Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83 results about "Balance design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

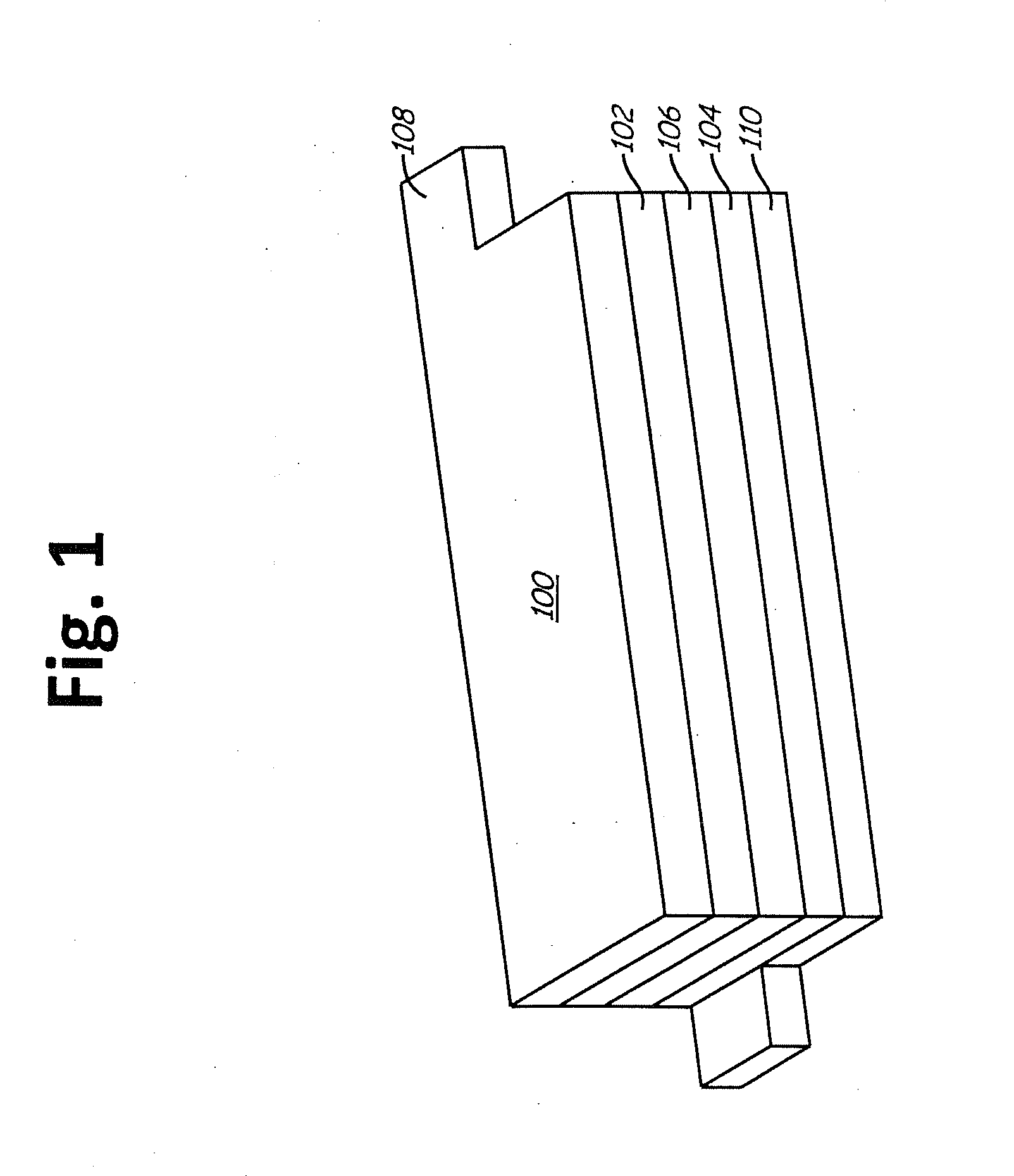

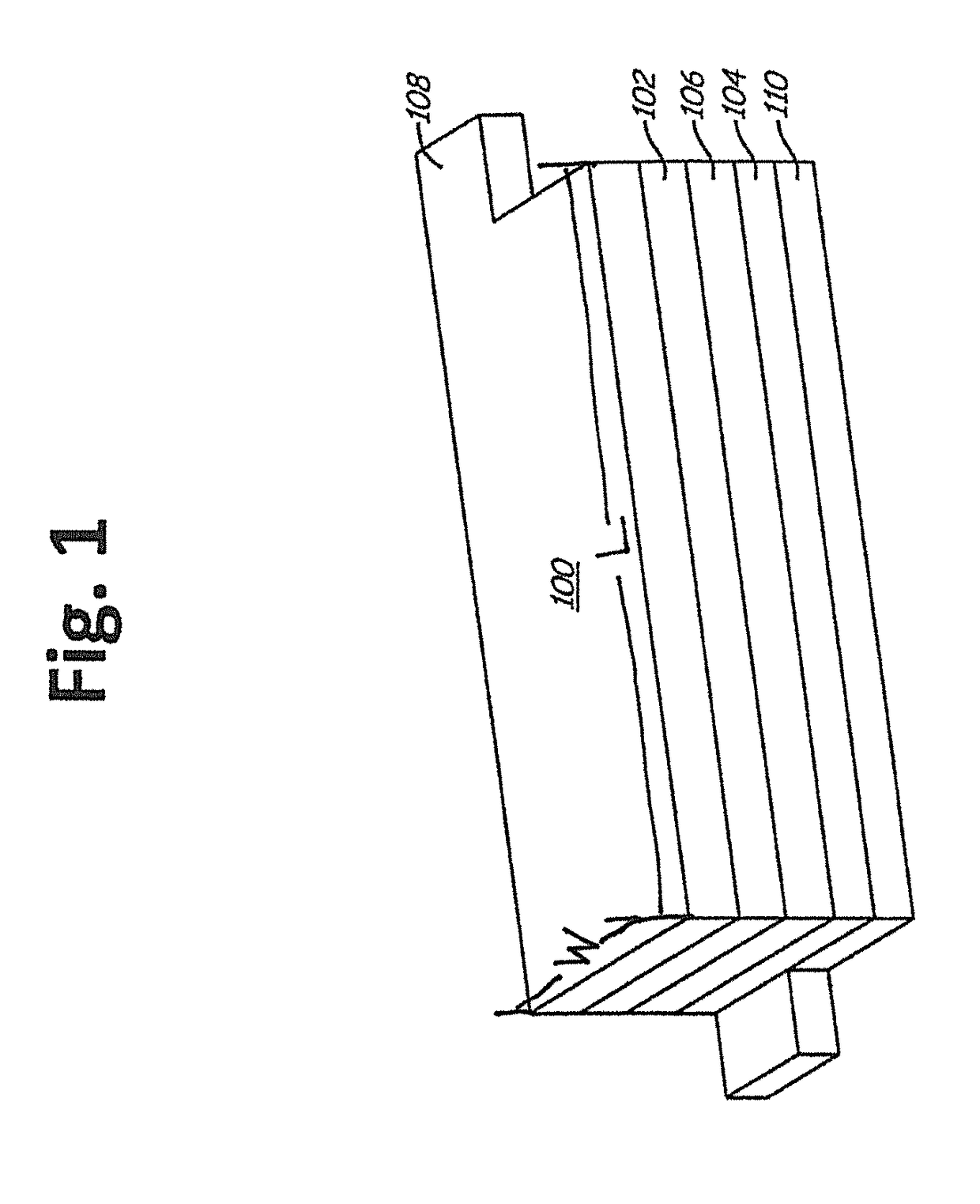

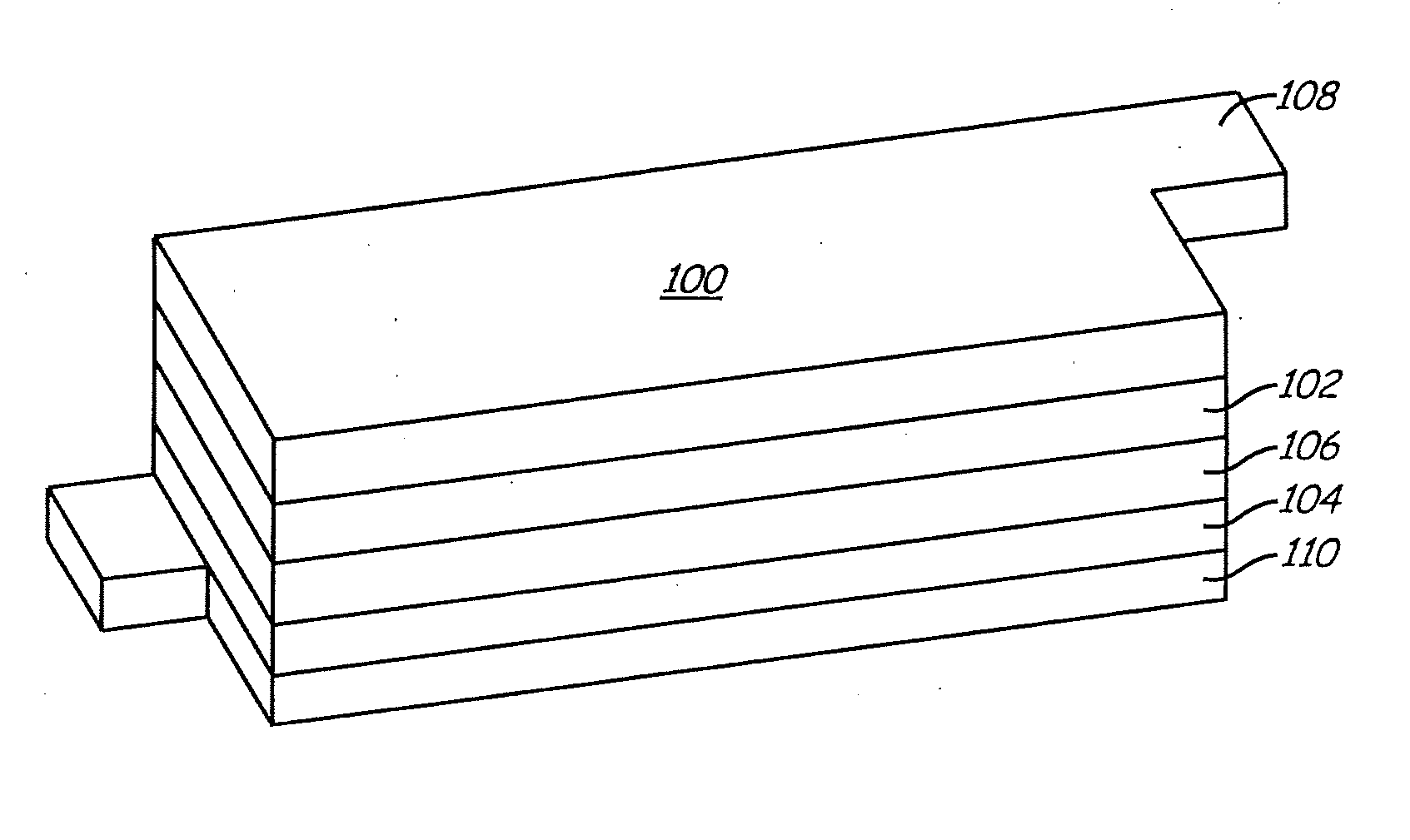

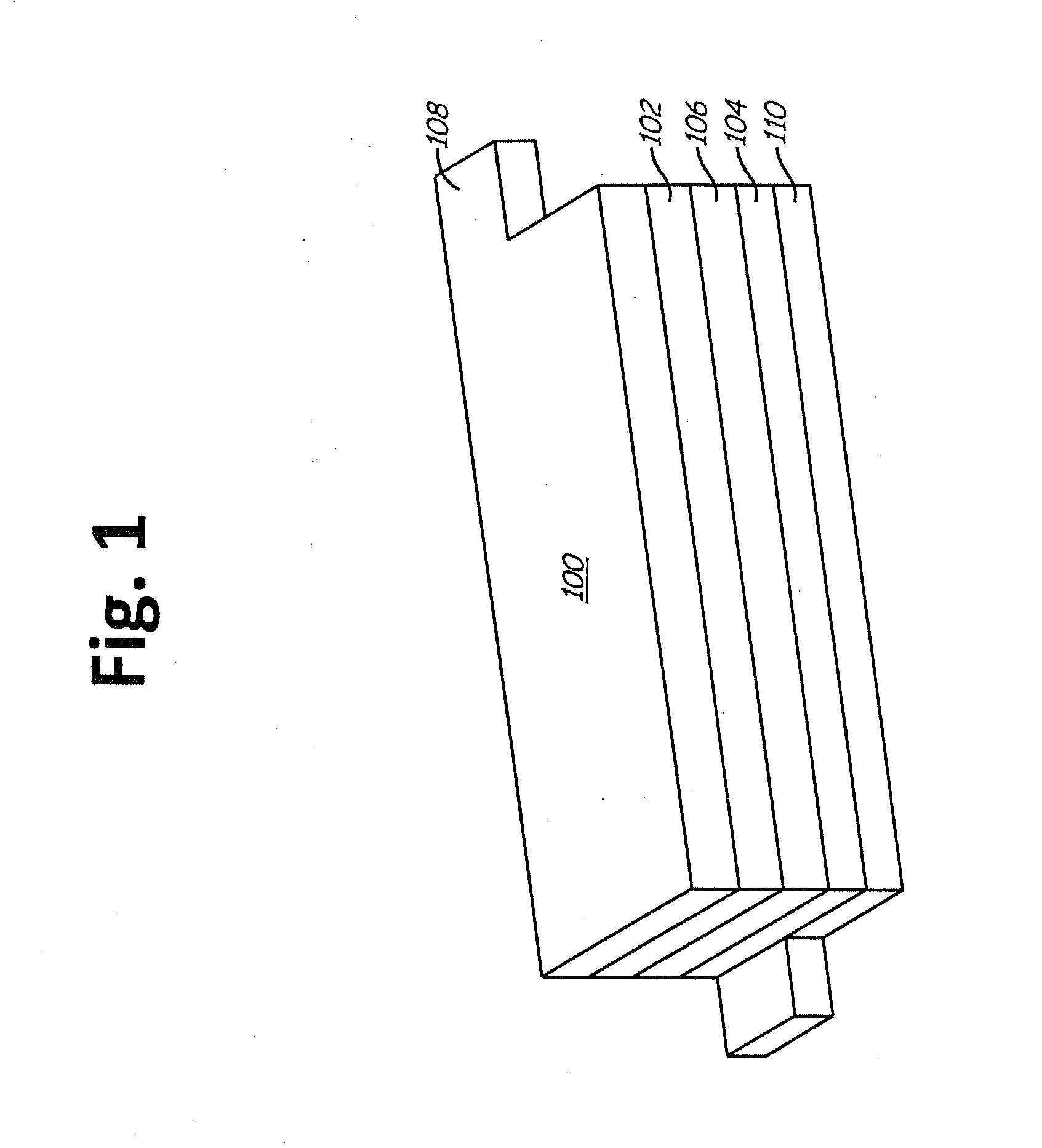

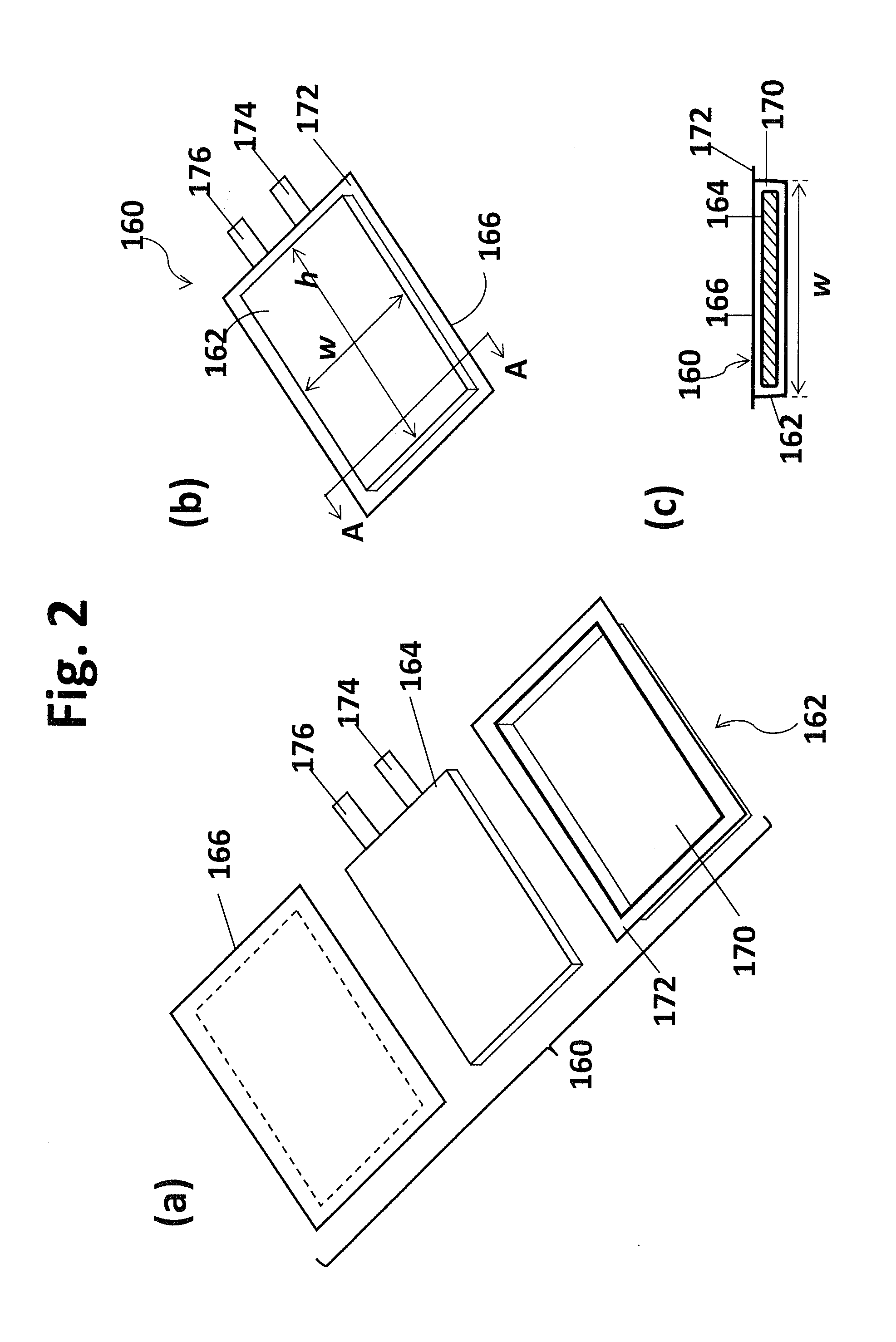

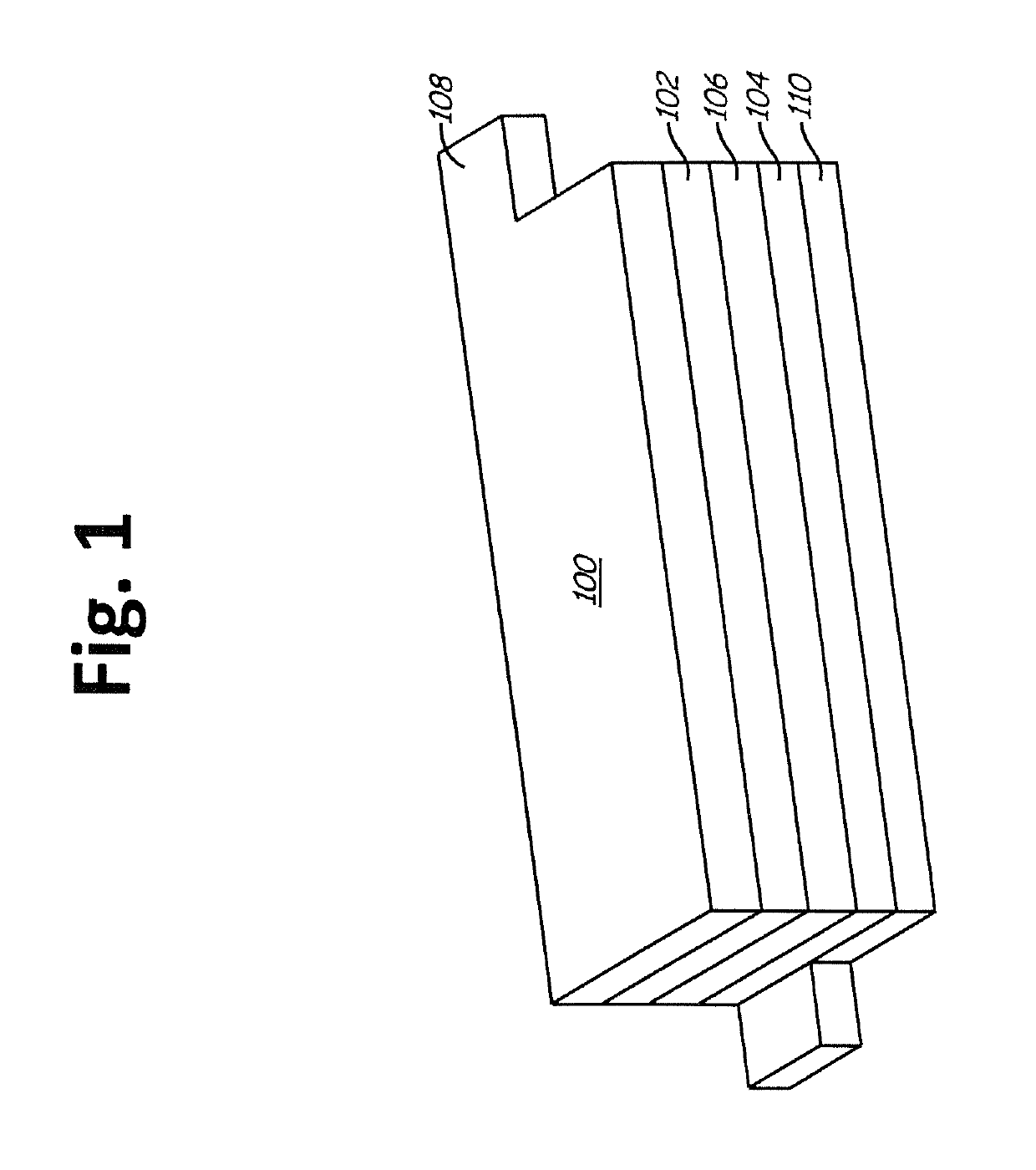

