Pipe-cutting feeding device

A tube cutting and tube material technology, applied in the field of automatic feeding devices, can solve the problems of low degree of automation, low work efficiency, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following is a further detailed description of the pipe cutting automatic feeding device of the present invention through specific examples.

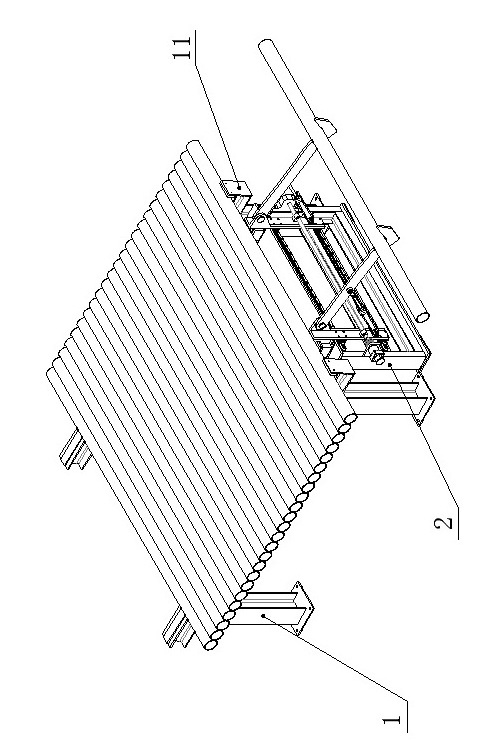

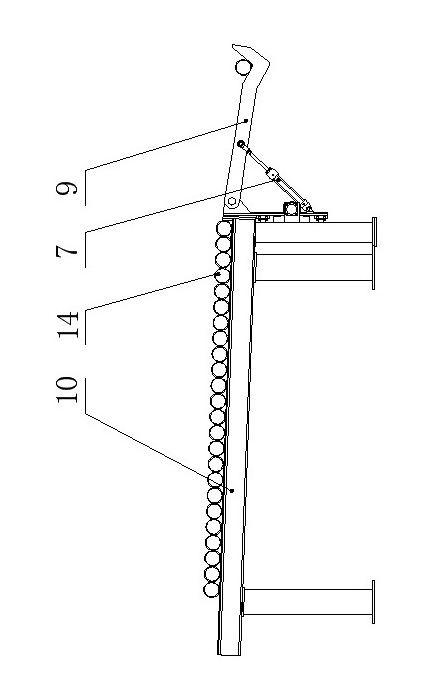

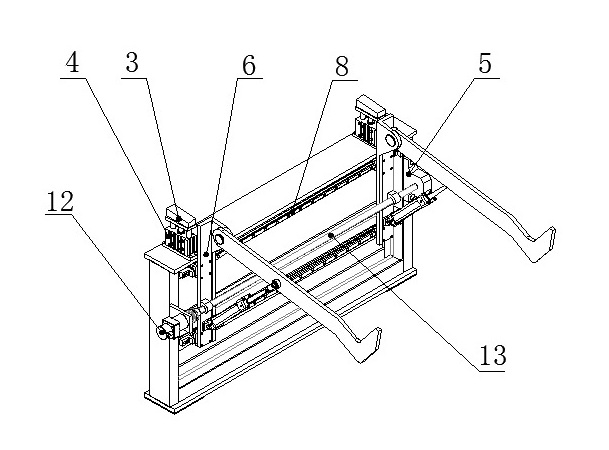

[0011] Such as Figure 1-Figure 2 As shown, the automatic pipe cutting and feeding device includes a pipe storage rack 1 and a feeding rack 2. The tube storage rack 1 is provided with a baffle 11 and an inclined raceway 10, and the feeding rack 2 is provided with two sets of pallets. 3. The supporting plate 3 is connected with the jacking cylinder 4. There are two sets of lifting raceway devices 5 on the side of the loading rack 2. The lifting raceway device 5 is connected with the raceway support 6. The motor 12, the screw rod 13, and the raceway One end of the support 6 is connected with the lifting arm 9, the other end is connected with the lifting cylinder 7, the middle part of the raceway support 6 is connected with the screw rod 13, and the loading frame is also provided with two groups of guide rails 8, and the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com