Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Computer-integrated manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control entire production process. This integration allows individual processes to exchange information with each other and initiate actions. Although manufacturing can be faster and less error-prone by the integration of computers, the main advantage is the ability to create automated manufacturing processes. Typically CIM relies of closed-loop control processes, based on real-time input from sensors. It is also known as flexible design and manufacturing.

Computer integrated manufacturing techniques

InactiveUS7069101B1Process Control OptimizationQuality improvementData processing applicationsSemiconductor/solid-state device manufacturingConsequence analysisManufacturing technology

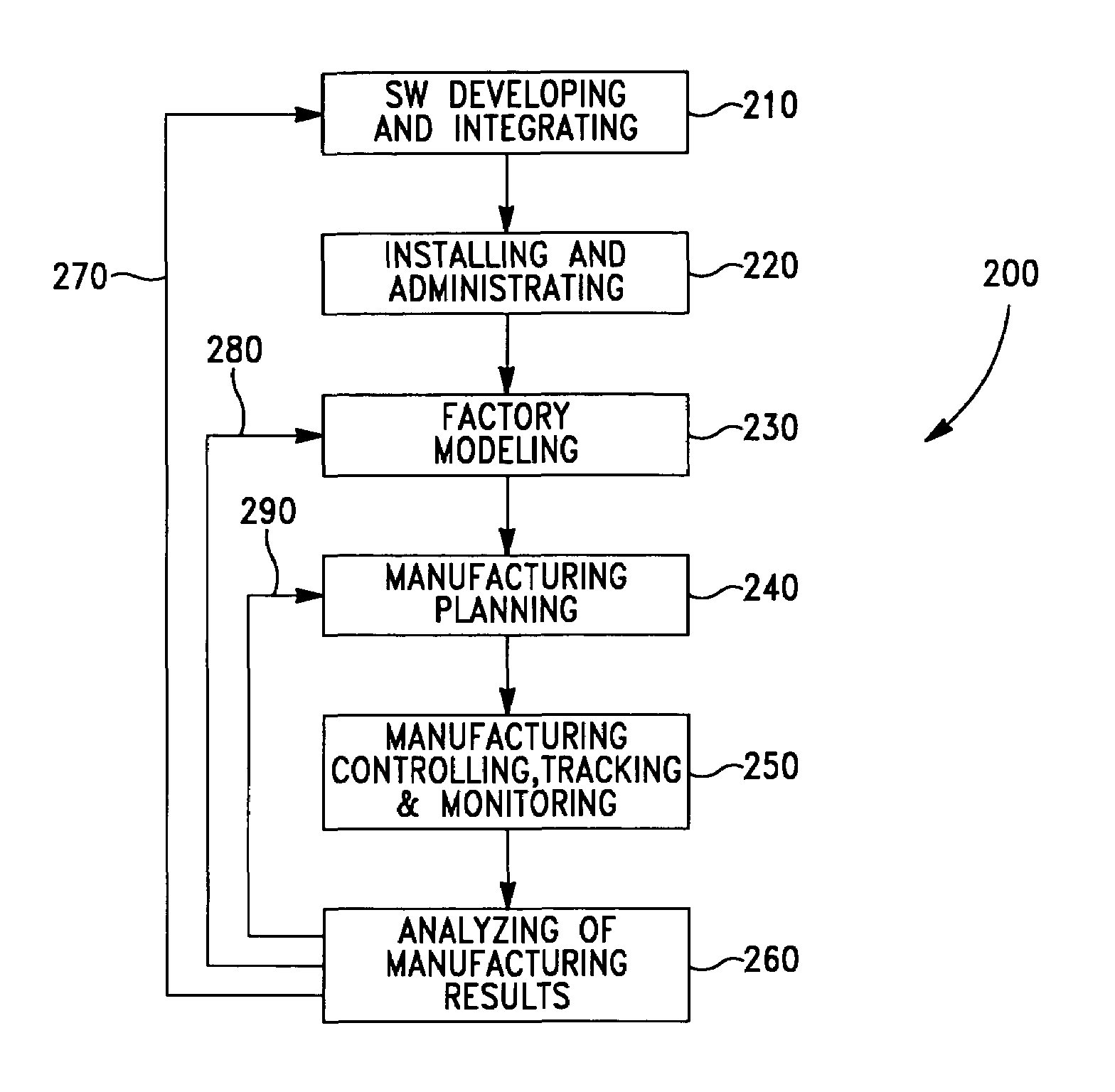

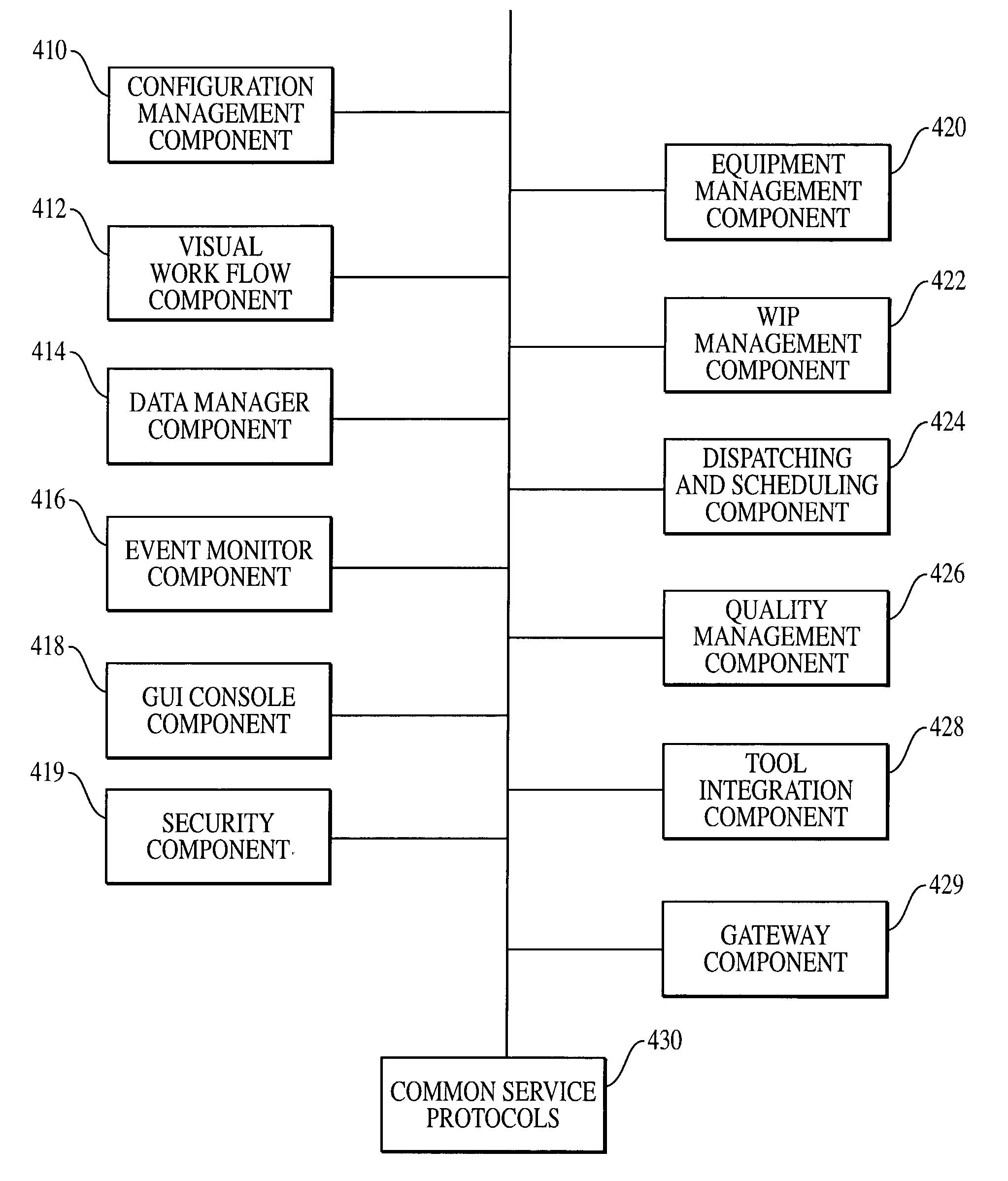

The present invention provides a novel distributed factory system framework including a novel factory automation lifecycle (200) having lifecycle activities for SW developing and integrating (210), installing and administrating (220), factory modeling (230), manufacturing planning (240), manufacturing controlling, monitoring and tracking (250) and analyzing of manufacturing results (260). The factory lifecycle comprises framework components. The distributed factory system framework also includes application components and software building blocks. The framework components are adapted for managing the application components, while the application components are utilized to provide instructions for managing a process such as a wafer fab. The building blocks are adapted for forming or modifying framework and application components. The distributed factory system framework provides computer implemented methods for integrating processing systems and facilitates process and equipment changes.

Owner:APPLIED MATERIALS INC

Fabrication rules based automated design and manufacturing system and method

InactiveUS6847853B1Detecting faulty computer hardwareComputer programmed simultaneously with data introductionComputer-integrated manufacturingPower component

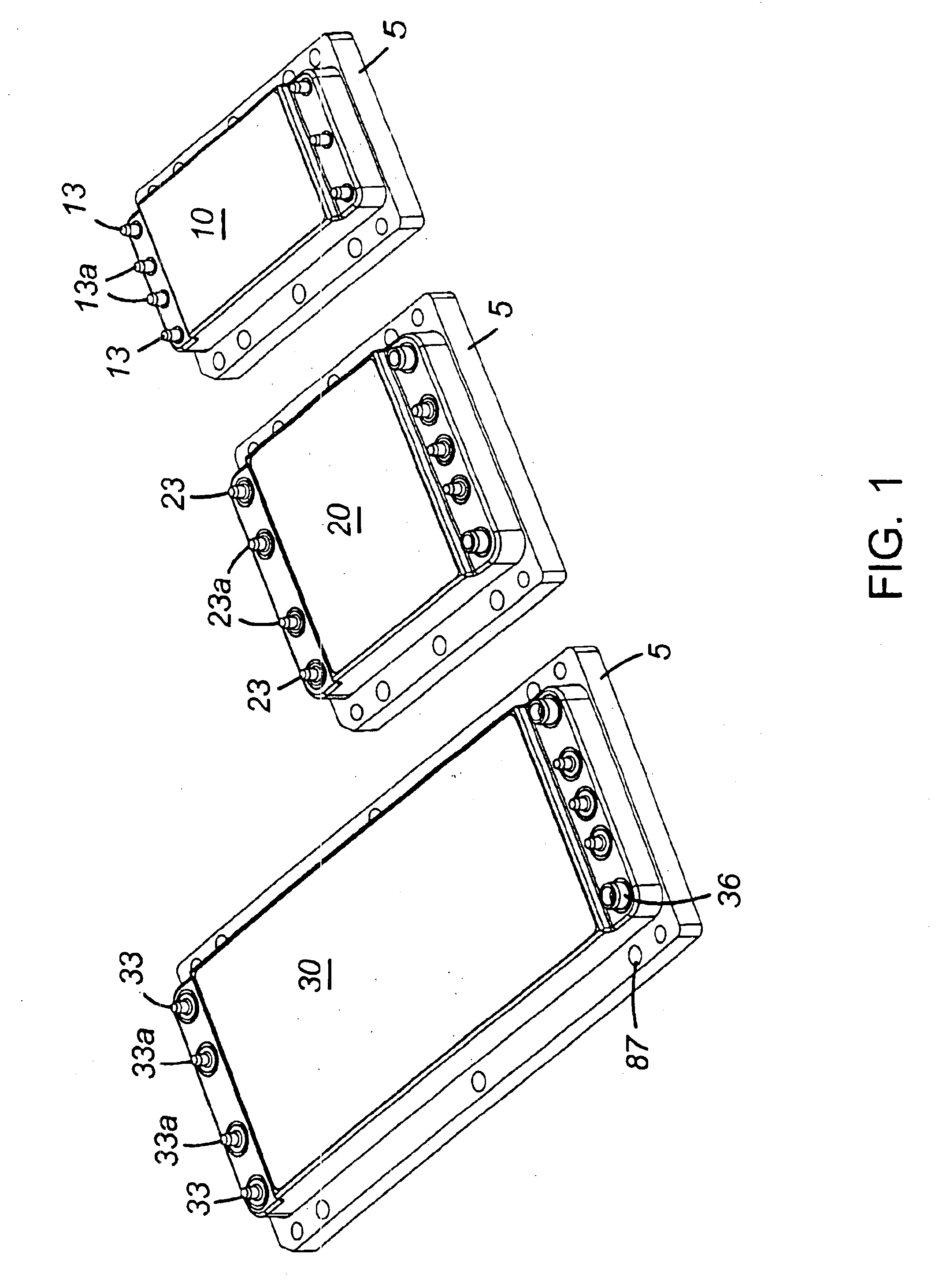

An automated custom power supply design system uses an expert system containing a set of rules, including manufacturing limitations to limit design choices and ensure feasibility and manufacturability of the design. A design interface collects specifications from a user. A complement of power components for satisfying the electrical specifications is defined and mechanical specifications for each component are provided by the system for use in creating the mechanical design. After the mechanical design is established a thermal analysis is performed and the completed design is returned to a host computer. After an order is received, a computer integrated manufacturing system generates all of the specifications required to manufacture the components for the system and the system.

Owner:VLT

Computer integrated manufacturing techniques

InactiveUS7174230B2Data processing applicationsSemiconductor/solid-state device manufacturingConsequence analysisManufacturing technology

The present invention provides a novel distributed factory system framework including a novel factory automation lifecycle (200) having lifecycle activities for SW developing and integrating (210), installing and administrating (220), factory modeling (230), manufacturing planning (240), manufacturing controlling, monitoring and tracking (250) and analyzing of manufacturing results (260). The factory lifecycle comprises framework components. The distributed factory system framework also includes application components and building blocks. The framework components are adapted to for managing the application components, while the application components are utilized to provide instructions for managing a process such as a wafer fab. The building blocks are adapted for forming or modifying framework and application components. The distributed factory system framework provides computer implemented methods for integrating processing systems and facilitates process and equipment changes.

Owner:APPLIED MATERIALS INC

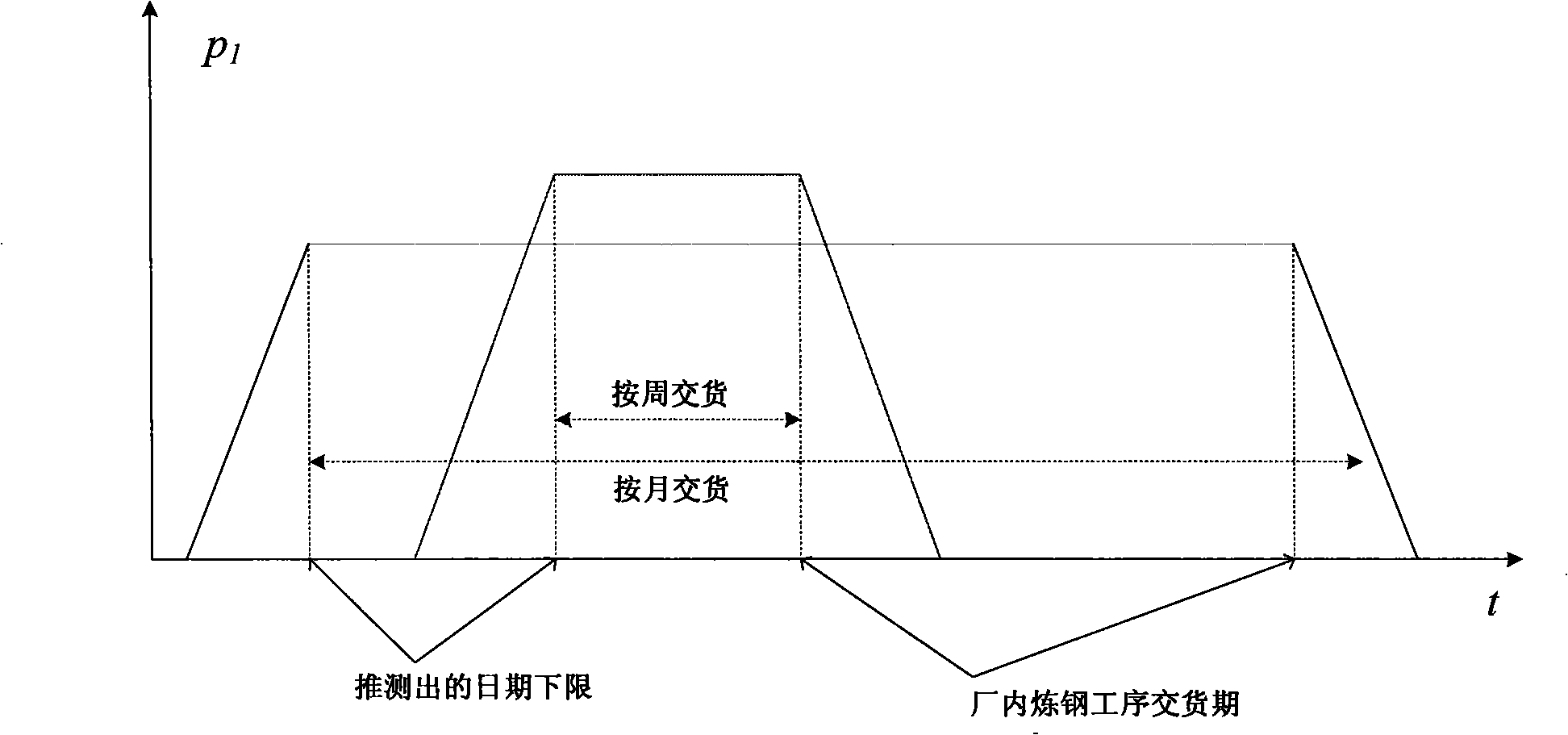

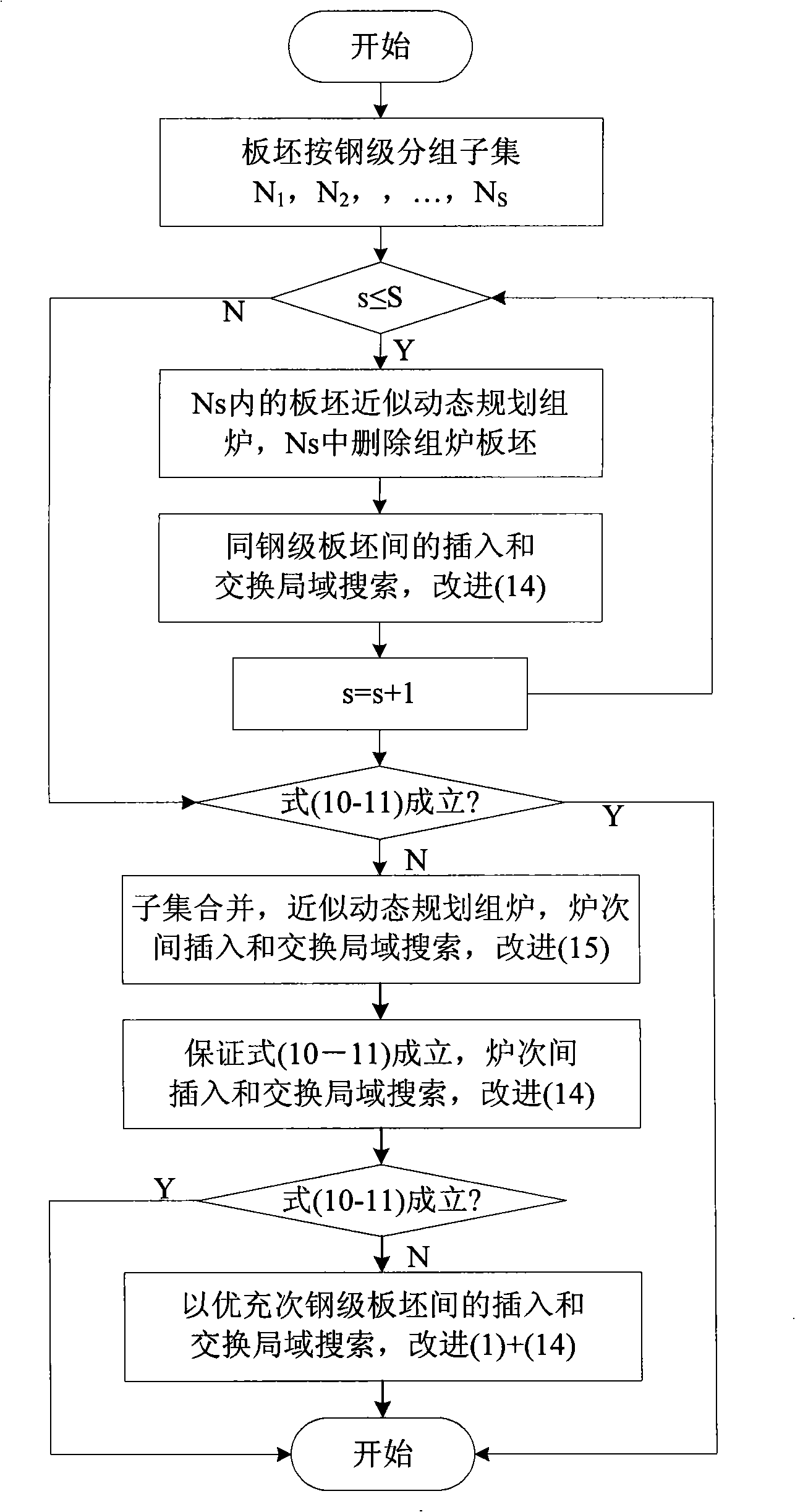

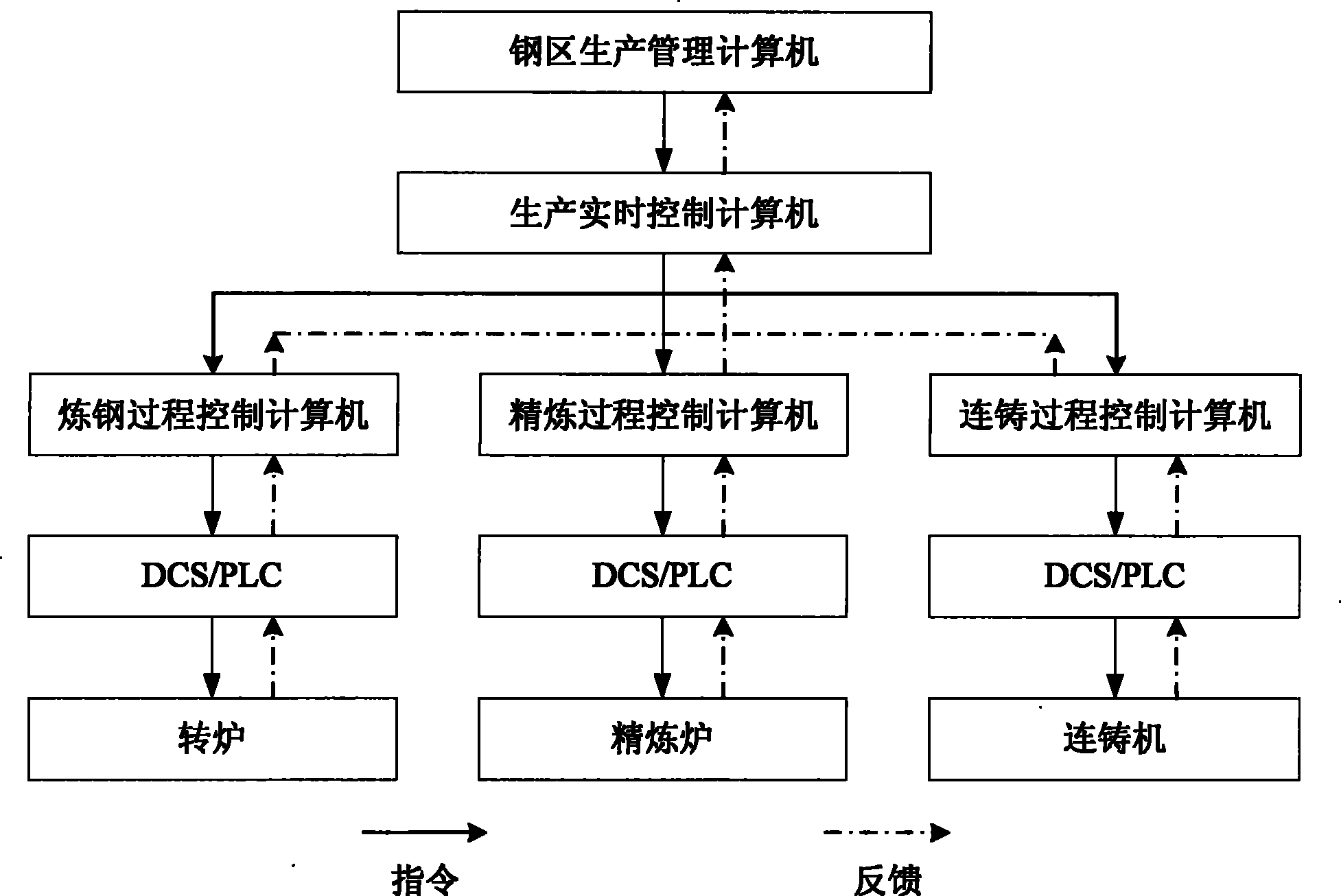

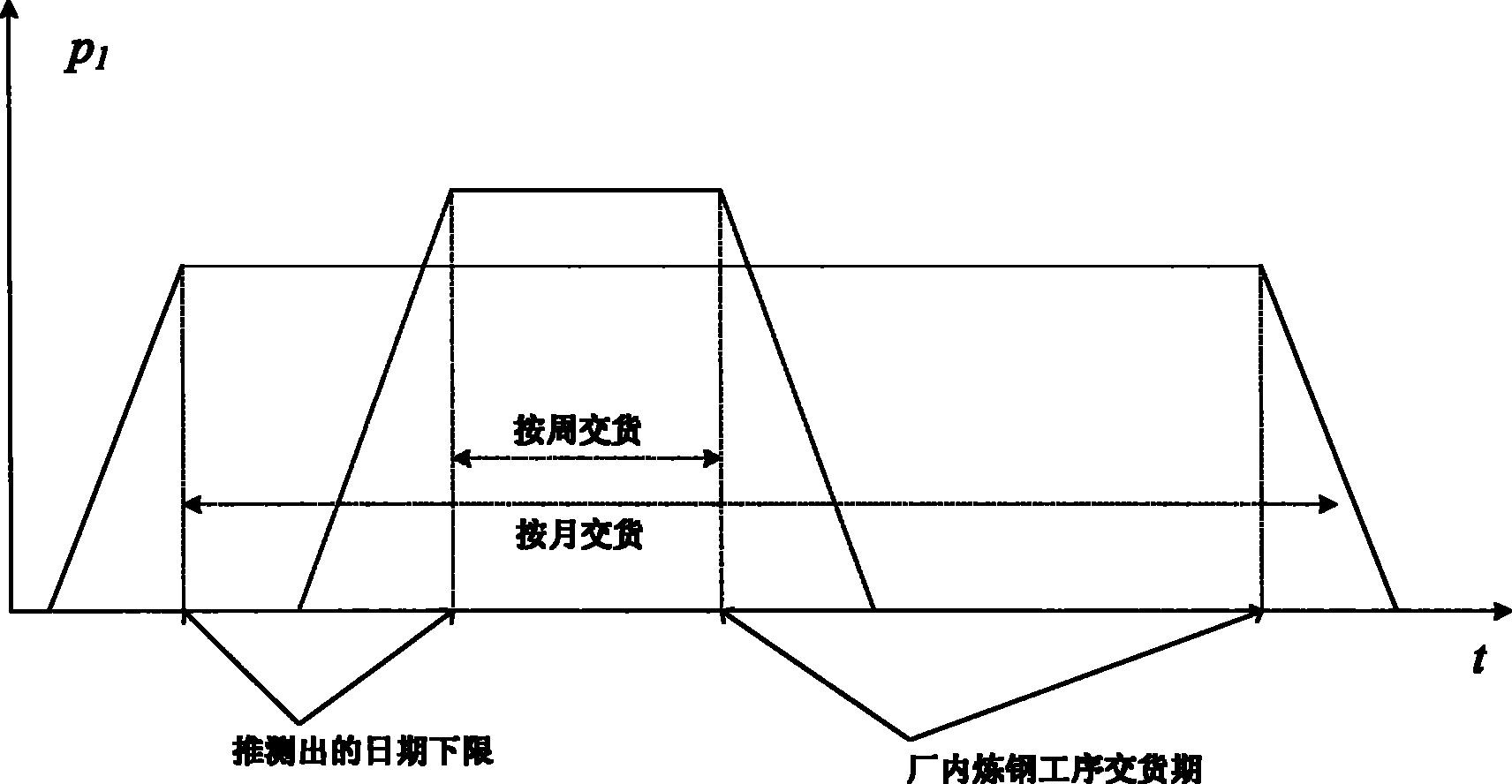

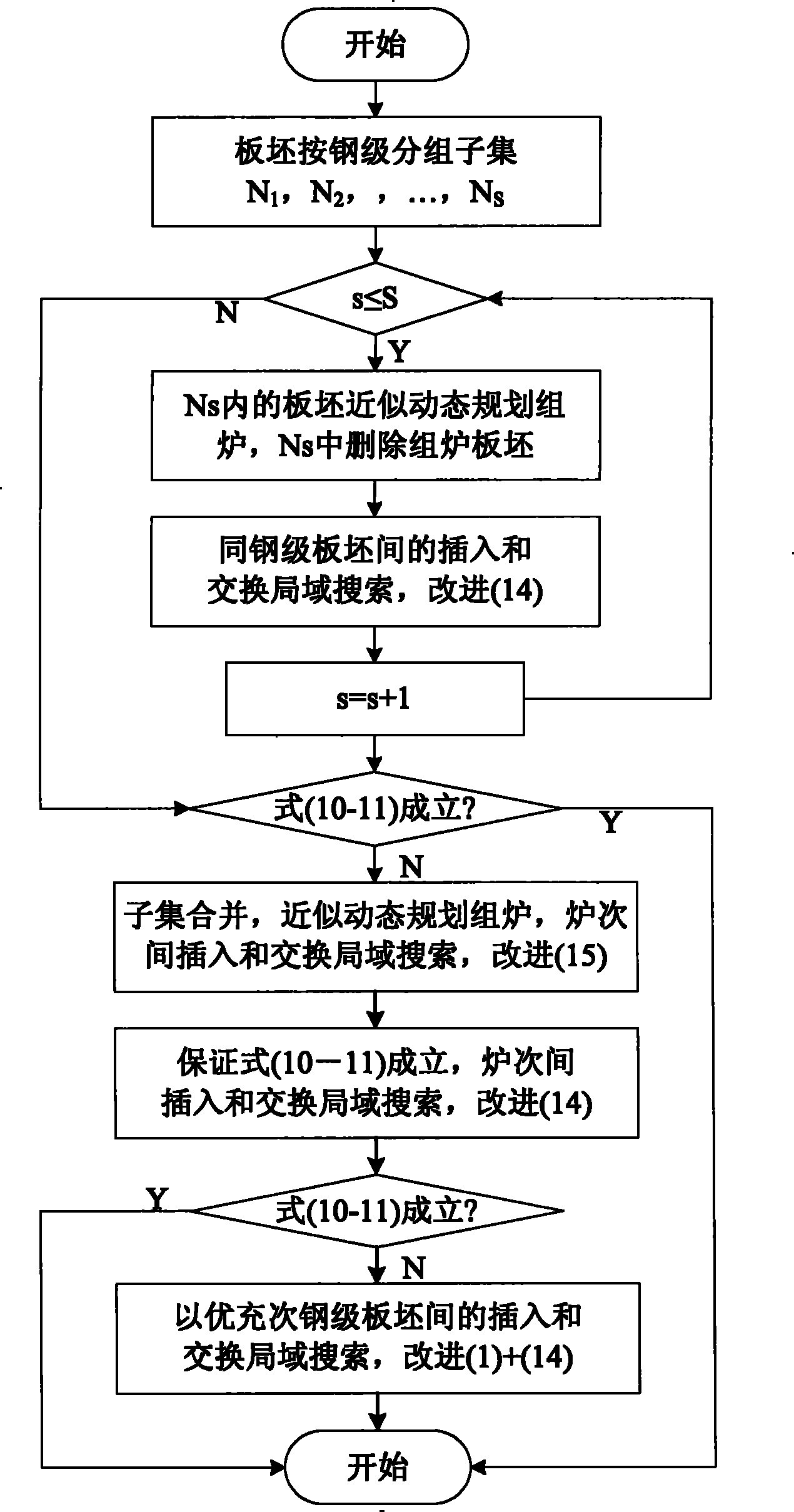

Method and system for automatically making steel-smelting continuous casting furnace sub batch plan

