Process for reducing collophanite flotation tailing grade

A technology for flotation of tailings and colloidal phosphate rock, applied in flotation, solid separation, grain treatment, etc., to achieve the effect of improving the recovery rate of concentrate, reducing consumption, and widening the value of industrial promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The ore type is high-magnesium collophosite, numbered 1 # , the chemical element analysis results are shown in Table 1:

[0044] Table 1 1 # Ore chemical element analysis table

[0045]

[0046] Original process treatment 1 # High Magnesium Collin Phosphate

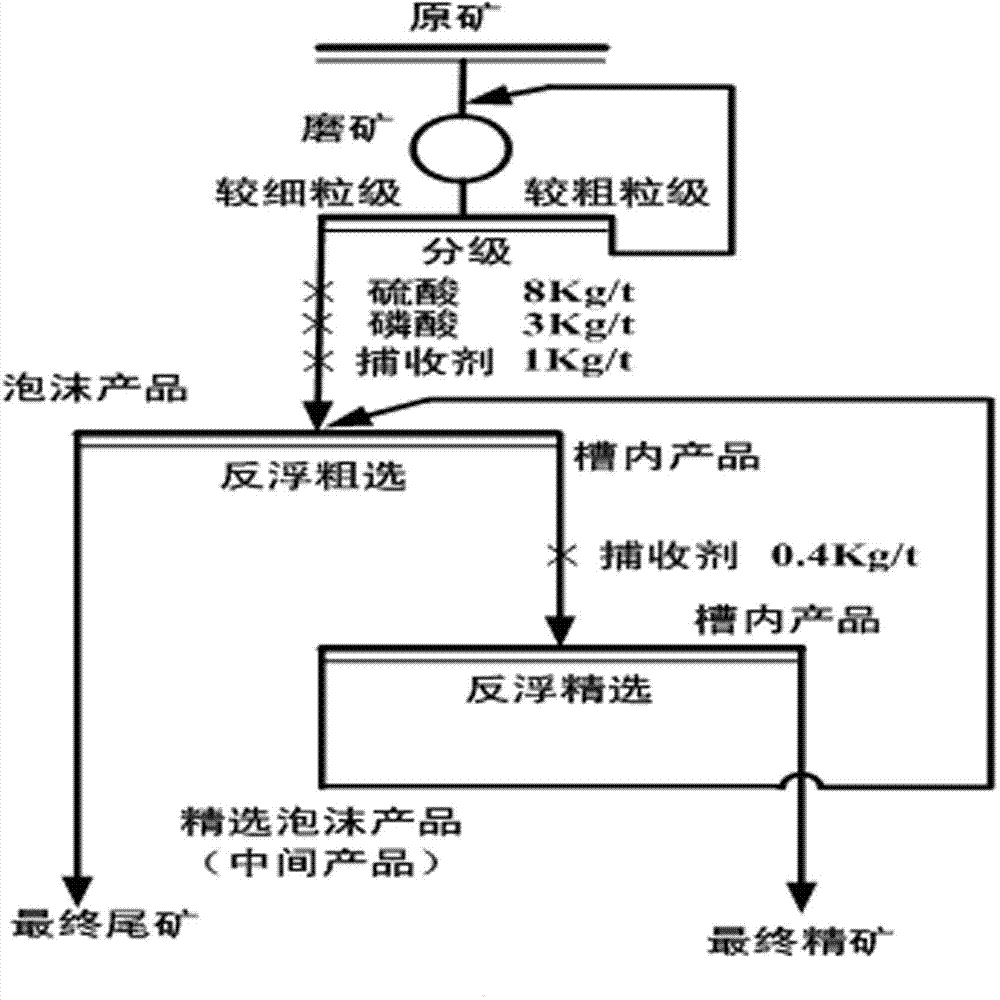

[0047] See the process flow figure 1 , using a single reverse flotation process. First, the high-magnesium collephinite is ground, and the ground products enter the hydrocyclone for classification; the coarser-grained products obtained by the classification operation are returned to the mill for grinding, and the finer-grained products The concentration is -0.074mm and the content accounts for 90.00%; then reverse flotation roughing is carried out, the roughing foam product is used as the final tailings, the product in the roughing tank is reverse flotation and selected, and the selected foam product is returned to the roughing process as an intermediate product to form Closed loop operation, the product in...

Embodiment 2

[0061] The ore type is high-magnesium collophosite, numbered 2 # , the chemical element analysis results are shown in Table 4:

[0062] Table 4 2 # Ore chemical element analysis table

[0063]

[0064] Original process treatment 2 # High Magnesium Collin Phosphate

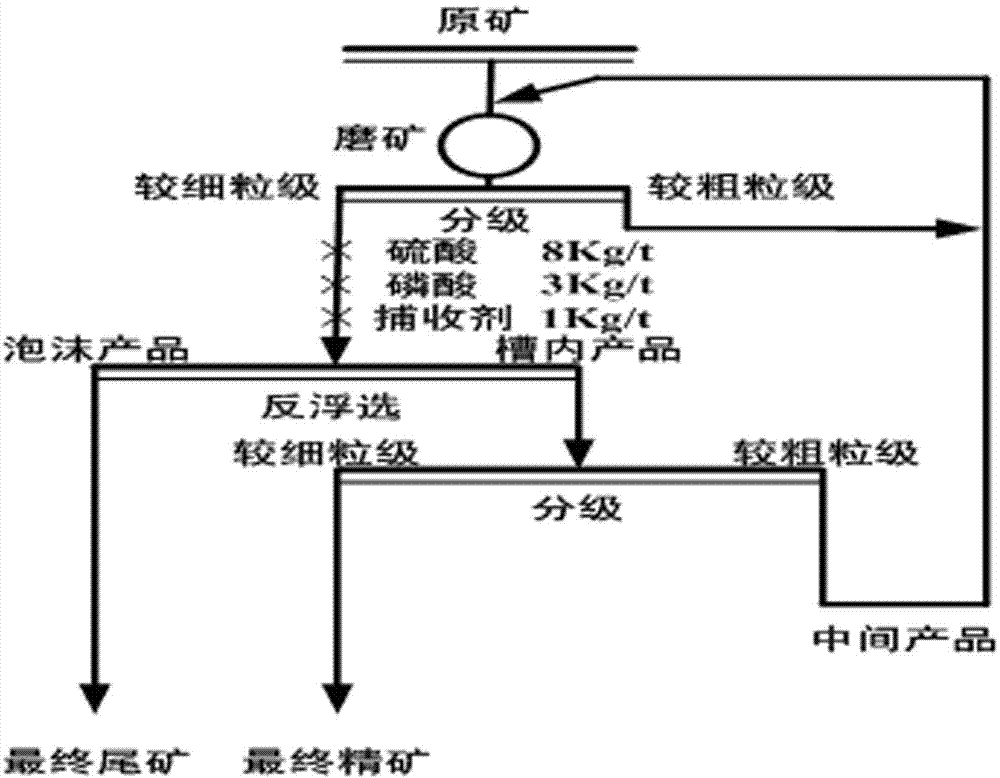

[0065] See the process flow Figure 5 , using a single reverse flotation process to grind the high-magnesium collophosite, and the ground products enter the hydrocyclone for classification; the coarser-grained products obtained by the classification operation are returned to the mill for regrinding, and the finer-grained products have fineness The content of -0.074mm accounts for 92.45%. Fine-grained products are subjected to reverse flotation roughing; roughing foam products are used as final tailings, products in the roughing tank are reverse-floated and selected, and selected foam products are returned to roughing as intermediate products. The selection process forms a closed loop operation, and the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com