Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80 results about "Vinylacetylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinylacetylene is the organic compound with the formula C₄H₄. The colourless gas was once used in the polymer industry. It is composed of both alkyne and alkene groups and is the simplest enyne. Vinylacetylene is extremely dangerous because in high enough concentrations (typically > 30 mole percent, but pressure dependent) it can auto-detonate (explode without air being present) especially at elevated pressures, such as those seen in chemical plants processing C4 hydrocarbons. An example of such an explosion occurred at a Union Carbide plant in Texas City in 1969.

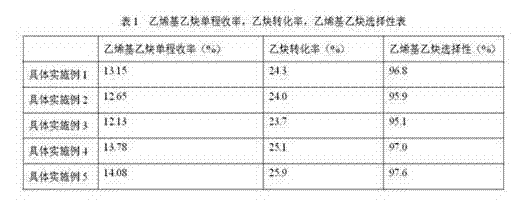

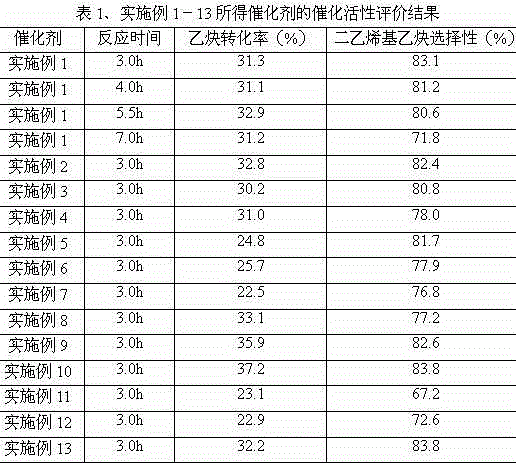

Vinyl acetylene hydrogenation catalyst and preparation method and applications thereof

InactiveCN103285876AStrong hydrogenation activityHigh selectivityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsVinylacetyleneActive component

The invention provides a vinyl acetylene hydrogenation catalyst and a preparation method and applications thereof, wherein the vinyl acetylene hydrogenation catalyst comprises the following compositions in parts by weight: 0.01-30 parts of active component, 40-99.989 parts of carriers and catalyst promoter, wherein the mole ratio of the catalyst promoter to the active component is (0.1-10):1. According to the vinyl acetylene hydrogenation catalyst, the acetylene hydrogenation activity and butadiene selectivity are high, the vinyl acetylene hydrogenation catalyst can be effectively used in vinyl acetylene hydrogenation reaction so as to further efficiently prepare butadiene.

Owner:TSINGHUA UNIV

Method for hydrotreating butadiene tail gas

ActiveCN103787815AReduce loadReduce energy consumptionHydrocarbon by hydrogenationHydrocarbon purification/separationVinylacetyleneButene

The invention provides a method for hydrotreating alkynes-rich butadiene tail gas. The method comprises the following steps: extracting butadiene tail gas, a selective hydrogenation is carried out in a one-section hydrogenation reactor, vinylacetylene is performed with hydro-conversion to 1,3-butadiene; the one-section hydrogenation reaction products are seperared, a part which is rich in 1,3-butadiene is sent to a butadiene extraction device, other part is performed with the selective hydrogenation reaction through a second-section hydrogenation reactor, alkynes and dialkene are performed with hydro-conversion to 1-butylene, two hydrogenation reaction products are sent to a recovery device of 1-butylene. The method is capable of fully recovering the valuable substances in the butadiene tail gas, and the economic benefit is obvious.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for increasing utilization value of mixed C4

ActiveCN103382147AHigh chemical added valueIncrease added valueHydrocarbon by hydrogenationHydrocarbon by metathesis reactionIsomerizationAlkyne

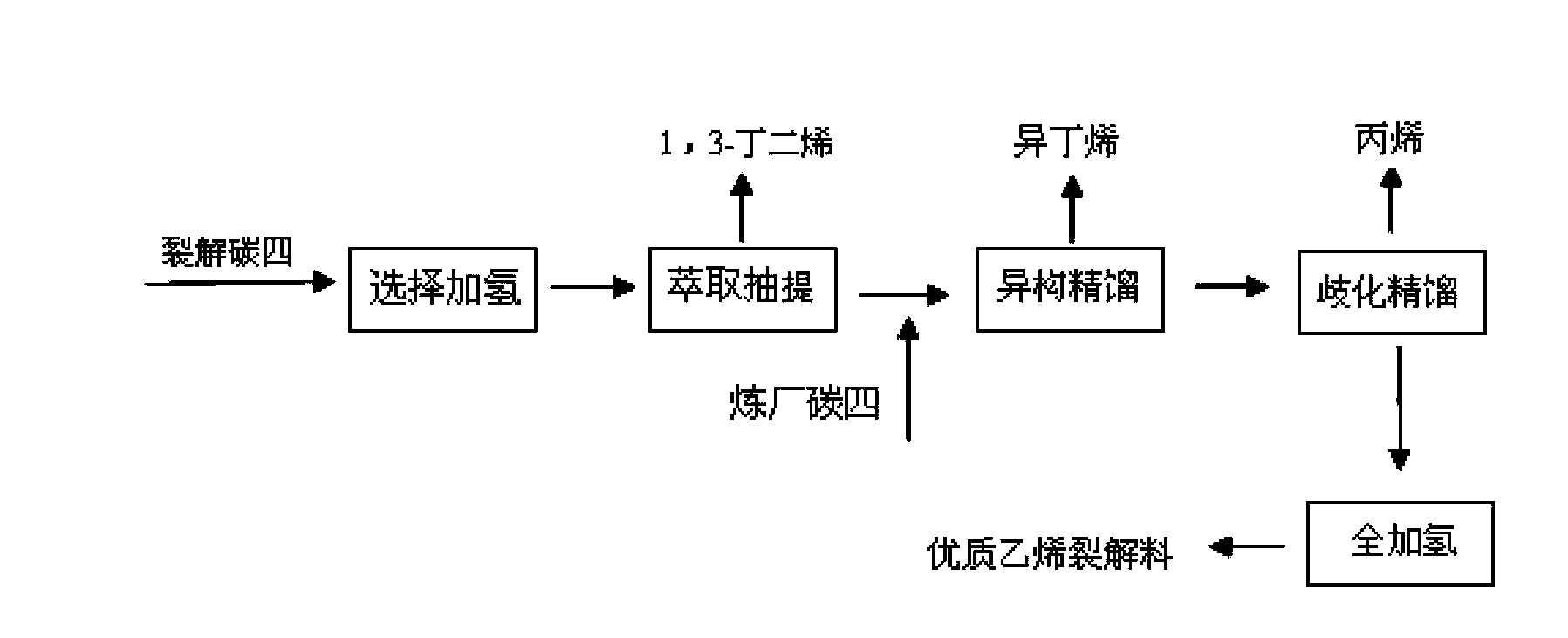

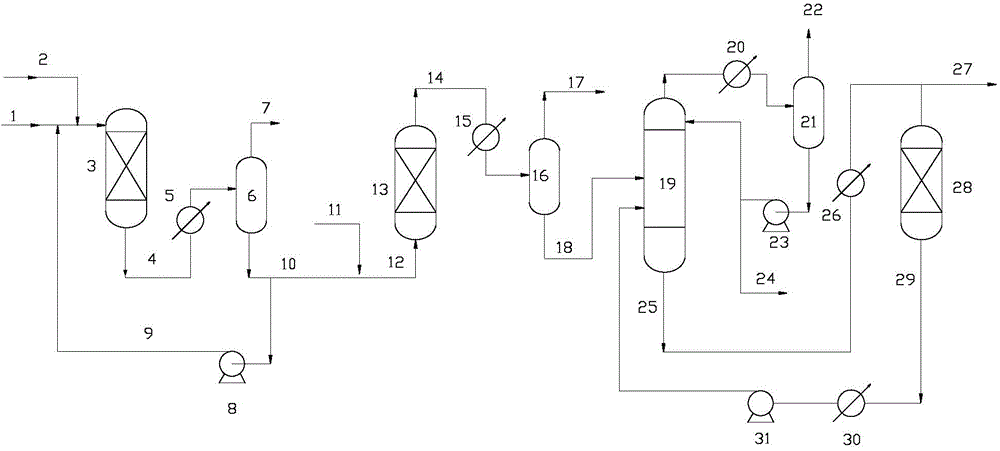

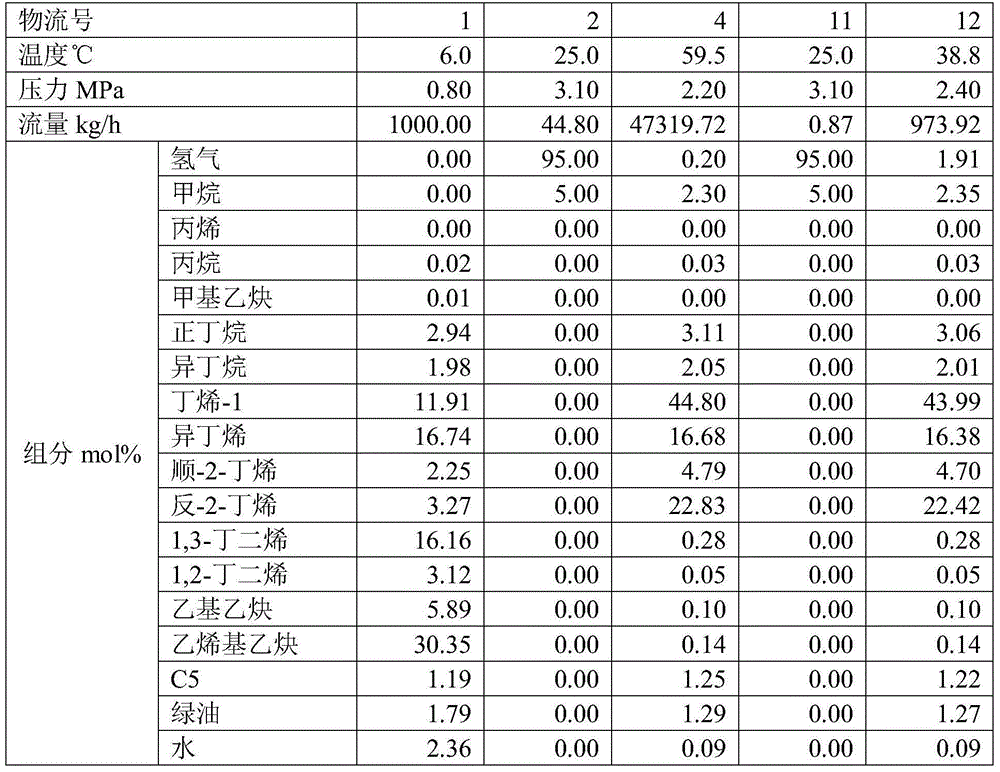

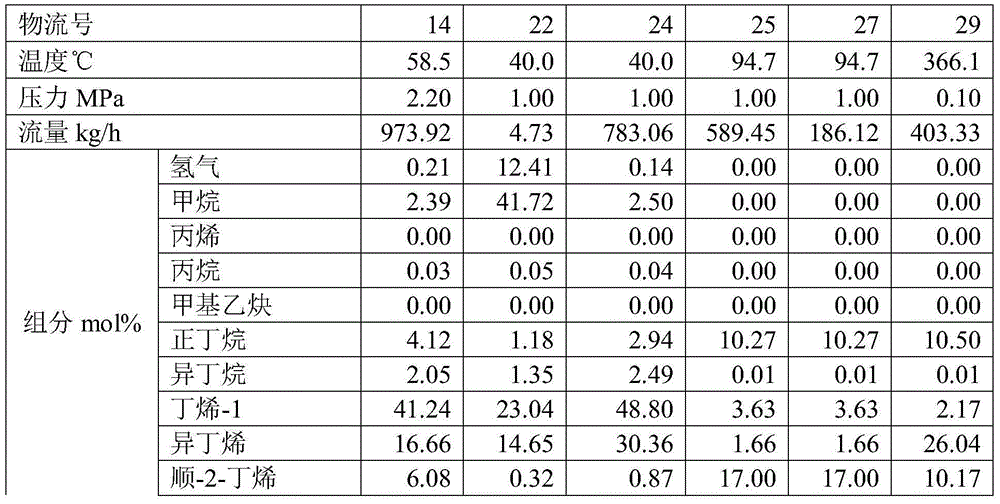

The invention relates to a method for increasing the utilization value of mixed C4. The method comprises the following steps: cracking C4, carrying out selective hydrogenation for removal of alkynes and allowing vinylacetylene and 1-butyne to produce 1,3-butadiene and 1-butylene through hydrogenation, wherein the content of alkynes in hydrogenation products is less than 15*10<-9>; subjecting obtained materials to extraction and rectification so as to allow 1,3-butadiene to be separated from other C4 fractions, mixing residual C4 material flow with C4 produced in a refinery plant, subjecting obtained mixed C4 to a hydroisomerization reaction so as to allow 1-butylene in the mixed C4 to be isomerized into 2-butylene and separating isomerization products so as to obtain an isobutene product; and introducing residual C4 material flow into a disproportionation unit, allowing 2-butylene in the residual C4 material flow and ethylene to undergo disproportionation so as to produce propylene, carrying out separation and allowing unreacted ethylene and residual C4 material flow to undergo full hydrogenation so as to enable all the unsaturated hydrocarbons to undergo hydrogenation saturation. According to the method, the content of alkenes in the hydrogenation products is lower than 1%, and the products can be used as high-quality ethylene cracking materials.

Owner:PETROCHINA CO LTD

Hydrogenation method of butadiene extraction tail gas

InactiveCN105585411AIncrease productionTake advantage ofHydrocarbon by isomerisationHydrocarbon by hydrogenationVinylacetyleneIsomerization

The invention provides a hydrogenation method of butadiene extraction tail gas. A selective hydrogenation reaction is carried out to tail gas, which is rich in alkynes, from a butadiene extraction apparatus in a first-stage hydrogenation reactor and a second-stage hydrogenation reactor to completely convert vinyl acetylene, ethyl acetylene and butadiene into 1-butene through hydrogenation. A reaction product then is fed into a product separation column to obtain a product being rich in 1-butene and isobutene at the top of the column, wherein the product is suitable for being used as a raw material in a MTBE / 1-butene apparatus. The material in the bottom of the column then passes through an isomerization reactor to convert n-butene into isobutene which is then circulated into the product separation column. The method can fully recycle valuable substances in the butadiene extraction tail gas and has significant economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

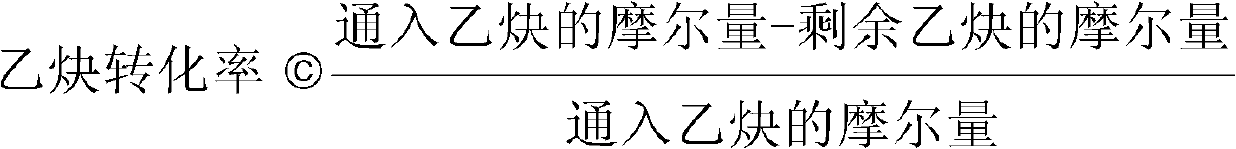

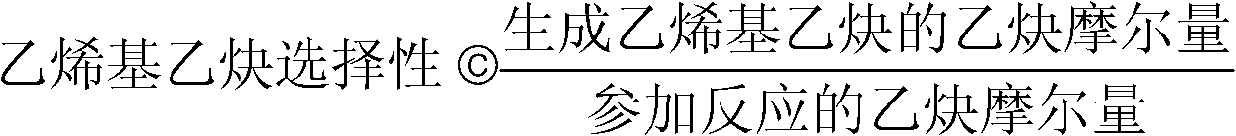

Improved water system nieuwland catalyst and application method thereof

InactiveCN101733150AImprove conversion rateHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsVinylacetyleneEther

The invention relates to an improved water system nieuwland catalyst and an application method thereof. The catalyst comprises cuprous chloride, ammonium chloride and aqueous solution of hydrochloric acid in a nieuwland catalytic system, and also comprises organic amine, organic ion liquid and organic ether. In the specific preparation step, the addition sequence of the cuprous chloride, the ammonium chloride and the hydrochloric acid is adjusted, and the organic amine, the organic ion liquid and the organic ether are sequentially added into the mixture. The catalyst improves the performance of the conventional nieuwland catalyst, and can improve the conversion per pass of acetylene and the selectivity of vinyl acetylene simultaneously in a process of preparing the vinyl acetylene by applying the nieuwland catalyst; and the organic amine, the organic ion liquid and the organic ether are less in dosage and can be recycled, and thus the improved water system nieuwland catalyst has the advantages of low cost, simple method, high efficiency and the like.