ActiveCN101303588AImprove scienceSolving inefficienciesTotal factory controlProgramme total factory controlSteelmakingOutcome assessment

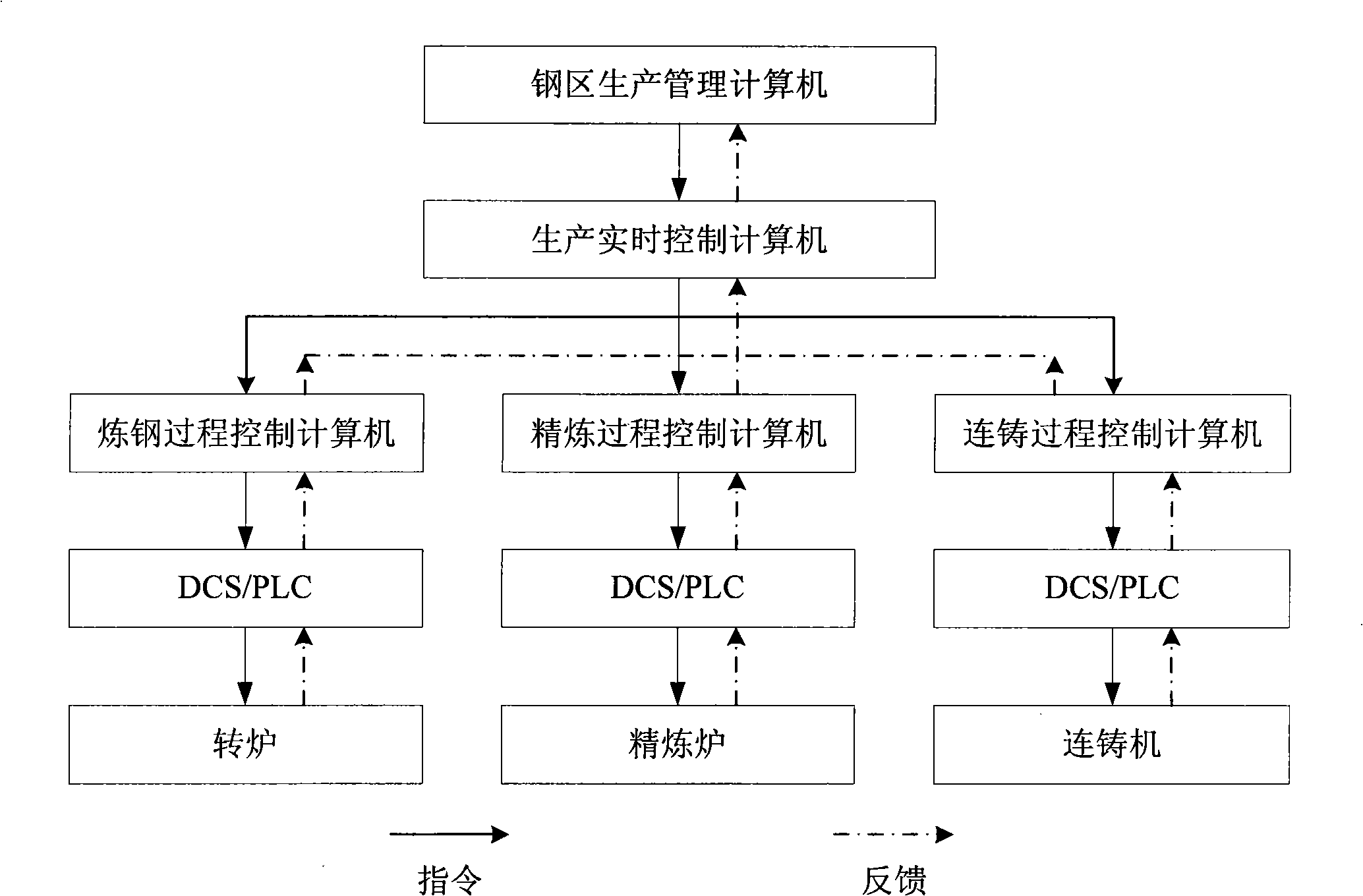

The invention relates to an automatic planning method of a steelmaking and continuous casting heat batch plan and a system thereof, belonging to the IT field and including the following steps: 1, data collection; 2, construction of model; 3, optimization solution; 4, outcome assessment; 5, human-computer interaction; 6, sending down for executing. All indexes of the heat batch plan result obtained by adopting mathematical model and optimization algorithm of the invention are superior to that of the heat batch plan result obtained by the existing on-site manual planning pattern, in addition, the planning time (about 5 minutes) of the automatic planning method of the invention is far shorter than the planning time (about 2-3 hours) of the manual planning pattern. Therefore, the automatic planning method of the invention improves the scientificity of the traditional manual planning pattern, enhances planning level and quality, solves the problem of low efficiency in the manual planning pattern, and provides a scientific method for planning the on-line heat batch plan on a computer integrated manufacturing system in a steel enterprise.

Owner:NORTHEASTERN UNIV

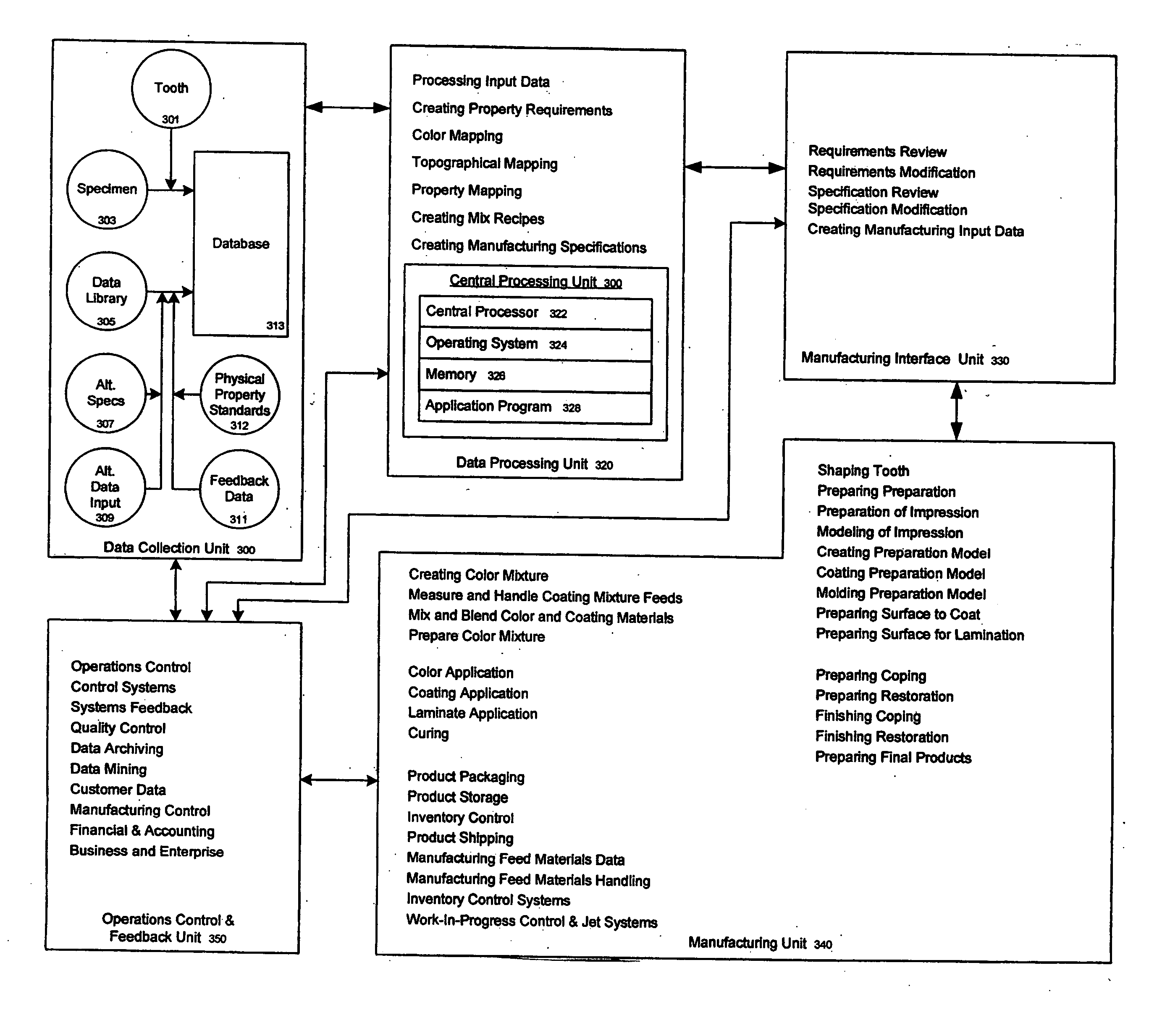

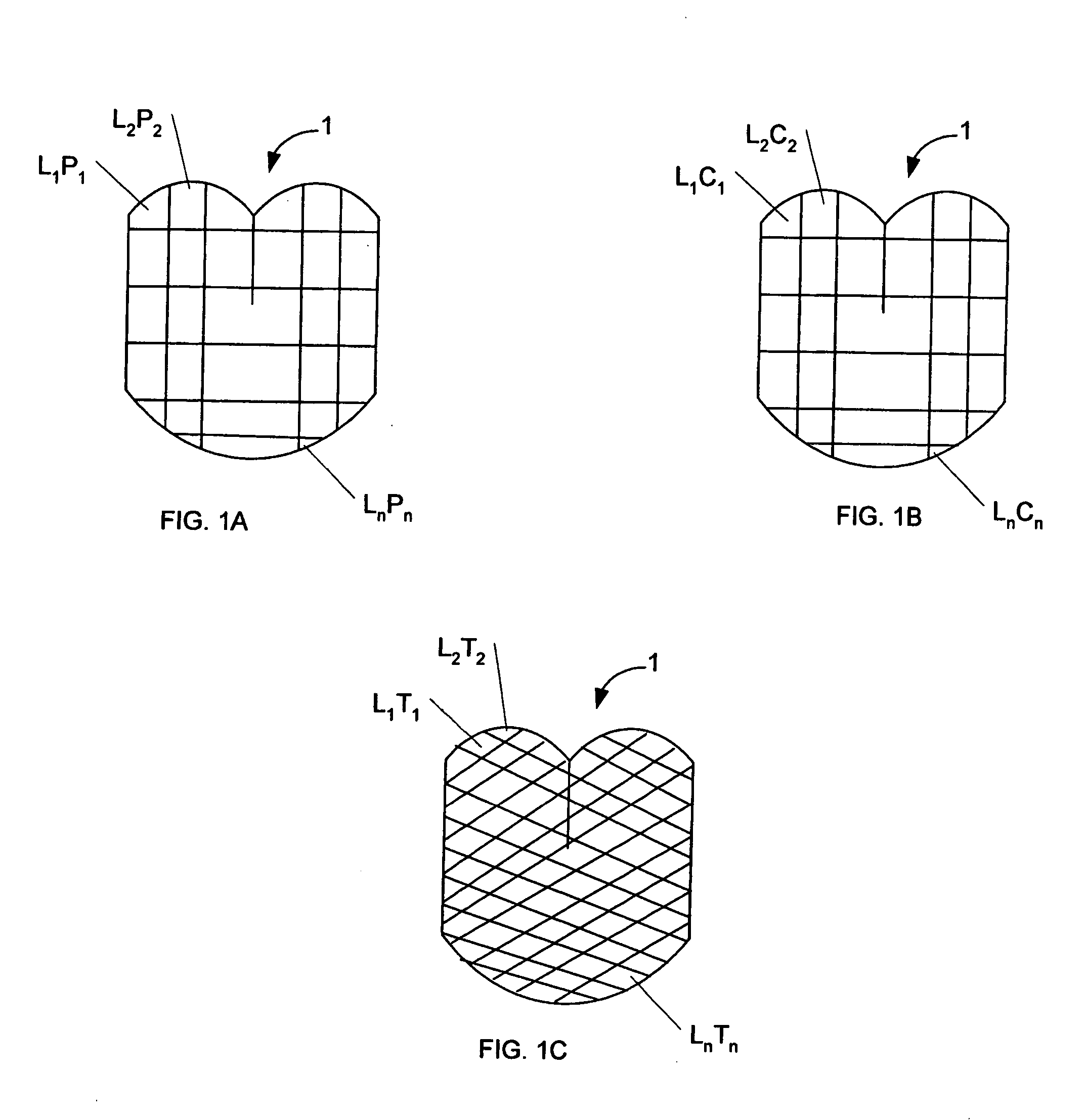

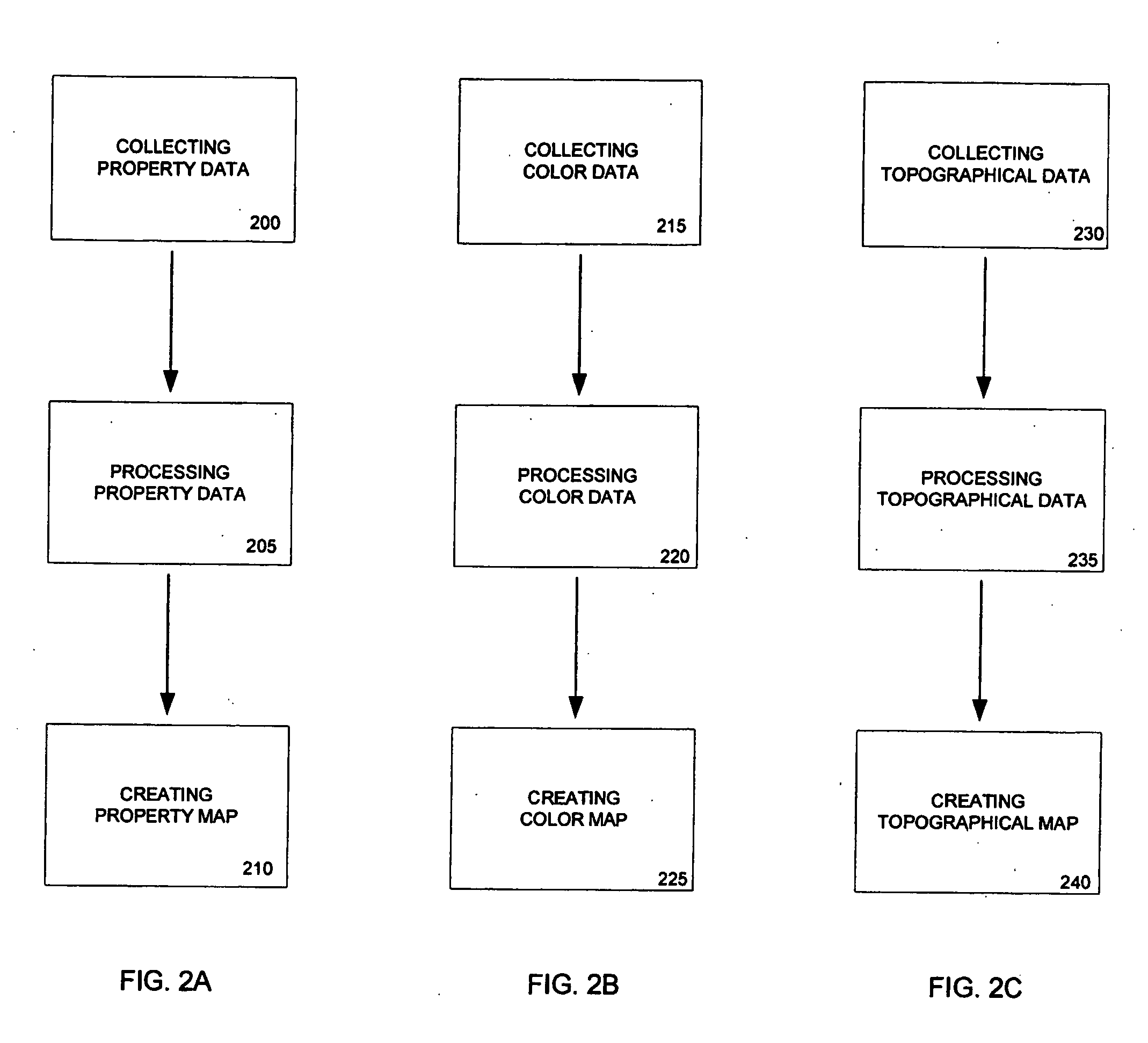

System, method, computer program product and apparatus for producing dental restorations

InactiveUS20050170315A1Minimize wasted materialLow costArtificial teeth3D printingComputer-integrated manufacturingComputerized system

Systems, methods and computer program products for producing dental restorations that can include the use of a computer integrated manufacturing system. Using this system, physical properties of a tooth are collected, for the automated manufacturing of a dental restoration. The invention, in one embodiment, includes creating a color map comprising at least one color value, a computer program product for producing a dental restoration layer, as well as a method for producing a dental restoration using a computerized system.

Owner:GERBER SCI PROD INC

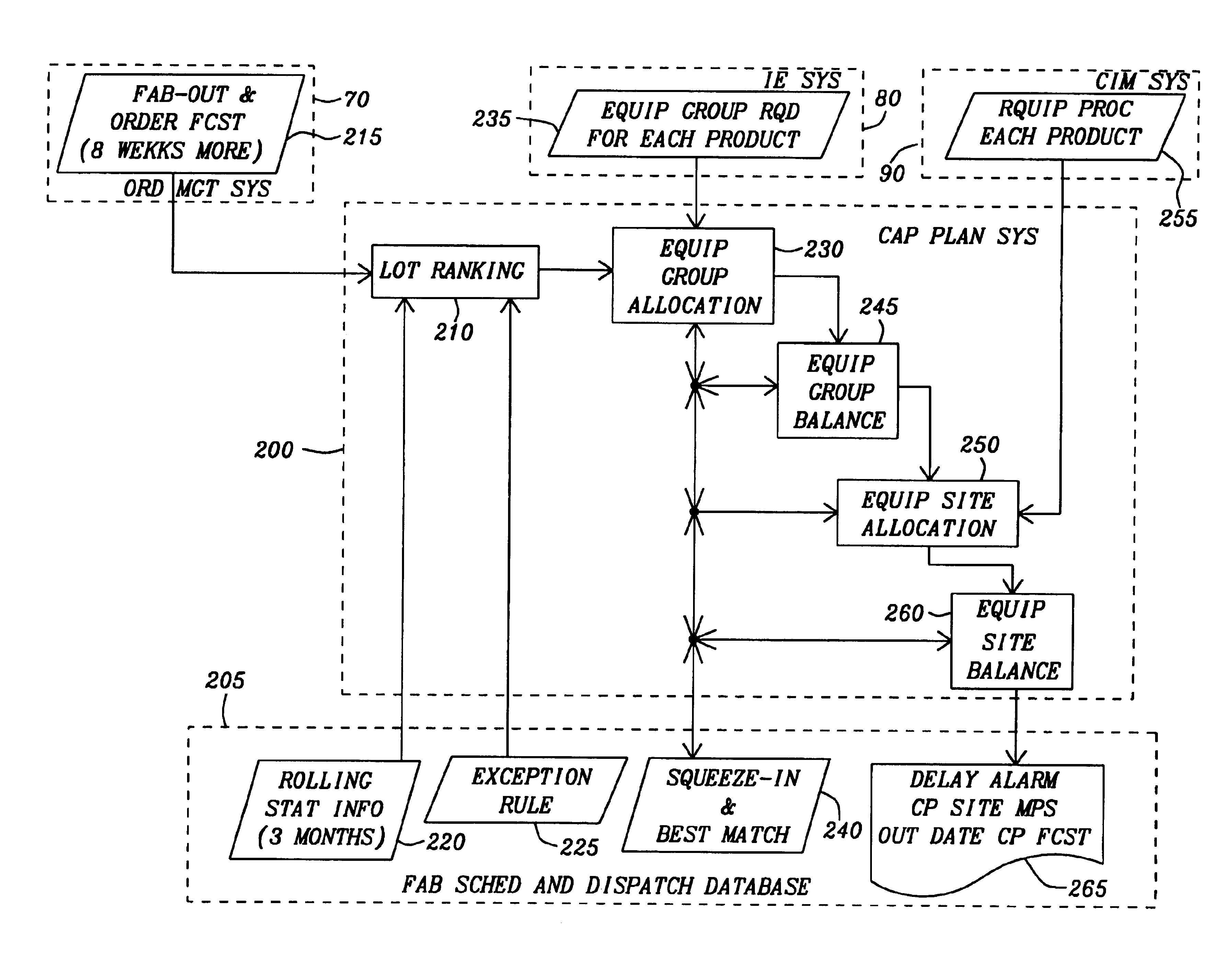

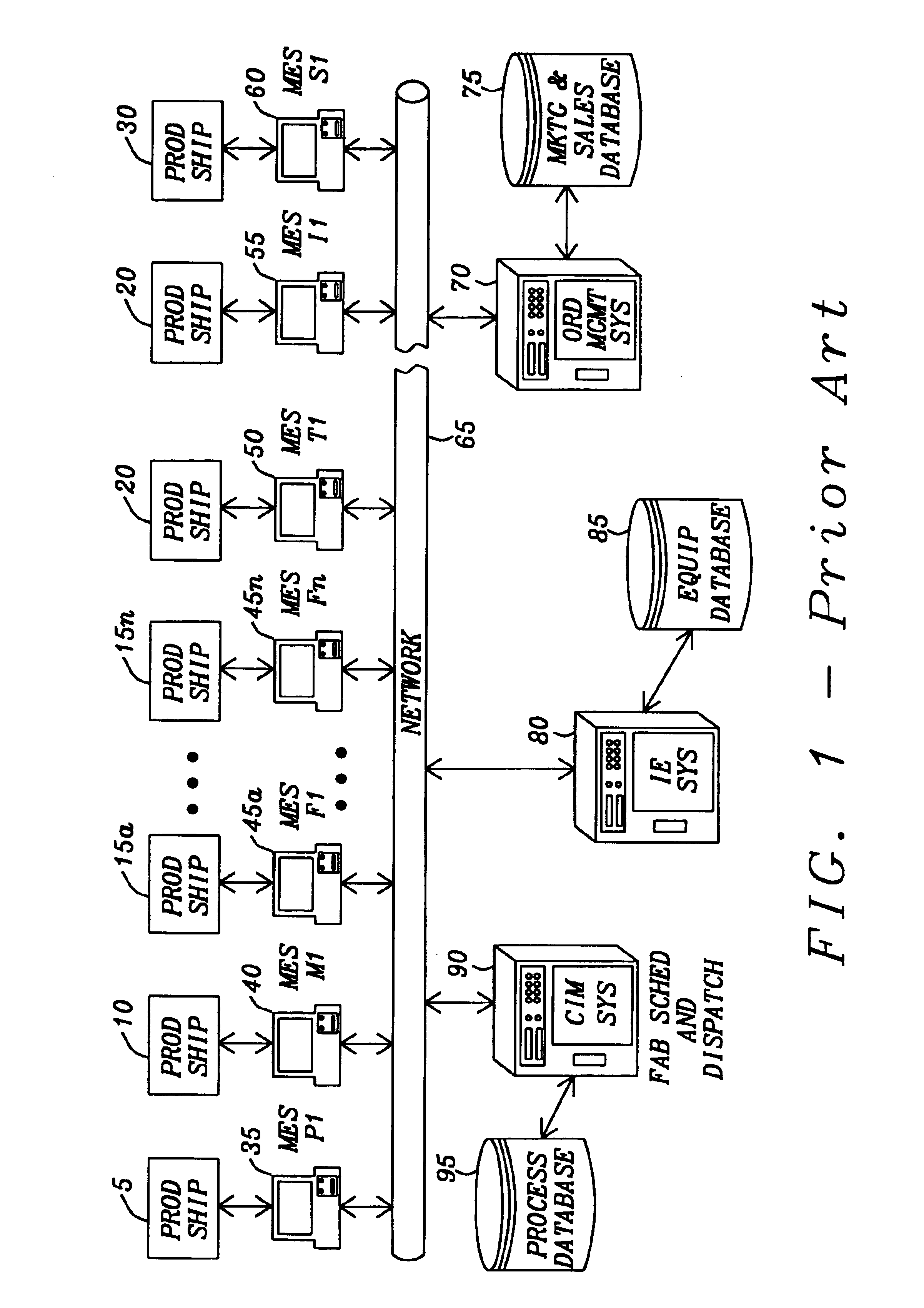

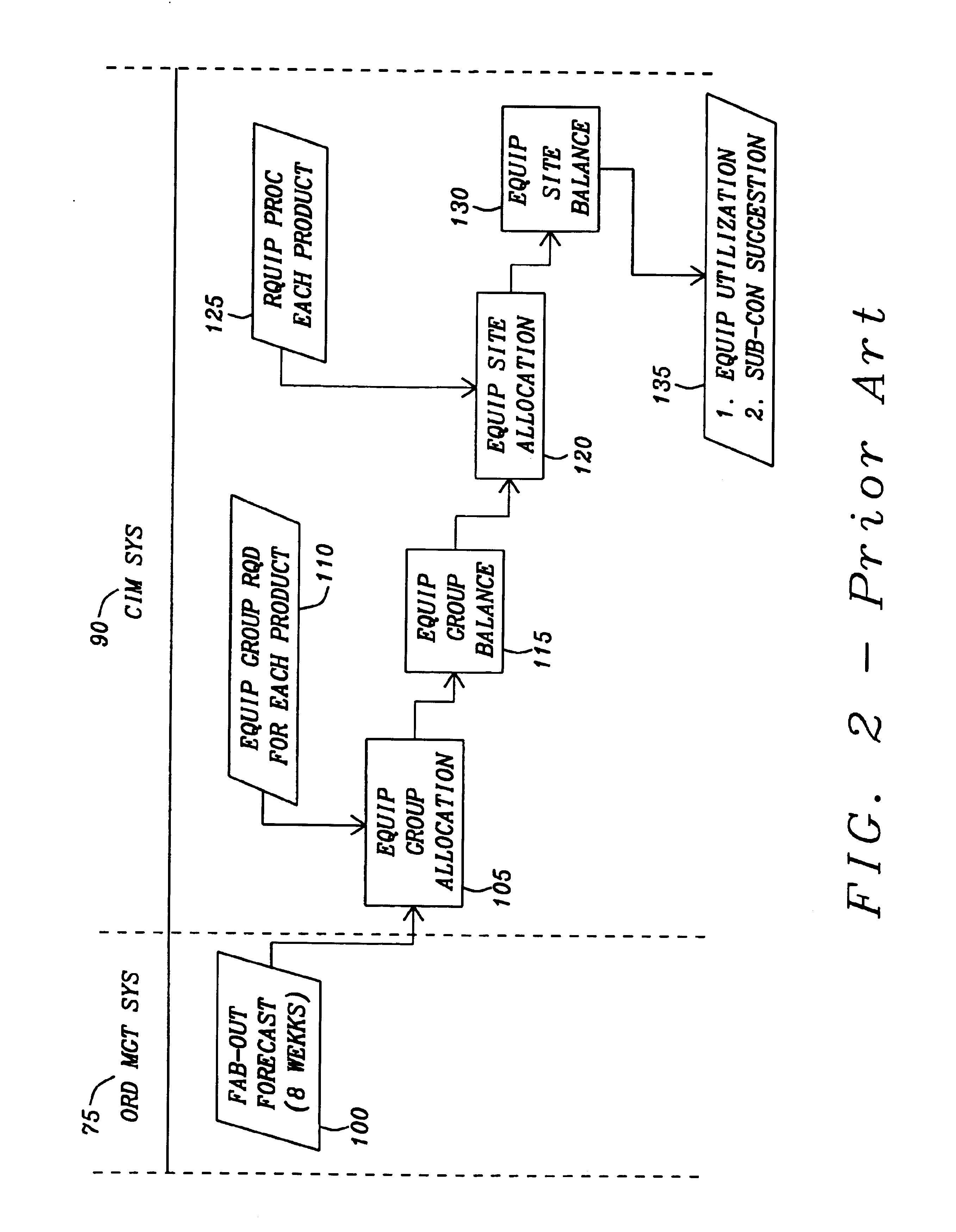

Heuristics for efficient supply chain planning in a heterogeneous production line

InactiveUS6920366B1Low utilizationMaintenance operationResourcesSpecial data processing applicationsOrder management systemComputer-integrated manufacturing

A computer integrated manufacturing system executes a program process that performs a capacity planning method that allocates usage of a plurality of manufacturing elements of a manufacturing enterprise by major and minor apparatus, squeezing for overhead cost consideration, and site balance for maintain basic operation. The program process begins by receiving at least one fabrication forecast describing scheduling and types of product lots that are predicted to be fabricated within a first period of time by the manufacturing enterprise from at least one order management system of the manufacturing enterprise. Rolling statistics of products lots fabricated during a second period of time are retrieved from a data retention device of the computer integrated manufacturing system. Capacity planning for the allocation of the product lot predicted to be fabricated by the manufacturing elements is performed.

