Method for preparing methyldiphenylchlorosilane and reactor thereof

A technology of methylphenyldichlorosilane and methyldichlorosilane, which is applied in the field of preparation of methylphenyldichlorosilane, can solve the problems of reducing production costs and non-scaled continuous reactors, and achieves convenient maintenance, The effect of high yield and simple product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

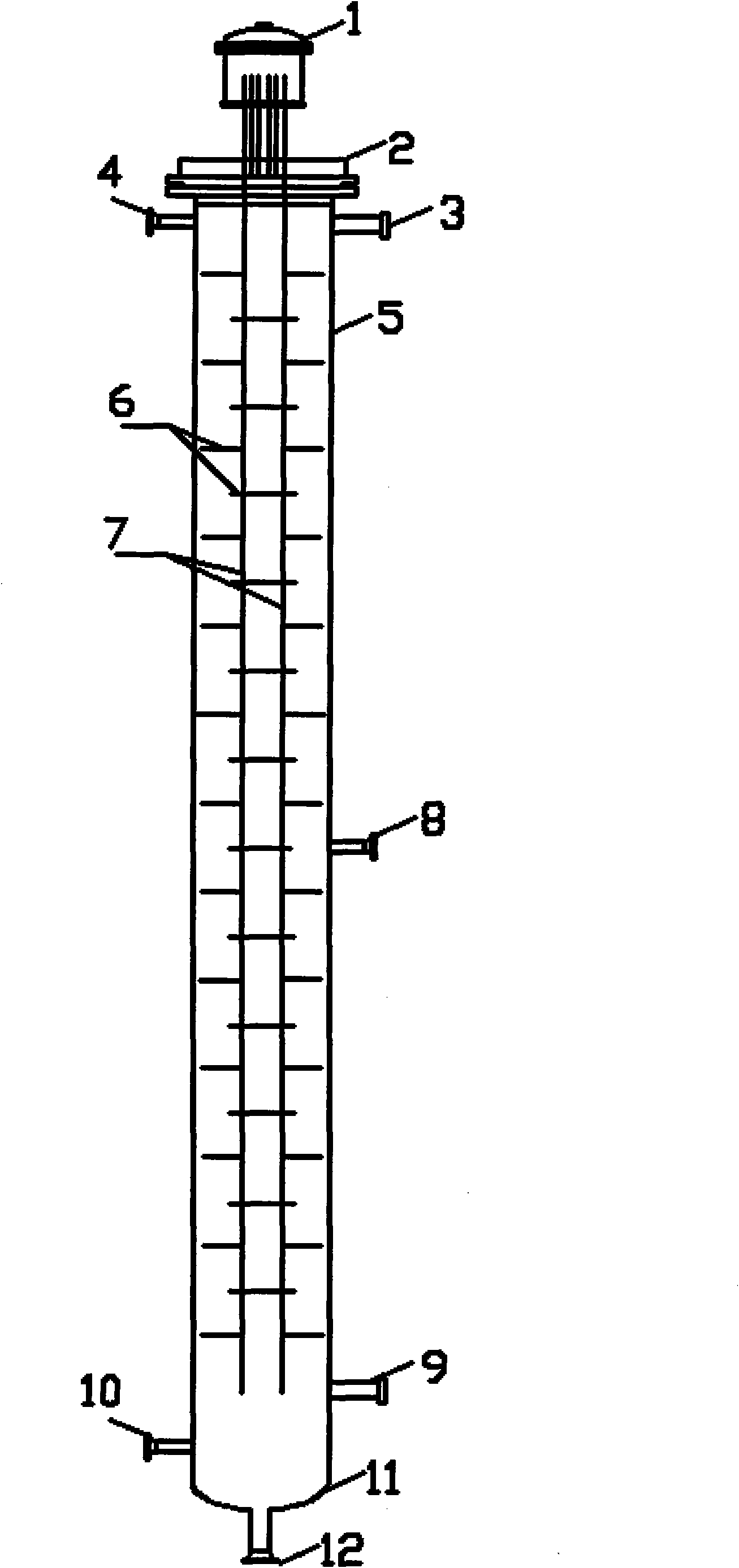

[0027] Such as figure 1 As shown in the reactor of the present invention, an explosion-proof junction box 1, an upper connection flange 2, and a feed port 3 are installed on the top of the cylinder body 5, and the feed port 3 is welded on the bottom of the upper connection flange 2, and at the bottom of the cylinder body 5 There are temperature measuring points 4 and 10 in the upper and lower sections, and pressure measuring points 8 in the middle. There are baffles 6 and electric heating rods 7 inside the cylinder. It passes through and is welded on the baffle; the lower part of the cylinder body 5 is equipped with a discharge port 9 , a lower head 11 and a lower cleaning flange 12 .

