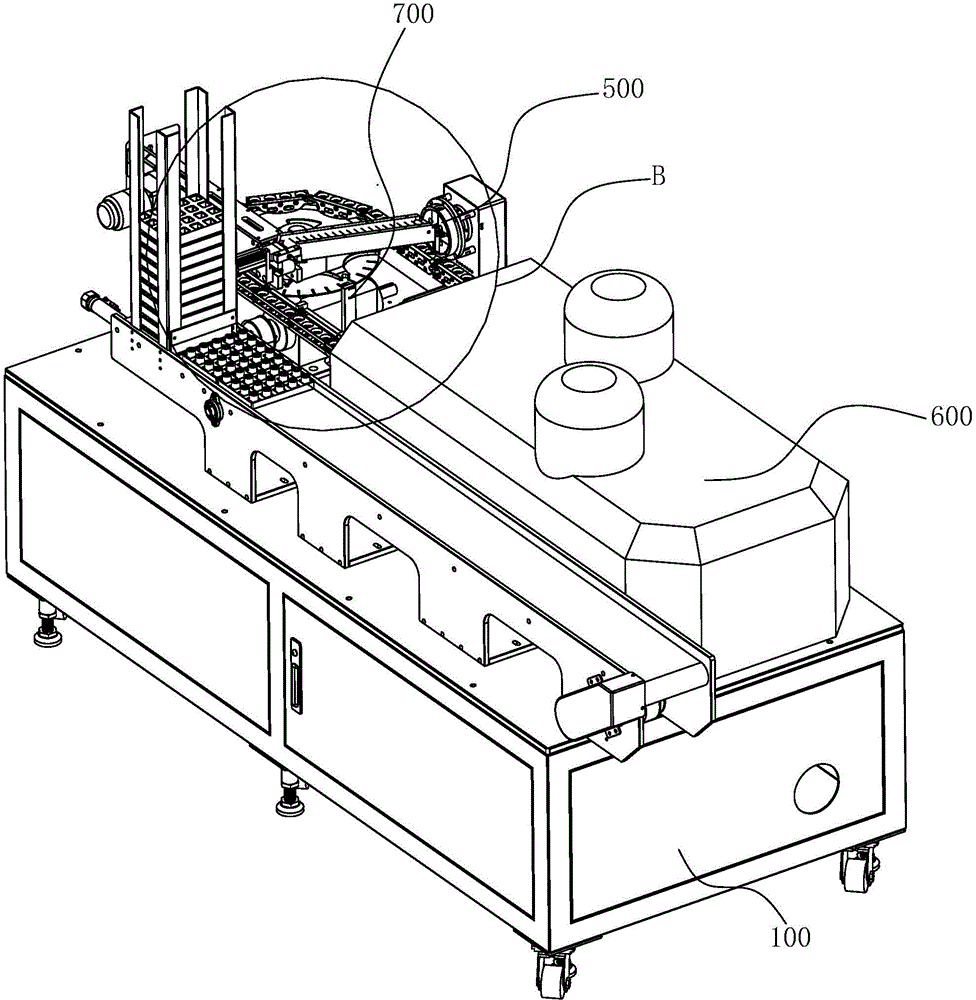

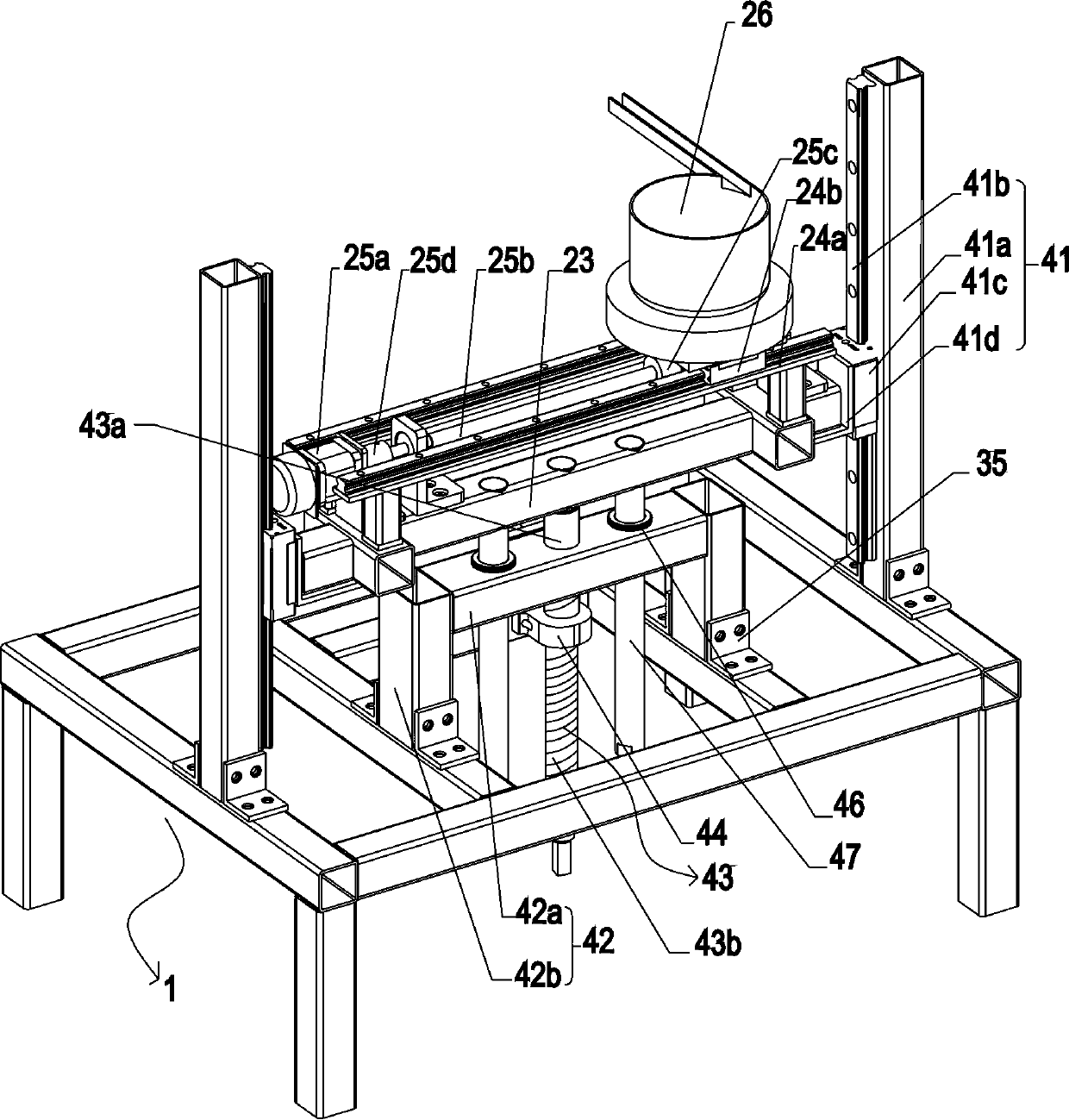

Battery cleaning equipment

ActiveCN104438232AImprove the level of automated productionMeet cleaning requirementsCleaning using toolsCleaning using liquidsElectrical batteryEngineering

Battery cleaning equipment is used for sequentially cleaning, dewatering, turning over and drying a battery and loading the battery on a plate and comprises a base, a conveying passage, a cleaning device, a dewatering box, a turning-over device, a drying box and a plate loading device. Through the coordinative cooperation of all the mechanical parts, the battery sequentially passes through the cleaning device, the dewatering box, the turning-over device, the drying box and the plate loading device on the conveying passage. Due to the structural design of the cleaning device, the cleaning requirement for the battery is met, and the cleaning cleanliness of the battery is improved. Due to the structural design of the turning-over device, the battery is turned over into the vertical state from the lying state to get ready for the follow-up battery loading work. According to the battery cleaning equipment, the production efficiency is improved, the production cost is reduced, the harm to human health is reduced, and the mechanical automation production level is improved.

Owner:EVE ENERGY CO LTD

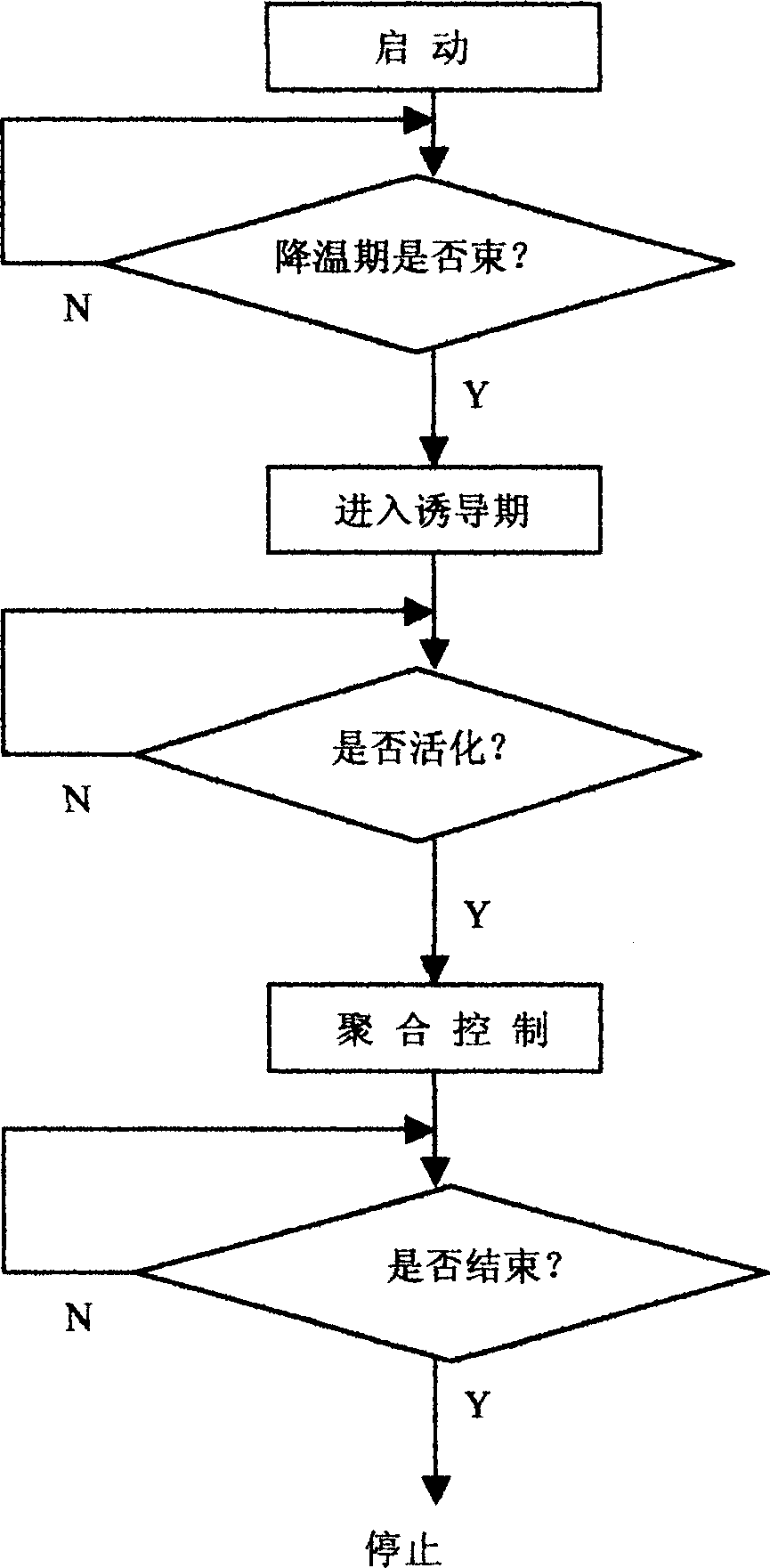

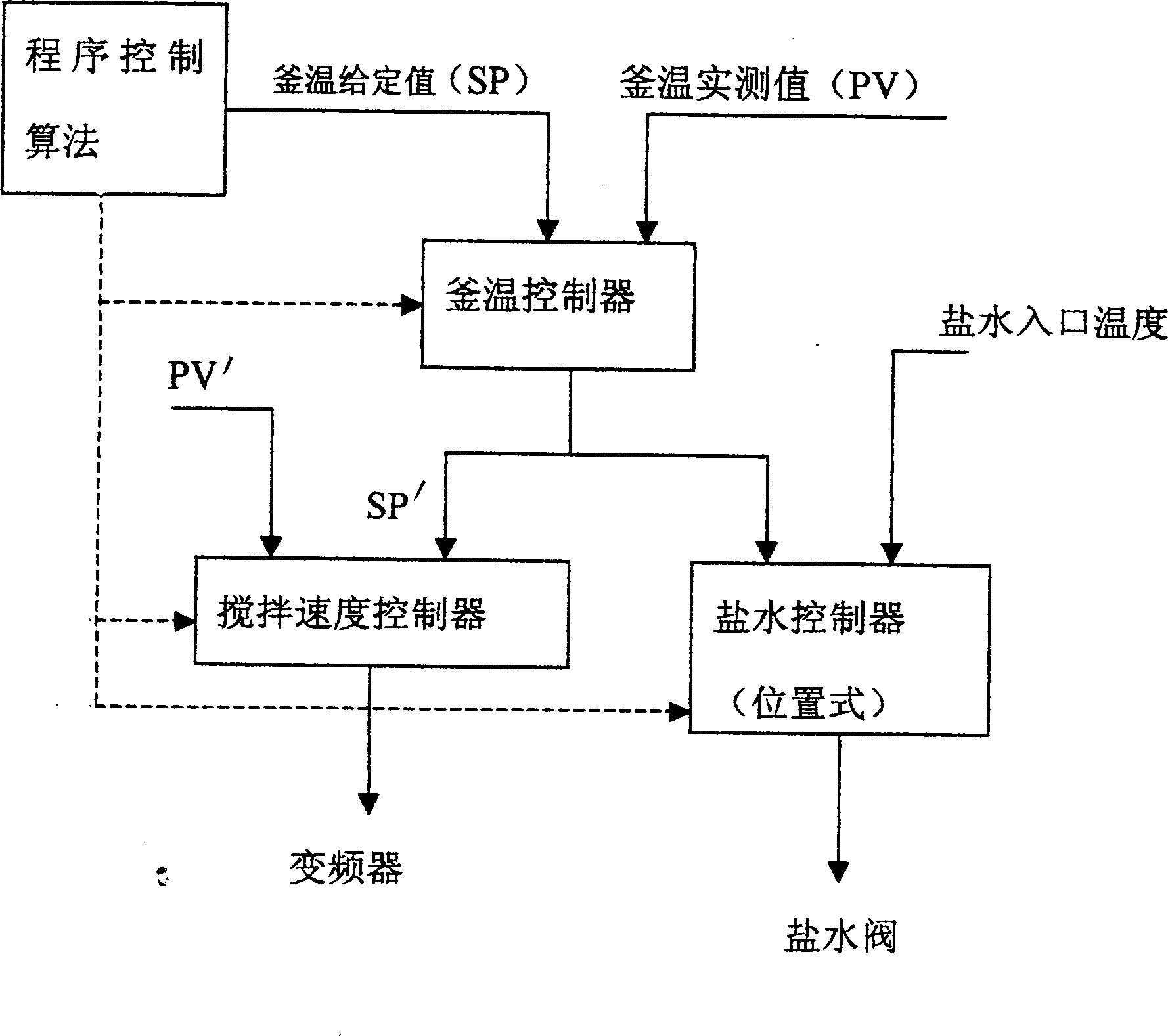

Full-automatic control method using fuzzy control for temp of polymerizing reactor

InactiveCN1390858APut an end toReduce labor intensityProgramme controlComputer controlAutomatic controlProgrammable logic controller

A full-automatic fuzzy control method for the temp of polymerizing reactor features that in programmable logic controller (PLC), there are reaction period program controller, reactor temp controller,stirring speed controller and saline controller, the variation of reactor temp gradient is monitored for judging if activating is needed, a desired temp for relative reaction period is automatically set up, and the stirring speed and the flow of cooling saline is regulated. Its advantages are high effect and high quantity and quality of product.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

