Cold extruding automatic production line

An automatic production line and cold extrusion technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high labor intensity, low degree of automation, and potential safety hazards in the operation of hydraulic presses, etc., so as to improve the level of automated production , Solve the effect of low manual production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

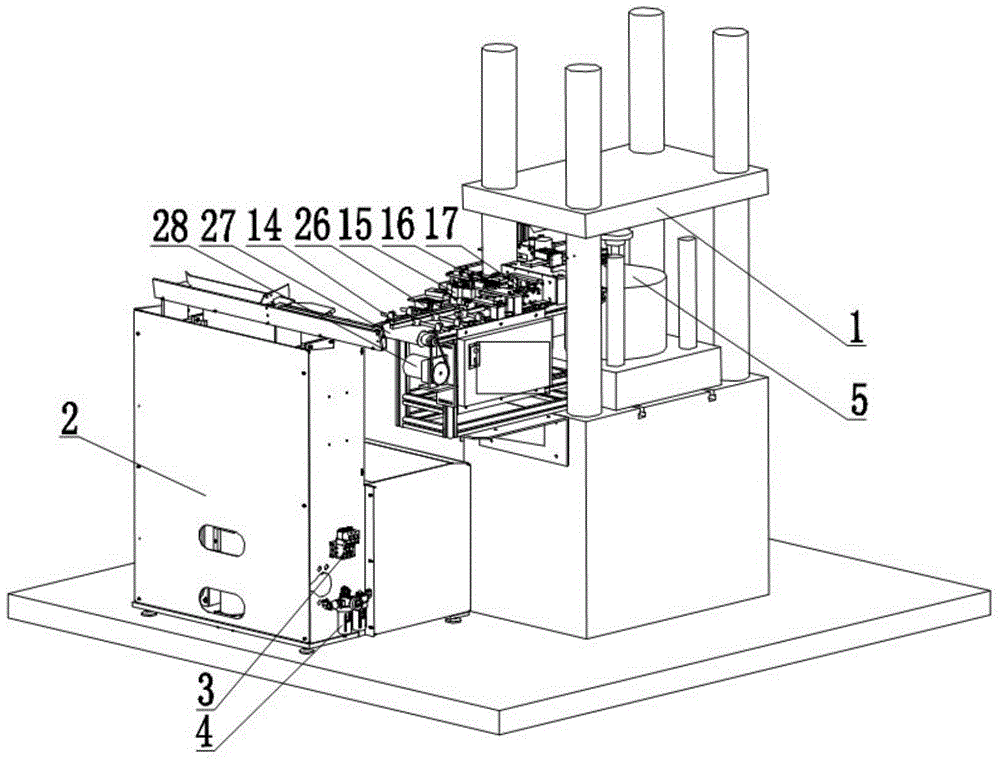

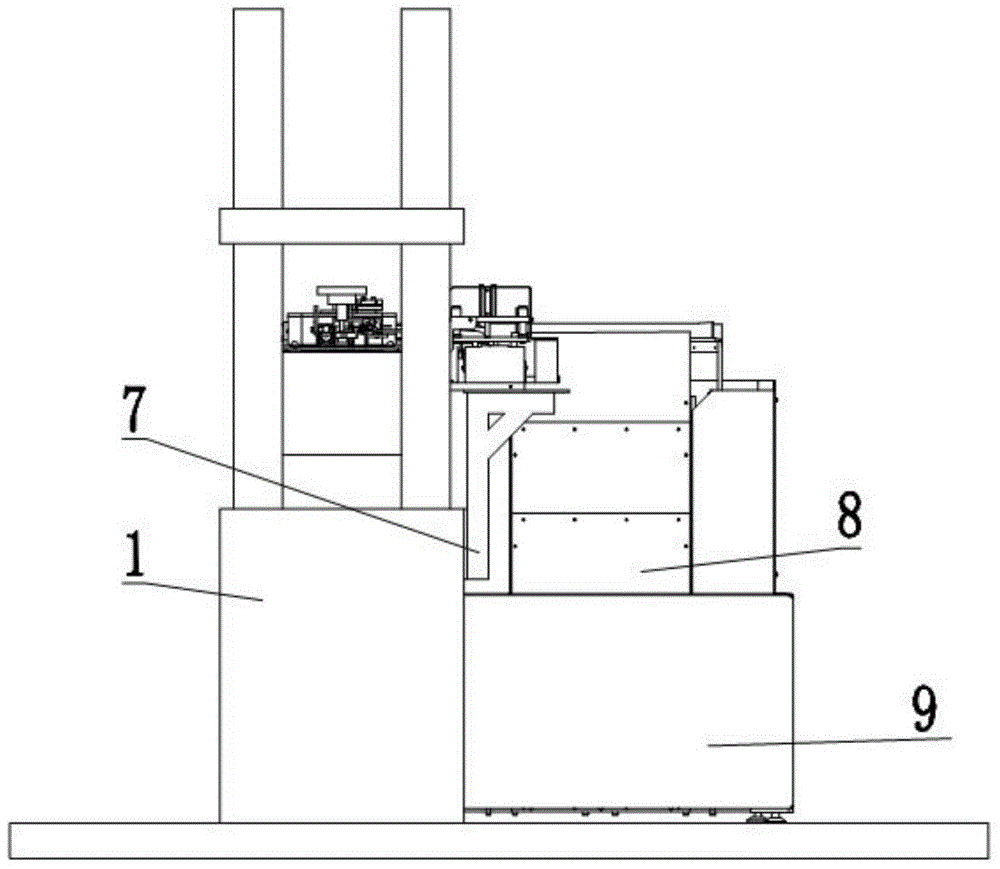

[0032] Automatic production line structure of the present invention is as Figure 1-4 shown.