Owner:TAIWAN SEMICON MFG CO LTD

Preparation method of colorized zirconia-structured ceramic

The invention discloses a preparation method of colorized zirconia-structured ceramic. The zirconia ceramic material doped only with a stabilizer is white or light yellow. With the adoption of the method of doping other rare oxides, the zirconia ceramic in various colours is made; therefore, the application of zirconia ceramic material to the fields with appearance requirement such as clocks and watches, ornaments and crafts is widen by utilization of excellent mechanical property and coloured appearance of the zirconia ceramic material doped with the other rare oxides. The method provided by the invention comprises the steps of mixing the colorant-containing yttrium-zirconium ceramic mixed powder with adhesives, performing CIM (computer integrated manufacturing) injection moulding, thermally pressing in vacuum and sintering, and obtaining the colorized zirconia-structured ceramic.

Owner:JIANGXI UNIV OF SCI & TECH

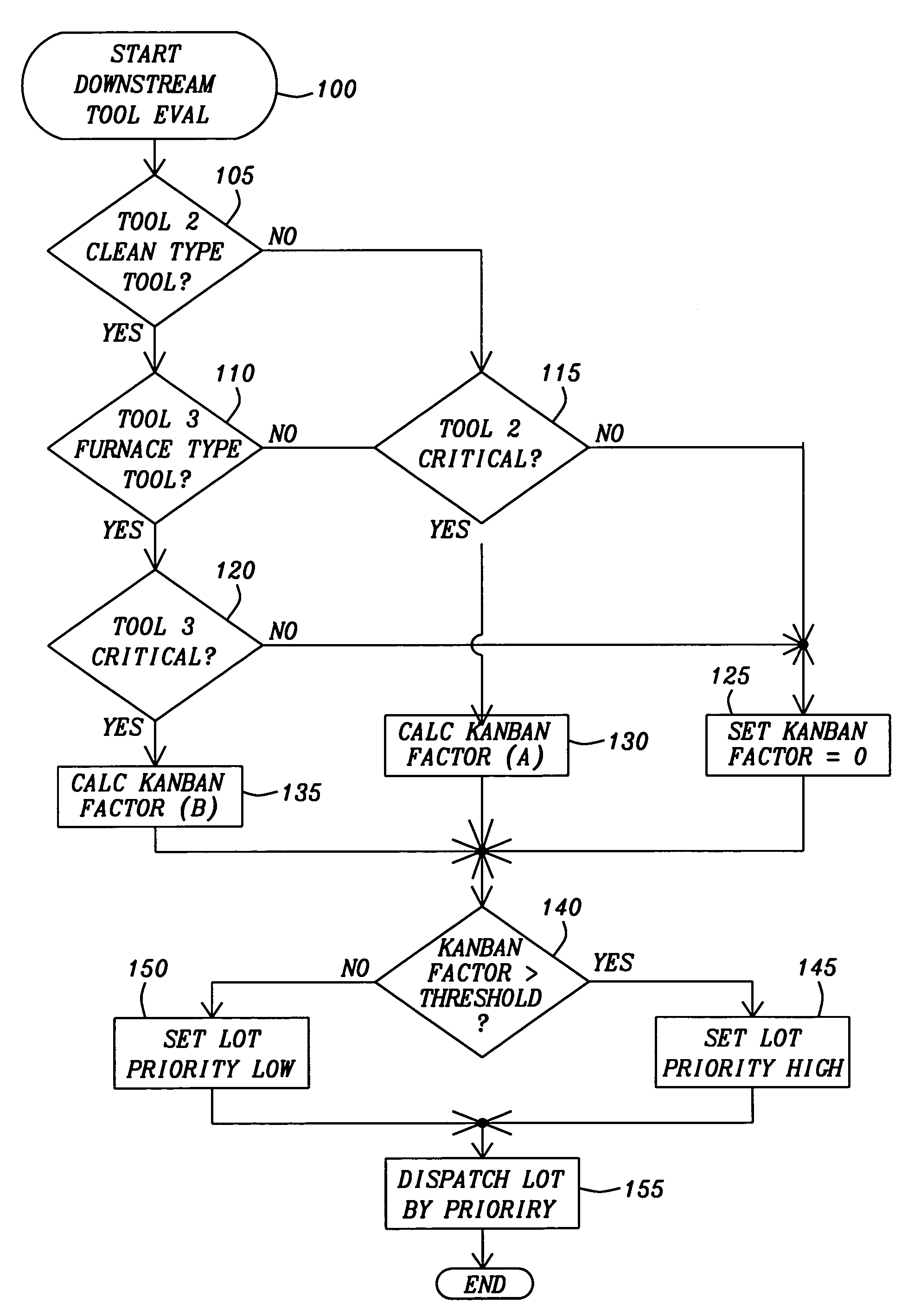

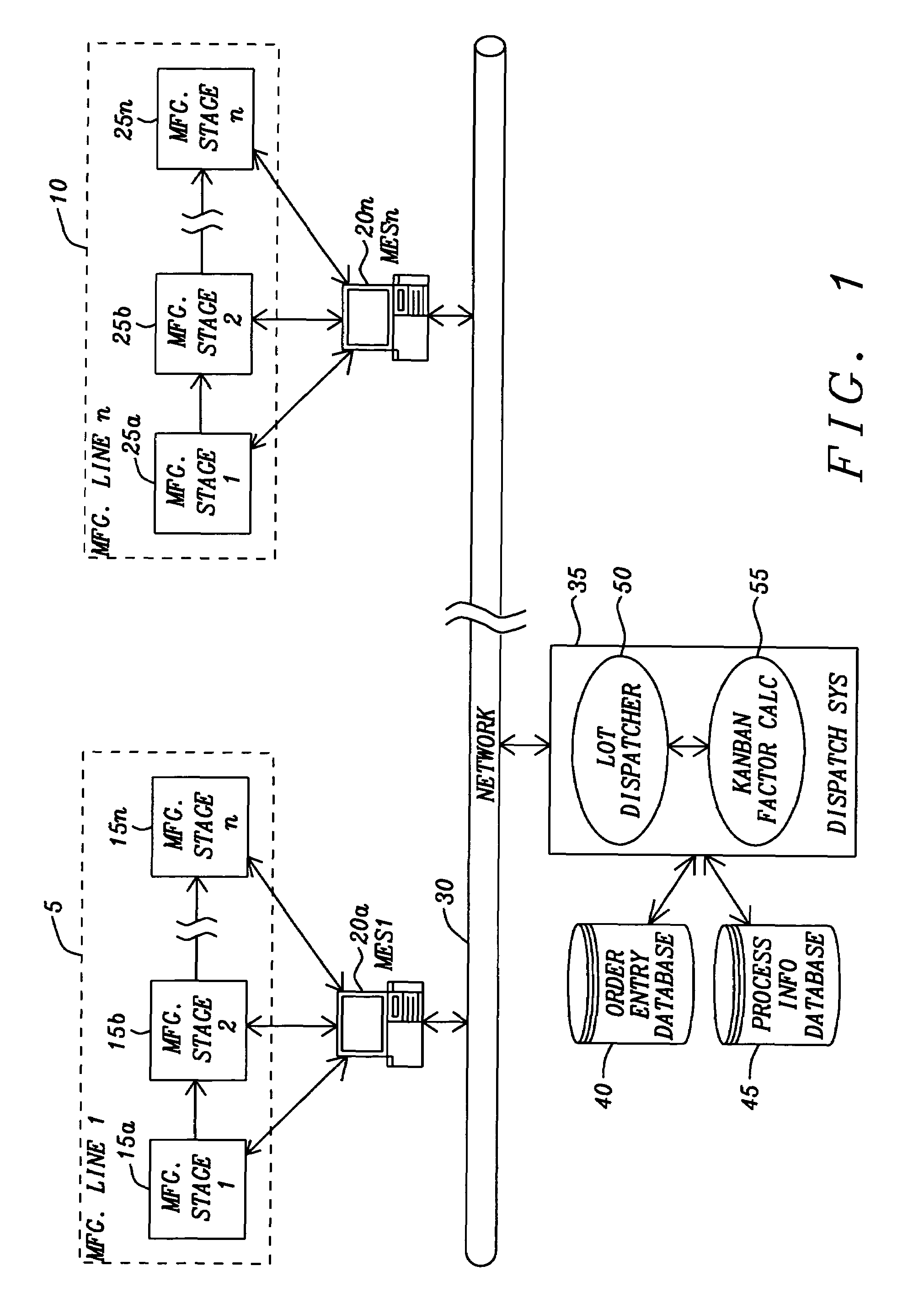

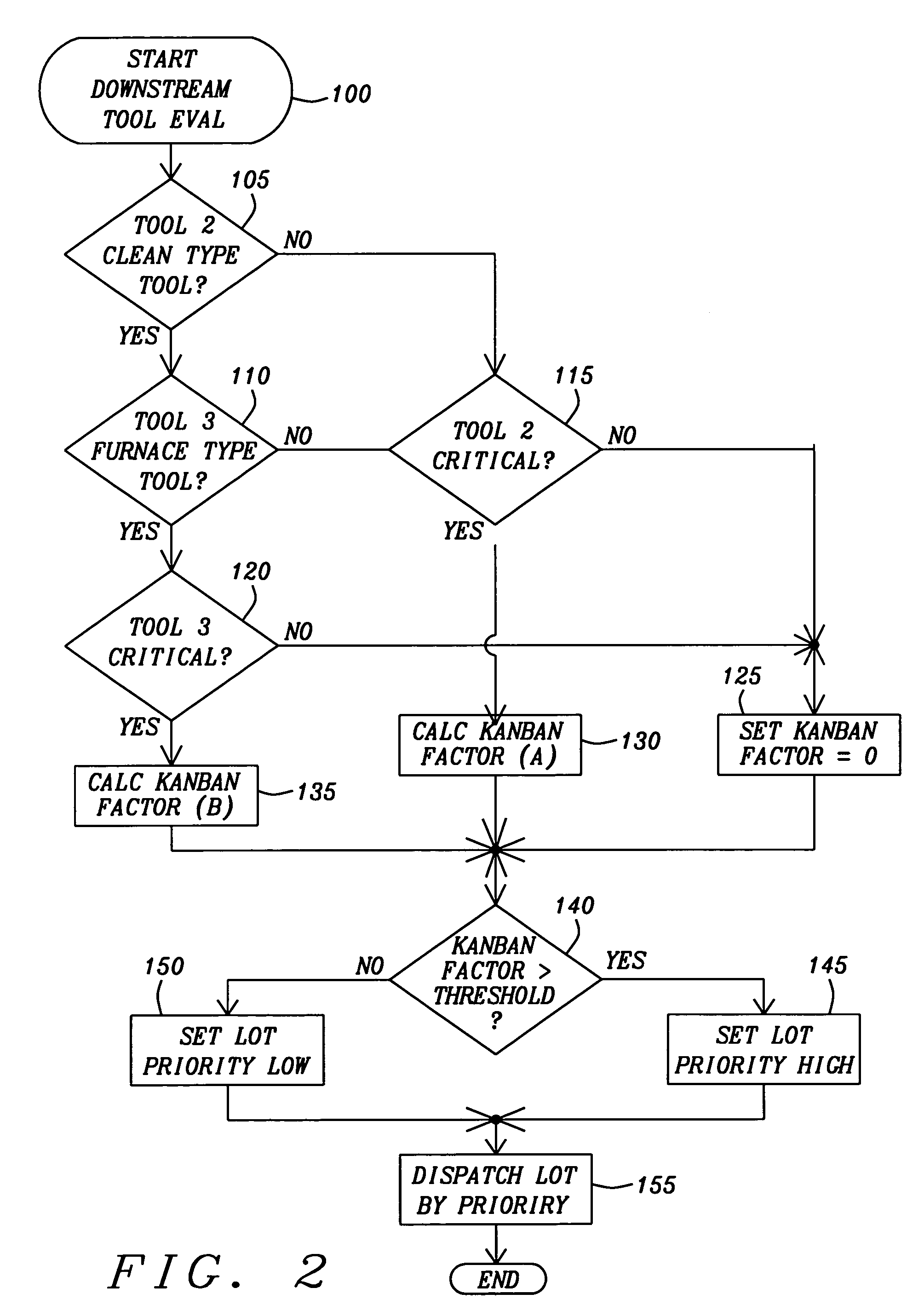

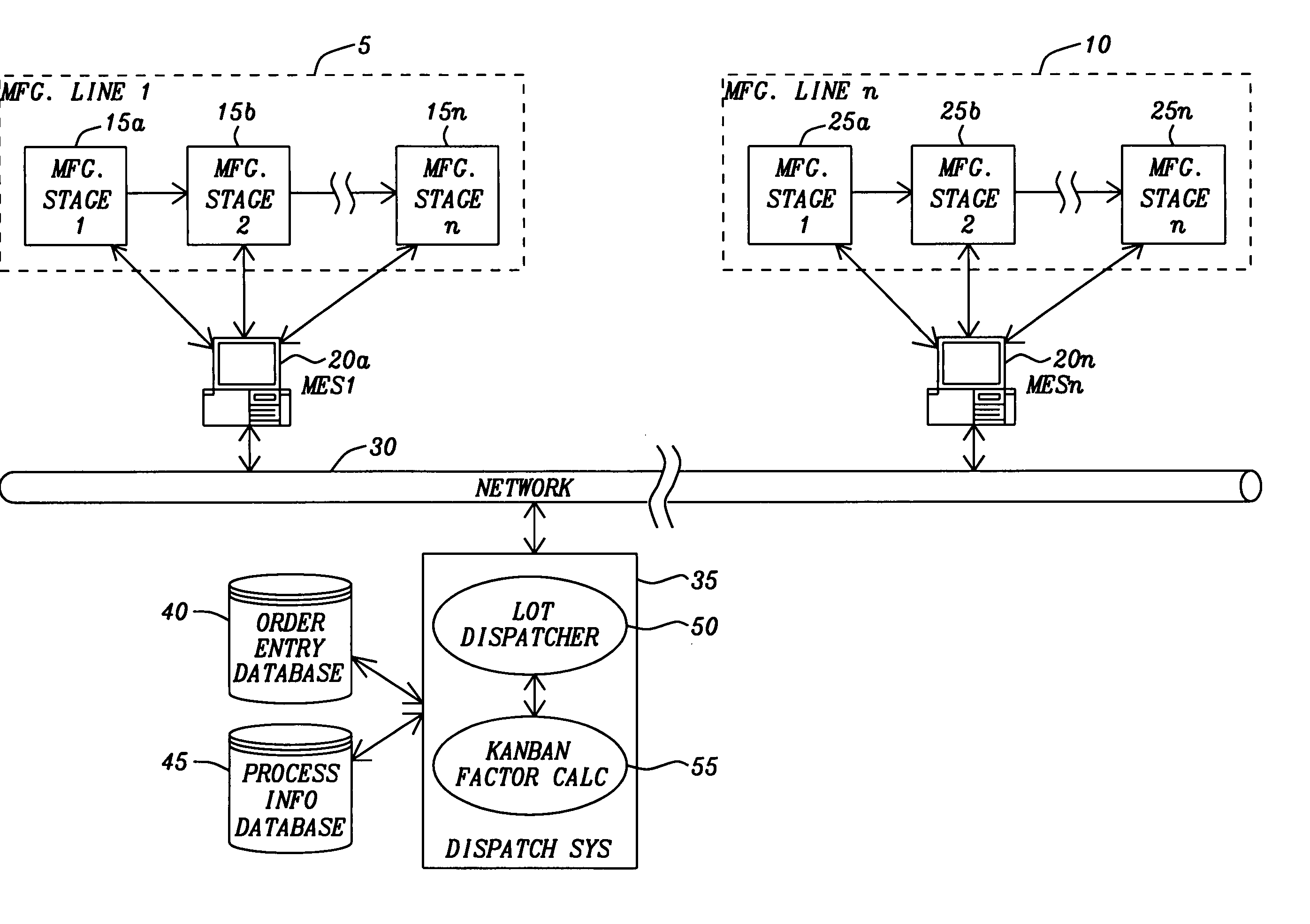

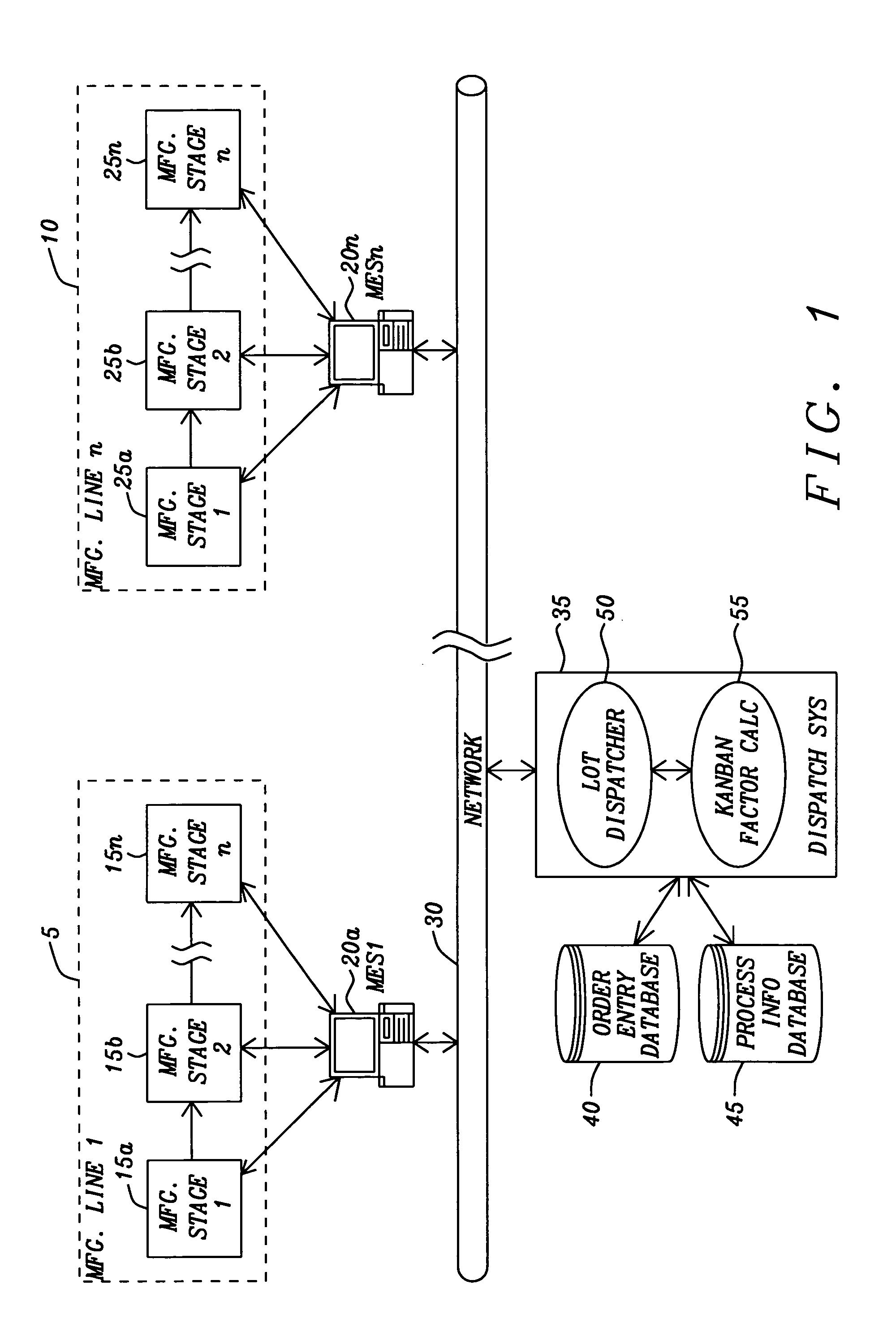

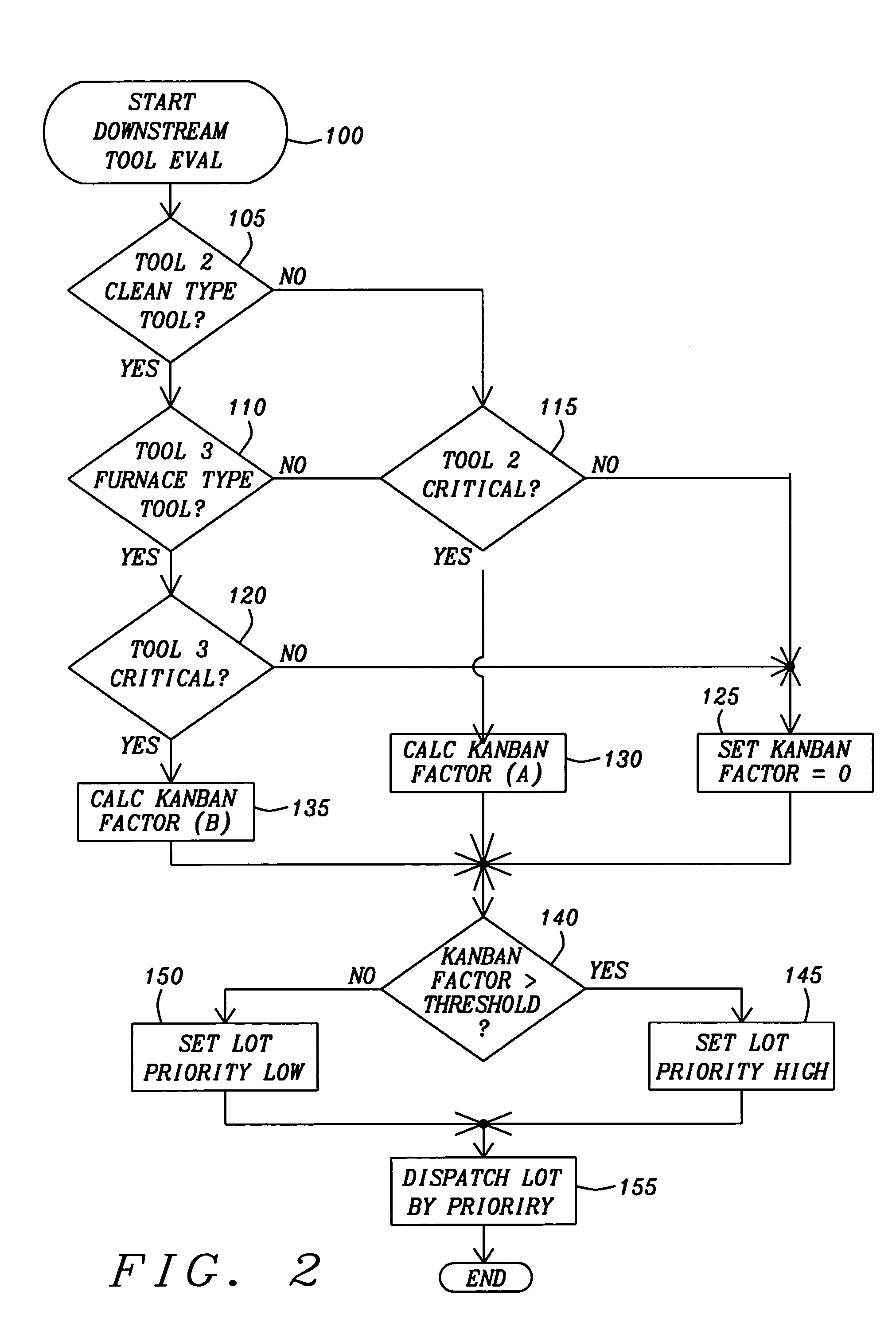

Dynamically adjusting the distribution for dispatching lot between current and downstream tool by using expertise weighting mechanism

A system and method that prioritizes product lots for fabrication and dispatching to manufacturing equipment establishes priorities for dispatching product lots based on a criticality factor and establishes a priority for dispatching product lots to manufacturing equipment based on processing capability and the efficiency of manufacturing equipment. A computer integrated manufacturing system executes a program process that functions as a lot dispatcher and a priority factor calculator. The lot dispatcher is in communication with an order entry system to receive requests for fabrication and with a process information system to receive procedures defining which manufacturing equipment is required. A manufacturing information system provides the lot dispatcher with a criticality factor and a queue level for each piece of manufacturing equipment. Then the current group of pieces of manufacturing equipment is followed with a balanced loading.