Owner:CHONGQING UNIV

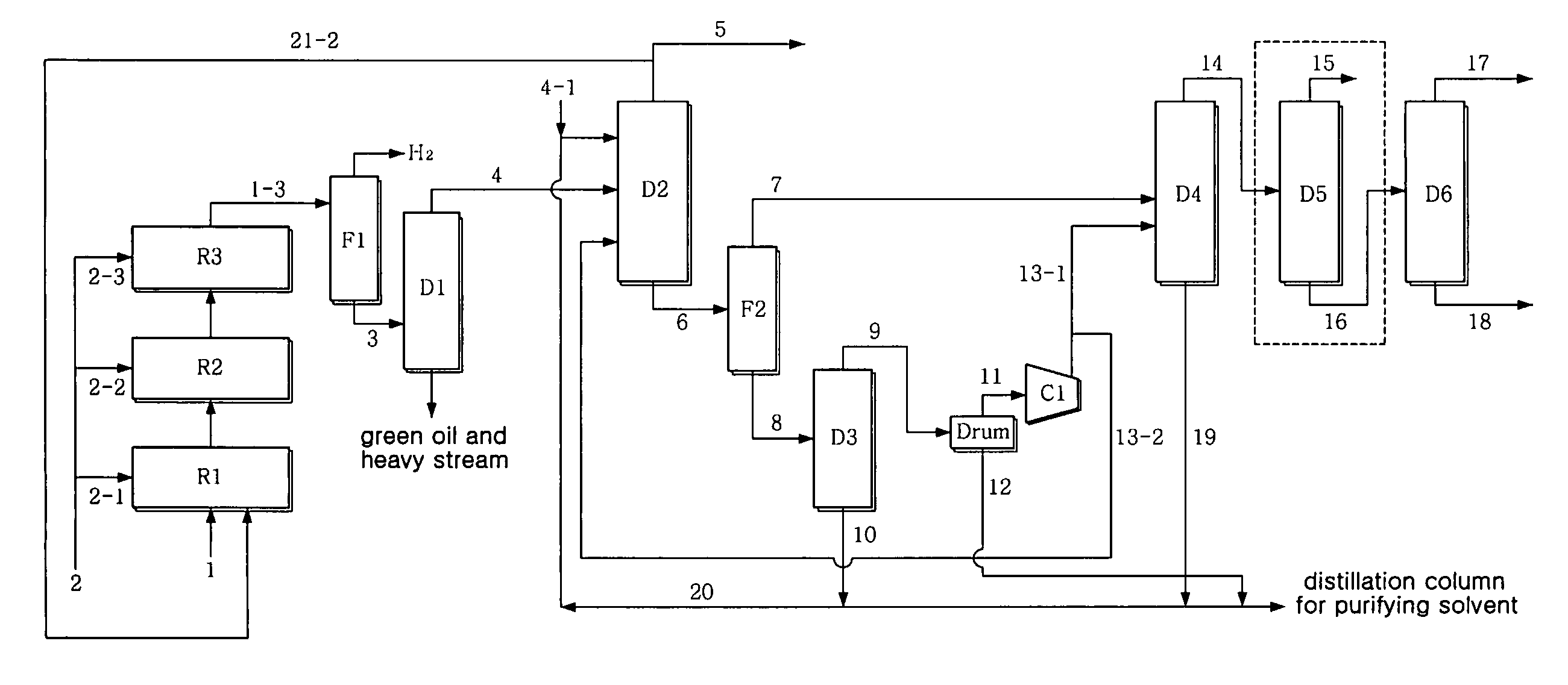

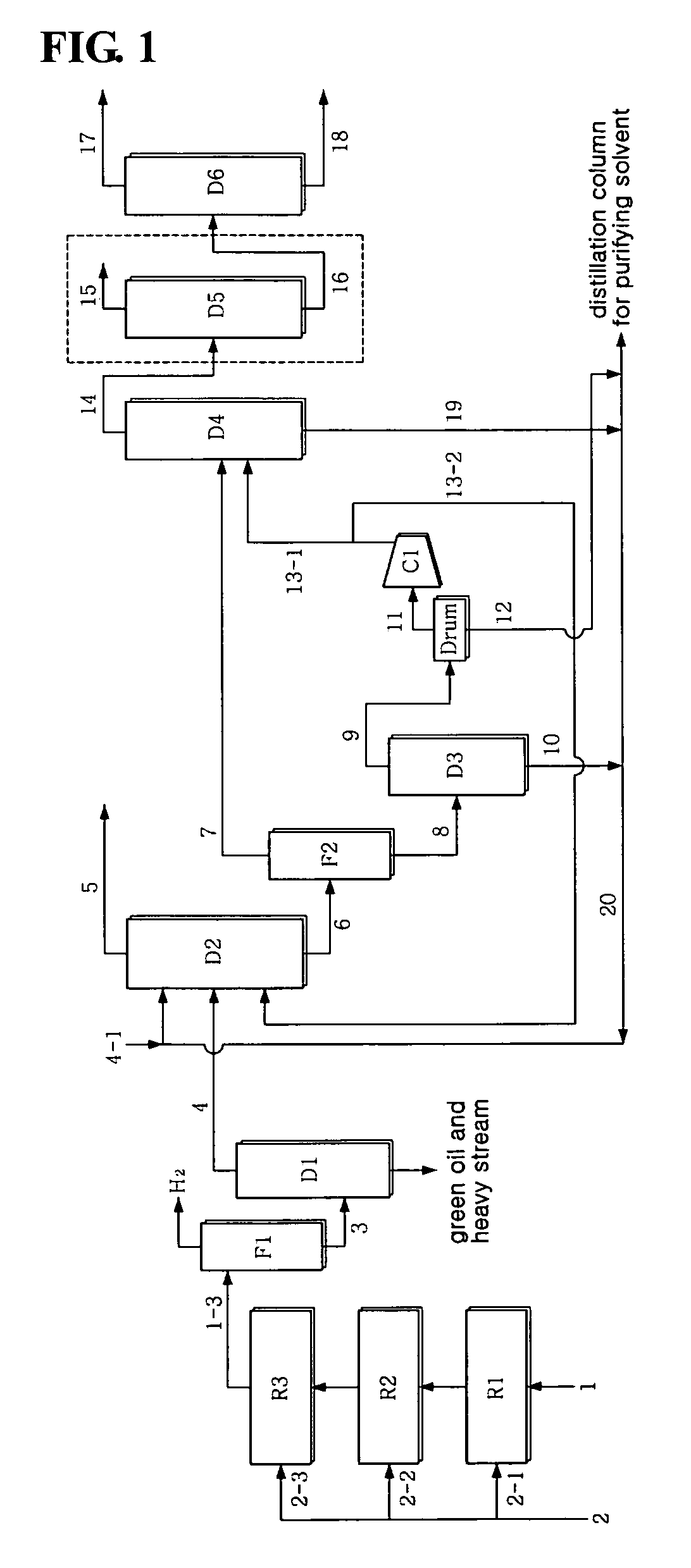

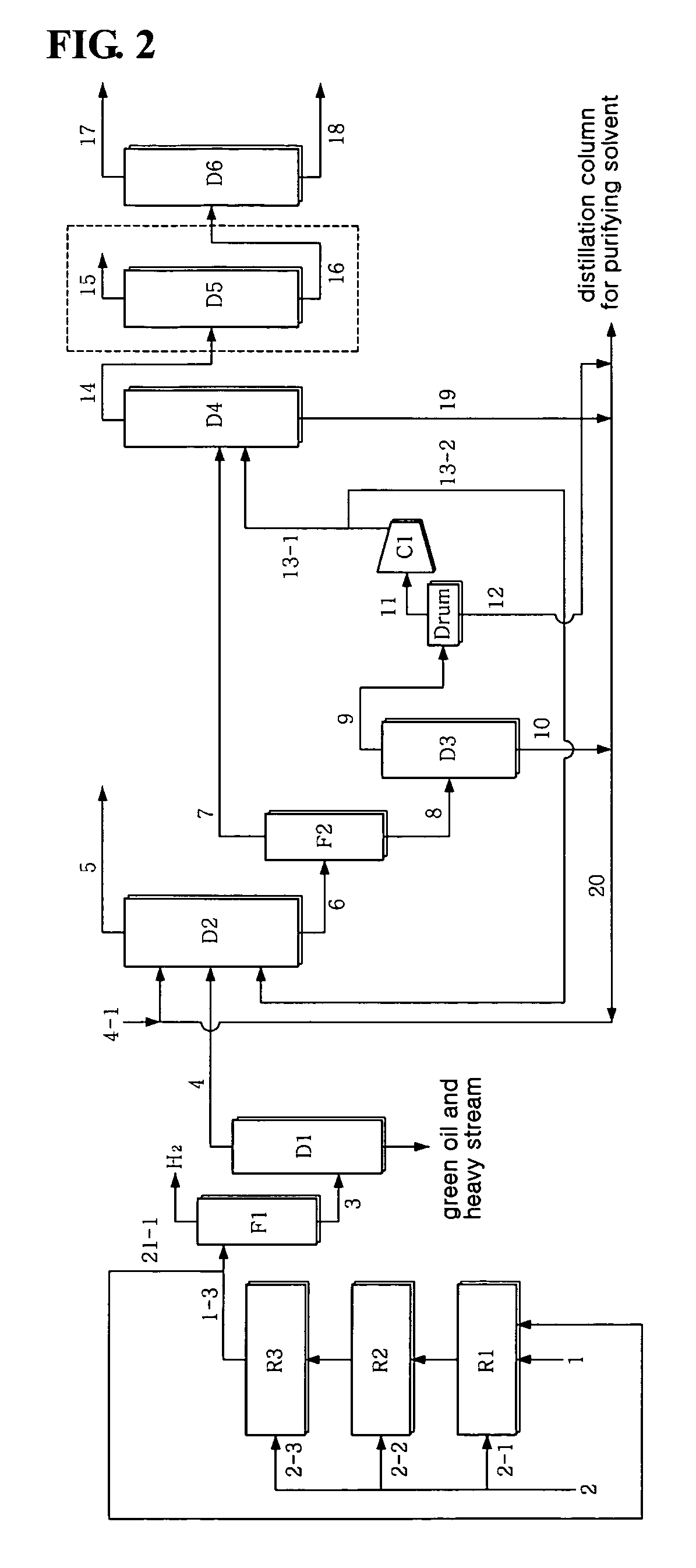

Process for 1,3-butadiene separation from crude C4 stream with acetylene converter

ActiveCN101821361AReduce accumulation timeReduce logistics lossDistillation purification/separationTreatment with hydrotreatment processesVinylacetyleneButene

Disclosed is a method of recovering 1,3 -butadiene from a C4 stream containing butane, isobutane, 2-butene, 1-butene, isobutene, butadiene and acetylene. The process of recovering highly pure 1,3 -butadiene includes acetylene conversion for selectively converting acetylene through liquid-phase hydrogenation, so that the acetylene content is decreased to 70 wt ppm or less, and 1,3 -butadiene extraction using an extractive distillation column, a pre-separator, a solvent stripping column, a solvent recovery column, and a purification column. Through the acetylene conversion, the concentration of vinylacetylene is decreased to 70 wt ppm or less, after which 1,3-butadiene is recovered using only one extractive distillation column, thereby considerably decreasing the degree of utility and the loss of streams in the course of extraction. The number of units necessary for the process is decreased, thus remarkably reducing the time during which impurities can accumulate in a processing unit.

