Production line supervision system

A technology for monitoring systems and production lines, applied to record carriers used by machines, instruments, and induction record carriers, etc. It can solve problems that affect production efficiency, low accuracy, and inability to track product information in real time, so as to improve productivity and work distance. Remote, automatic and fast information collection and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

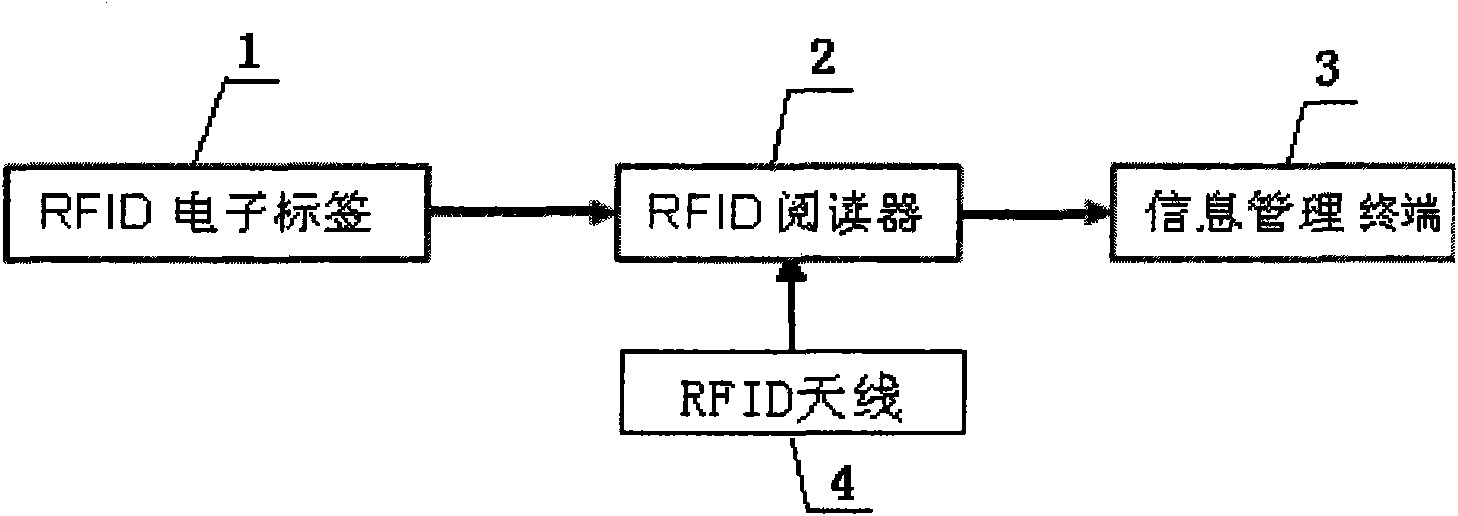

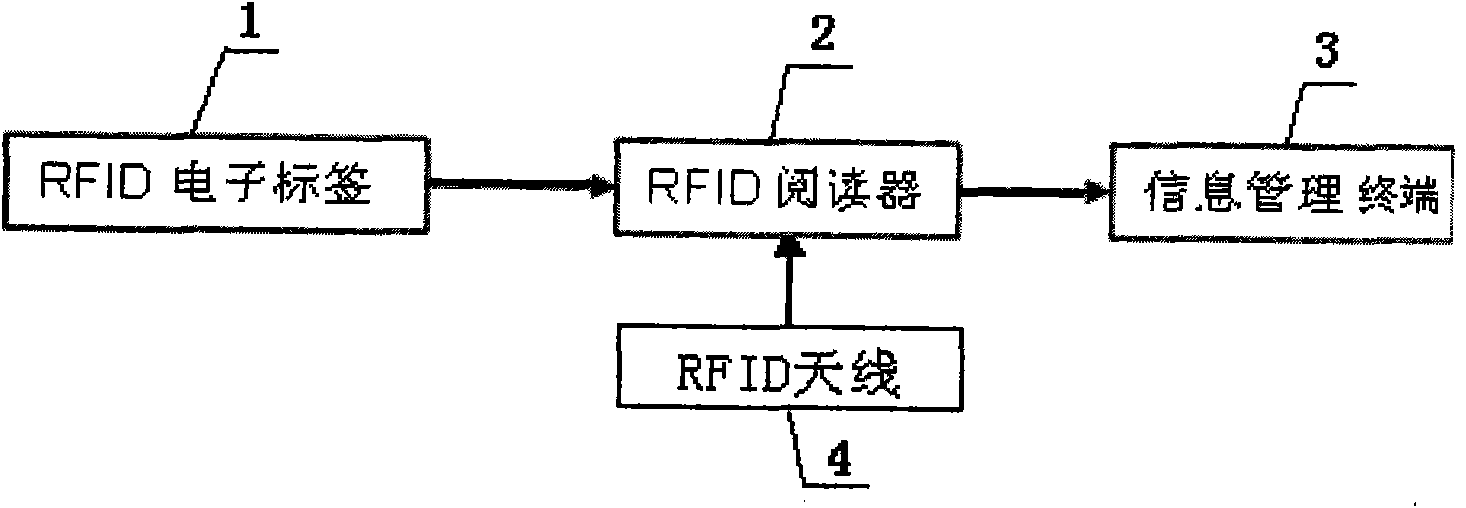

[0018] Such as figure 1 As shown, it is a structural block diagram of the production line supervision system according to the present invention. The supervision system mainly includes an RFID electronic tag 1, an RFID reader 2 and an information management terminal 3 arranged on a product or a pallet. The RFID reader 2 reads electronic After the signal on the tag 1 is transmitted to the information management terminal 3, the RFID reader 2 is a fixed reader installed at the node of the production line. When a product on the production line passes through a node, the fixed reader reads the information corresponding to the RFID electronic tag on the product, and transmits it to the information management terminal 3 in time for information management.

[0019] The RFID supervision system also includes an RFID antenna 4, which is connected to the RFID reader 2, and at least one RFID antenna is installed at each production line node to improve communication stability. In this way, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com