Automatic feeding mechanism for slitting of internal combustion engine air cylinder sleeve

An internal combustion engine cylinder, automatic feeding technology, applied in metal processing and other directions, can solve the problems of increasing labor costs, reducing production efficiency, affecting production continuity, etc., and achieving the effect of reducing labor intensity, improving production efficiency, and improving the level of automated production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

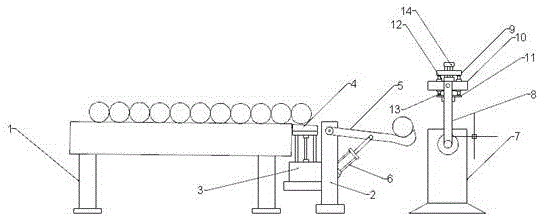

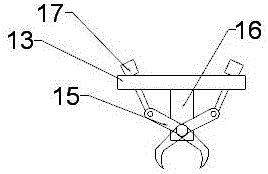

[0018] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0019] An automatic feeding mechanism for slitting processing of cylinder liners of internal combustion engines, the composition of which comprises:

[0020] A material storage unit for stacking cylinder liner headers to be cut and processed, the material storage unit includes a material storage rack 1, the height of the top end surface of the material storage rack 1 gradually decreases along the feeding direction, and placed on it Due to the effect of gravity, the cylinder liner header has a tendency to slide downwards. Considering its frictional resistance, vibrators or rollers can be installed on the top surface selectively.

[0021] The cylinder liner manifolds on the storage rack 1 are sequentially arranged along the feeding dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com