Owner:SK INNOVATION CO LTD

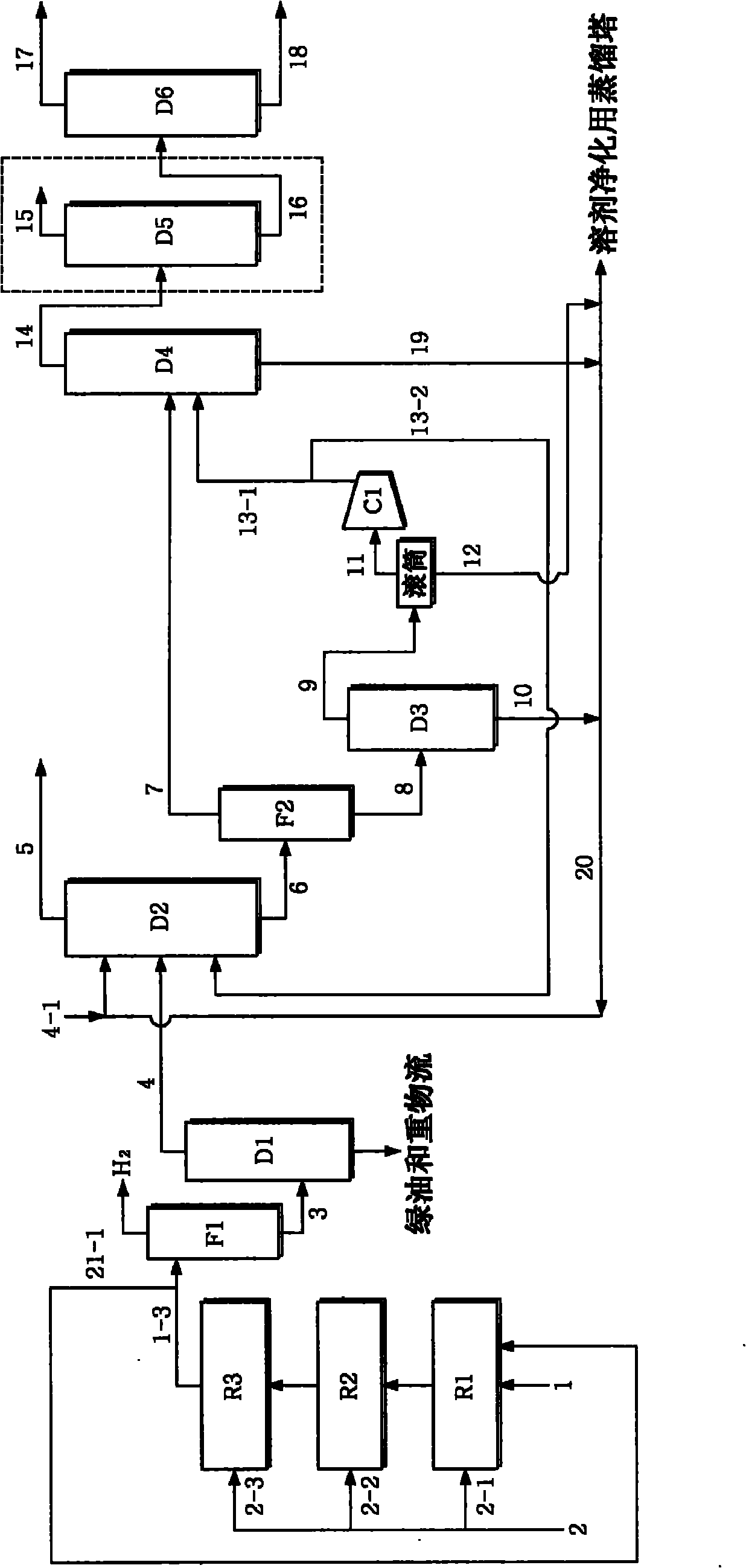

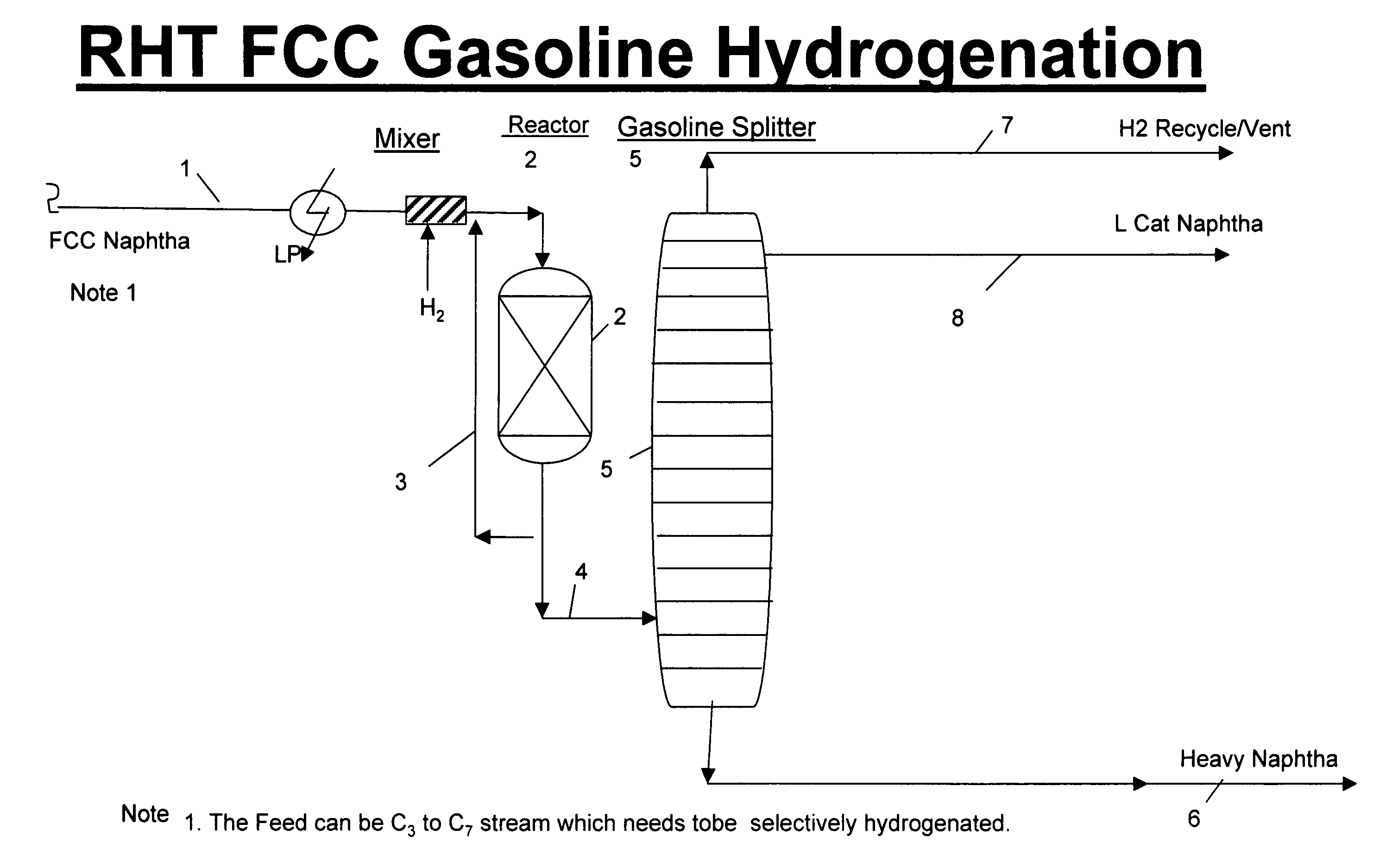

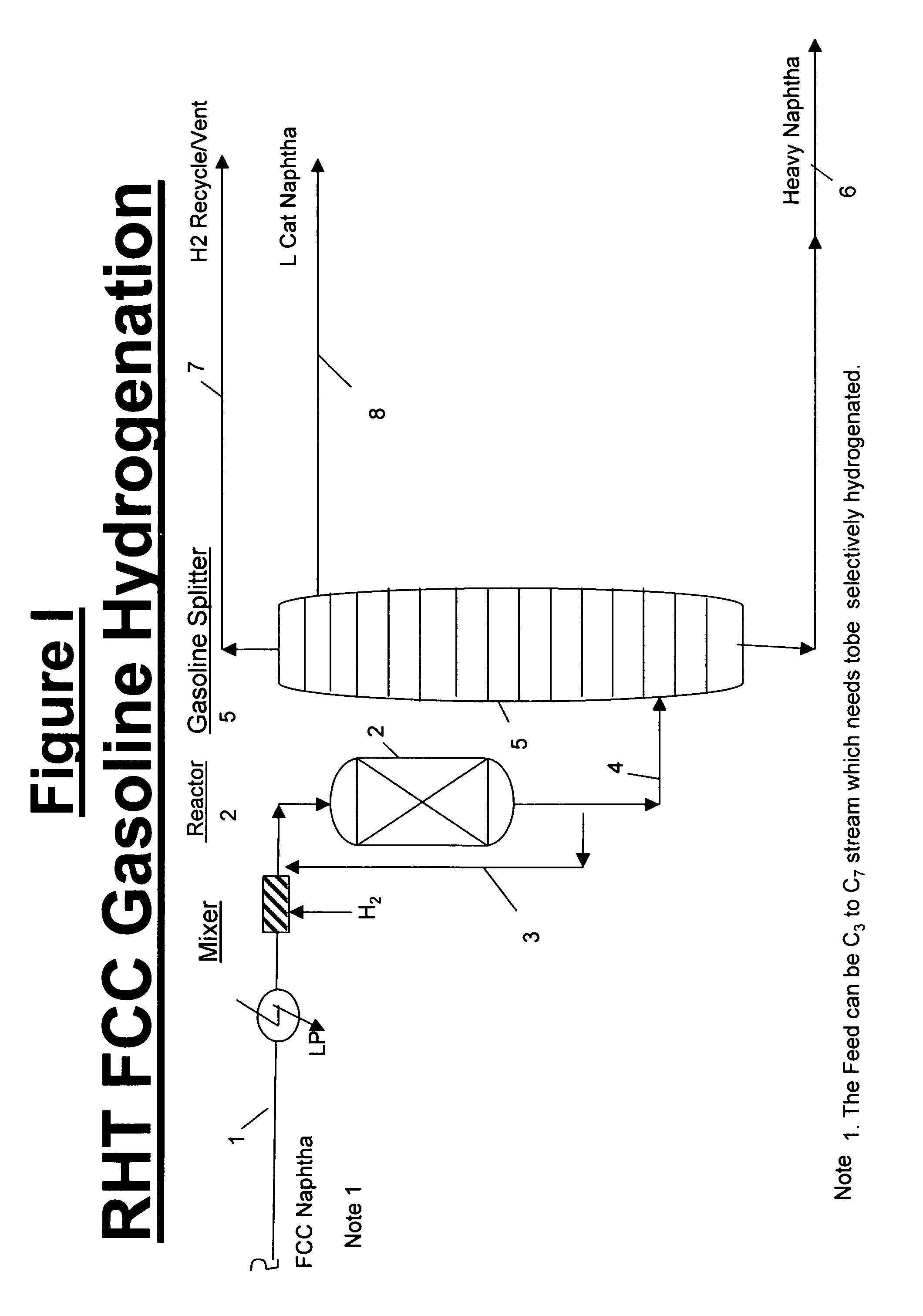

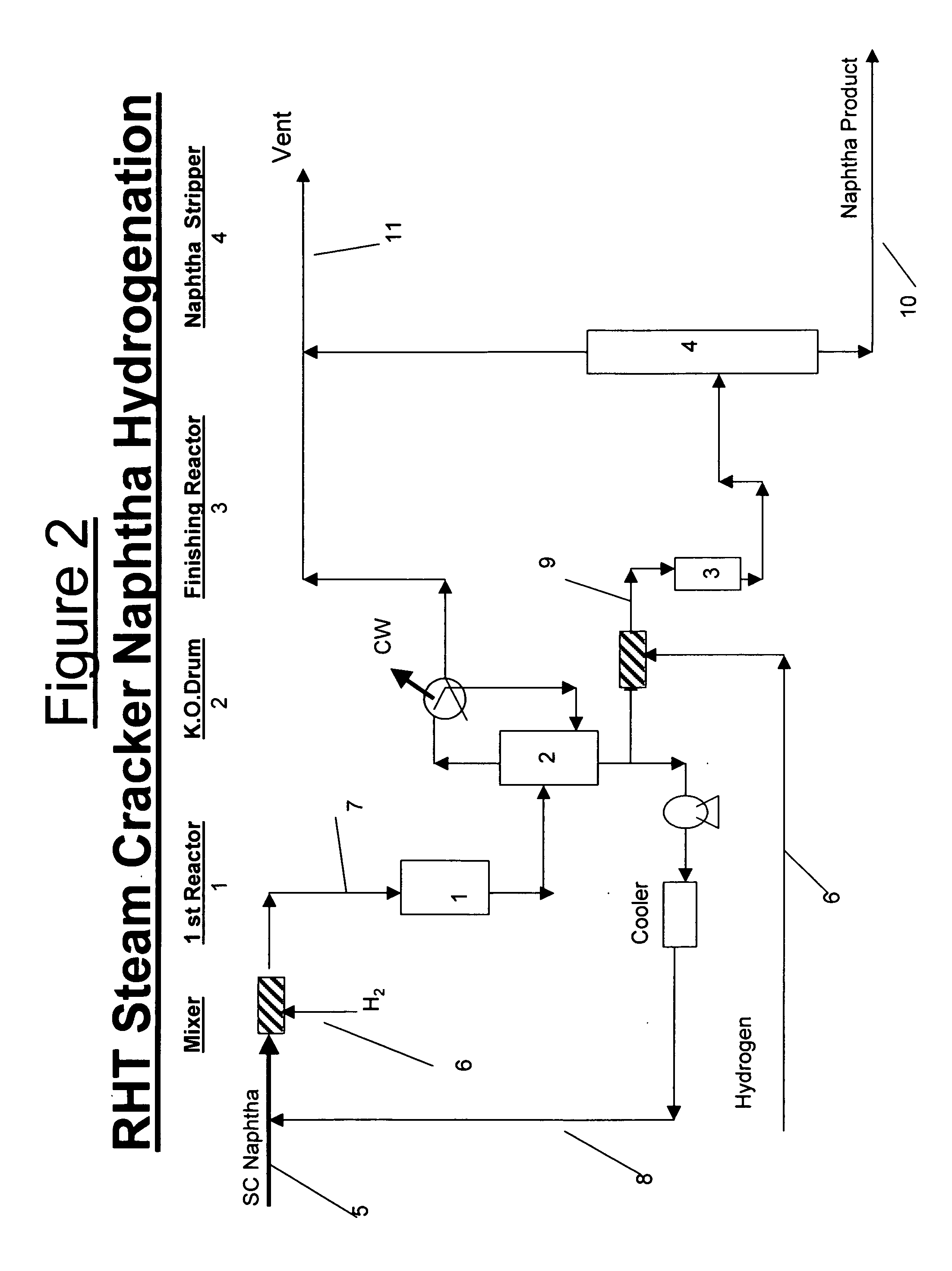

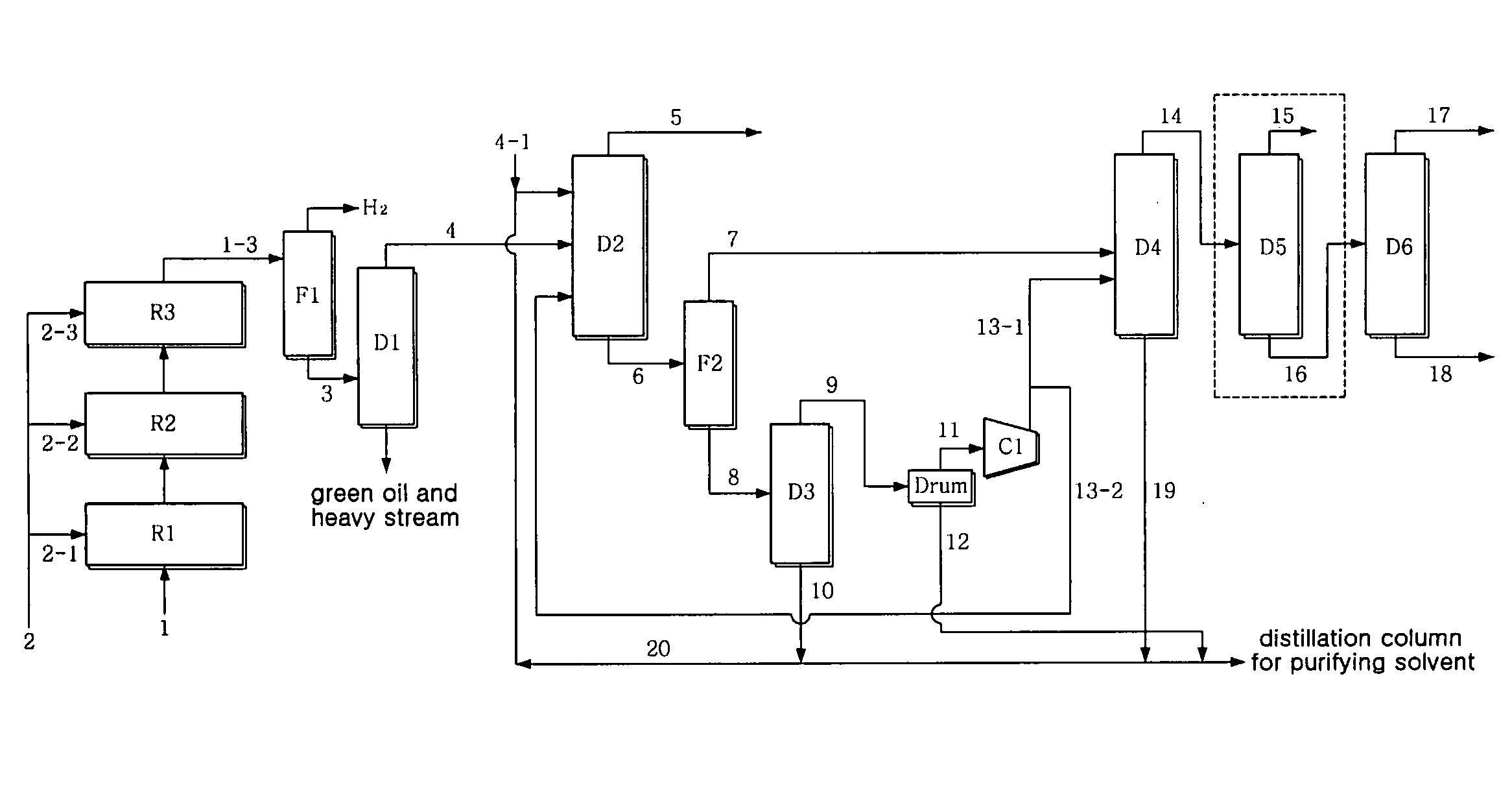

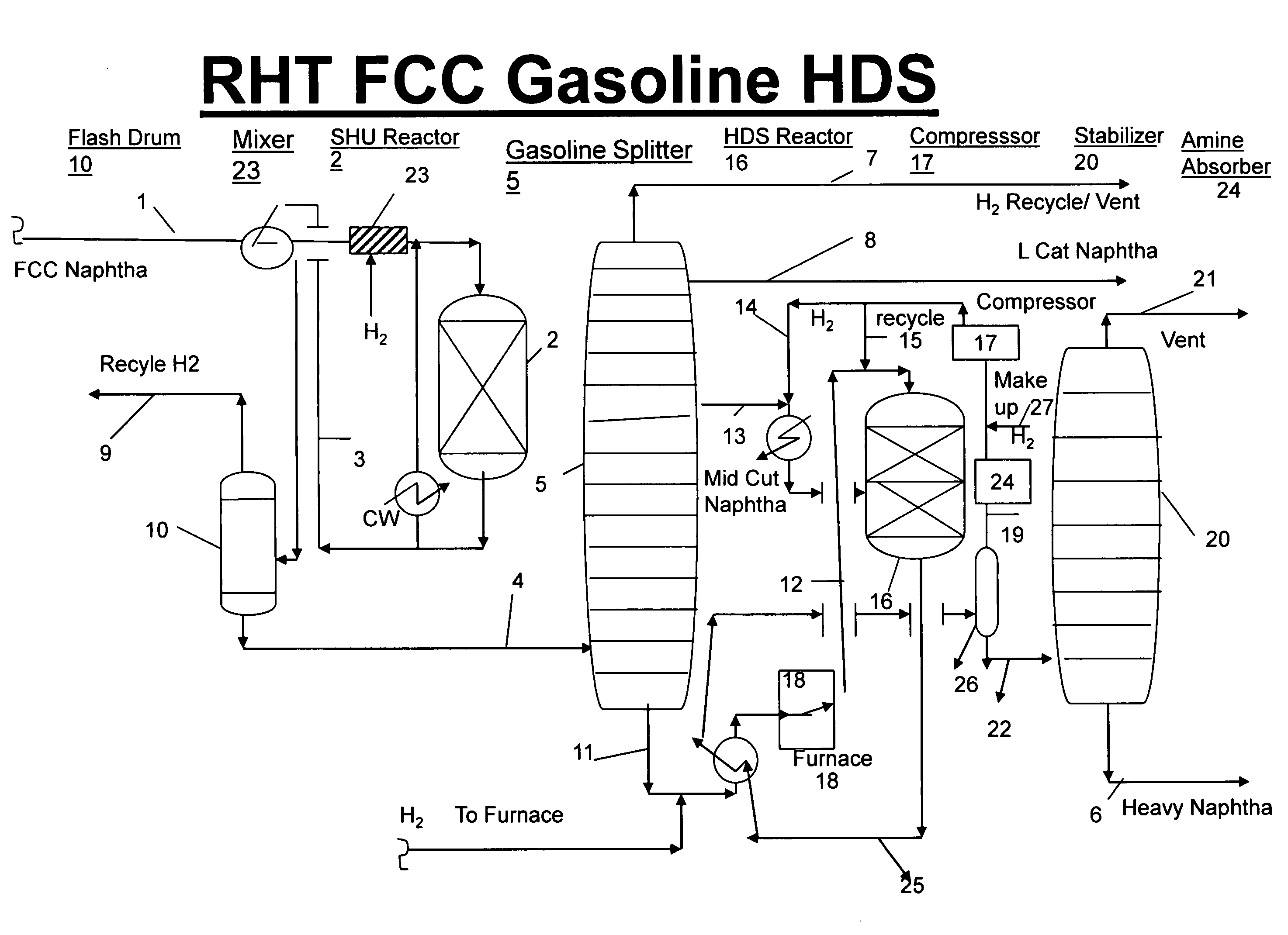

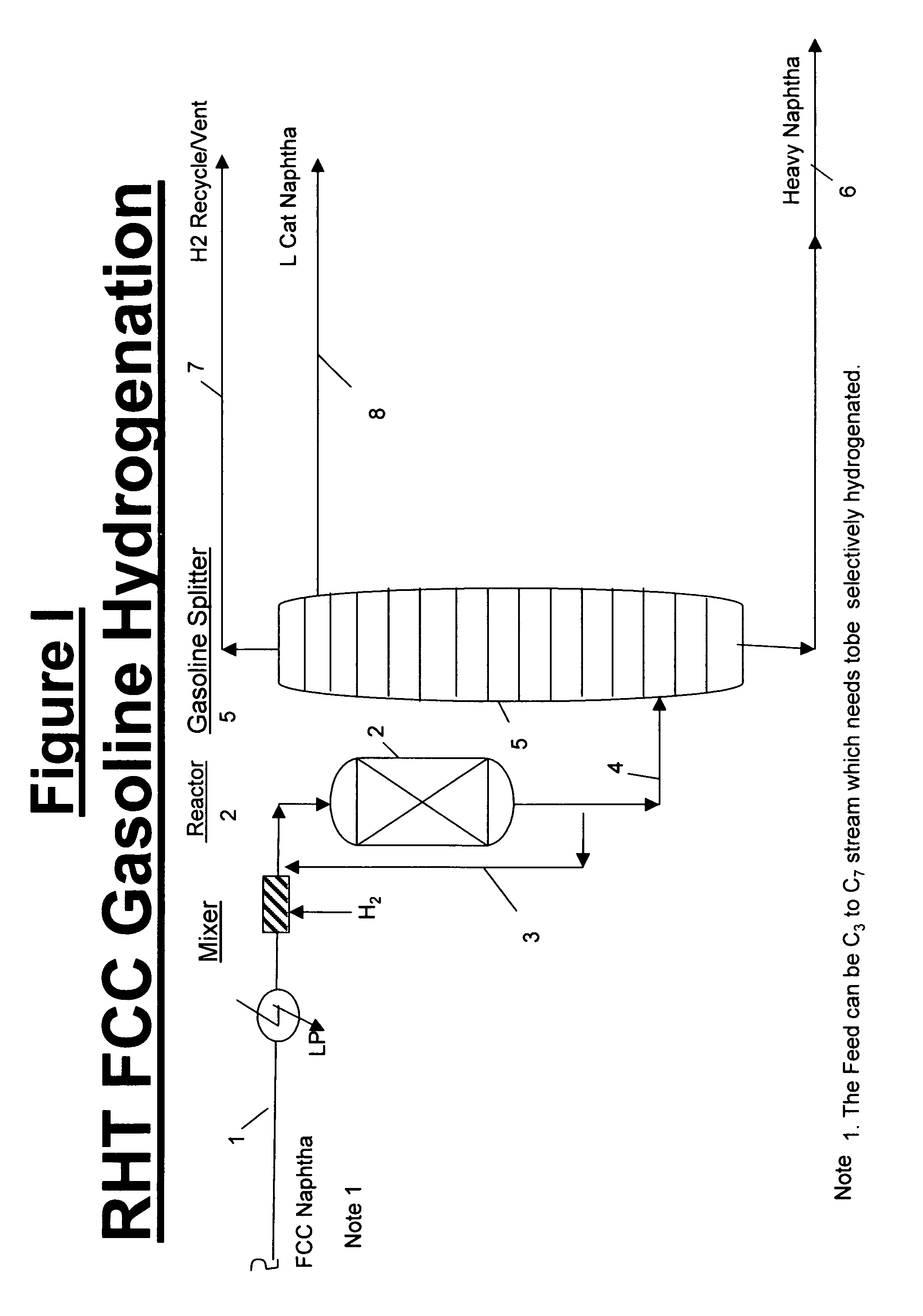

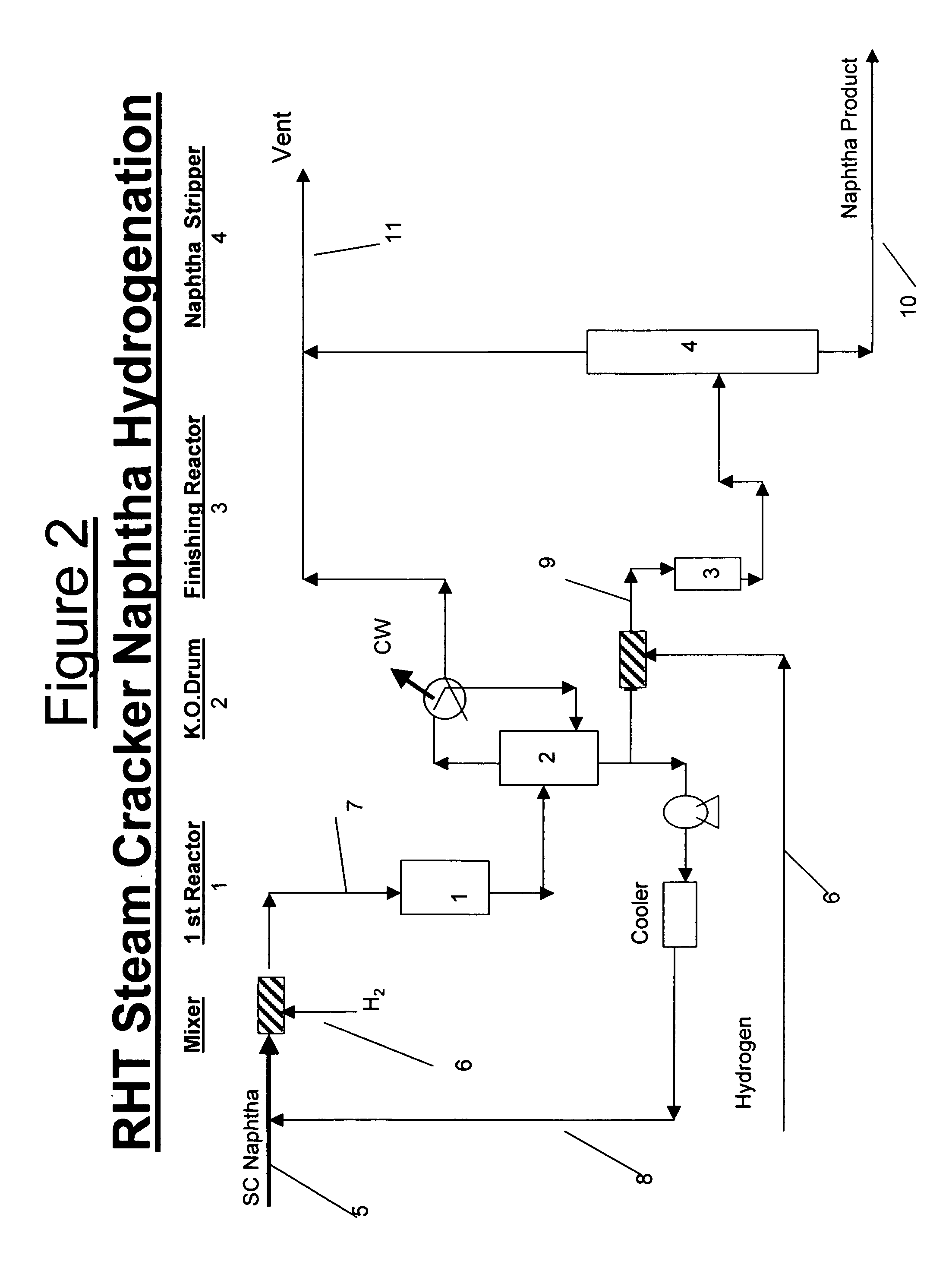

Optimum process for selective hydrogenation/hydro-isomerization, aromatic saturation, gasoline, kerosene and diesel/distillate desulfurization (HDS). RHT-hydrogenationSM, RHT-HDSSM

InactiveUS20080073250A1Simple configurationIncrease cetane numberHydrocarbon by hydrogenationHydrocarbon purification/separationIsomerizationDistillation

A process for selective hydrogenation of C3 / C4 / C5 / C6 / C7 and LCN, hydro-isomerization of olefins, benzene saturation and hydrodesulfurization of Gasoline, Kerosene and Diesel together with aromatic saturation of LCO is being provided so as to provide optimum technology at low cost with unique configuration. The technology is user friendly and uses conventional catalyst. These configurations cover both the options of installing the bulk catalyst in the distillation column with chimneys trays, hence essentially all the reaction takes place in the liquid phase in single or multiple beds or with fixed bed down flow or up flow reactor configuration. The configurations shown in the figures depicts that the fixed bed reactors are integrated with the Distillation Column and this art helps in lowering the Capital costs and the reactors are operating in single phase or two-phase conditions. The art is applicable to MAPD, vinyl acetylene, C3, C4, C5, C6, C7 mixed hydrocarbon stream, and LCN diolefin selective hydrogenation. It includes the process for hydro-isomerization of Butene-2 to Butene-1, or visa versa, removal of Isobutylene and Isobutane by distillation after hydro isomerization, benzene hydrogenation to Cyclohexane, hydrodesulfurization of FCC gasoline, coker gasoline or any other Naphtha stream together with hydrodesulfurization of Diesel / Kerosene from any of the refinery units.

Owner:REFINING HYDROCARBON TECH RHT

Catalyst for preparing vinyl acetylene and application method thereof

InactiveCN101786022AIncrease conversion rate per passImprove conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsVinylacetyleneOrganic solvent

The invention discloses a catalyst for preparing vinyl acetylene and an application method thereof; the components of the catalyst include cuprous chloride, water, organic solvent, organic amine salt and organic ionic liquid. The application method includes steps that: under deoxygenation condition, the organic amine salt is dissolved in the solution of the organic solvent; and then cuprous chloride and organic ionic liquid are added to the solution; acetylene gas is introduced while the temperature is maintained constantly to produce vinyl acetylene. The invention improves the performance of an acetylene dimerization catalytic system, also increases the conversion per pass of acetylene and vinyl acetylene selectivity, produces less byproduct during reaction, greatly reduces the content of acetylene high polymer and accordingly reduces the separation difficulty and the production cost.