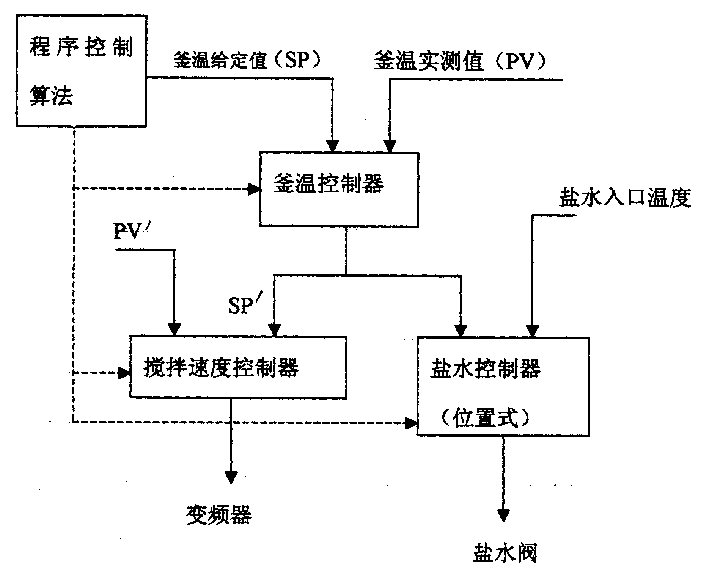

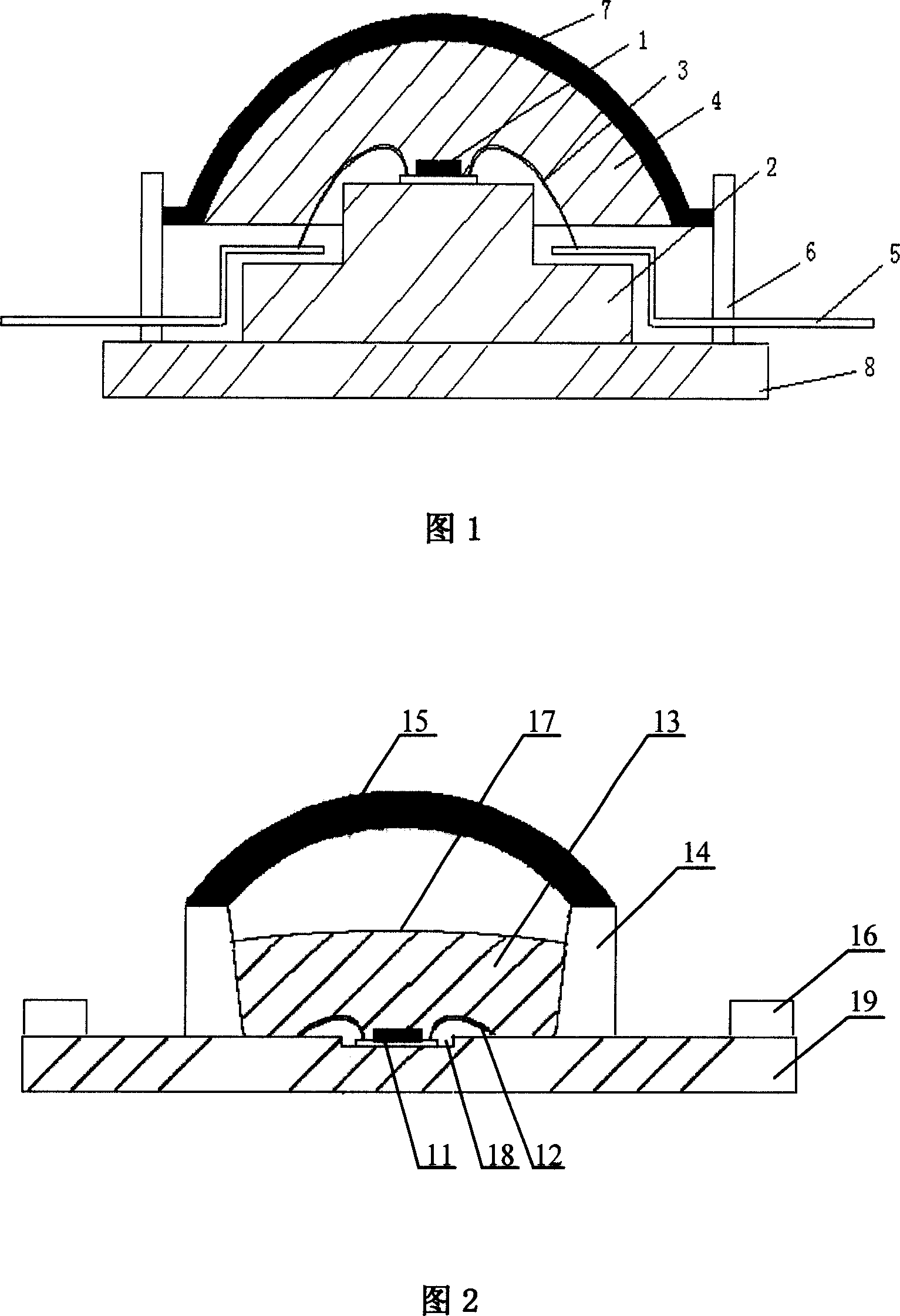

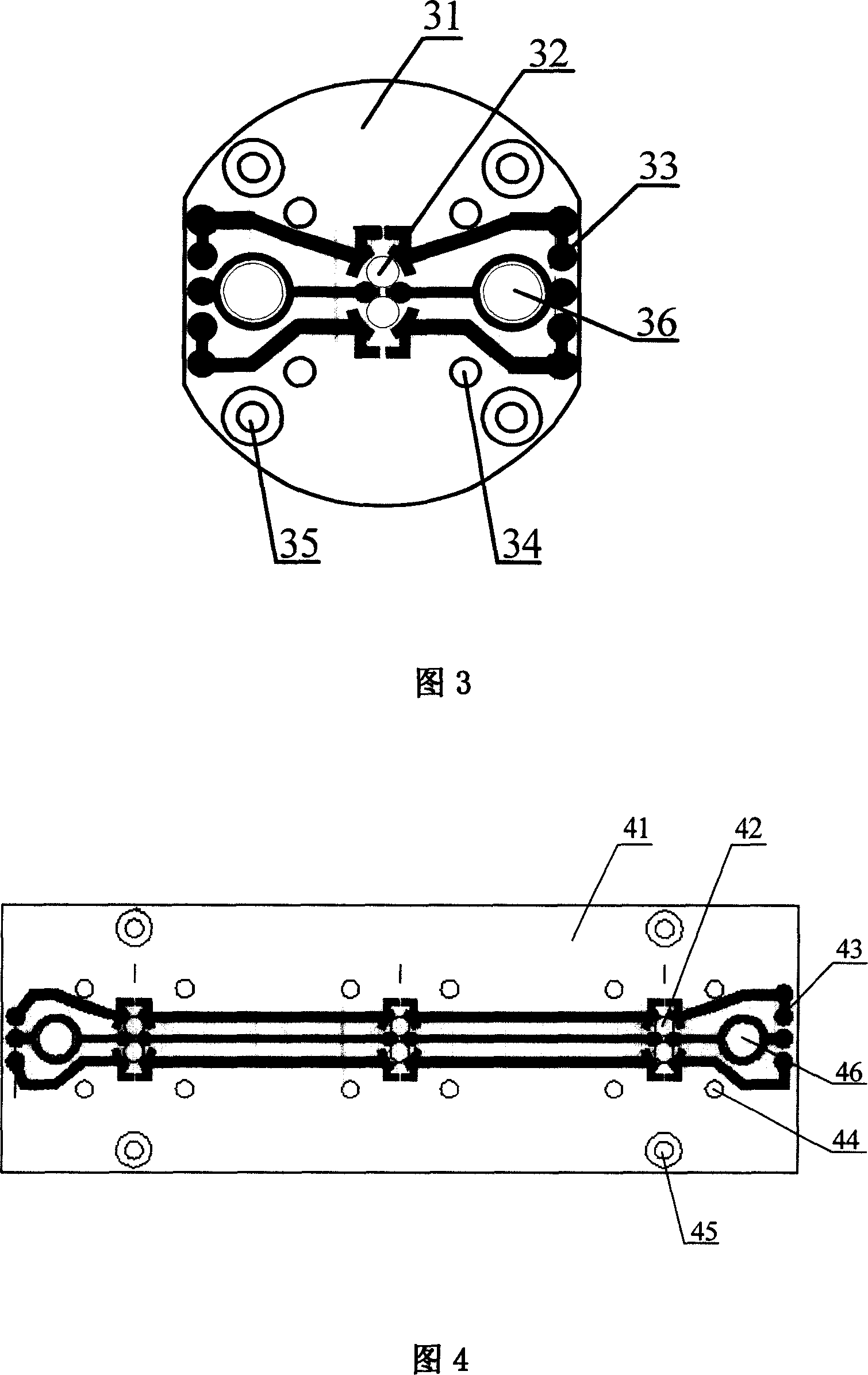

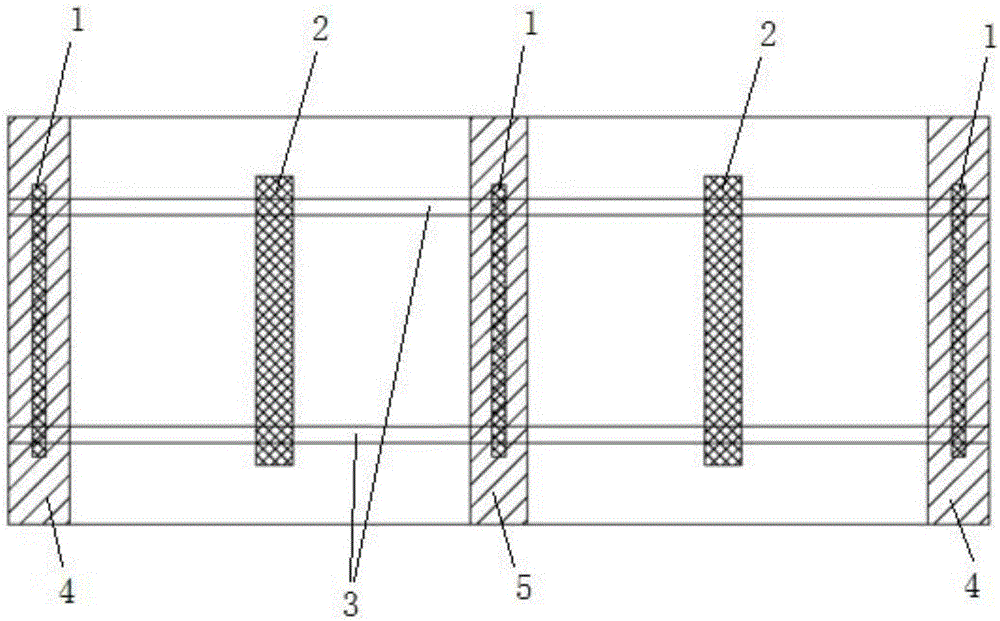

High power LED two-dimension light source

InactiveCN101097973AReduce volumeSimplify the manufacturing processSemiconductor devicesSilver plateEffect light

The invention provides a high-power LED two-dimension light source, wherein an aluminum-base printed circuit board is directly welded or adhered with a high-power LED chip, the chip welded area is processed with a bowl-shape concave which circumference is furnished and plated with silver to form a light reflective area, the chip is arranged with a light reflective bowl with silver plated at inner surface to be fixed on the aluminum-base circuit board, a chip light outlet is packed with silicon-type transparent resin, in curvature shape, the light reflective bowl is covered with a lens unit, arranged with an electric connecting structure. The invention can be used to produce mono product or multiple beamed product, with standard distance connecting port, surface light source with low cost and high integration, better heat radiation, and uniform lighting effect, which can be used as general semi-conductor lighting source of variable lamps.

Owner:NANJING HANDSON SCI & TECH CORP

Automatic basket cleaning all-in-one machine

InactiveCN106077004ARealize automatic operation and cleaningIncrease productivityDrying using combination processesHollow article cleaningDrive motorEngineering

The invention discloses an automatic basket cleaning all-in-one machine which comprises a rack body, wherein a conveying mechanism, a basket high-pressure flushing mechanism, a rotary type basket drying device and an automatic sub-packing and collecting mechanism are arranged on the rack body in a matched manner; the conveying mechanism comprises a plurality of rotatable roller bodies and a drive motor set for driving the roller bodies to rotate; and the drive motor set is in driving connection to the roller bodies through a belt body. The automatic basket cleaning all-in-one machine not only can efficiently carry out high-pressure flushing and disinfecting on a polluted industrial plastic basket, but also can realize automatic operation of the whole process, so that a worker is prevented from being polluted or injured in a cleaning and disinfecting process, and safety of enterprise production is improved; and meanwhile, environmental pollution caused by cleaning is reduced, so that the automatic basket cleaning all-in-one machine has a very important practical application and popularization value on production enterprises of the field.