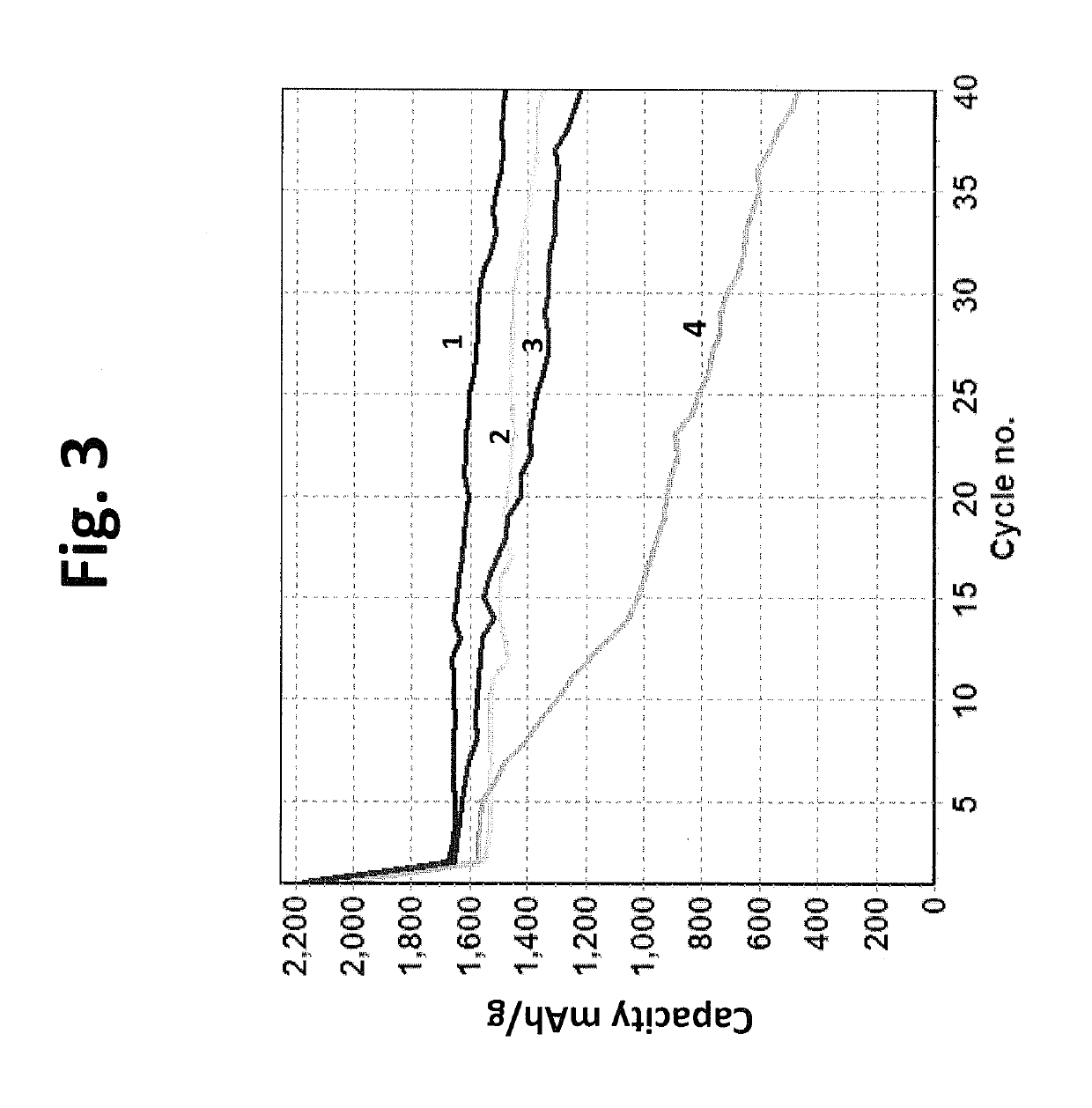

Battery designs with high capacity anode materials and cathode materials

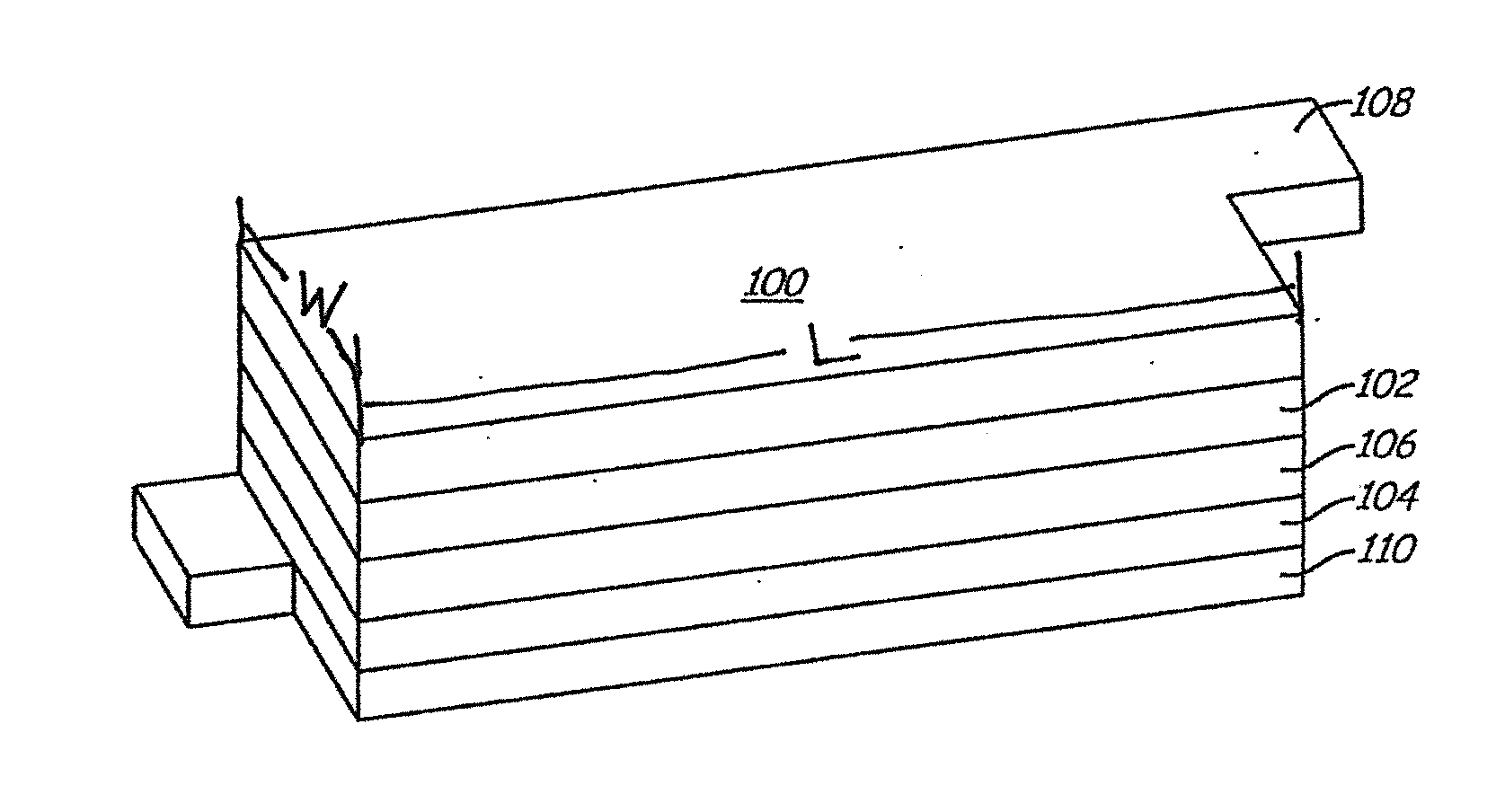

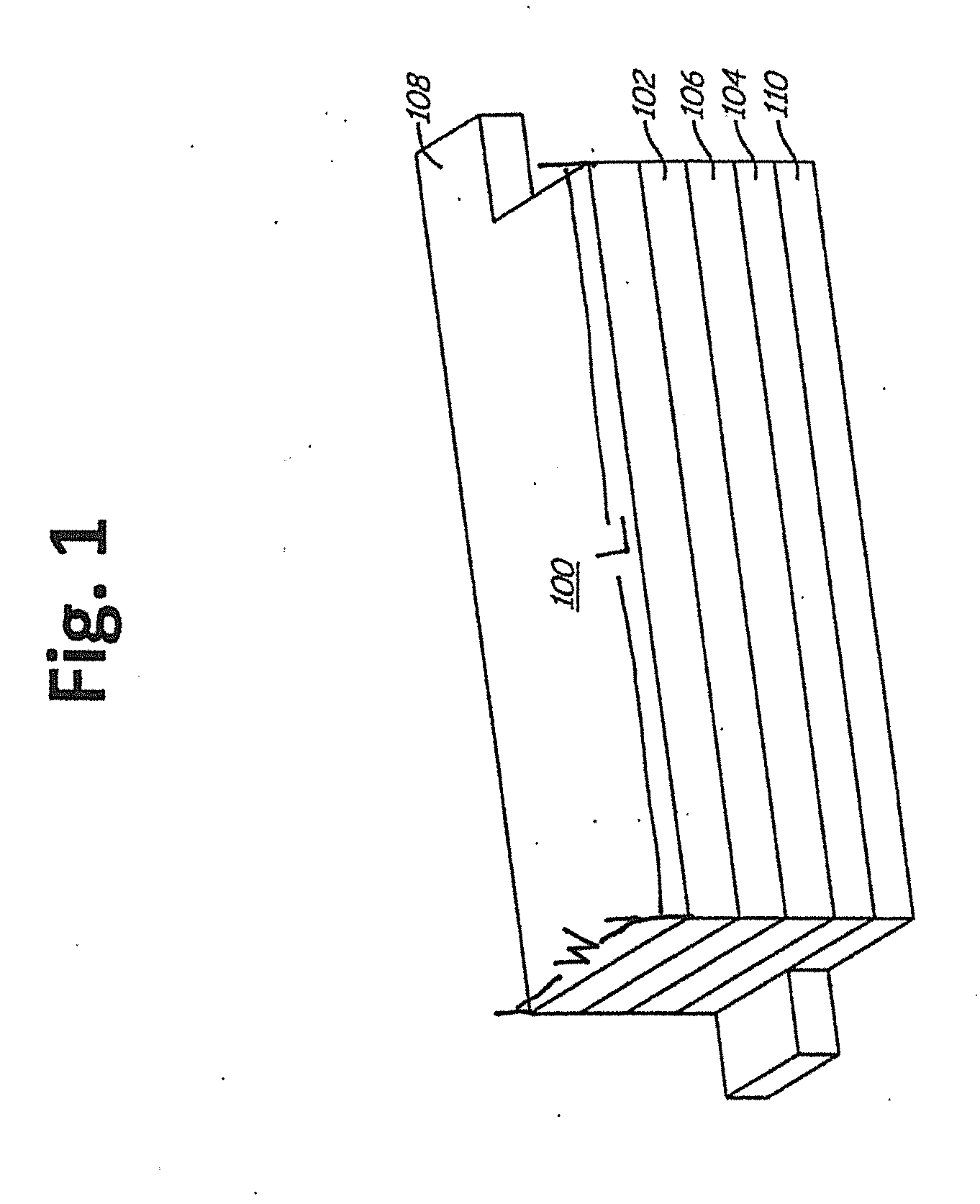

ActiveUS20140065464A1Primary cell to battery groupingMaterial nanotechnologyHigh energyDischarge rate

Improved high energy capacity designs for lithium ion batteries are described that take advantage of the properties of high specific capacity anode active compositions and high specific capacity cathode active compositions. In particular, specific electrode designs provide for achieving very high energy densities. Furthermore, the complex behavior of the active materials is used advantageously in a radical electrode balancing design that significantly reduced wasted electrode capacity in either electrode when cycling under realistic conditions of moderate to high discharge rates and / or over a reduced depth of discharge.

Owner:IONBLOX INC

Battery cell engineering and design to reach high energy

Improved high energy capacity designs for lithium ion batteries are described that take advantage of the properties of high specific capacity anode active compositions and high specific capacity cathode active compositions. In particular, specific electrode designs provide for achieving very high energy densities. Furthermore, the complex behavior of the active materials is used advantageously in a radical electrode balancing design that significantly reduced wasted electrode capacity in either electrode when cycling under realistic conditions of moderate to high discharge rates and / or over a reduced depth of discharge.

