Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Reduce accumulation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

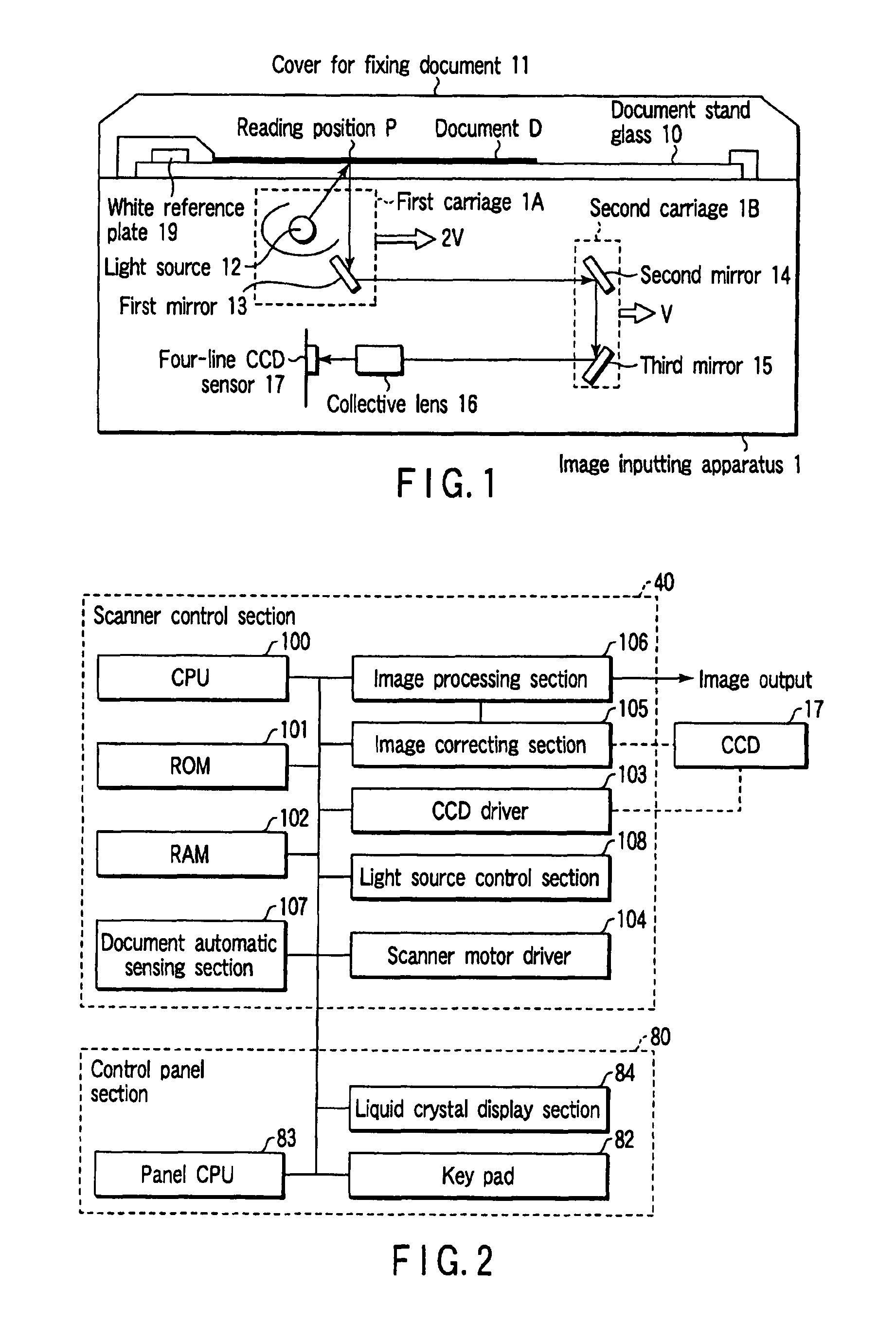

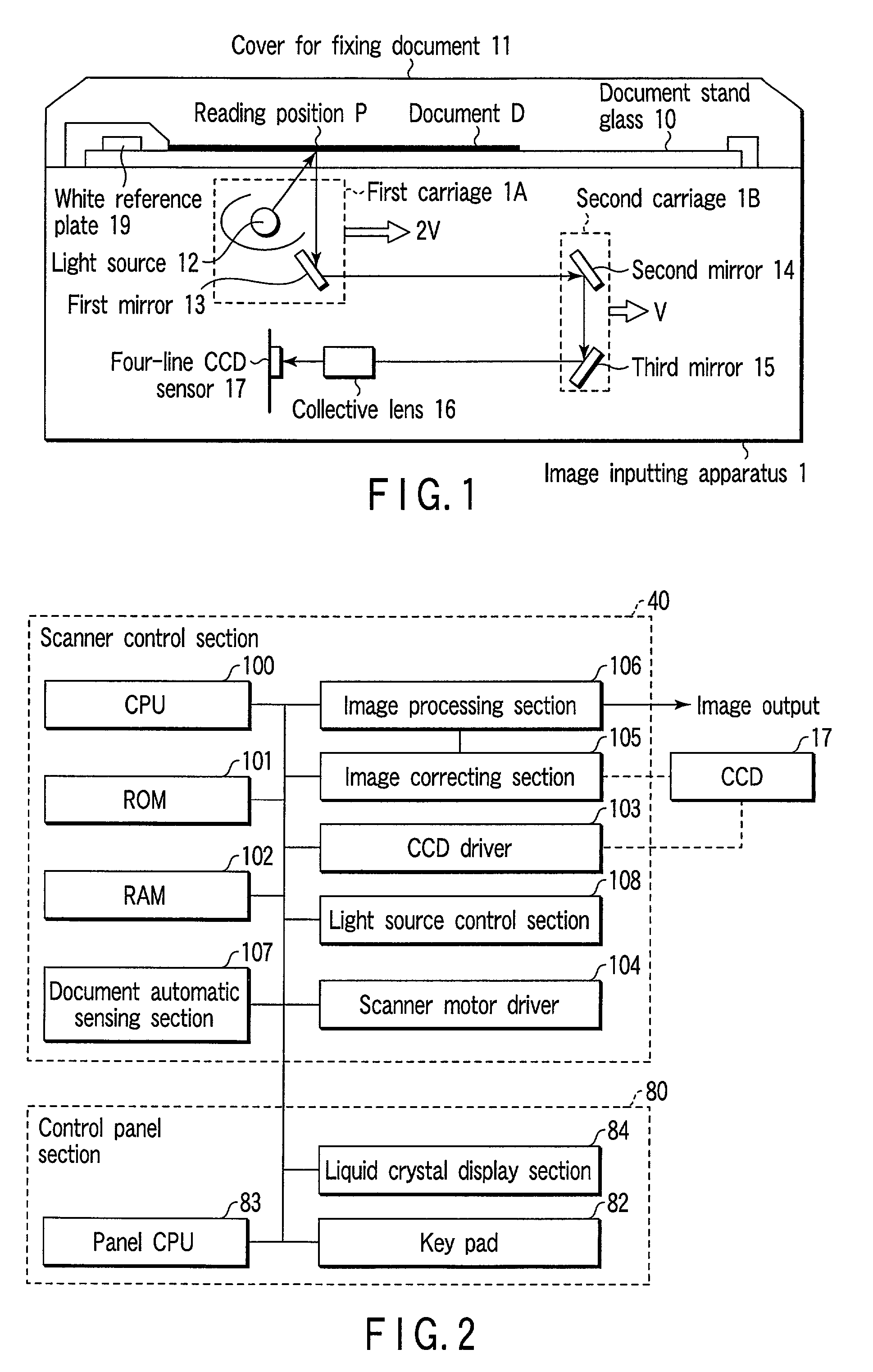

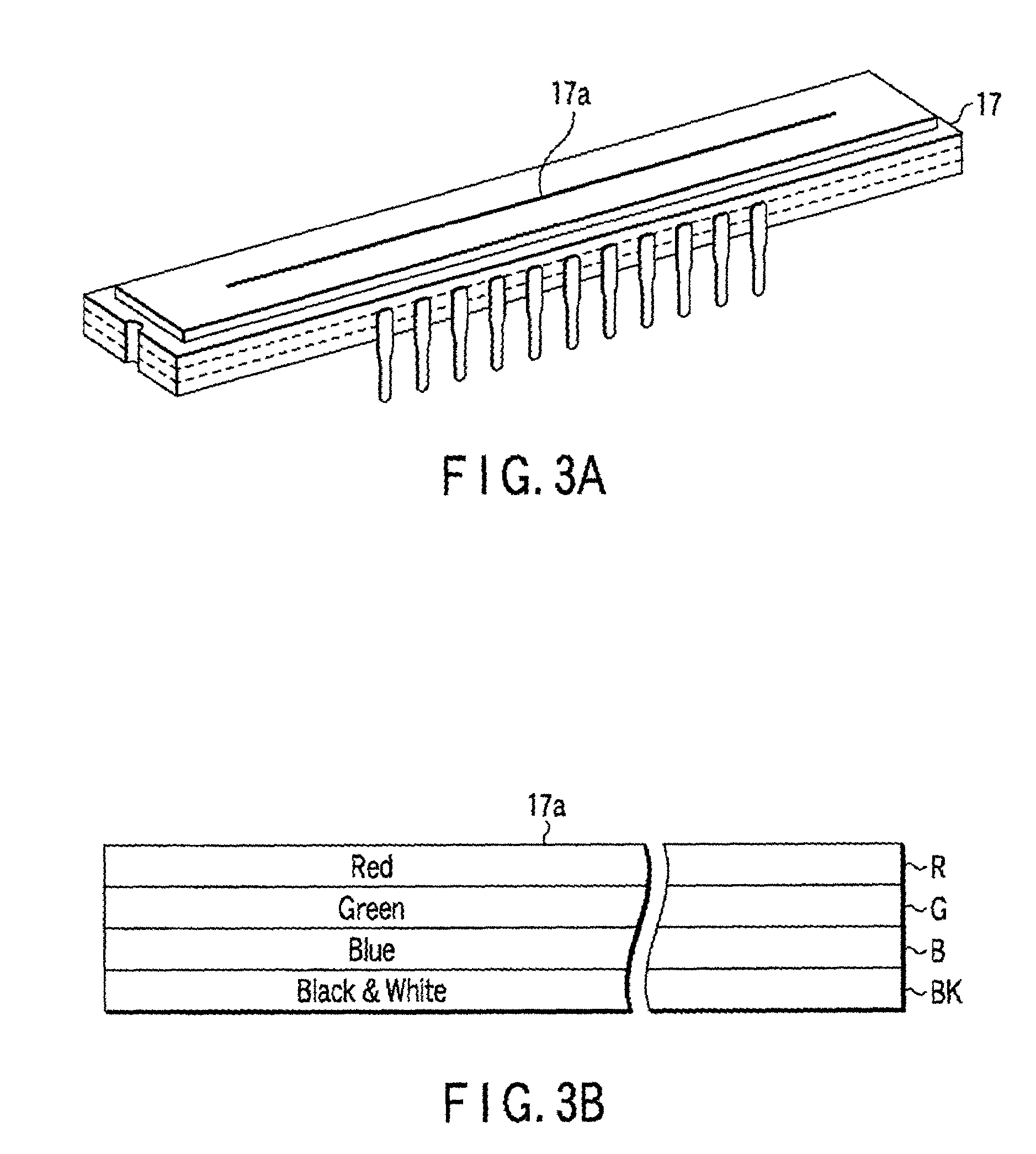

Image inputting apparatus and image forming apparatus using four-line CCD sensor

ActiveUS6958835B2Photoelectric converting efficiency (sensitivity) of the line sensorPhotoelectric converting efficiency of the line sensorPictoral communicationLine sensorImage formation

A four-line CCD sensor is structured by line sensors R, G, B in which color filters are respectively disposed on surfaces of light receiving elements, and a line sensor BK at which no color filter is disposed. Amplitudes of signals which are outputted from the line sensors R, G, B at a time of reading a color document, and an amplitude of a signal which is outputted from the line sensor BK at a time of reading a monochrome document are adjusted so as to be substantially equal to one another. In a case in which a color document is read, outputs of the line sensors R, G, B are selectively provided, and in a case in which a monochrome document is read, output of the line sensor BK is selectively provided.

Owner:KK TOSHIBA +1

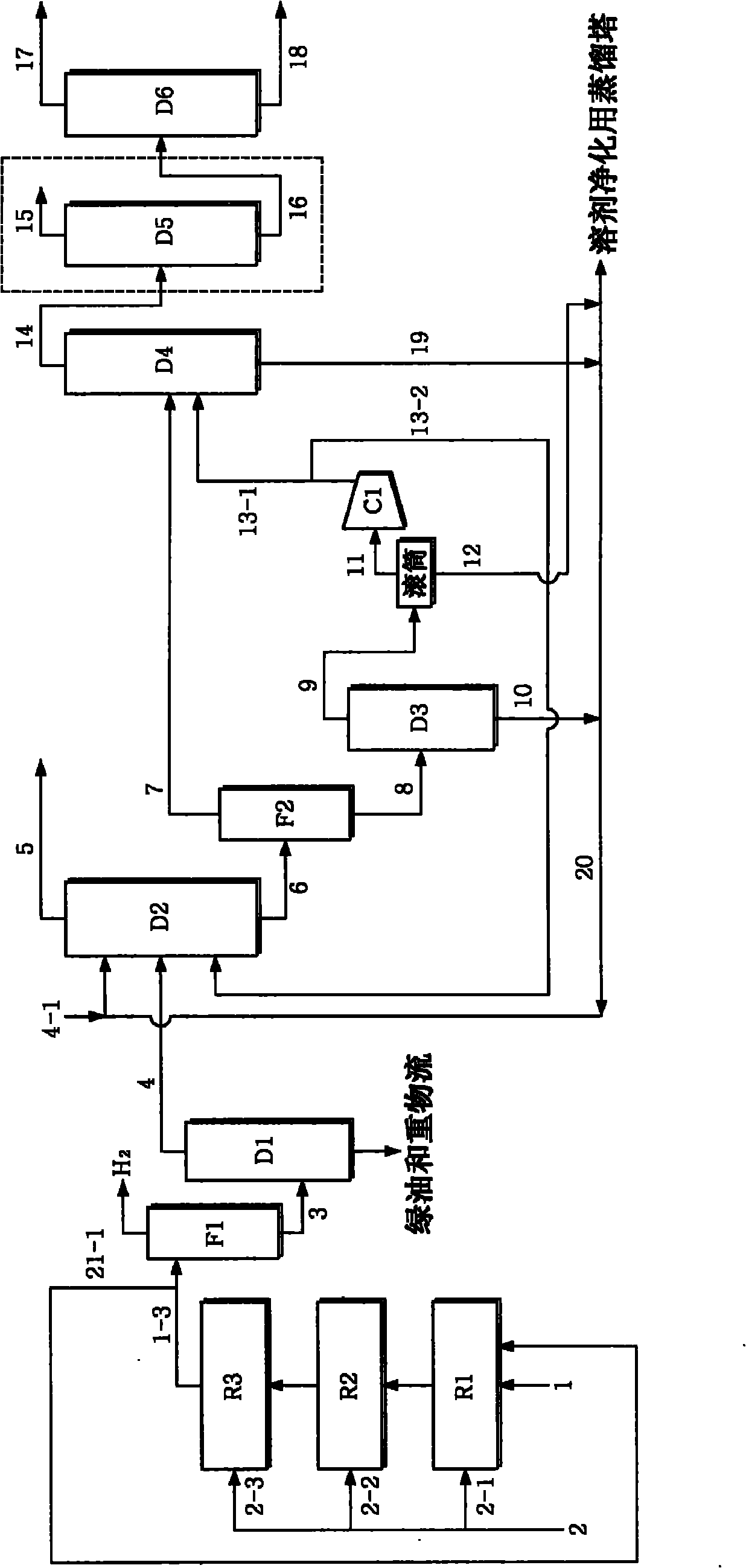

Process for 1,3-butadiene separation from crude C4 stream with acetylene converter

ActiveCN101821361AReduce accumulation timeReduce logistics lossDistillation purification/separationTreatment with hydrotreatment processesVinylacetyleneButene

Disclosed is a method of recovering 1,3 -butadiene from a C4 stream containing butane, isobutane, 2-butene, 1-butene, isobutene, butadiene and acetylene. The process of recovering highly pure 1,3 -butadiene includes acetylene conversion for selectively converting acetylene through liquid-phase hydrogenation, so that the acetylene content is decreased to 70 wt ppm or less, and 1,3 -butadiene extraction using an extractive distillation column, a pre-separator, a solvent stripping column, a solvent recovery column, and a purification column. Through the acetylene conversion, the concentration of vinylacetylene is decreased to 70 wt ppm or less, after which 1,3-butadiene is recovered using only one extractive distillation column, thereby considerably decreasing the degree of utility and the loss of streams in the course of extraction. The number of units necessary for the process is decreased, thus remarkably reducing the time during which impurities can accumulate in a processing unit.