Owner:陈华强

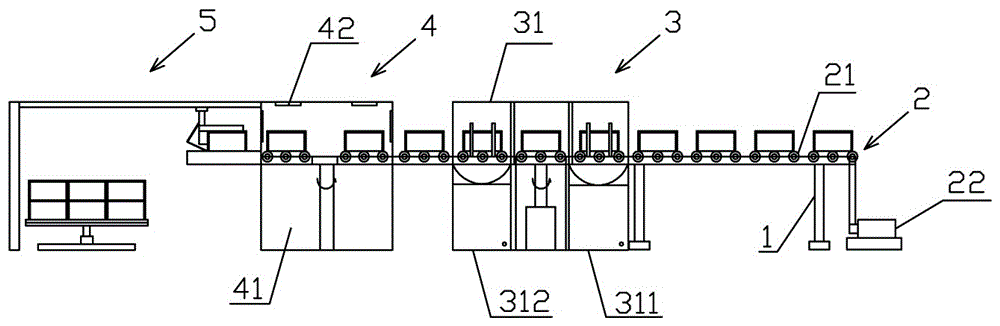

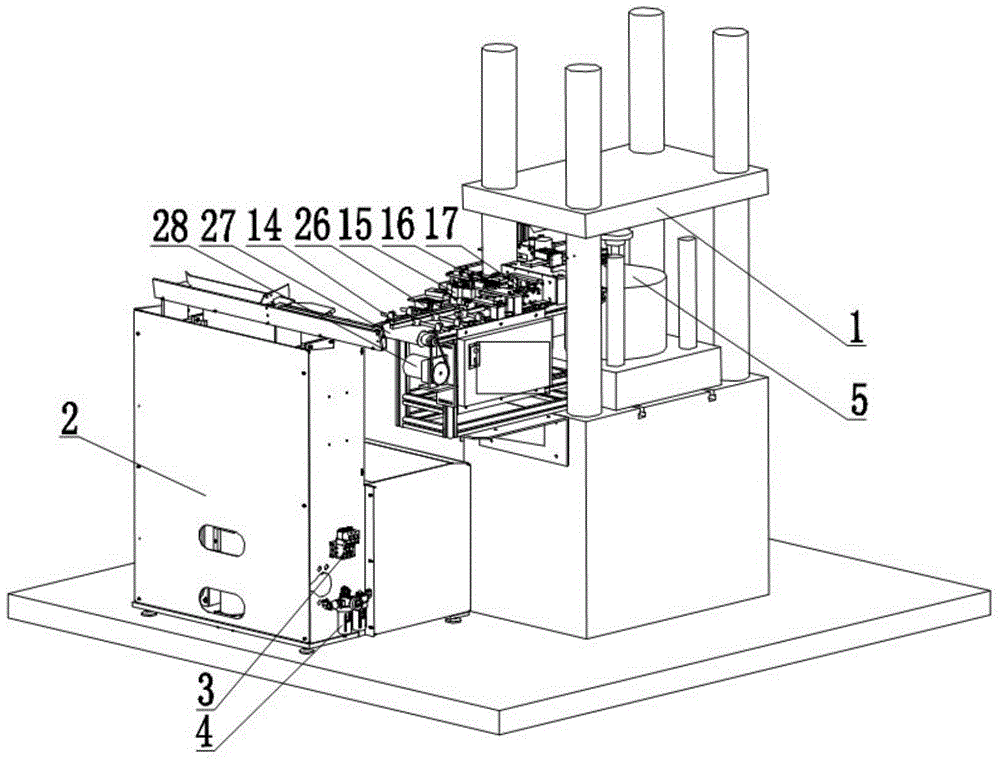

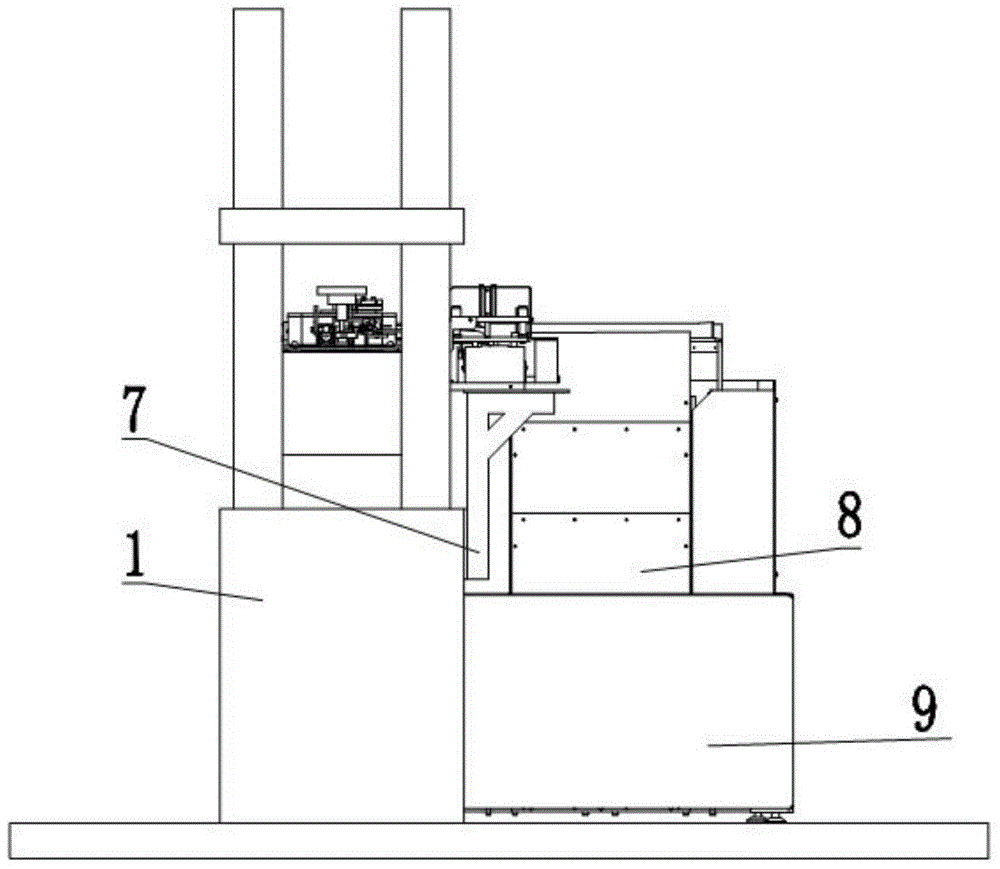

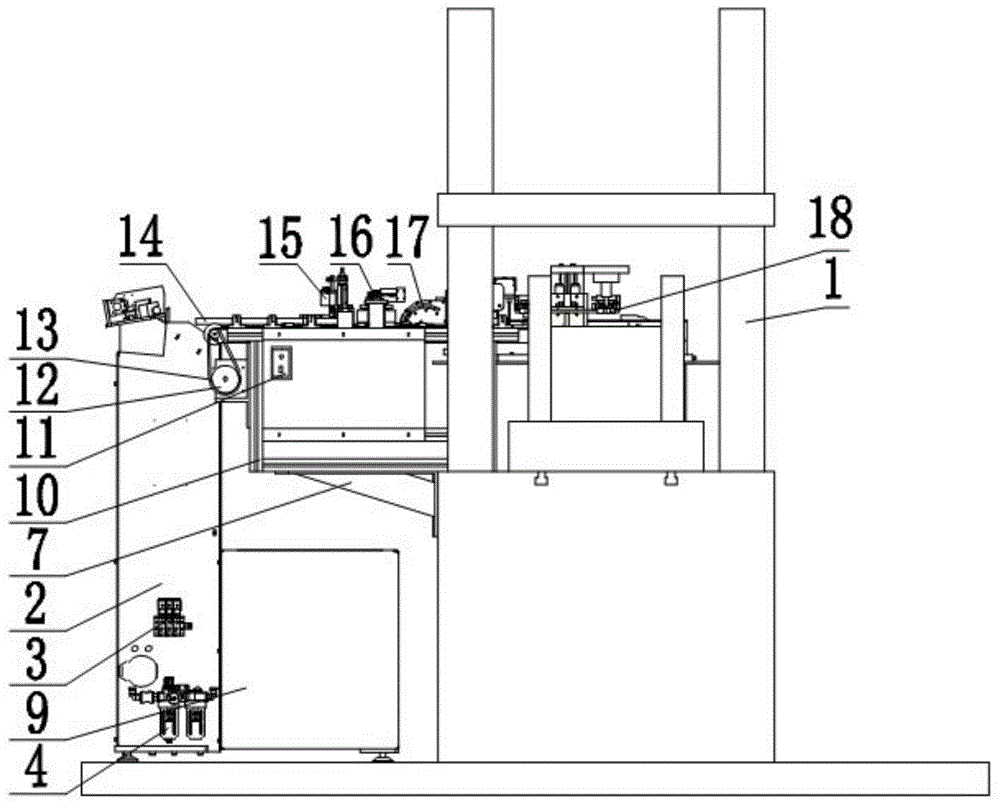

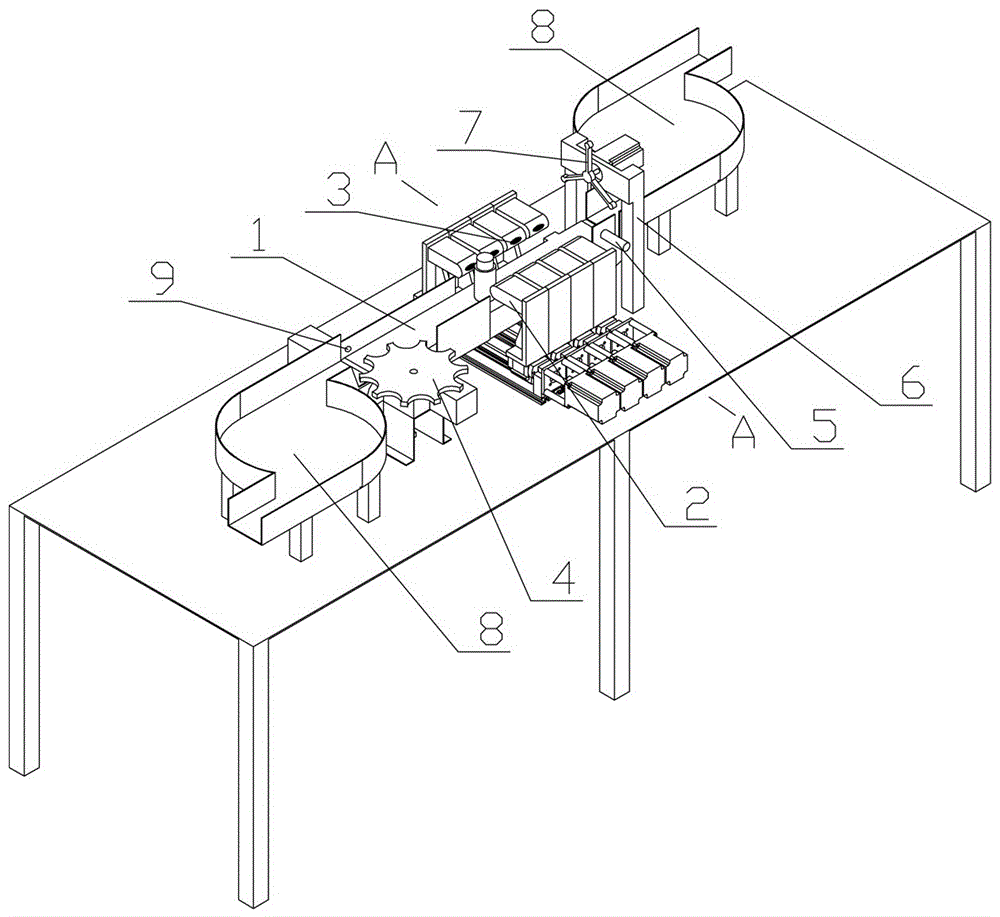

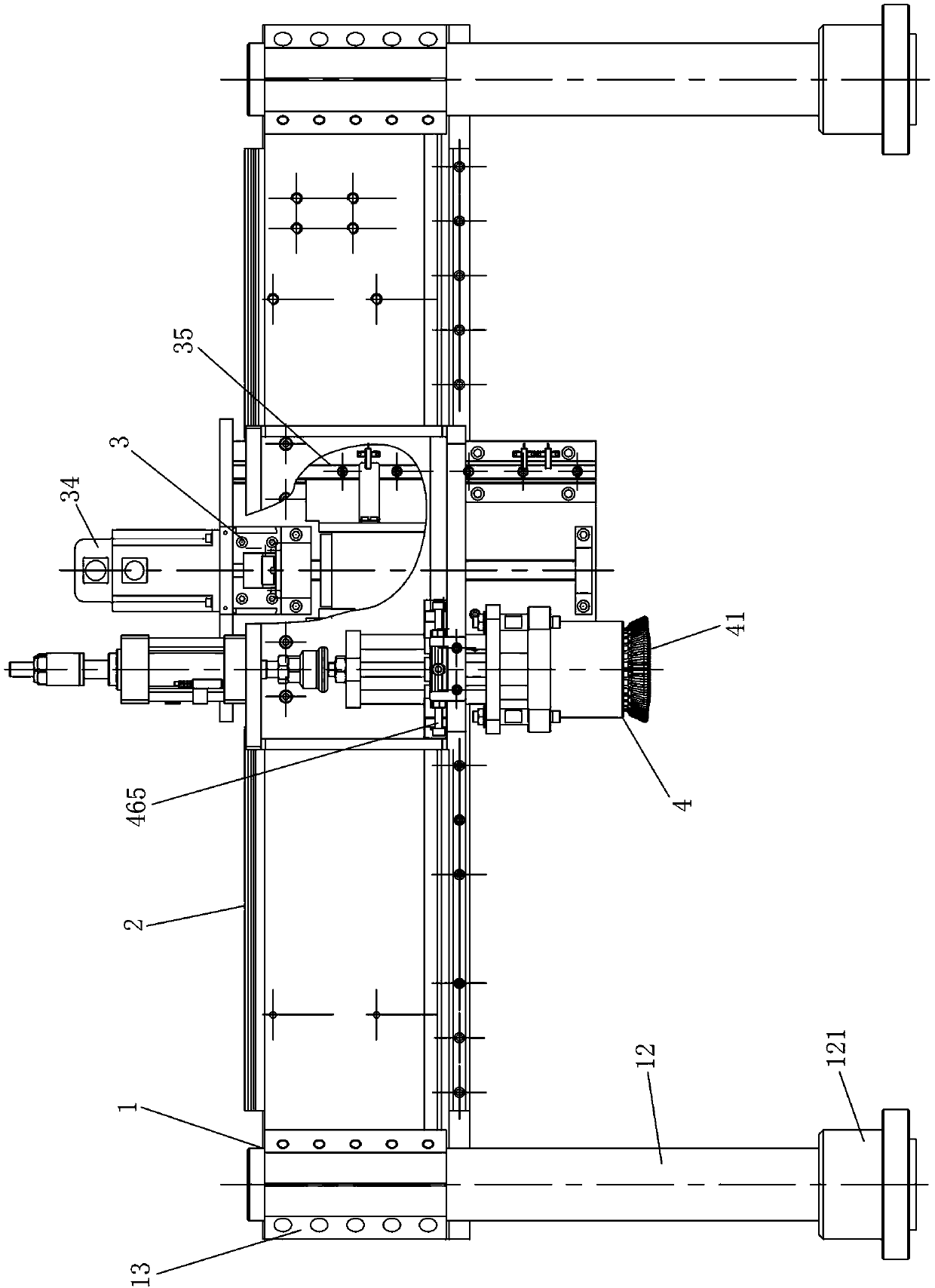

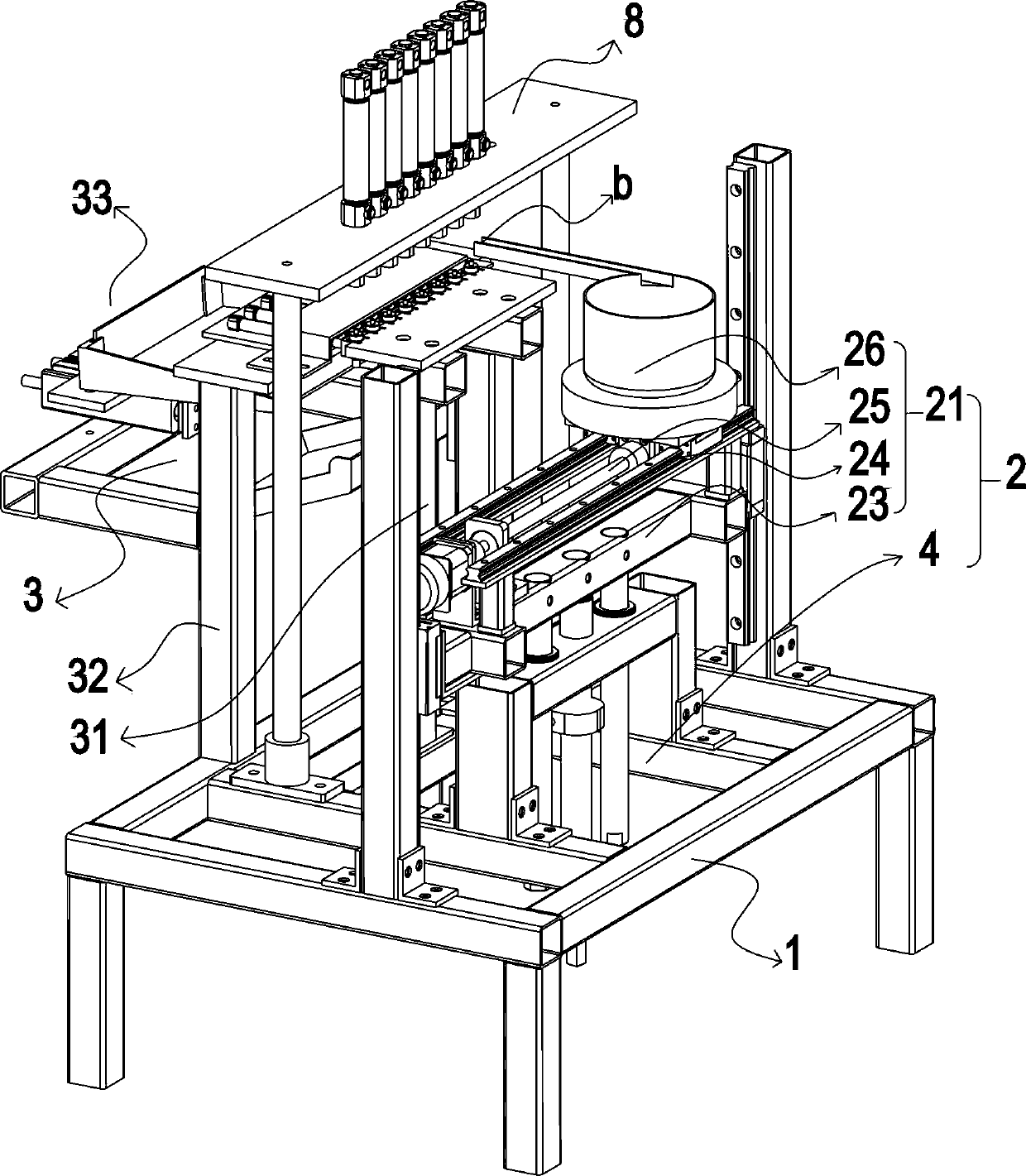

Cold extruding automatic production line

ActiveCN104624831AImprove the level of automated productionMetal-working feeding devicesStripping-off devicesProduction lineEngineering

The invention discloses a cold extruding automatic production line, and belongs to the technical field of automatic production. The automatic production line comprises a main rack, a control device, a loading device, a feeding device, a loading and blanking manipulator device and a hydraulic device, wherein bar steel is sent into the feeding device by the loading device, and the disordered bar steel is organized into the upright bar steel with chamfers facing downward by the feeding device; a bar steel detection photoelectric sensor is triggered when the bar steel reaches the tail end of the feeding device, and information is passed to the loading and blanking manipulator device; the blank fetching and charging are completed by one gripper of the loading and blanking manipulator, the workpiece grabbing and charging are completed by the other gripper of the loading and blanking manipulator, and the hydraulic device is triggered to complete the stamping. According to the cold extruding automatic production line, the existing problems that the artificial production efficiency is low and security risks exist are solved, and the automatic production level of engineering is improved.

Owner:合肥海渡工业机器人有限公司

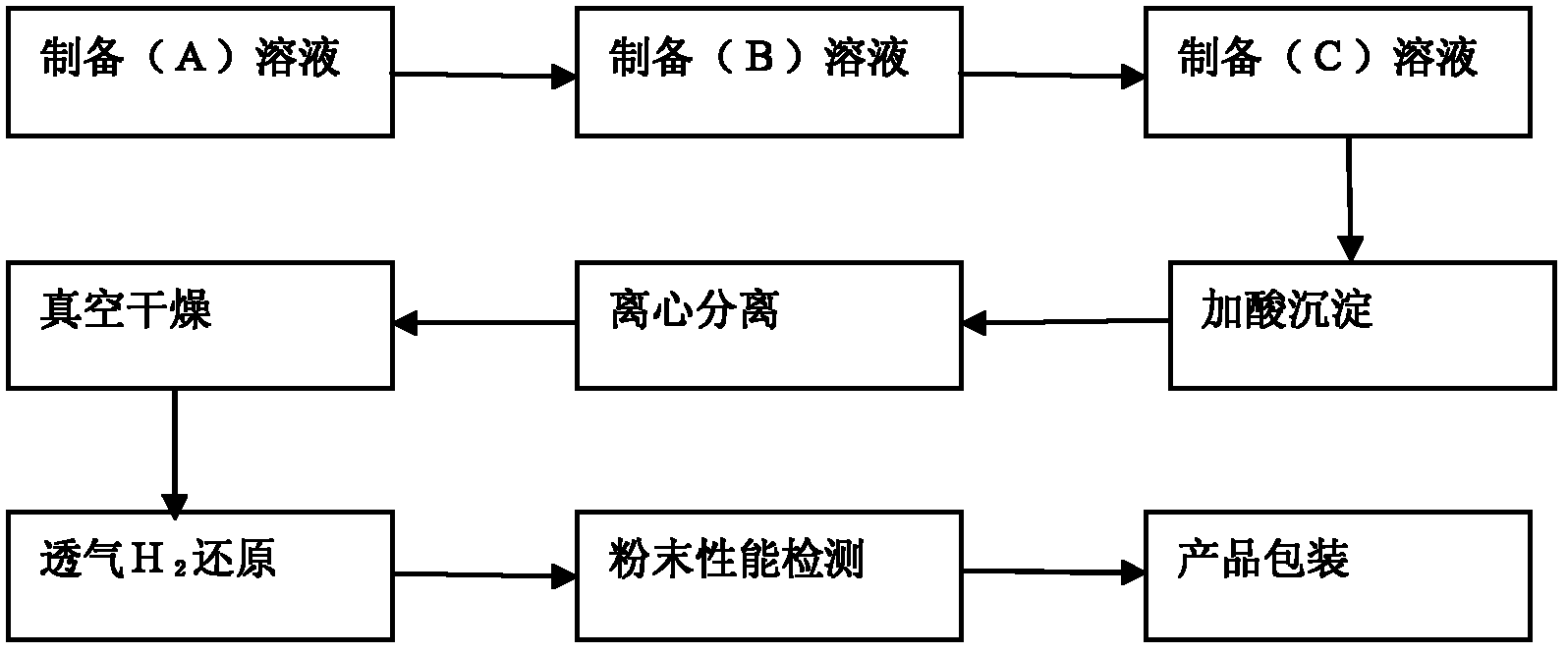

Method for preparing nano-tungsten powder by using sulfuric acid precipitation-H2 breathable reduction process

The invention belongs to the technical field of preparation of metal powder which belongs to a metal material, in particular to a method for preparing nano-tungsten powder by using a sulfuric acid precipitation-H2 breathable reduction process, which is suitable for large-scale industrial production of nano-tungsten powder. The method is characterized by comprising: performing a precipitation reaction under the common action of a separant and a dispersing agent by using diluted solution of ammonium tungstate and diluted aqueous solution of sulfuric acid to obtain nano particular tungstic acid precipitate, performing centrifugal separation at high speed, washing repeatedly, drying under vacuum, reducing in a continuous breathable H2 reduction furnace, and finally obtaining nano tungsten powder with an average particle size of less than or equal to 35 nano meters. The method has the advantages that: the cost is low; the production efficiency is high; the equipment is simple; the process is short; the investment is small; and continuous and automatic large-scale production can be realized easily.

Owner:UNIV OF SCI & TECH BEIJING

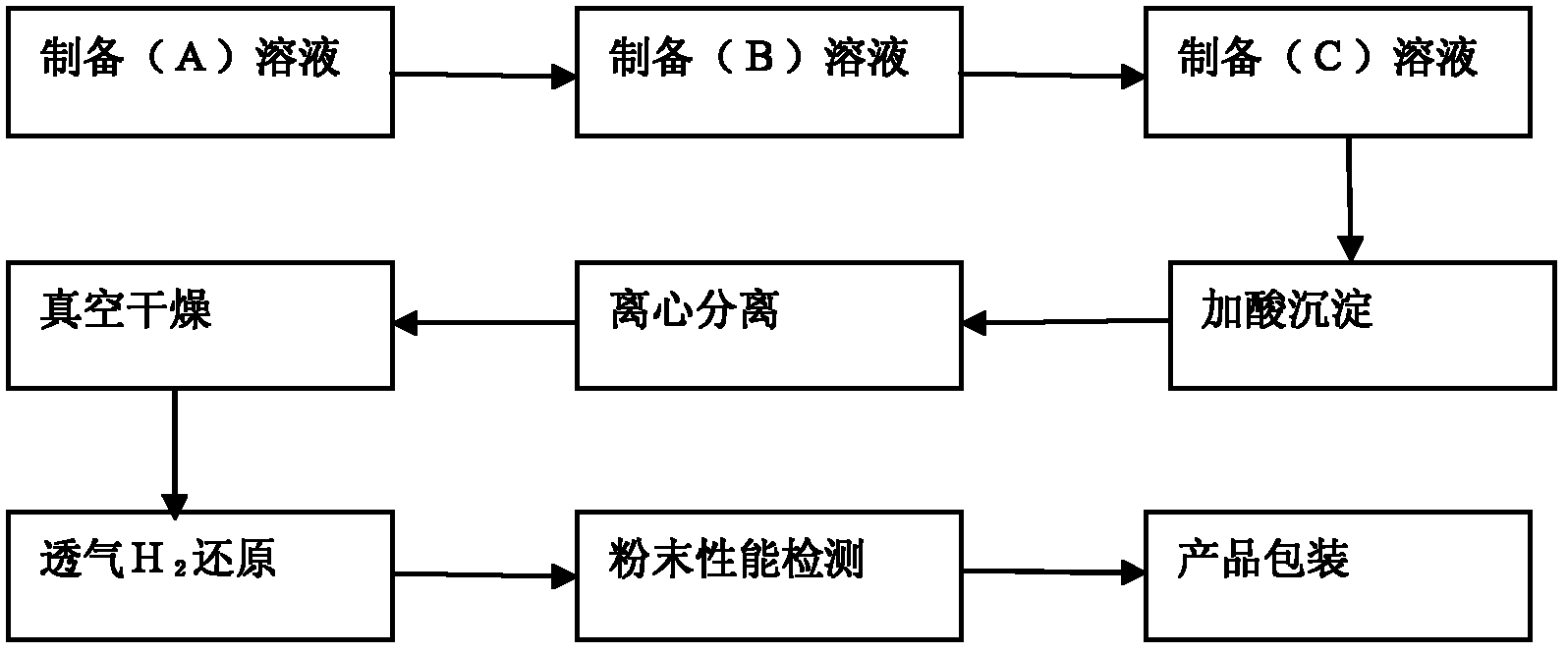

Automatic measuring method and automatic measuring system for temperature of vertical flue of coke oven

ActiveCN106382991ASimple compositionSmall footprintRadiation pyrometryEnergy inputBrickCombustion chamber

The invention relates to an automatic measuring method and an automatic measuring system for temperature of a vertical flue of a coke oven. Through a temperature measuring device walking track compiling process, a combustion chamber positioning process, a noise bridge brick identification process and a continuous temperature measuring process, the temperature of each vertical flue is determined according to a temperature curve which is measured in the continuous temperature measuring process, the number of the combustion chamber, a time stamp and nose bridge brick identification information. According to the automatic detecting method and the automatic detecting system, existing equipment in a coke oven production system is sufficiently utilized, such as a carbonizing chamber code disc and a coal charger track; three movable temperature measuring devices are utilized for simultaneously measuring the temperatures of the vertical flues in different areas; a ground PLC workstation compiles the temperature measuring device walking track and makes a walking plan according to a coke pushing plan; continuous temperature measurement is performed on the vertical flues periodically on the condition that normal operation of a coke oven coal charger is not affected; and furthermore opening or closing of a fire observing hole cover is not required in the temperature measuring process, thereby greatly improving temperature measuring efficiency and furthermore improving timeliness in performing tempering on the coke oven.

