Liquid plastic bottle leak detector for production line and detecting method thereof

A technology for packaging liquids and plastic bottles. It is used in fluid tightness testing, machine/structural component testing, measuring devices, etc. to improve work efficiency, improve the level of production automation, and achieve the effect of uniform and relative strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

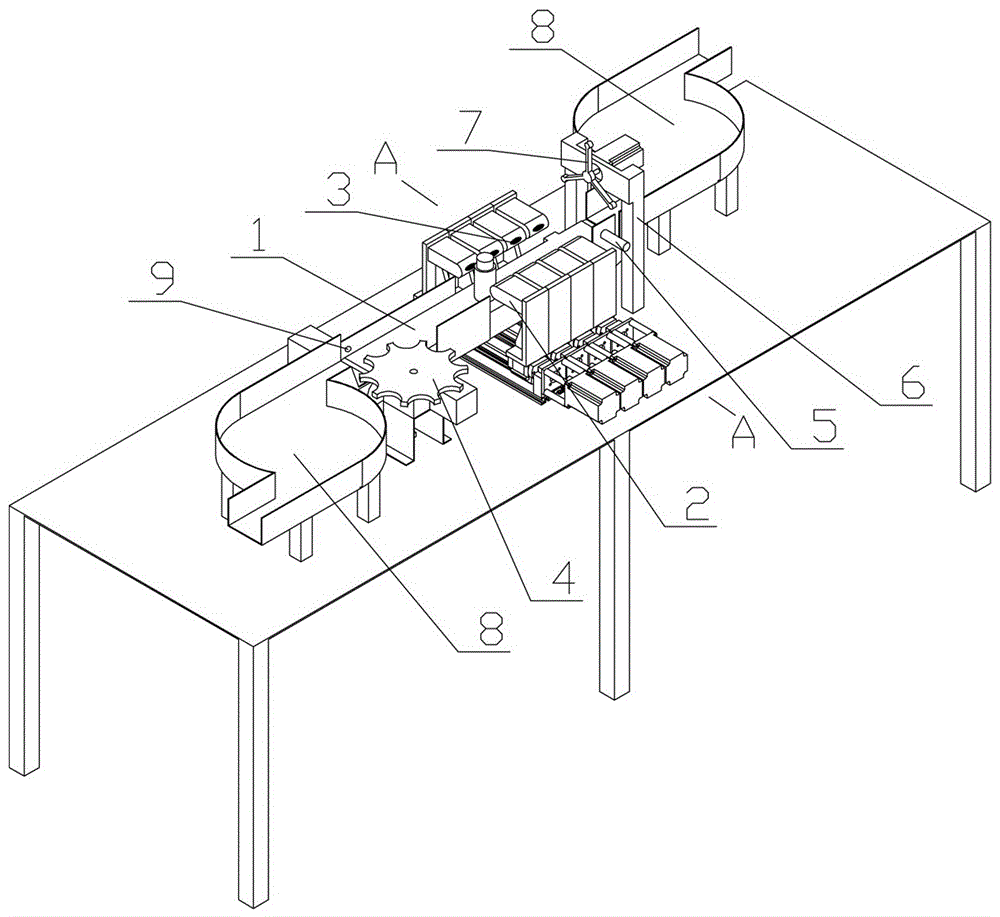

[0027] Such as figure 1 As shown in the figure, a leak detection machine for packaging liquid plastic bottles in a production line has a number of manipulators arranged side by side on both sides of the conveyor belt 1 in the traveling direction. The manipulators are connected to the transmission device. 2 structure, a pressure sensor 3 is provided on one of the chucks 2 of each manipulator; the pressure sensor 3 is connected to the external PLC control cabinet; a distributor 4 is provided at the entrance of the conveyor belt 1, and the distribution enters the conveyor belt 1 The bottle spacing, the distributor 4 is a disc structure with evenly distributed opening slots around the circumference, by setting the structure of the opening slots, it can realize the equidistant distribution of plastic bottles of different shapes; at the entrance of the conveyor belt 1 there is a Start detection sensor 9.

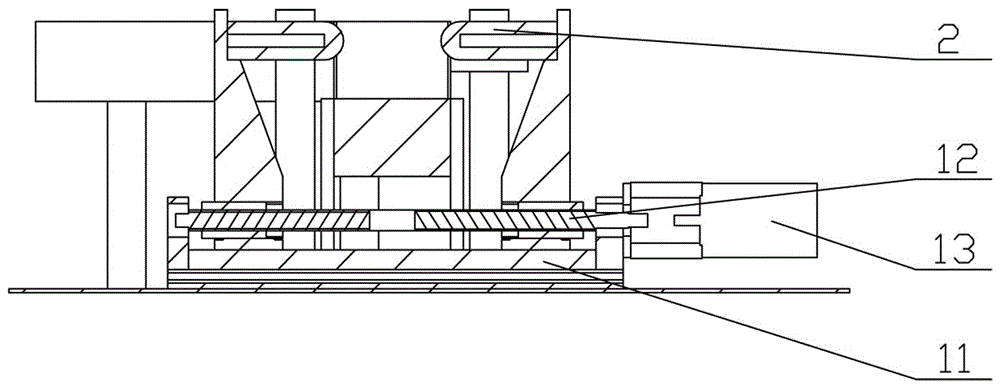

[0028] A photoelectric sensor 5 is provided at the exit of the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com