Method for preparing vinylacetylene

A technology of vinyl acetylene and acetylene, which is applied in the field of preparation of vinyl acetylene, which can solve the problems of large polymers, difficult to further increase the yield of vinyl acetylene, unsatisfactory vinyl acetylene yield, etc., and achieve the suppression of associated high polymer The effect of the generation of compound, the increase of MVA one-way yield, and the increase of MVA selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

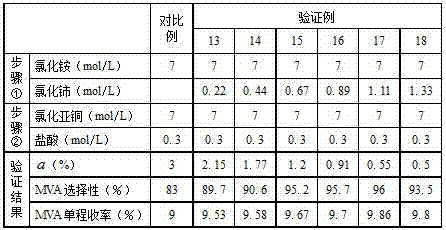

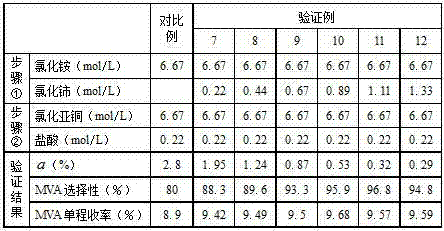

[0011] A method for preparing vinyl acetylene, the method is to continuously fill a closed reactor containing a catalyst system with acetylene gas under heating conditions, so that acetylene can undergo a dimerization reaction under the action of the catalyst system to generate ethylene The catalyst system includes main catalyst cuprous chloride, auxiliary solvent ammonium chloride, hydrochloric acid and water. In the present invention, there is also promoter cerium chloride in the catalyst system; the steps of the method are as follows:

[0012] ① Put co-solvent ammonium chloride, co-catalyst cerium chloride and water into the reactor. 3 Nitrogen bubbling and stirring at a flow rate of / h to fully dissolve the ammonium chloride and cerium chloride (under the following proportioning conditions, it can be fully dissolved after 30 minutes);

[0013] ② While maintaining the temperature of 70-90°C, add cuprous chloride and hydrochloric acid to the reactor in turn, and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com