Owner:ACRE AUTOMATION CO LTD MCC

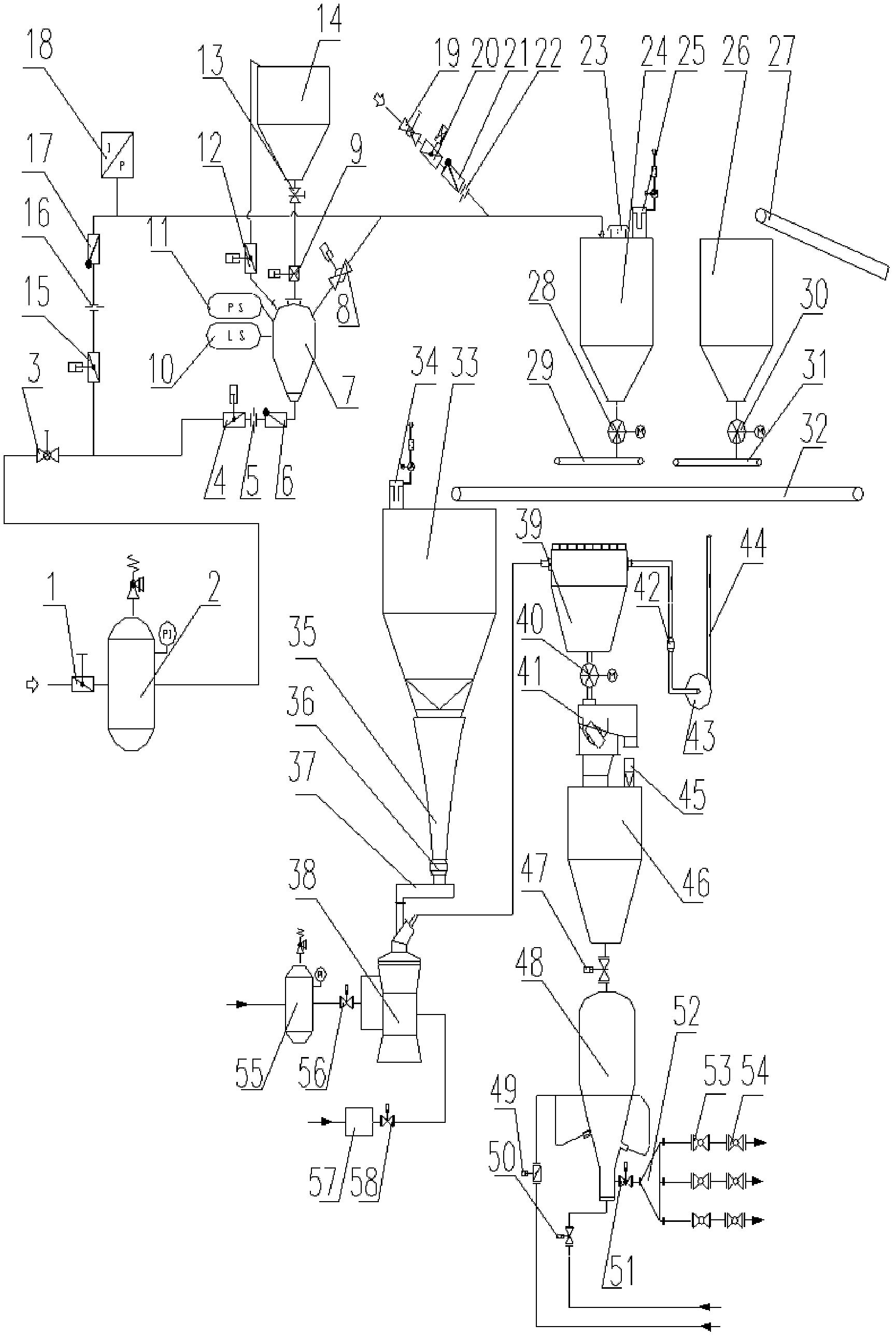

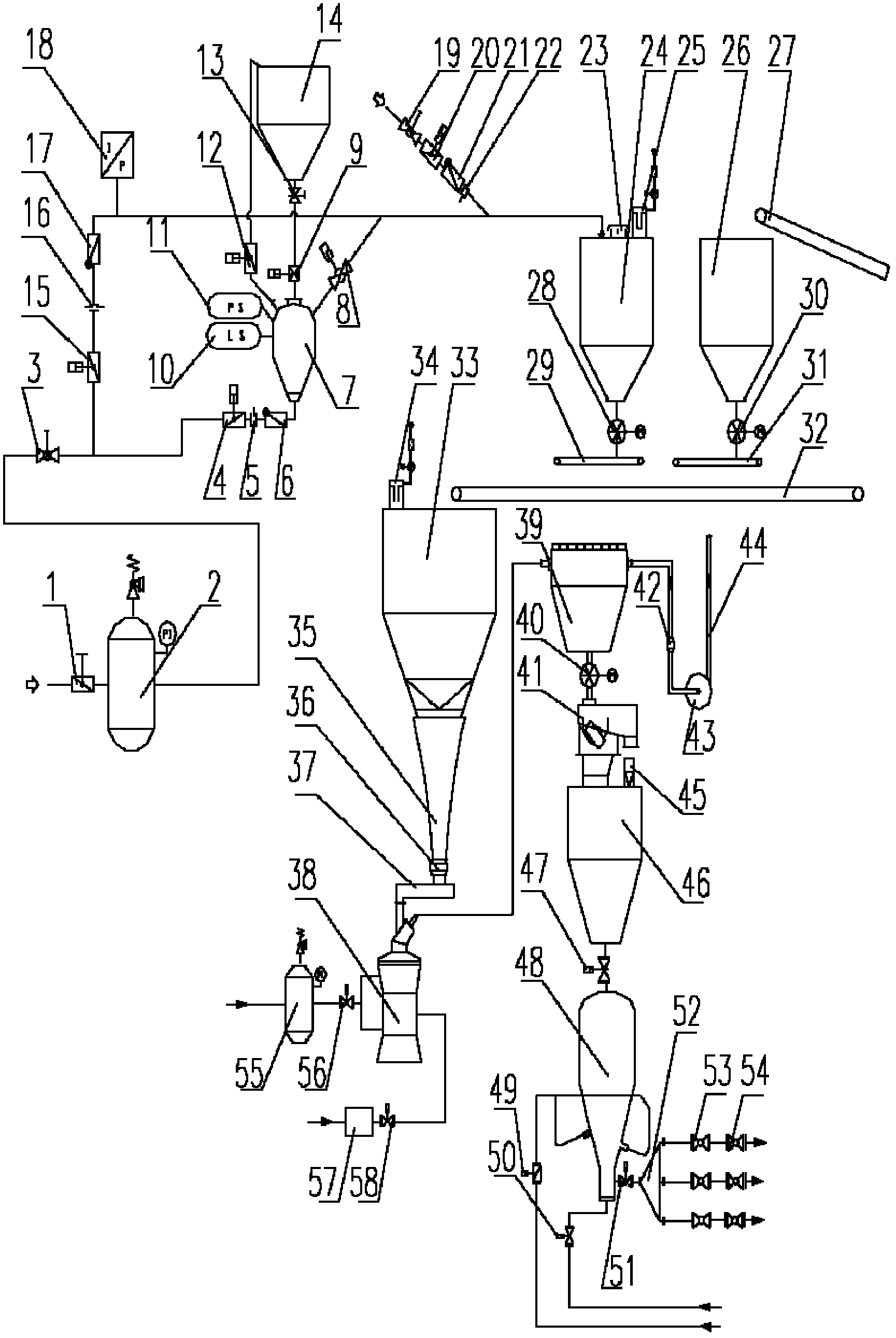

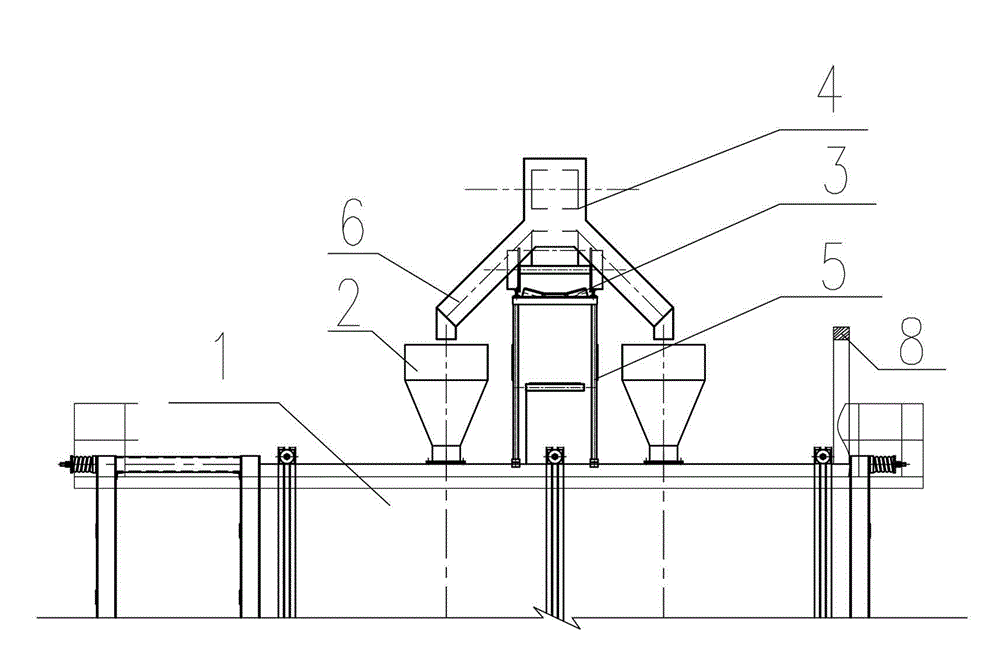

Pneumatic conveying and blast furnace injecting device for coke oven dust-removing ash and using method thereof

ActiveCN102633122AReduce labor intensityRealize the concept of production and operationBlast furnace componentsBlast furnace detailsProcess engineeringCoke oven

The invention discloses a pneumatic conveying and blast furnace injecting device for coke oven dust-removing ash and a using method of the device. The pneumatic conveying and blast furnace injecting device comprises a coke oven dust-removing ash pneumatic conveying air source unit, a coke oven dust-removing ash pneumatic conveying main unit, a gas-pressure balance unit, an ash conveying pipeline travel cleaning unit, a coke oven dust-removing ash and secondary coal distribution unit, a coke oven dust-removing ash and secondary coal grinding unit, a coke oven dust-removing ash and secondary coal grinded material collection unit, a pulverized coal baking unit, a coke oven dust-removing ash and secondary coal grinding process safe-extinguishment unit and a blast furnace injecting unit. The device completely solves the problem that coke oven dust-removing ash is used as one of the biggest coked environmental pollution sources by long-distance sealed pneumatic conveying, is safe and reliable in operation, improves the environmental protection benefit, the energy efficiency and the automatic production level, achieves full-automatic production operation, reduces the labour intensity of a worker and achieves the production management idea based on humanistic theory.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Liquid plastic bottle leak detector for production line and detecting method thereof

InactiveCN106353037ARealize automatic eliminationLabor savingFluid-tightness measurementProduction lineEngineering

The invention relates to a liquid plastic bottle leak detector for production line, several mechanical hands are arranged on both end sides of moving directions of conveyor belt, the mechanical hands are connected with drive device, the clamping part of each mechanical hand is composed of a symmetrical clamping head, a pressure sensor is mounted on each clamping head, the pressure sensor is connected with external PLC control cabinet; a distributor is arranged at the entry end of the conveyor belt, the distributor arranges the distance of bottles entering the conveyor belt; a start detecting sensor is arranged at the entry end of conveyor belt. The bottle leak detector can detect the seal condition of plastic bottles by pressing lightly on the bottles, the device can realize effective identification so that products can be 100% detected, which avoids the problems caused by manual detecting, saves a lot of labor costs and improves the degree of automation of production enterprises.

Owner:阎文

Automatic enameled wire conveyor line based on visual inspection system

ActiveCN110844591AImprove automationImprove the level of automated productionWrappingWrapper twisting/gatheringVisual inspectionChain conveyor

The invention discloses an automatic enameled wire conveyor line based on a visual inspection system. The automatic enameled wire conveyor line comprises a handling unit, an inspection unit, a prepackaging unit, and a packing unit; the handling unit comprises a first handling assembly, and a first transfer assembly and a first conveyor which are arranged on the inner side of the first handling assembly; the first transfer assembly is arranged on one side of the first conveyor; the inspection unit comprises a visual inspection assembly arranged on the first conveyor, and a quality inspection assembly located at one end of the first conveyor; the prepackaging unit is connected with the quality inspection assembly; the packing unit is arranged at one end of the prepackaging unit; and the first transfer assembly comprises a bearing platform and a chain conveyor, and the bearing platform is arranged on the chain conveyor. According to the automatic enameled wire conveyor line, through mutual cooperation of the arranged handling unit, the inspection unit, the prepackaging unit and the packing unit, full-automatic packaging of an enameled wire can be achieved; the production automation level of the enameled wire is improved, and the operating process saves time and labors; and the production efficiency of the enameled wire is improved greatly, and the production cost of the enameled wire is reduced.

Owner:DONGGUAN SUN CABLE EQUIP CO LTD

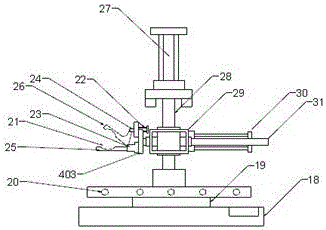

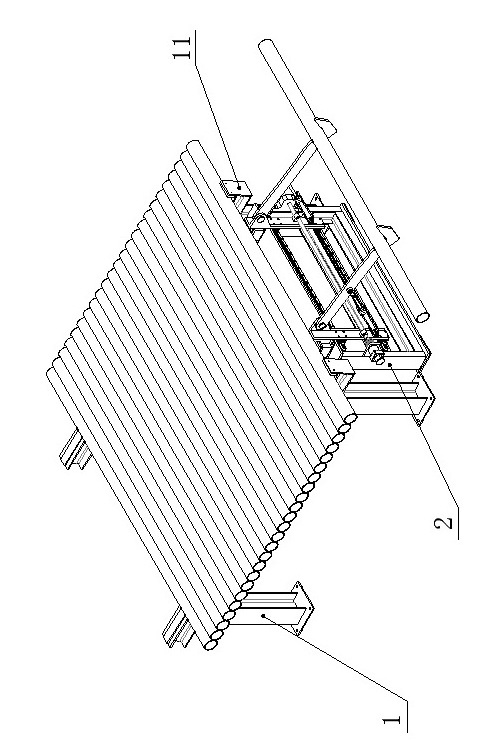

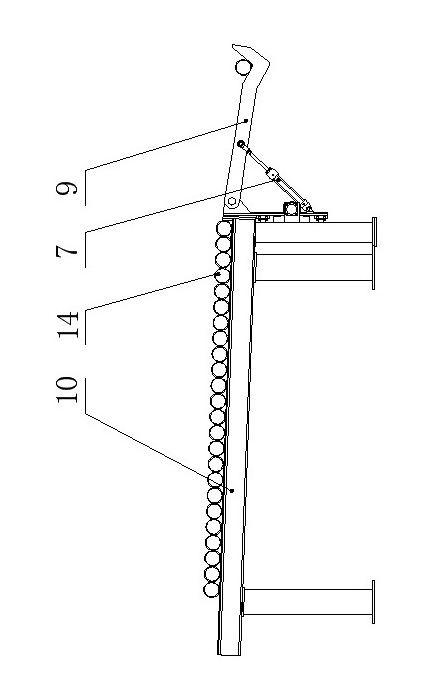

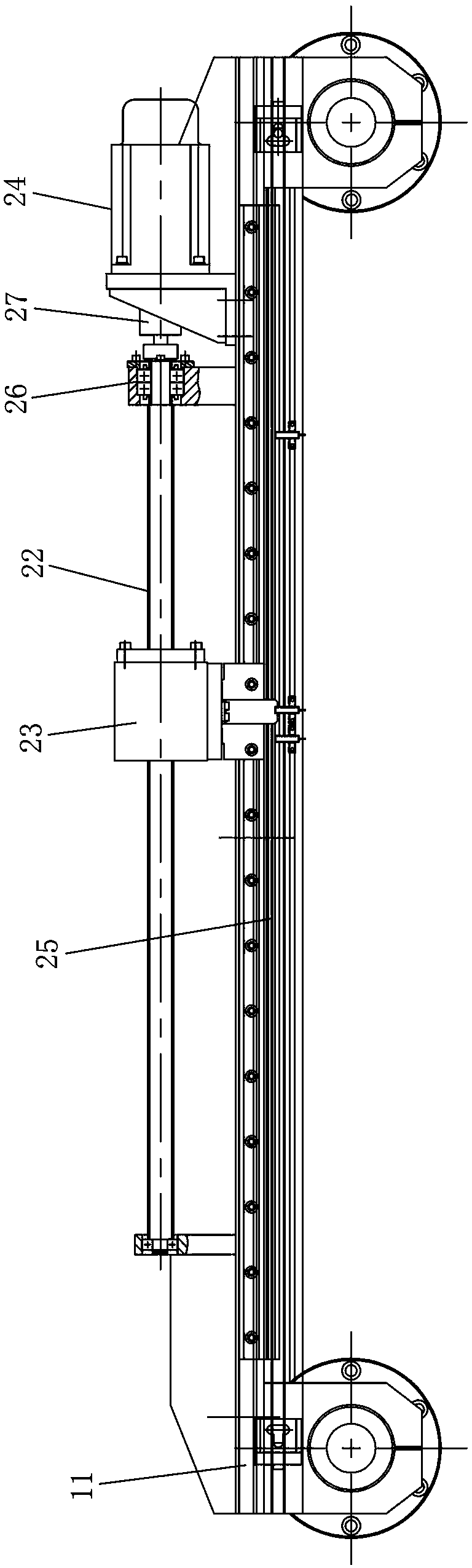

Automatic feeding mechanism for slitting of internal combustion engine air cylinder sleeve

InactiveCN106041613AReduce labor intensityCompact structureMetal working apparatusInternal combustion enginePiston rod

The invention discloses an automatic feeding mechanism for slitting of an internal combustion engine air cylinder sleeve. The automatic feeding mechanism comprises a storage unit used for stacking air cylinder sleeve header pipes to be slit, a separation unit used for separating out the air cylinder sleeve header pipe located at the innermost end of a storage frame, and a transferring unit used for transferring the air cylinder sleeve header pipes. The separation unit comprises a base, a first air cylinder, a jacking plate, a carrying rod and a second air cylinder, wherein the base is located at the tail end of the storage frame, the first air cylinder is arranged on the lateral wall, near the storage frame, of the base, the tail end of a piston rod of the first air cylinder is connected with the jacking plate, the first air cylinder drives the jacking plate to ascend and descend vertically so that the single air cylinder sleeve header pipe falling onto the jacking plate can be conveyed to the carrying rod, one end of the carrying rod is hinged to the top of the base, a V-shaped groove is formed in the other end of the carrying rod, and the second air cylinder is arranged on the lateral wall of the base. The automatic feeding mechanism has the beneficial effects of being compact in structure, being easy to control, and improving production efficiency and the automatic production level.

