Catalytic system, preparation method thereof, and preparation method of vinyl acetylene by the same

A vinyl acetylene and catalytic system technology, applied in the chemical industry, can solve the problems of reducing the selectivity of vinyl acetylene, reducing the service life of the catalyst, and low selectivity of vinyl acetylene, and achieves reduced effective conversion rate, low production cost, and selectivity sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

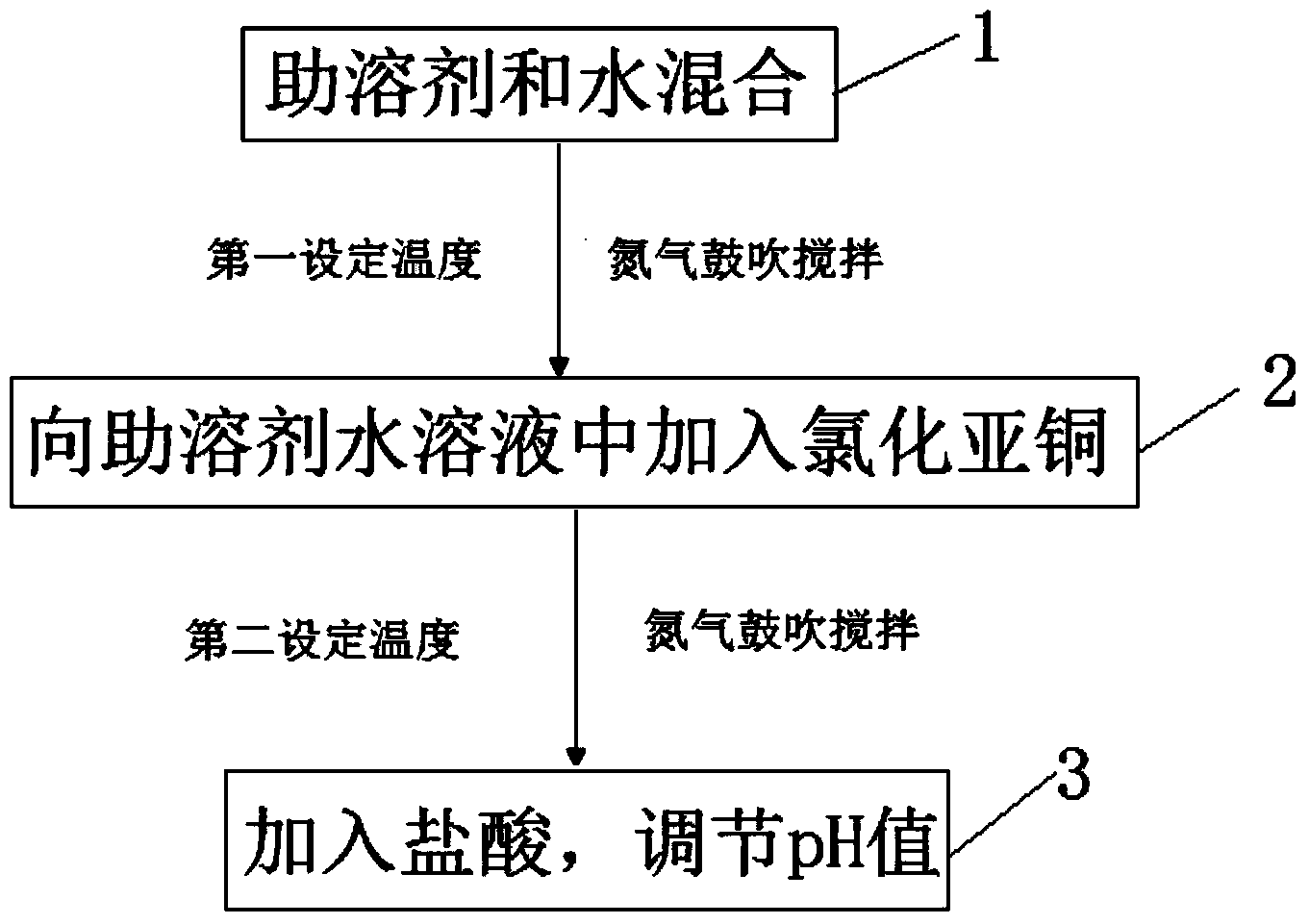

[0028] A method for the preparation of a catalytic system for catalyzing the dimerization of acetylene to prepare vinyl acetylene, such as figure 1 Shown, the preparation method of this catalytic system mainly comprises the following steps:

[0029] 1. Add co-solvent and water into the reactor with nitrogen gas, stir at the first set temperature to dissolve all the co-solvent, and obtain an aqueous solution of co-solvent;

[0030] Wherein, before adding water and co-solvent to the reactor in this step, just with 110-155 -1 Nitrogen was passed into the reactor at a space velocity of at least one hour to get rid of the air in the reactor, and then in the preparation process of the subsequent catalytic system, the nitrogen was consistent at 110-155 -1 The space velocity is continuously passed into the reactor. Preferably, the reactor in this step is a bubbling reactor. The first set temperature is 30-90°C, preferably 60-90°C. In addition, the co-solvent in this step is a chlo...

Embodiment 1

[0046] (1) Take 110h -1 -155h-1 Nitrogen gas is passed into the bubble reactor at the space velocity. After 1-2 hours, 21-30g of water and 8.0g of ammonium chloride are added to the bubble reactor. Stir with air blowing to dissolve all the ammonium chloride.

