Test method of safe critical partial pressure of vinyl acetylene gas

A vinyl acetylene and gas technology, applied in the direction of material explosiveness, etc., can solve the problems of lack of data on the decomposition critical pressure of unstable gas, inability to accurately measure and observe the decomposition of unstable gas, etc., and achieve the effect of saving test time and accurate testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

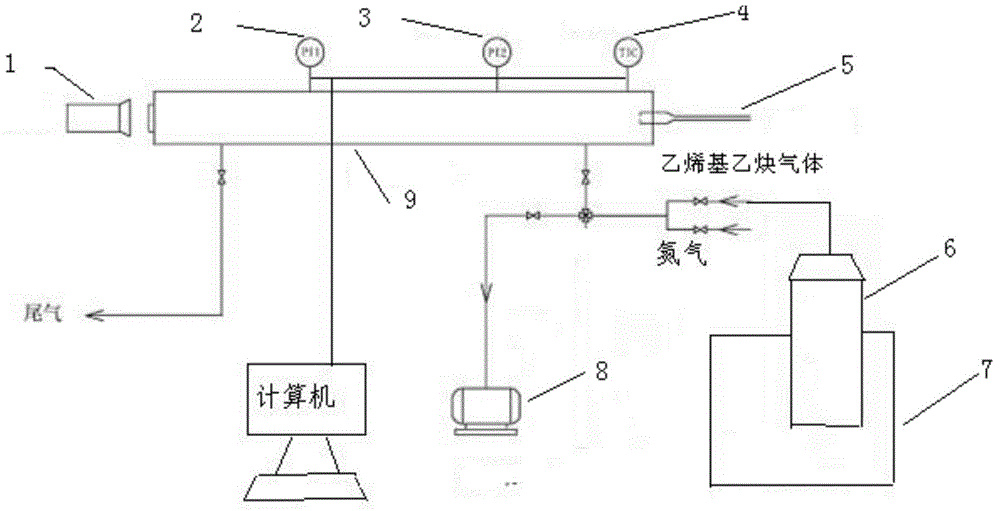

[0024] Such as figure 1 As shown, the pressure sensitivity explosion testing device of the present invention includes a camera, a vacuum gauge, a pressure detection device, a thermometer, an ignition device, a steel cylinder, a gas preheating device, a vacuum pump and a detonation tube, wherein:

[0025] Gas preheating device and detonation tube are used to preheat pressure-sensitive gas to obtain the required temperature under high temperature and high pressure working conditions;

[0026] Pressure detection equipment and pressure detection equipment are installed on the detonation tube, and the measured temperature and pressure are fed back to the computer control device;

[0027] The heating system of the detonation tube is electric heating.

[0028] According to the temperature and pressure of vinyl acetylene gas under butadiene extraction process conditions, different ignition energies are used to study the safety critical pressure of vinyl acetylene gas under different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com