Owner:SK INNOVATION CO LTD

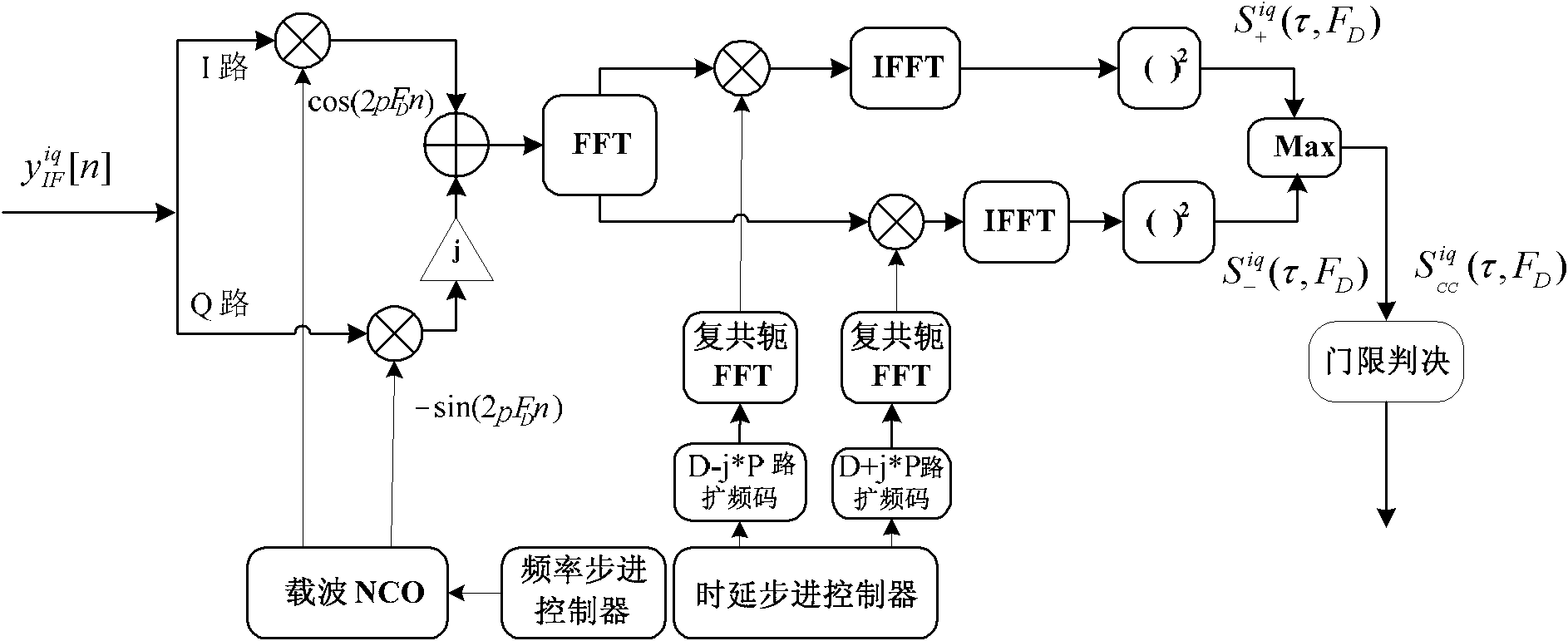

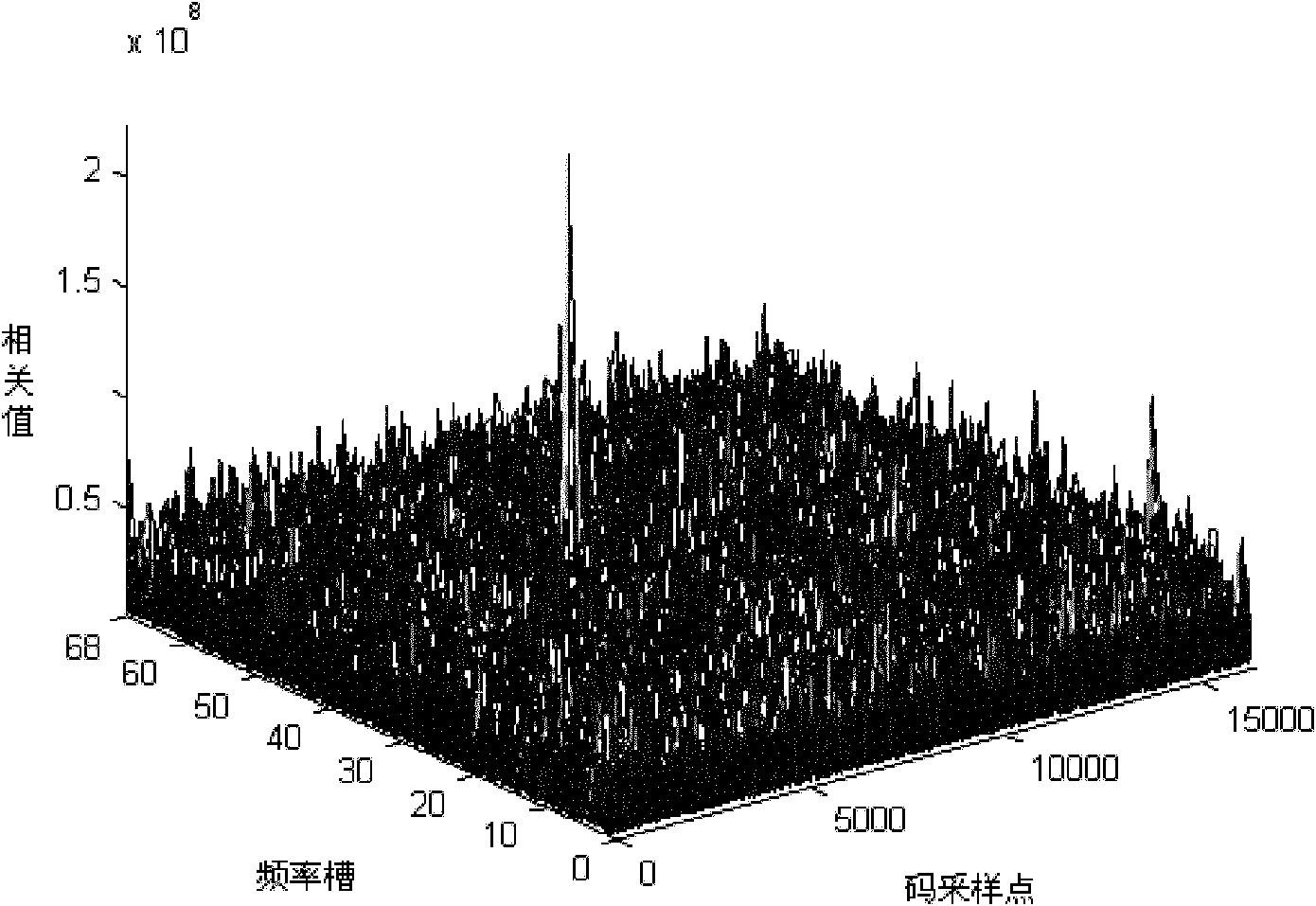

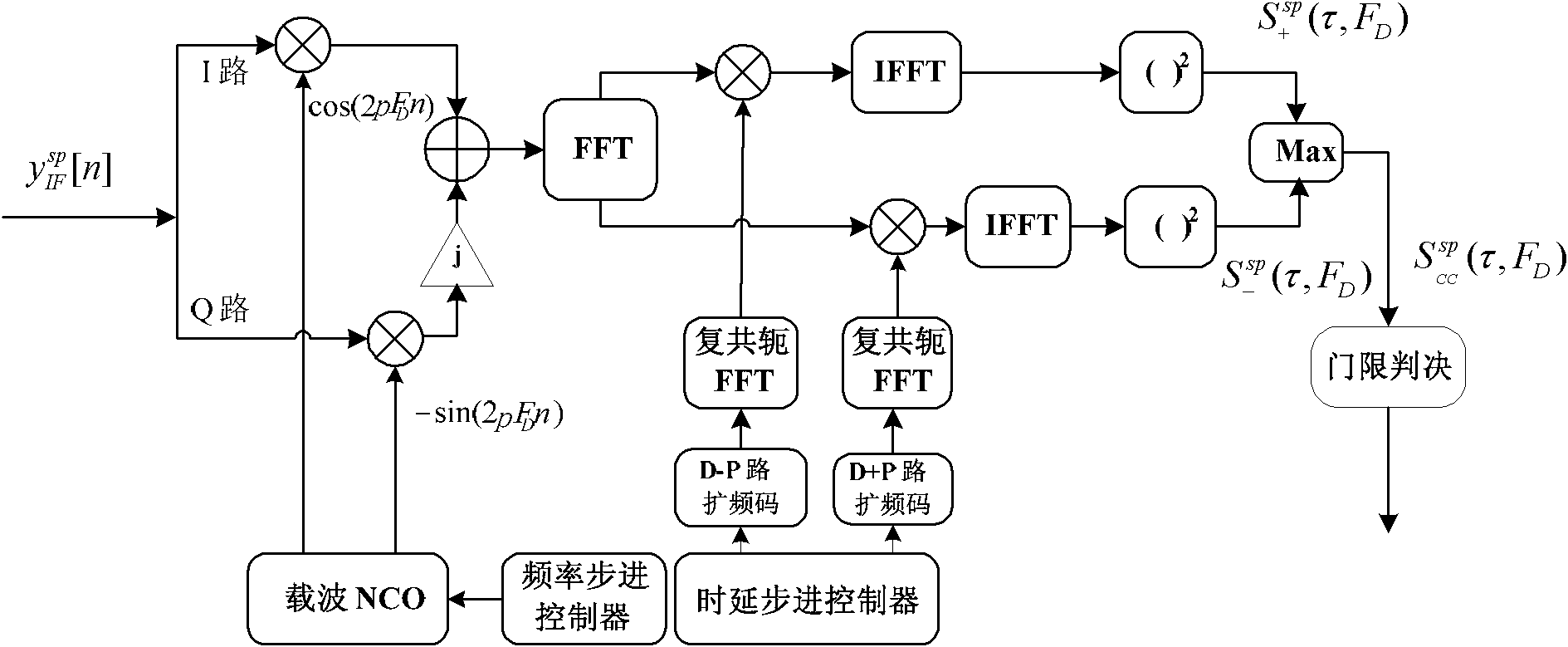

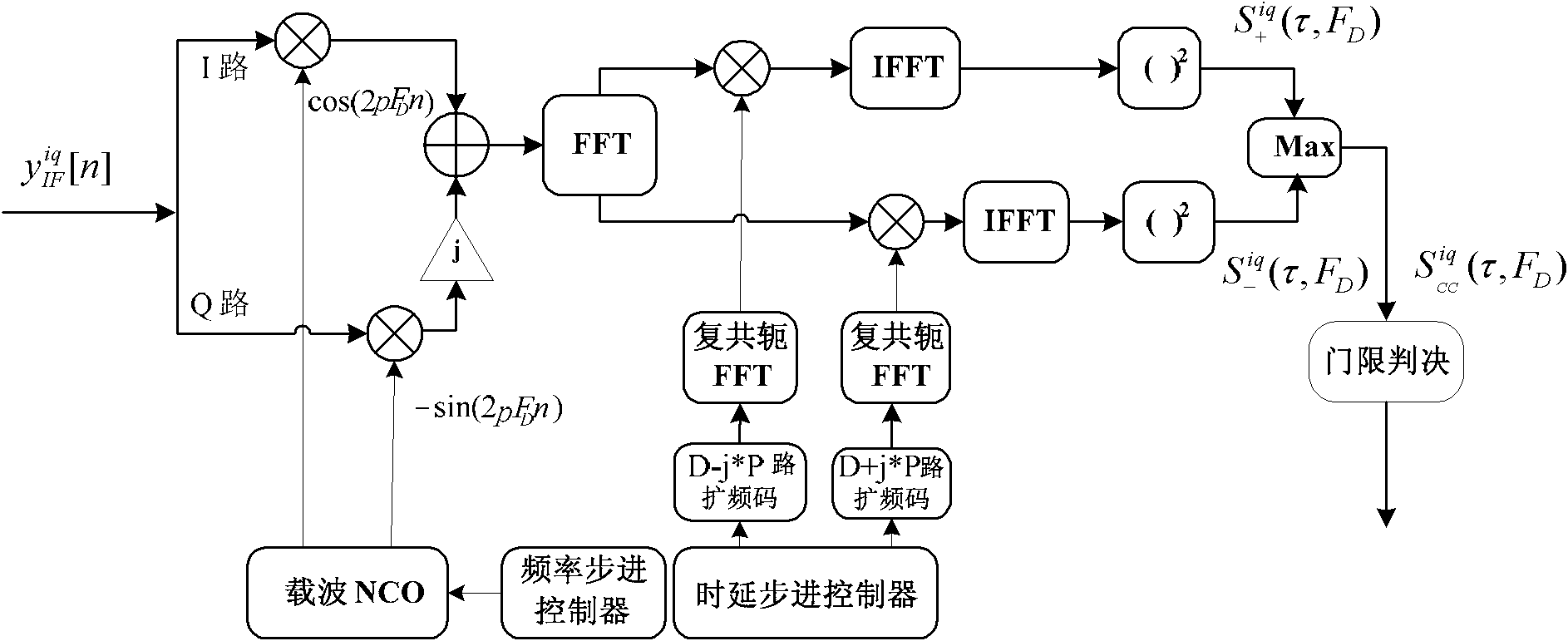

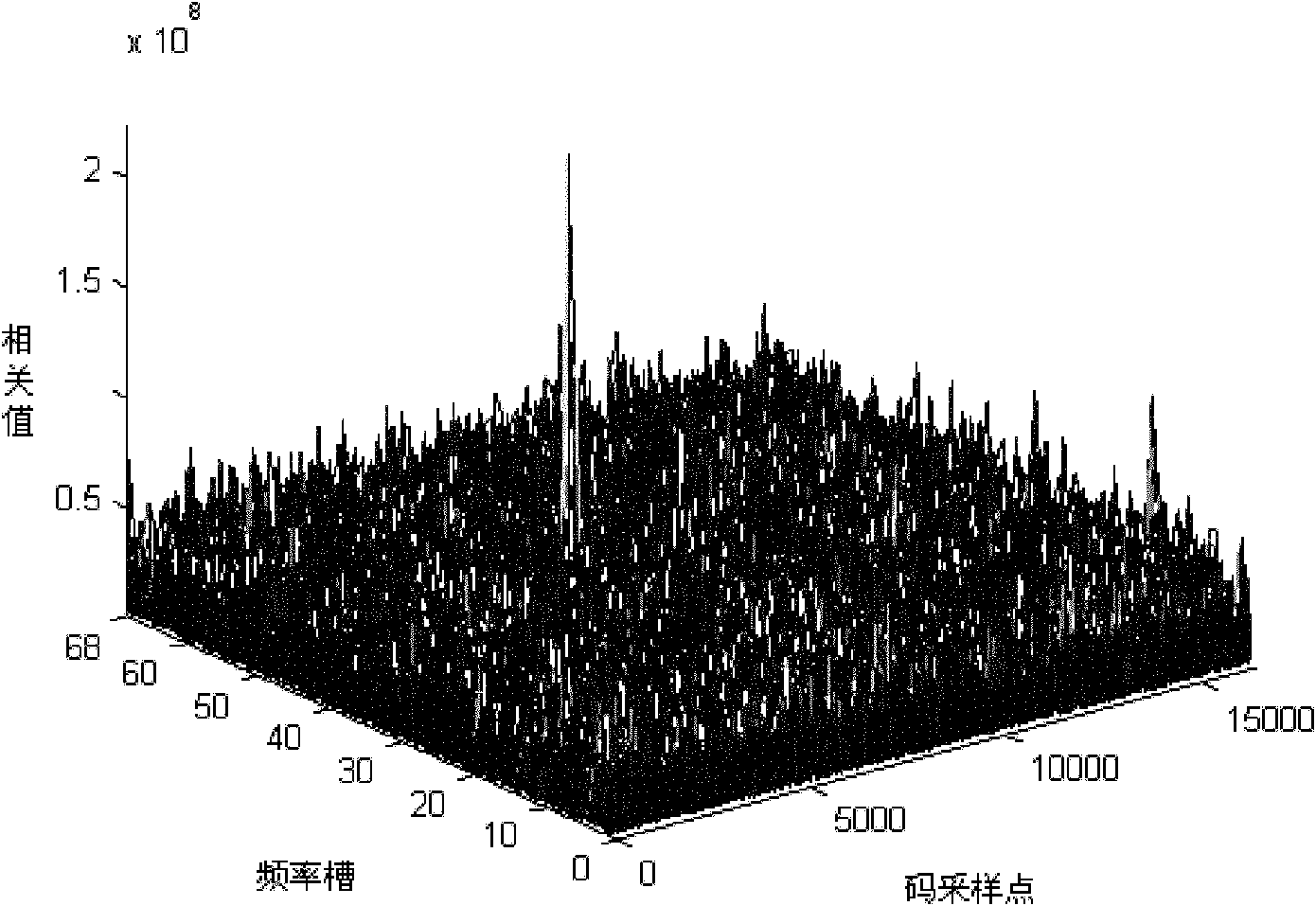

A frequency-domain coherent joint acquisition method for GNSS data/pilot mixed signals

InactiveCN102279402AReduce accumulation timeEfficient captureSatellite radio beaconingComputer scienceMarine navigation

The invention relates to a frequency domain coherent joint capture method of a GNSS data / pilot mixed signal, more particularly to a coherent joint capture method of a GNSS data / pilot mixed signal. According to a traditional single-channel capture method, energies of a new-system navigation signal can not fully utilized, so that capture performance is poor; however, the above-mentioned problem canbe solved according to the invention. The method comprises the following steps that: with utilization of a phase relationship between a data channel signal and a pilot channel signal, coherent processing is carried out on the signals of the two channels aiming at a GNSS data / pilot mixed signal, and then capture is completed. The invention is suitable for application in a capture process of a GNSSdata / pilot mixed signal.