Owner:CHONGQING UNIV

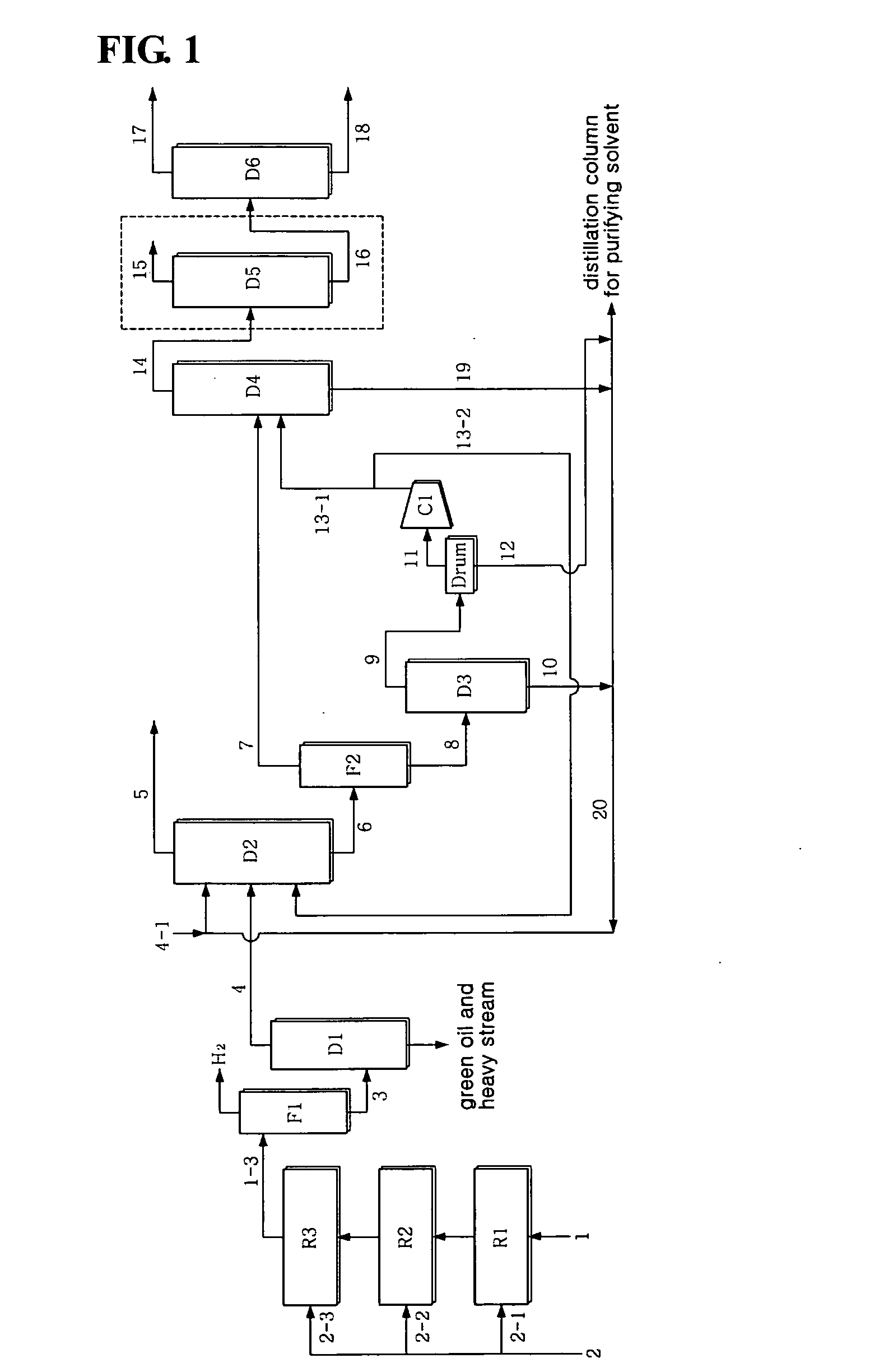

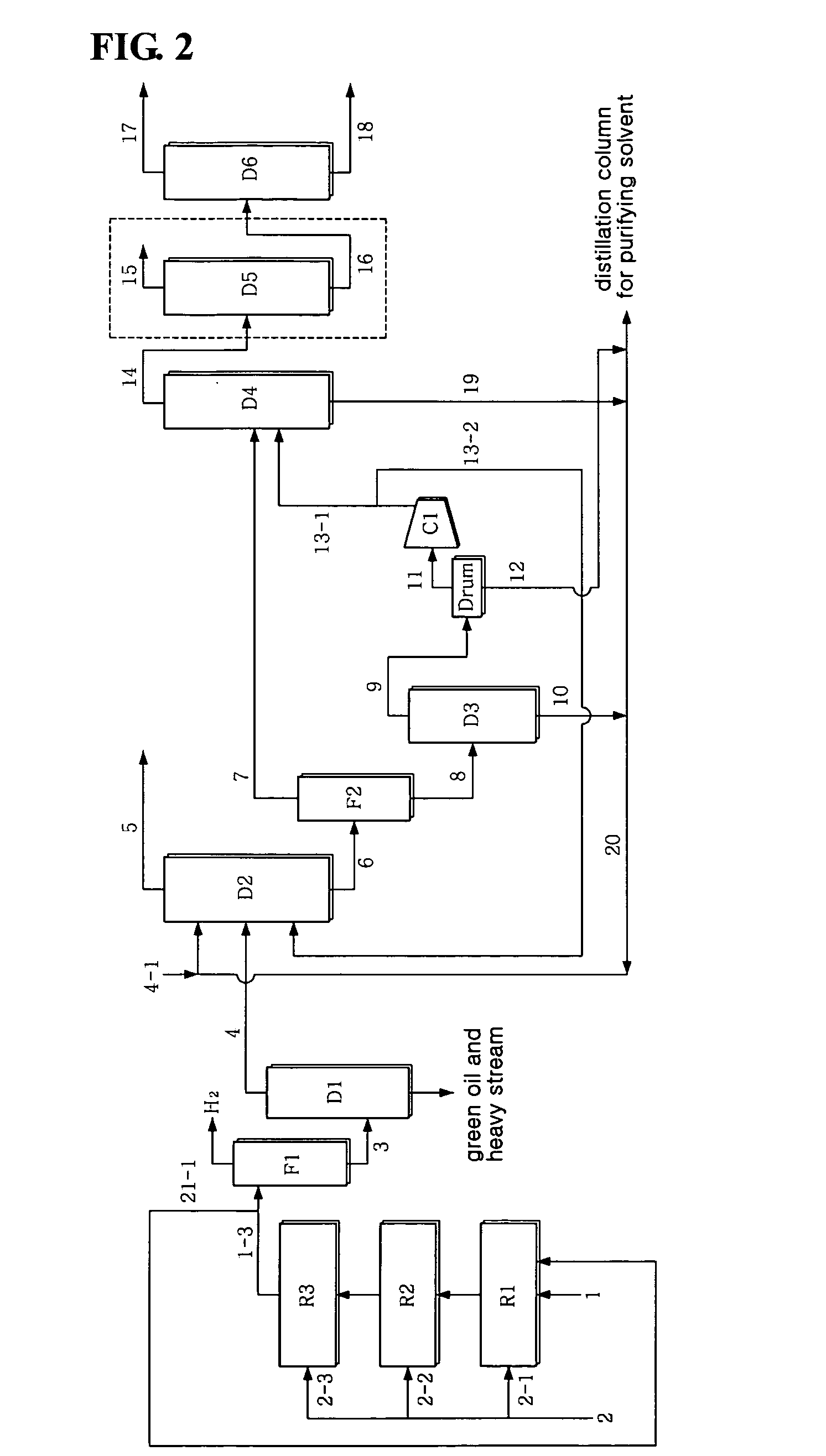

Process for 1,3-butadiene separation from a crude c4 stream with acetylene converter

ActiveUS20100137664A1Promote recoveryReduce the number of unitsDistillation purification/separationHydrocarbonsVinylacetyleneButene

Disclosed is a method of recovering 1,3-butadiene from a C4 stream containing butane, isobutane, 2-butene, 1-butene, isobutene, butadiene and acetylene. The process of recovering highly pure 1,3-butadiene includes acetylene conversion for selectively converting acetylene through liquid-phase hydrogenation, so that the acetylene content is decreased to 70 wt ppm or less, and 1,3-butadiene extraction using an extractive distillation column, a pre-separator, a solvent stripping column, a solvent recovery column, and a purification column. Through the acetylene conversion, the concentration of vinylacetylene is decreased to 70 wt ppm or less, after which 1,3-butadiene is recovered using only one extractive distillation column, thereby considerably decreasing the degree of utility and the loss of streams in the course of extraction. The number of units necessary for the process is decreased, thus remarkably reducing the time during which impurities can accumulate in a processing unit.

Owner:SK INNOVATION CO LTD

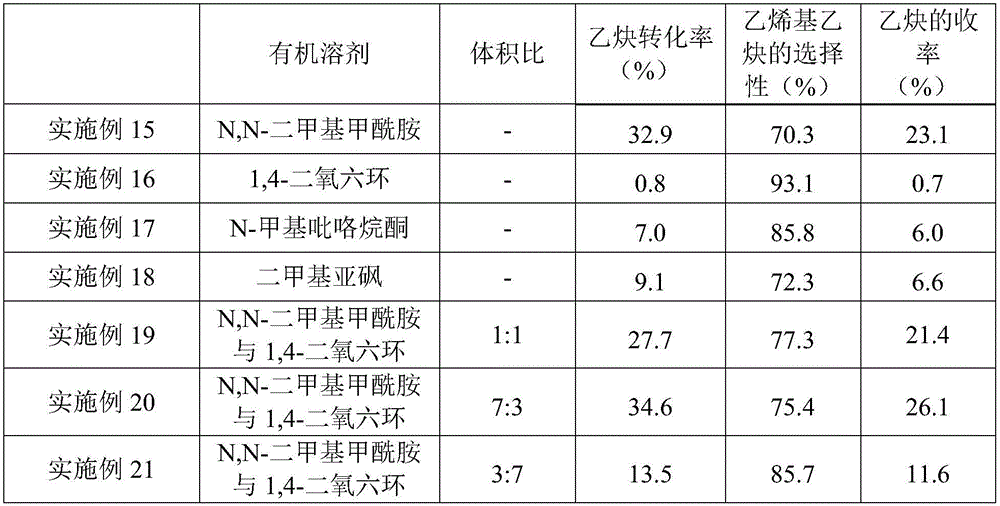

Acetylene copolymer nonaqueous system catalyst and method for preparing vinyl acetylene

InactiveCN101940953AImprove stabilityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsVinylacetyleneNitrogenous heterocyclic compound

The invention relates to an acetylene copolymer nonaqueous system catalyst and a method for preparing vinyl acetylene. The catalyst comprises cuprous chloride, organic ether, organic ion liquid, organic amine hydrochlorides, organic pentatomic or hexahydric nitrogen heterocyclic ring compounds, and N,N-dimethyl formamide. In the process of preparing vinyl acetylene, the cuprous chloride is added after other components are thoroughly mixed. The catalyst improves the properties of the prior Nieuland catalyst, and can keep the conversion per pass of the acetylene to be constant, obviously enhance the selectivity of the target product vinyl acetylene and the single-pass conversion rate of acetylene at the same time; and since the amounts of organic pentatomic or hexahydric nitrogen heterocyclic ring compounds, and organic ion liquid is small, and all the components can be recycled, so that the invention also has the advantages of low cost, simple method, high efficiency and the like.

Owner:CHONGQING UNIV

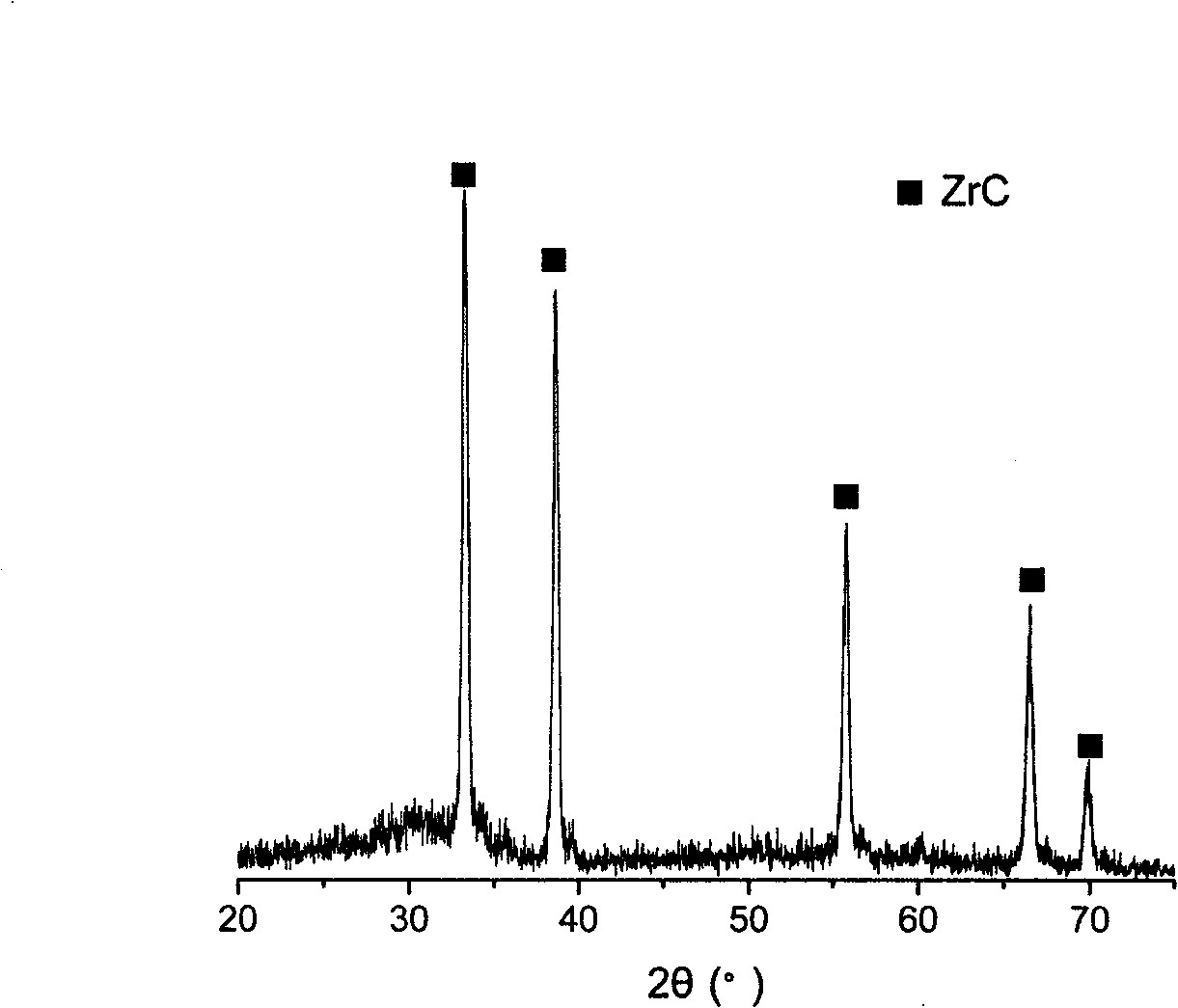

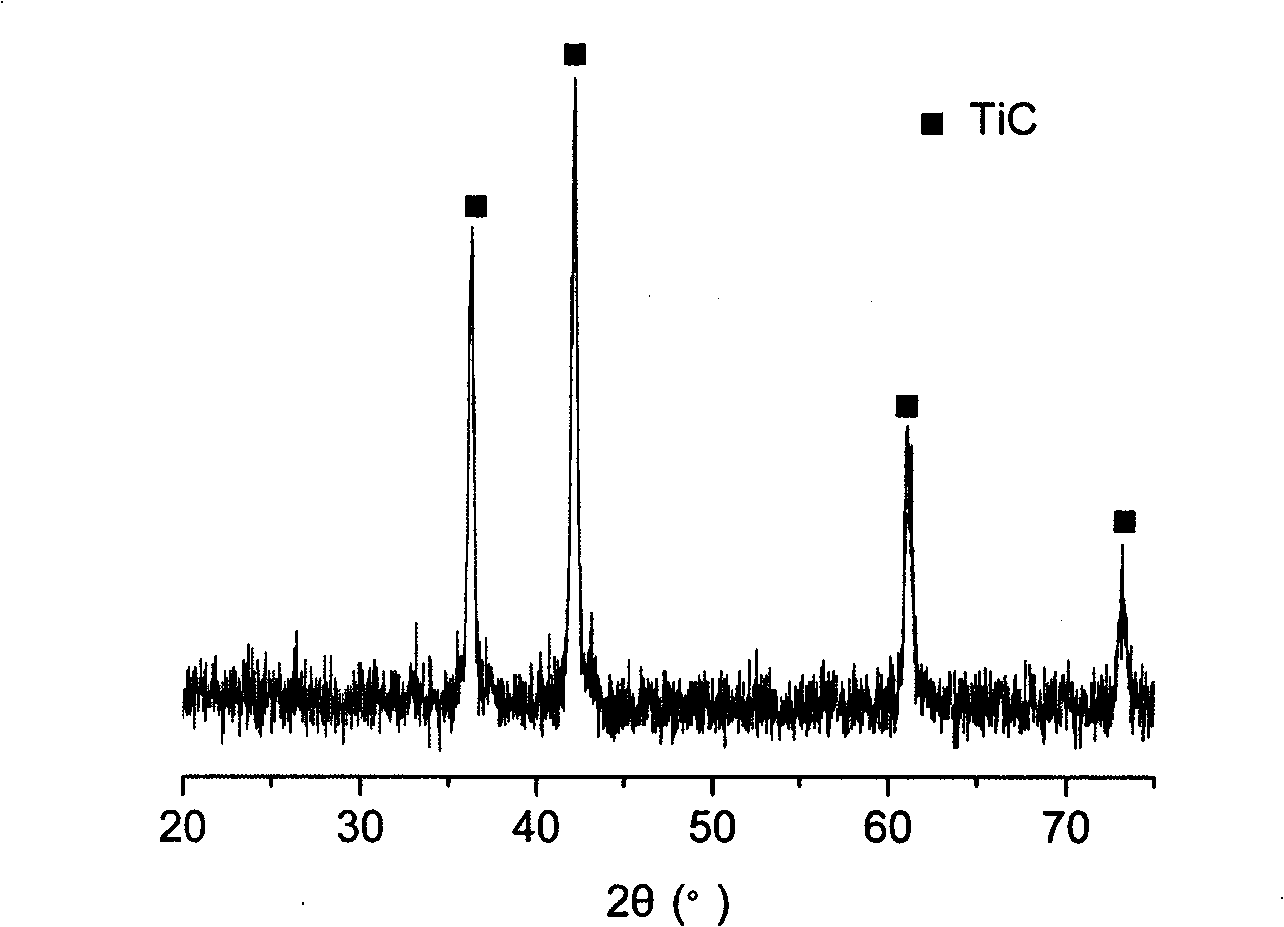

Precursor solution of carbide ceramic, carbide ceramic and preparation thereof

The invention discloses precursor solution for carbide ceramics. The precursor solution uses an alkoxy compound of more than one refractory metal as solute, and uses divinylbenzene, vinyl group acetylenyl benzene or diacetylene-benzene as solvent, and the molar ratio of the solute to the solvent is 1 to between 0.2 and 2. The invention also discloses carbide ceramics and a preparation method thereof. The method comprises the following preparation steps: the precursor solution of the invention is evenly mixed and heated to between 150 and 300 DEG C, and then is insulated for 0.5 to 4 hours; the precursor after low temperature crosslinking treatment is heated to between 1, 200 and 1, 800 DEG C in an inert atmosphere or under a vacuum condition, and then is insulated for 0.5 to 2 hours for high temperature pyrolysis; and the carbide ceramics is obtained after temperature reduction. The precursor solution has the advantages of low viscosity, good stability, simple preparation process, and so on. The method for preparing the carbide ceramics has the advantages of high impregnation efficiency, simple crosslinking process, high ceramics yield, and so on.