Owner:TAIWAN SEMICON MFG CO LTD

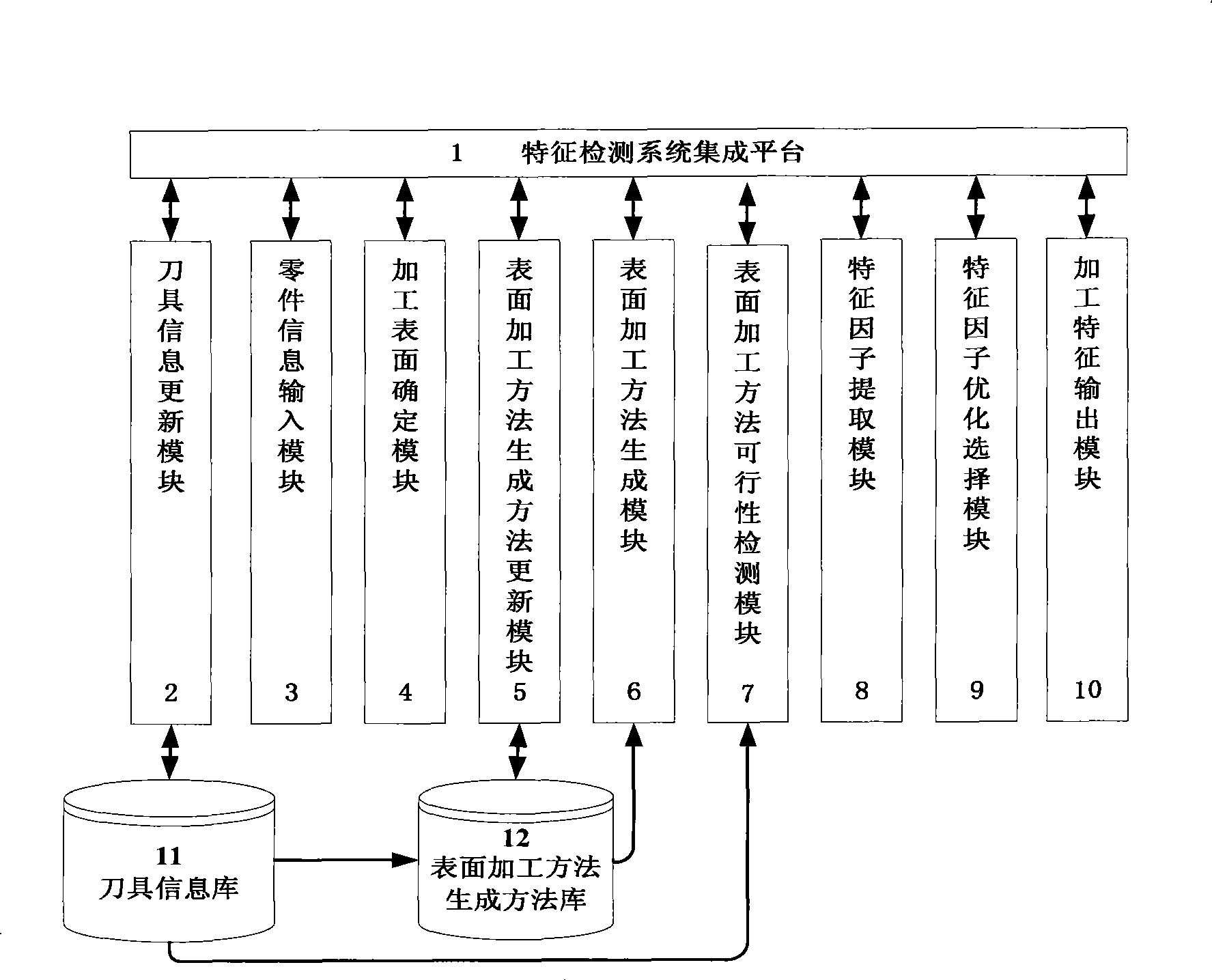

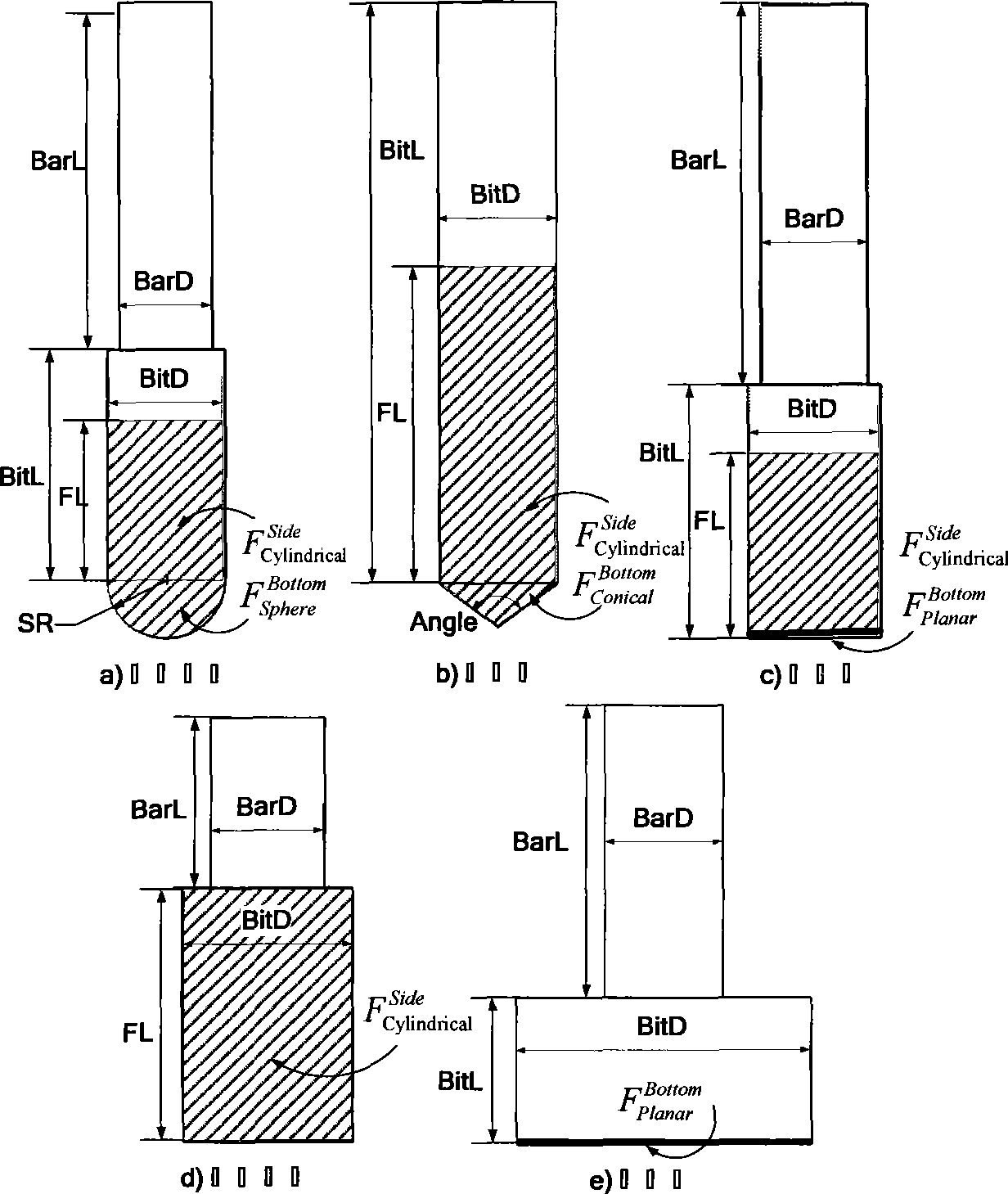

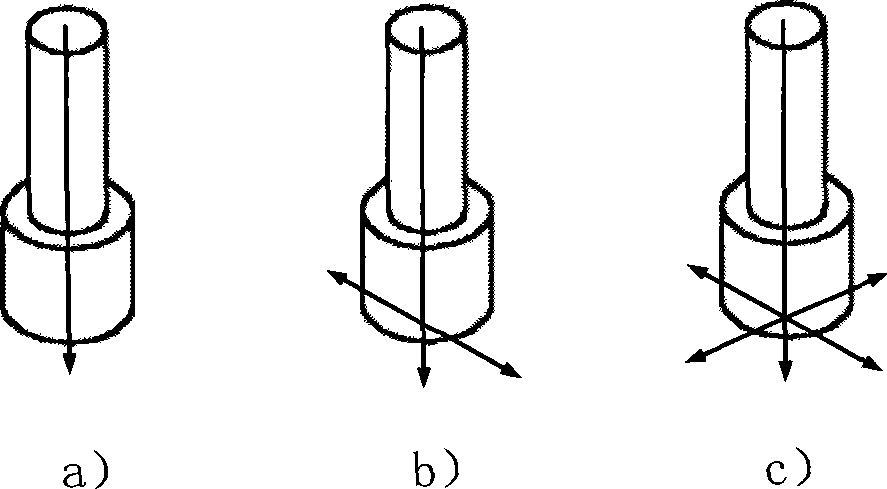

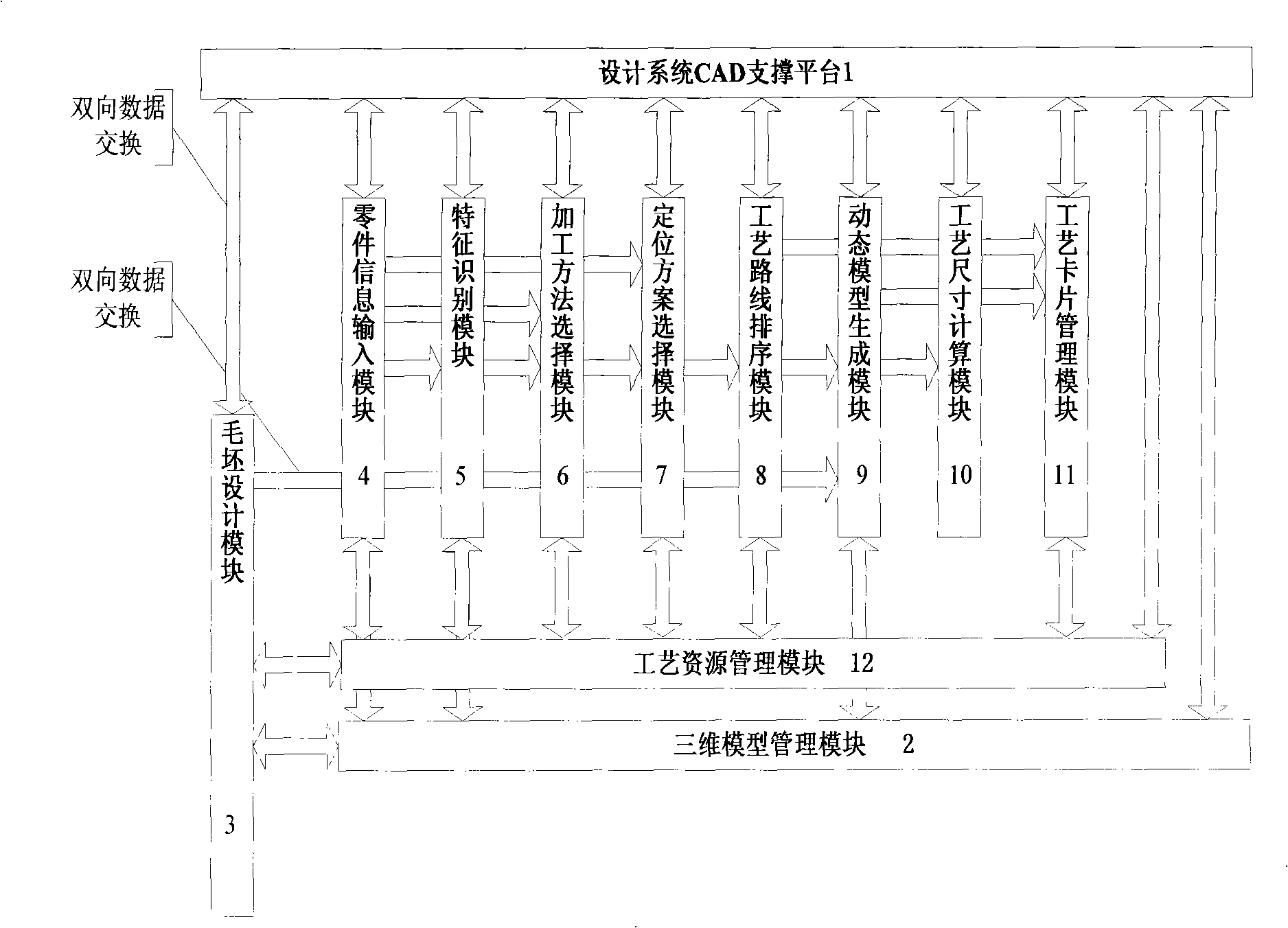

System and method for part process feature detection in three-coordinate numerical control machining

InactiveCN101464676AAvoid the problem of difficult detection of complex intersecting featuresNumerical controlNumerical controlSystem integration

The invention relates to a system and a method used for detecting part machining features in 3-axis numerical control machining in the technical field of computer integrated manufacturing. The system comprises a feature detection system integration platform, a tool information renewal module, a part information input module, a machined surface determination module, a plane machining method generating method renewal module, a plane machining method generating module, a plane machining method feasibility detection module, a characteristic factor extracting module, a characteristic factor optimal selection module, a machining feature output module, a tool information base and a plane machining method generating method base. The invention can achieve feature detection of complex parts in the environment of 3-axis numerical control machining; the machining features are clustered by surfaces, have no fixed topological structure, are independent of a predetermined feature pattern base, and can explain complex features and feature interactions; and the feature detection fully considers the actual machining resources in the machining environment, so that the detected machining features certainly has machinability.

Owner:SHANGHAI JIAO TONG UNIV

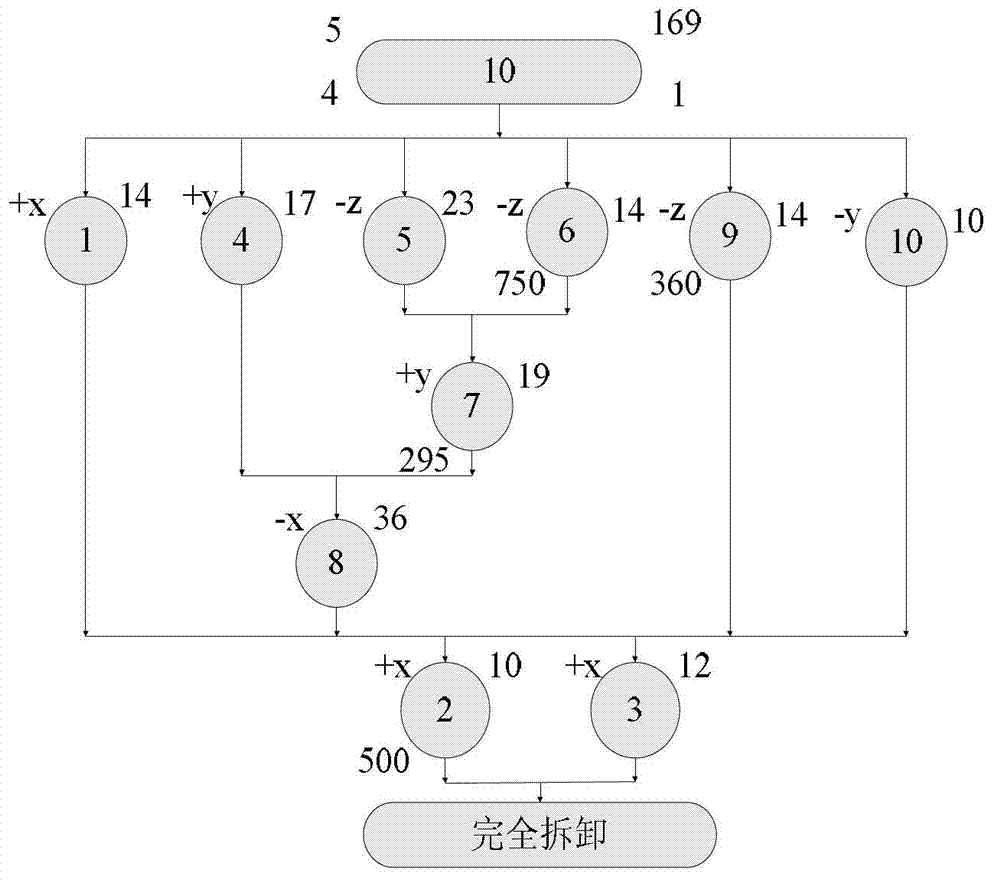

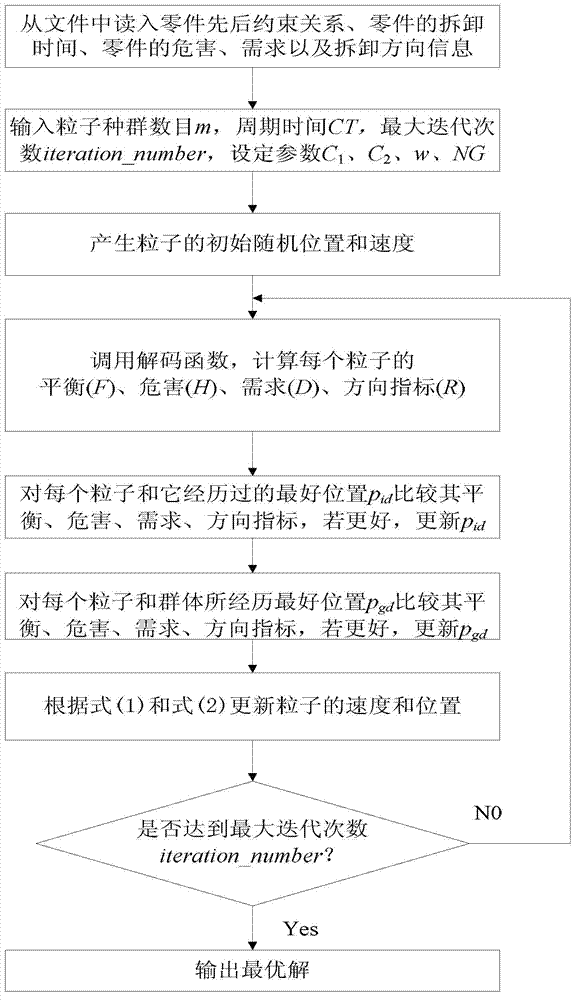

Balance control method of multi-objective disassembly line

InactiveCN102830621ASolve balance problemsSolve control problemsAdaptive controlIdle timeComputer-integrated manufacturing

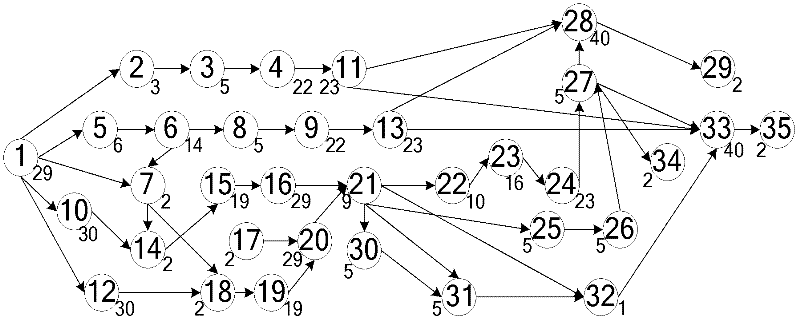

The invention discloses a balance control method of a multi-objective disassembly line. The method is characterized by planning a complex disassembly line in a reasonable time, and proposing a relatively optimal solution. The solution comprises division of work stations, arrangement of tasks in the work stations and beats of the assembly line. According to the invention, under the premise of meeting precedence relations and beats constraints, five aspects of the assembly line are collaboratively considered: (1) minimizing number of work stations, that is, minimizing total idle time; (2) equalizing the idle time of each work station as much as possible, that is, balancing time of each work station; (3) removing harmful parts as soon as possible; (4) removing high demand parts as soon as possible; and (5) minimizing change of disassembly direction. The method is close to disassembly environment in actual production, and therefore, the balance design planning and reasonable control of the disassembly line are realized, thereby improving the efficiency of the disassembling line, and optimizing conditions of an actual production and manufacturing system. The method can be applied to modeling and analyzing software of a manufacturing system, management and control module of a computer integrated manufacturing system and actual control.

Owner:SOUTHWEST JIAOTONG UNIV

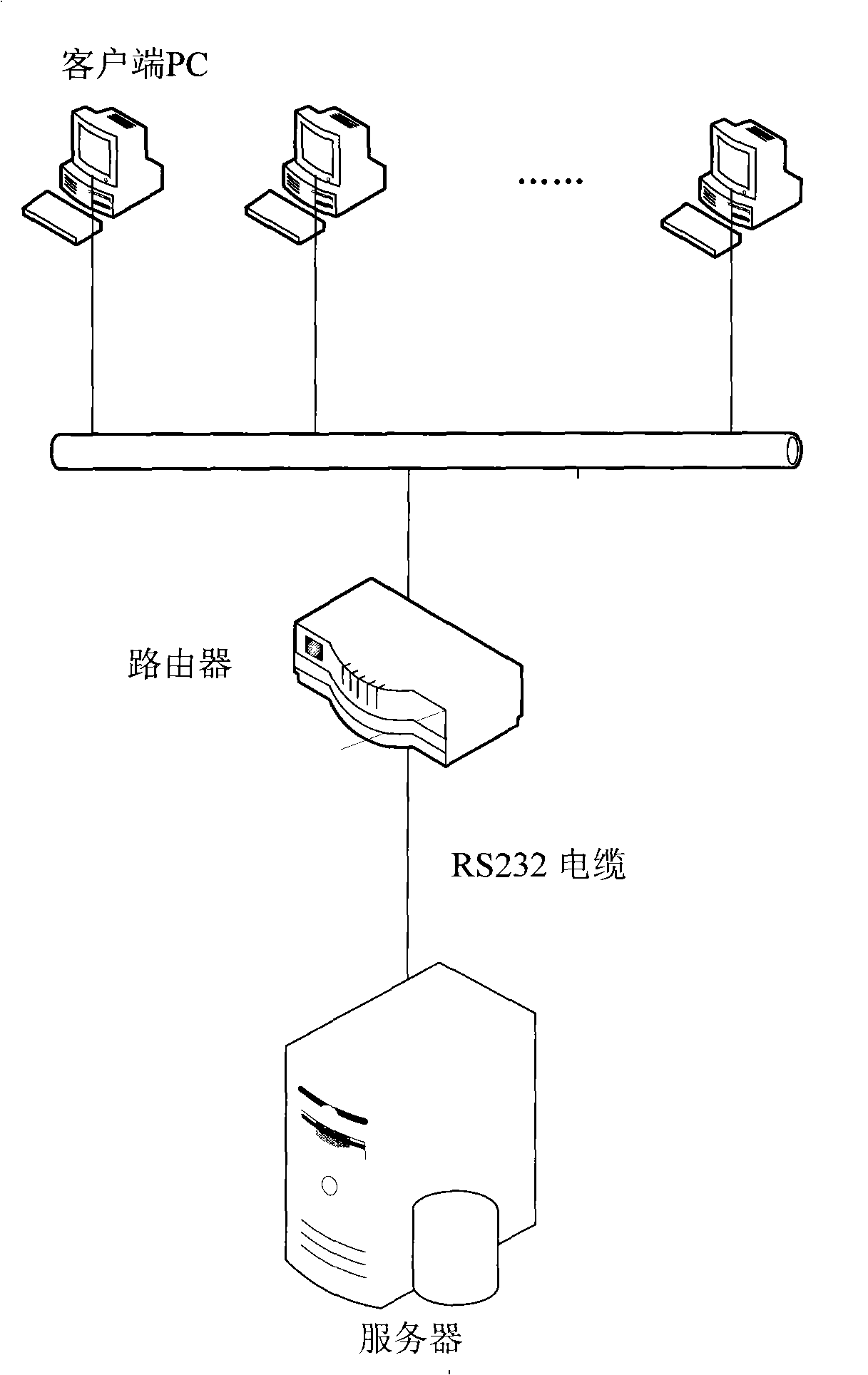

Steel-making manufacturing execution management system based on visualized heat tracking

InactiveCN103116822AClear understanding of on-site production situationQuality improvementElectrical energyResourcesApplication serverDatabase server

The invention discloses a steel-making manufacturing execution management system based on visualized heat tracking. The system is used for connecting a production and marketing system and a workshop in-situ control and comprises a heat tracking platform, an application server, a database server and a client end. By means of the steel-making manufacturing execution management system, molten steel condition of each heat can be tracked, and the system has the advantages that information integration is high, data analysis ability is strong, process trace feedback is timely and clear and the like. The system can be a link for enterprise computer integrated manufacturing system (CIMS) information integration, and therefore a manufacturing business environment which is fast in response and flexible and refined can be provided for a user, the user is helped to lower cost, deliver goods on time, improve product quality and service quality.

Owner:HUNAN STEERING SCI & TECH DEV

Balancing control method for single-sided assembly line

InactiveCN102566423ASolve balance problemsSolve control problemsAdaptive controlComputer-integrated manufacturingSystems management

The invention discloses a balancing control method for a single-sided assembly line. Production conditions are optimally controlled on the single-sided assembly line which has a first kind of balancing problems to balance loads of each station, and a reasonable and optimal scheme is provided for the complicated problems about planning and improvement of a production line within reasonable time. The scheme comprises dividing of work stations, arrangement of tasks in the work stations and computation of a cycle of the production line. The method has the advantages that: on the premise that the cycle of an assembly line is set, the number of the work stations is decreased, and the balance rate of the assembly line is optimized; by taking an assembly line balance rate index as an optimization target, the problems about balancing design planning and reasonable control of the assembly line can be effectively solved; and the method can be applied to manufacturing system modeling and analysis software, a computer integrated manufacturing system management and control module and an actual control module.