Owner:HARBIN INST OF TECH

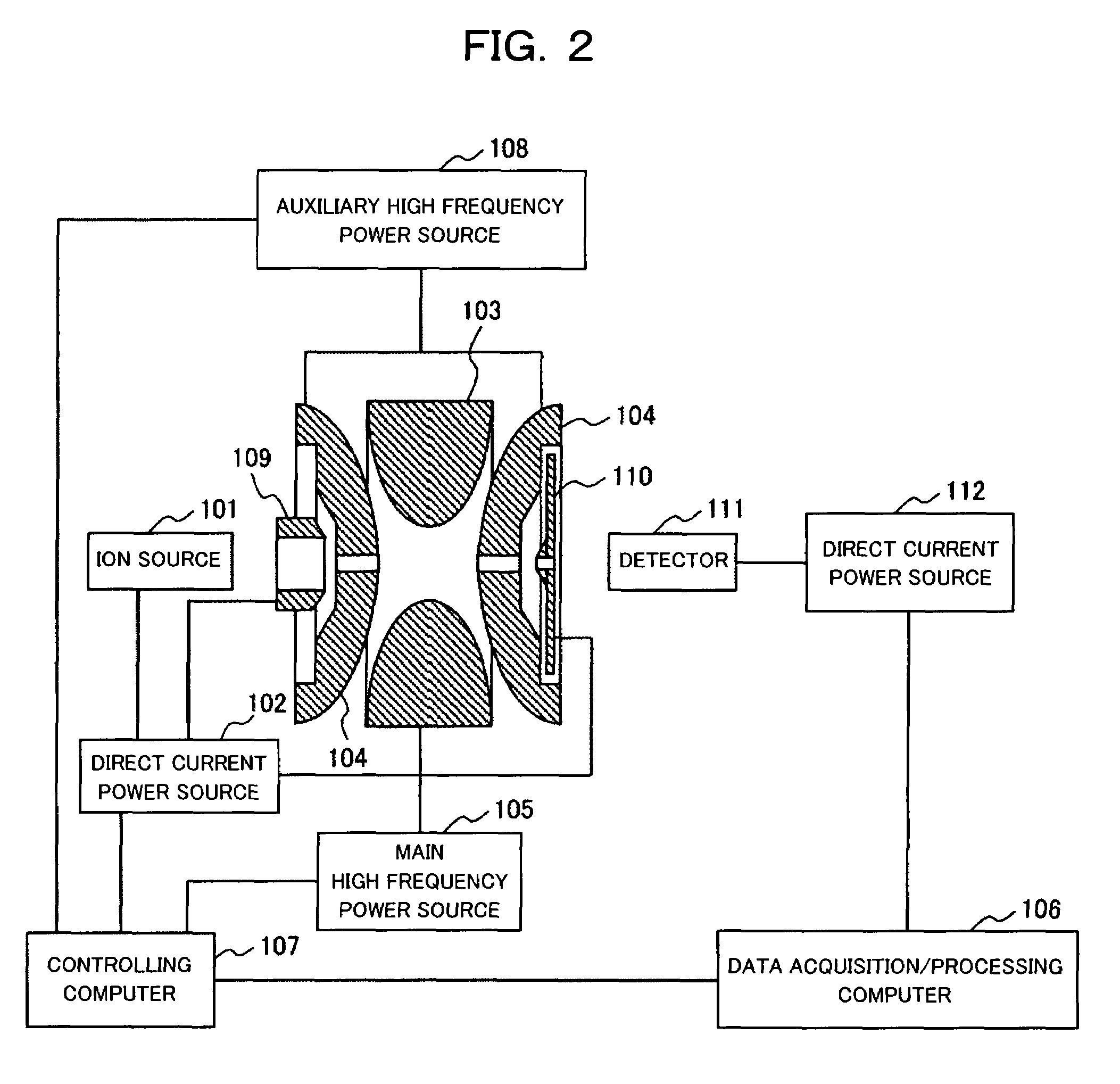

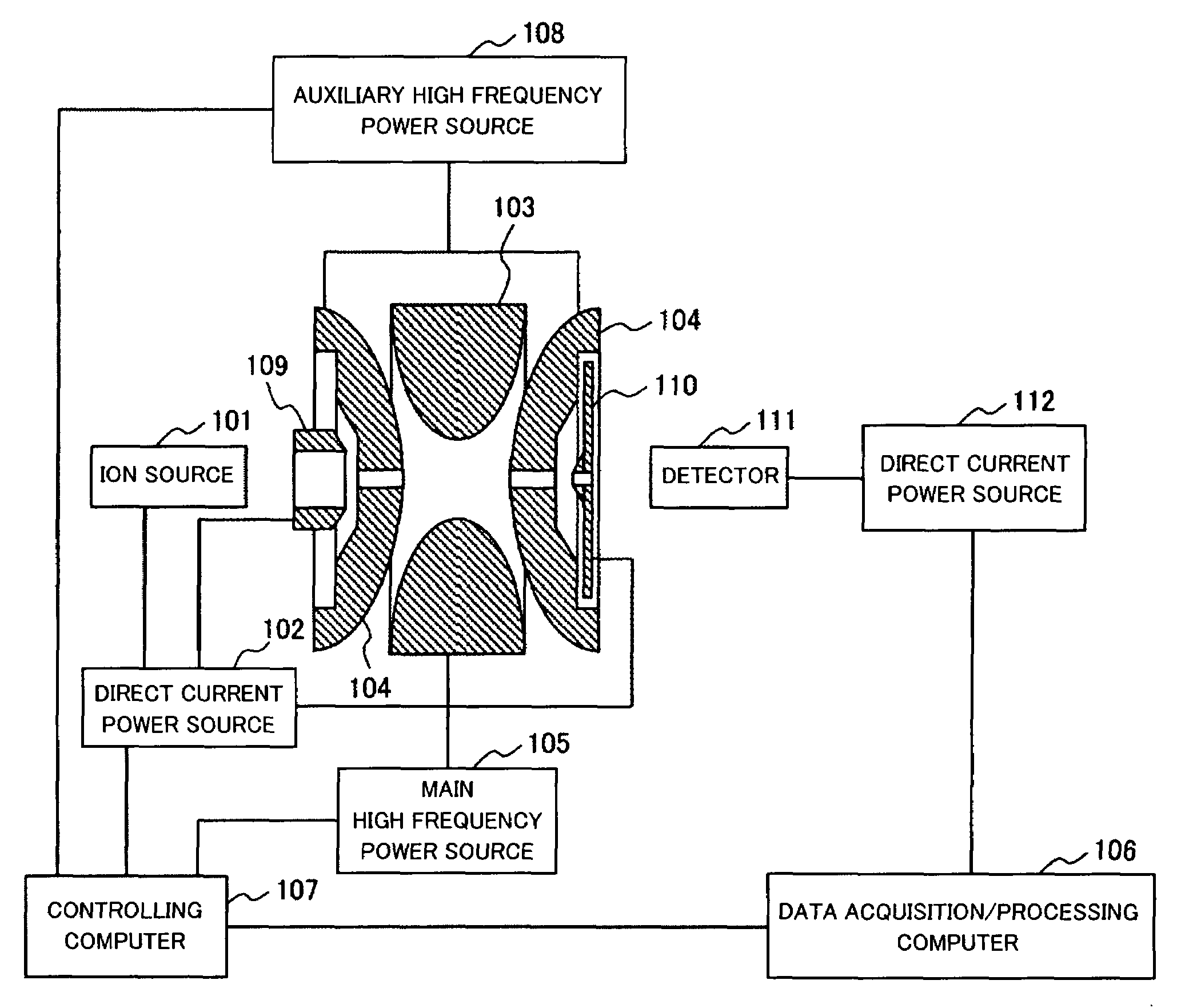

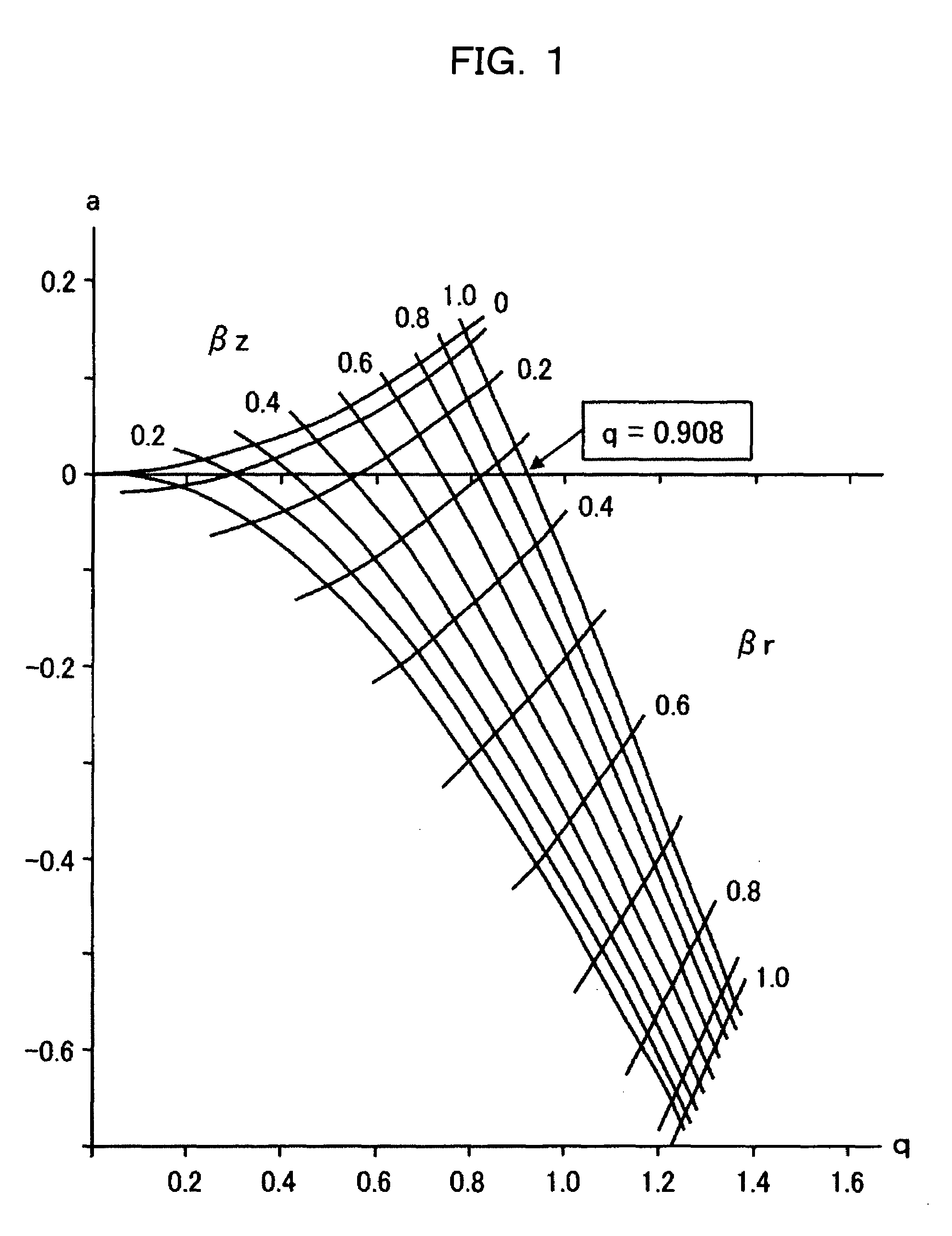

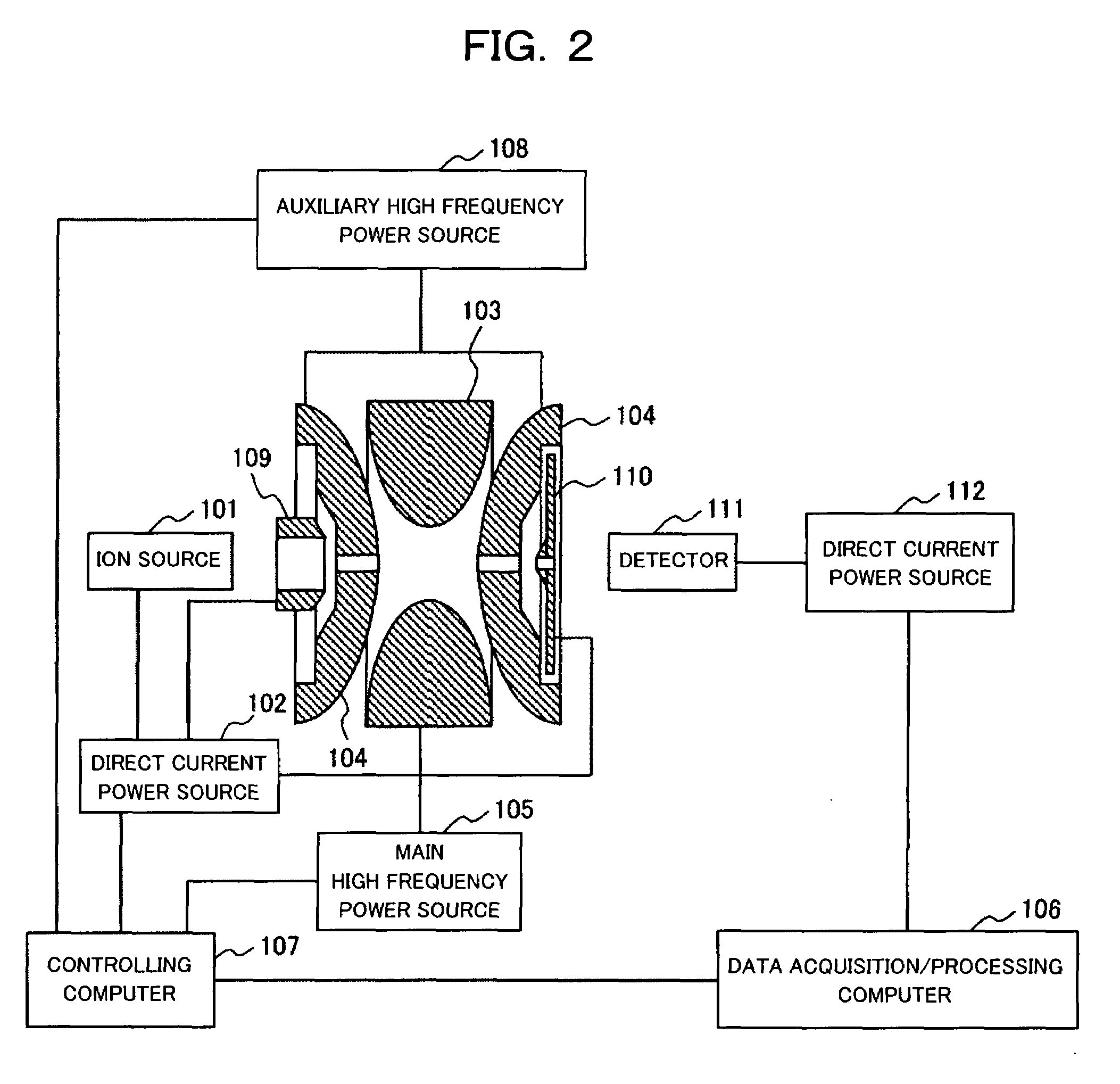

Ion trap mass spectrometry method

InactiveUS20080054173A1High strengthExcellent reproducible MS/MS spectrumSamples introduction/extractionIsotope separationIon trap mass spectrometryHigh frequency power

According to an aspect of the present invention, there are provided an ion trap mass spectrometry method and an ion trap mass spectrometry device using a mass spectrometer, the mass spectrometer including: an ion source part for ionizing a sample; an ion trap part for trapping ions generated in the ion source; a main high frequency power source for applying a main high frequency voltage to the ion trap part, and an auxiliary high frequency power source for applying an auxiliary high frequency voltage thereto; and a detector for detecting the ions ejected from the ion trap. The ion trap mass spectrometry method and the ion trap mass spectrometry device includes the steps of: accumulating desired ions into the ion trap part by ejecting undesired ions while accumulating ions into the ion trap part; and ejecting undesired ions that remain in the ion trap part and leaving the desired ions in the ion trap part are repeated alternately.