Owner:NAT UNIV OF DEFENSE TECH

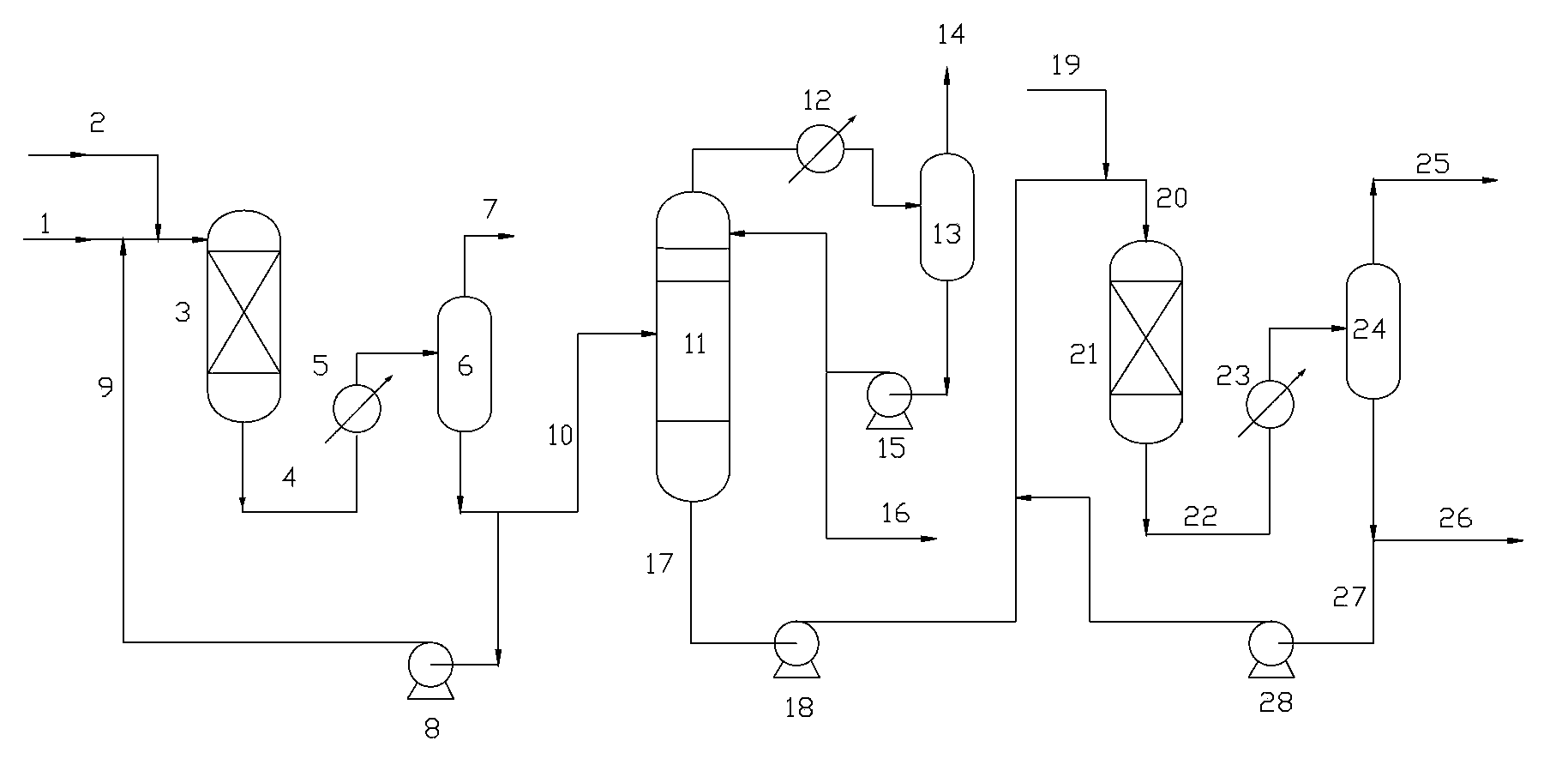

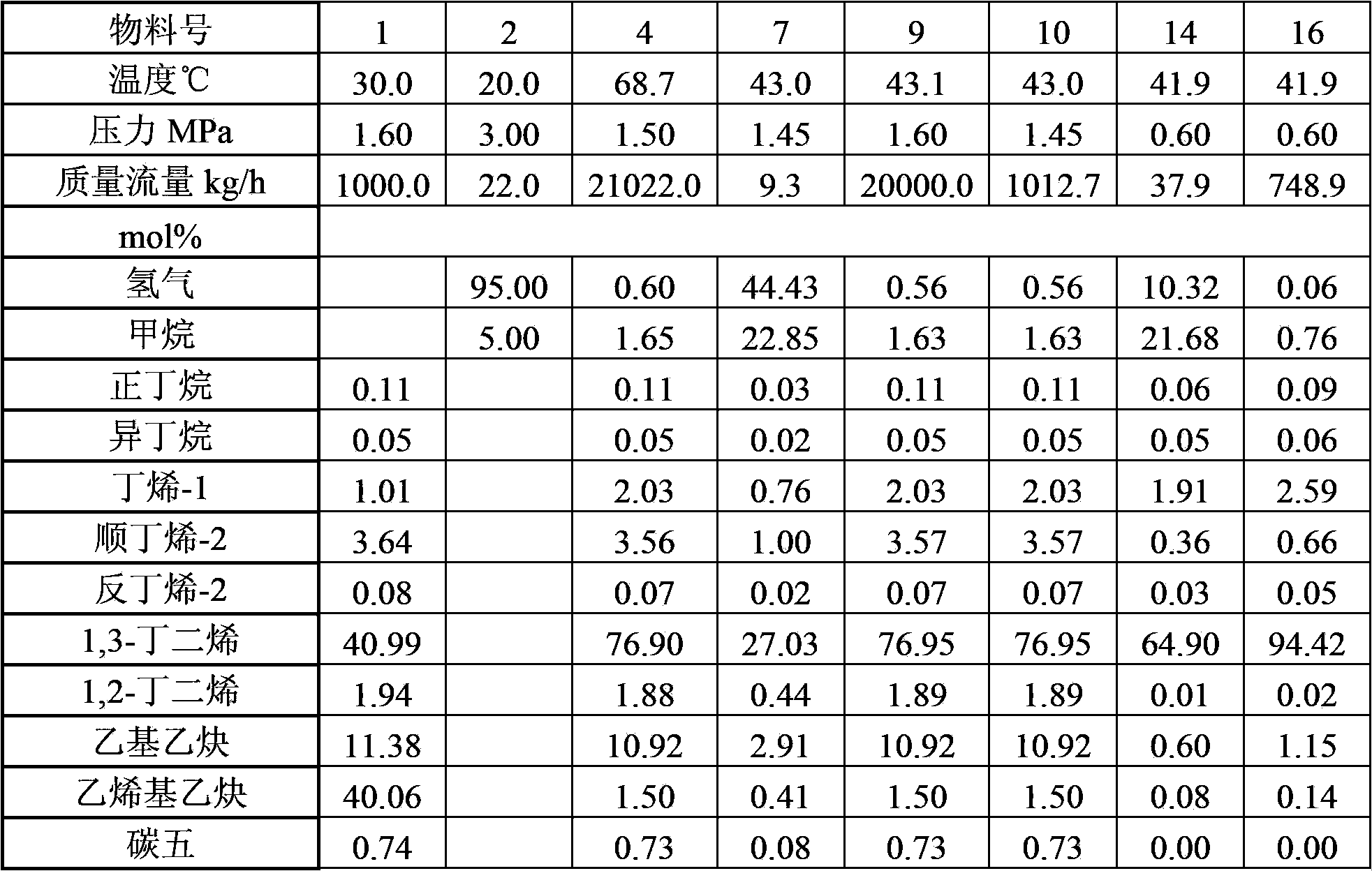

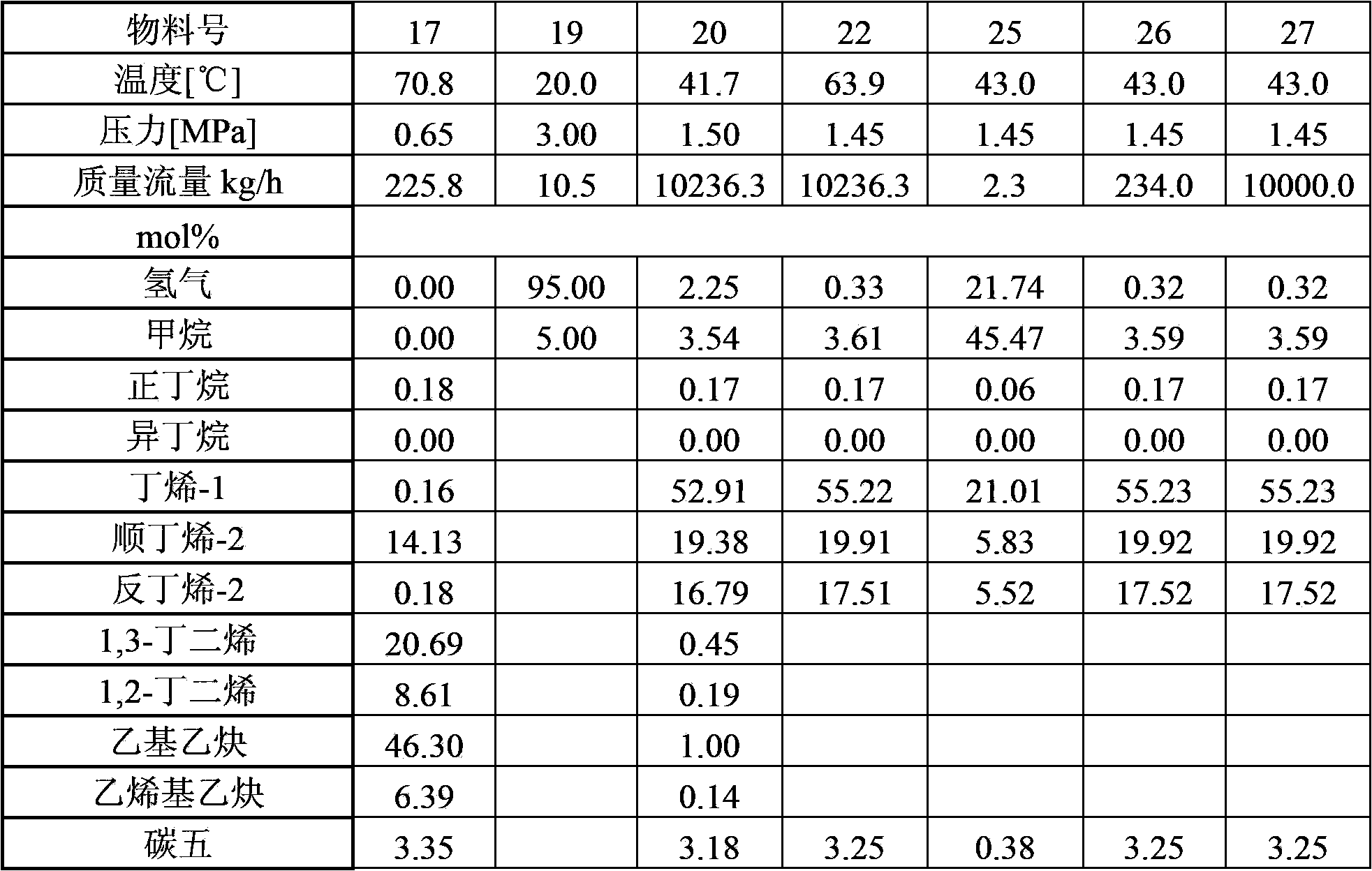

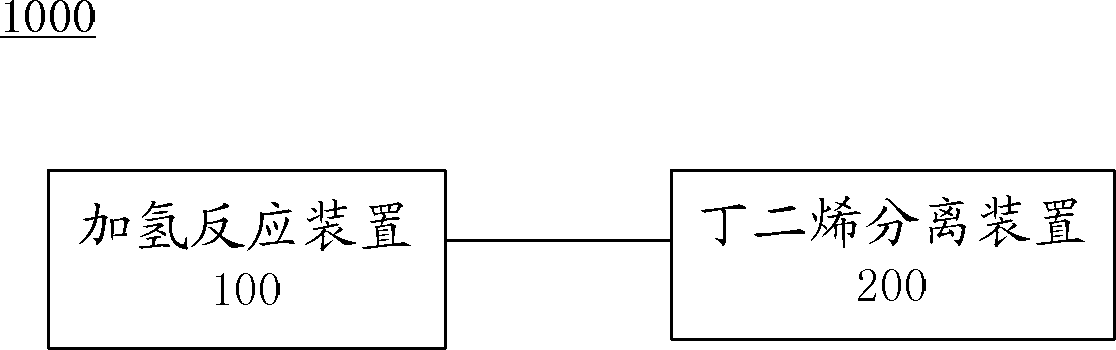

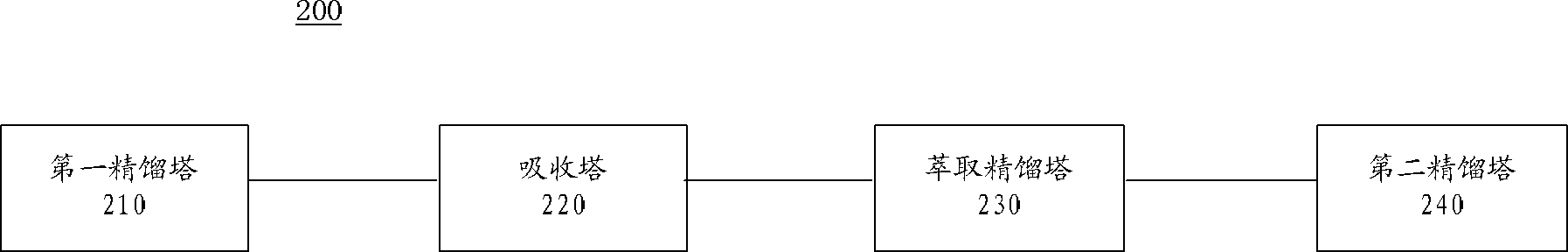

Method and system for preparing butadiene

ActiveCN102627519AImprove efficiencyImprove securityHydrocarbon by hydrogenationDistillation purification/separationVinylacetyleneHydrogenation reaction

The invention relates to a method and a system for preparing butadiene. The method for preparing the butadiene comprises the steps as follows: enabling vinyl acetylene and hydrogen to be subjected to hydrogenation reaction so as to obtain a first mixture containing the butadiene; and separating the butadiene from the first mixture. Due to the method, the butadiene can be effectively prepared with the vinyl acetylene as a raw material, the method is safe and reliable, and the production cost can be remarkably reduced.

Owner:ANHUI ANQING SHUGUANG CHEM GRP +1

Method for synthesizing vinylacetylene through acetylene dimerization

InactiveCN102775266AImprove solubilitySave operating timeHydrocarbonsHydrocarbon preparationSingle processSynthesis methods

The invention provides a method for synthesizing vinylacetylene through acetylene dimerization by aiming at the problems that in the prior art, the process for synthesizing vinylacetylene through acetylene dimerization is complicated, the production cost is too high, the single process conversion rate of the acetylene and the selectivity of the vinylacetylene are not high, and the like. According to the method, cuprous chloride is adopted as major catalysts, urea is adopted as cocatalysts, ammonium chloride is adopted as cosolvents, water is adopted as solvents, hydrochloric acid provides acid environment required by the reaction, and the reaction temperature is 70 to 90 DEG C, wherein in 45L water, the addition of the cuprous chloride is 0.30kmol, the addition of the urea is 0.06kmol to 0.14 kmol, the addition of ammonium chloride is 0.18kmol to 0.42kmol, and the addition of the hydrochloric acid is 0.3L. The dissolution of the ammonium chloride and the cuprous chloride is accelerated, the operation time before the reaction is shortened, the generation of high polymers is inhibited, the condition of air path blockage caused by polymers is avoided, and the method belongs to a novel, efficient, stable, environment-friendly and economic synthesis method.

Owner:CHONGQING UNIV

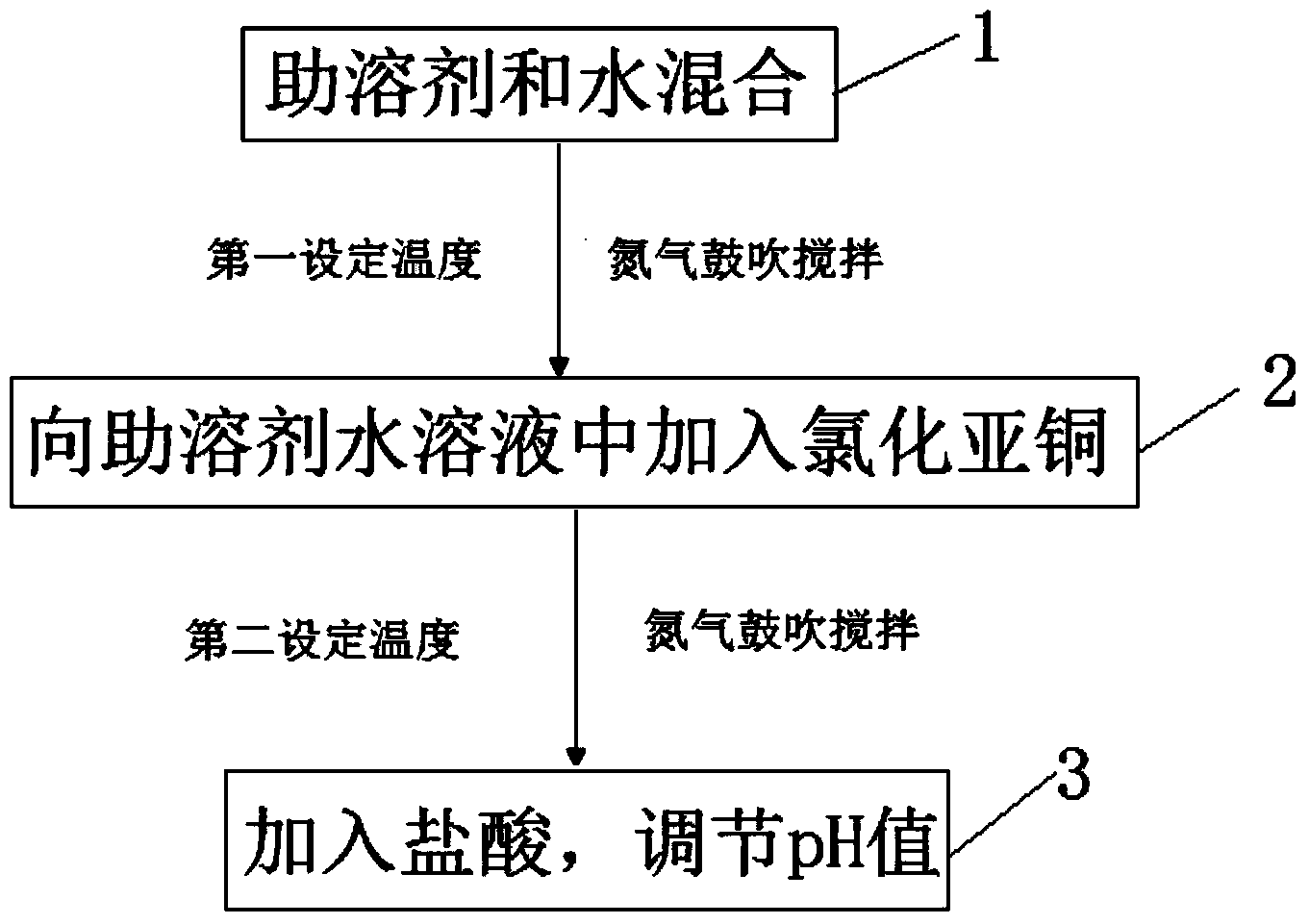

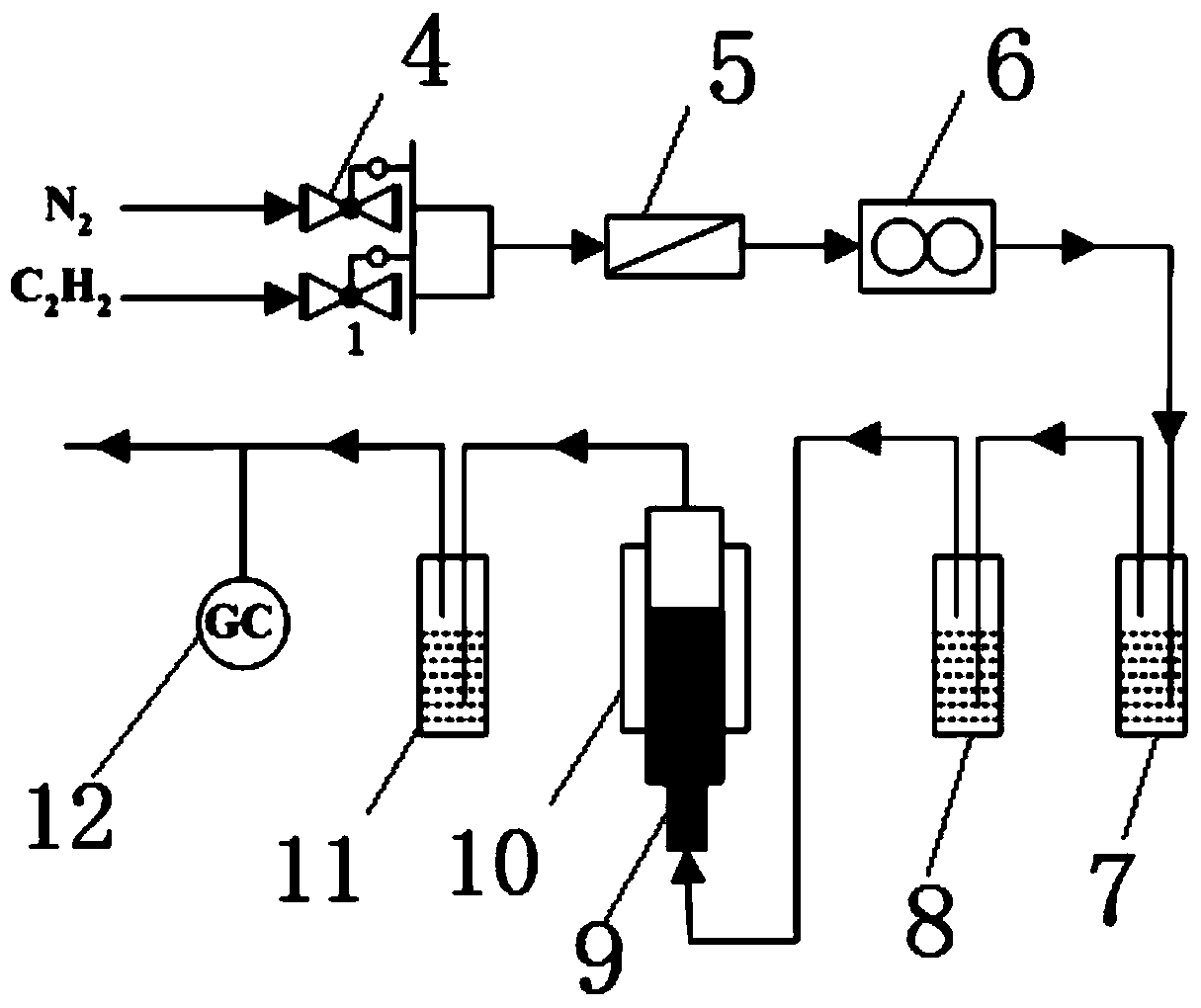

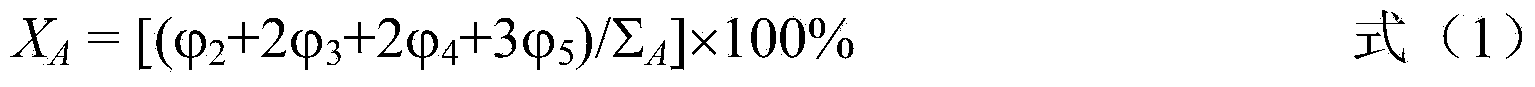

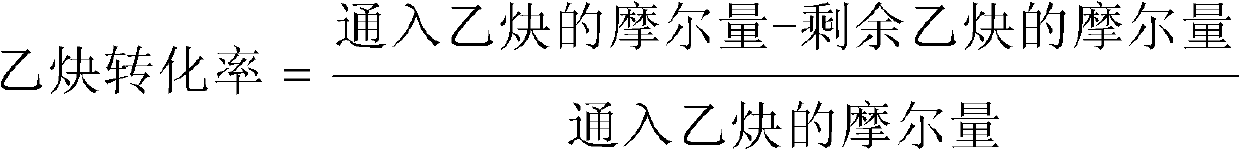

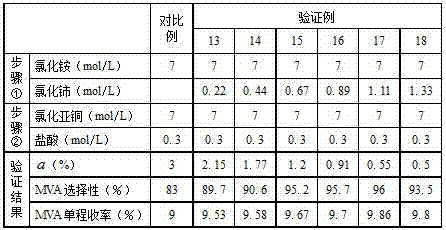

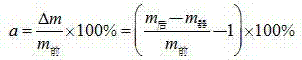

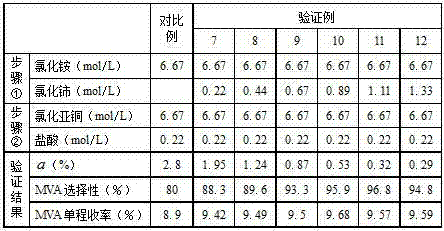

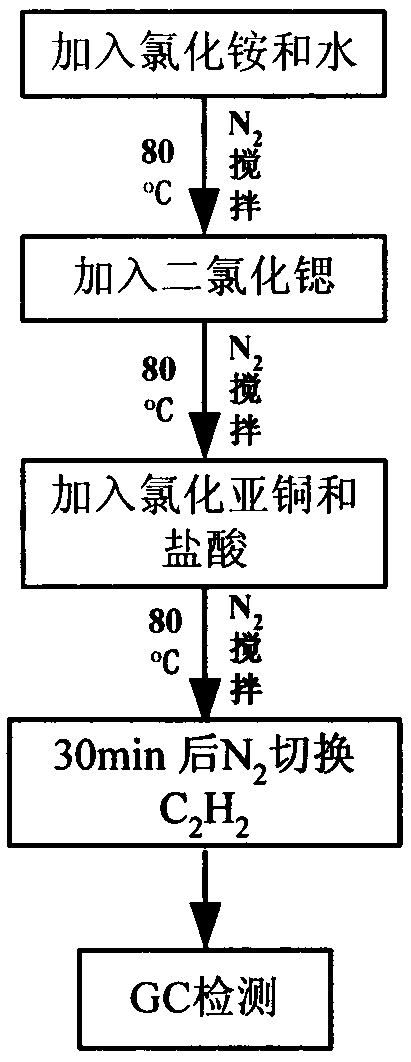

Catalytic system, preparation method thereof, and preparation method of vinyl acetylene by the same

ActiveCN104209144AImprove effective conversion rateHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsChemical industryVinylacetylene

The invention discloses a catalytic system, a preparation method thereof, and a preparation method of vinyl acetylene by the same, relates to the field of chemical industry, and solves the problems of large quantity of generated by-products and polymers and low selectivity of vinyl acetylene in vinyl acetylene production by using acetylene dimerization method in the prior art. A main technical scheme of the invention is as below: the catalytic system is used for catalyzing acetylene dimerization to produce vinyl acetylene. The preparation method of the catalytic system mainly comprises the following steps: adding a cosolvent and water into a reactor with nitrogen, and stirring under a first set temperature to thoroughly dissolve the cosolvent to obtain a cosolvent aqueous solution; and under a second set temperature, adding a main catalyst of cuprous chloride and a ligand polyethylene glycol solvent in the cosolvent aqueous solution to cuprous chloride, thoroughly dissolving cuprous chloride, and adding an acid solution to obtain the catalytic system. The invention is mainly used to improve the selectivity of vinyl acetylene and effective conversion rate of acetylene in the production process of acetylene dimerization method for preparation of vinyl acetylene.