Owner:ZYNP GRP ANHUI CO LTD

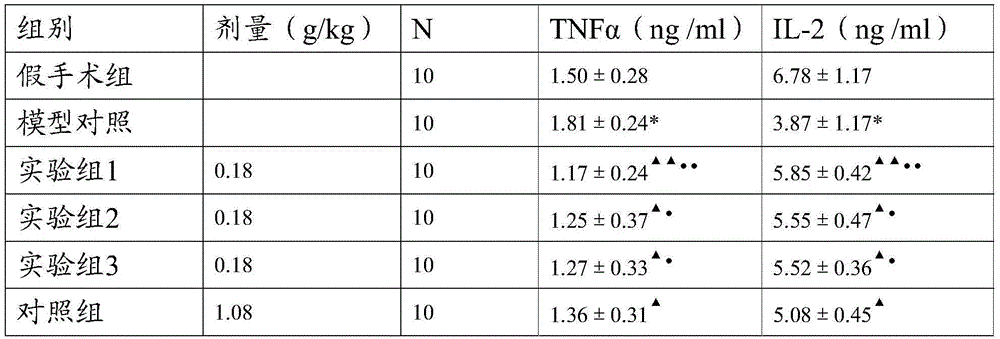

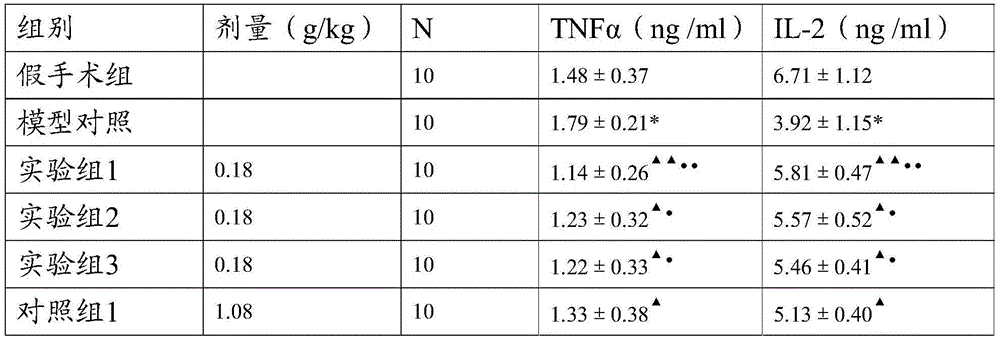

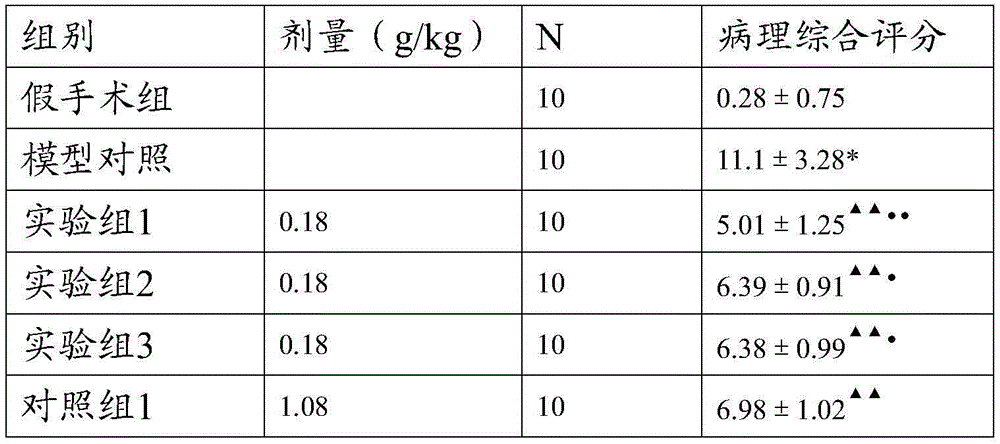

Traditional Chinese medicine granules and preparation method and use thereof

InactiveCN104523603AExtract completelyProduct quality is easy to controlGranular deliverySexual disorderDiseaseAlcohol

The invention provides traditional Chinese medicine granules and a preparation method and use thereof. The traditional Chinese medicine granules are prepared from the following medicinal raw materials equal in weight: cassia twigs, poria cocos, moutan barks, red peony roots and peach kernels as well as a proper amount of auxiliary materials. The preparation method comprises the following steps: extracting volatile oil from cassia twigs and poria cocos; clathrating the volatile oil by beta-cyclodextrin; extracting residues with other medicinal raw materials by an ethanol solution with volume concentration of 70-90%; collecting and concentrating to obtain an alcohol extract; extracting the residues by water; collecting and concentrating; adding the alcohol extract; uniformly mixing; adding the proper amount of auxiliary materials and a volatile oil clathrate compound; granulating; and sub-packaging. The preparation method provided by the invention remarkably improves the pharmacodynamic action of cassia twigs and poria cocos, and the effect of the prepared traditional Chinese medicine granules in treating gynecological diseases, particularly gynecological chronic pelvic inflammatory disease, is remarkably improved.

Owner:BEIJING HANDIAN PHARMA CO LTD

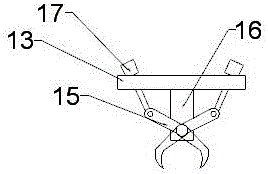

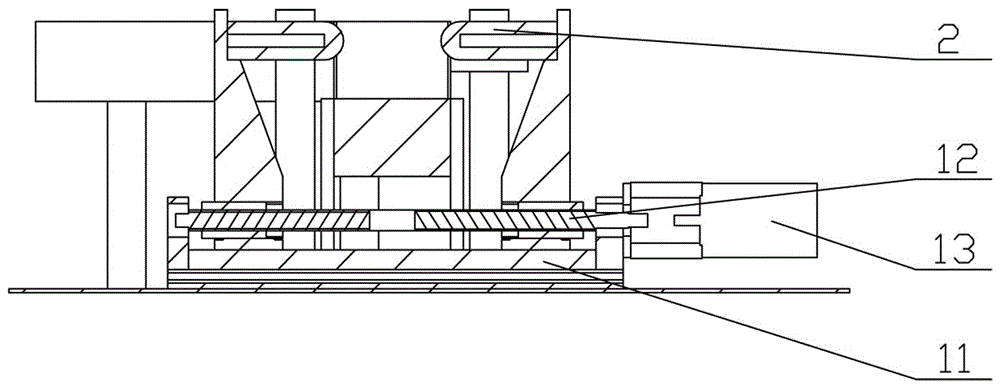

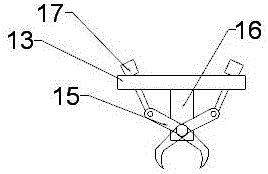

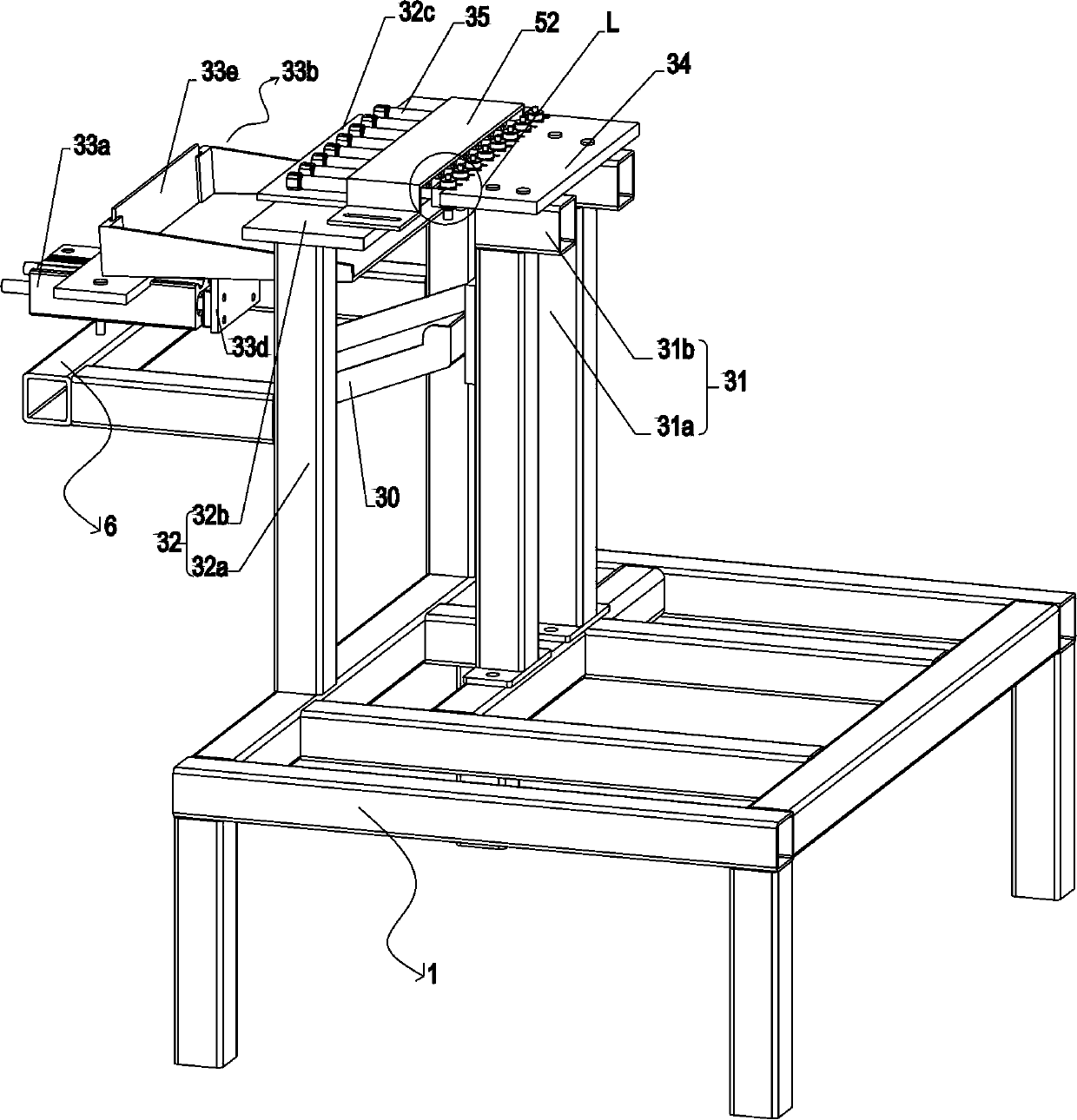

Automatic integrated line clamping and threading device for motor rotor

The invention discloses an automatic integrated line clamping and threading device for a motor rotor. The automatic integrated line clamping and threading device comprises a support assembly, a mechanical hand and a driving assembly, wherein the mechanical hand is used for wholly clamping and releasing a coil assembly formed by a splitting torsion head, the driving assembly is used for driving the mechanical hand to move between a line clamping station and a threading station, and the driving assembly is arranged on the support assembly. The mechanical hand is provided with a plurality of clamping jaws and a clamping and releasing driving assembly, wherein the clamping jaws are evenly arranged around the circumference of the mechanical hand, and the clamping and releasing driving assembly is used for driving the clamping jaws to synchronously act to clamp or release the coil assembly. The automatic integrated line clamping and threading device has the advantages of being high in production efficiency, high in product consistency, precise in action, stable and reliable in working, capable of greatly saving manpower resources and the production cost, and the like.

Owner:长沙优力恩自动化科技有限公司

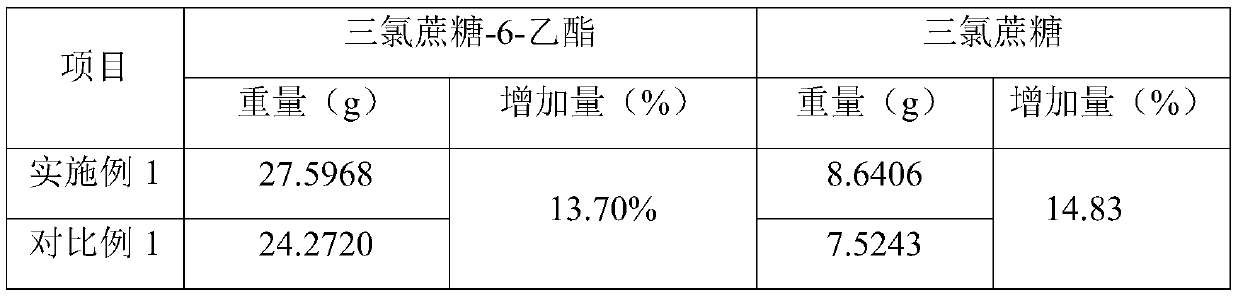

Preparation method for sucralose

ActiveCN109956982AReduce lossShort process routeSugar derivativesSugar derivatives preparationSucroseEthyl ester

The invention discloses a preparation method for sucralose. The method includes the following steps: performing neutralization treatment on a reaction liquid obtained by chlorinating sucrose-6-ethyl ester to obtain a neutralization solution, removing a salt from the neutralization solution and then adding an extraction agent, separating an extract phase including 4, 1', 6'-sucralose-6-ethyl esterand tertiary amide, removing a tertiary amide solvent in the extraction phase, then directly adding alkali for performing a deacylation reaction to obtain a sucralose crude product liquid, and then subjecting separation and purification to obtain a sucralose fine product. The method has the advantages of simple and short process, high yield, low production cost, and the like.

Owner:WENGYUAN GUANGYE QINGYI FOOD TECH +1

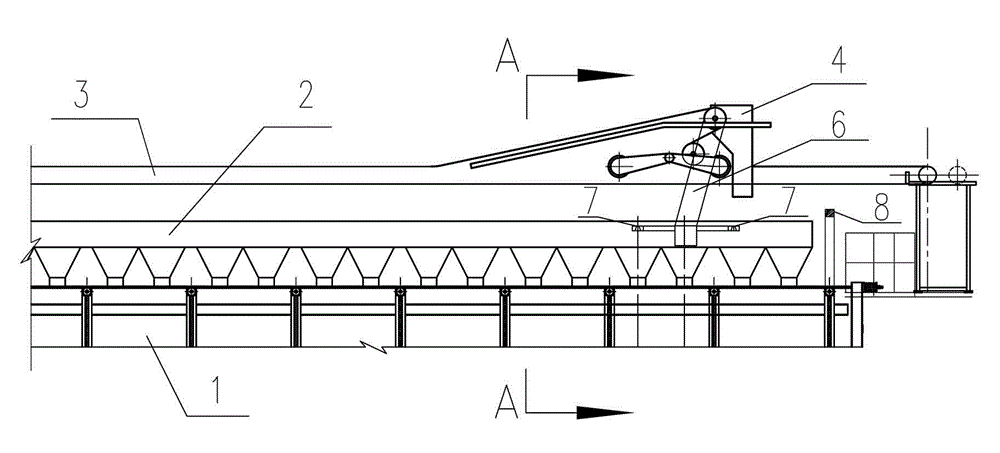

Automatic feeding system and method

ActiveCN104930855AImprove the level of automated productionReduce labor intensityCharge manipulationControl devices for furnacesSystem stabilityMechanical engineering

The invention relates to an automatic feeding system and method, and especially relates to a pot type calcinator automatic feeding system and method, wherein the pot type calcinator is used for producing anodes, cathodes, electrodes and carbon graphitized materials which are used for aluminium in the carbon industry. The automatic feeding system comprises two rows of pot type calcinators and receiving hoppers, and each receiving hopper is arranged on one pot type calcinator, a supporting steel structure is arranged between the two rows of pot type calcinators, a belt is arranged on the supporting steel structure, a mobile discharging dolly is arranged on the belt, two side discharging channels of the discharging dolly are communicated with the upper end of a laying-off slide pipe, and the lower ends of the laying-off slide pipe is arranged on the receiving hoppers. The automatic feeding system and method are advantaged in that the production automation level of the pot type calcinators can be increased, the labor intensity of workers is reduced, the feeding process can be controlled on line, and uniform feeding can be achieved, the system stability and the production stability can be improved, and the product quality can be guaranteed.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