Owner:HITACHI HIGH-TECH CORP

Full-automatic negative pressure fermentation and deodorization device and production process for organic fertilizer

InactiveCN1970507AReduced throughput timeReduced fermentation spaceBio-organic fraction processingOrganic fertiliser preparationAir filterDeodorant

The invention discloses full-automatic negative pressure ferment, deodorant device and manufacturing technique of organic fertilizer, which comprises the following parts: sealing negative pressure plant, computer system, self-vent lid, blowing-in set, air exhaust set, pump, sprinkle device, carwash effluent pond, temperature-wetness sensor, pressure sensor, turning over machine, fertilizer piling ferment groove, negative pressure control butterfly, air filter and pipe set, wherein the conduct connects temperature-wetness and pressure sensor, which is controlled by computer.

Owner:上海中懋新生物科技工程有限公司

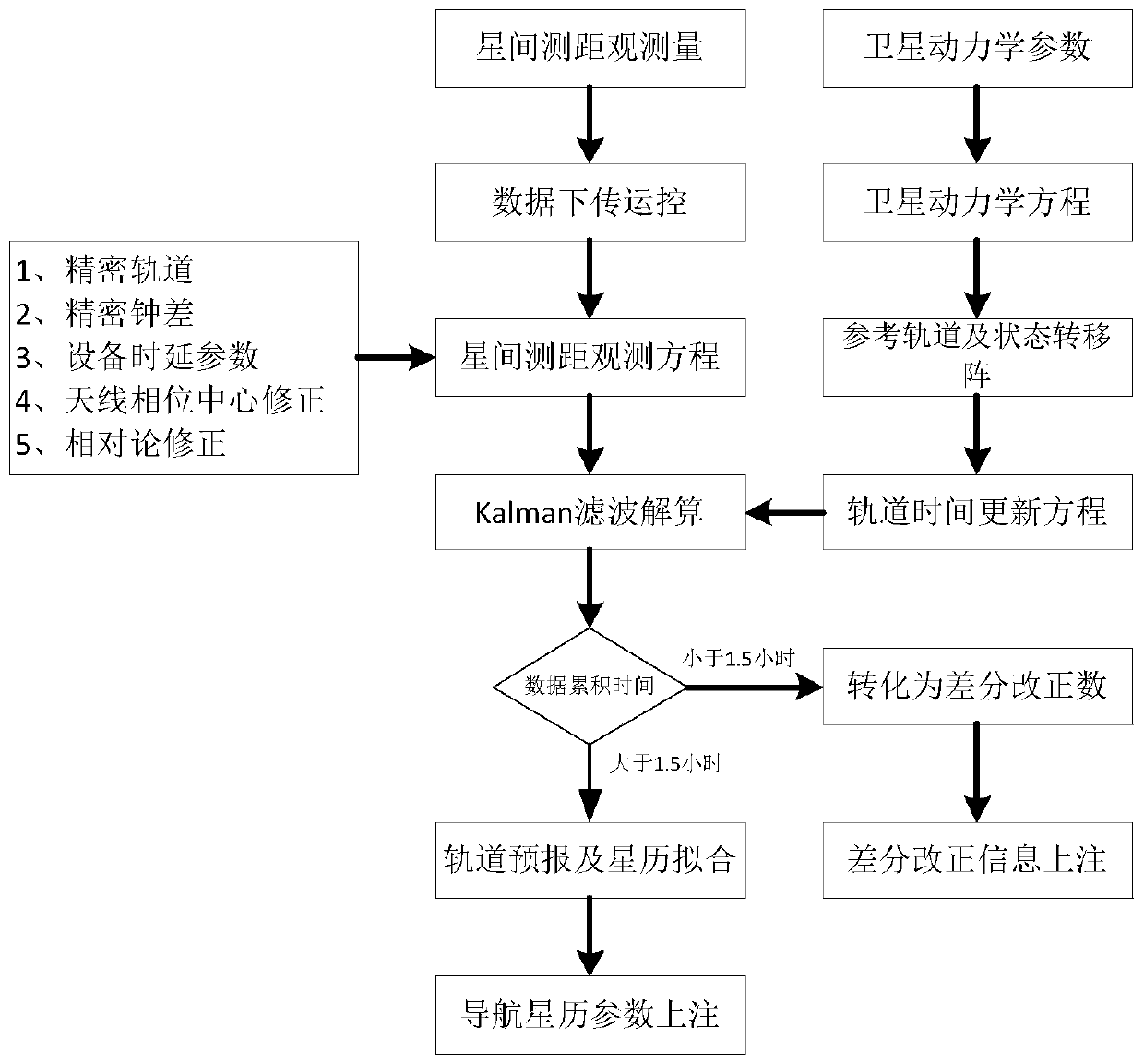

Method for realizing rapid recovery of GEO satellite after maneuvering through inter-satellite measurement

ActiveCN110426720AObservation accuracy is excellentImprove orbit accuracySatellite radio beaconingHigh level techniquesDynamic modelsObservation data

The invention provides a method for realizing rapid recovery of a GEO satellite after maneuvering through inter-satellite measurement. Inter-satellite bidirectional ranging observation data between the GEO satellite and a configurable chain Beidou satellite can be obtained by utilizing an inter-satellite link load; a non-maneuverable Beidou satellite orbit serves as a reference, an orbit determination observation equation is established by utilizing the inter-satellite ranging observation amount between the non-maneuverable Beidou satellite orbit and the GEO satellite, and a satellite state time updating equation can be built by utilizing an orbit dynamics model of the GEO satellite after maneuvering; the observation equation and the satellite state time updating equation are used, the sixnonsingular orbital elements serve as to-be-estimated parameters, a precise orbit of the GEO satellite after maneuvering is obtained, and by using the improved orbit, satellite position information of the GEO satellite after maneuvering is obtained through an upper injection differential correction mode or an orbit forecast and navigation ephemeris parameter fitting mode. The method effectively shortens the time of Beidou GEO satellite navigation positioning service interruption caused by orbital maneuvering, and improves the continuity and availability of services of a satellite navigation system.

Owner:中国人民解放军61540部队

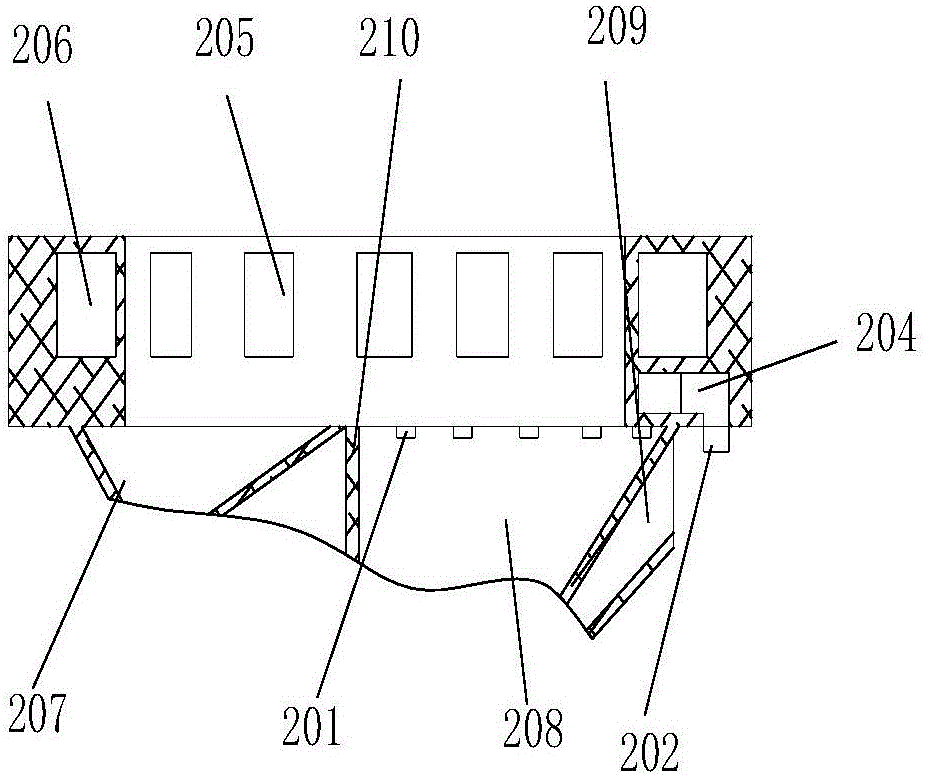

Vehicle-mounted hidden intelligent toilet

InactiveCN105662261ANot easy to scaleAvoid cloggingClimate change adaptationExcrement fertilisersEngineeringPollution

The invention relates to a vehicle-mounted hidden intelligent toilet and belongs to the technical field of sanitary equipment. The vehicle-mounted hidden intelligent toilet comprises a toilet body fixed to the interior of a vehicle seat, wherein a cushion used for opening the toilet body is arranged on the seat; a urine collecting area, an excrement collecting area and an exhaust system are arranged in the toilet body; the exhaust system is capable of exhausting gas in the toilet body out of a vehicle; the urine collecting area is communicated and provided with a urine processing system; the excrement collecting area is communicated and provided with an excrement processing system and a compressed air flushing system; a sealing element capable of sealing an opening of the toilet body and a spray deodorization system deodorizing the toilet body are arranged on the cushion. The vehicle-mounted hidden intelligent toilet can effectively eliminate odor and ensure the quality of air in the vehicle; an intelligent control system performs real-time biochemical treatment on collected excrement to obtain a pollution-free fertilizer, the whole treatment process is water-free, pollution-free and environmentally-friendly, and the aims of turning waste into treasure, saving water and keeping environmentally-friendly and ecological are achieved.

Owner:重庆市伟凡环保科技有限公司

Full automatic negative pressure fermentation and deodorization device for organic fertilizer and production process

InactiveCN1566030AReduced throughput timeReduced fermentation spaceBio-organic fraction processingOrganic fertiliser preparationAir filterFully automatic

The invention discloses a fully automatic negative pressure fermentation and deodorization device for organic fertilizer and production process, wherein the device comprises airtight type negative pressure plant, a computer system, an automatic exhausting hood, a pressure fan assembly, an extract fan assembly, a water pump, a watering device, a carwash cesspool, a temperature and moisture inductor, a pressure inductor, a compost fermentation groove, a negative pressure control air throttle, an air filter and conduit combination. The production process comprises fertilizer raw material stacking, air-supplying, fermentation, turning, air-supplying and material discharge.

Owner:蔡文志

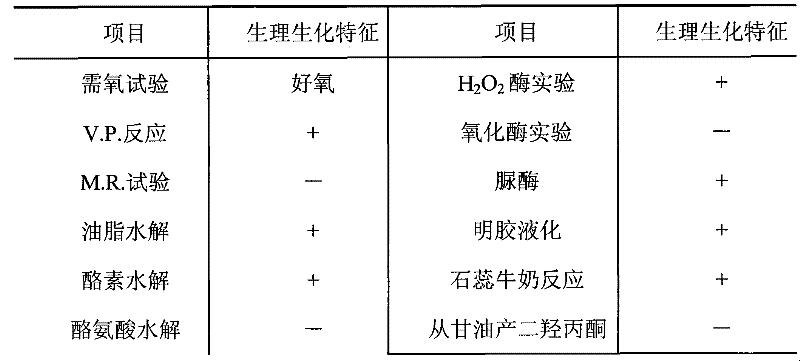

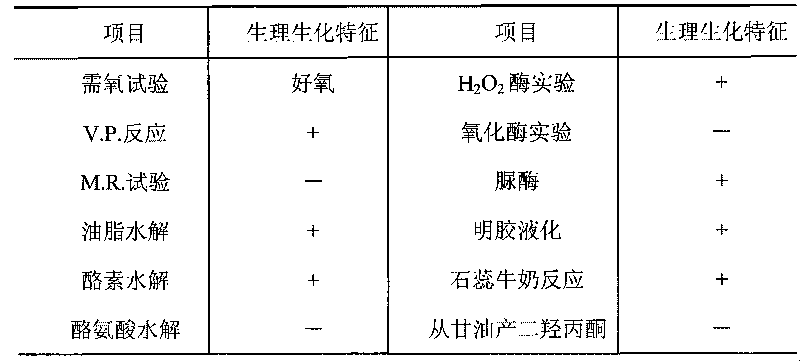

Bacillus subtilis and application thereof in biocatalysis production of niacinamide

ActiveCN101712944AHigh total enzyme activityReduce accumulation timeBacteriaMicroorganism based processesHigh concentrationNiacinamide

The invention belongs to the biochemical industry field and discloses a Bacillus subtilis and an application thereof in biocatalysis production of niacinamide. The nitrile hydratase produced by the Bacillus subtilis with CGMCC NO. 3342 can catalyze 3-cyanopyridine for hydration to generate niacinamide. The technology using Bacillus subtilis with CGMCC NO.3342 for biocatalysis production of niacinamide is used, and 3-cyanopyridine serves as a substrate, Bacillus subtilis with CGMCC NO. 3342 serves as a biocatalyst, and the mode of coupling and replenishing the substrate and the biocatalyst is adopted for catalytic hydration to obtain the niacinamide. The invention effectively lowers toxic action on cells by high-concentration substrates and products and is favorable for obtaining high-concentration niacinamide hydration liquid; the concentration of the niacinamide is not lower than 25%, which is favorable for product separation.