Owner:SHIHEZI UNIVERSITY

Vinyl acetylene product and preparation method thereof

InactiveCN103288572ALow costEfficient productionHydrocarbonsHydrocarbon preparationVinylacetyleneReaction system

The invention provides a vinyl acetylene product and a preparation method thereof. According to the preparation method, a nonaqueous phase catalyst is used to ensure that acetylene is subjected to dimerization reaction, and in the reaction process, an acid gas is introduced into a reaction system. By adopting the method for preparing vinyl acetylene, the service life of the nonaqueous phase catalyst can be prolonged, so that the vinyl acetylene can be efficiently prepared.

Owner:TSINGHUA UNIV

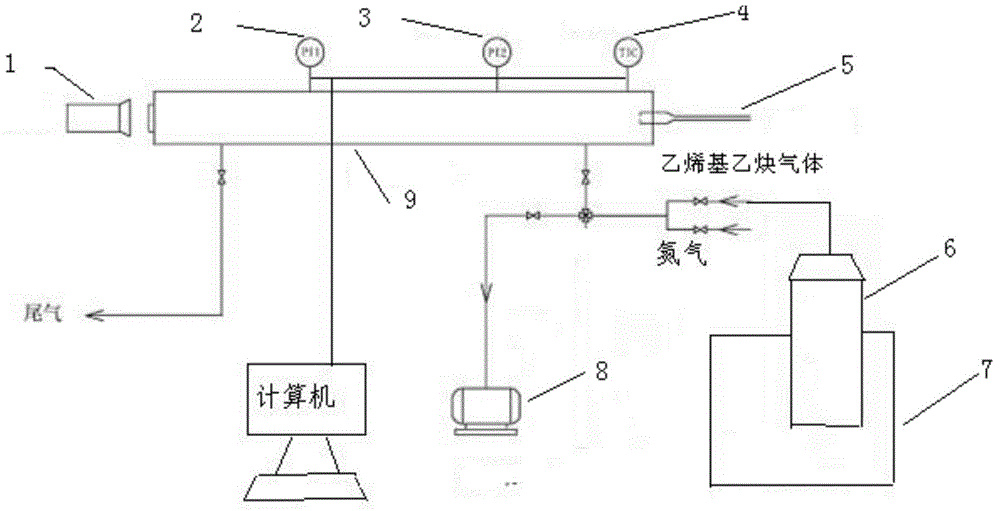

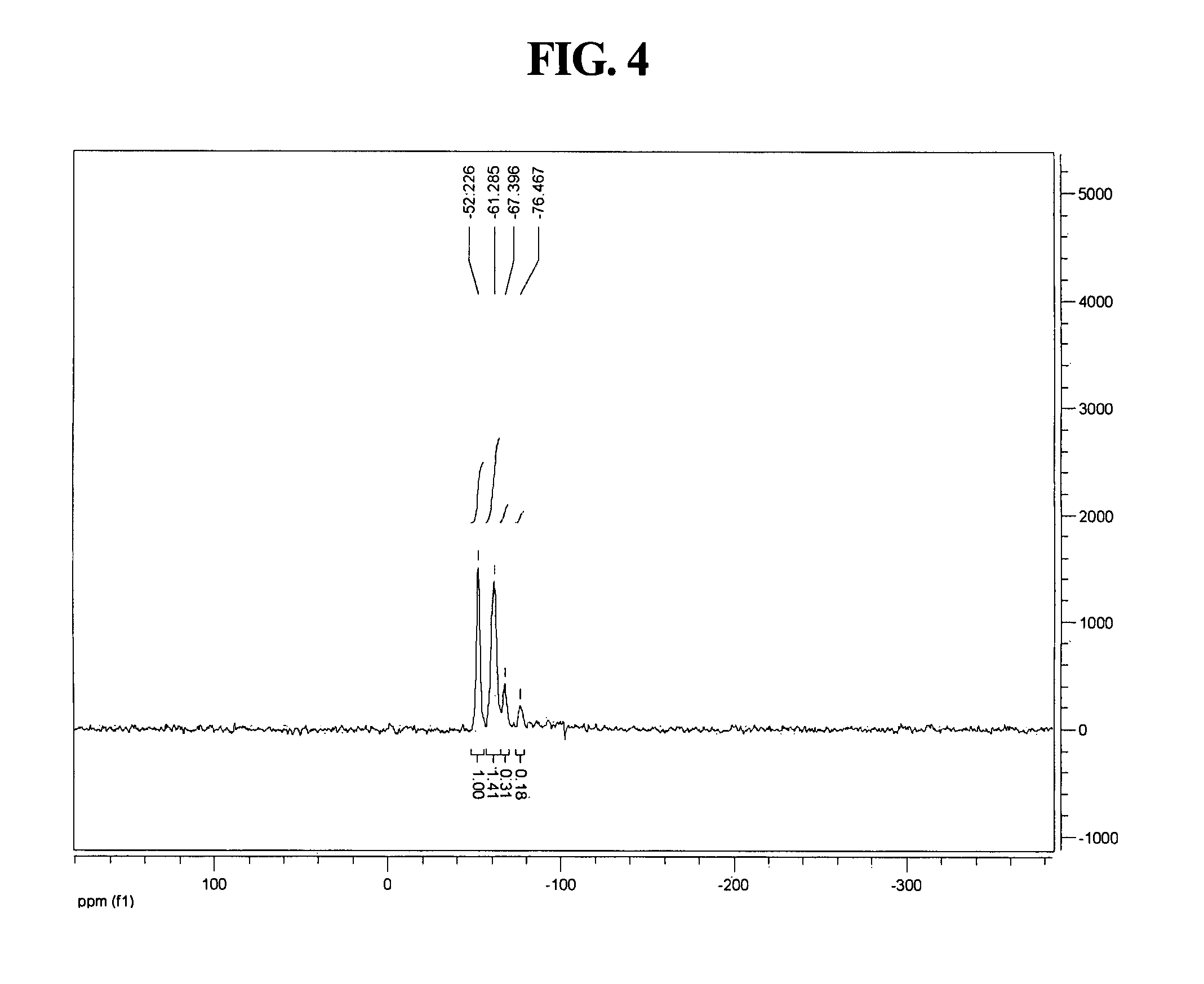

Test method of safe critical partial pressure of vinyl acetylene gas

InactiveCN104931529AQuickly get the critical decomposition pressureTest accurateMaterial exposibilityVinylacetyleneDecomposition

The invention relates to a test method of safe critical partial pressure of vinyl acetylene gas by using an explosive decomposition testing device. The test method comprises the following steps: (1) vacuumizing; (2) preheating vinyl acetylene gas; (3) testing ignition. The test method is capable of accurately and quickly testing the critical pressure of explosive decomposition of the vinyl acetylene gas in the absence of oxygen; the tested critical pressure range is wide; the temperature in the test process can be accurately controlled; meanwhile, the stability of the vinyl acetylene gas under the high-temperature and high-pressure condition can be observed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing vinylacetylene

InactiveCN102964198ASuppress generationHigh selectivityPhysical/chemical process catalystsHydrocarbonsVinylacetyleneCerium

The invention relates to a method for preparing vinylacetylene. According to the method, cerium chloride serving as a promoter is added to the catalyzing system on the basis of a nieuwland catalyst system, and the mixing ratio of components and the processing steps of the vinylacetylene are correspondingly adjusted. During the dimerization reaction of acetylene, the generation of associated polymers can be inhibited well, and the amount of generated associated polymers is greatly reduced; and furthermore, the selectivity of the vinylacetylene (MVA) which is the target product can be effectively improved, and the output is raised as well.

Owner:CHONGQING YOUCUI SCI & TECH

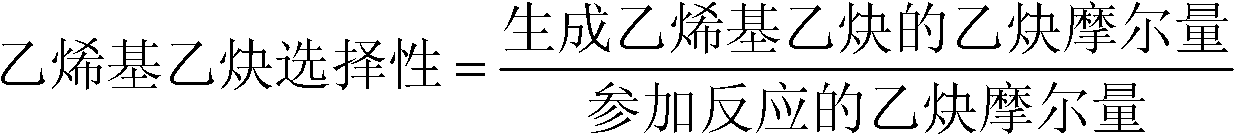

Method for preparing vinylacetylene through acetylene dimerization by utilizing modified nieuwland catalyst

InactiveCN103467236AEasy to makeLow costPhysical/chemical process catalystsHydrocarbonsStrontium chloride hexahydrateEthyl Chloride

The invention relates to a method for preparing vinylacetylene through acetylene dimerization by utilizing a strontium chloride modified nieuwland catalyst and an application method. The method is characterized in that a strontium chloride hexahydrate is used as a cocatalyst, cuprous chloride is used as a main catalyst, ammonium chloride is used as a cosolvent, an acid environment is provided by hydrochloric acid, and water is used as a solvent to prepare a copper-strontium-inorganic chloride salt complex to serve as the catalyst. Under the condition, the generation of high polymers in the acetylene dimerization reaction is obviously reduced and the selectivity of vinylacetylene is significantly improved.

Owner:SHIHEZI UNIVERSITY

Process for 1,3-butadiene separation from a crude C4 stream with acetylene converter

ActiveUS9062262B2Promote recoveryUtilization degree decreaseDistillation purification/separationHydrocarbonsVinylacetyleneButene

Disclosed is a method of recovering 1,3-butadiene from a C4 stream containing butane, isobutane, 2-butene, 1-butene, isobutene, butadiene and acetylene. The process of recovering highly pure 1,3-butadiene includes acetylene conversion for selectively converting acetylene through liquid-phase hydrogenation, so that the acetylene content is decreased to 70 wt ppm or less, and 1,3-butadiene extraction using an extractive distillation column, a pre-separator, a solvent stripping column, a solvent recovery column, and a purification column. Through the acetylene conversion, the concentration of vinylacetylene is decreased to 70 wt ppm or less, after which 1,3-butadiene is recovered using only one extractive distillation column, thereby considerably decreasing the degree of utility and the loss of streams in the course of extraction. The number of units necessary for the process is decreased, thus remarkably reducing the time during which impurities can accumulate in a processing unit.

Owner:SK INNOVATION CO LTD

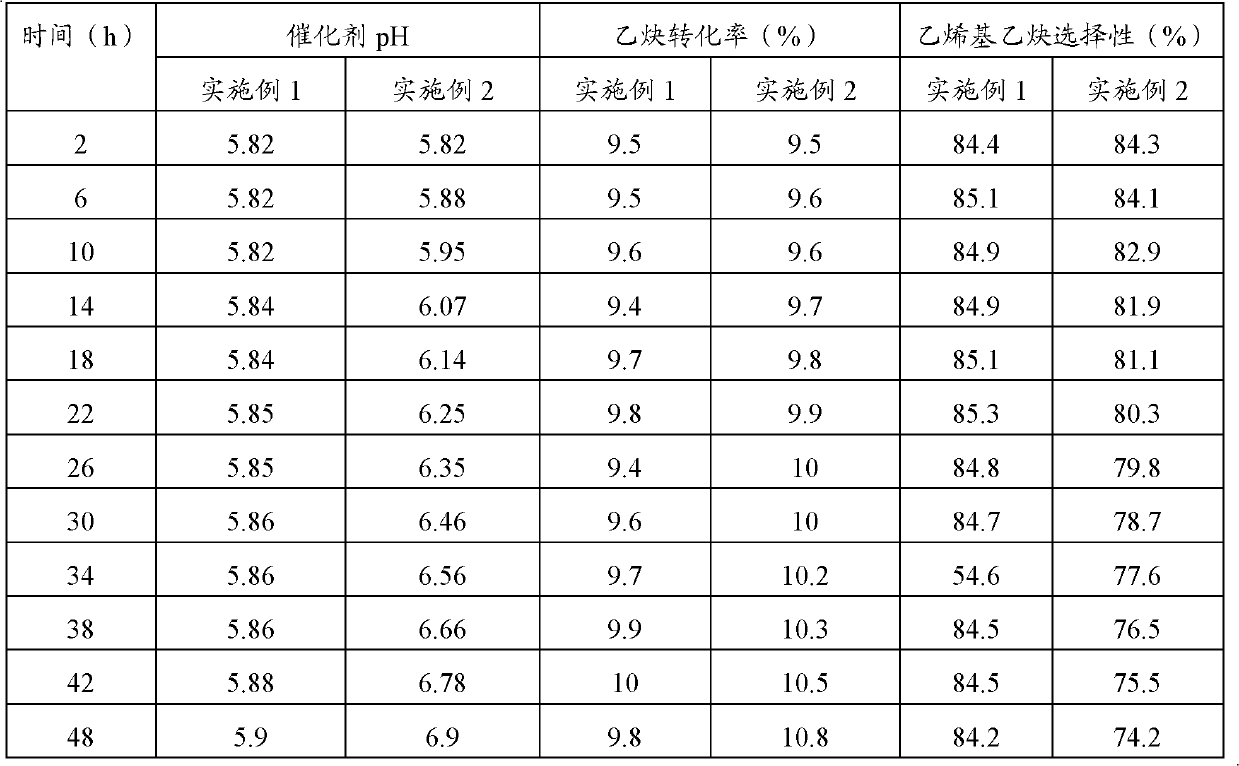

Nieuwland catalyst as well as preparation method and application thereof

ActiveCN103285931ALow costImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsVinylacetyleneActive component

The invention provides a Nieuwland catalyst as well as a preparation method and an application thereof. The Nieuwland catalyst comprises the following components in parts by weight: 20 to 40 parts of CuCl as an active component and 1 to 20 parts of buffering agent, wherein the pH value of catalyst is kept within the range of 4.5 to 6.8 through the buffering agent. The Nieuwland catalyst has the good stability in an acetylene dimerization reaction, so that the Nieuwland catalyst can be efficiently applied to the production of vinyl acetylene.

Owner:ANHUI ANQING SHUGUANG CHEM GRP +1

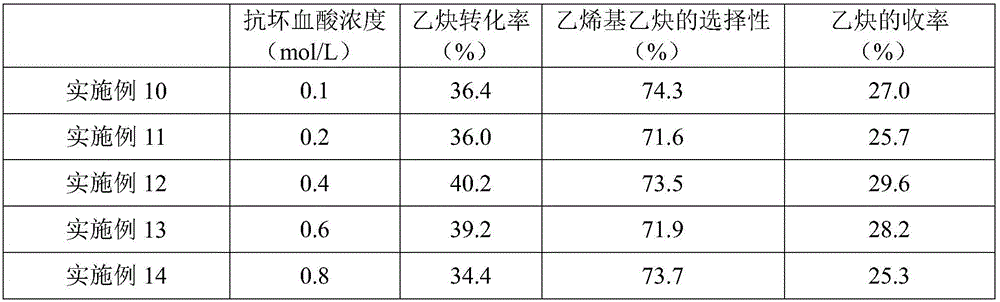

Acetylene dimerization nonaqueous-phase catalyst and application thereof

ActiveCN105749982AIncrease conversion rate per passOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsSodium ascorbateSulfite salt

The invention relates to an acetylene dimerization nonaqueous-phase catalyst and application thereof. The acetylene dimerization nonaqueous-phase catalyst comprises a main catalyst, a cosolvent, an organic solvent and a reducing agent, wherein the main catalyst is cuprous chloride; the cosolvent is organic amine hydrochloride; the reducing agent is a mixture of one or more than two selected from a compound containing two or more hydroxys, sodium sulfite and copper powder; the compound containing two or more hydroxys refers to ascorbic acid, sodium ascorbate, kalium ascorbate, glucose, fructose and the like. The application of the catalyst in acetylene dimerization reaction comprises the following steps of: adding the catalyst into a reactor, then introducing acetylene into the reactor, and performing a dimerization reaction on acetylene at a reaction temperature of 60-90 DEG C and an acetylene airspeed of 100-250 h<-1>, so as to generate vinylacetylene. The catalyst is added with weak reducing agents such as ascorbic acid, so as to inhibit Cu<1+> of catalytic active ingredients in a reaction solution from being converted into Cu<2+>, and the conversion per pass of acetylene is increased.

Owner:SHIHEZI UNIVERSITY

Optimum process for selective hydrogenation/hydro-isomerization, aromatic saturation, gasoline, kerosene and diesel/distillate desulfurization (HDS). RHT-hydrogenationSM, RHT-HDSSM

InactiveUS7959793B2Simple configurationIncrease cetane numberHydrocarbon by hydrogenationHydrocarbon purification/separationIsomerizationKerosene

A process for selective hydrogenation of C3 / C4 / C5 / C6 / C7 and LCN, hydro-isomerization of olefins, benzene saturation and hydrodesulfurization of Gasoline, Kerosene and Diesel together with aromatic saturation of LCO is being provided so as to provide optimum technology at low cost with unique configuration. The technology is user friendly and uses conventional catalyst. These configurations cover both the options of installing the bulk catalyst in the distillation column with chimneys trays, hence essentially all the reaction takes place in the liquid phase in single or multiple beds or with fixed bed down flow or up flow reactor configuration. The configurations shown in the figures depicts that the fixed bed reactors are integrated with the Distillation Column and this art helps in lowering the Capital costs and the reactors are operating in single phase or two-phase conditions. The art is applicable to MAPD, vinyl acetylene, C3, C4, C5, C6, C7 mixed hydrocarbon stream, and LCN diolefin selective hydrogenation. It includes the process for hydro-isomerization of Butene-2 to Butene-1, or visa versa, removal of Isobutylene and Isobutane by distillation after hydro isomerization, benzene hydrogenation to Cyclohexane, hydrodesulfurization of FCC gasoline, coker gasoline or any other Naphtha stream together with hydrodesulfurization of Diesel / Kerosene from any of the refinery units.

