Acetylene dimerization nonaqueous-phase catalyst and application thereof

A catalyst, non-aqueous phase technology, applied in the field of acetylene dimerization non-aqueous phase catalysts, can solve the problems of low selectivity of vinyl acetylene, low single-pass conversion rate, reduced catalyst service life, etc., and achieve the effect of increasing single-pass conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

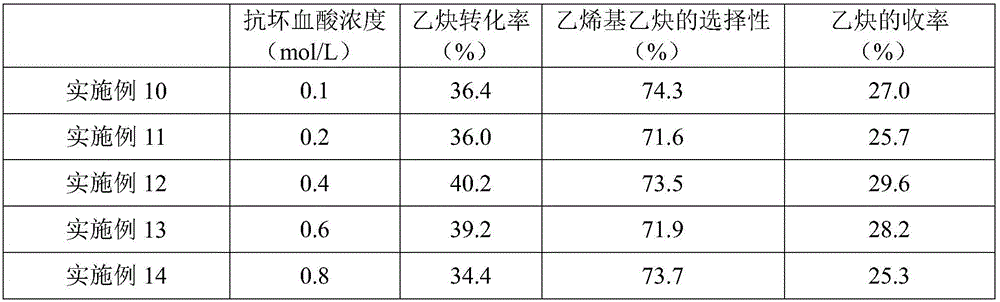

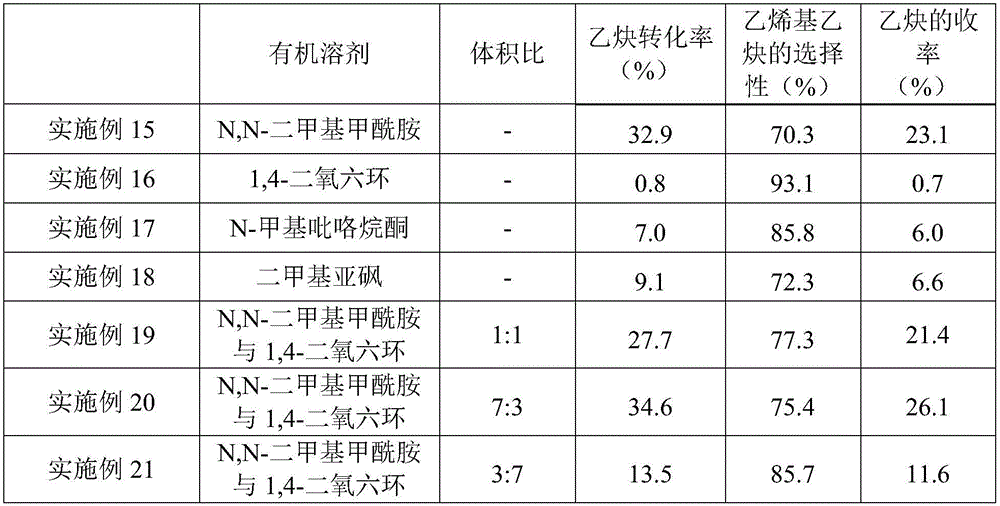

[0023] Add 7 mL of N,N-dimethylformamide and 3 mL of 1,4-dioxane mixed organic solvent into the reactor, add 0.05 mol of ethylamine hydrochloride as a co-solvent, and pass nitrogen gas under the condition of 60-90°C to Ethylamine hydrochloride is fully dissolved; maintain a constant reaction temperature, add 0.006 mol of reducing agent ascorbic acid; under the condition of continuously bubbling nitrogen, finally add 8 g of main catalyst cuprous chloride, and continue to blow nitrogen for 30 minutes. After the catalyst is fully dissolved, switch nitrogen to acetylene and keep the acetylene space velocity at 100-250h -1 , the generated gas was monitored in real time by gas chromatography, the conversion rate of acetylene, the selectivity of vinyl acetylene and the yield of acetylene are shown in Table 1.

Embodiment 2

[0025] The reducing agent in the present embodiment is sodium ascorbate 0.006mol, and other reaction conditions are identical with embodiment 1. The conversion rate of acetylene, the selectivity of vinyl acetylene and the yield of acetylene are shown in Table 1.

Embodiment 3

[0027] The reducing agent in this embodiment is potassium ascorbate 0.006mol, and other reaction conditions are the same as in Example 1. The conversion rate of acetylene, the selectivity of vinyl acetylene and the yield of acetylene are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com