Owner:ANHUI RUIBANG BIOLOGICAL SCI & TECH CO LTD

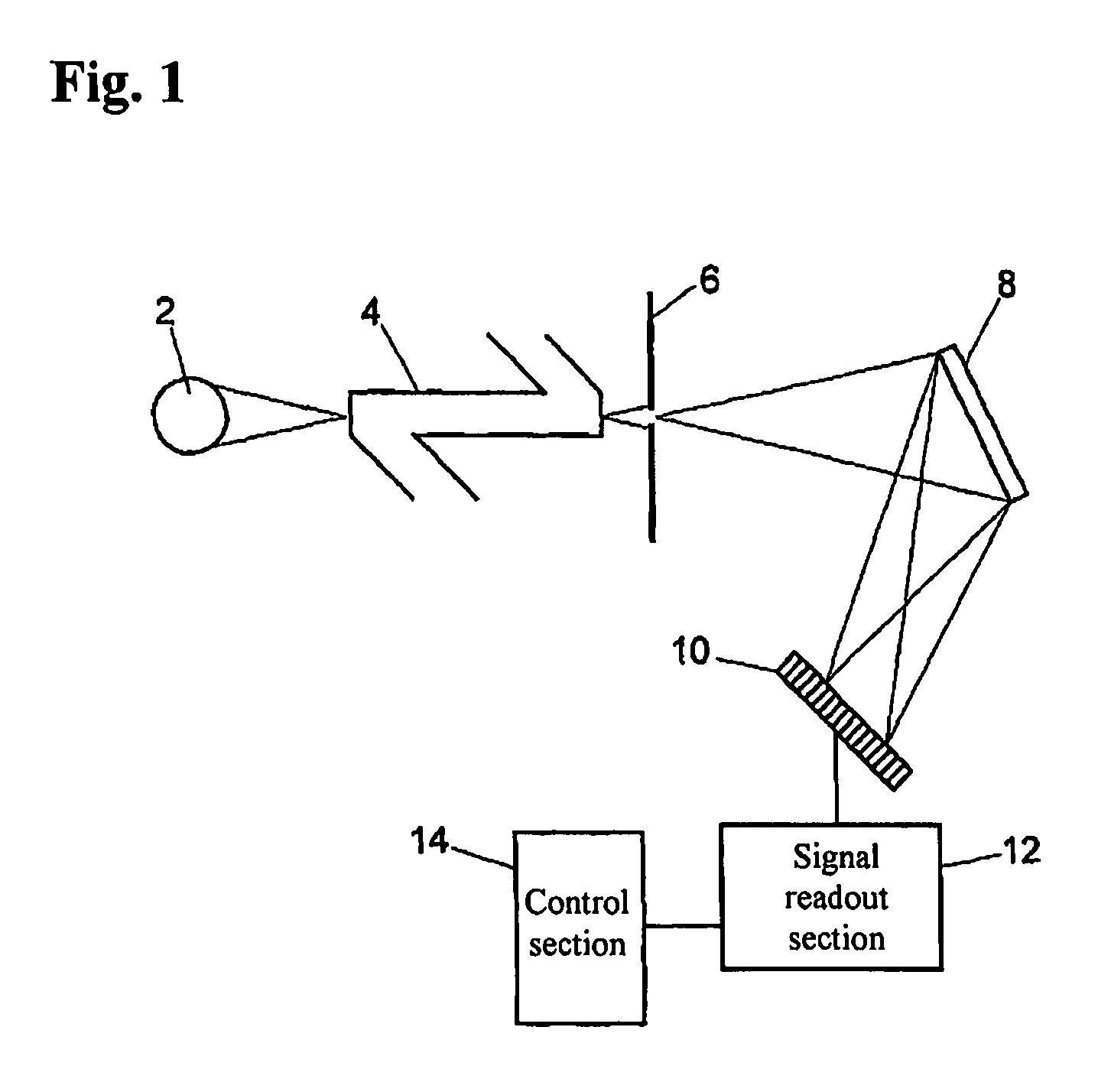

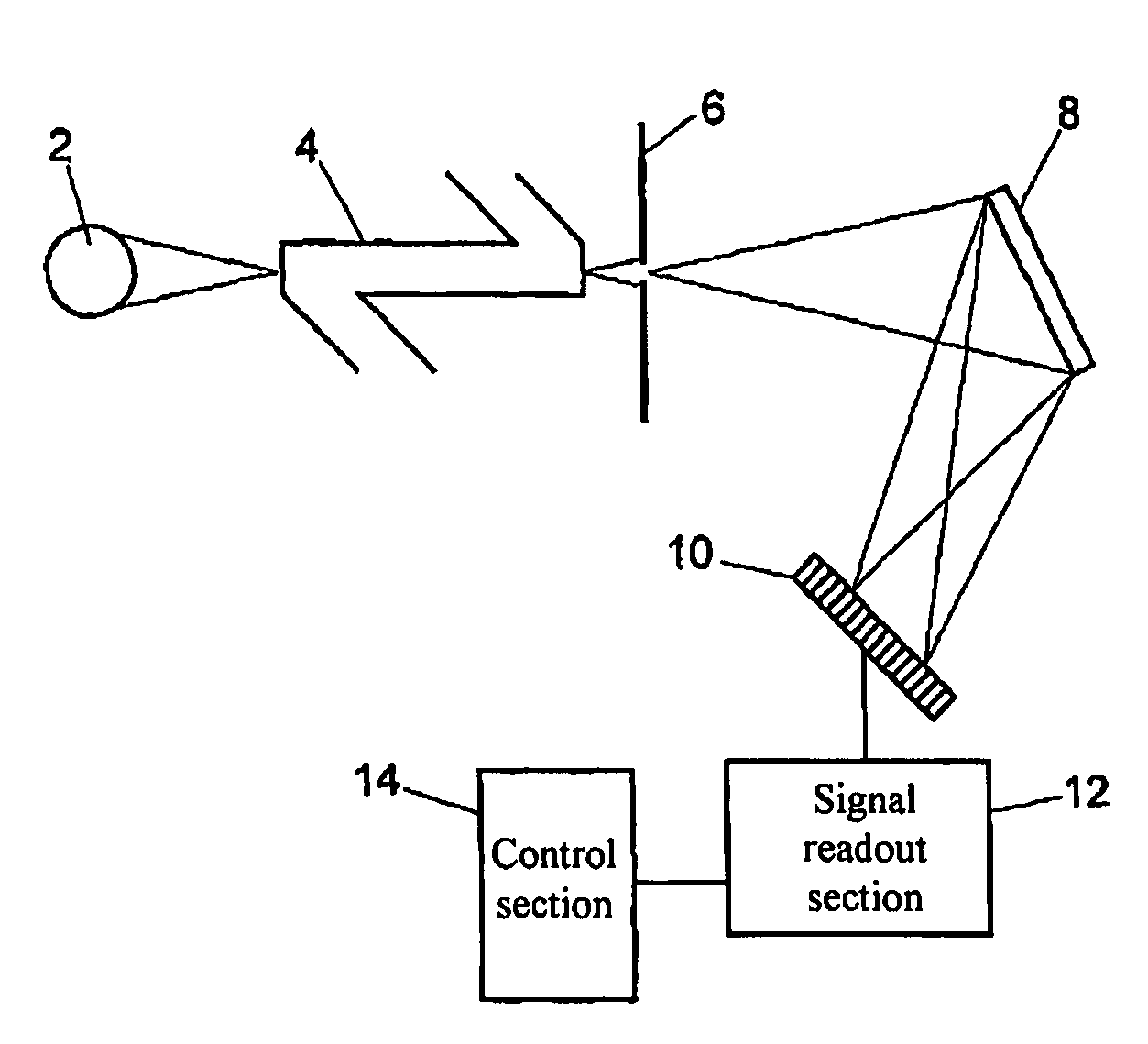

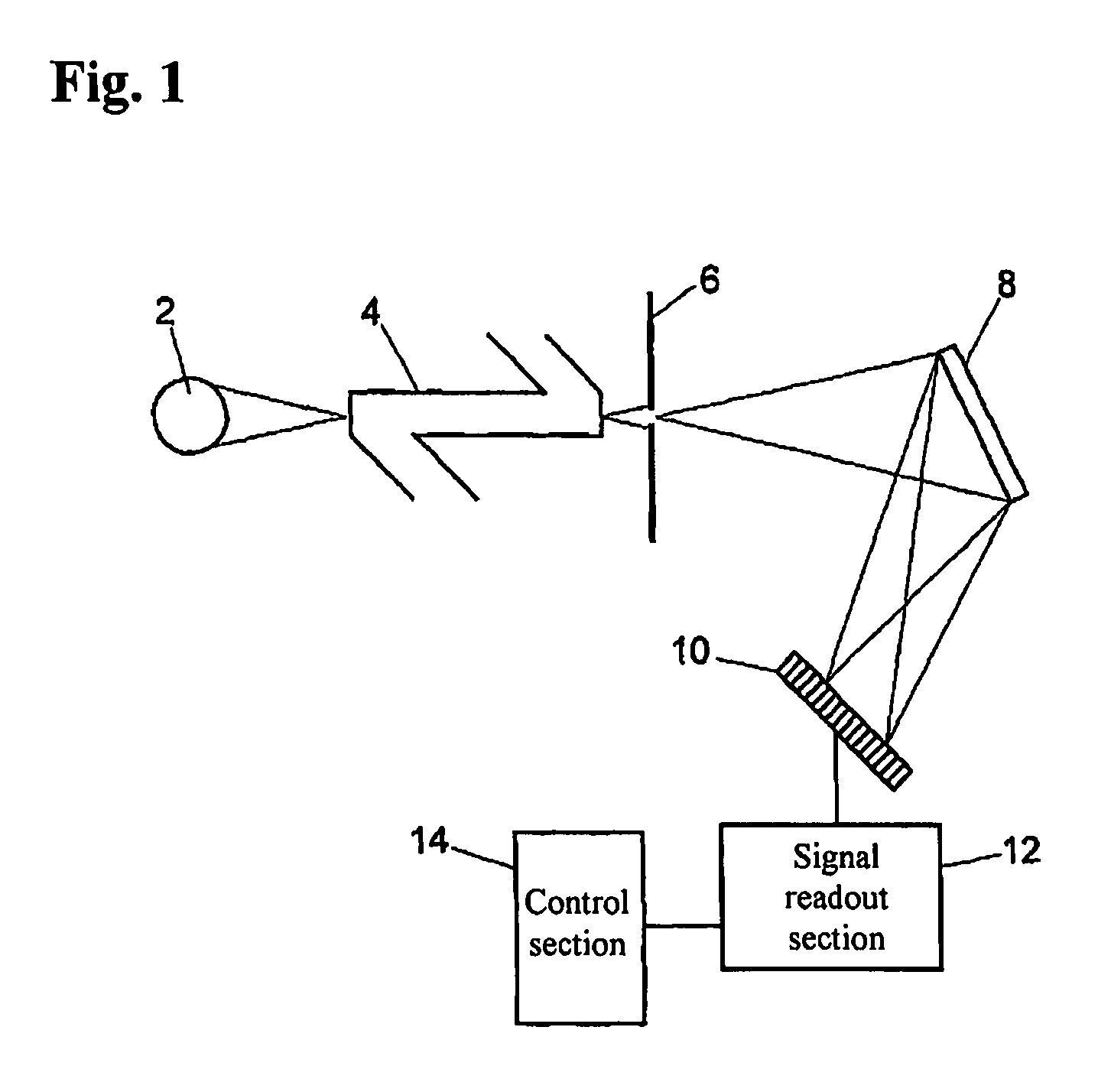

Spectrophotometer with optical system for spectrally dispersing measurement light and photodiode array

InactiveUS7511255B2Reduce chargeReduce signal strengthRadiation pyrometrySolid-state devicesFtir spectraPeak value

A spectrophotometer, in which an emission spectrum of the light source is measured. Based on the measured emission spectrum, a threshold is set to allow only an outstanding spectral intensity in a specific wavelength region to be greater than the threshold. Then, a ratio between the setup threshold and a peak spectral intensity in the specific wavelength region greater than the threshold is calculated. Then, an electric-charge accumulation time for a light-receiving element corresponding to a wavelength region equal to or less than the threshold is set at an upper limit of electric-charge accumulation time causing no saturation in any light-receiving element. Based on the ratio between the threshold and the peak spectral intensity in the specific wavelength region greater than the threshold, an electric-charge accumulation time for the light-receiving element corresponding to the specific wavelength region greater than the threshold is set.

Owner:SHIMADZU CORP

Spectrophotometer

InactiveUS20080067328A1Reduce chargeReduce signal strengthRadiation pyrometrySolid-state devicesPeak valueLength wave

A spectrophotometer, in which an emission spectrum of the light source is measured. Based on the measured emission spectrum, a threshold is set to allow only an outstanding spectral intensity in a specific wavelength region to be greater than the threshold. Then, a ratio between the setup threshold and a peak spectral intensity in the specific wavelength region greater than the threshold is calculated. Then, an electric-charge accumulation time for a light-receiving element corresponding to a wavelength region equal to or less than the threshold is set at an upper limit of electric-charge accumulation time causing no saturation in any light-receiving element. Based on the ratio between the threshold and the peak spectral intensity in the specific wavelength region greater than the threshold, an electric-charge accumulation time for the light-receiving element corresponding to the specific wavelength region greater than the threshold is set.

Owner:SHIMADZU CORP

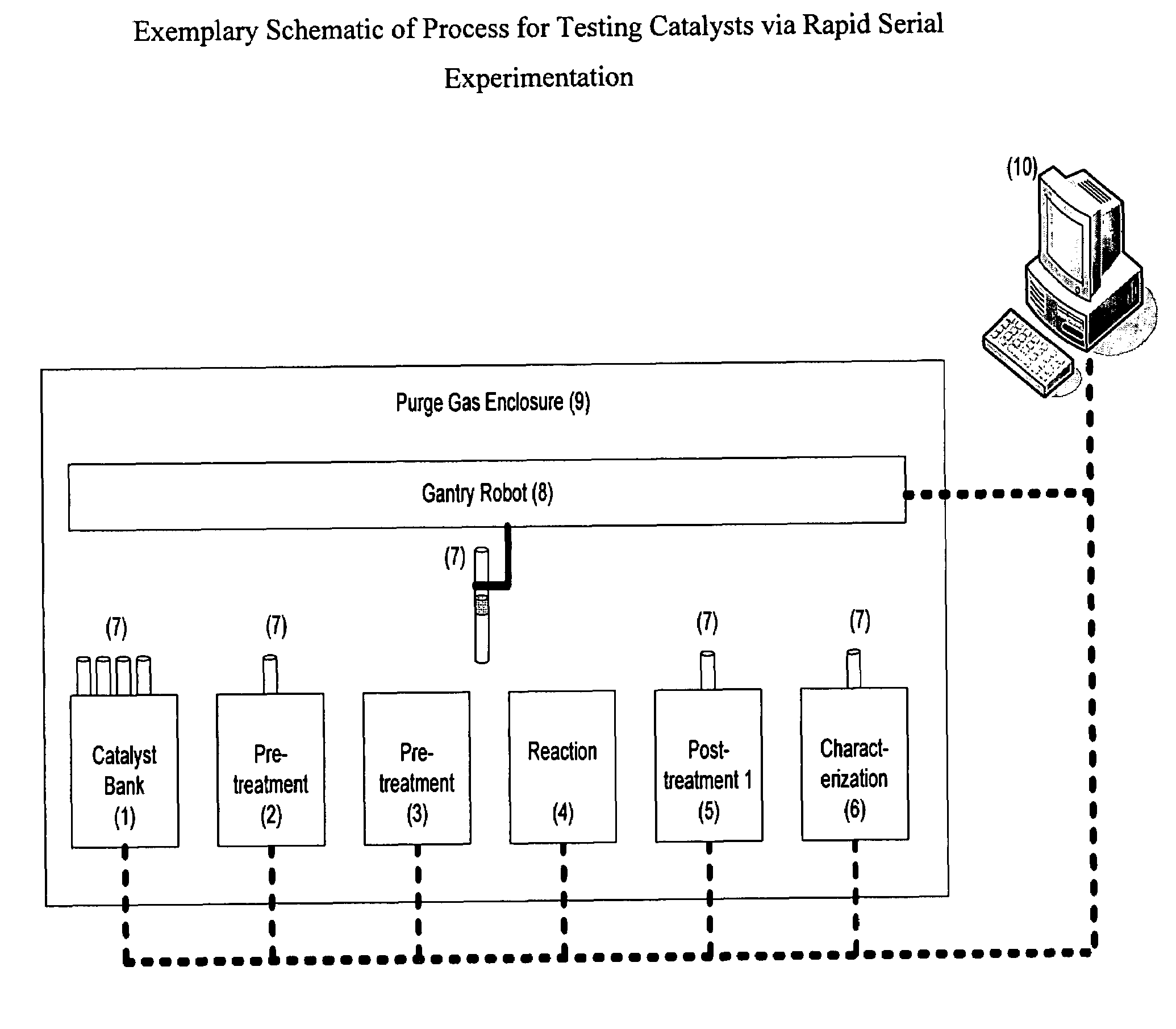

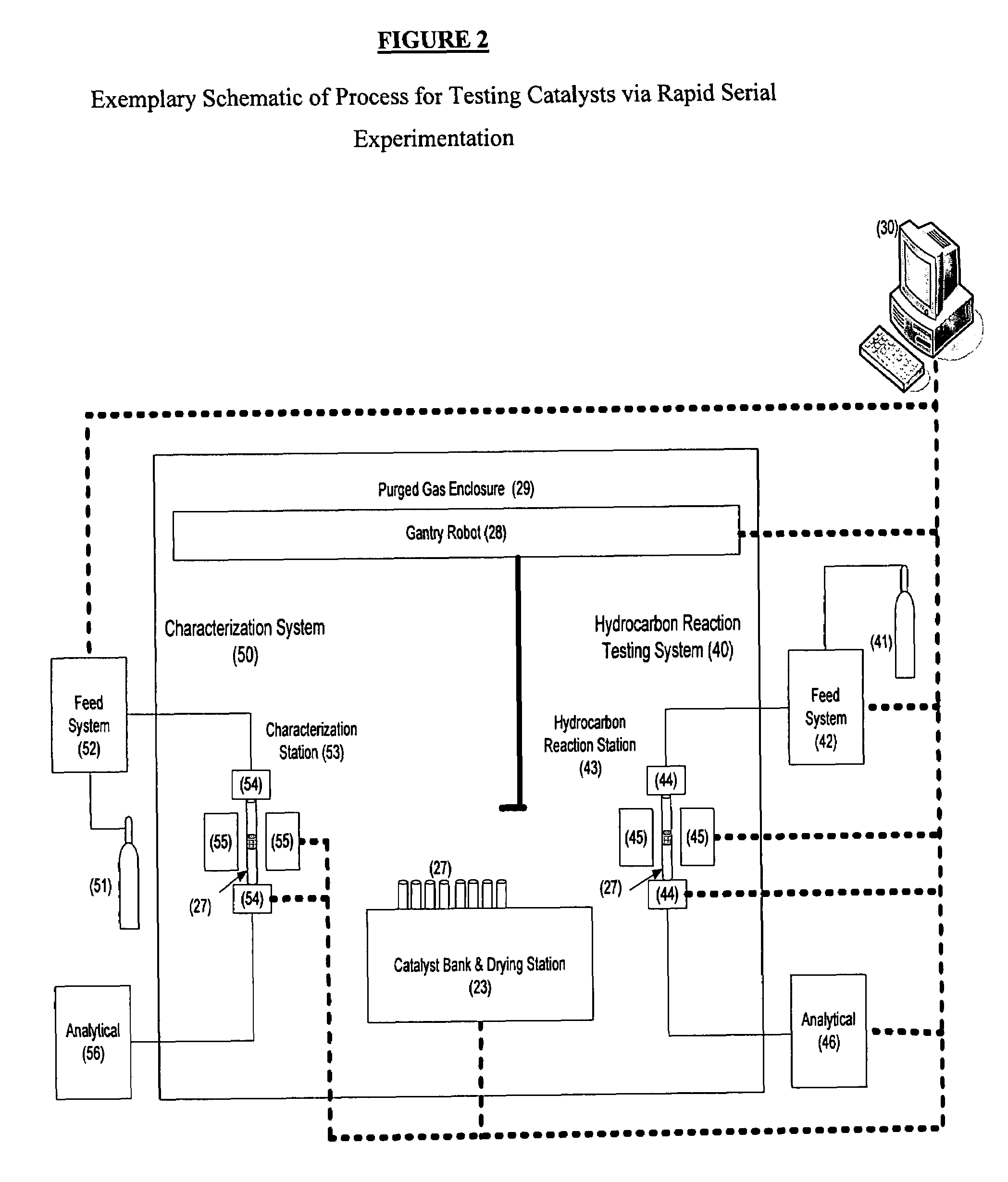

Rapid serial experimentation of catalysts and catalyst systems

InactiveUS20080014639A1Cycle fastShort reaction timeComponent separationAnalysis by thermal excitationProduct gasLaboratory test

The present invention relates to a method of testing catalysts and catalyst systems via a plurality of stations in which each station can accommodate a common reactor module in order to accomplish unattended, automated, rapid serial experimentation. The method includes the steps of: providing within a purged chamber a storage station of pre-loaded catalyst reactors, a hydrocarbon reaction station, one or more additional pre-treatment and / or post-treatment stations in series with said hydrocarbon reaction station, and a robotic means for moving catalyst reactors within the purged chamber between stations, pre-treating the pre-loaded catalyst reactor with a treatment gas in the post-treatment station, reacting the pre-loaded catalyst reactor with a hydrocarbon reactant in the hydrocarbon reaction station, post-treating the pre-loaded catalyst reactor with a treatment gas in the post-treatment station, and repeating the foregoing steps such that the pre-treating, reacting and post-treating steps occur simultaneously for two different pre-loaded catalyst reactors. The advantages of the present invention include improved accuracy, reproducibility and quality of test data generated, increased testing throughput rate, providing for automated unattended operation of the device, providing for the ability the ability to program a variety of sequences and settings, providing for the combination of a variety of processes (pre-treatment, HC reaction testing, post-treatment, aging, and characterization), and providing for higher temperature operation. The method finds application in laboratory test environments, and in particular in high throughput testing environments.

