Automatic production line system of face tissue plant

An automatic production line and face towel technology, applied in packaging automatic control, packaging, packaging protection, etc., can solve the problems of increasing production time and the number of packaging employees, reducing production efficiency, etc., to improve the level of production automation, reduce workload, The effect of increasing income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

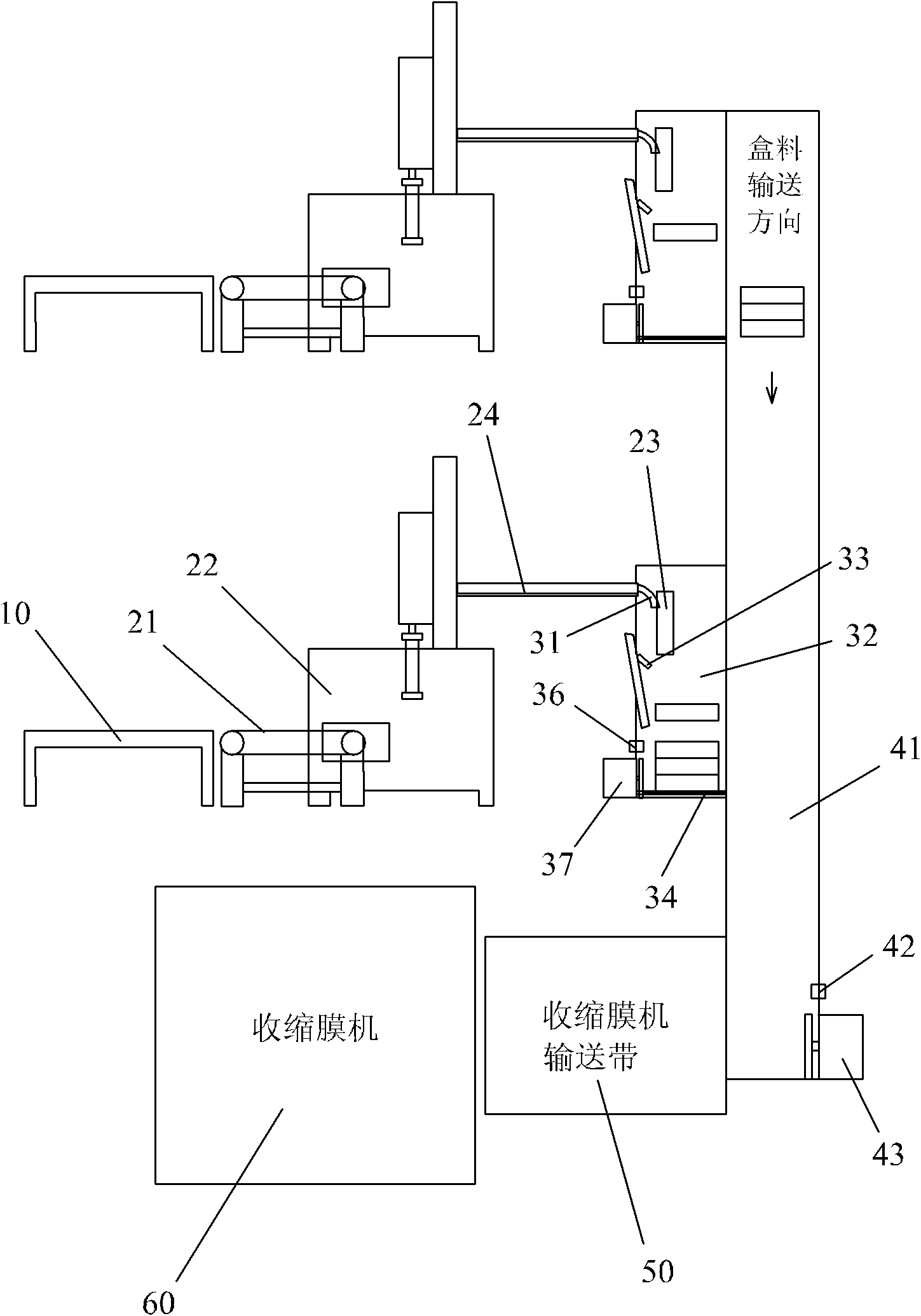

[0023] see figure 1 As shown, after the facial tissue machine produces facial tissue, the workman puts the facial tissue on the workbench 10 on the feeding belt 21, and the feeding belt 21 and the box sealing machine 22 are linked together, and the facial tissue has completed the box sealing process in the sealing machine 22 (facial tissue into the box, the facial tissue box 23 is glued to seal the box), and the facial tissue box 23 drops onto the first conveyer belt 31 one by one by the facial tissue box conveying track 24 (in the process of falling, due to its own weight and impact, it will Produce position change, face towel box 23 can not be neatly arranged according to the requirement of production), have added drop device and reversing device in this process.

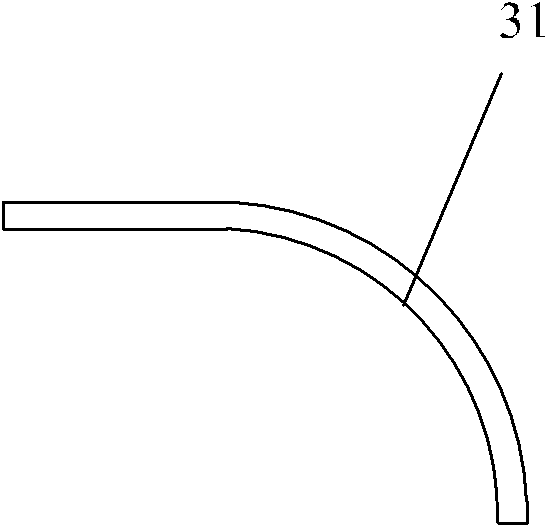

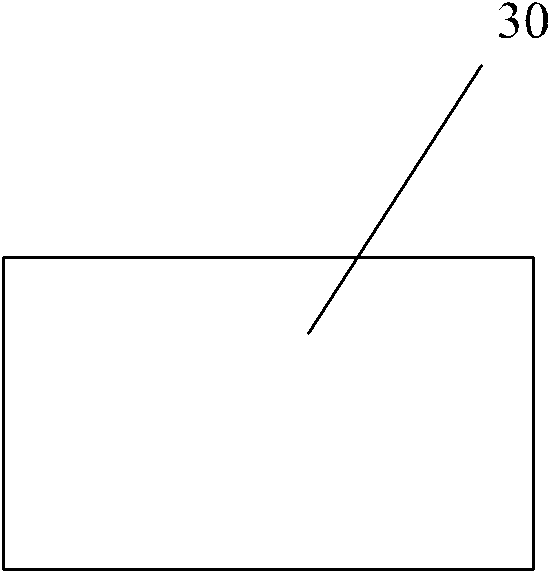

[0024] like Figure 2A and Figure 2B As shown, the above-mentioned dropping device is a drop guide 30, which is installed at the end of the facial tissue box conveying track 25, and the drop guide 30 is a curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com