Owner:SOUTHWEST JIAOTONG UNIV

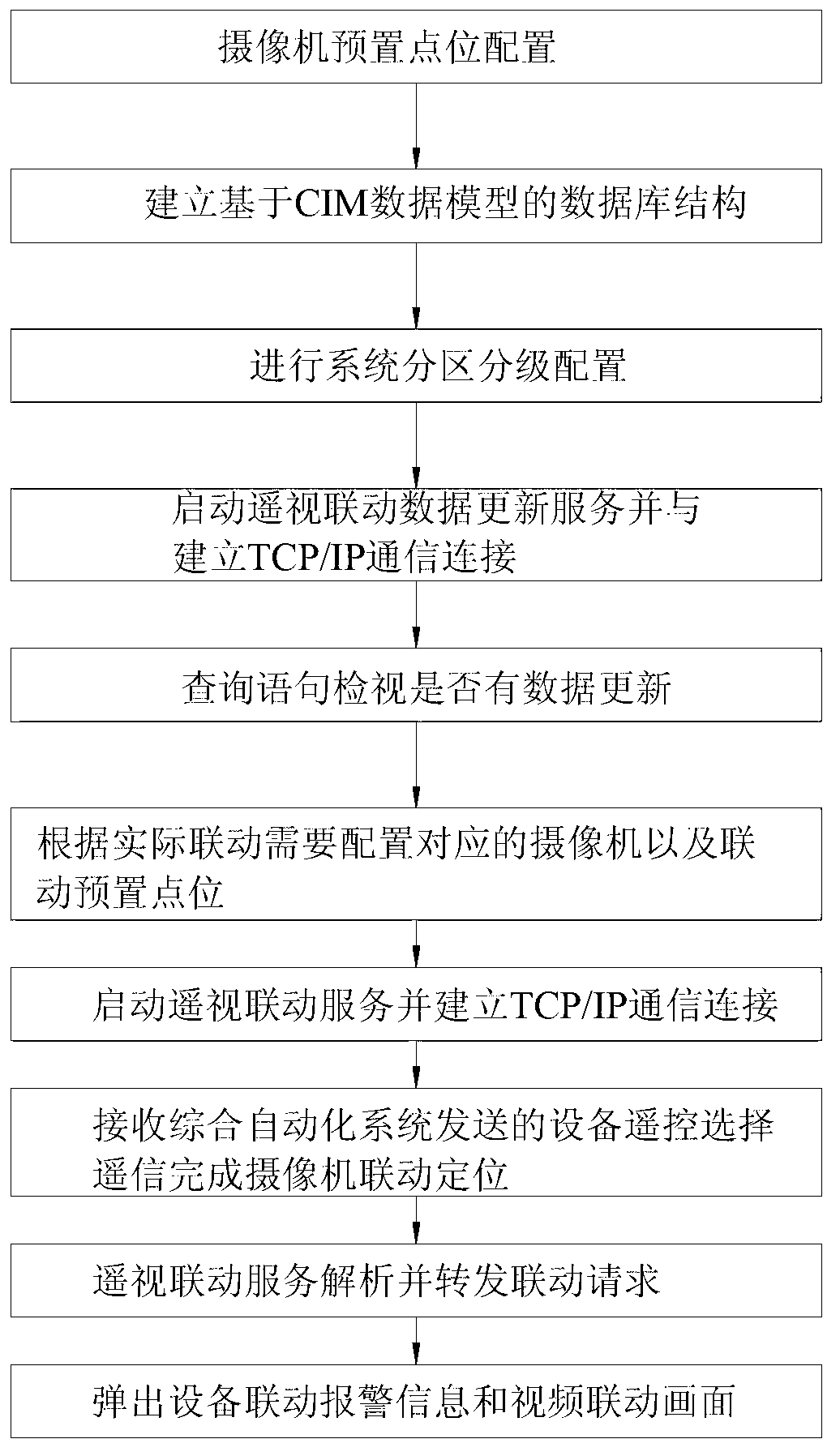

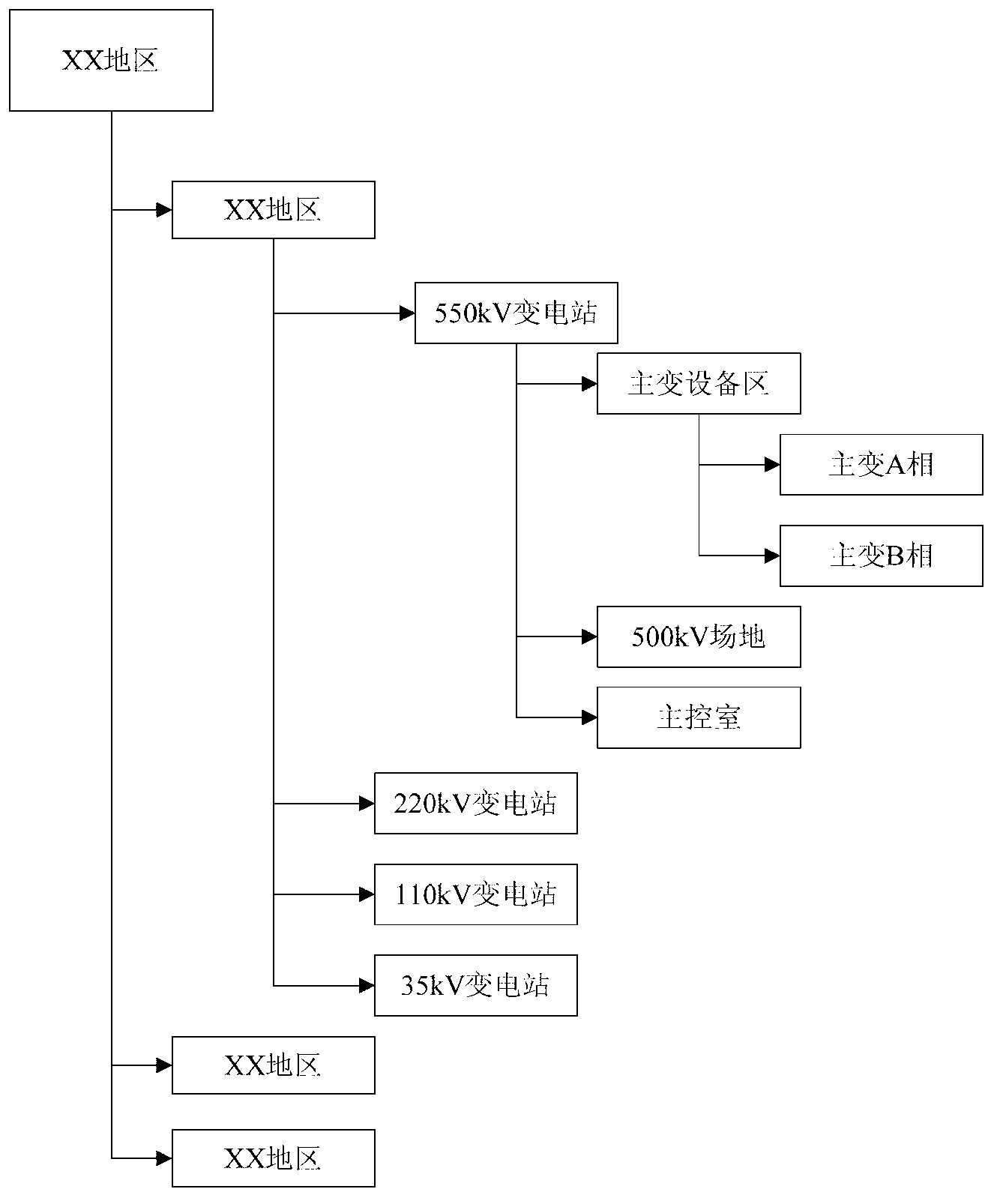

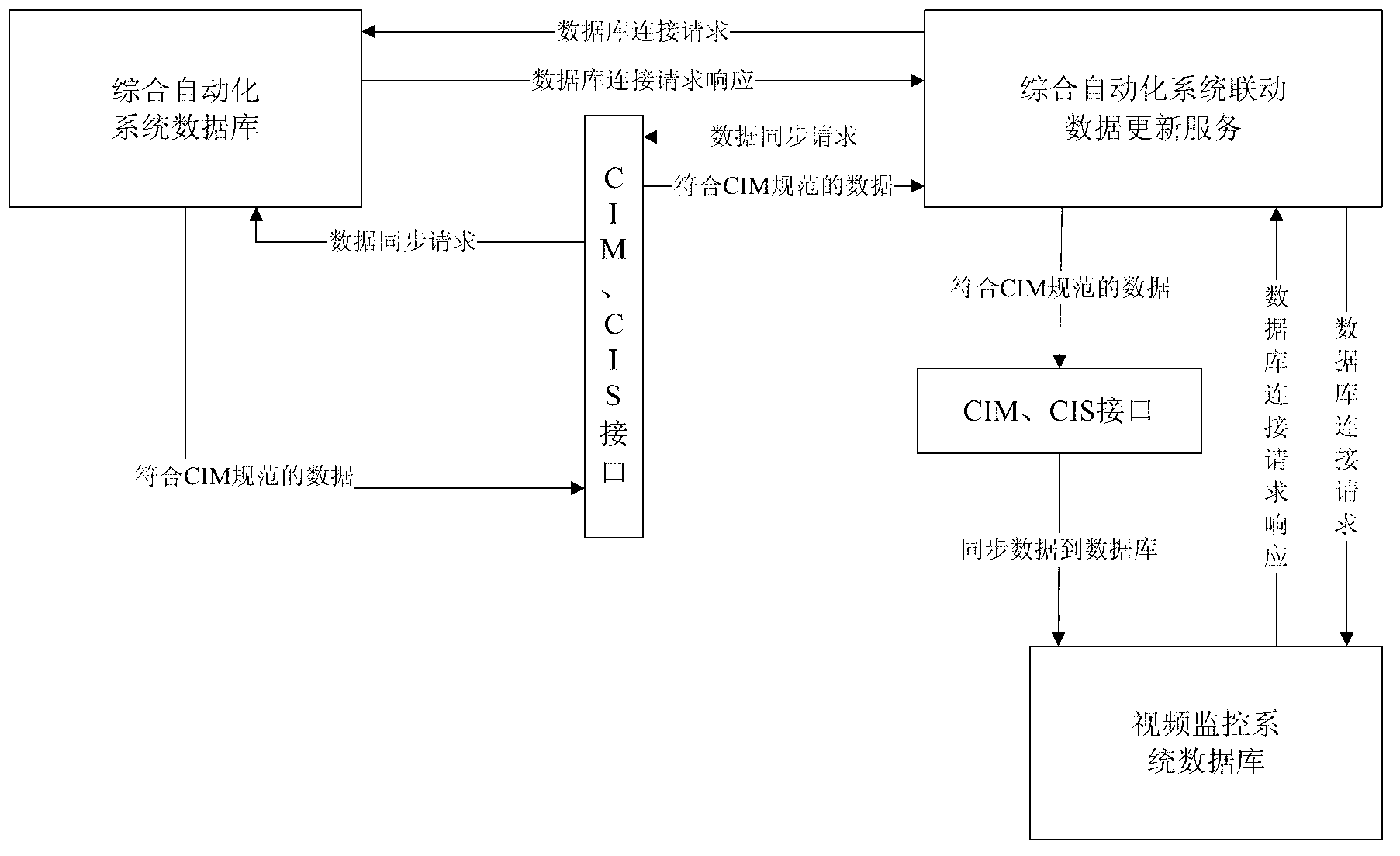

Remote vision linkage method for electric power master station and substation based on computer integrated manufacturing (CIM) data model

ActiveCN103023147AEasy to manageAvoid Operation InterferenceCircuit arrangementsClosed circuit television systemsVideo monitoringComputer-integrated manufacturing

The invention relates to the technical field of intelligent power grids, in particular to a remote vision linkage method for an electric power master station and a substation based on a computer integrated manufacturing (CIM) data model. The remote vision linkage method includes: arranging a preset point position of a camera, building a data base structure based on the CIM data model, conducting system subarea classification configuration, starting remote vision linkage data updating service, building transmission control protocol (TCP) / internet protocol (IP) communication connection, inquiring whether statement inspection has data updating, arranging a corresponding camera and a linkage preset point position according to actual linkage requirements, starting remote vision linkage service and building TCP / IP communication connection, receiving device remote control selecting telecommand sent by a comprehensive automatic system, finishing camera linkage locating, analyzing remote vision linkage service, forwarding a linkage request, and popping out device linkage alarming information and a video linkage image. By means of the method, a traditional operation method that a video monitoring system is independent from the comprehensive automatic system is thoroughly changed, and users can use a video image resource to assist safety production operation of the substation from the electric scheduling special perspective.

Owner:YIBIN POWER SUPPLY COMPANY STATE GRID SICHUAN ELECTRIC POWER +1

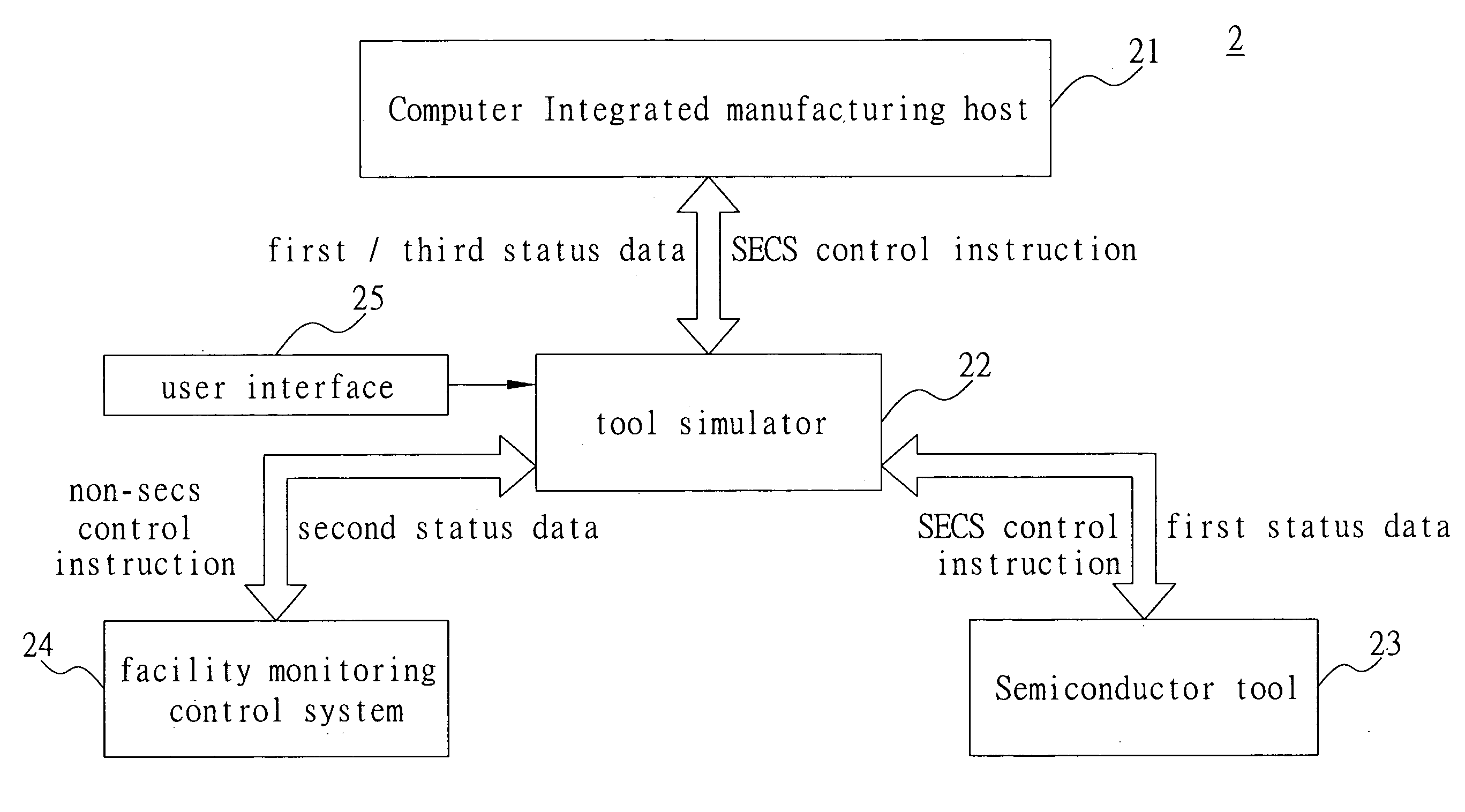

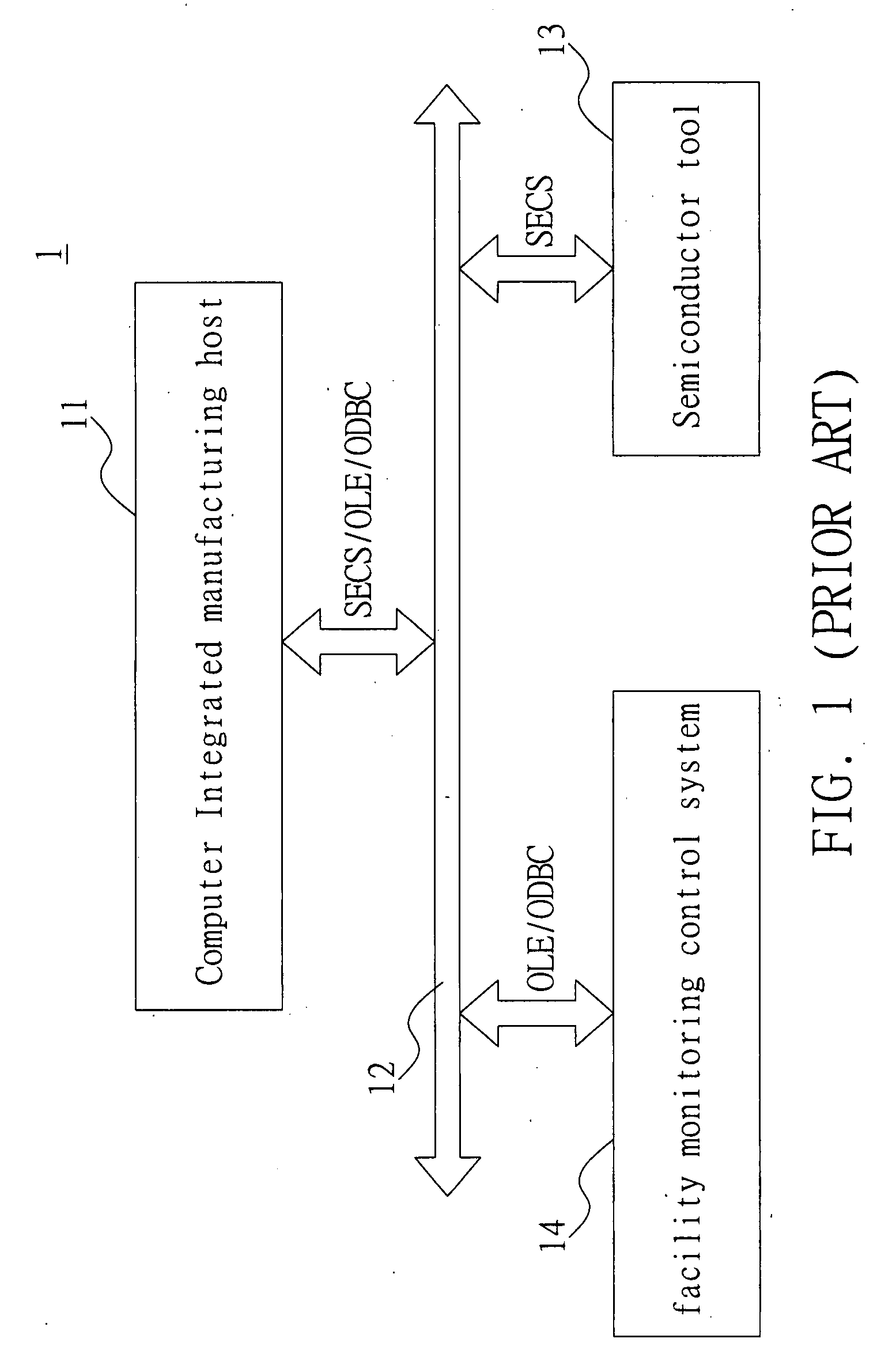

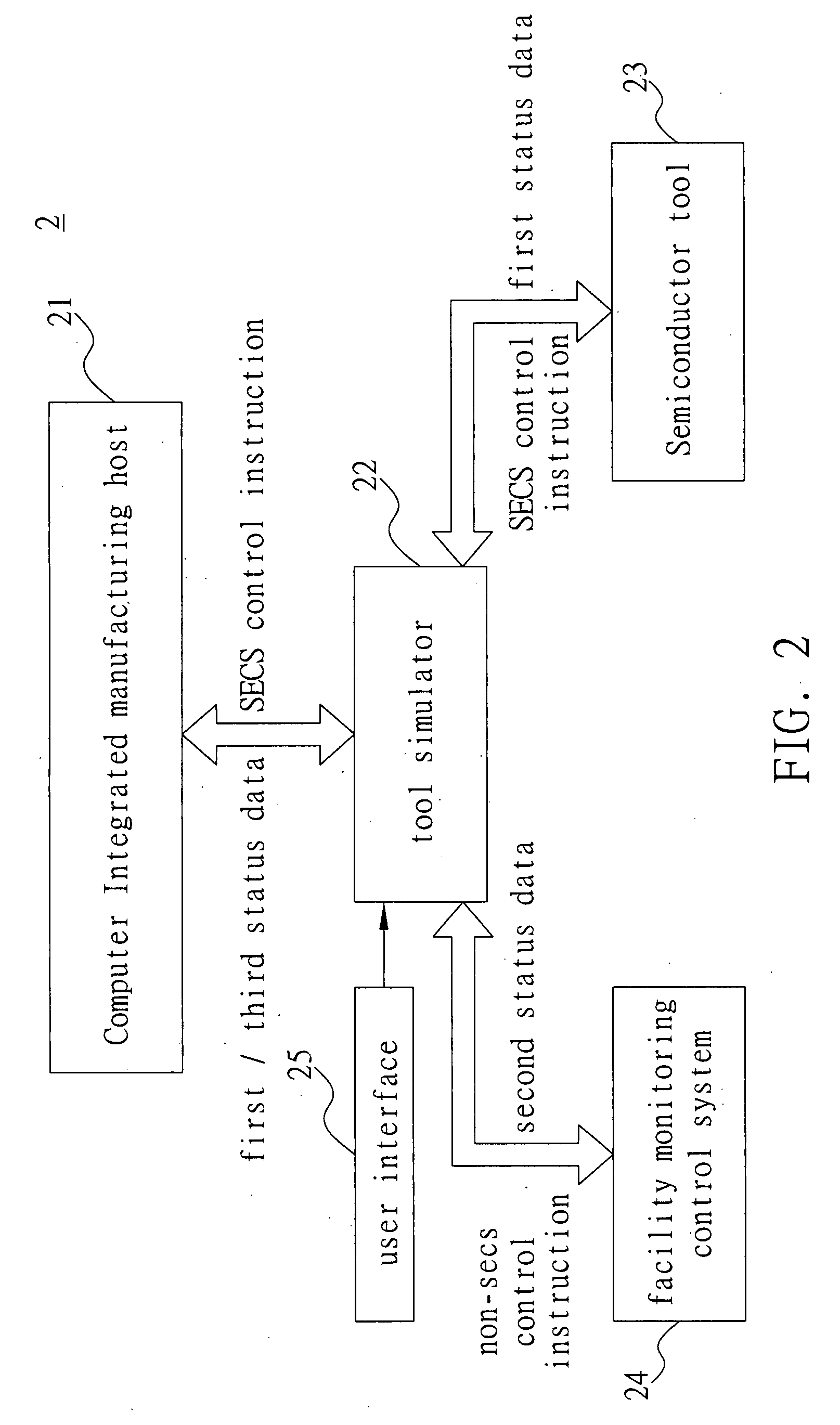

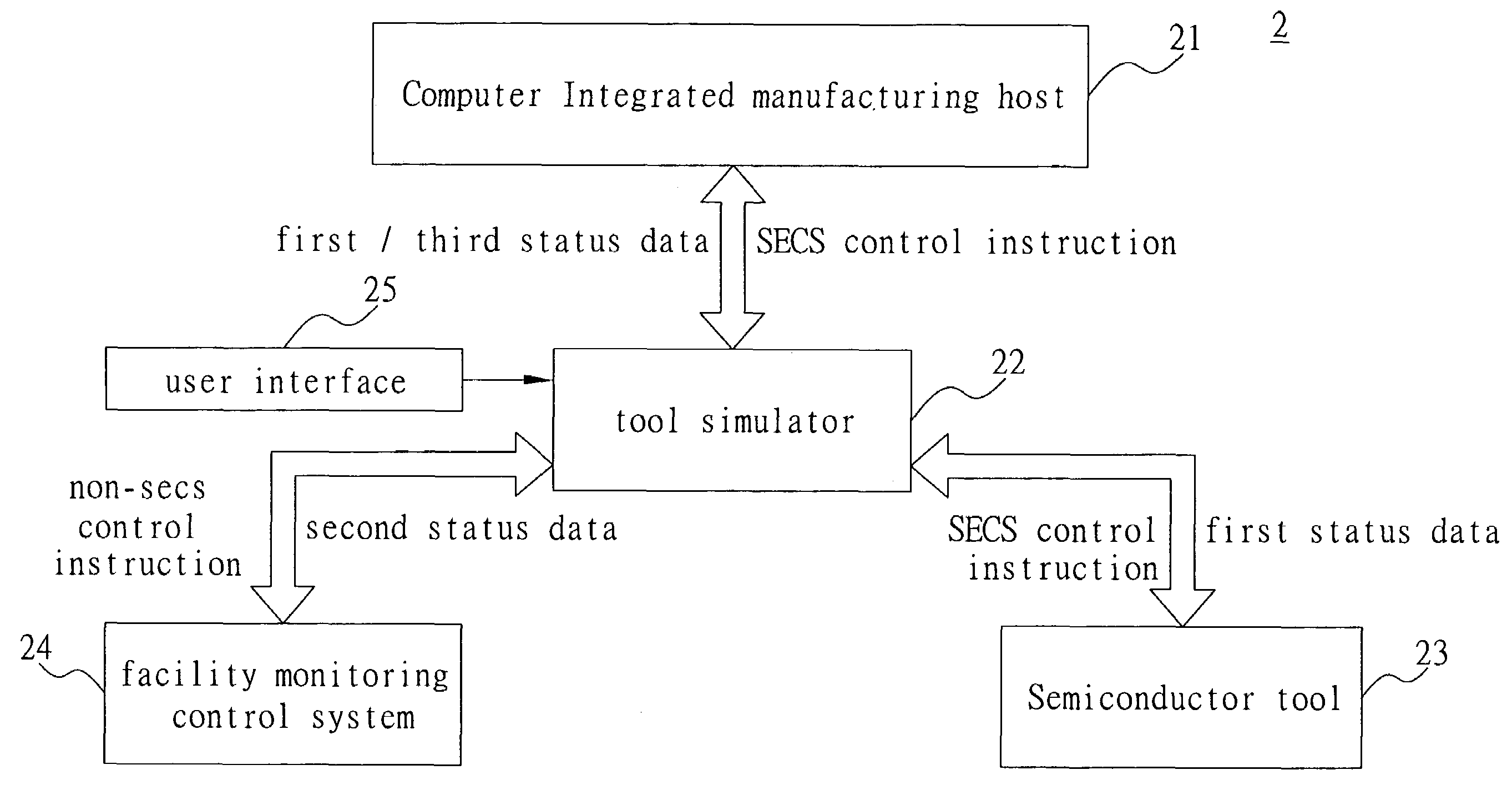

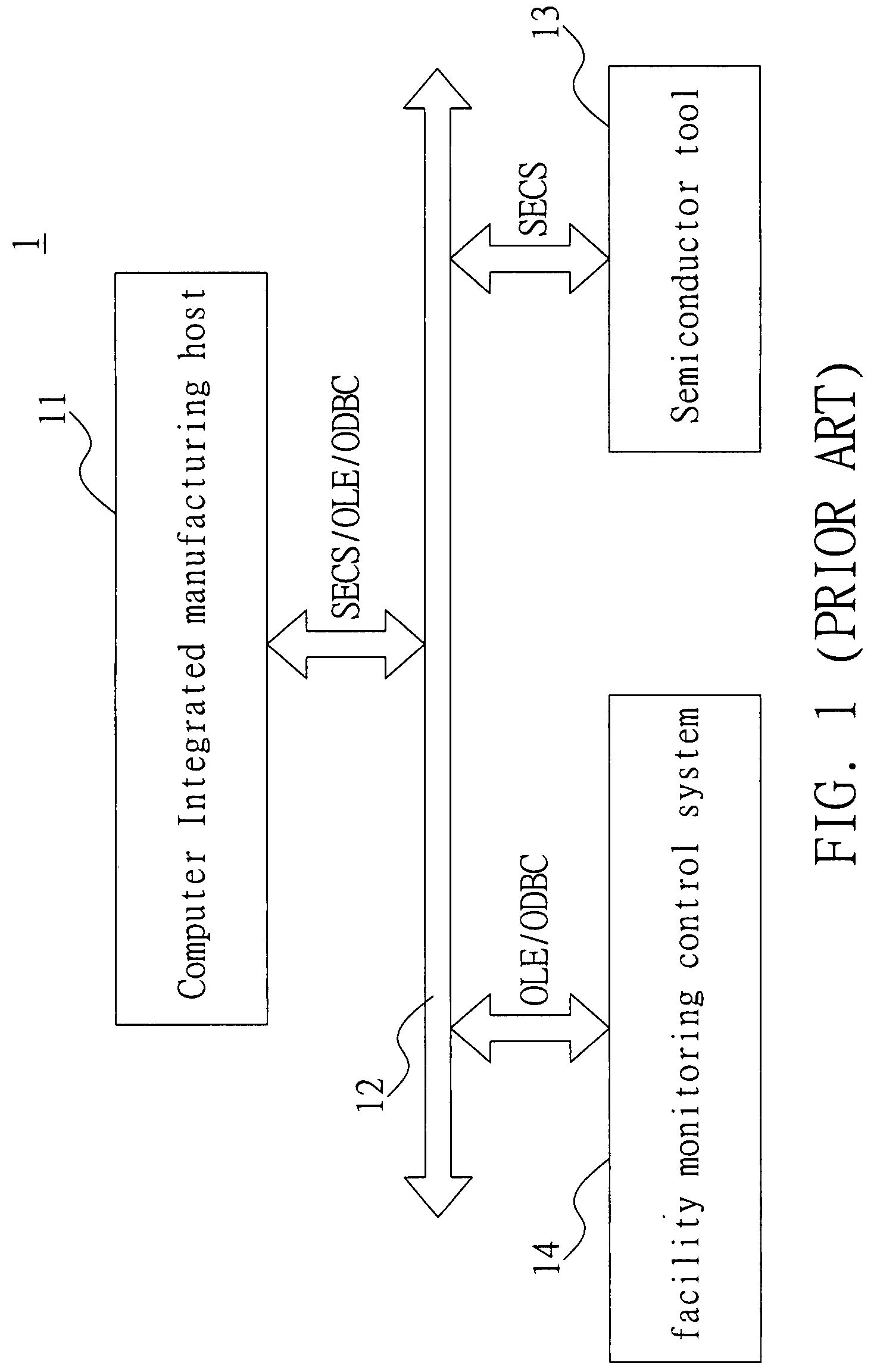

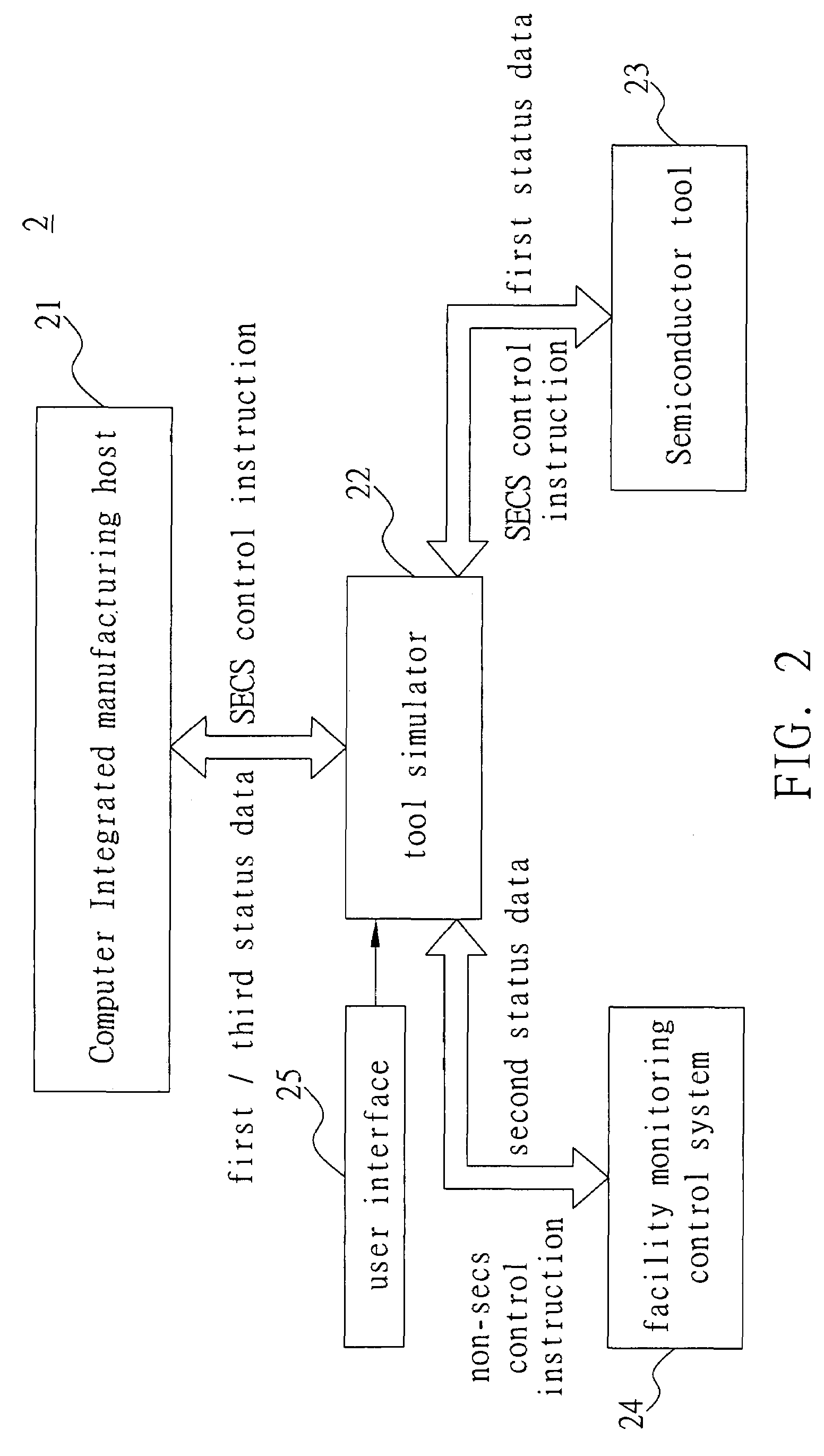

Real-time fault detection and classification system in use with a semiconductor fabrication process

