Vinyl acetylene product and preparation method thereof

A technology for vinyl acetylene and acetylene, applied in the field of vinyl acetylene products and their preparation, can solve the problems of affecting the preparation efficiency of vinyl acetylene, shortening the life of the catalyst, needing to be improved, etc., and achieves efficient preparation, long life of the catalyst, and less time required Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

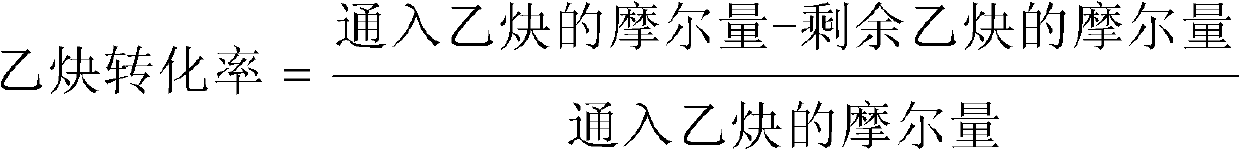

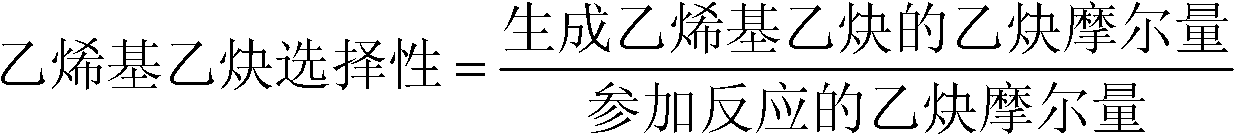

[0020] Weigh 55ml of dimethylformamide organic solvent into a two-necked flask, heat to 60°C, add co-solvent ethylamine hydrochloride to it, after the co-solvent is completely dissolved, then add active component CuCl, and at the same time pass nitrogen to protect To prevent the cuprous chloride from being oxidized, stir for 30 minutes until CuCl is completely dissolved, and the desired catalyst solution is obtained. Pour the catalyst into a glass bubbling bed reactor with an aspect ratio of 5, and pass nitrogen gas for 20 minutes to completely discharge the air in the reactor, then switch the gas to acetylene, and feed acetylene and HCl gas into the reactor , in order to carry out acetylene dimerization reaction to prepare vinyl acetylene. Among them, during the reaction process, the reaction temperature is maintained at 65°C, and the space velocity of acetylene is 200h -1 , the space velocity of HCl gas 3h -1 . In addition, before passing acetylene into the reactor, acety...

Embodiment 2

[0022] According to the method of Example 1, vinyl acetylene was prepared. Wherein, the difference from Example 1 is: no HCl gas is introduced during the reaction.

Embodiment 3

[0024] According to the method of Example 1, vinyl acetylene was prepared. Wherein, the difference from Example 1 is that the reaction temperature is 70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com