[0047] (2) At a temperature of 60-90° C., add 14.81 g of main catalyst cuprous chloride and 3.0 g of ligand polyethylene glycol with an average molecular weight of 600 successively in the above-mentioned reactor filled with ammonium chloride aqueous solution. 110-155 -1 Under space velocity nitrogen bubbling and stirring, the cuprous chloride was fully dissolved, and 0.1 mL of hydrochloric acid was added to adjust its pH value to obtain a catalytic system.

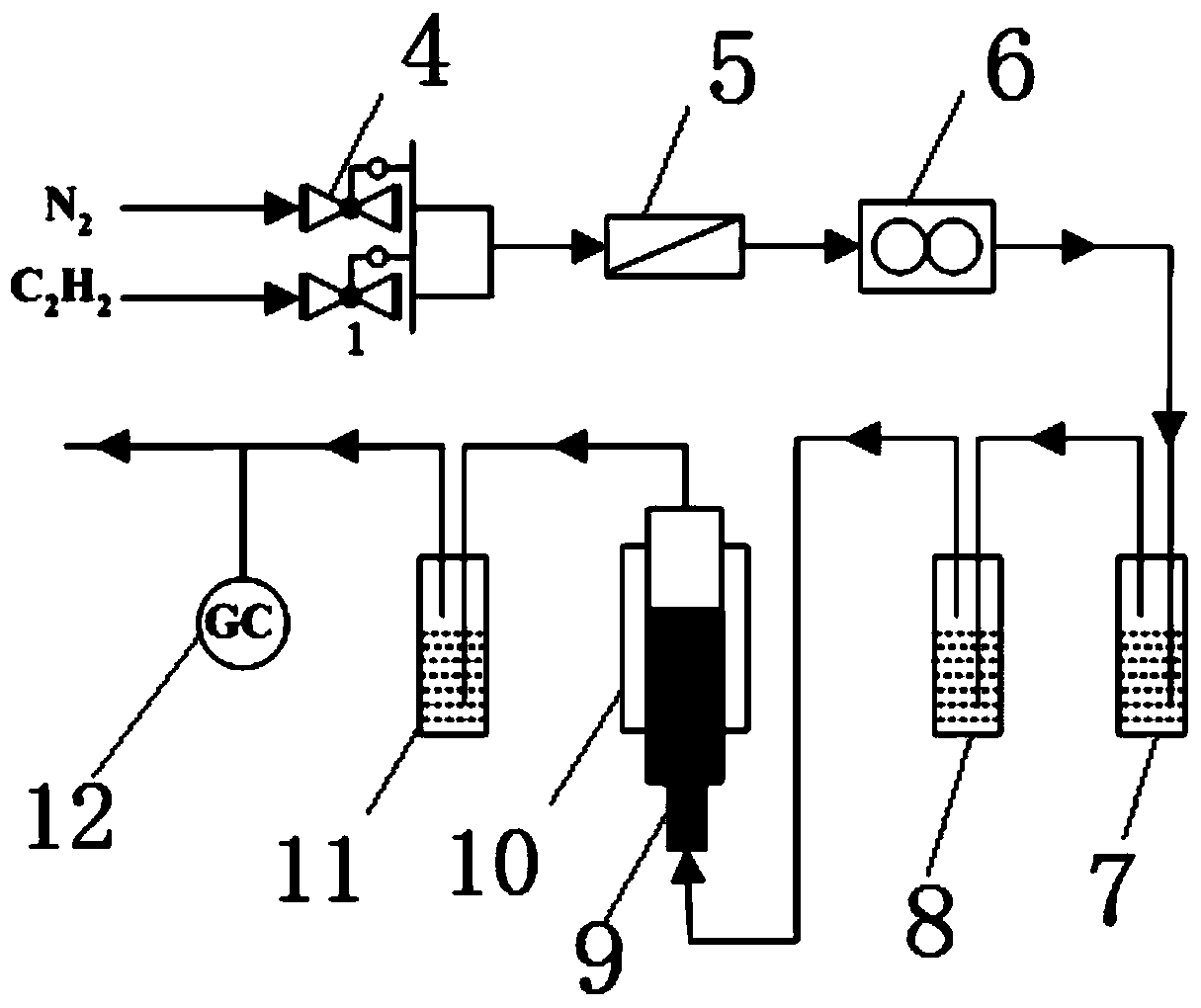

[0048] (3) Passing acetylene gas instead of nitrogen into the catalytic system in the above step, and bubbling and stirring at a temperature of 60-90° C., so as to cause dimerization of acetylene to obtain vinyl acetylene.

Embodiment 2

[0050] (1) Take 110h -1 -155h -1 Nitrogen gas is passed into the bubble reactor at the space velocity. After 1-2 hours, 21-30g of water and 8.0g of ammonium chloride are added to the bubble reactor. Stir with air blowing to dissolve all the ammonium chloride.

[0051] (2) At a temperature of 60-90° C., add 14.81 g of main catalyst cuprous chloride and 3.0 g of ligand polyethylene glycol with an average molecular weight of 400 in the above-mentioned reactor filled with ammonium chloride aqueous solution. 110-155 -1 Under space velocity nitrogen bubbling and stirring, the cuprous chloride was fully dissolved, and 0.1 mL of hydrochloric acid was added to adjust its pH value to obtain a catalytic system.

[0052] (3) Passing acetylene gas instead of nitrogen into the catalytic system in the above step, and bubbling and stirring at a temperature of 60-90° C., so as to cause dimerization of acetylene to obtain vinyl acetylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com