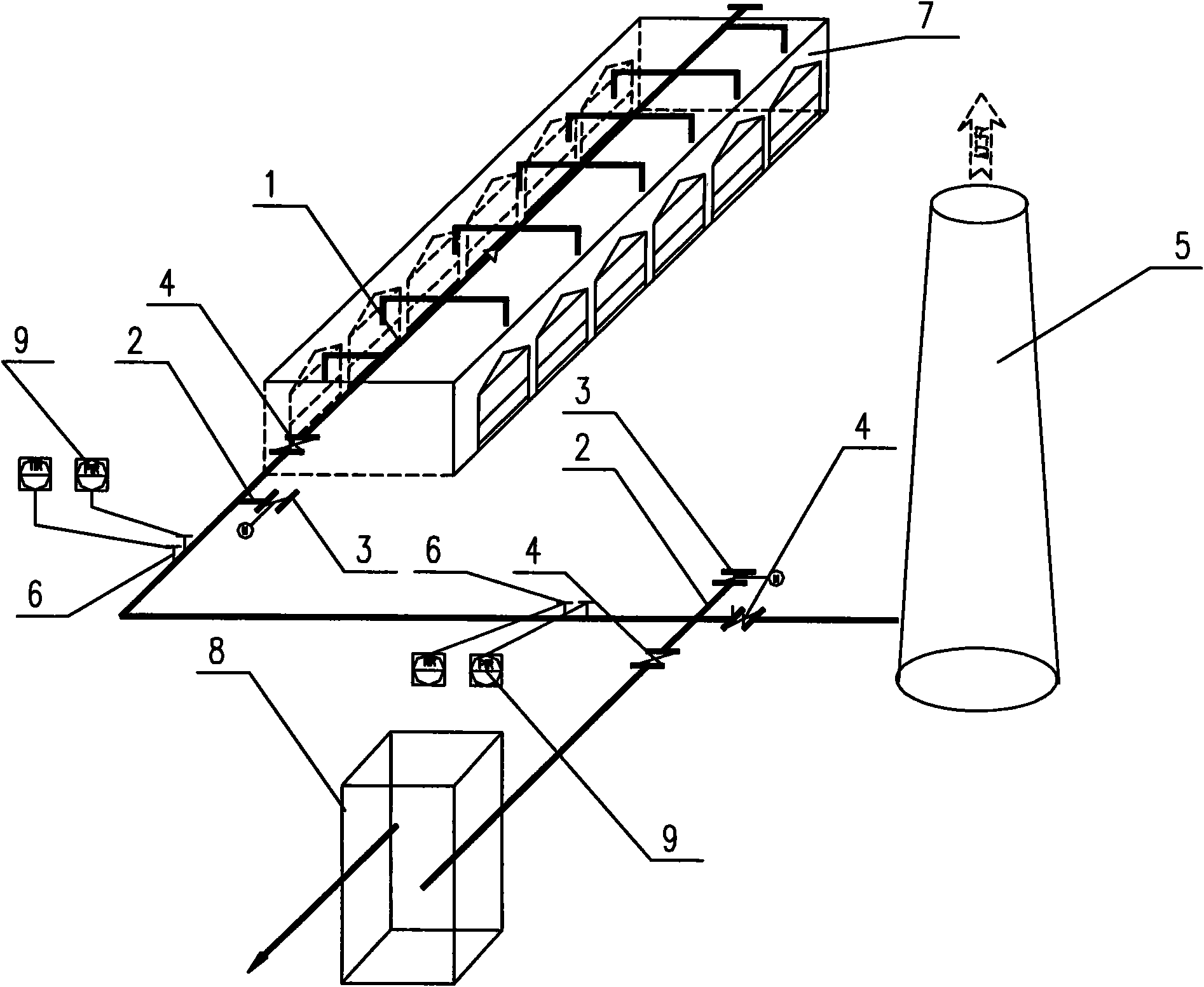

Cold-side adjustment method for temperature and pressure of high temperature flue gas system of heat recovery coke oven

ActiveCN101624525AImprove the level of automated productionExtended service lifeBeehive ovensHorizontal chamber coke ovensCold sideFlue gas

The invention relates to a method and a device for adjusting the temperature and the pressure of a high temperature flue gas pipeline of a heat recovery coke oven (also called non-recovery coke oven when the residual heat of the coke oven flue gas is not recovered), which achieve the automatic adjustment and control of the pressure and the temperature of a high temperature flue gas system by adjusting an air suction port arranged on the high temperature flue gas pipeline operated by negative pressure and adjusting the air suction volume of the high temperature flue gas system, wherein when a cold end adjusting device is adopted, the method for adjusting the pressure by changing the opening of a cutting flashboard on the original high temperature flue gas pipeline can be replaced completely, and the adjustment is convenient and quick. The method and the device are suitable for the high temperature gas systems of various newly-constructed, reconstructed and expanded heat recovery coke ovens, have simple process and device structures and convenient operation, reduce the labor intensity of workers, can achieve automatic adjustment, improve the production automation level of the heat recovery coke oven, and prevent environmental pollution.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

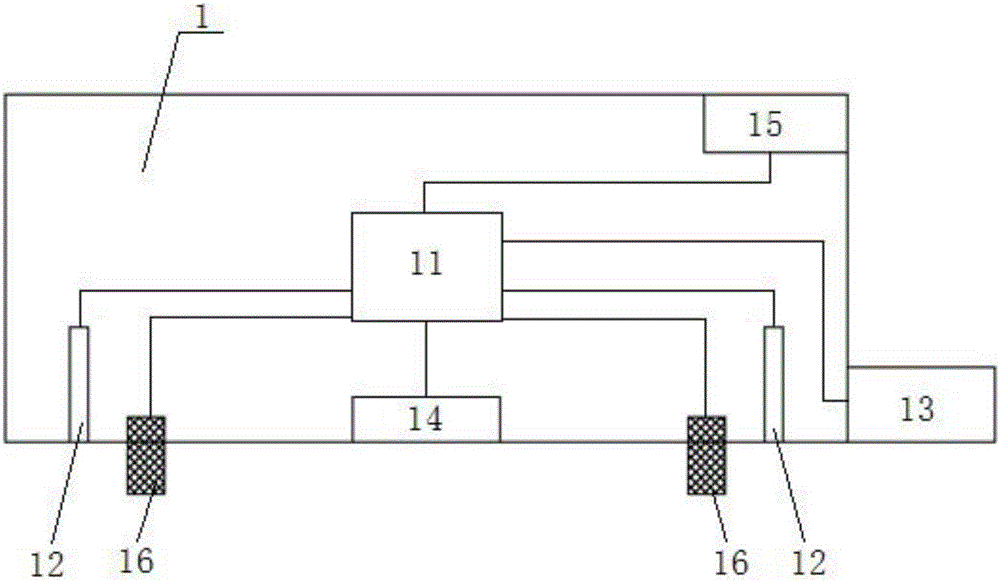

Production line supervision system

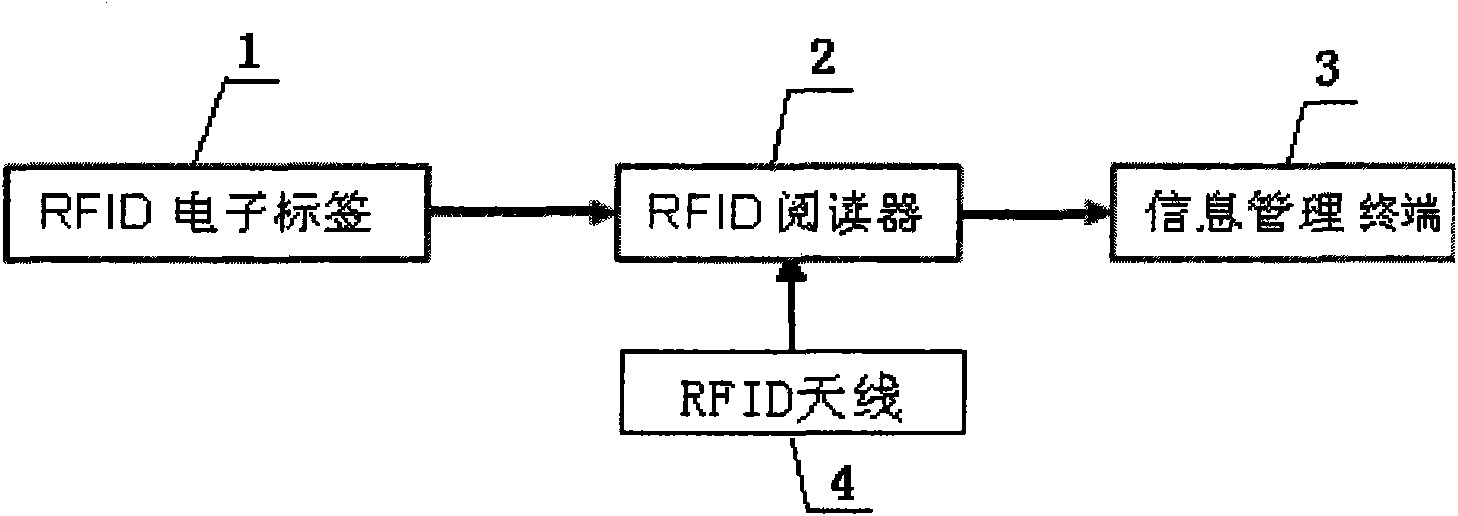

InactiveCN102314628AWorking distanceHigh precisionSensing record carriersRecord carriers used with machinesProduction lineComputer terminal

The invention provides a production line supervision system, which mainly comprises a radio frequency identification (RFID) electronic label which is arranged on a product or a tray, an RFID reader and an information management terminal, wherein the RFID reader reads the information on the electronic label and then transmits the information to the information management terminal, and the RFID reader is a fixed reader which is installed on a production line node. The RFID supervision system also comprises an RFID antenna, wherein the RFID antenna is connected with the RFID reader, and the RFID reader is connected with the information management terminal. The RFID supervision system has the advantages that: the working distance is long, the precision is high, the information can be automatically and quickly collected and processed, and the environmental adaptability is good.

Owner:常州高特电子技术有限公司

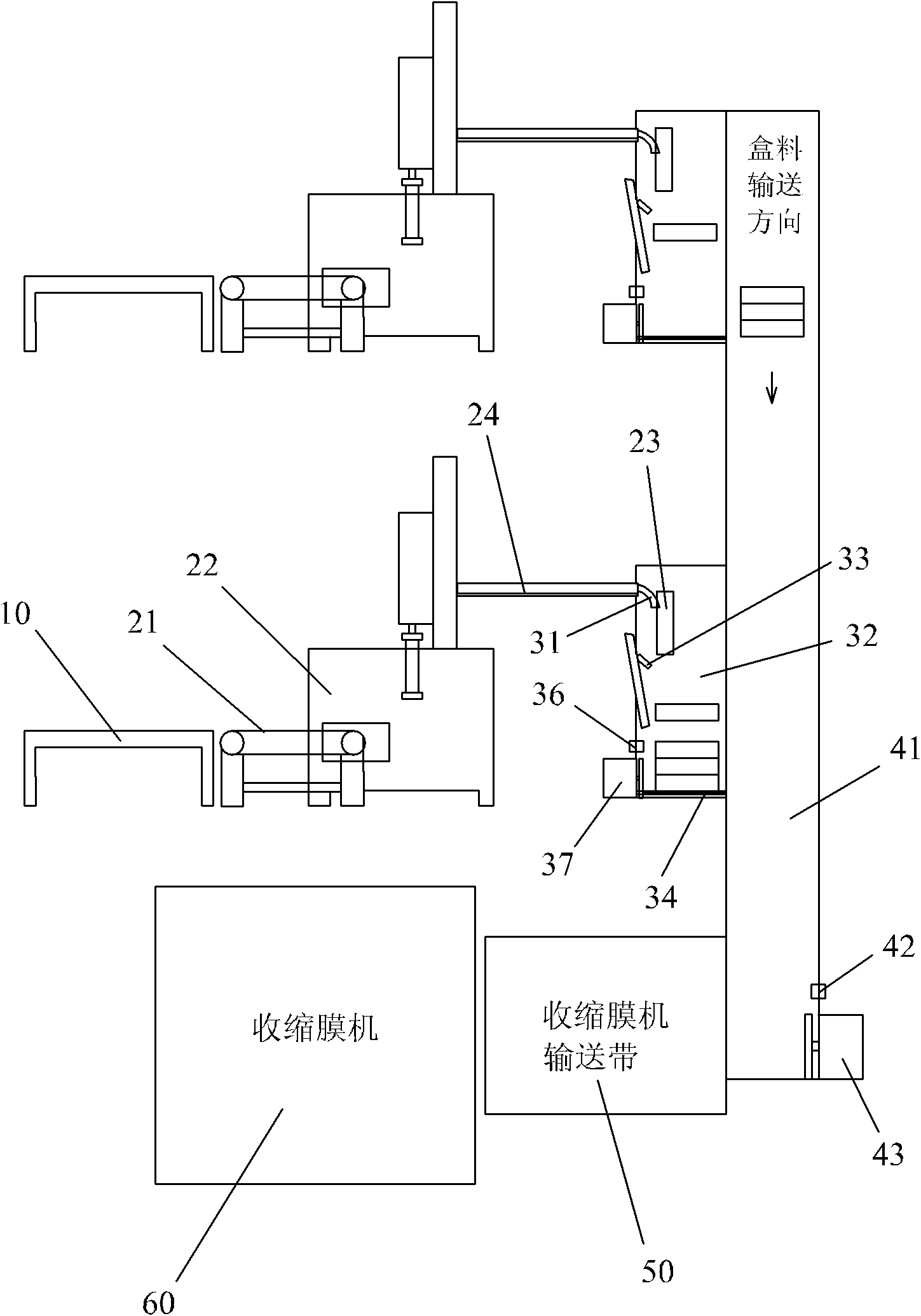

Automatic production line system of face tissue plant

InactiveCN102180286AReduce workloadFully automatedPackaging automatic controlProduction lineEngineering

The invention relates to an automatic production line system of a face tissue plant. The automatic production line system comprises a feeding belt, a box sealing machine connected with the feeding belt, and a first conveying belt, wherein the box sealing machine is used for sealing a certain amount of face tissue into a face tissue box; the first conveying belt is used for receiving face tissue boxes dropping off from a face tissue box conveying rail; a dropping off device which is convenient for the face tissue boxes to drop off along the conveying direction and not to be upside down is arranged at the end of the face tissue box conveying rail; and a reversing device is installed on the side surface of the first conveying belt and is used for changing the moving direction of the face tissue boxes on the first conveying belt. The automatic production line system introduces an automatic box loading technology and a face tissue box packaging technology, realizes the automatic connectionof processes of feeding the face tissue into boxes and packaging the face tissue box, meets the production requirement, and improves the production efficiency.