Owner:REFINING HYDROCARBON TECH RHT

Method for improving raffinate product yield of acetonitrile-process 1,3-butadiene extracting apparatus

ActiveCN104030872AReduce concentrationImprove operational safetyDistillation purification/separationButeneVinylacetylene

Owner:SINOPEC ENG +1

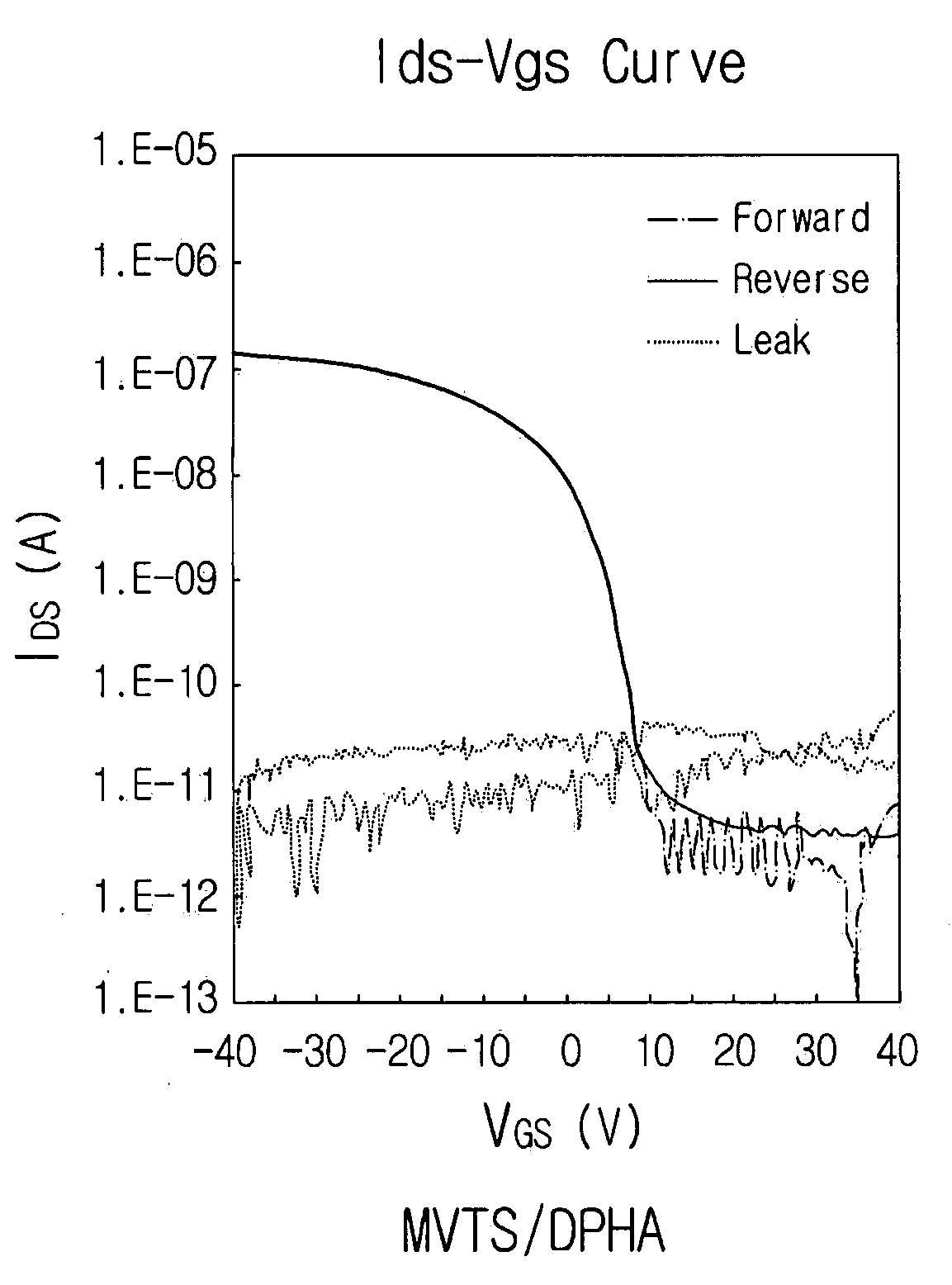

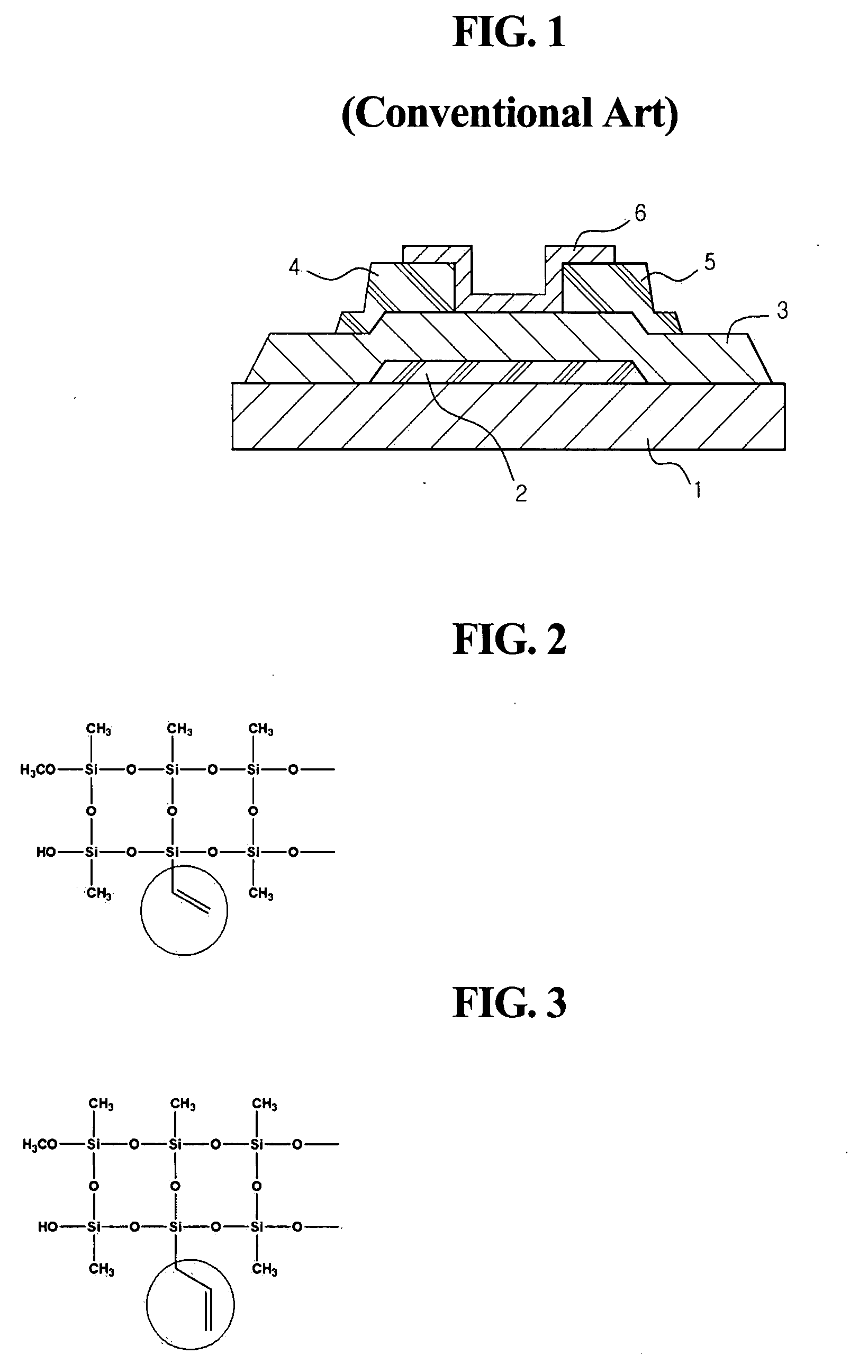

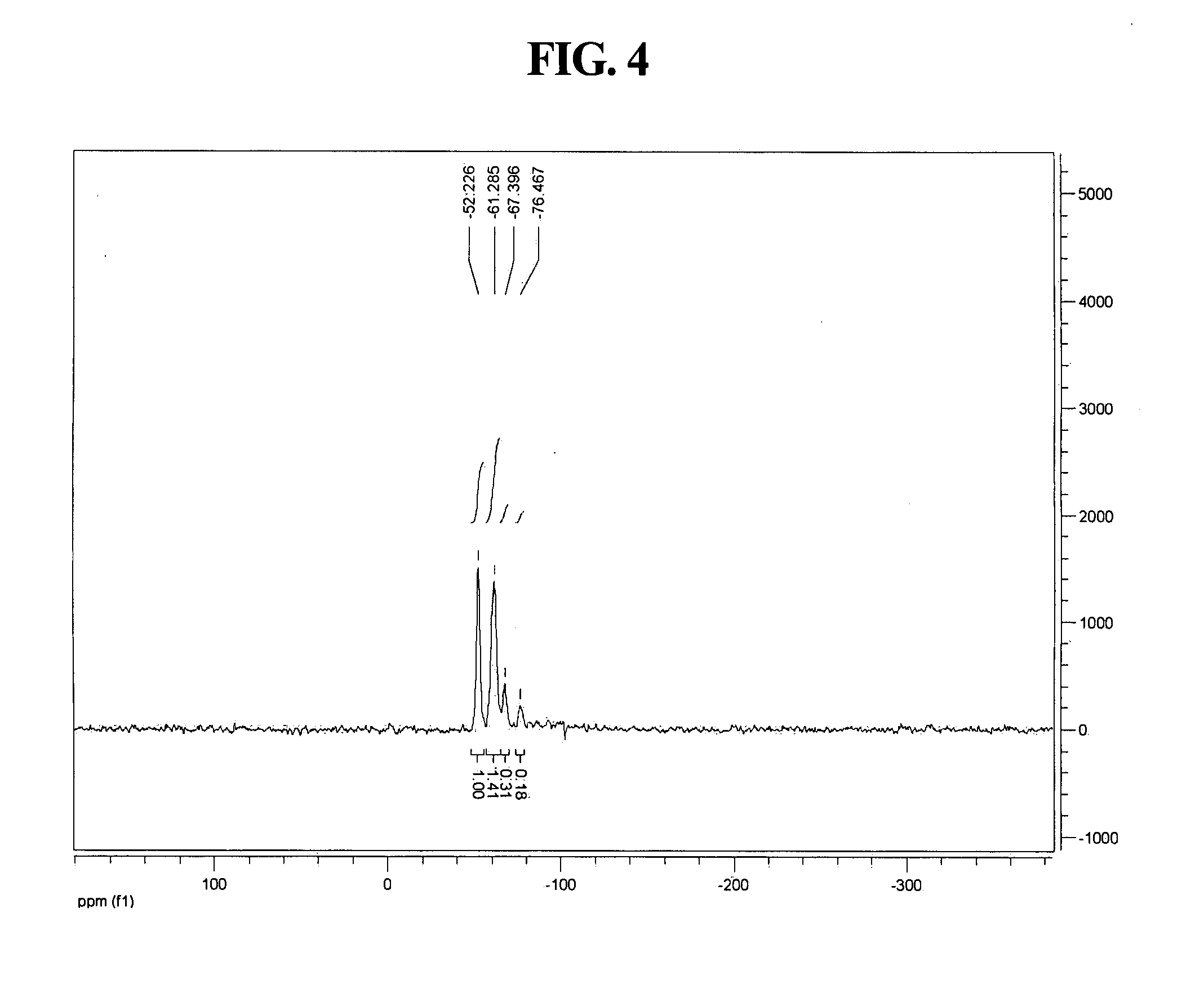

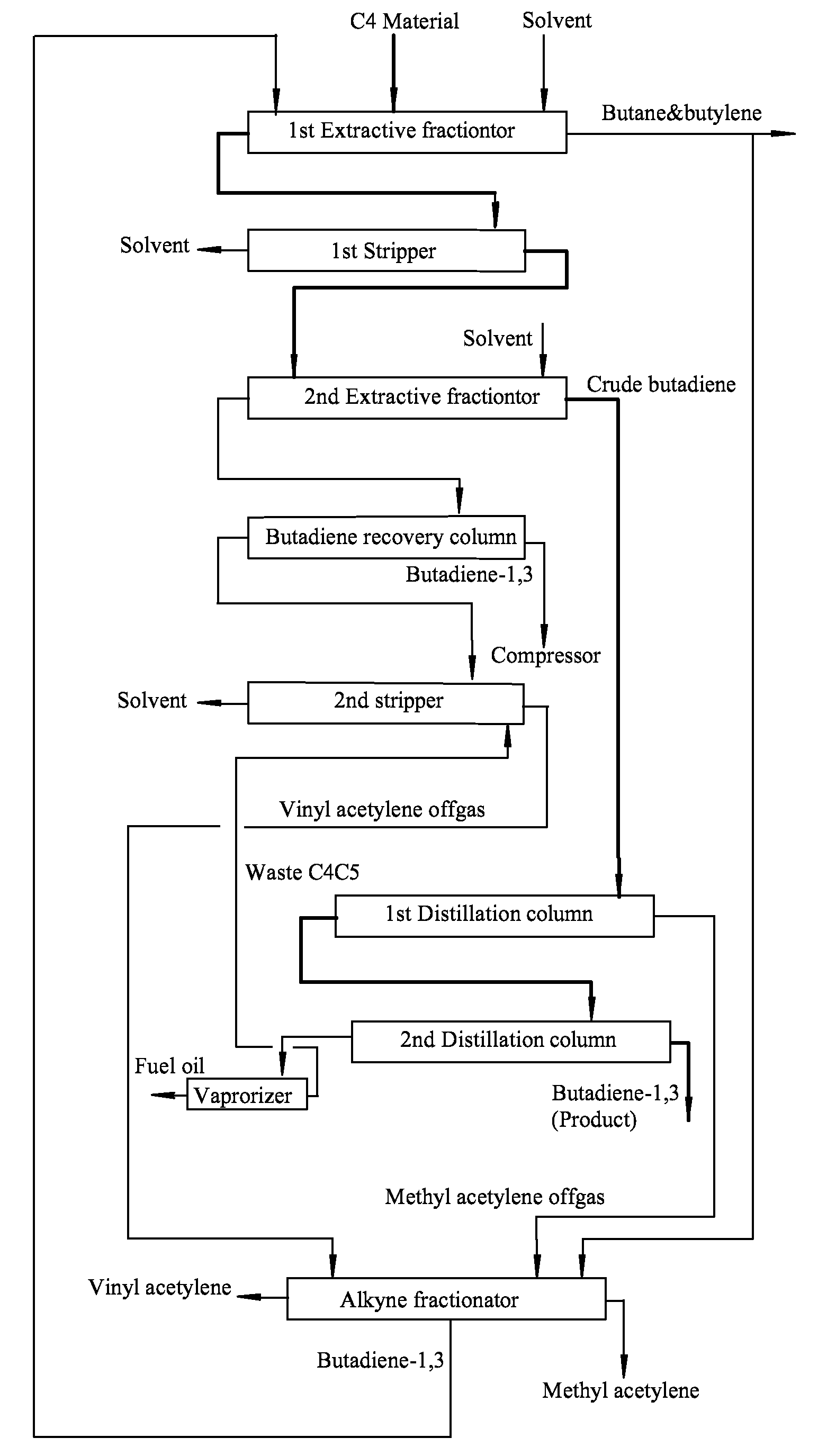

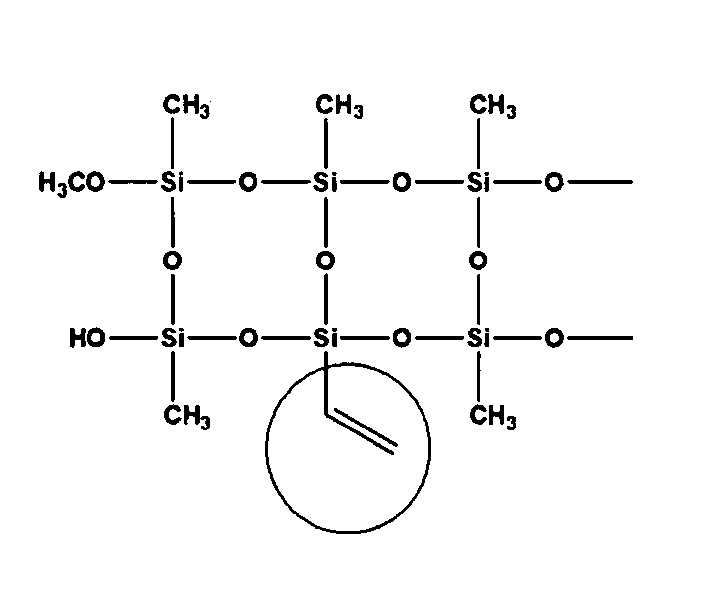

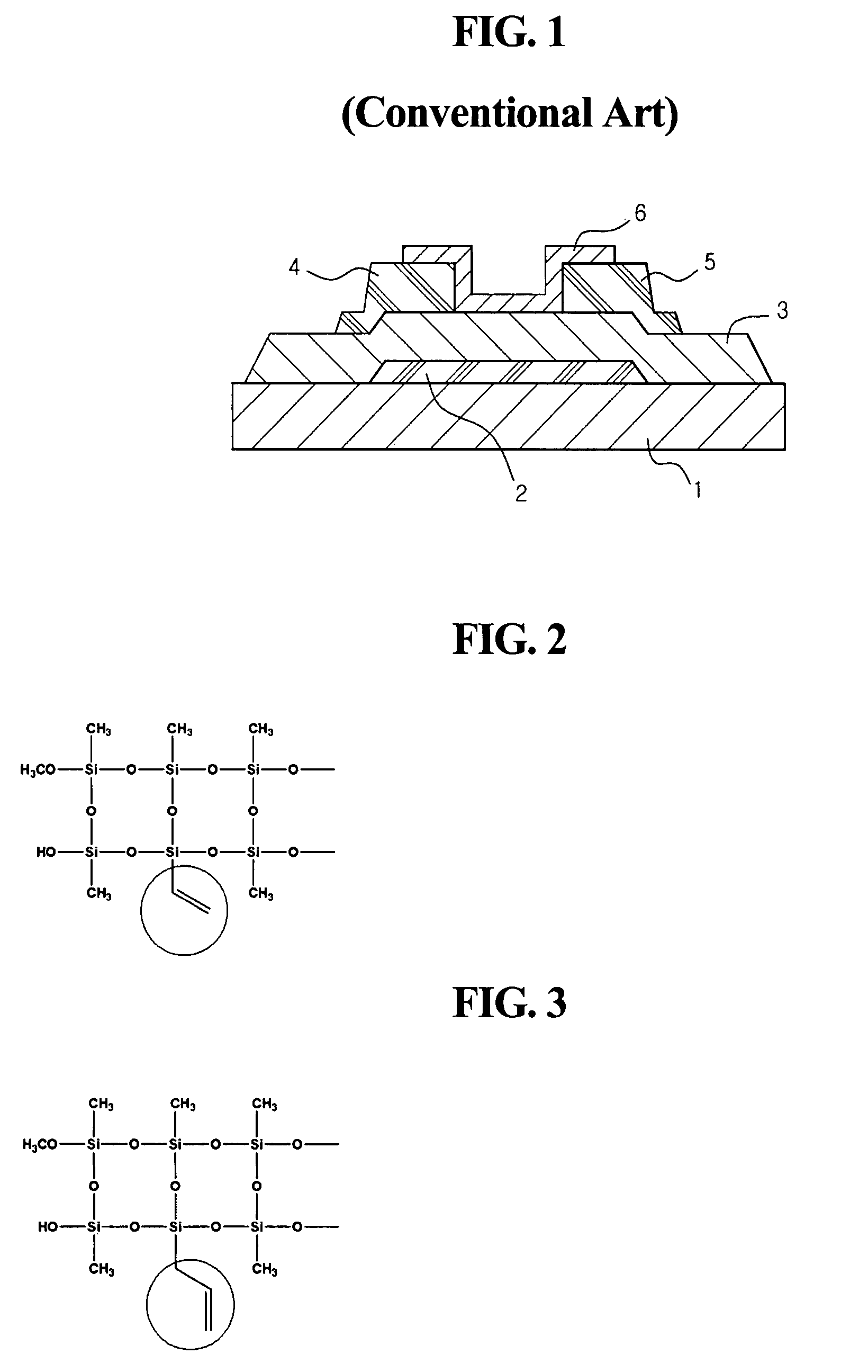

Composition and organic insulator prepared using the same

ActiveUS20080111129A1Facilitate cross-linkingSmall lagSolid-state devicesSemiconductor/solid-state device manufacturingHysteresisVinylacetylene

Disclosed is a composition for preparing an organic insulator, including an organic silane material, having a vinyl group, an acetylene group or an acryl group as a functional group for participating in a crosslinking reaction, a crosslinking agent, and a solvent for dissolving the above components. The organic insulator of example embodiments may be provided in the form of a solid insulating film, which may increase charge mobility while decreasing the threshold voltage and operating voltage of OTFTs, and which also may generate relatively slight hysteresis.

