Precursor solution of carbide ceramic, carbide ceramic and preparation thereof

A technology of precursors and carbides, which is applied in the preparation process of ultra-high temperature carbide ceramics and the field of precursor solution of ultra-high temperature carbide ceramics, which can solve the problems of low yield of cracking and conversion ceramics, low concentration of precursors, and low yield of ceramics and other problems, to achieve the effect of shortening the impregnation-cracking cycle, simplifying the preparation process, and improving material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

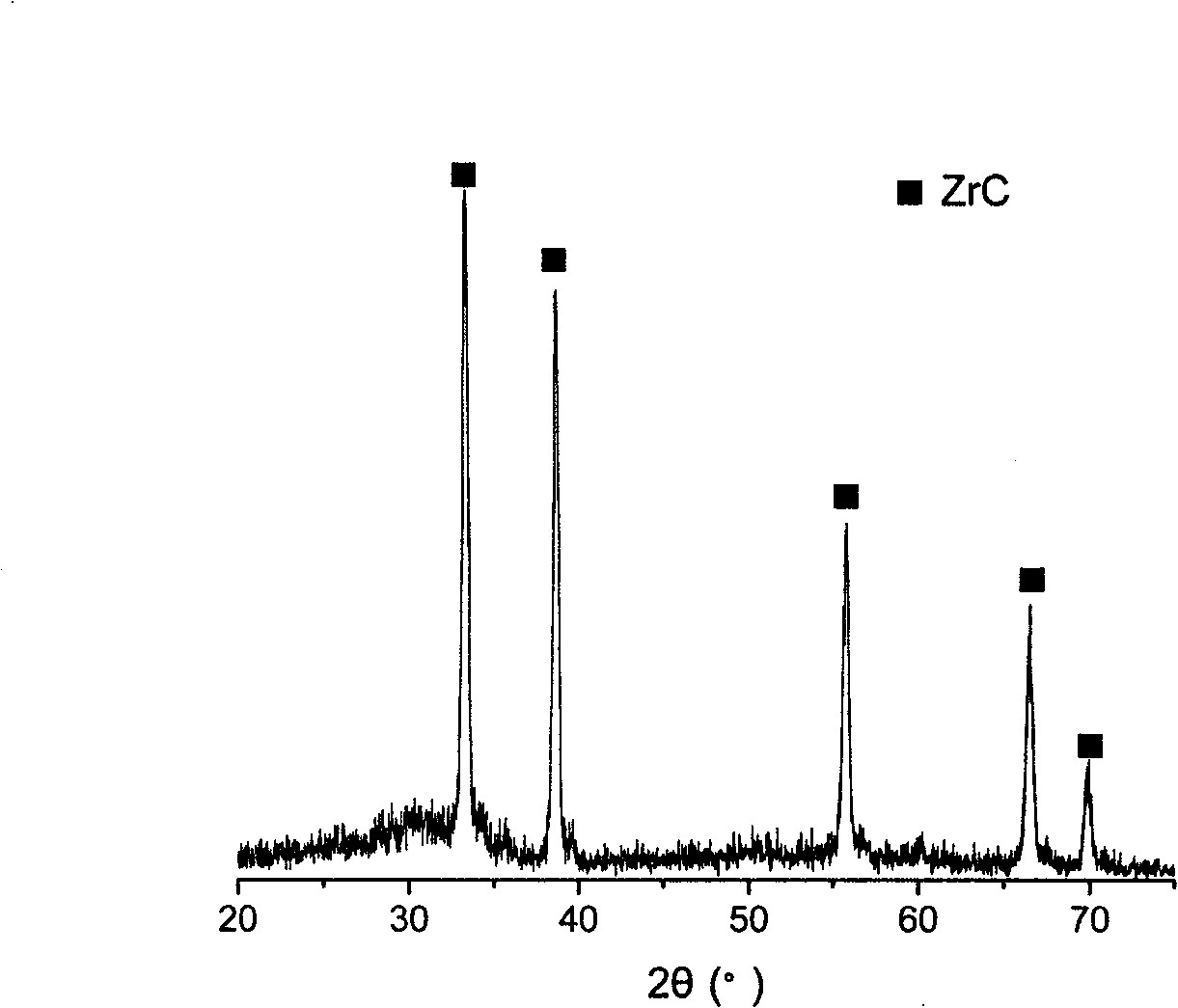

[0024] A zirconium carbide (ZrC) ceramic precursor solution of the present invention, the solution uses zirconium tetra-n-butoxide as a solute, divinylbenzene as a solvent, and the solute and solvent are mixed in a molar ratio of 1:0.8.

[0025] A zirconium carbide ceramic prepared by using the zirconium carbide ceramic precursor solution prepared above, the specific preparation process includes the following steps: after sealing the zirconium carbide ceramic precursor solution prepared above, stirring for 2 hours; The zirconium ceramic precursor solution was placed in a drying oven, and the temperature was rapidly raised to 180 °C at a heating rate of 10 °C / min, and kept for 4 hours to allow crosslinking; the low-temperature crosslinked zirconium carbide ceramic precursor was placed in a cracking furnace , under the protection of argon, the temperature was rapidly raised to 1600°C, and the temperature was kept for 0.5h for high-temperature cracking, and zirconium carbide ceram...