Owner:VINDA PAPER (CHINA) CO LTD

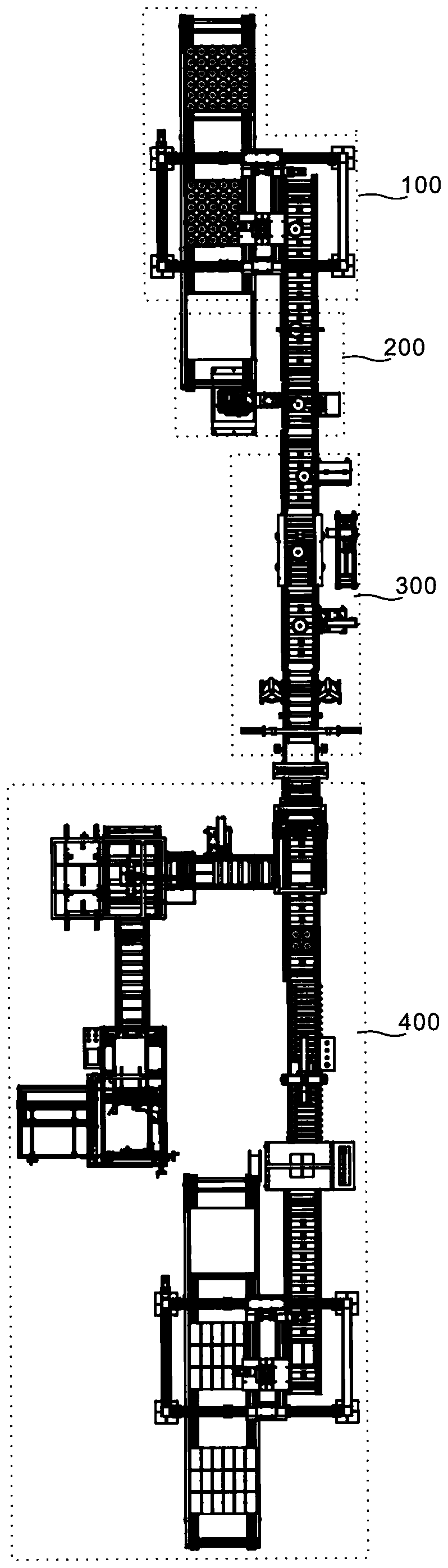

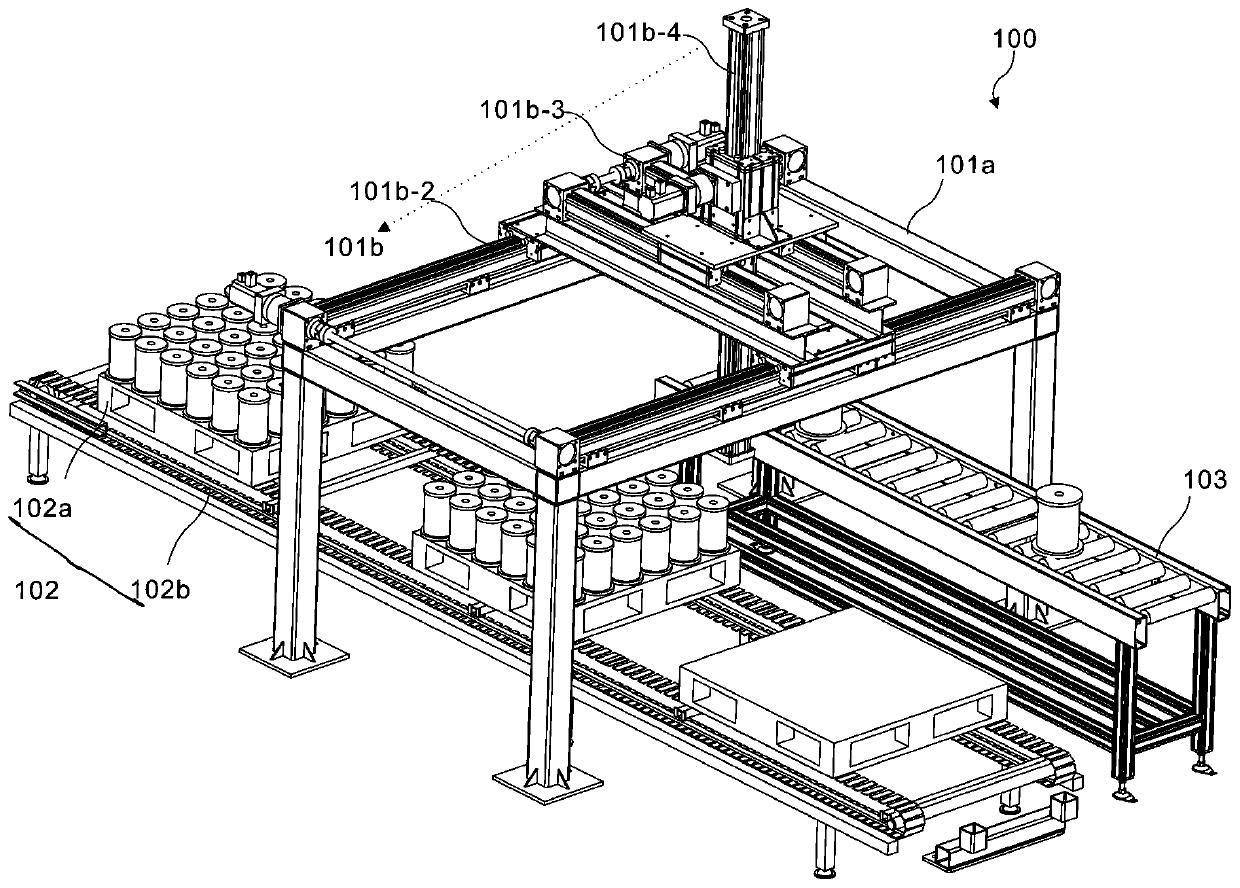

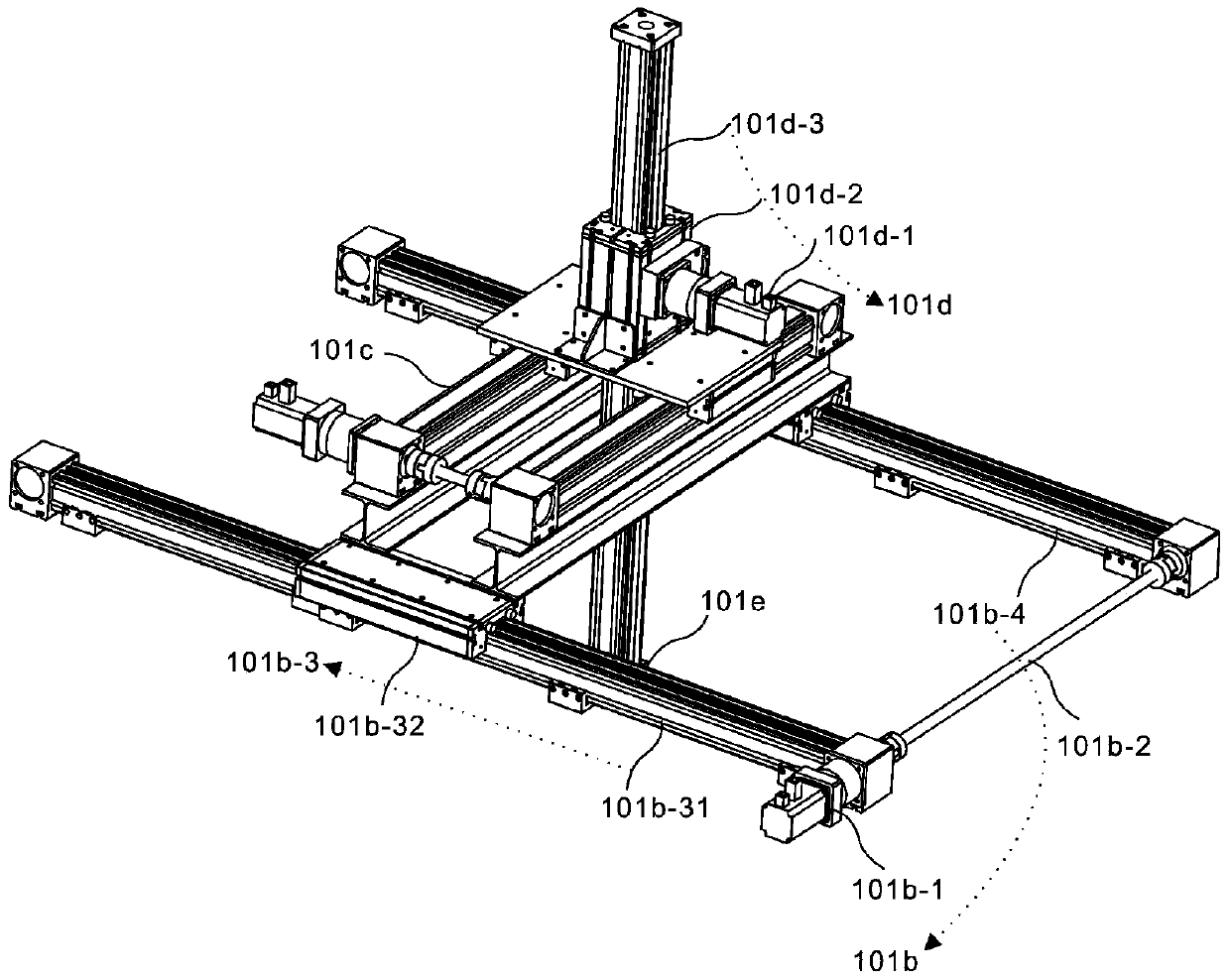

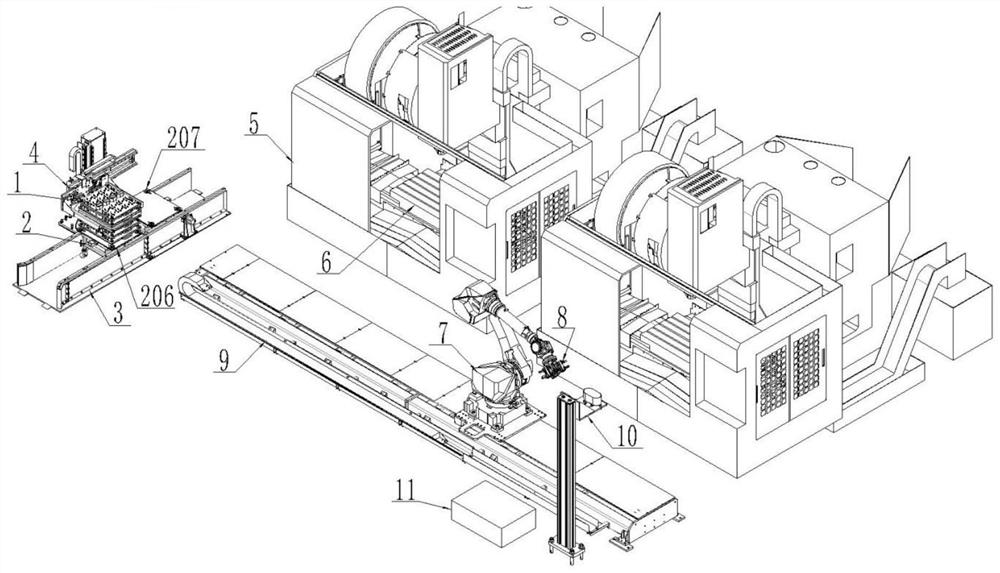

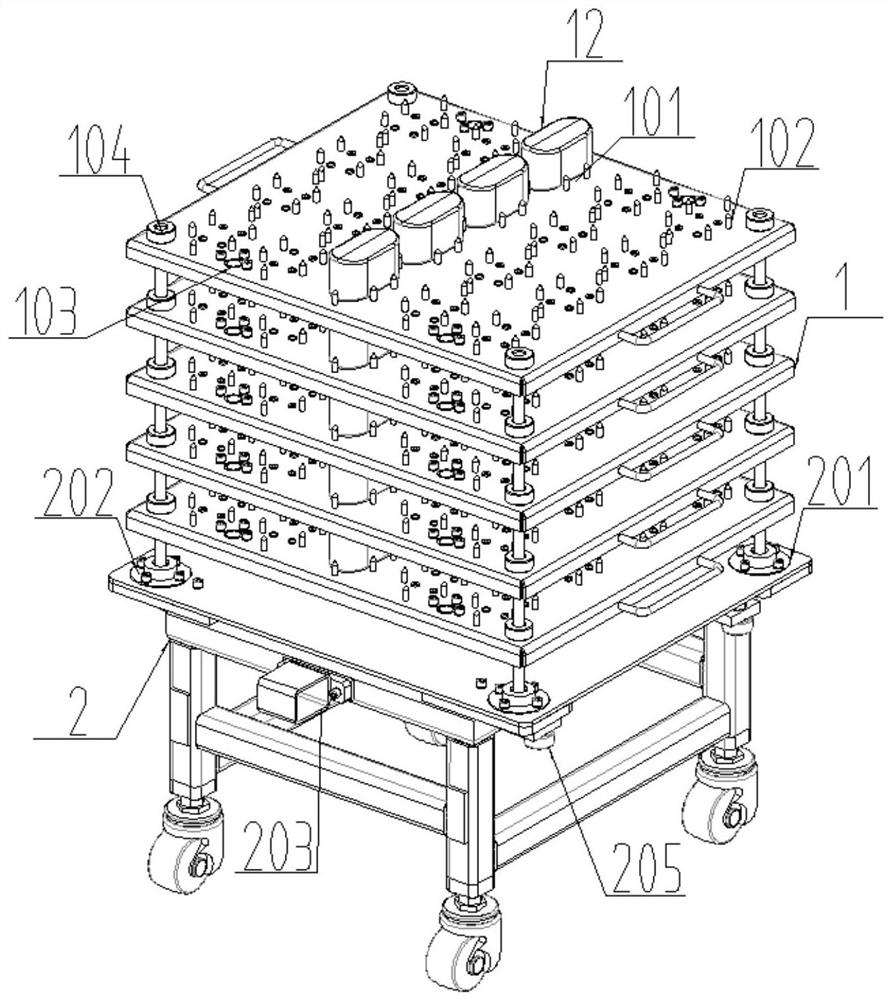

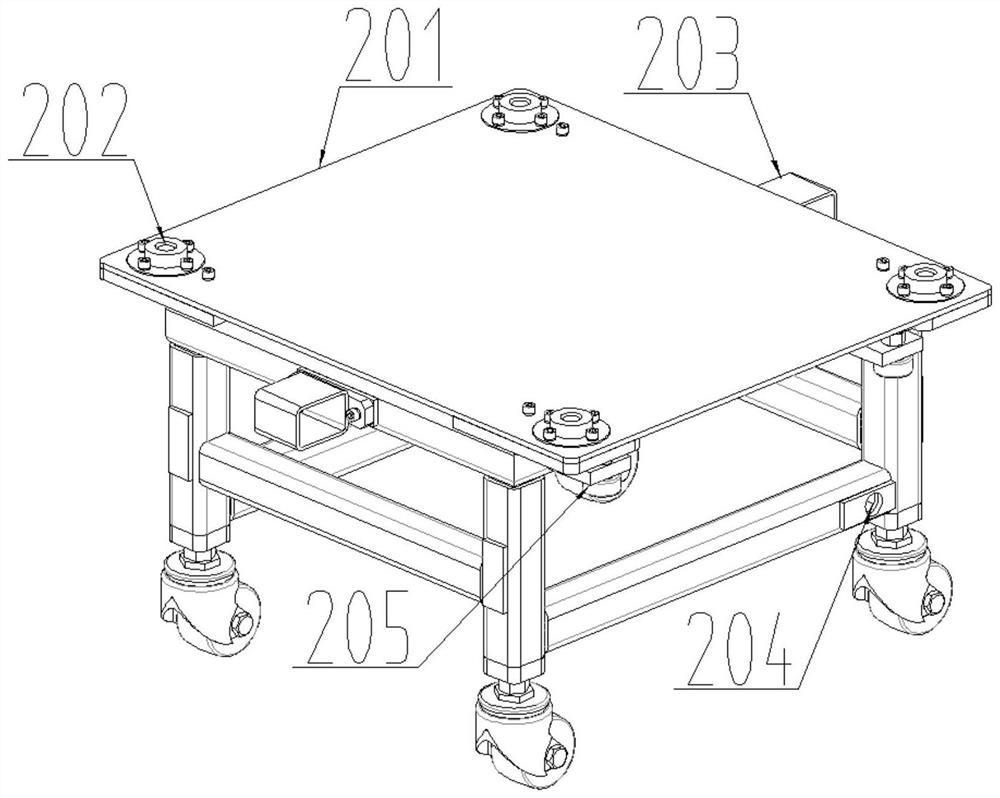

Automatic connecting ring production system and process

ActiveCN112278757AImprove efficiencyAvoid Positioning ErrorsStacking articlesDe-stacking articlesProcess engineeringManufacturing engineering

The invention discloses an automatic connecting ring production system and a process, and relates to the field of connecting ring production and manufacturing. The automatic connecting ring productionsystem is characterized in that the automatic production system is used for producing and manufacturing connecting rings, the automatic production system comprises a feeding and discharging system, amachining system and a transferring system, the feeding and discharging system is used for receiving and storing connecting ring blanks and storing and sending out machined connecting ring finished products, the machining system is used for carrying out machining on the blanks and semi-finished products of the connecting rings, and the transferring system is used for carrying out moving and transferring on workpieces between the feeding and discharging system and the machining system. According to the automatic connecting ring production system and the process, the three subsystems of the automatic production system cooperate with each other, so that the automatic production level is high; and in the automatic connecting ring production process using the system, an operator only needs tooperate feeding and discharging, and the productivity is liberated.

Owner:四川融至精密机械有限公司

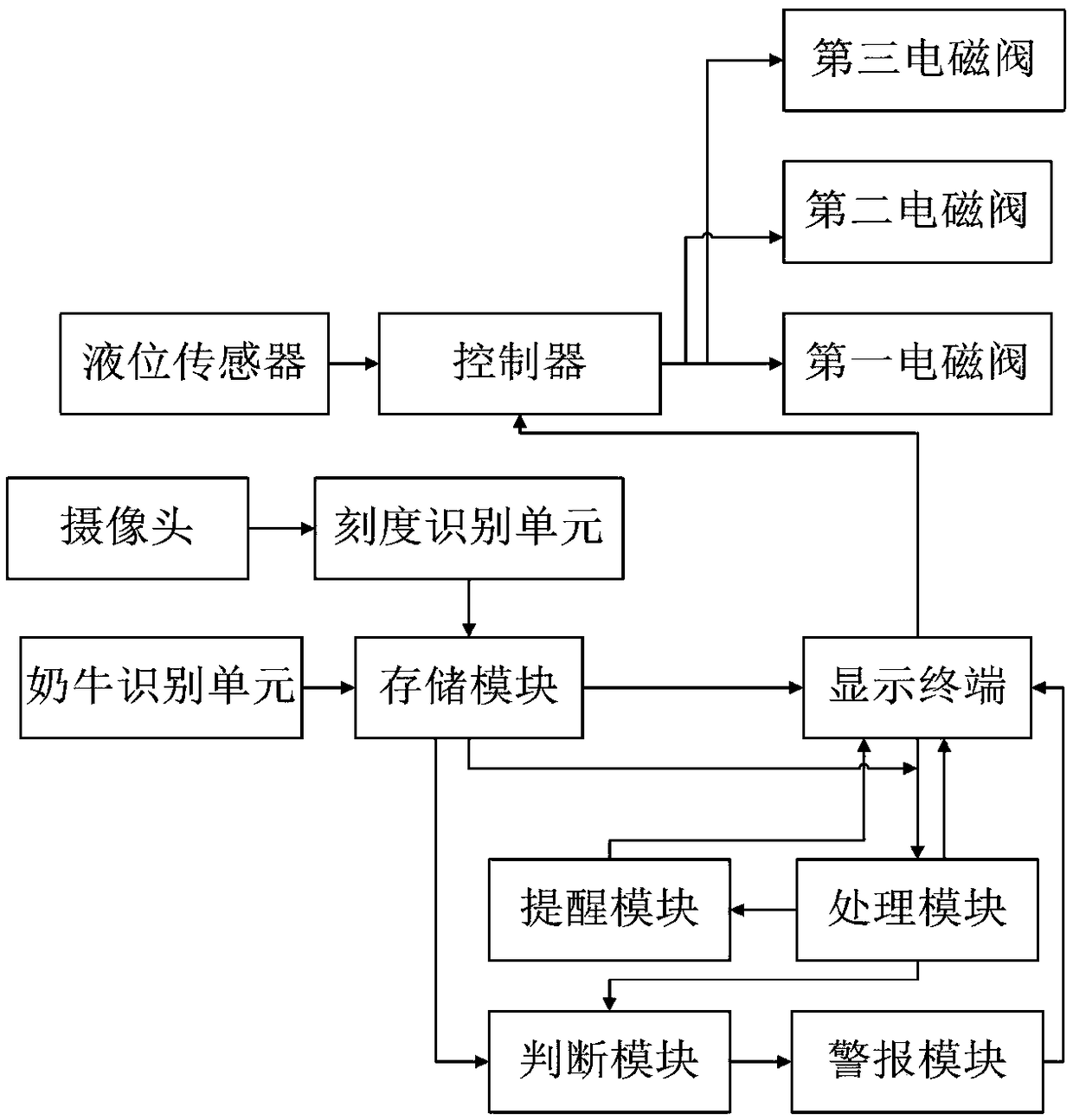

Automatic milk yield monitoring system for dairy cows based on image recognition

InactiveCN109258479ARealize automatic readingAchieve recordCo-operative working arrangementsAlarmsRelevant informationMonitoring system

The invention discloses an automatic milk yield monitoring system for dairy cows based on image recognition, which comprises a milking system, wherein the milking system comprises a milking machine, amilk bottle, a liquid level sensor and a controller; a monitoring platform, which comprises a display terminal for remote operation of a user and a milk cow information database internally arranged in the display terminal; the milk cow information database records the relevant information of each milk cow; a scale identification system, which is in communication connection with the monitoring platform and comprises a camera, a cow identification unit, a scale identification unit and a storage module. The automatic milk yield monitoring system for the dairy cows can accurately position the liquid level in the milk bottle and automatically identify and read scales, is easy to operate, saves labor force, and achieves automation of milk yield monitoring of the dairy cows.