ActiveUS20080154421A1Improve production yieldProgramme controlDigital computer detailsComputer-integrated manufacturingHealth condition

A real-time fault detection and classification (FDC) system, which is in use with a semiconductor fabrication process having a first sub-fabrication process and a second sub-fabrication process, includes a computer integrated manufacturing (CIM) host adopting a SEMI equipment communication standard (SECS), a semiconductor tool for executing the first sub-fabrication process and generating first status data in conformity with the SECS, a non-semiconductor tool for executing the second sub-fabrication process and generating second status data in conformity with a predetermined connectivity standard different from the SECS, and a tool simulator connecting the tool simulator with the semiconductor tool and the non-semiconductor tool for receiving the first and second status data and transforming the second status data into third status data in conformity with the SECS such that the CIM host can classify the first and third status data according to a predetermined classification technique and get a control over equipment health conditions of the semiconductor tool as well as the non-semiconductor tool.

Owner:IND TECH RES INST

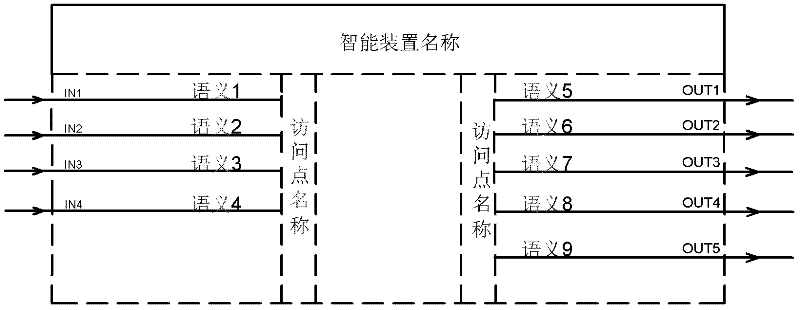

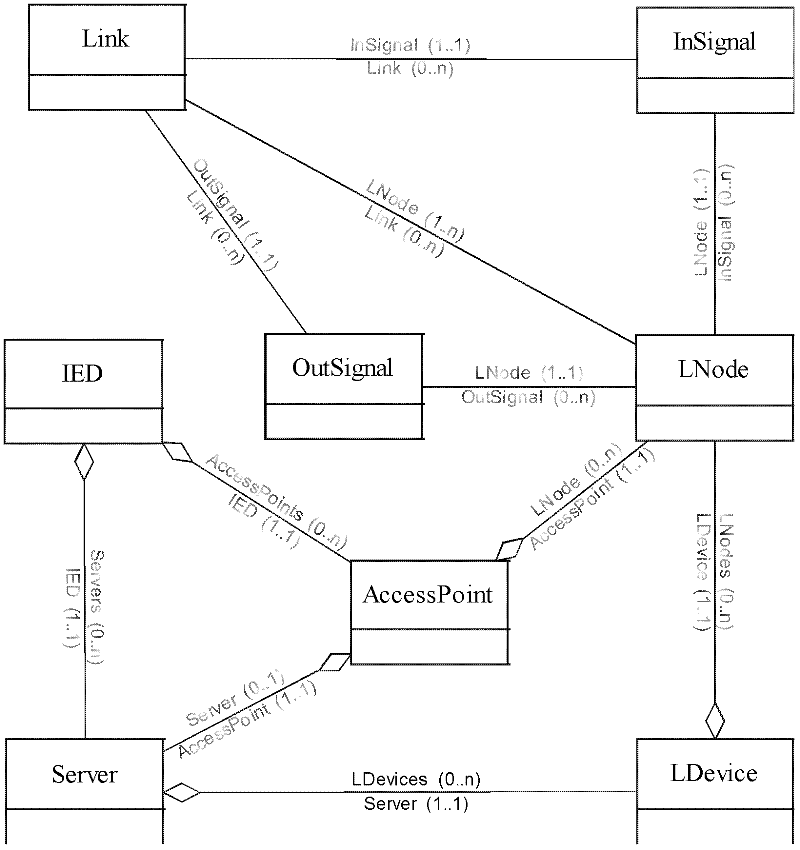

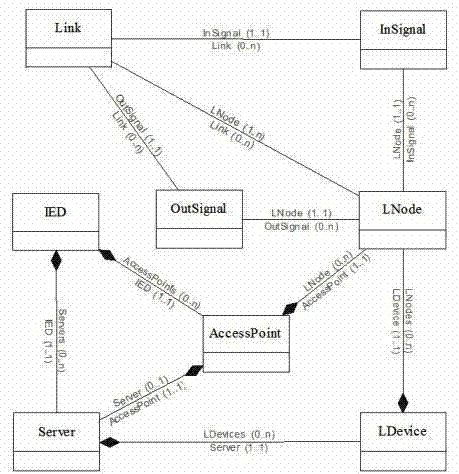

Graphical and rdf model building method for smart substation design

ActiveCN102262703AProcess stabilityGuide the construction wellSpecial data processing applicationsVirtual terminalGraphics

The invention provides a method for constructing a figure and an RDF (Radio Direction Finder) model for designing an intelligent transformer substation. The method provided by the invention comprises the following steps of: utilizing the RDF to describe an IEC61850 model through utilizing the same form of an IEC61970CIM (Computer Integrated Manufacturing) to obtain an RDFSchema of the IEC61850 model for assuring the structure of the IEC61850 model object. The structure of the IEC61850 model object comprises model types, mode type attributes and incidence relations between the model types. By utilizing the method to design model types of the intelligent device and virtual terminals and a design tool of a graphics primitive development secondary system, the engineering design of the secondary system of the intelligent transformer substation can go deep into a logical layer so that an interoperable relation of logical functions can be described by means of imaging and the design assignment of the intelligent transformer substation can be smoothly processed. The model of a primary system is described by utilizing the IEC61970-CIM model so that the compatibility and the interoperability between the model and the primary system model data utilized by a dispatching mechanism can be realized.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

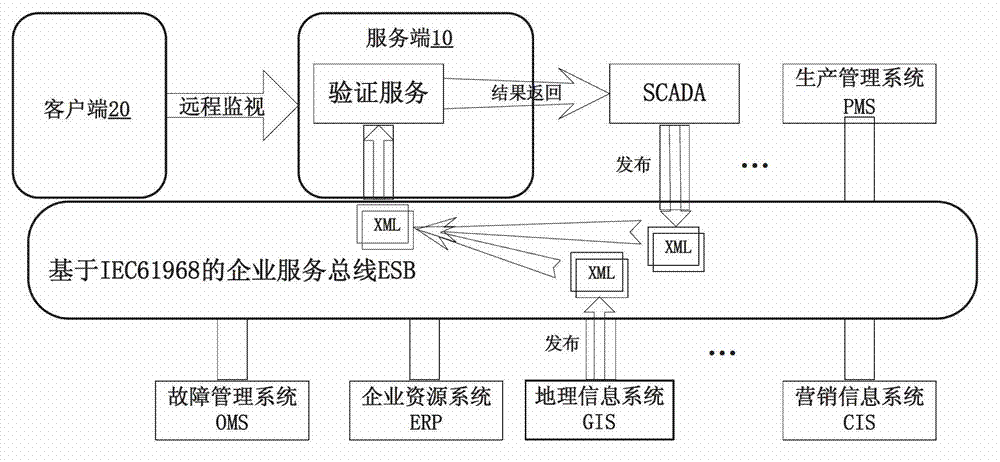

Online information verification system based on international electrotechnical commission (IEC) 61968 enterprise service bus (ESB)

ActiveCN103078920AConvenient intercommunicationSolve information silosBus networksWeb serviceComputer-integrated manufacturing

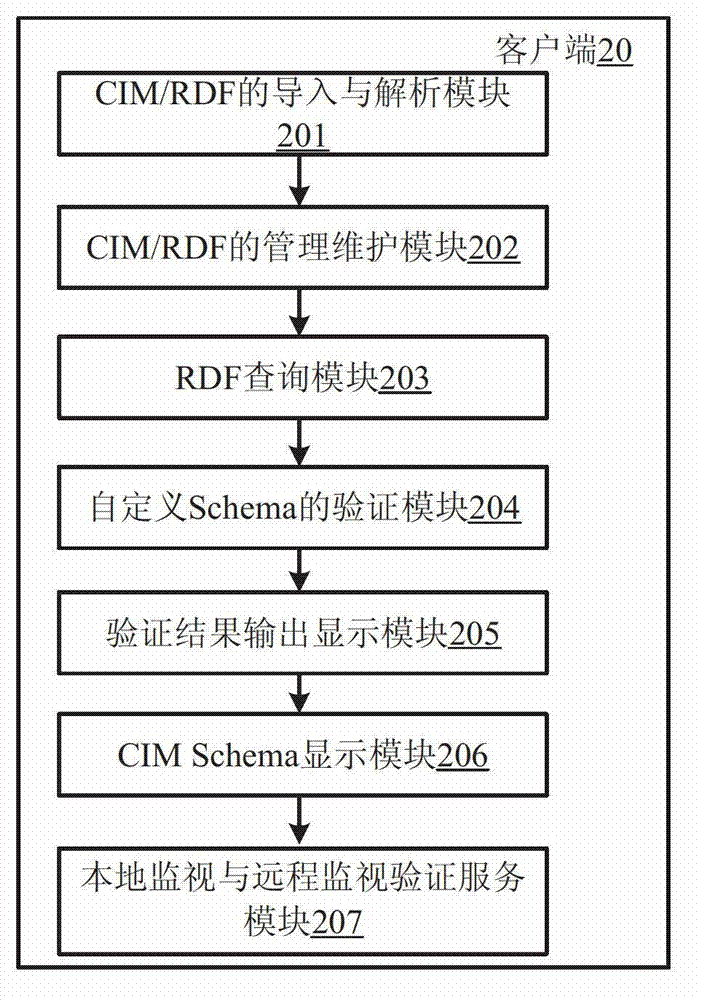

The invention discloses an online information verification system based on an international electrotechnical commission (IEC) 61968 enterprise service bus (ESB). The system comprises a client and a server, wherein the server is arranged on the ESB on basis of a Web Services technology, and is used for receiving extensible markup language (XML) information which is sent from the ESB for checking, extracting the data loaded in an XML information body, providing consistent online verification with standard information for the ESB and feeding a checking result back; and the client comprises a computer integrated manufacturing (CIM) / radio description framework (RDF) leading-in and analyzing module, an RDF management and maintenance module, an RDF query module, a custom Schema verification module, a verification result output and display module, a CIM Schema display module and a local monitoring and remote monitoring verification service module. The system is used for solving the information standard defects of the current power ESBs, and a bus verification mechanism is provided.

Owner:STATE GRID CORP OF CHINA +1

Dynamically adjusting the distribution for dispatching lot between current and downstream tool by using expertise weighting mechanism

InactiveUS20050113955A1Computer controlSimulator controlComputer-integrated manufacturingOrder entry

A system and method that prioritizes product lots for fabrication and dispatching to manufacturing equipment establishes priorities for dispatching product lots based on a criticality factor and establishes a priority for dispatching product lots to manufacturing equipment based on processing capability and the efficiency of manufacturing equipment. A computer integrated manufacturing system executes a program process that functions as a lot dispatcher and a priority factor calculator. The lot dispatcher is in communication with an order entry system to receive requests for fabrication and with a process information system to receive procedures defining which manufacturing equipment is required. A manufacturing information system provides the lot dispatcher with a criticality factor and a queue level for each piece of manufacturing equipment. Then the current group of pieces of manufacturing equipment is followed with a balanced loading.

Owner:TAIWAN SEMICON MFG CO LTD

Real-time fault detection and classification system in use with a semiconductor fabrication process

ActiveUS7640070B2Improve production yieldProgramme controlDigital computer detailsComputer-integrated manufacturingHealth condition

Owner:IND TECH RES INST

Three-dimensional visualized process design system and its design method

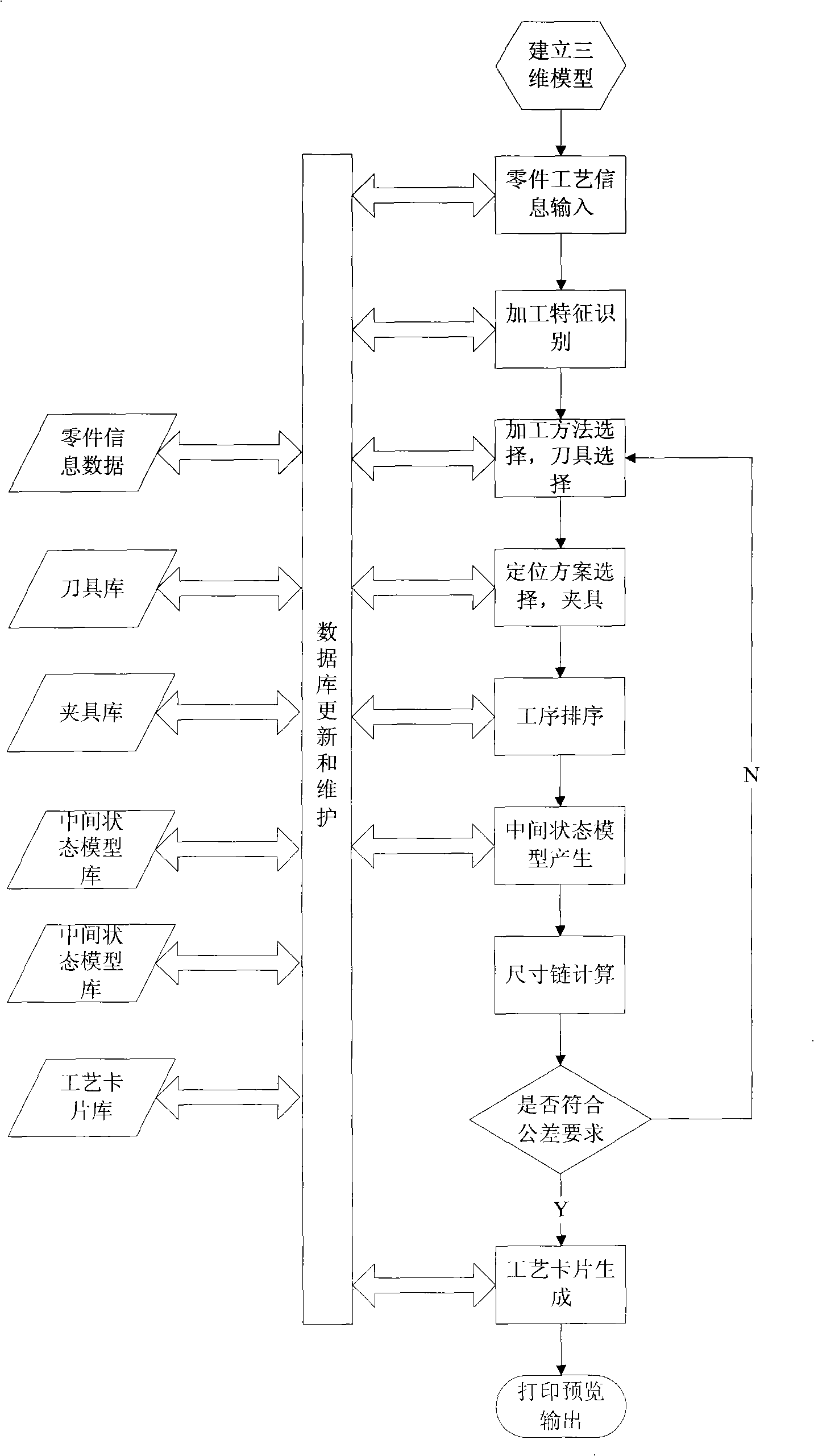

InactiveCN101339575BConvenience and intelligenceImprove intelligenceSpecial data processing applicationsComputer-integrated manufacturingIntermediate state

The invention relates to a three-dimension visualization process design system and a design method thereof, belonging to the computer integrated manufacturing field. In the invention, a three-dimension model is built on the supporting platform of a design system CAD, and other models carry out process design by taking the CAD system as a support and the three-dimension model as a basis; the features of the three-dimension model are identified automatically or semi-automatically by a feature identification module; the determination of a processing chain, the design of a clamping scheme, and the selection of a cutter and a clamp are respectively finished according to the identified features by a processing method selecting and positioning scheme design module; the sequencing of the processing features is finished by process sequencing; the generation of an intermediate state model leads the process design to be imagery and visual; the calibration of tolerance is finished by a process dimension calculation module; and various process cards which meet the requirements are output by a process card management module. The system and the method of the invention have the advantages of visual process design, good intelligence, high efficiency, and good quality, etc.

Owner:SHANGHAI JIAO TONG UNIV

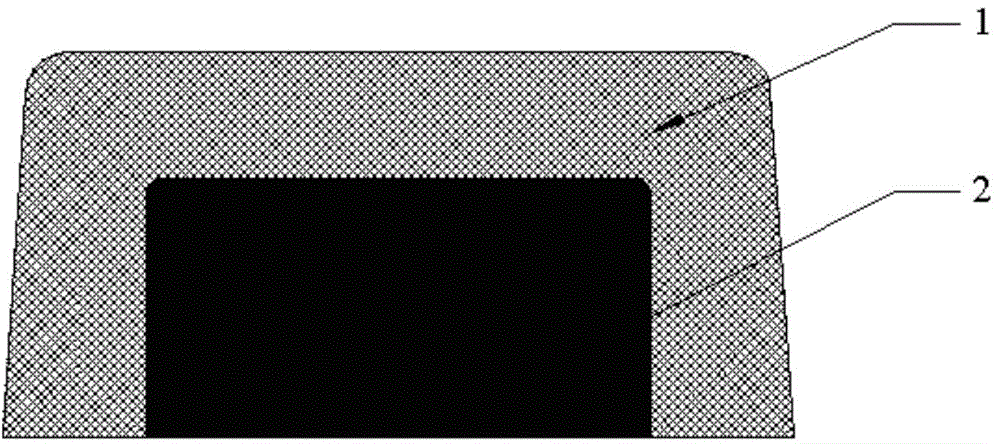

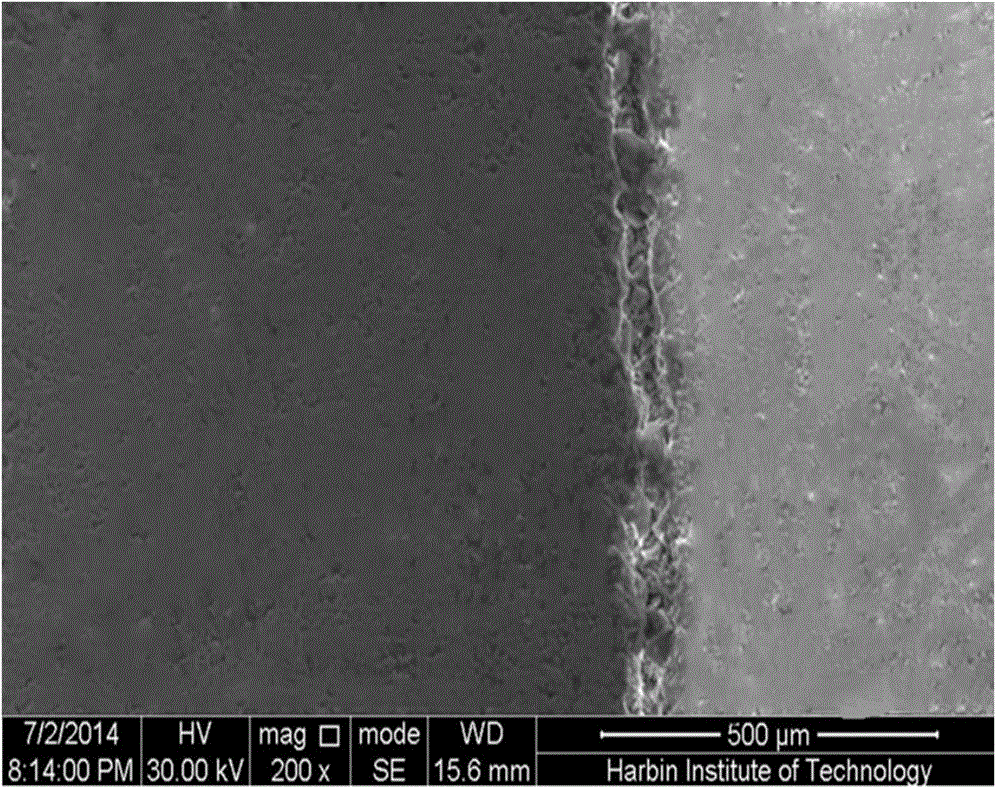

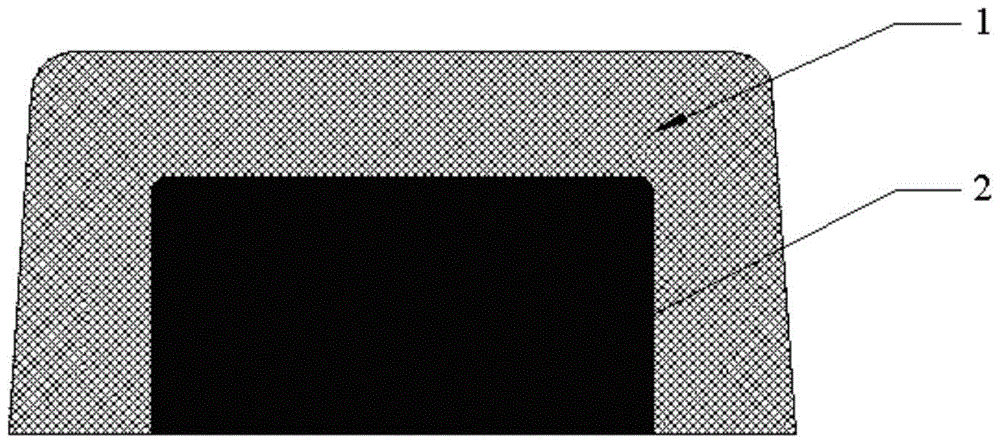

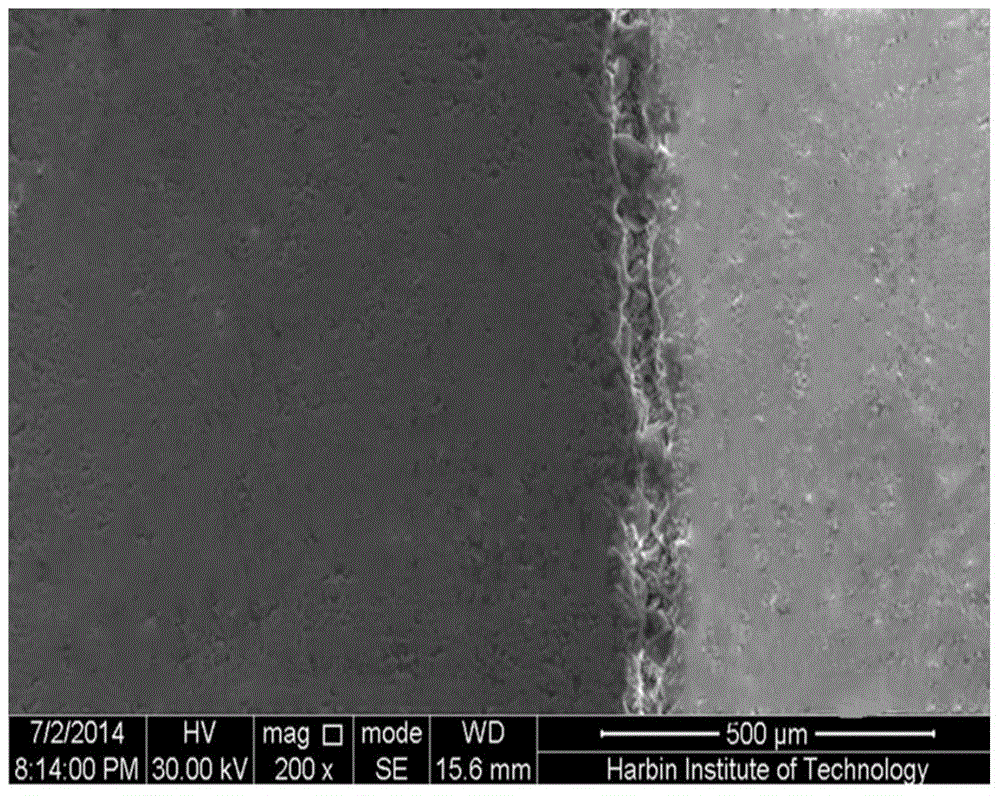

CIM (Computer Integrated Manufacturing)-process-based hot-work die steel material surface modification method

ActiveCN104550837AHigh strengthHigh wear resistance and high temperature resistanceComputer-integrated manufacturingBond strength

The invention discloses a CIM (Computer Integrated Manufacturing)-process-based hot-work die steel material surface modification method, relates to a hot-work die steel material surface modification method, and aims to solve the problem that a ceramic / hot-work die steel composite die prepared by a conventional hot-work die steel material surface modification method is low in bonding strength, maladaptive to the long-time continuous thermal shock and thermal corrosion of molten or semi-solid metal to the die in an extrusion casting process, short in service life and high in cost. The method comprises the following steps of 1, modifying Y2O3-stable zirconium oxide powder; 2, performing mixing; 3, performing injection molding; 4, performing degreasing and sintering to obtain a zirconium oxide ceramic / hot-work die steel composite die. The thickness of zirconium oxide ceramic in the obtained zirconium oxide ceramic / hot-work die steel composite die is 10 to 15mm, and the shear strength of the connection interface can reach 68 to 70MPa. The CIM-process-based hot-work die steel material surface modification method can be implemented.