[0033] The automatic production line of the present invention includes: a general frame, a general control device, a feeding device, a material feeding device, a loading and unloading manipulator device, and a hydraulic device; Disordered bars are sorted into upright bars with chamfers facing down one by one. When the bars reach the end of the feeding device, the photoelectric switch for material detection is triggered, and the information is transmitted to the loading and unloading manipulator. A mechanical claw of the loading and unloading manipulator completes the billet The other mechanical claw completes the grabbing and feeding of the workpiece, and triggers the hydraulic device to complete the stamping. The feeding device includes: a feeding machine 2, a solenoid valve 3, a pressure regulating valve 4, a feeding machine push plate 8, a feeding machine silo 9, and a bar guide ...

Embodiment 2

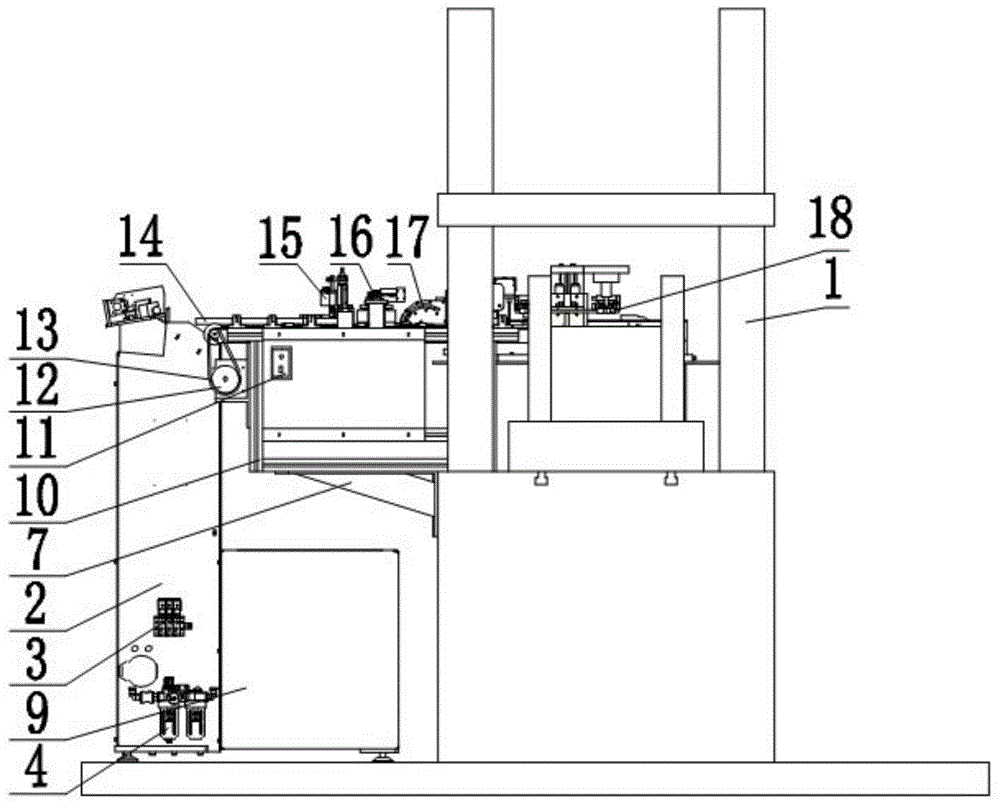

[0038] The three-dimensional structural diagram of the material feeding device of the automatic production line of the present invention is as follows: Figure 5 shown.

[0039] The material sorting and feeding device includes: a feeder frame, a conveying device, a chamfering detection device, a side pushing device 26, a rotating device, a turning device, a material distributing device, and a feeding device.

[0040] Wherein the transmission device includes: a conveyor belt 27, a motor 28, a guide bar 14, a switch / speed regulating panel 11, a gear 12, and a chain 13. The chamfering detection device comprises a magnetic switch, a chamfering detection mechanism 15, and a chamfering detection motion cylinder. The rotation device includes a rotation position detection photoelectric switch 24 , a rotation mechanism 16 , a rotation action cylinder, and a rotation guide baffle plate 25 . The overturning device comprises an overturning position discharging photoelectric switch 23, a...

Embodiment 3

[0043] The three-dimensional structural diagram of the loading and unloading manipulator device of the automatic production line of the present invention is as follows: Image 6 shown.

[0044] The loading and unloading manipulator device includes: a loading and unloading frame and an execution device; the loading and unloading frame includes a base plate 20 and a linear module 21; the execution device is controlled by a general control device; the execution device includes a moving device, First manipulator claw, second manipulator claw; Described mobile device comprises linear bearing 34, bearing fixed plate 35, wiring fixed plate 22, manipulator transverse connecting plate 40, manipulator longitudinal connecting plate 39; Described linear bearing connects mobile device with Linear module; the first manipulator claw and the second manipulator claw all contain a grabbing success detection mechanism 33; the first manipulator claw and the second manipulator claw are connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com