Owner:SAMSUNG ELECTRONICS CO LTD

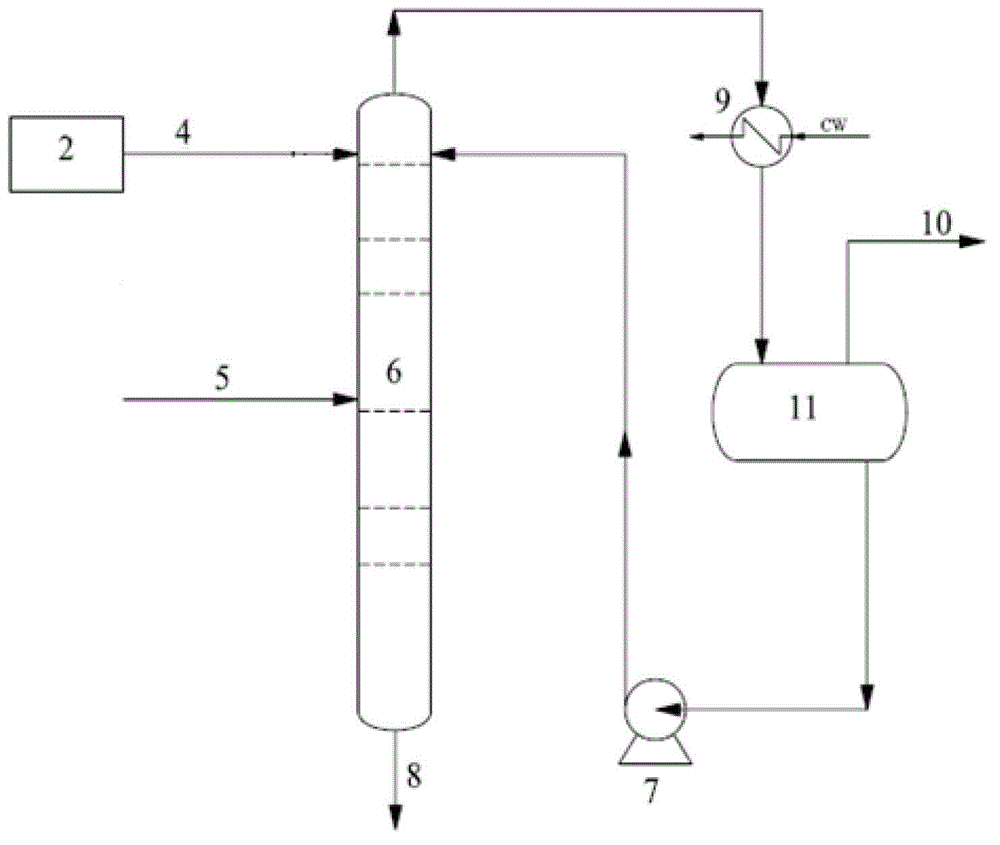

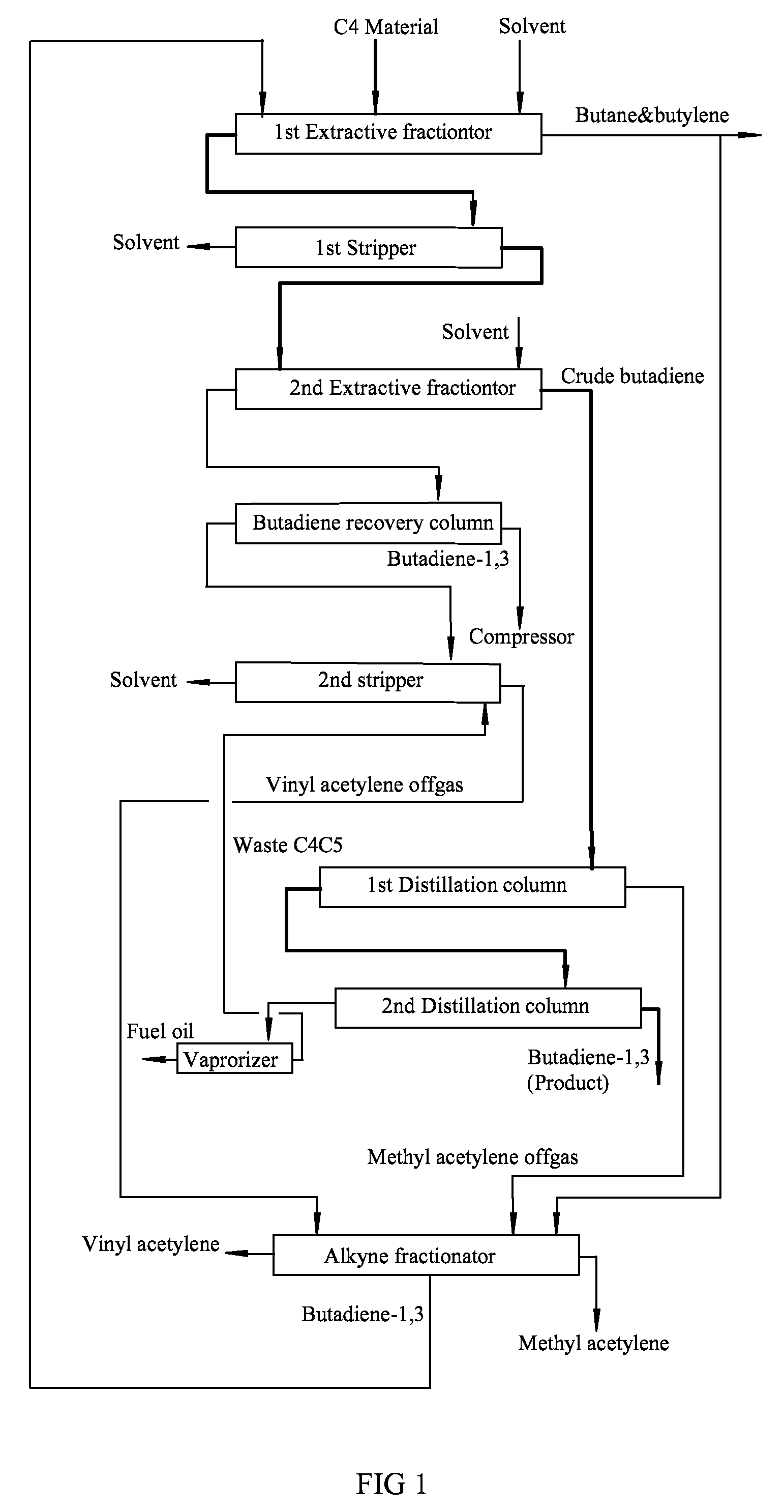

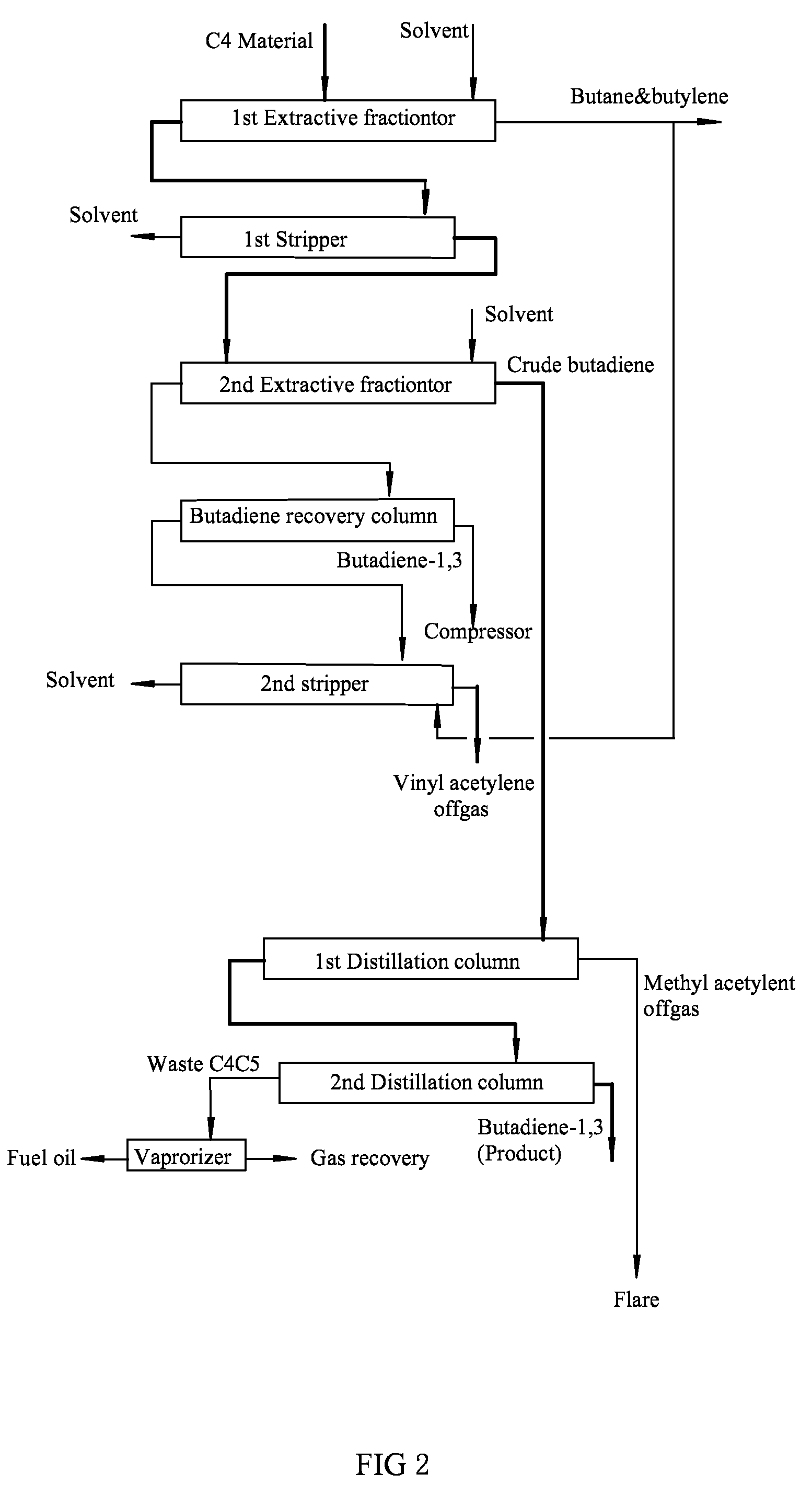

Process of butadiene-1, 3 extraction

InactiveUS20090234172A1Increase productionImprove planting effectDistillation purification/separationHydrocarbonsVinylacetyleneButadiene Dioxide

This invention presents a process of butadiene-1,3 extraction. The process consists of the procedure of 1st extractive fractionation, 2nd extractive fractionation, distillation and alkyne fractionation. This invention can improve the yield and capacity of butadiene extraction unit by adding an alkyne fractionator to the existing butadiene extraction unit and appropriately adjusting the process condition of 1st and 2nd extractive fractionators. This invention can decrease the energy and material consumption per unit of butadiene-1,3, which greatly improved the economic profit. The investment on various scales of butadiene extraction units for adding alkyne fractionator is almost same. Further more, the profit is in direct proportion with the scale of a plant and output is in several to some dozens of folds to investment. After the implementation of this invention, the discharge of vinyl acetylene offgas can be reduced by around 3400 tons per year, which mitigate the pollution on environment and save energy. The effect of energy saving and emission reduction is remarkable.

Owner:WANG MINGHUA +2

Catalyst for preparing divinylacetylene by acetylene trimerization

InactiveCN102614929AOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsVinylacetylenePolymer science

The invention relates to a catalyst for preparing divinylacetylene by acetylene trimerization. The catalyst consists of cuprous chloride, organic ion liquid, organic amine hydrochloride and an aid, wherein the aid is N'N-dimethylformamide or N-methyl pyrrolidone; and a mass ratio of the cuprous chloride to the organic ion liquid to the organic amine hydrochloride to the aid is 5.3:(0.2-1.5):(2.0-5.3):(4.1-8.5). Experiments prove that the catalyst has high catalytic activity of ethylene trimerization and selectivity of the divinylacetylene.

Owner:中国平煤神马控股集团有限公司

Mixed butane component selective hydrogenation catalyst and preparation method

ActiveCN109759060ATaking into account the activityTake into account optionalityHydrocarbon by hydrogenationCatalyst activation/preparationManganeseAlkyne

The invention discloses a mixed butane component selective hydrogenation catalyst and a preparation method. The mixed butane component selective hydrogenation catalyst comprises active components anda supporting carrier, wherein the active components are palladium and manganese, and the supporting carrier is a mixture of gammaAl2O3, CeO2-ZrO2 and attapulgite; the palladium accounts for 0.08-1.5%of the supporting carrier; the manganese accounts for 3-5% of the supporting carrier; and the mass ratio of the gammaAl2O3 to the CeO2-ZrO2 to the attapulgite is (50-60):(30-40):(10-20). The specificsurface area of the supporting carrier is 120-180 m<2> / g; the activity and selectivity of the catalyst are effectively taken into account; and the active ingredients Pd and Mn mutually act, so that the removal depth of butadiene, butane alkyne and vinyl acetylene is favorably improved and the yield of single butene is improved. Before the mixed butane component selective hydrogenation catalyst isused, activation is not required; the mechanical strength is high; and dusting is unlikely to happen. The mixed butane component selective hydrogenation catalyst has the advantages of convenience in use, long service life and the like and can be widely applied to large-scale industrial production.

Owner:华谊高新纯化技术(大连)有限公司

Composition and organic insulator prepared using the same

Disclosed is a composition for preparing an organic insulator, including an organic silane material, having a vinyl group, an acetylene group or an acryl group as a functional group for participating in a crosslinking reaction, a crosslinking agent, and a solvent for dissolving the above components. The organic insulator of example embodiments may be provided in the form of a solid insulating film, which may increase charge mobility while decreasing the threshold voltage and operating voltage of OTFTs, and which also may generate relatively slight hysteresis.

Owner:SAMSUNG ELECTRONICS CO LTD

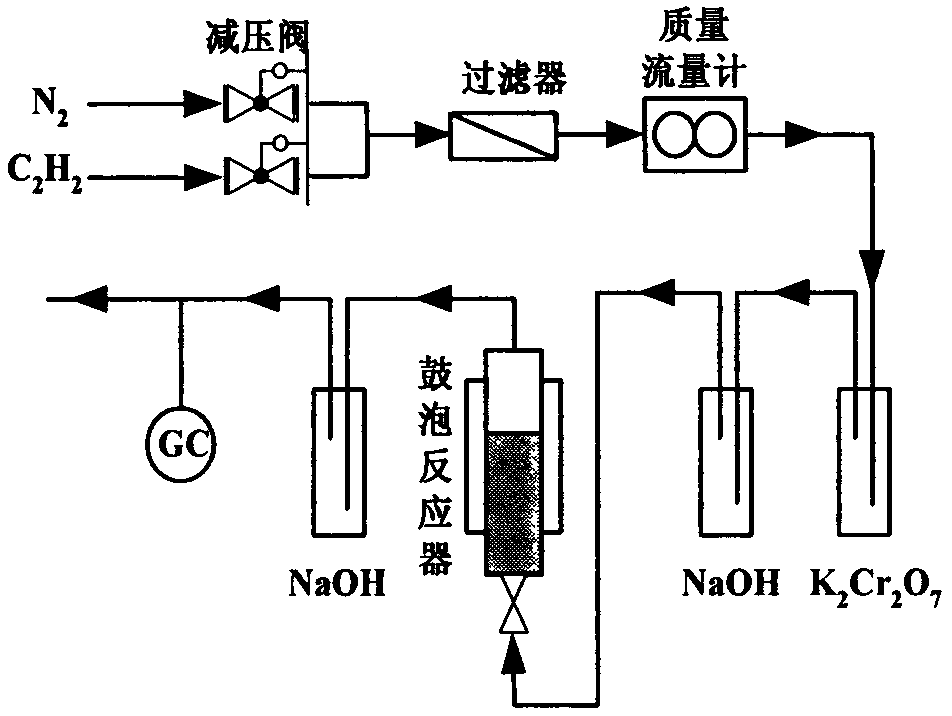

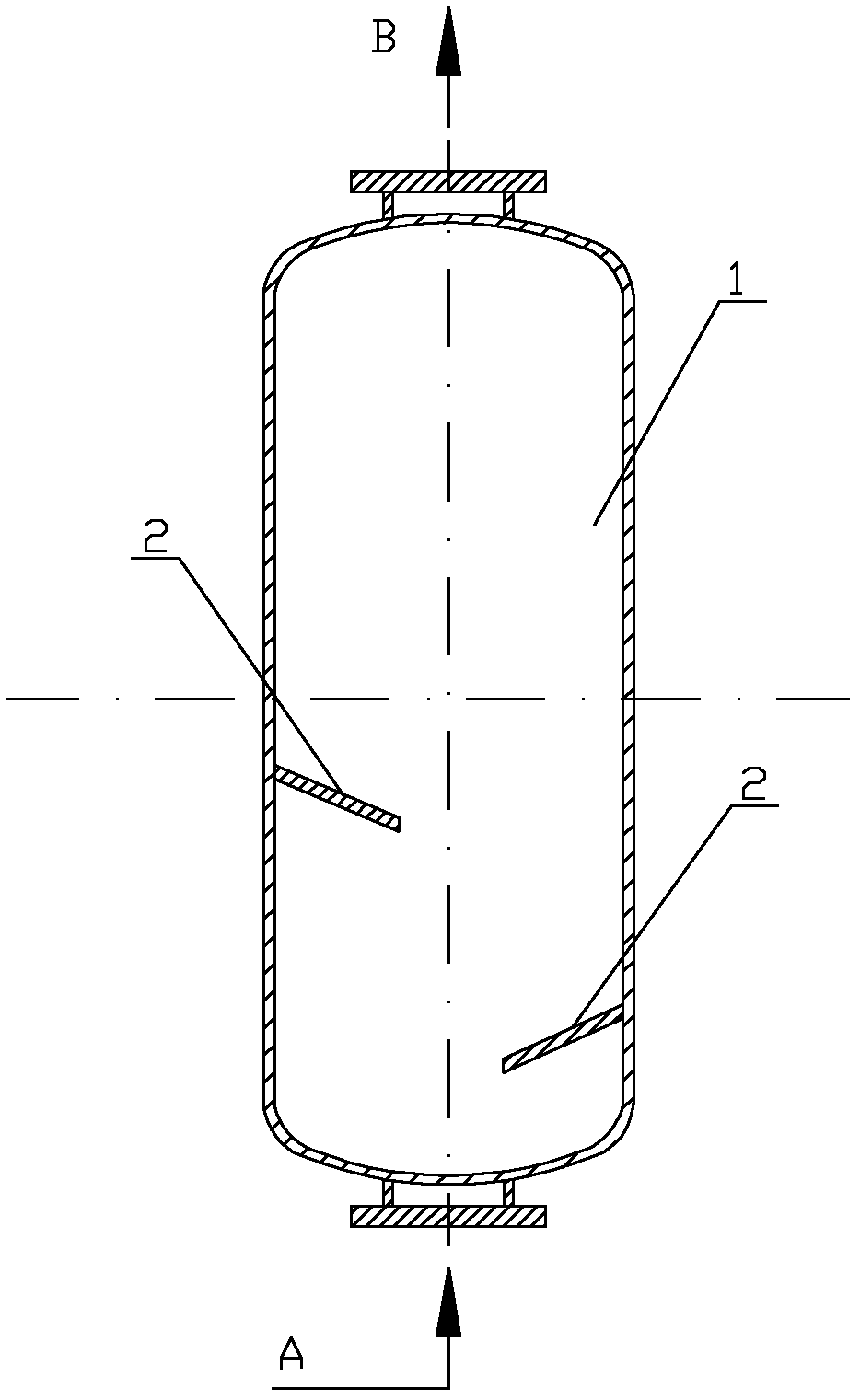

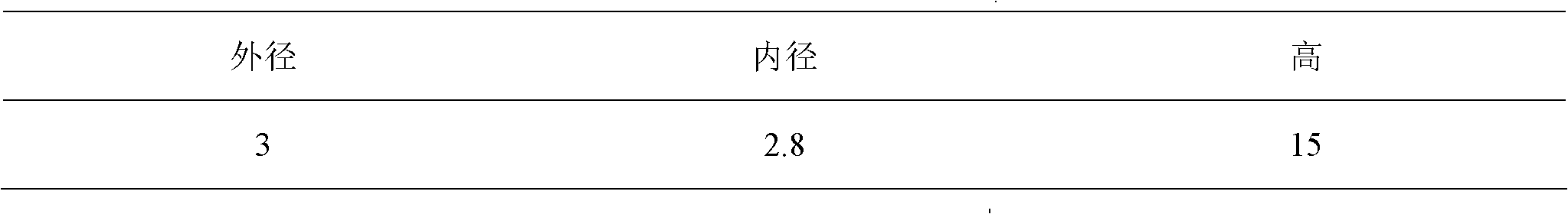

Bubble tower reactor for enhancing acetylene dimerization

InactiveCN102580630AIncrease reaction rateReduce backmixingHydrocarbons from unsaturated hydrocarbon additionLiquid-gas reaction processesVinylacetyleneEngineering

In order to solve the problems of serious backmixing of fluid, low selectivity of vinyl acetylene, large side output of high polymers and the like in the bubble tower reactor / void tower in the prior art, the invention provides a bubble tower reactor for enhancing acetylene dimerization. The bubble tower reactor comprises a bubble tower, wherein 2 to 8 baffles are connected to the inner wall of the bubble tower, are a circle, a rectangle or a polygon and preferably are the rectangle, and one short edge of the rectangle is in circular arc transition; and the optimum thickness of each baffle is 1 / 2 of the wall thickness of the bubble tower, the optimum width of each baffle is 3 times the wall thickness of the bubble tower, and an included angle between the lower surface of each baffle and the tower wall is 30 to 120 degrees. The bubble tower reactor has a simple structure and is convenient to manufacture and low in equipment cost; the backmixing of acetylene gas can be reduced effectively under the same working condition, so that the average concentration of the acetylene gas is improved, the reaction speed of acetylene dimerization is improved, the further contact of products and acetylene is reduced, and the conversion rate of the acetylene and the selectivity of the vinyl acetylene can be improved.

Owner:CHONGQING UNIV

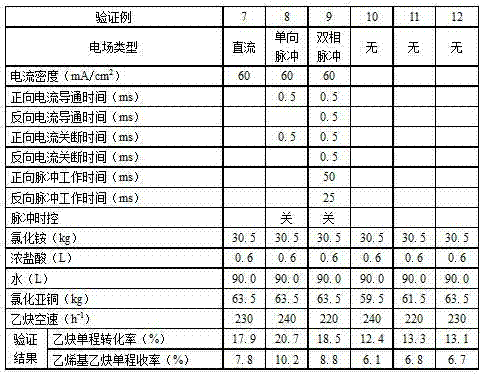

Method for preparing vinyl acetylene by electric field enhanced acetylene dimerization

The invention provides a method for preparing vinyl acetylene through electric-field-enhanced dimerization of acetylene. The method is characterized in that: based on the existing Nieuland catalyst, the proportion is adjusted, and the electric field enhancement is supplemented during the entire acetylene dimerization process. Two electrodes of the established electric field are copper electrodes installed in a reaction device, and the current density of the electrodes is 40-60 mA / cm<2>. Verification shows that: under the action of the electric field, the catalysis performance of Nieuland catalyst in the proportion provided in the invention is enhanced to a certain extent, thereby the one-way conversion rate of acetylene and the yield of vinyl acetylene are improved.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com