Owner:HARBIN INST OF TECH

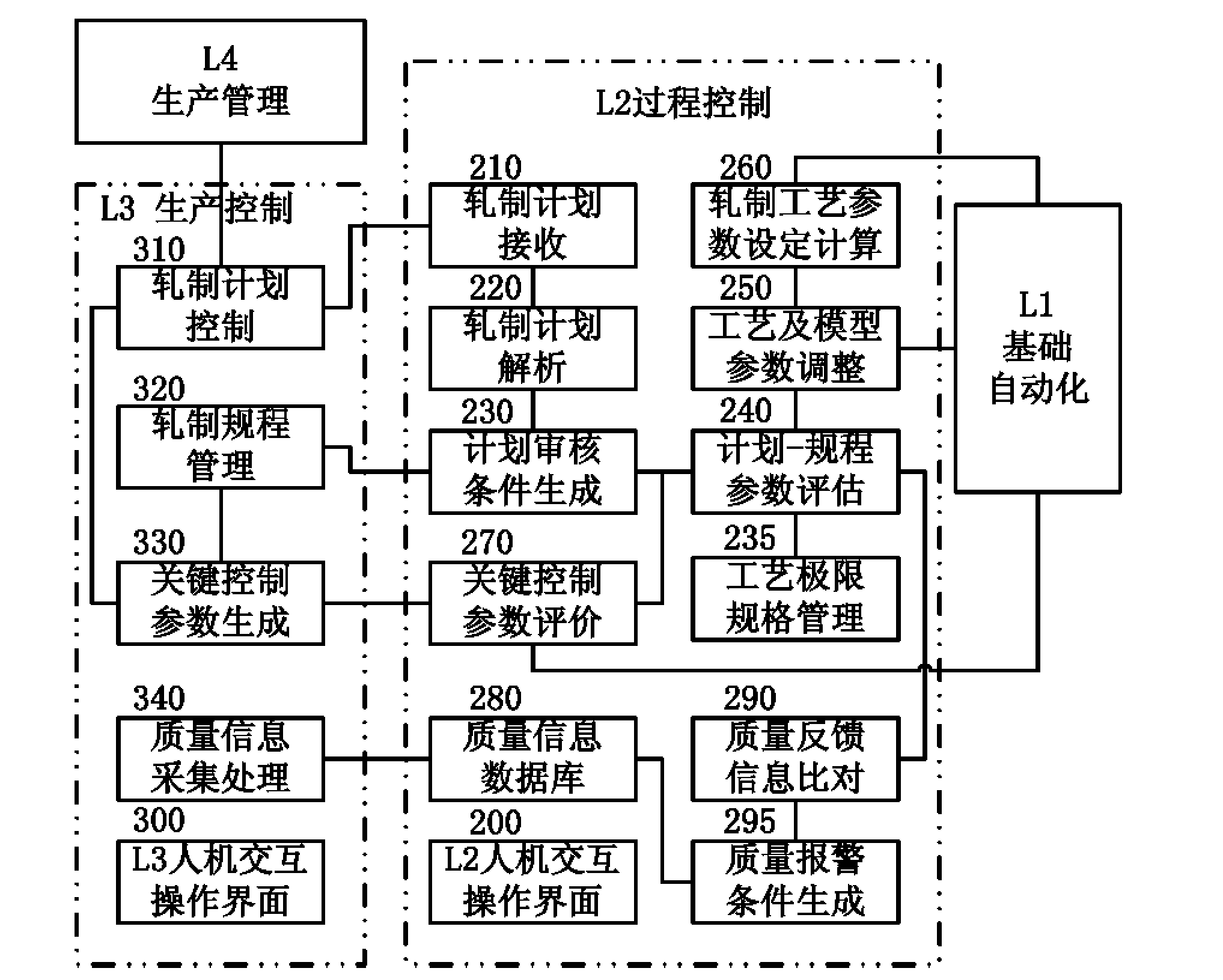

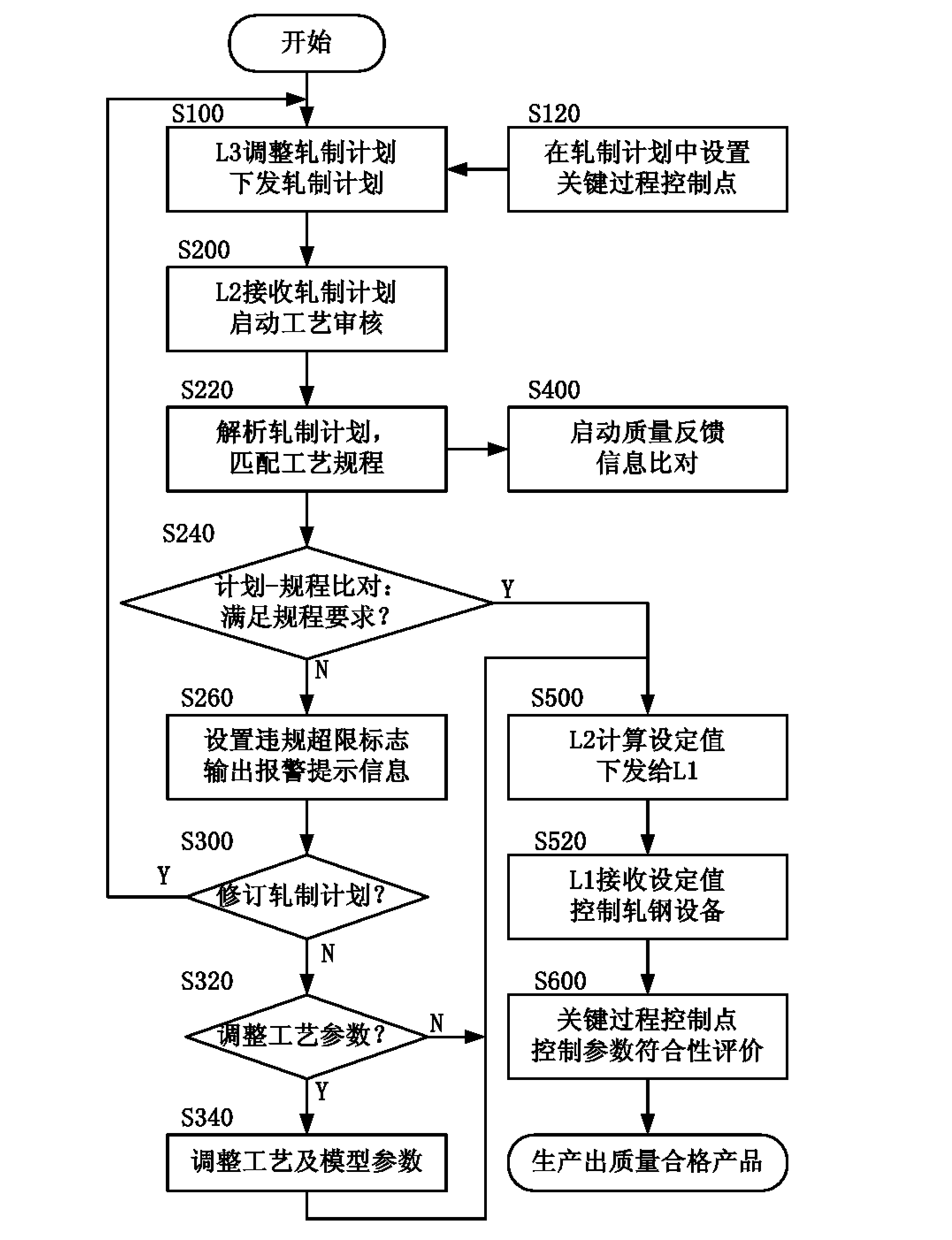

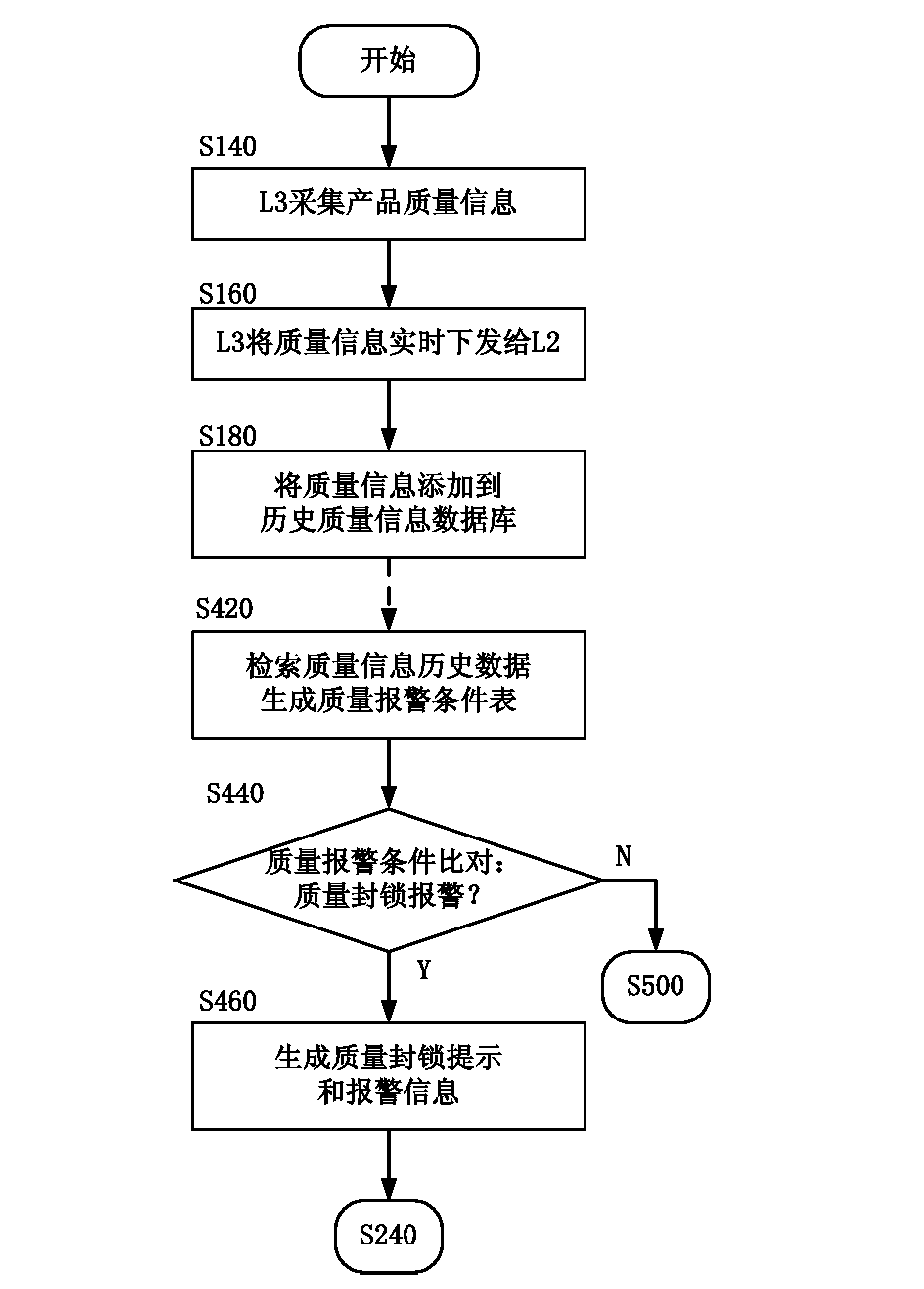

Online rolling plan dynamic pre-analysis and self-adjustment system and method

ActiveCN102591286BFully automatedImprove review efficiencyTotal factory controlProgramme total factory controlComputer-integrated manufacturingModel parameters

The invention relates to CIM (Computer Integrated Manufacturing) applicable for overall factory control and discloses an online rolling plan dynamic pre-analysis and self-adjustment system and method having quality information feedback. The online rolling plan dynamic pre-analysis and self-adjustment system comprises a rolling plan analysis module, a plan review condition generation module and a plan-regulation parameter evaluation module, wherein a rolling regulation management module and the rolling plan analysis module are connected to the plan-regulation parameter evaluation module through the plan review condition generation module; and the e plan-regulation parameter evaluation module is connected to a rolling technical parameter setting and calculating module through a technology and model parameter adjustment module. The method comprises the steps of: analyzing the rolling plan; comparing the rolling plan with the rolling regulation; screening regulation items; generating a plan review condition table and setting a rule-breaking and limit-exceeding mark; and displaying limit specification of the technology and prompting and automatically adjusting technological parameters. According to the online rolling plan dynamic pre-analysis and self-adjustment system and method, disclosed by the invention, automatic plan review is realized, plan reviewing efficiency is improved and the problem that plan defects cannot be discovered in time and exactly due to missed detection and misjudgment of artificial review can be avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

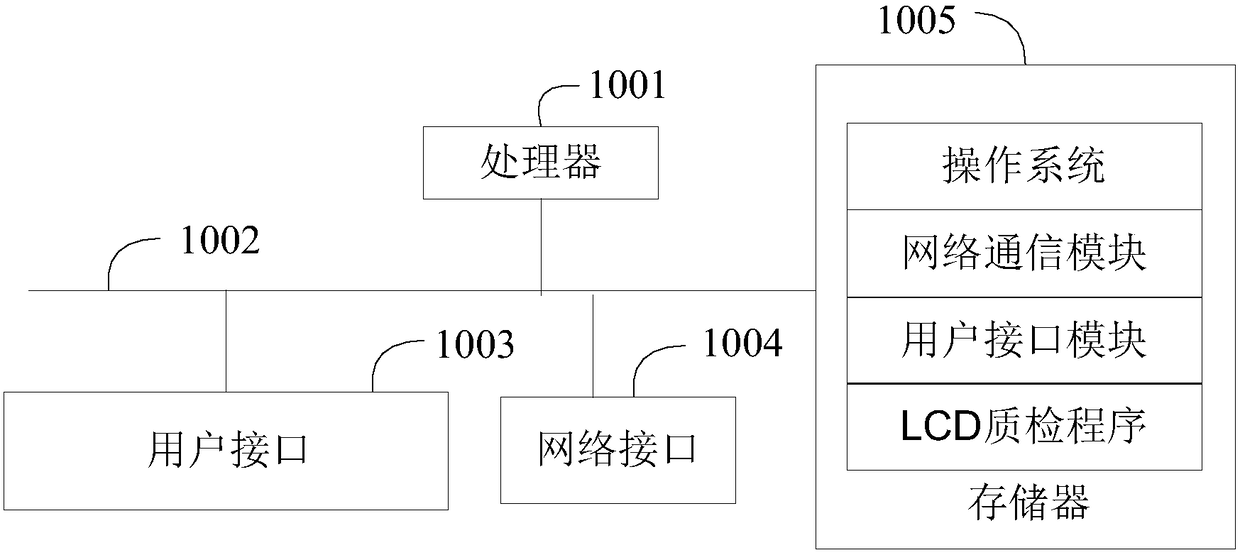

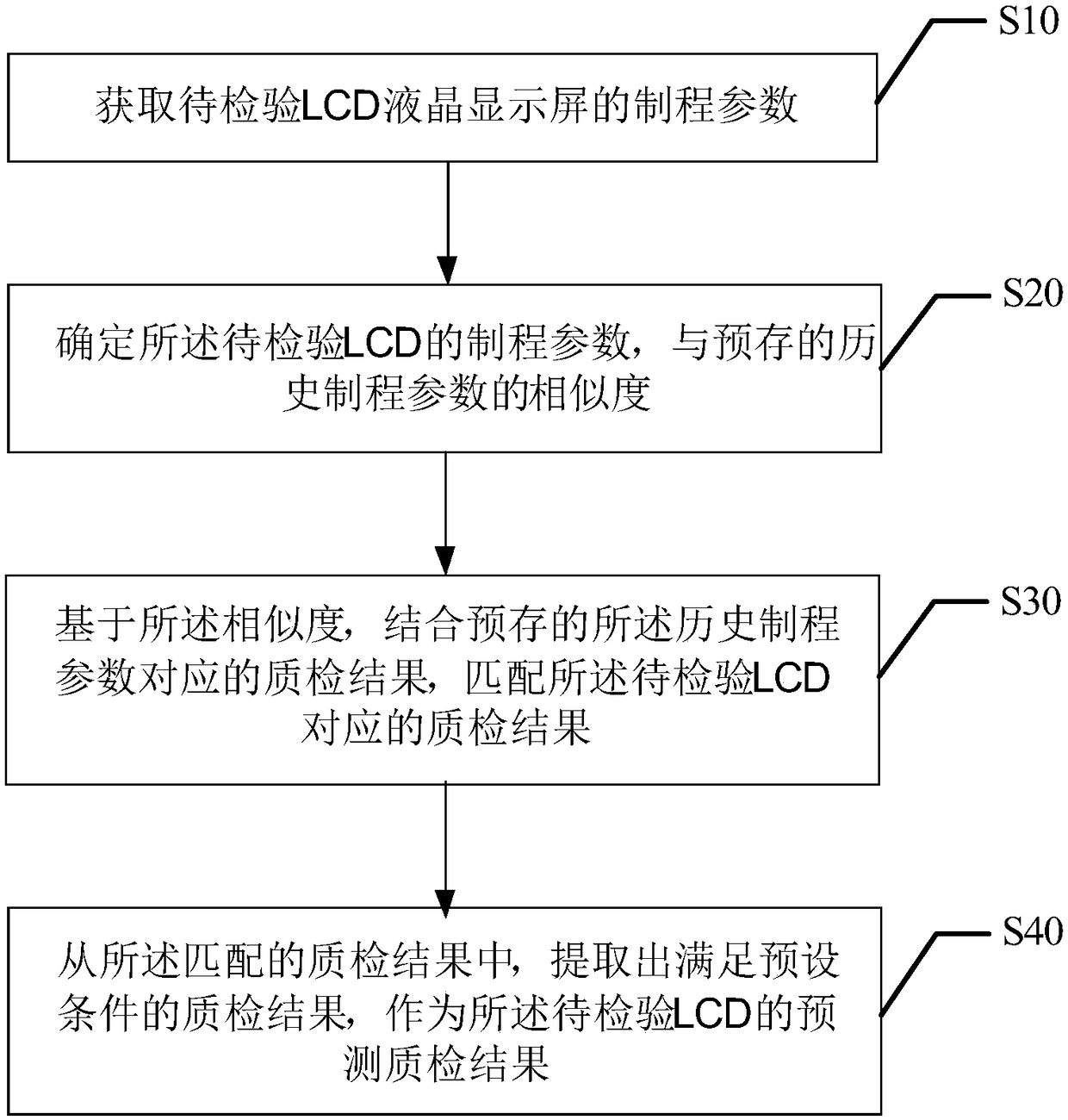

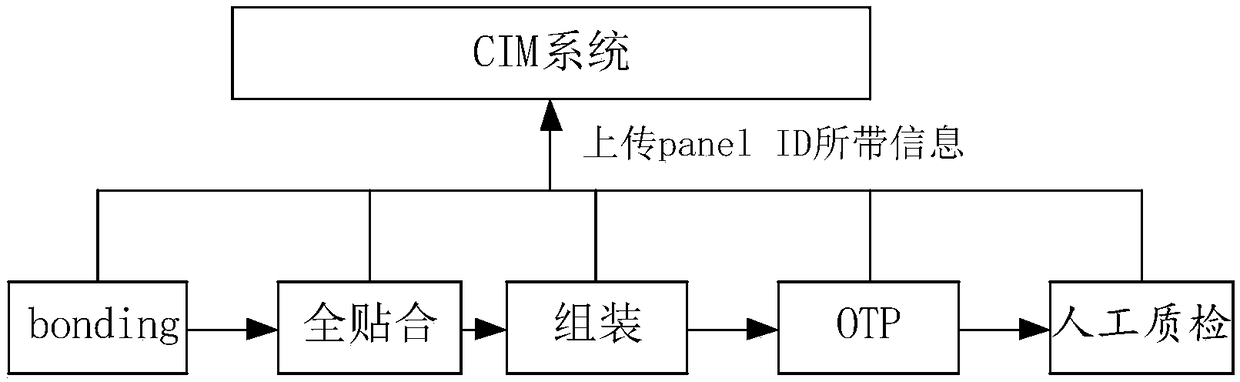

LCD (liquid crystal display) quality check method and device, CIM (computer integrated manufacturing) system and computer storage medium

ActiveCN108227250AImprove the detection rateReduce labor costsNon-linear opticsLiquid-crystal displayComputer-integrated manufacturing

The invention discloses an LCD quality check method, comprising: acquiring process parameters of an LCD under check; determining similarity between the process parameters of the LCD under check and historical process parameters that are pre-stored; matching quality check results corresponding to the LCD under check based on the similarity in conjunction with quality check results corresponding tothe historical process parameters that are prestored; extracting from the matched quality check results, quality check results meeting preset conditions to act as predictive quality check results forthe LCD under check. The invention also discloses an LCD quality check device, a CIM (computer integrated manufacturing) system and a computer storage medium. The LCD quality check method and device,the CIM system and the computer storage medium can save manpower and time costs, and can provide increased optical defect detection rate for LCD products and reduced misjudgment upon an optical defect.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

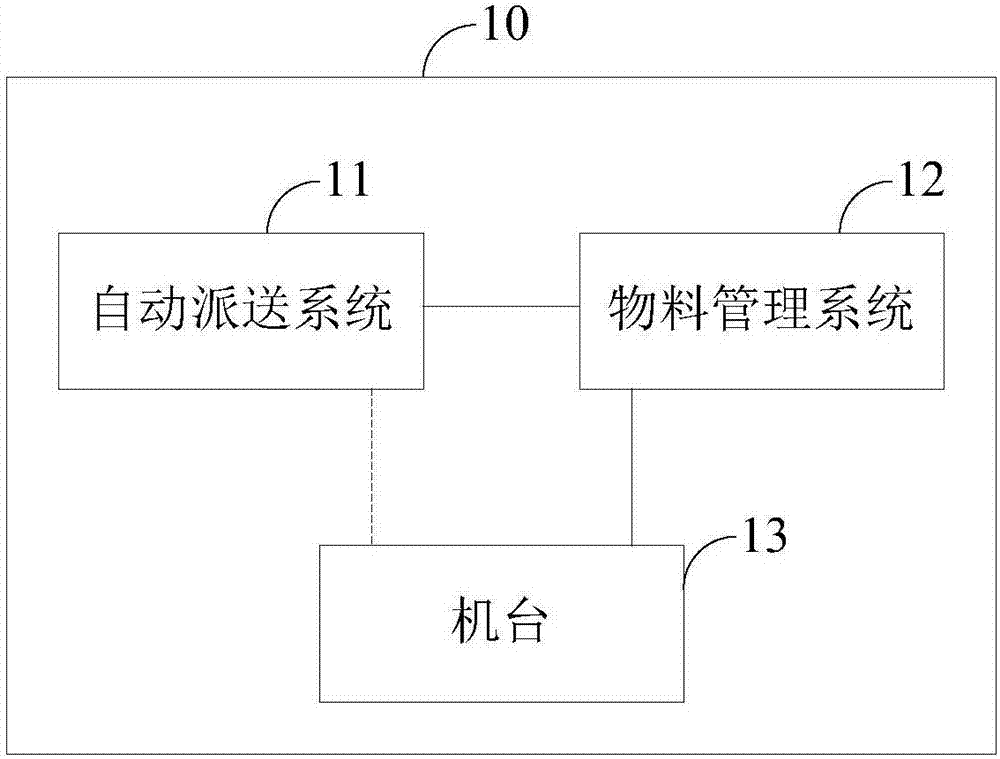

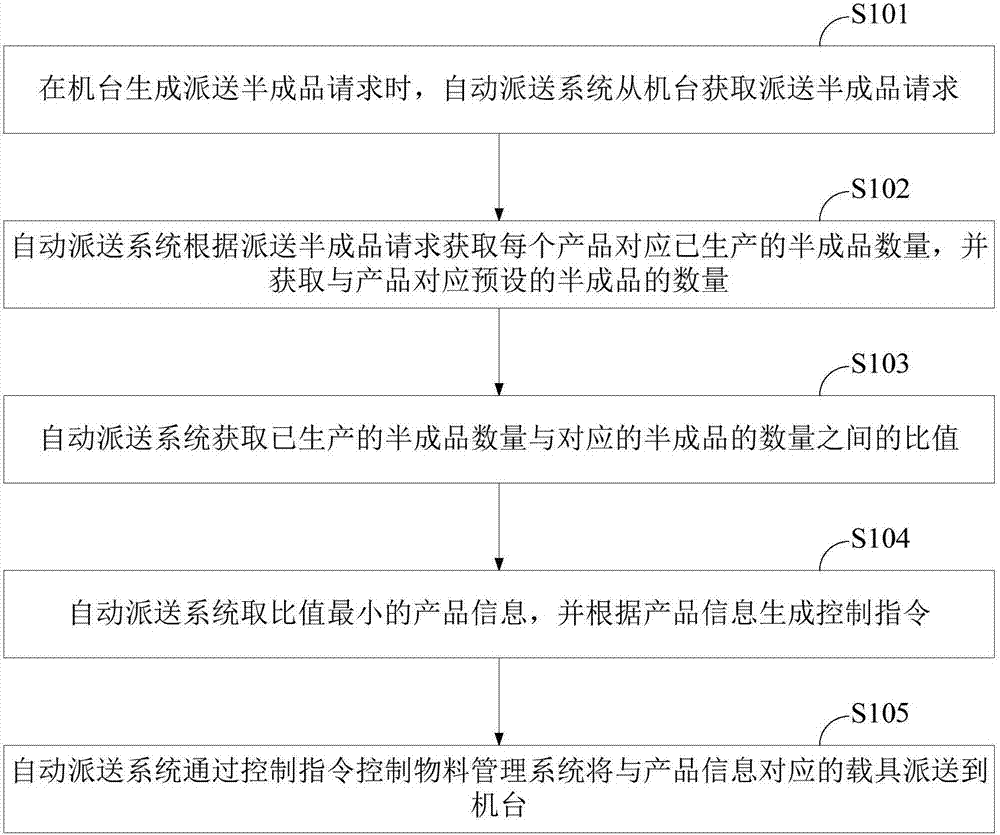

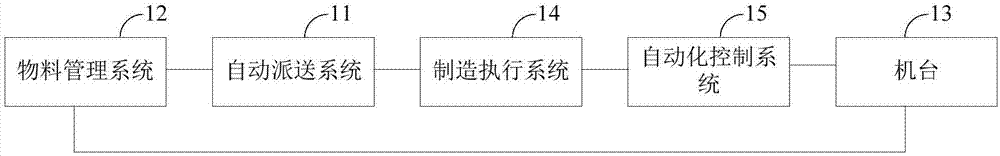

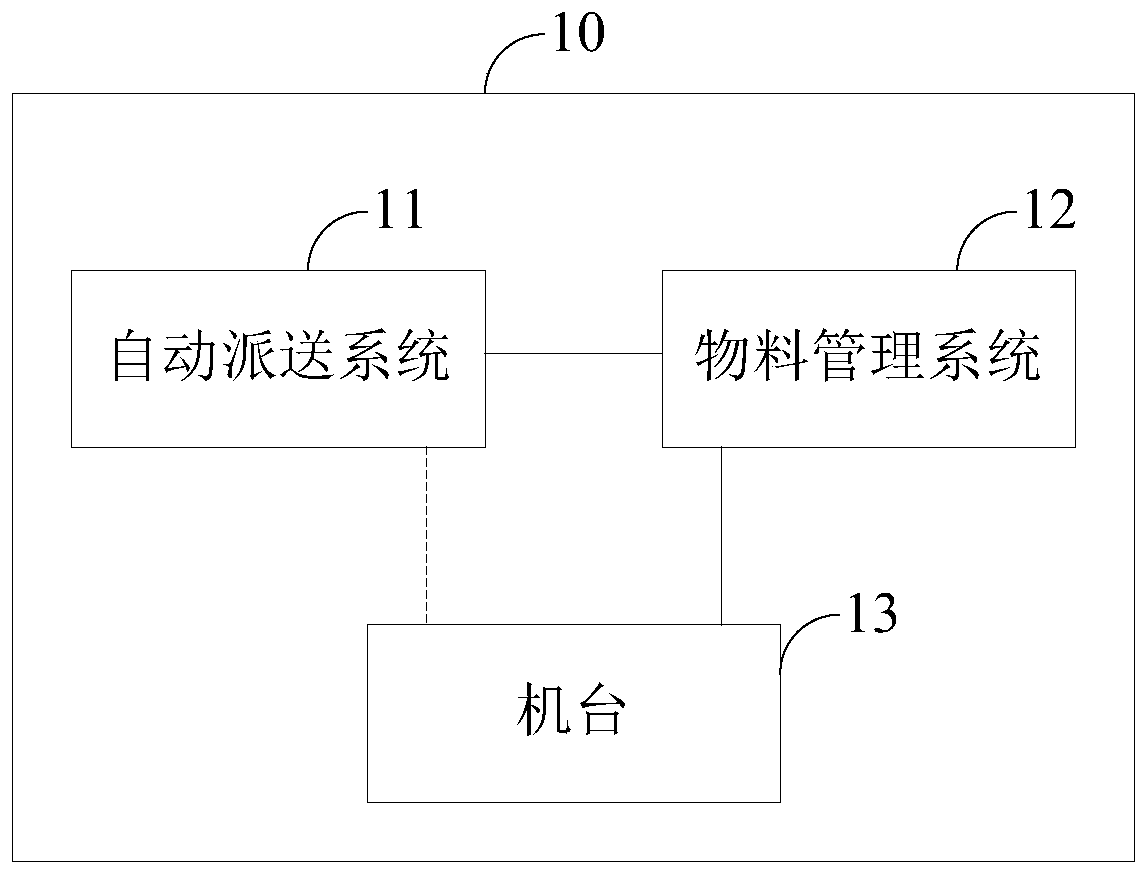

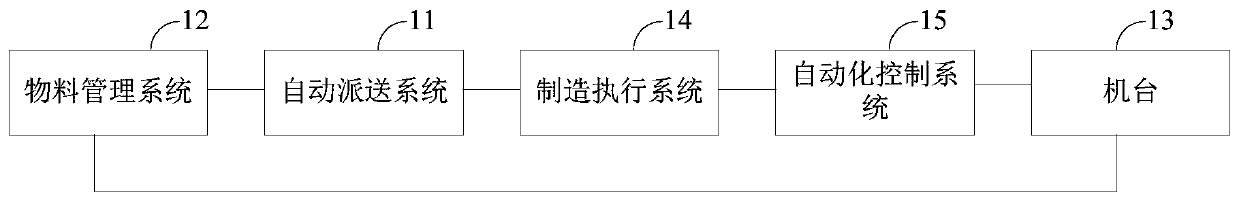

Computer integrated manufacturing system and a manufacturing method thereof

ActiveCN107168253AFast deliveryReduce accumulation timeTotal factory controlProgramme total factory controlComputer-integrated manufacturingWork in process

