Automatic detection system and detection method for volatile organic compound

An organic compound and automatic detection technology, applied in the detection field, can solve problems affecting the accuracy of measurement results, loss of production capacity, and hysteresis of manual measurement, so as to reduce storage downtime, ensure normal production, and improve measurement coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

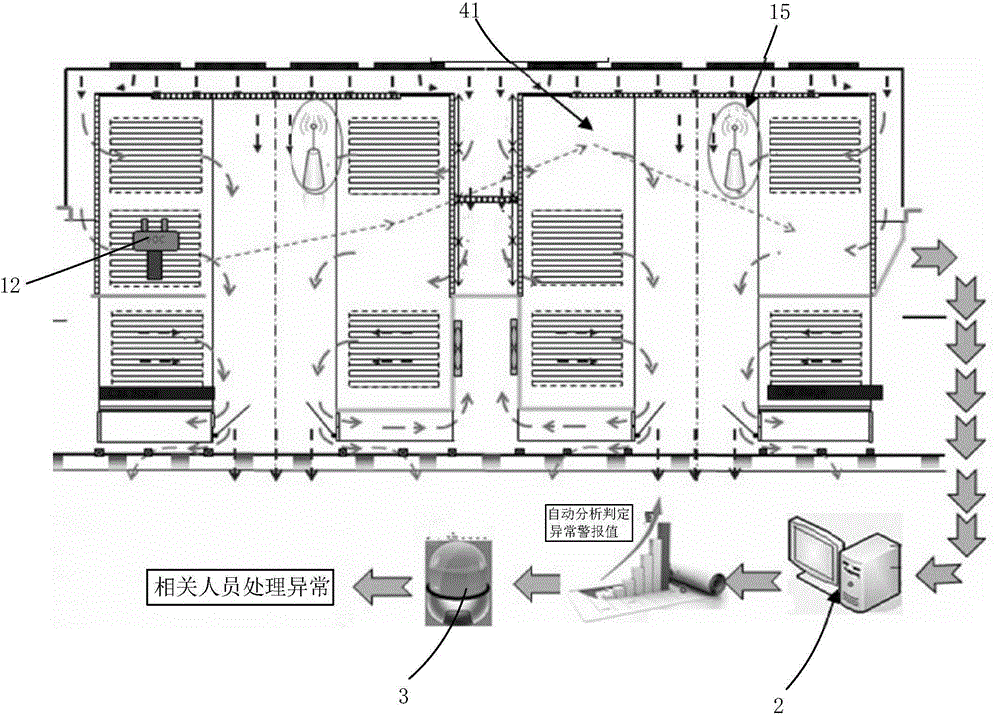

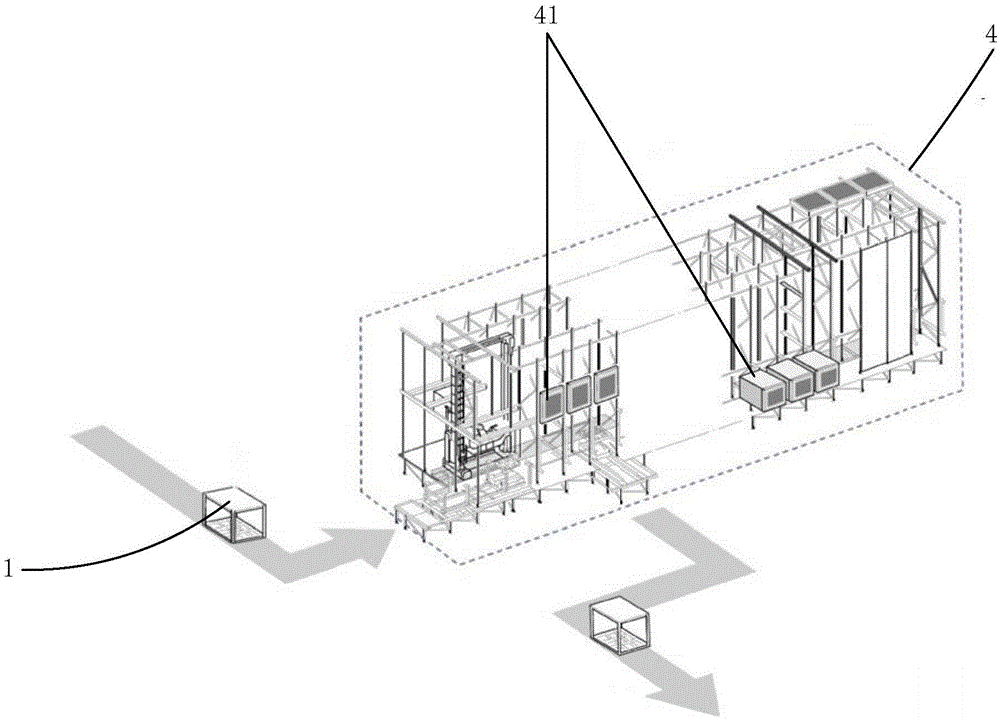

[0042] see Figure 1 to Figure 3 , the present invention firstly provides an automatic detection system for volatile organic compounds, including an automatic material handling system, a detection unit 1 , a server 2 , and a feedback unit 3 .