Owner:EXXON RES & ENG CO

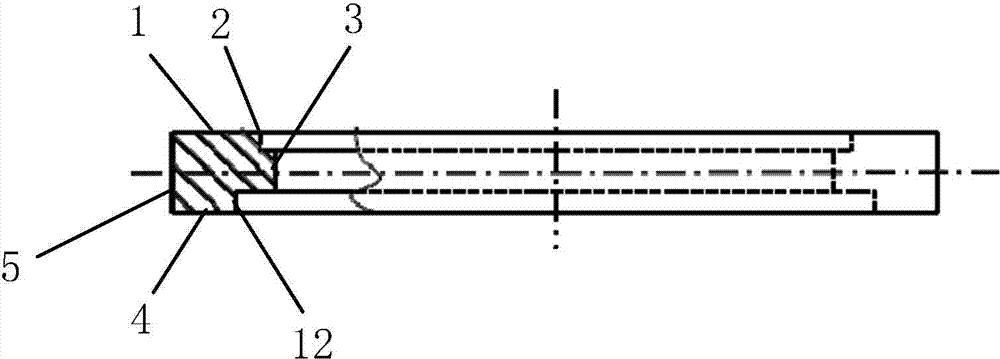

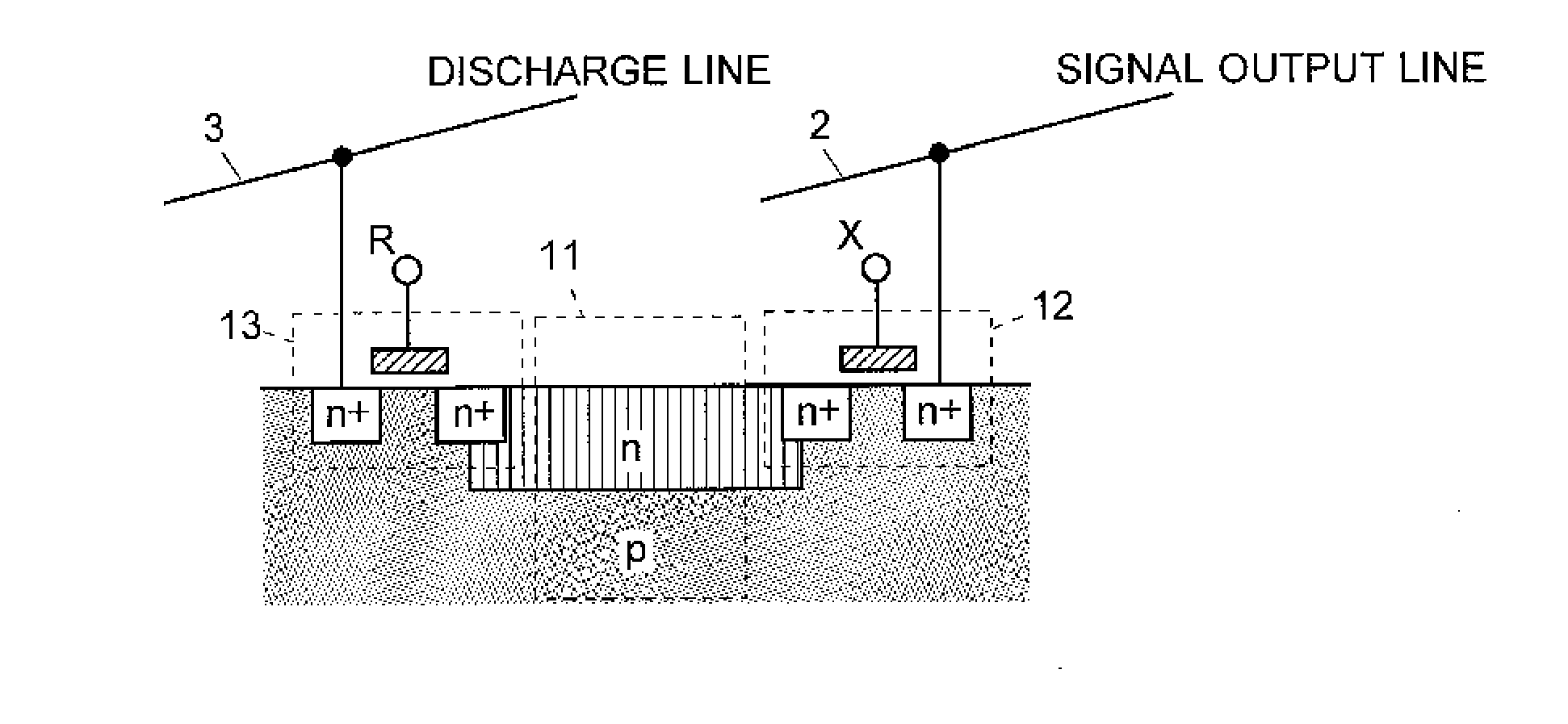

Linear image sensor and driving method therefor

InactiveUS20150296160A1Reduce accumulation timeLong accumulation timeTelevision system detailsTelevision system scanning detailsShift registerEngineering

A logical gate circuit (5) and four stages of flip flips (4a-4d) are assigned to each pixel (1). A controller (7) inputs four phase identification signals into the logical gate circuit (5) and also inputs a start signal STR into a shift register (4) synchronously with the four mutually different phases defined by the phase identification signals. During one round of scanning all the pixels (1) for a readout control, if an enable signal ENBL is set to “0” while an output of a phase identification circuit (110) is “1”, a charge accumulation time at the pixel (1) concerned becomes equal to a readout period T. If the enable signal ENBL is set to “1” while the output of the phase identification circuit (110) is “1”, electric charges accumulated in a photodiode (11) until that point are entirely discarded, so that the charge accumulation time becomes shorter than the readout period T. Thus, the charge accumulation time at each pixel (1) can be controlled to ensure an adequate SN ratio while avoiding signal saturation at some pixels even if the light source has a bright line at a specific wavelength.

Owner:SHIMADZU CORP +1

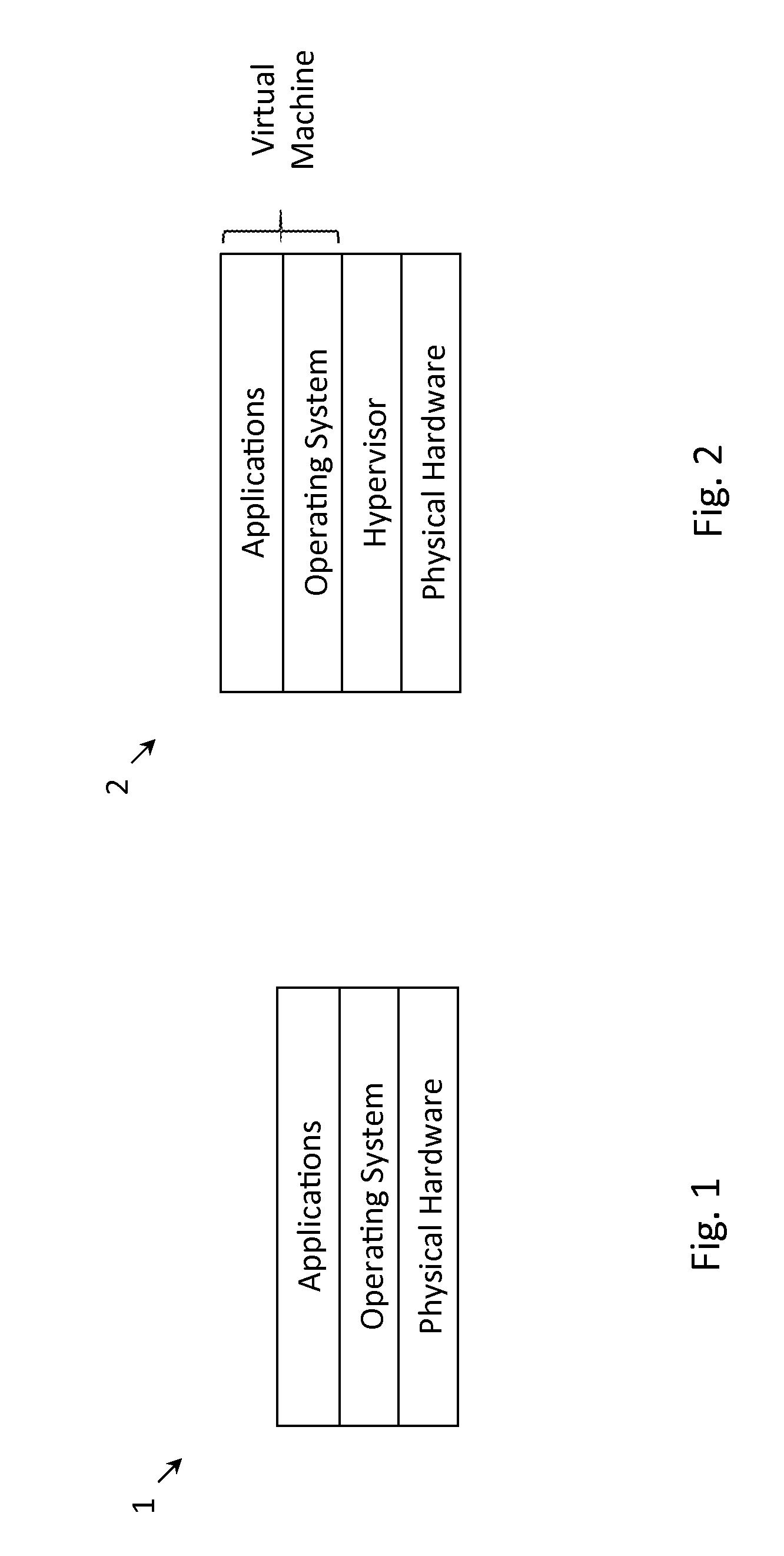

Methods and systems for creating and removing virtual machine snapshots based on groups of metrics

ActiveUS20160063014A1Minimize impactSignificant changeDigital data information retrievalError detection/correctionVirtual machineHypervisor

Techniques are described herein which minimize the impact of virtual machine snapshots on the performance virtual machines and hypervisors. In the context of a volume snapshot which may involve (i) taking virtual machine snapshots of all virtual machines associated with the volume, (ii) taking the volume snapshot, and (iii) removing all the virtual machine snapshots, the virtual machine snapshots may be created in a first order and removed in a second order. Specifically, snapshots for busy virtual machines (i.e., virtual machines with higher disk write activity) may be created last and removed first. Consequently, snapshots of busy virtual machines are retained for the shorter periods of time, thereby minimizing the effect of virtual machine snapshots on those virtual machines (and their associated hypervisors) that would be most negatively impacted by virtual machine snapshots.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

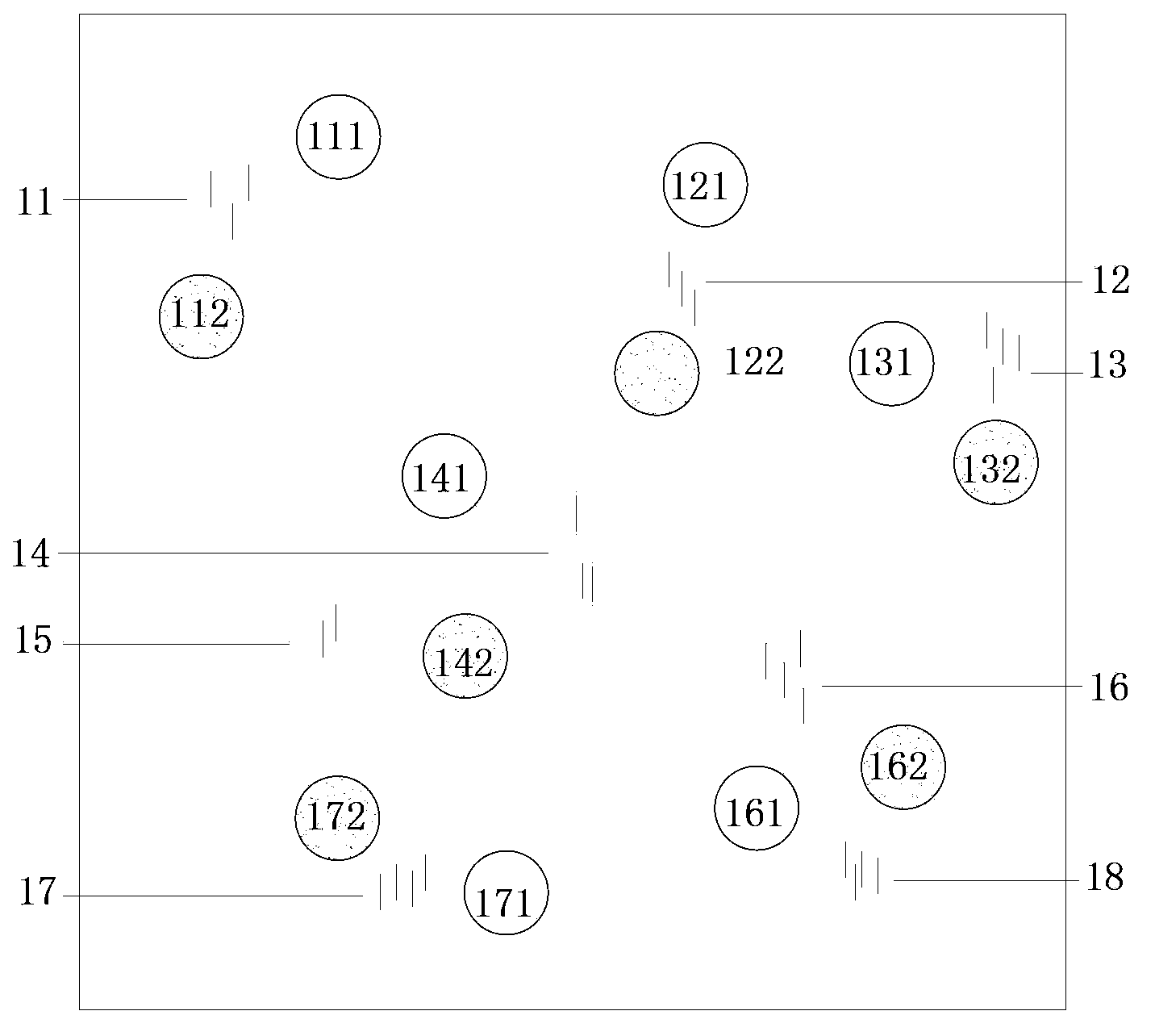

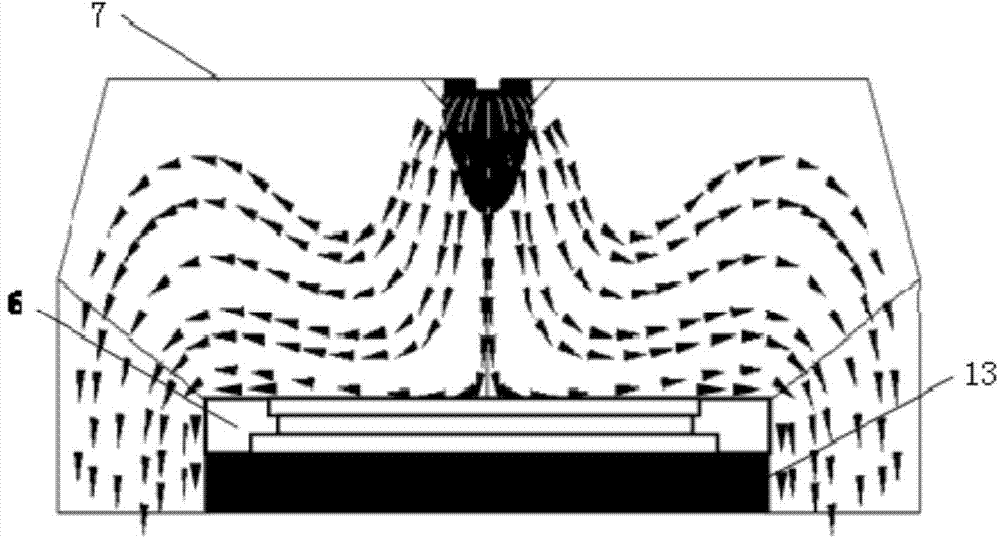

1.5 [mu]m wavelength aerosol detection laser radar based on pulse coding and signal decoding method