The invention discloses a computer integrated manufacturing system and a manufacturing method thereof. The system at least comprises an automatic delivery system, a material management system and a bench. The automatic delivery system obtains a ratio of the number of produced semi-finished products to the corresponding number of semi-finished products; the automatic delivery system obtains product information with a smallest ratio and generates a control instruction based on the product information; and the automatic delivery system controls the material management system to deliver a carrier corresponding to the production information to the bench based on the control instruction. Therefore, the emergency carrier can be dispatched to the bench quickly and thus the cargo stacking time can be reduced; and thus the benefits of the enterprise can be increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method and system for automatically making sub batch plan for steel-smelting continuous casting furnace

ActiveCN101303588BImprove scienceSolving inefficienciesTotal factory controlProgramme total factory controlSteelmakingOutcome assessment

Owner:NORTHEASTERN UNIV LIAONING

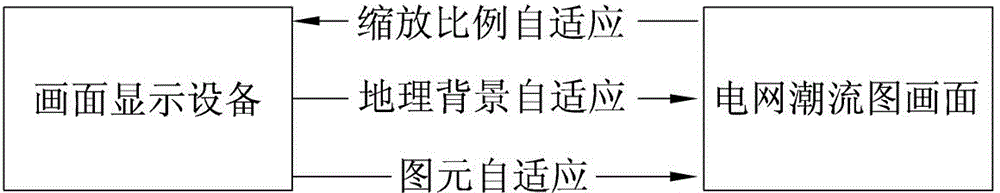

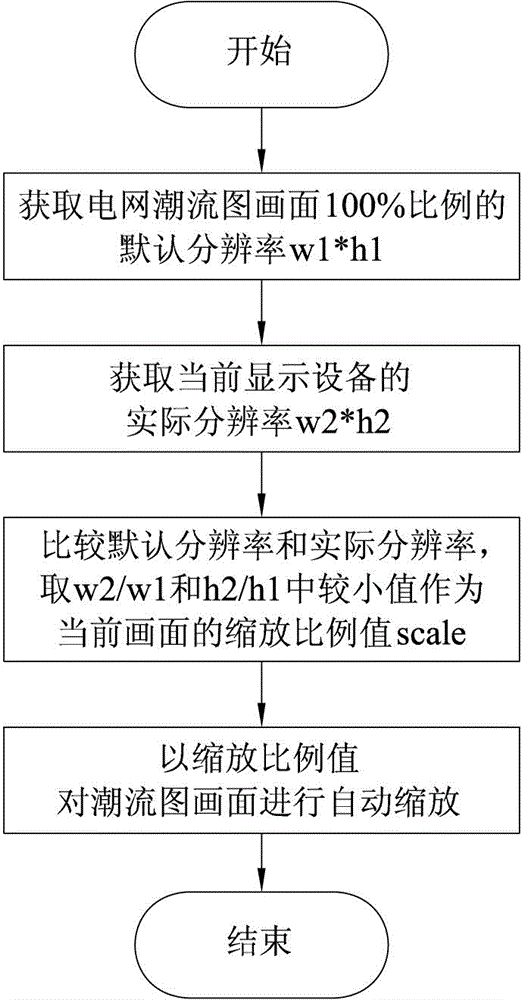

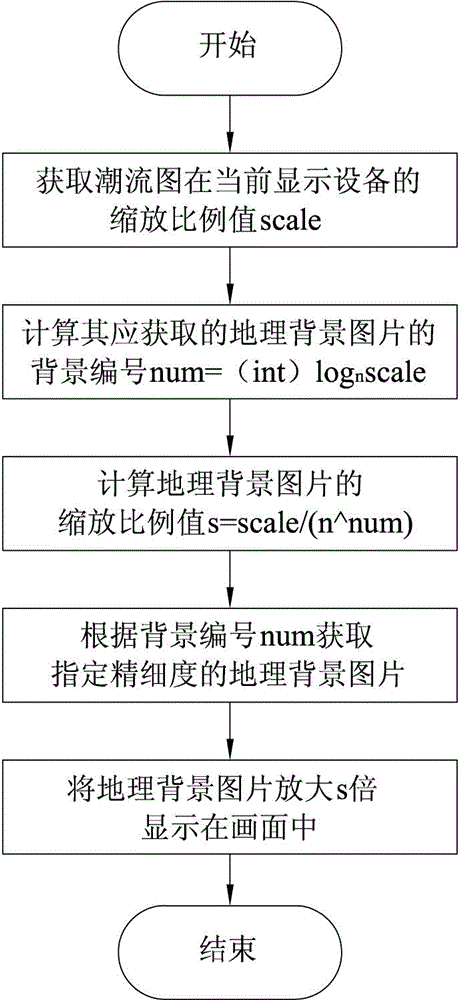

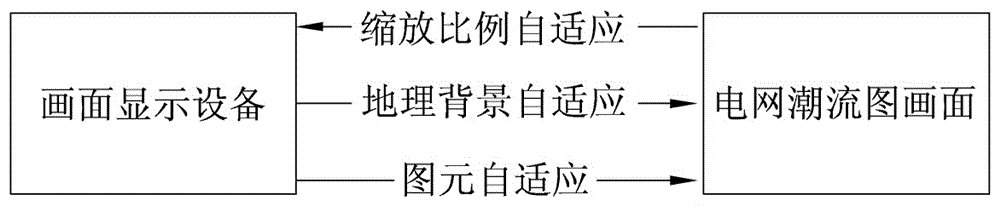

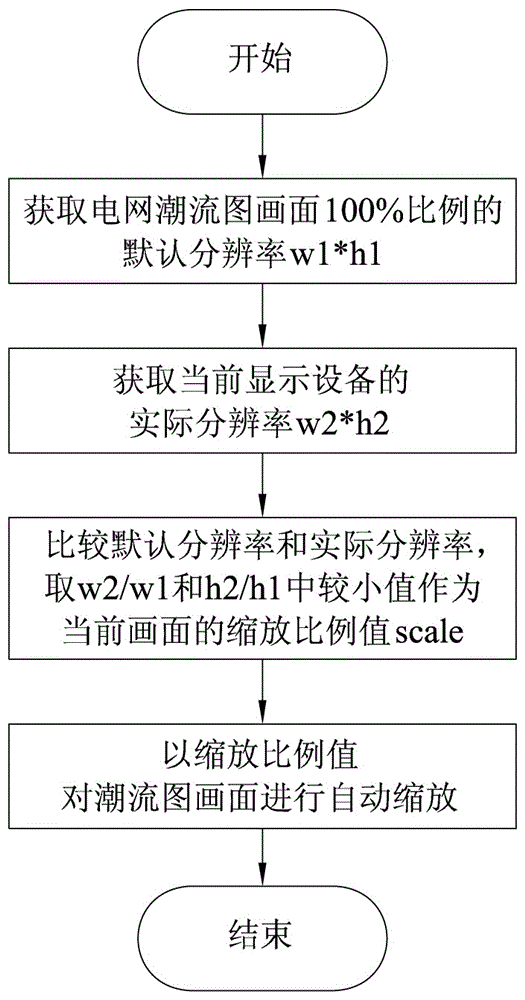

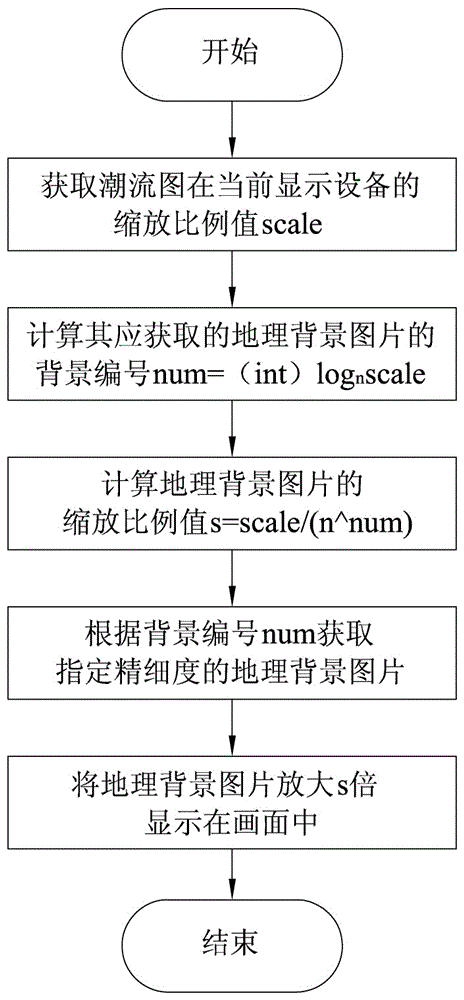

Power grid tidal current chart resolution adaption method based on CIM/G (Computer Integrated Manufacturing) specification

ActiveCN104103036AImprove usabilityImprove accuracyGeometric image transformationVisibilityImage resolution

The invention relates to a power grid tidal current chart resolution adaption method based on a CIM / G (Computer Integrated Manufacturing) specification. The power grid tidal current chart resolution adaption method comprises the following steps of scaling adaption, geographic background adaption and primitive adaption, wherein the step of scaling adaption comprises the following steps: according to an original power grid tidal current chart resolution and a current display equipment resolution, obtaining a scaling value; the step of geographic background adaption comprises the following steps:, sorting and numbering geographic background pictures, according to a set switching cardinal number, calculating the background number of the geographic background pictures, selecting one geographic background picture, calculating the scaling value of the geographic background picture, and carrying out uniform scaling; and the step of primitive adaption comprises the following steps: traversing and obtaining a primitive, and carrying out adaption processing to obtain the scaling value of the primitive, obtaining the visibility configuration of each primitive under the current scaling value, carrying out vector drawing according to the scaling value of a visible primitive, and refreshing to obtain and display an adapted power grid tidal current chart. Working efficiency is improved by the method, workloads are reduced, and the display usability, accuracy and attractiveness of the tidal current chart can be improved.

Owner:STATE GRID CORP OF CHINA +3

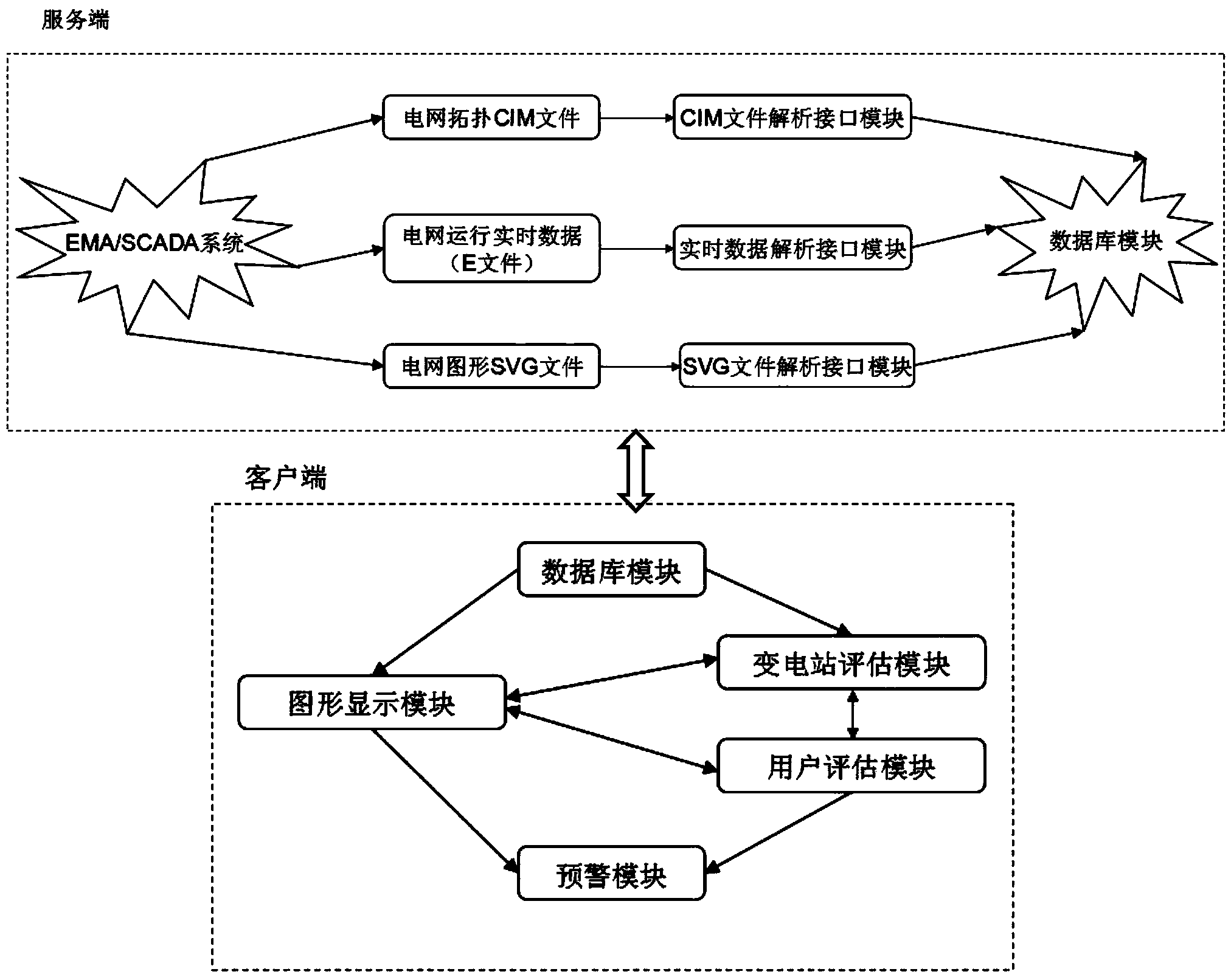

Transformer substation user evaluation system running based on regional power grid

ActiveCN104348108AImprove accuracyImprove work efficiencySupervisory desks/panelsCircuit arrangementsGraphicsReal-time data

The invention relates to a transformer substation user evaluation system running based on a regional power grid, and belongs to the technical field of electric power. The transformer substation user evaluation system comprises a client and a server, namely comprises a computer integrated manufacturing (CIM) file analysis interface, a real time data analysis interface, a scalable vector graphics (SVG) file analysis interface, a storage and a processor, and namely comprises a CIM file analysis interface module, a real time data analysis interface module, an SVG file analysis interface module, a database module, a transformer substation evaluation module, a user evaluation module, a graphic display module and an early warning module. Compared with the prior art, the transformer substation user evaluation system disclosed by the invention has the characteristics of being comprehensive in transformer substation and user evaluation, high in accuracy and efficiency, visual and fast.

Owner:STATE GRID CORP OF CHINA +4

Computer integrated manufacturing system and its manufacturing method

ActiveCN107168253BFast deliveryReduce accumulation timeTotal factory controlProgramme total factory controlComputer-integrated manufacturingWork in process

The invention discloses a computer integrated manufacturing system and a manufacturing method thereof. The system at least comprises an automatic delivery system, a material management system and a bench. The automatic delivery system obtains a ratio of the number of produced semi-finished products to the corresponding number of semi-finished products; the automatic delivery system obtains product information with a smallest ratio and generates a control instruction based on the product information; and the automatic delivery system controls the material management system to deliver a carrier corresponding to the production information to the bench based on the control instruction. Therefore, the emergency carrier can be dispatched to the bench quickly and thus the cargo stacking time can be reduced; and thus the benefits of the enterprise can be increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

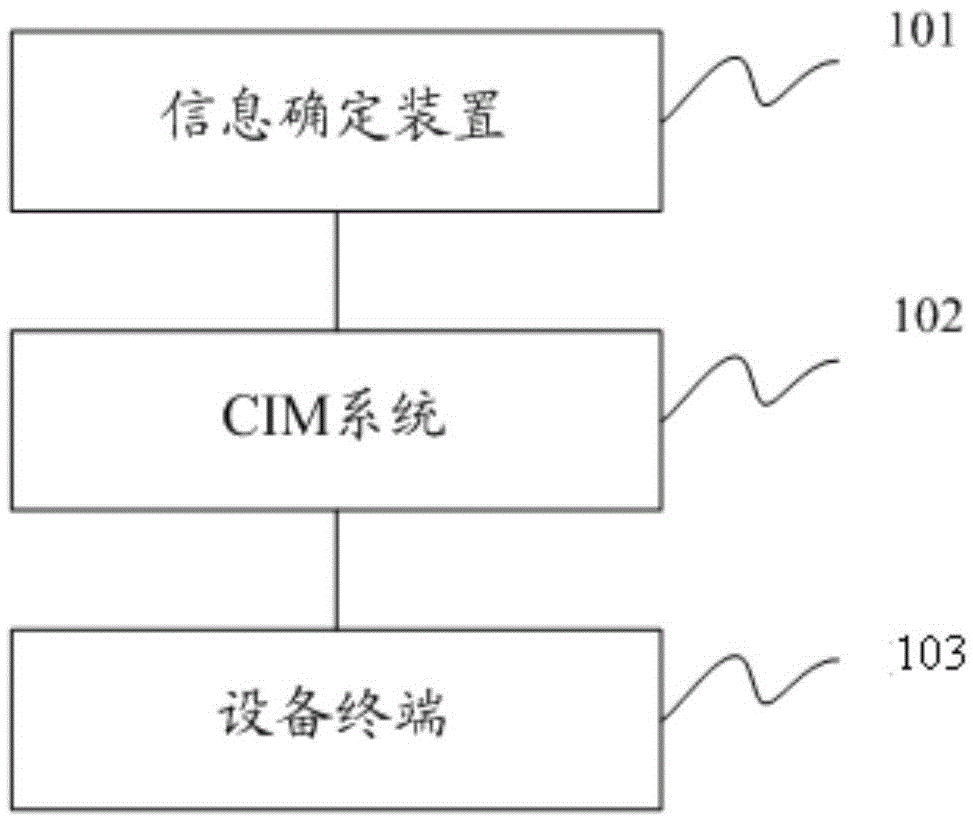

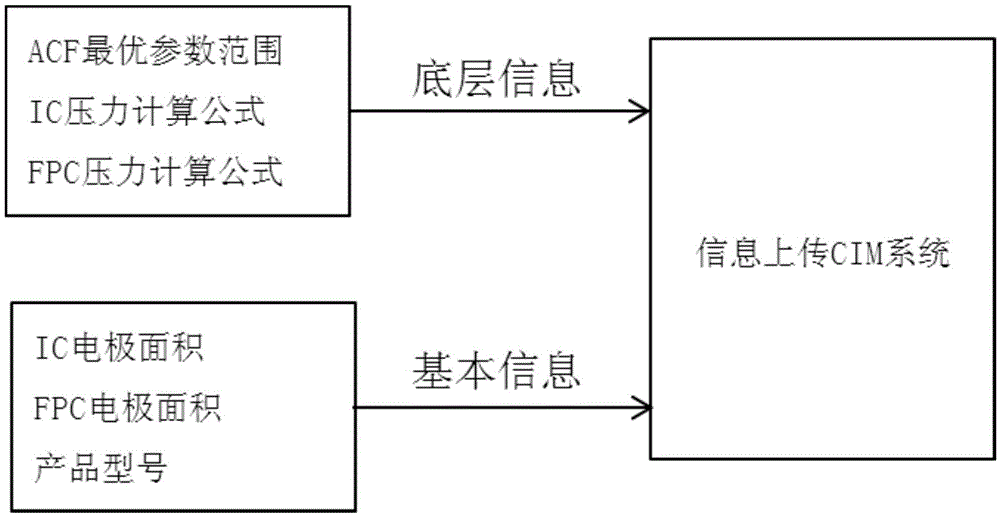

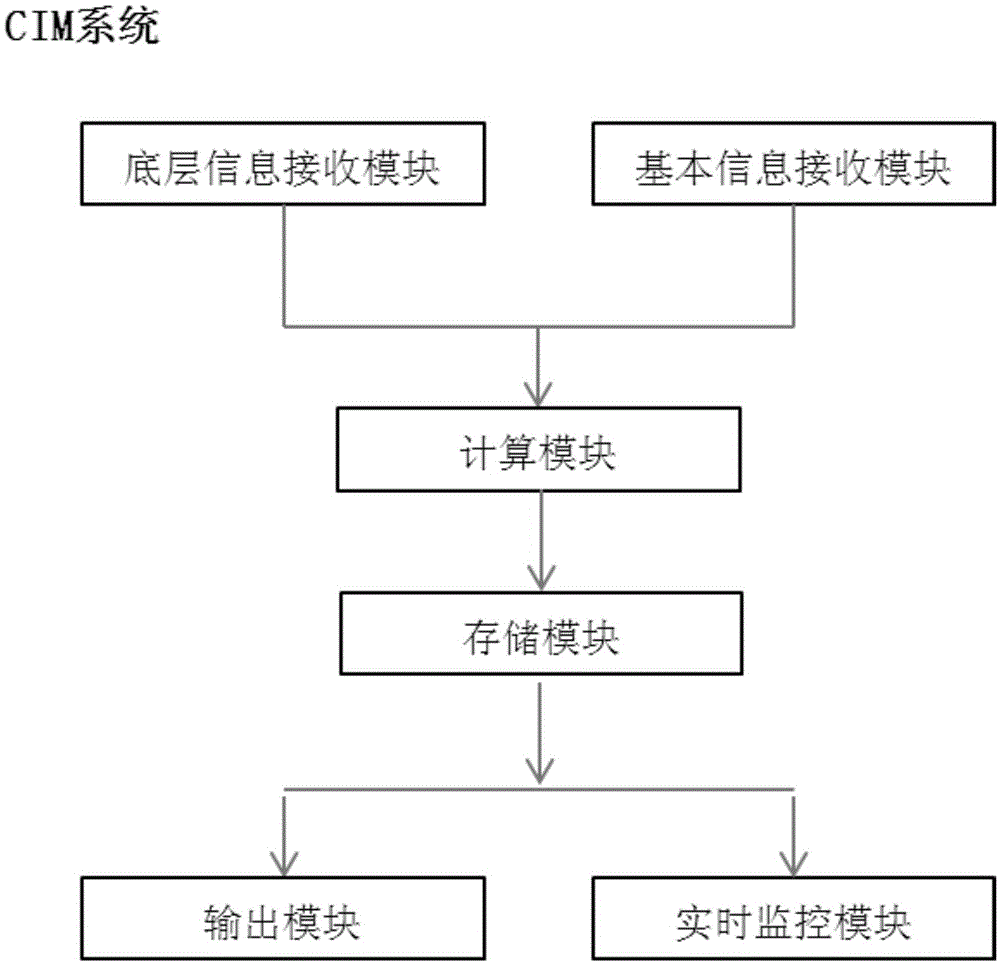

Product production system and method

InactiveCN105652837ATotal factory controlProgramme total factory controlComputer-integrated manufacturingAnisotropic conductive adhesive

The invention discloses a product production system and method for improving the production efficiency and the production quality of the products. The product production system comprises an information determination device, a CIM (Computer Integrated Manufacturing) system and an equipment terminal, wherein the information determination device is used for determining the optimal parameter range of ACF (Anisotropic Conductive Adhesive) and sending root information comprising the optimal ACF parameter range and basic information to a production and intelligent collection CIM system; the CIM system is used for receiving the root information and the basic information sent by the information determination device, calculating and storing production required process parameters according to the root information and the basic information, outputting the production required process parameters to the equipment terminal, monitoring the process parameters fed back in real time in a production process, and producing an alarm signal when the parameters are not in accordance with the production required process parameters; and the equipment terminal is used for receiving and searching the production required process parameters sent by the CIM system, performing the production according to the production required process parameter and feeding the process parameters during production back to the CIM system in real time.

Owner:BOE TECH GRP CO LTD +1

A method for surface modification of hot work die steel materials based on cim process

ActiveCN104550837BHigh strengthHigh wear resistance and high temperature resistanceComputer-integrated manufacturingZirconia ceramic

The invention discloses a CIM (Computer Integrated Manufacturing)-process-based hot-work die steel material surface modification method, relates to a hot-work die steel material surface modification method, and aims to solve the problem that a ceramic / hot-work die steel composite die prepared by a conventional hot-work die steel material surface modification method is low in bonding strength, maladaptive to the long-time continuous thermal shock and thermal corrosion of molten or semi-solid metal to the die in an extrusion casting process, short in service life and high in cost. The method comprises the following steps of 1, modifying Y2O3-stable zirconium oxide powder; 2, performing mixing; 3, performing injection molding; 4, performing degreasing and sintering to obtain a zirconium oxide ceramic / hot-work die steel composite die. The thickness of zirconium oxide ceramic in the obtained zirconium oxide ceramic / hot-work die steel composite die is 10 to 15mm, and the shear strength of the connection interface can reach 68 to 70MPa. The CIM-process-based hot-work die steel material surface modification method can be implemented.

Owner:HARBIN INST OF TECH

Adaptive Method of Grid Power Flow Diagram Resolution Based on CIM/G Code

ActiveCN104103036BImprove usabilityImprove accuracyGeometric image transformationComputer-integrated manufacturingUsability

The invention relates to a power grid tidal current chart resolution adaption method based on a CIM / G (Computer Integrated Manufacturing) specification. The power grid tidal current chart resolution adaption method comprises the following steps of scaling adaption, geographic background adaption and primitive adaption, wherein the step of scaling adaption comprises the following steps: according to an original power grid tidal current chart resolution and a current display equipment resolution, obtaining a scaling value; the step of geographic background adaption comprises the following steps:, sorting and numbering geographic background pictures, according to a set switching cardinal number, calculating the background number of the geographic background pictures, selecting one geographic background picture, calculating the scaling value of the geographic background picture, and carrying out uniform scaling; and the step of primitive adaption comprises the following steps: traversing and obtaining a primitive, and carrying out adaption processing to obtain the scaling value of the primitive, obtaining the visibility configuration of each primitive under the current scaling value, carrying out vector drawing according to the scaling value of a visible primitive, and refreshing to obtain and display an adapted power grid tidal current chart. Working efficiency is improved by the method, workloads are reduced, and the display usability, accuracy and attractiveness of the tidal current chart can be improved.

Owner:STATE GRID CORP OF CHINA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com