Embodiment 2

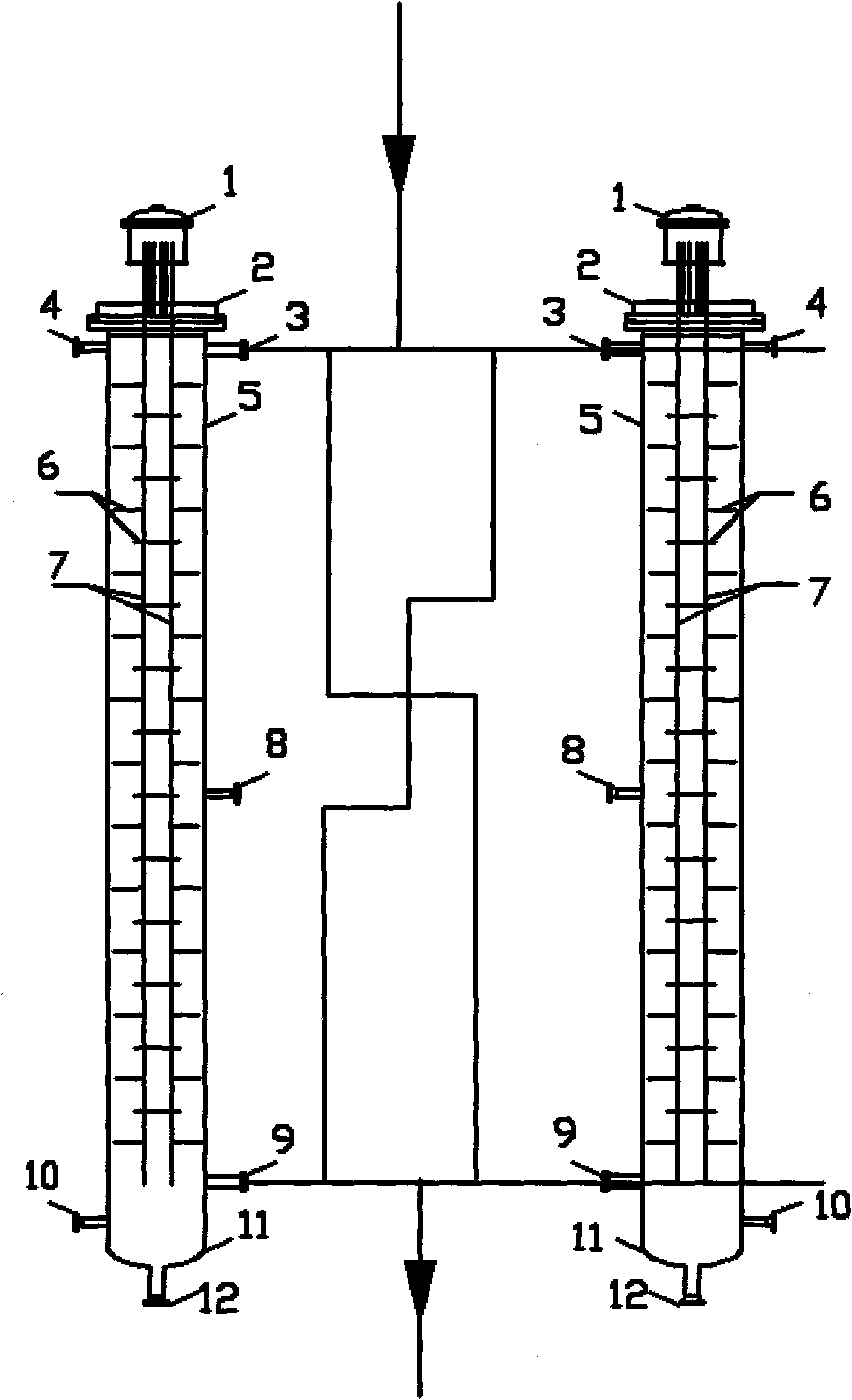

[0029] Such as figure 2 As shown, the specific structure of a single reactor is the same as that of the reactor in Example 1, and two identical reactors are connected in parallel and in series, so as to achieve any matching of the two reactors by changing the switch of the valve to meet the requirements of the reactor. different needs in the process.

Embodiment 3

[0031] The reactor is as in Example 2. After vaporizing methylchlorosilane, chlorobenzene, and chloroform respectively, they are respectively overheated to 400°C. 100mol / h of dichlorosilane, 120mol / h of chlorobenzene, and 10mol / h of chloroform are continuously fed into the reactor, wherein the reactor is equipped with an electric heater, and the temperature of the reactor is controlled at 450°C and the pressure is at 0.5MPa , run for 100h, after the synthesis gas is condensed, the non-condensable gas (mainly hydrogen chloride, methane, hydrogen and a small amount of methyldichlorosilane) is vented, and the amount of vented air accounts for about 5% of the total feed amount. Obtain condensate 2274Kg (accounting for 95% of feed amount), rectification obtains methyl dichlorosilane, chlorobenzene, benzene, methyl trichlorosilane, methyl phenyl dichlorosilane and high boiler, methyl dichlorosilane Silane and chlorobenzene were recovered to continue the reaction, and the yield of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com