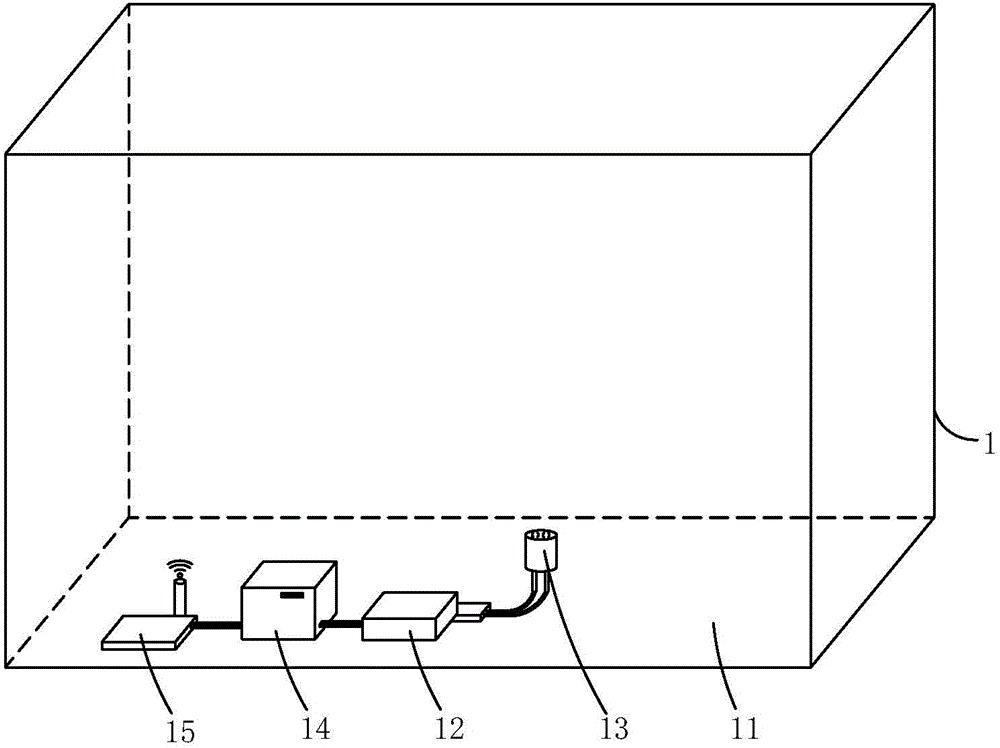

[0043] like figure 1 As shown, the detection unit 1 includes a carrier 11, a measurement module 12 disposed inside the carrier 11, a sampling module 13 connected to the measurement module 12, and a power supply module 14 electrically connected to the measurement module 12. , and a communication module 15 electrically connected to the power supply module 14 , the carrier 11 is set in an open manner so that the sampling module 13 can obtain samples of the area to be tested.

[0044] like figure 2As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com