Owner:GUIZHOU MINZU UNIV

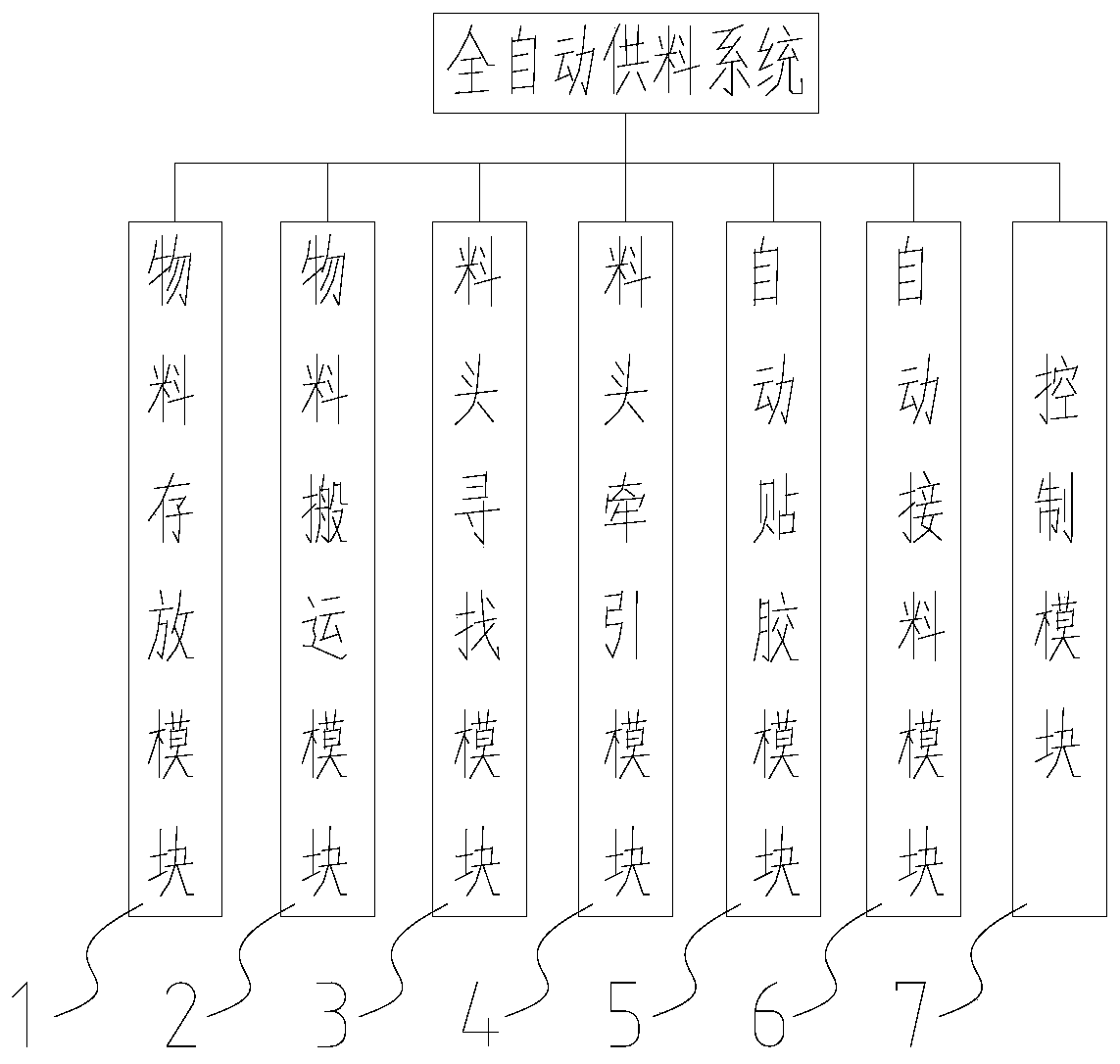

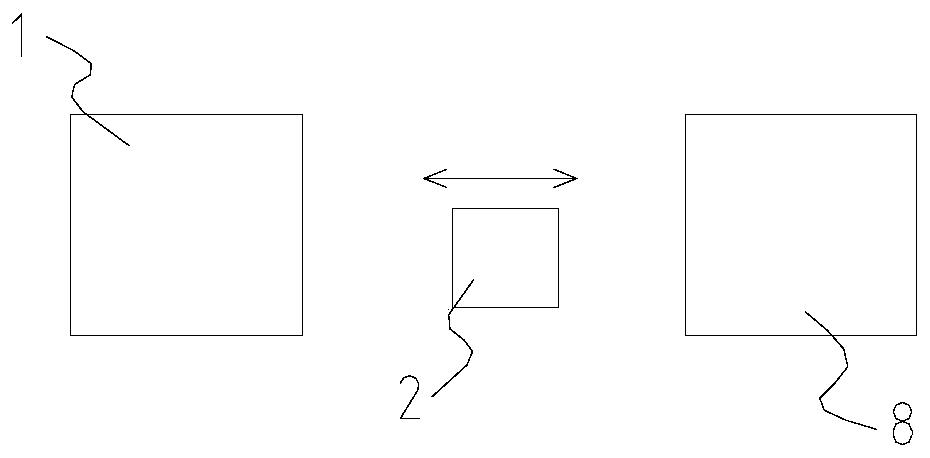

Fully-automatic supply method

ActiveCN110371739AReduce labor intensityAvoid Kind of MistakesArticle deliveryWebs handlingMaterial typeComputer module

The invention discloses a fully-automatic supply method. The fully-automatic supply method comprises the following steps ofa carrying step of carrying materials to a using station; a process of searching material heads on the surfaces of the materials after carrying the materials to the using station; a step of pulling the material heads to a rubberizing station to accomplish material head surfacerubberizing; and a step of pulling the material heads to an automatic material receiving module to accomplish material receiving. The fully-automatic supply method is extremely high in automatic andintelligent level, greatly increases production speed of equipment, greatly improves the automatic production level of the equipment, reduces labor intensity of a worker, can effectively avoid material type errors and material mounting errors in a loading process of rolled materials, and reduces an equipment failure shutdown rate caused by the material problem.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

Automatic feeding and discharging device and airtight detection device of infusion connector

The invention discloses an automatic feeding and discharging device and an airtight detection device of an infusion connector. Through the arrangement of a feeding device, a lead screw pair driving mechanism drives a vibrating disk to sequentially feed all inserting holes in the guiding direction of a transverse guide mechanism, the labor pressure of workers is relieved, and the production efficiency is improved; after feeding is finished, the airtight detection mechanism is used for automatically detecting the air tightness of the infusion connector, then the detection result is fed back to amaterial receiving air cylinder, if a defective product is found, a defective product recovery mechanism moves to the lower part of a detection station, a piston rod of the material receiving cylinder corresponding to the defective product is retracted, so that the defective product fall into a defective product recovery mechanism, then the defective product recovery mechanism is reset, finally,the piston rod of the material receiving air cylinder corresponding to the qualified product is retracted, so that the qualified product slides into a transfer box through a qualified product guide disc, the quality of the finished products can be automatically classified and recovered, errors caused by manual selection and classification are avoided, and the automatic production level is furtherimproved.

Owner:FOSHAN POLYTECHNIC

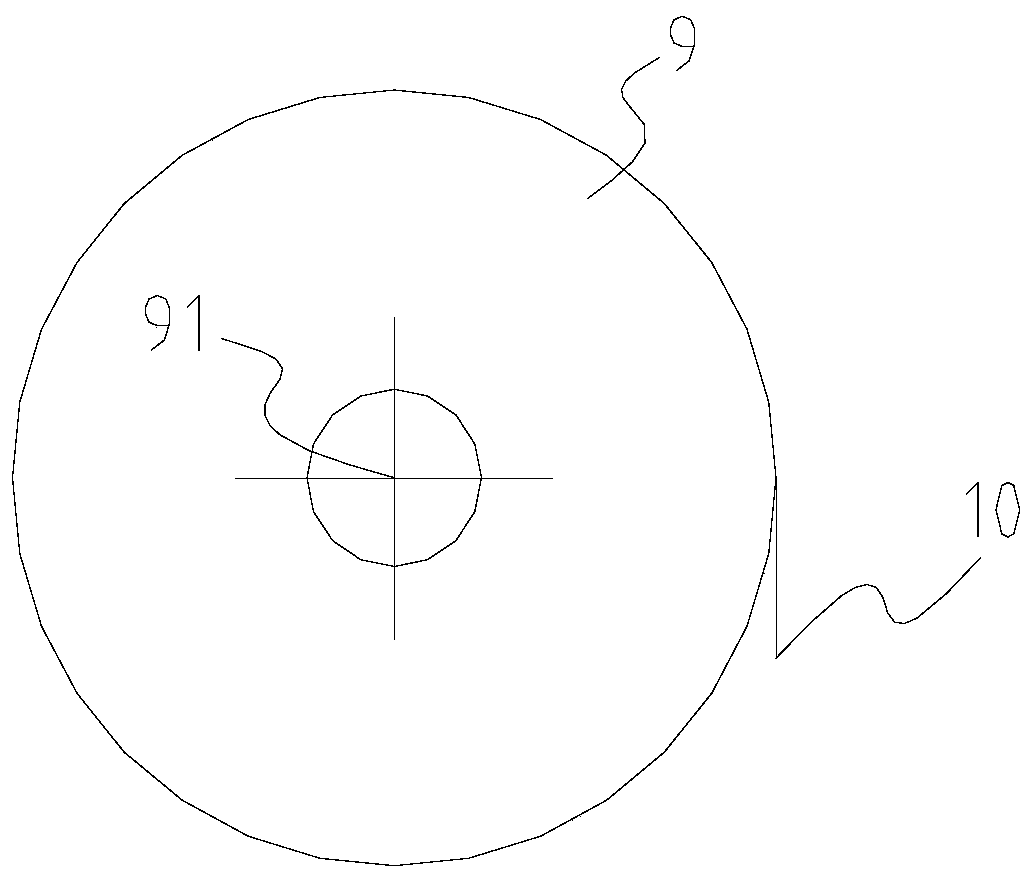

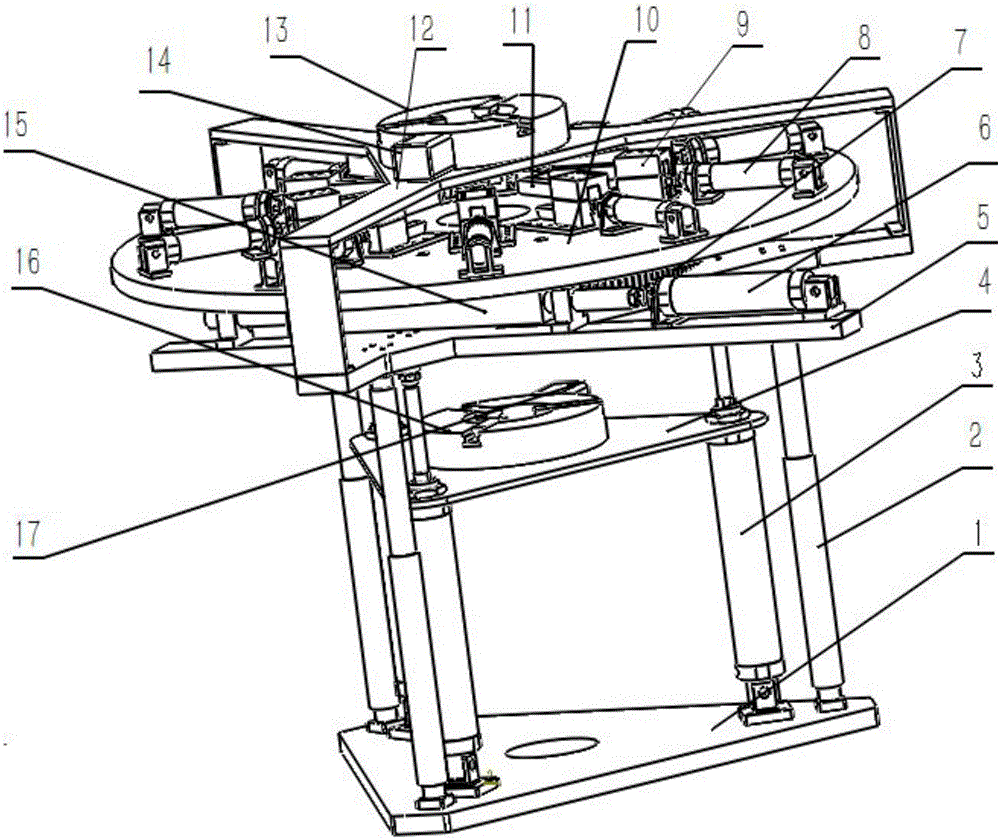

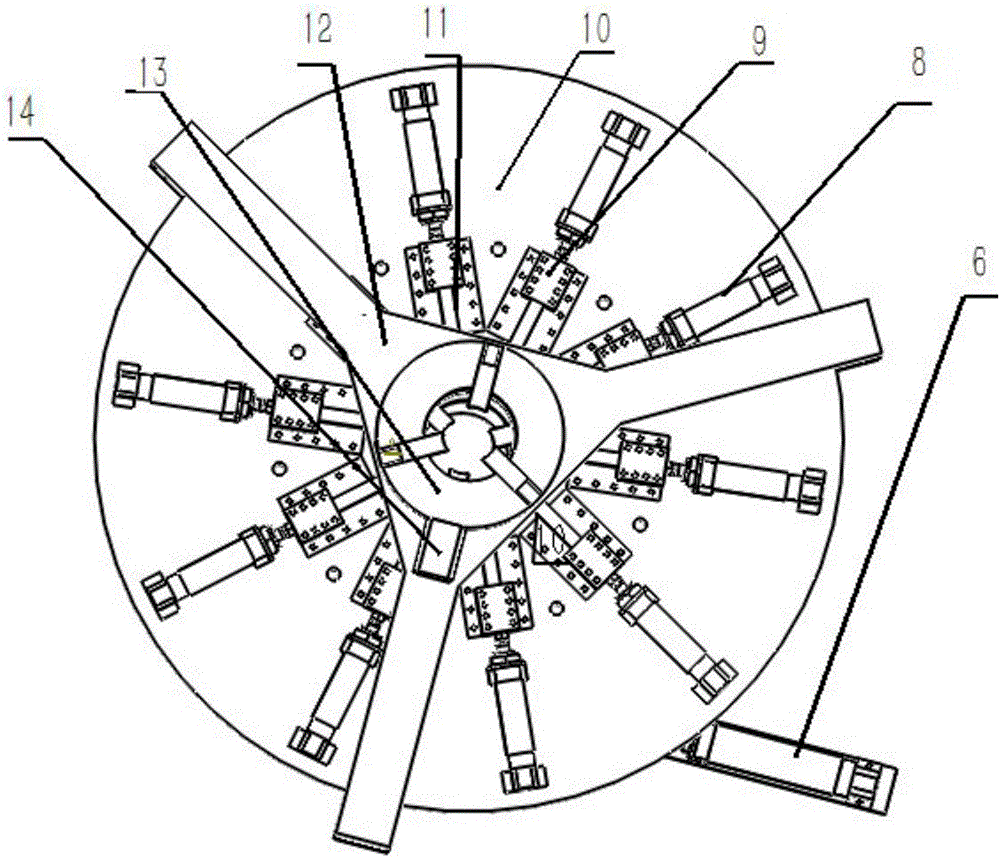

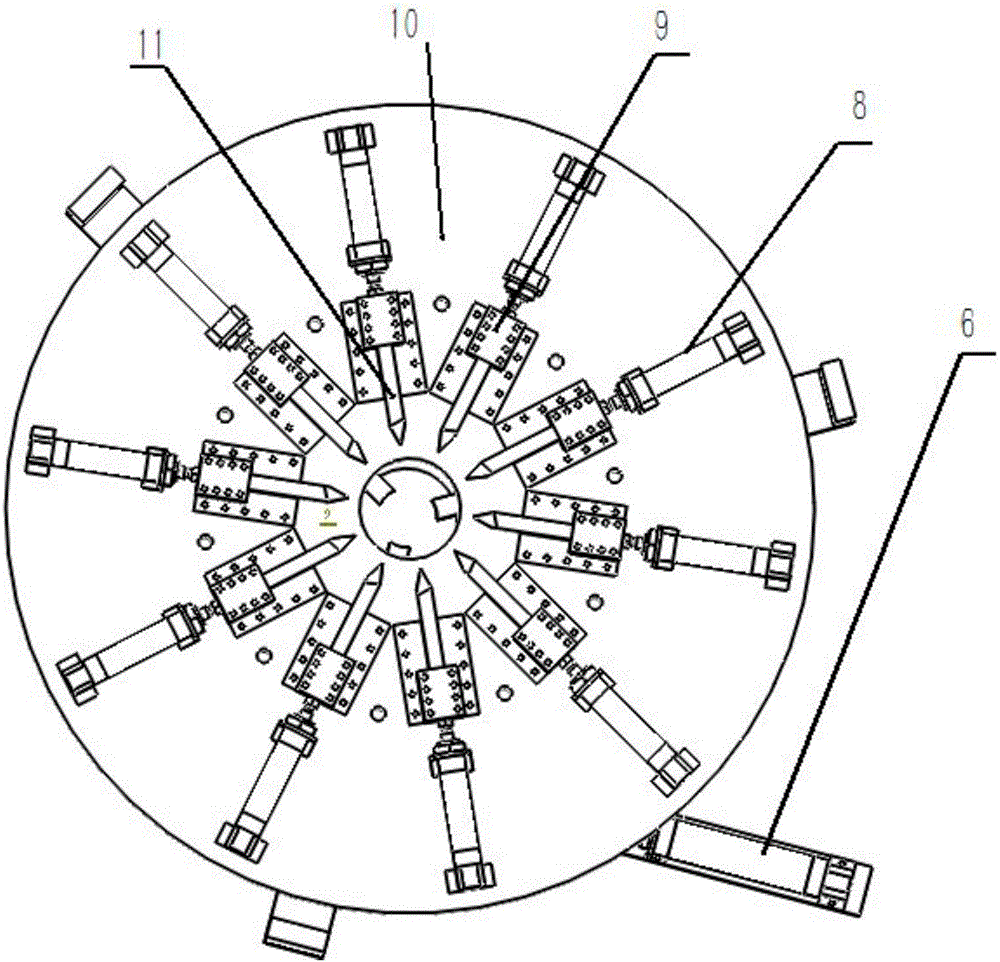

Automatic wire stripping machine

InactiveCN106486934AReduce manufacturing costImprove the level of automated productionApparatus for removing/armouring cablesDegrees of freedomMechanical engineering

An automatic wire stripping machine comprises a base, an upper platform, a turntable, a rotating platform, an upper clamping disc and a lower clamping disc, wherein the upper platform is arranged above the base; the lower clamping disc is arranged between the base and the upper platform; the rotating platform is arranged above the upper platform; the turntable is located between the rotating platform and the upper platform; the upper clamping disc is located above the rotating platform; and the center of the base is provided with a round hole. The wire stripping machine has two degrees of freedom, which are respectively a degree of freedom in a vertical direction and a degree of freedom in a rotation direction. Movement in the vertical direction is along the length direction of the wire, movement of the rotation direction is around the circumferential direction of the wire, the rotating platform can only perform repeated rotation movement in a certain angle range, whole-circumference cutting can be carried out on the sheath or the insulated layer of the wire under combined effects of multiple cutters, and under combined effects of the degree of freedom in the vertical direction and the degree of freedom in the rotation direction, the purpose of cutting off the sheath or the insulated layer can be achieved.

Owner:SHANGHAI DIANJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com