ActiveCN112965086AImprove signal-to-noise ratioEasy to identifyElectromagnetic wave reradiationICT adaptationBeam splitterRadar systems

The invention relates to a 1.5 [mu]m wavelength aerosol detection laser radar based on pulse coding and a signal decoding method. According to the laser radar, the output end of a seed laser, the input ends and output ends of a first electro-optical modulator, a second electro-optical modulator, an optical fiber amplifier and a beam splitter, and the input end of a collimator are connected in sequence; the output end of a receiving telescope, the input ends and output ends of a filter, an indium gallium arsenic quantum detector, an acquisition card and a computer and the input end of a waveform generator are connected in sequence; and the input end of an energy detection channel is connected with the output end of the beam splitter, the output end of the energy detection channel is connected with the input end of the acquisition card, and the output end of the waveform generator is connected with the first electro-optical modulator and the second electro-optical modulator. According to the laser radar and the method, the fuzzy distance of a time-of-flight method is broken through, the size is reduced, meanwhile, the stability of a radar system is improved, the identification capacity for large-particle-size aerosol distribution is improved, the cloud penetrating capacity is improved, and detection equipment is provided for researching atmospheric science.

Owner:UNIV OF SCI & TECH OF CHINA

Rapid serial experimentation of catalysts and catalyst systems

InactiveUS7482164B2Cycle fastShort reaction timeComponent separationAnalysis by thermal excitationComputer moduleProduct gas

The present invention relates to a method of testing catalysts and catalyst systems via a plurality of stations in which each station can accommodate a common reactor module in order to accomplish unattended, automated, rapid serial experimentation. The method includes the steps of: providing within a purged chamber a storage station of pre-loaded catalyst reactors, a hydrocarbon reaction station, one or more additional pre-treatment and / or post-treatment stations in series with said hydrocarbon reaction station, and a robotic means for moving catalyst reactors within the purged chamber between stations, pre-treating the pre-loaded catalyst reactor with a treatment gas in the post-treatment station, reacting the pre-loaded catalyst reactor with a hydrocarbon reactant in the hydrocarbon reaction station, post-treating the pre-loaded catalyst reactor with a treatment gas in the post-treatment station, and repeating the foregoing steps such that the pre-treating, reacting and post-treating steps occur simultaneously for two different pre-loaded catalyst reactors. The advantages of the present invention include improved accuracy, reproducibility and quality of test data generated, increased testing throughput rate, providing for automated unattended operation of the device, providing for the ability the ability to program a variety of sequences and settings, providing for the combination of a variety of processes (pre-treatment, HC reaction testing, post-treatment, aging, and characterization), and providing for higher temperature operation. The method finds application in laboratory test environments, and in particular in high throughput testing environments.

Owner:EXXON RES & ENG CO

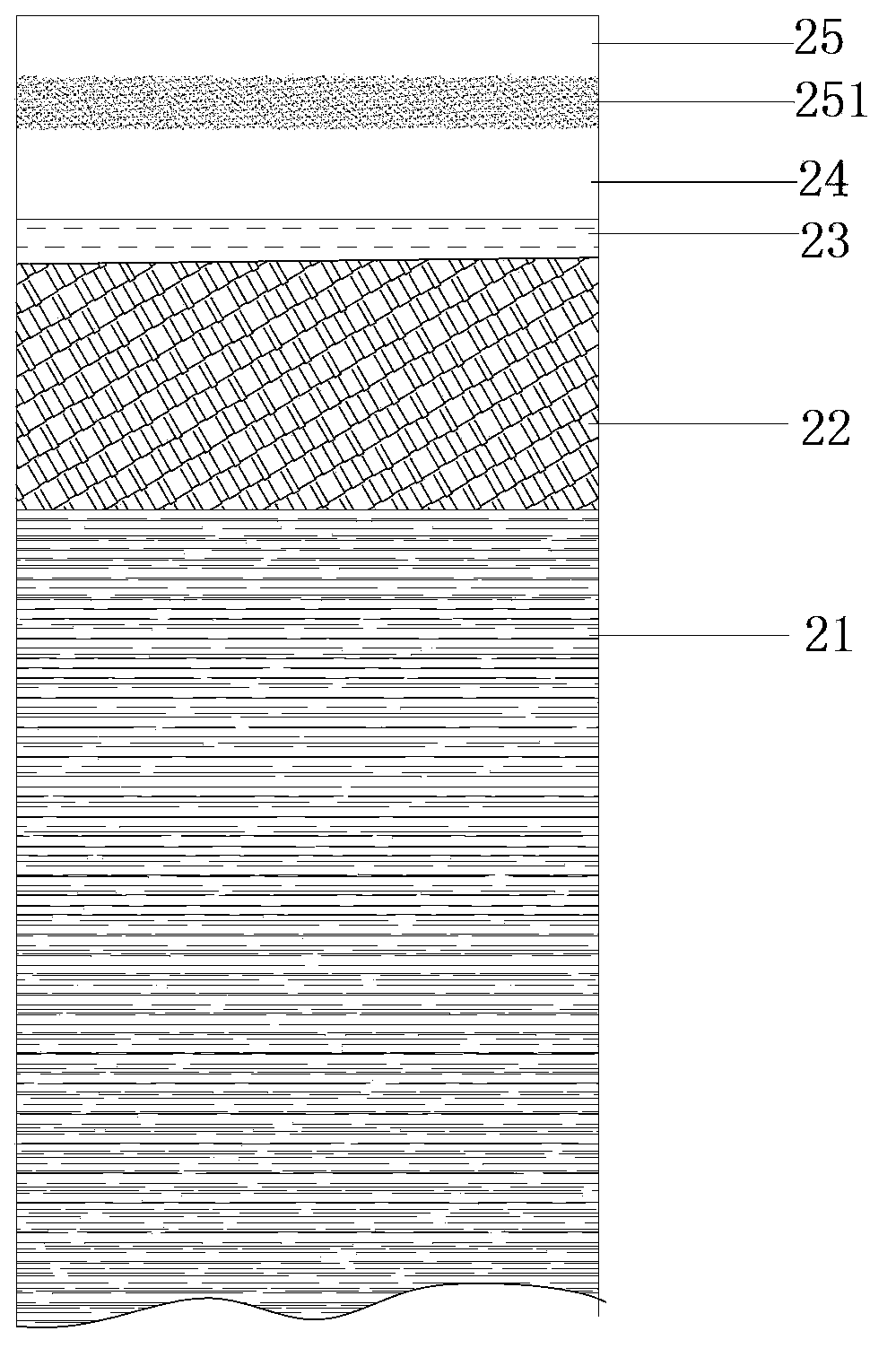

Back-illuminated high-speed photodiode receiving chip and manufacturing method thereof

ActiveCN106784118BIncrease absorption lengthImprove quantum efficiencySemiconductor devicesIndiumEngineering

The invention provides a back lighting type photodiode receiving chip and a manufacturing method thereof. The chip comprises an epitaxial layer, the epitaxial layer comprises a P-shaped table face, an N-shaped table face and an indium phosphide substrate; the P-shaped table face comprises an InGaAs absorbing layer, an InGaAsP gradient layer, a reflective mirror layer, an indium phosphide top layer and an InGaAs contact layer; the N-shaped table face comprises an indium phosphide buffer layer; the indium phosphide buffer layer, the InGaAs absorbing layer, the InGaAsP gradient layer, the reflective mirror layer, the indium phosphide top layer and the InGaAs contact layer are grown on the indium phosphide substrate in sequence; an integrated micro lens is arranged at one side of the indium phosphide substrate, and the integrated micro lens and the indium phosphide buffer layer are at the different sides of the indium phosphide substrate. According to the back lighting type photodiode receiving chip and a manufacturing method, on the condition of guaranteeing that chip diffused source area keeps constant, the light absorption area of the chip is expanded, the problem of low coupling efficiency caused by small chip diffused source area is solved, and through the addition of the reflective mirror layer, the quantum efficiency of the chip can be improved.

Owner:SHENZHEN PHOGRAIN INT TECH DEV

Bacillus subtilis and application thereof in biocatalysis production of niacinamide

ActiveCN101712944BHigh total enzyme activityReduce accumulation timeBacteriaMicroorganism based processesHigh concentrationNiacinamide

The invention belongs to the biochemical industry field and discloses a Bacillus subtilis and an application thereof in biocatalysis production of niacinamide. The nitrile hydratase produced by the Bacillus subtilis with CGMCC NO. 3342 can catalyze 3-cyanopyridine for hydration to generate niacinamide. The technology using Bacillus subtilis with CGMCC NO.3342 for biocatalysis production of niacinamide is used, and 3-cyanopyridine serves as a substrate, Bacillus subtilis with CGMCC NO. 3342 serves as a biocatalyst, and the mode of coupling and replenishing the substrate and the biocatalyst is adopted for catalytic hydration to obtain the niacinamide. The invention effectively lowers toxic action on cells by high-concentration substrates and products and is favorable for obtaining high-concentration niacinamide hydration liquid; the concentration of the niacinamide is not lower than 25%, which is favorable for product separation.

Owner:ANHUI RUIBANG BIOLOGICAL SCI & TECH CO LTD

Reclamation method for sunk paddy field caused by mining in mountainous regions

ActiveCN103039147BImprove applicabilityEasy to operateSoil lifting machinesSoil-working methodsSoil scienceWater leakage

The invention relates to a reclamation method for a sunk paddy field caused by mining in mountainous regions and belongs to the technical field of improvement and utilization of environment, ecology and damaged fields. The method includes: performing topsoil stripping to fissured positions where fissures are created by mining sinking and lead to water leakage of the paddy field; covering water holding materials on fissured areas after topsoil stripping; compacting the covered water holding materials, pouring slurry and standing; performing topsoil backfilling and grinding to the fissured areas after slurry pouring and standing, and flattening to enable the fissured areas to be a whole with pieces of the paddy field around the fissured areas; and irrigating, nourishing and improving the paddy field after backfilling and grinding. By the method, the cultivation land where the fissures are created by mining sinking and lead to water leakage of the paddy field can restore the paddy field utilization mode and reach production level of a normal paddy field as soon as possible, a stable self-maintaining farmland ecological system can be formed, a paddy field protecting system can be formed, soil microbial content can be increased, physicochemical property of soil can be improved, and benign farmland ecological system circulation can be formed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Novel, healthy, environment-friendly and skin-care multifunctional cleanser powder and preparation process therefor

InactiveCN106520385AImprove performanceLess irritatingInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsMaterials scienceCleanser

The invention belongs to the technical field of cleanser powder and particularly provides novel, healthy, environment-friendly and skin-care multifunctional cleanser powder. The multifunctional cleanser powder is mainly prepared from the following raw materials in parts by weight: 8-11 parts of sodium benzosulfonate, 8-11 parts of benzenesulfonic acid, 1-3 parts of water, 1-3 parts of urea, 1-3 parts of adeps lanae, 25-32 parts of sand, 0.8-1.1 parts of carboxymethyl cellulose, 4-6 parts of tartaric acid, 127-135 parts of sodium silicate and 1-3 parts of olive oil. The invention further correspondingly provides a preparation process for the multifunctional cleanser powder. The process comprises the steps of carrying out grouped compounding on all the raw materials, carrying out stirring and mixing, carrying out screening and carrying out granulating. The pH of a solution of the multifunctional cleanser powder provided by the invention is always in a neutral-to-alkalescent range, and the multifunctional cleanser powder is good and stable in decontamination effect and noncorrosive to skin and is environmentally friendly. The preparation process provided by the invention is simple in step, low in energy consumption and free of generation of waste gases, waste water and waste residues and is healthy and environmentally friendly.

Owner:张立超

Method for accumulating fermented grains of baijiu under high temperature by utilizing disc koji-making machine

InactiveCN106754098AGuaranteed normal heatingIncrease productivityAlcoholic beverage preparationEngineeringYeast

The invention discloses a method for accumulating fermented grains of baijiu under high temperature by utilizing a disc koji-making machine, belonging to the technical field of wine brewing. The method comprises the following steps: (1) preheating, namely starting the disc koji-making machine and introducing hot air; (2) adding the distiller yeast, namely putting the fermented grains into the disc koji-making machine through a conveyor belt, paving a yeast room through a distiller yeast adding auger and uniformly stirring by a yeast-turning machine; (3) accumulating and culturing, namely starting and atomizing the disc koji-making machine, introducing hot air, changing the hot air temperature following the increasing of time, starting to ferment the fermented grains, increasing the temperature and then stopping introducing hot air and atomizing, blowing air and reducing the temperature when the increased temperature meets the technological requirement for the product temperature; (4) discharging the yeast, namely conveying the cooled fermented grains into a fermentation vessel and fermenting. According to the invention, the disc koji-making machine is utilized to accumulate the fermented grains of baijiu under high temperature; the fermented grains can be maintained under the environments of heat insulation, moisture preservation and heating in the fourth to seventh accumulation processes under the lowest air temperature; the normal temperature rise of the fermented grains is guaranteed; the accumulation time is shortened; the production efficiency is improved.

Owner:HUBEI UNIV OF TECH

Image inputting apparatus and image forming apparatus using four-line CCD sensor

ActiveUSRE42742E1Photoelectric converting efficiency (sensitivity) of the line sensorPhotoelectric converting efficiency of the line sensorPictoral communicationLine sensorImage formation

A four-line CCD sensor is structured by line sensors R, G, B in which color filters are respectively disposed on surfaces of light receiving elements, and a line sensor BK at which no color filter is disposed. Amplitudes of signals which are outputted from the line sensors R, G, B at a time of reading a color document, and an amplitude of a signal which is outputted from the line sensor BK at a time of reading a monochrome document are adjusted so as to be substantially equal to one another. In a case in which a color document is read, outputs of the line sensors R, G, B are selectively provided, and in a case in which a monochrome document is read, output of the line sensor BK is selectively provided.

