Catalyst for preparing divinylacetylene by acetylene trimerization

A technology of divinyl and catalysts, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

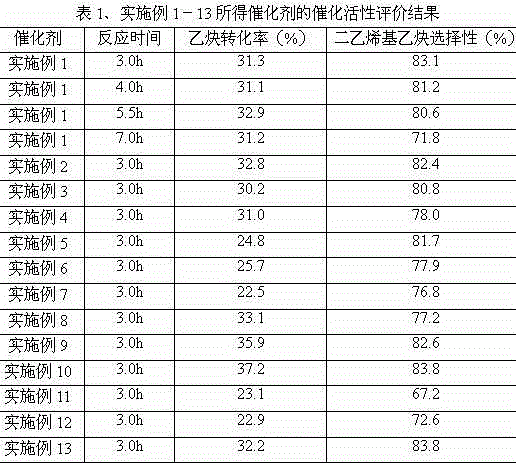

Examples

Embodiment 1

[0019] A catalyst for the preparation of divinylacetylene by trimerization of acetylene, the catalyst consists of 40g of cuprous chloride, 3.1g of [Bmim]Br, 30g of methylamine hydrochloride and 61.7g of N-methylpyrrolidone.

[0020] Utilize above-mentioned catalyst to prepare the method for divinyl acetylene, this method comprises the steps:

[0021] ①Preparation of solution: at 40°C, feed nitrogen into the bubble reactor to remove the air, add organic amine hydrochloride, organic ionic liquid and additives in proportion, after mixing evenly, seal the bubble reactor, and continue Inject nitrogen to remove air (emptying time 30 minutes);

[0022] ② Dissolution of cuprous chloride: heat up to 80°C, add cuprous chloride in proportion, continue to feed nitrogen, and stir to dissolve completely;

[0023] ③Trimerization reaction: After the raw materials in the bubbling reactor are fully mixed, replace nitrogen with acetylene (the space velocity of acetylene is 110 ml·gcat -1 h -1...

Embodiment 2

[0026] The difference from Example 1 is that the quality of cuprous chloride used is 60g.

Embodiment 3

[0028] The difference from Example 1 is that the quality of cuprous chloride used is 80g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com