Embodiment 2

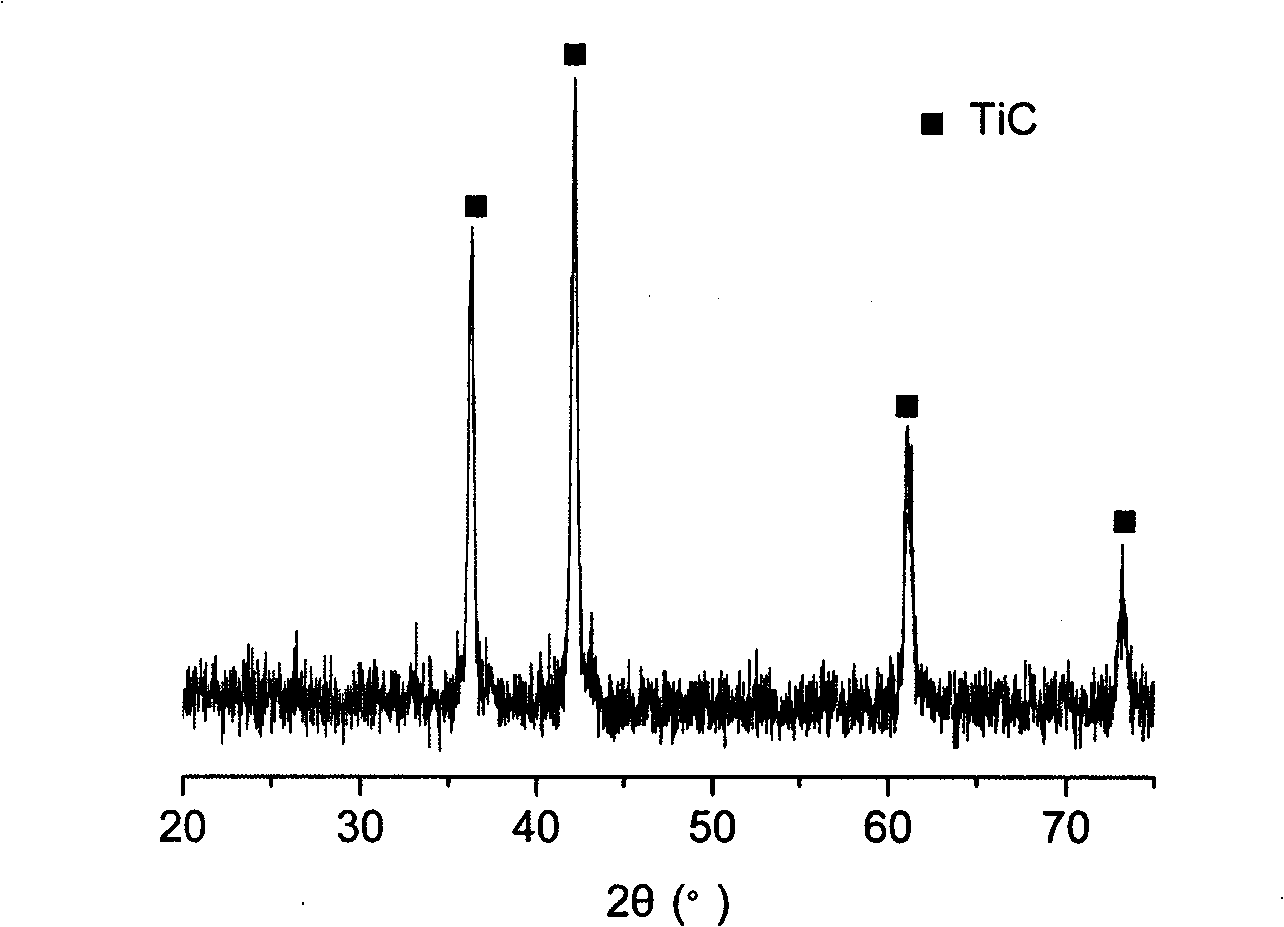

[0028] A titanium carbide (TiC) ceramic precursor solution of the present invention, the solution uses titanium ethoxide as a solute, divinylbenzene as a solvent, and the solute and solvent are mixed in a molar ratio of 1:0.6.

[0029] A titanium carbide ceramic prepared by using the titanium carbide ceramic precursor solution prepared above, the specific preparation process includes the following steps: after sealing the titanium carbide ceramic precursor solution prepared above, stirring for 0.5h; The titanium carbide ceramic precursor solution was placed in a drying oven, and the temperature was rapidly raised to 220 °C at a heating rate of 5 °C / min, and kept for 2 hours for cross-linking; the low-temperature cross-linked titanium carbide ceramic precursor was placed in a cracking furnace In the process, the temperature was rapidly raised to 1200 °C under vacuum conditions, and the temperature was kept for 1.5 hours for high-temperature pyrolysis, and titanium carbide cerami...

Embodiment 3

[0032]A kind of precursor solution of zirconium carbide (ZrC) ceramics and titanium carbide (TiC) ceramics mixture of the present invention, this solution is to be solute with tetra-n-butoxy zirconium and tetra-n-butoxy titanium, with diethynylbenzene as The solvent, the solute and the solvent are mixed in a molar ratio of tetra-n-butoxy zirconium: tetra-n-butoxy titanium: diethynylbenzene in a molar ratio of 1:0.8:1.3.

[0033] A mixture of zirconium carbide ceramics and titanium carbide ceramics prepared from the precursor solution of zirconium carbide ceramics and titanium carbide ceramics prepared above. The specific preparation process includes the following steps: combining the zirconium carbide ceramics prepared above After the precursor solution of the titanium-ceramic mixture was sealed, it was stirred for 2 hours; the uniformly stirred precursor solution of the zirconium carbide ceramic and titanium carbide ceramic mixture was placed in a drying oven, and the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com