Owner:KK TOSHIBA +1

Edge ring of etching device

ActiveCN103887138ARelieve pressureNot easy to pile upElectric discharge tubesSemiconductor/solid-state device manufacturingProduction rateEtching

The invention discloses an edge ring of an etching device. According to the edge ring of the etching device, the horizontal plane of the upper surface of an existing edge ring is improved into a plane which is oblique downwards, the flowing direction of airflow passing through the upper surface of the edge ring is changed, the defect that airflow can be blocked by the horizontal plane of the upper surface of the existing edge ring is overcome, products obtained through etching can be easily sucked and taken away by a molecular pump along the plane oblique downwards of the edge ring under the driving of the airflow which can turn along the oblique plane in a cavity, the problem that the products obtained through etching can be accumulated on the upper surface of the existing edge ring and can be stripped from the upper surface of the existing edge ring is solved, the cleaning period of a machine is guaranteed, and the production rate is increased. Meanwhile, the risk of pollution, caused by stripping of polymers, to the cavity is lowered obviously, and it is guaranteed that a high yield is obtained.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

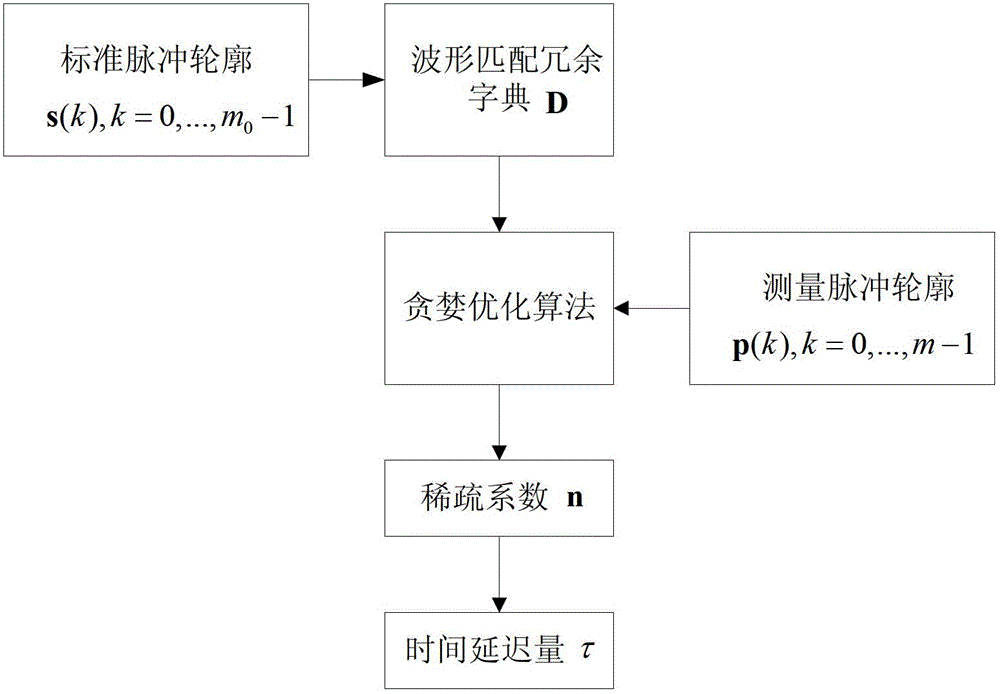

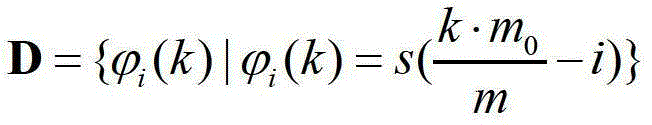

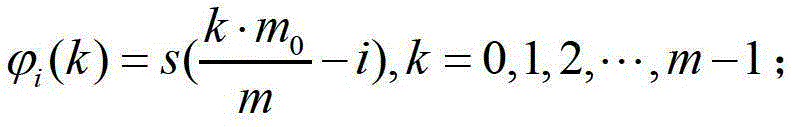

Time-delay measurement method for pulsar cumulative pulse profile using sparse representation

InactiveCN103217162BInfluence of measurement accuracyReduce computationInstruments for comonautical navigationEuclidean vectorSignal-to-quantization-noise ratio

The invention discloses an accumulated pulse profile time delay measurement method by sparse representation, and aims to mainly solve the problem that the sampling frequency and signal to noise ratio of pulse profiles can affect measurement accuracy in the prior art. The method is realized by the steps of: (1) conducting standard pulse profile sampling, and constructing a waveform matching redundant dictionary; (2) employing a greedy optimization algorithm to calculate a first-order sparse coefficient vector of the measurement pulse profile under the waveform matching redundant dictionary; and (3) according to the column corresponding to the only nonzero element in the first-order sparse coefficient vector, calculating the accumulated pulse profile time delay. Compared with the prior art, the method provided in the invention significantly reduces computation, improves the measurement precision of time delay, shortens the pulse profile accumulation time, and can be used for measurement of the time difference of arrival (TDOA) of the pulse from a spacecraft to a solar system barycenter.

Owner:XIDIAN UNIV

Incompletely plasticized plastic granulator and granulating method thereof

The invention discloses an incompletely plasticized plastic granulator which comprises a stand, a power device, a feeding device, a heating device, an extruding device, a dicing device and a discharging device, wherein the feeding device comprises a first thread sleeve section and a front part of a screw rod; and the extruding device comprises a second nut sleeve section, a third nut sleeve section and a middle-rear part of the screw rod. The plastic granulator disclosed by the invention has a reasonable structure; a granulating method is novel; the purposes of low energy consumption and high throughput can be realized in the whole production process; in addition, the quality and the value of the product can be well guaranteed; and the invention has favorable application value and market value.

Owner:东莞市吉田机械有限公司

Waterproof flame-retardant biological membrane and preparation process thereof

The invention discloses a waterproof flame-retardant biological membrane. According to the weight component ratio, the waterproof flame-retardant biological membrane comprises the following components: 85 to 95 parts of polylactic acid fiber, 5 to 8 parts of plasticizer, 1.1 to 1.3 parts of hydrophobic agent, 0.5 to 0.8 part of dispersing agent, 0.5 to 0.8 part of antioxidant, 0.5 to 0.9 part of vinyl ketone polymer additive, 0.4 to 0.8 part of starch phosphate reactive flame retardant, 0.2 to 0.4 part of lubricant and a proper amount of deionized water. The invention has the following advantages: when the produced biological membrane is discarded into the environment, the biological membrane is degraded and rotten in the environment, so that the environment is not polluted; the biologicalmembrane can be decomposed in an accelerated mode under the illumination condition, the degradation efficiency of the biological membrane is improved, and the pollutant accumulation time is shortened.

Owner:杭州奥风科技有限公司

Ion trap mass spectrometry method

InactiveUS7989764B2Reduce accumulation timeHigh strengthStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryHigh frequency power

According to an aspect of the present invention, there are provided an ion trap mass spectrometry method and an ion trap mass spectrometry device using a mass spectrometer, the mass spectrometer including: an ion source part for ionizing a sample; an ion trap part for trapping ions generated in the ion source; a main high frequency power source for applying a main high frequency voltage to the ion trap part, and an auxiliary high frequency power source for applying an auxiliary high frequency voltage thereto; and a detector for detecting the ions ejected from the ion trap. The ion trap mass spectrometry method and the ion trap mass spectrometry device includes the steps of: accumulating desired ions into the ion trap part by ejecting undesired ions while accumulating ions into the ion trap part; and ejecting undesired ions that remain in the ion trap part and leaving the desired ions in the ion trap part are repeated alternately.

Owner:HITACHI HIGH-TECH CORP

Frequency domain coherent joint capture method of GNSS data/pilot mixed signal

InactiveCN102279402BReduce accumulation timeEfficient captureSatellite radio beaconingComputer sciencePhase relationship

The invention relates to a frequency domain coherent joint capture method of a GNSS data / pilot mixed signal, more particularly to a coherent joint capture method of a GNSS data / pilot mixed signal. According to a traditional single-channel capture method, energies of a new-system navigation signal can not fully utilized, so that capture performance is poor; however, the above-mentioned problem canbe solved according to the invention. The method comprises the following steps that: with utilization of a phase relationship between a data channel signal and a pilot channel signal, coherent processing is carried out on the signals of the two channels aiming at a GNSS data / pilot mixed signal, and then capture is completed. The invention is suitable for application in a capture process of a GNSSdata / pilot mixed signal.

Owner:HARBIN INST OF TECH

Activated carbon for flue gas desulfurization, preparation method and preparation device

ActiveCN114275780AThe preparation process is environmentally friendlyLow costCarbon compoundsTransportation and packagingActivated carbonCarbonization

The invention discloses activated carbon for flue gas desulfurization, a preparation method and a preparation device.The preparation device comprises a feeding mechanism, an angle adjusting mechanism is arranged below the feeding mechanism, a smashing mechanism is further arranged on the feeding mechanism, a material guide plate is arranged below the feeding mechanism, a stirring barrel is arranged on one side of the material guide plate, and the stirring barrel is arranged on the other side of the feeding mechanism. A stirring mechanism is arranged in the stirring barrel; the preparation device provided by the invention improves the production efficiency of activated carbon, and greatly saves manpower and material resources; the invention further provides activated carbon for flue gas desulfurization. The activated carbon comprises lignite powder, sawdust, high-temperature modified asphalt, starch and vanadium pentoxide. The preparation method comprises the following steps: mixing and molding the materials, adding vanadium pentoxide, and carrying out carbonization and activation treatment; in the preparation of the activated carbon for flue gas desulfurization, the atmospheric environment is reduced, so that the preparation of the activated carbon is more environment-friendly, and meanwhile, the cost is lower.

Owner:江苏蓝电环保股份有限公司

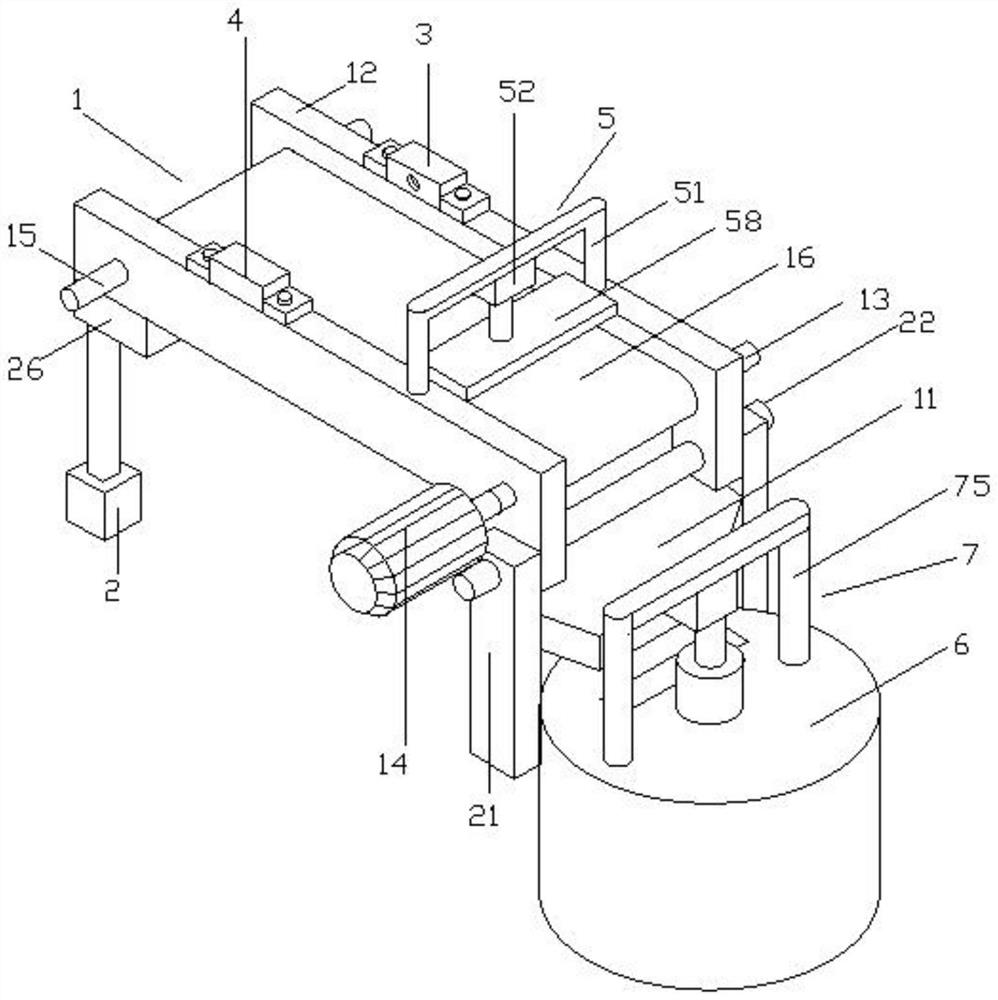

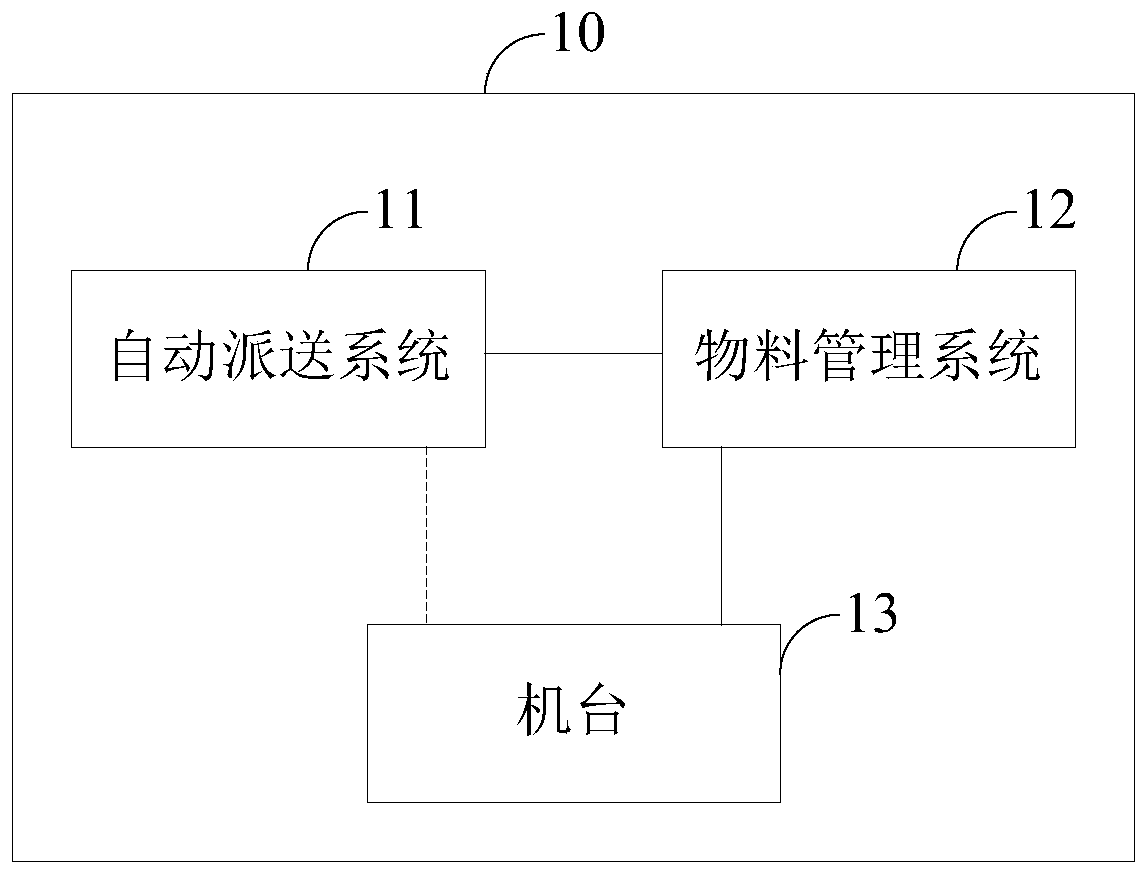

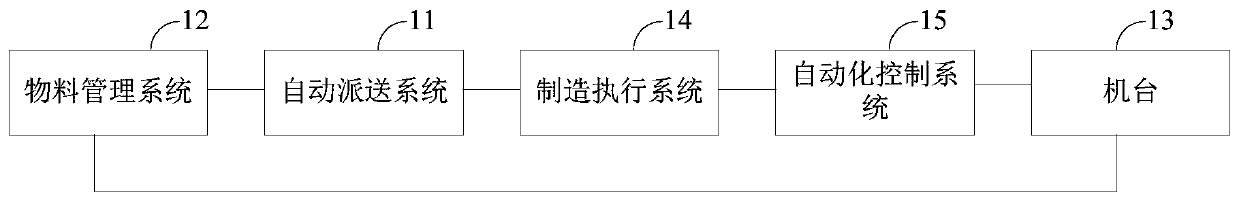

Computer integrated manufacturing system and its manufacturing method

ActiveCN107168253BFast deliveryReduce accumulation timeTotal factory controlProgramme total factory controlComputer-integrated manufacturingWork in process

The invention discloses a computer integrated manufacturing system and a manufacturing method thereof. The system at least comprises an automatic delivery system, a material management system and a bench. The automatic delivery system obtains a ratio of the number of produced semi-finished products to the corresponding number of semi-finished products; the automatic delivery system obtains product information with a smallest ratio and generates a control instruction based on the product information; and the automatic delivery system controls the material management system to deliver a carrier corresponding to the production information to the bench based on the control instruction. Therefore, the emergency carrier can be dispatched to the bench quickly and thus the cargo stacking time can be reduced; and thus the benefits of the enterprise can be increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![1.5 [mu]m wavelength aerosol detection laser radar based on pulse coding and signal decoding method 1.5 [mu]m wavelength aerosol detection laser radar based on pulse coding and signal decoding method](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/bad77d54-3530-4431-8fd0-8df3bacb2854/HDA0002942537490000011.png)

![1.5 [mu]m wavelength aerosol detection laser radar based on pulse coding and signal decoding method 1.5 [mu]m wavelength aerosol detection laser radar based on pulse coding and signal decoding method](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/bad77d54-3530-4431-8fd0-8df3bacb2854/HDA0002942537490000012.png)

![1.5 [mu]m wavelength aerosol detection laser radar based on pulse coding and signal decoding method 1.5 [mu]m wavelength aerosol detection laser radar based on pulse coding and signal decoding method](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/bad77d54-3530-4431-8fd0-8df3bacb2854/HDA0002942537490000013.png)