Owner:IONBLOX INC

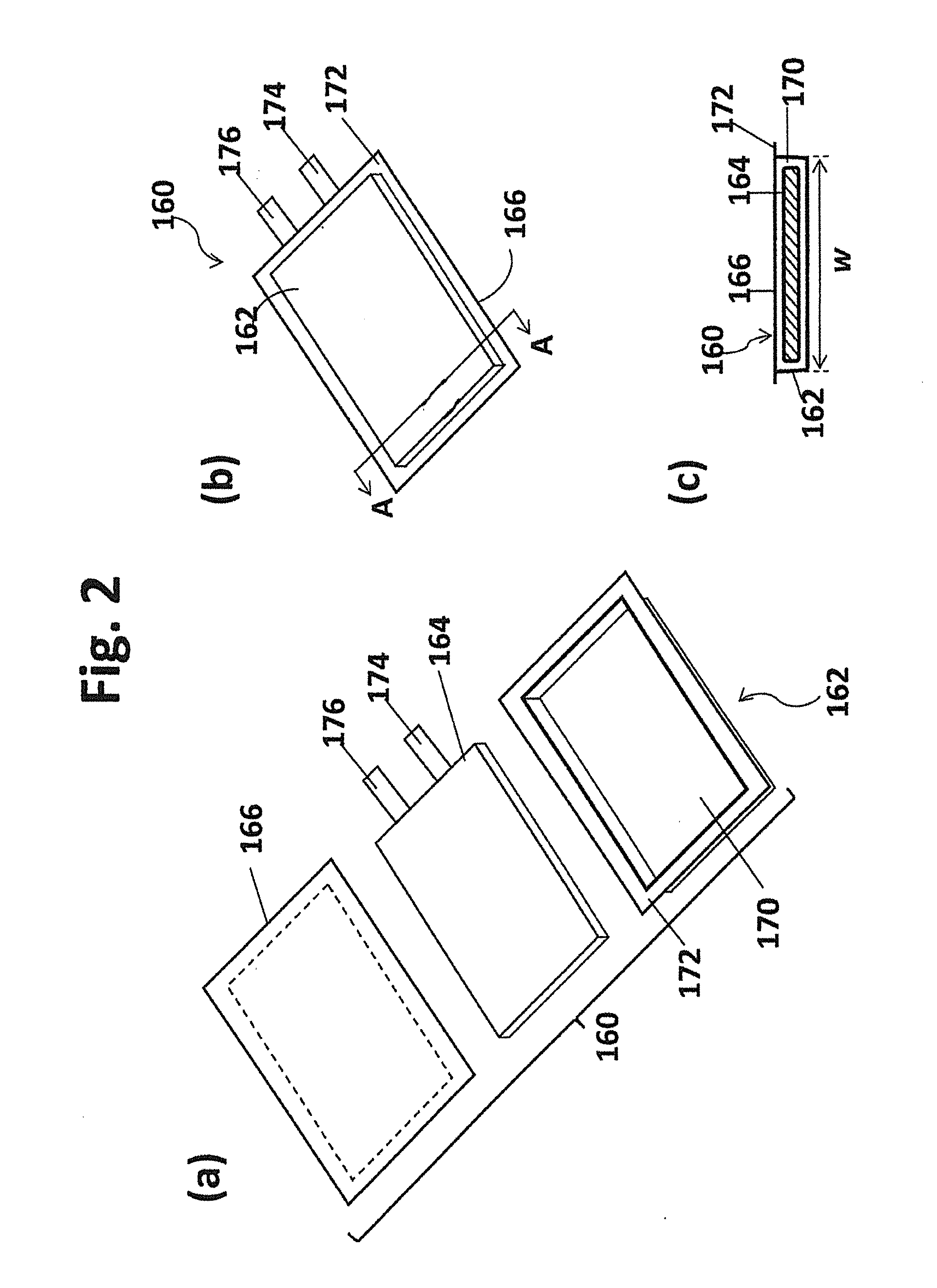

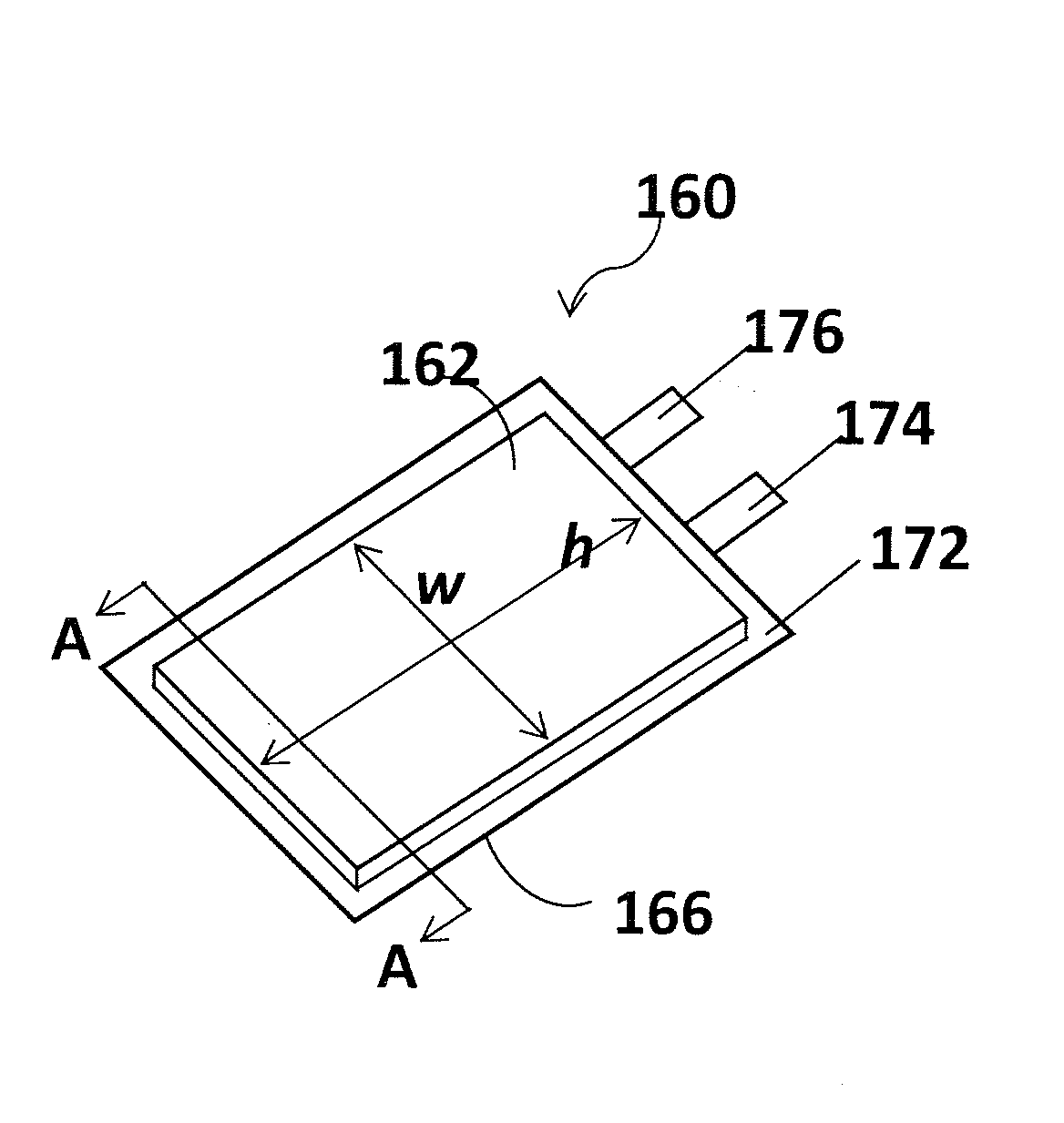

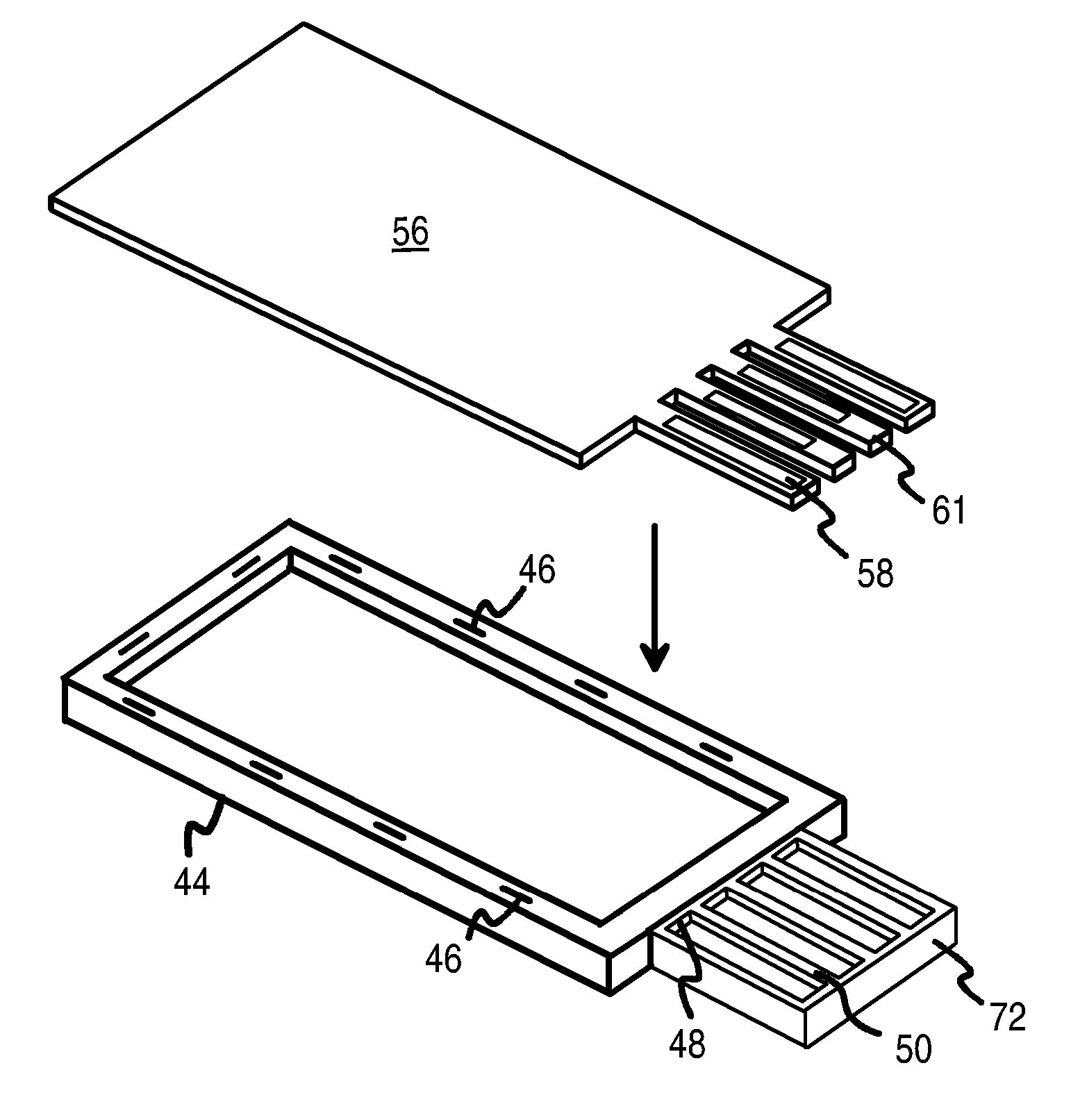

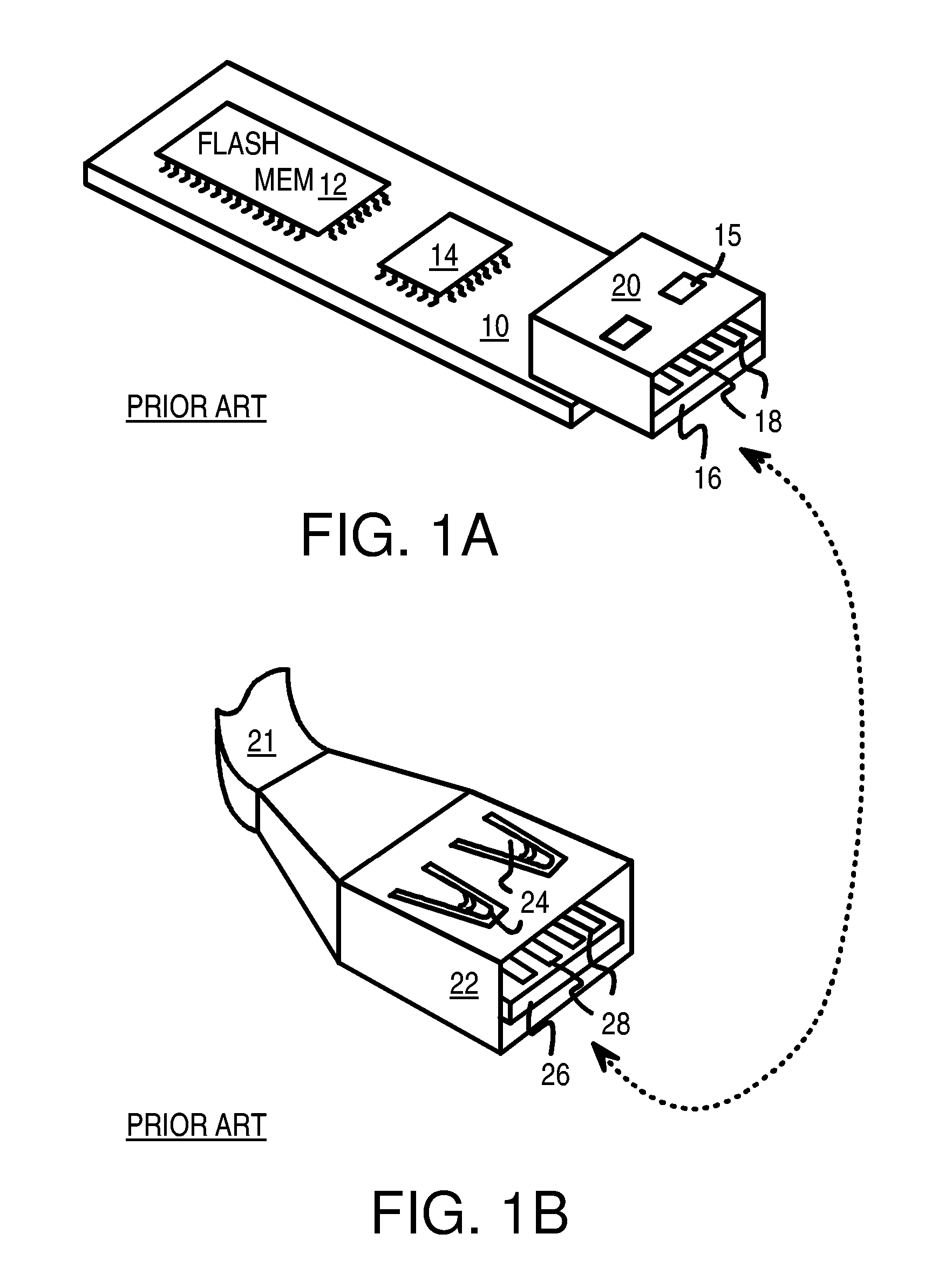

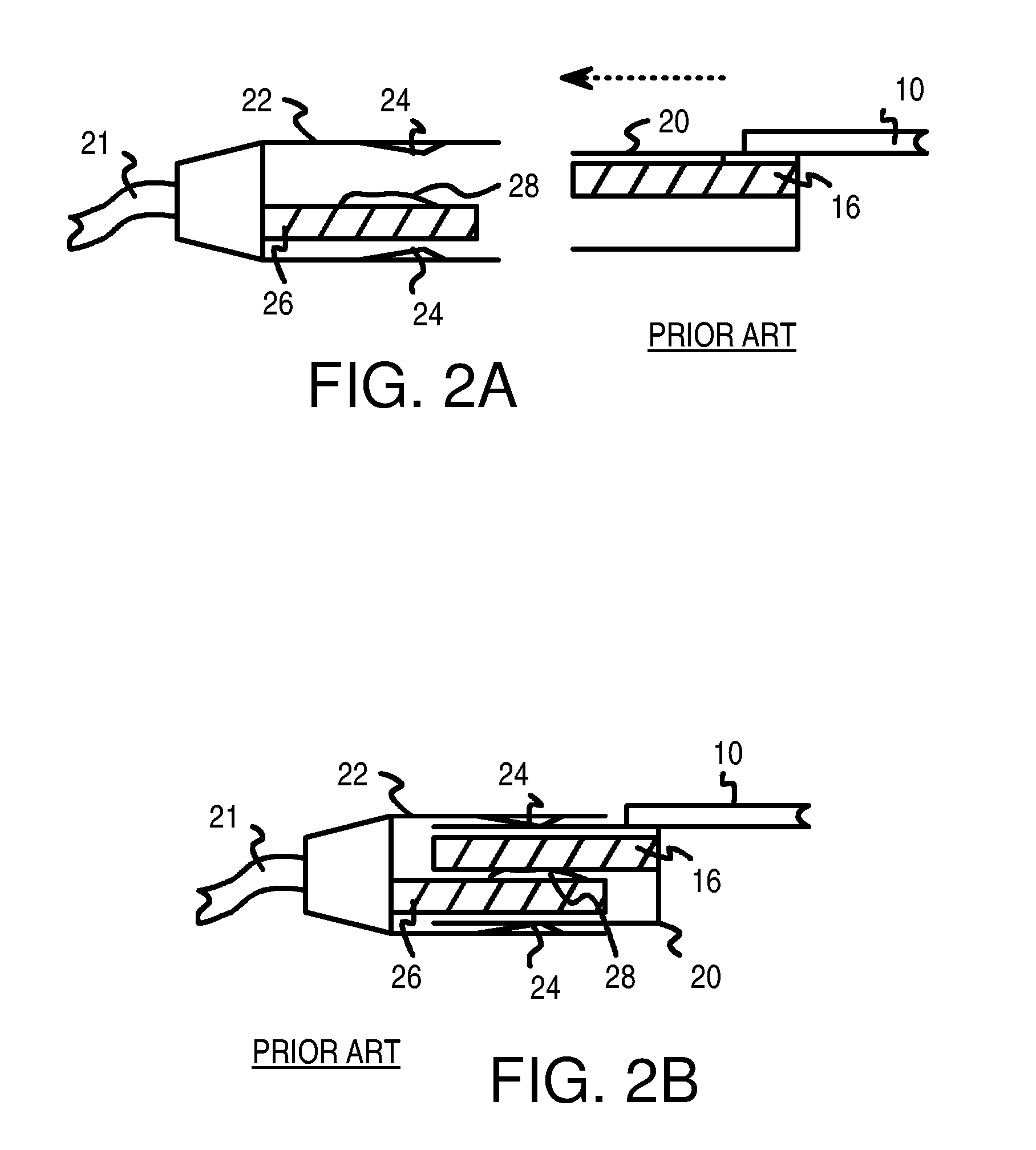

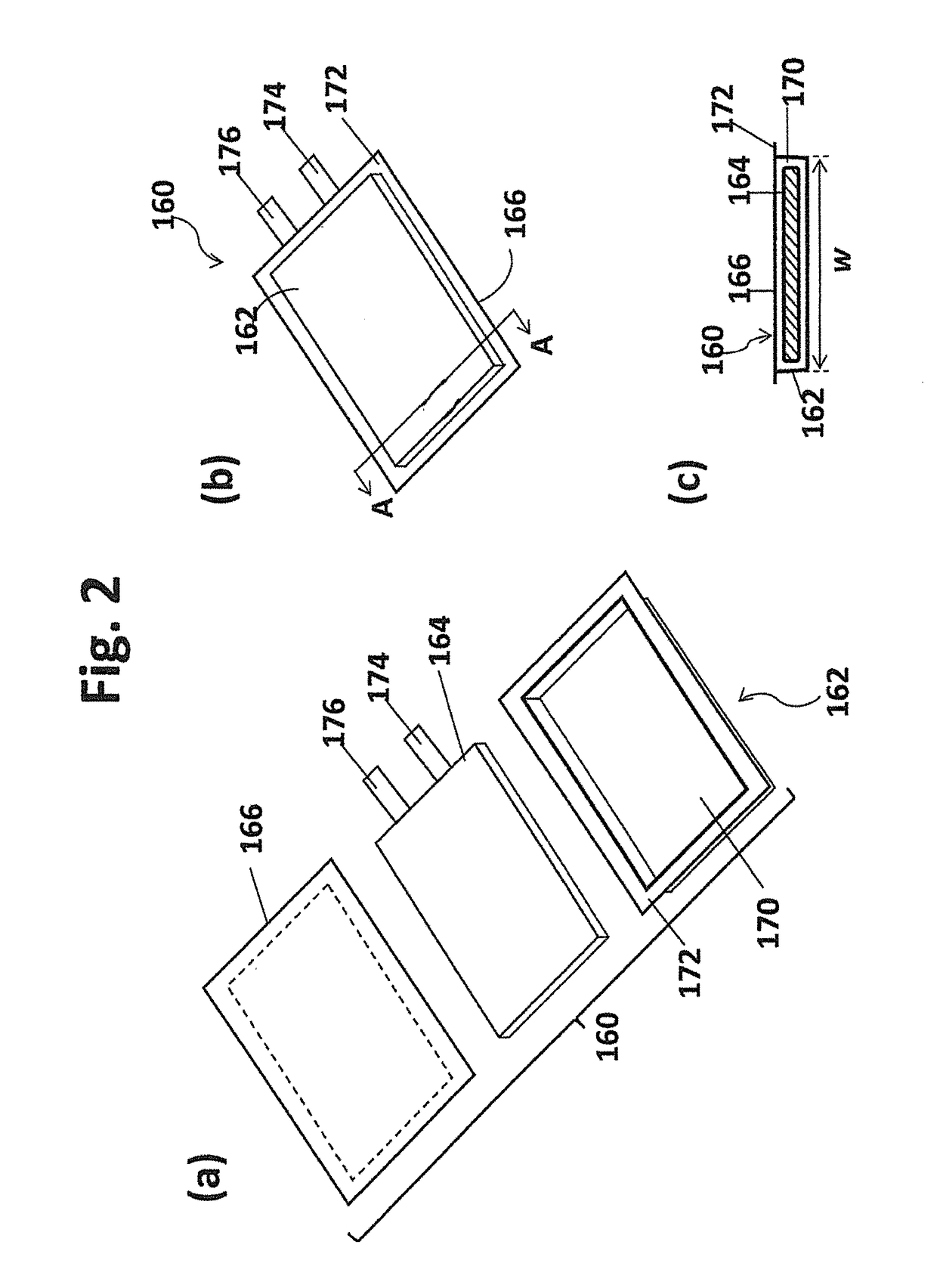

USB flash-memory card with perimeter frame and covers that allow mounting of chips on both sides of a PCB

InactiveUS7044802B2Electric discharge tubesSemiconductor/solid-state device detailsEngineeringMechanical engineering

A flash-memory-drive card has a Universal-Serial-Bus (USB) connector. The card has a printed-circuit board (PCB) that fits into a perimeter frame that surrounds the edges of the PCB. Metal or plastic upper and lower covers are snapped onto the frame to encapsulate the PCB. The USB connector can be a Full USB connector plug that extends from the perimeter frame and has a centerline approximately matching the PCB centerline for a balanced design, or can be a slim or reduced-height USB connector plug that has a frame closure bar that fits inside closure fittings on the perimeter frame. The USB connector can also be made from a frame extension that has four frame slots through the frame. The PCB has four PCB fingers that are inserted through the frame slots during assembly so that the PCB fingers fit within depressions in the frame extension to form the USB connector plug.

Owner:SUPER TALENT ELECTRONICS

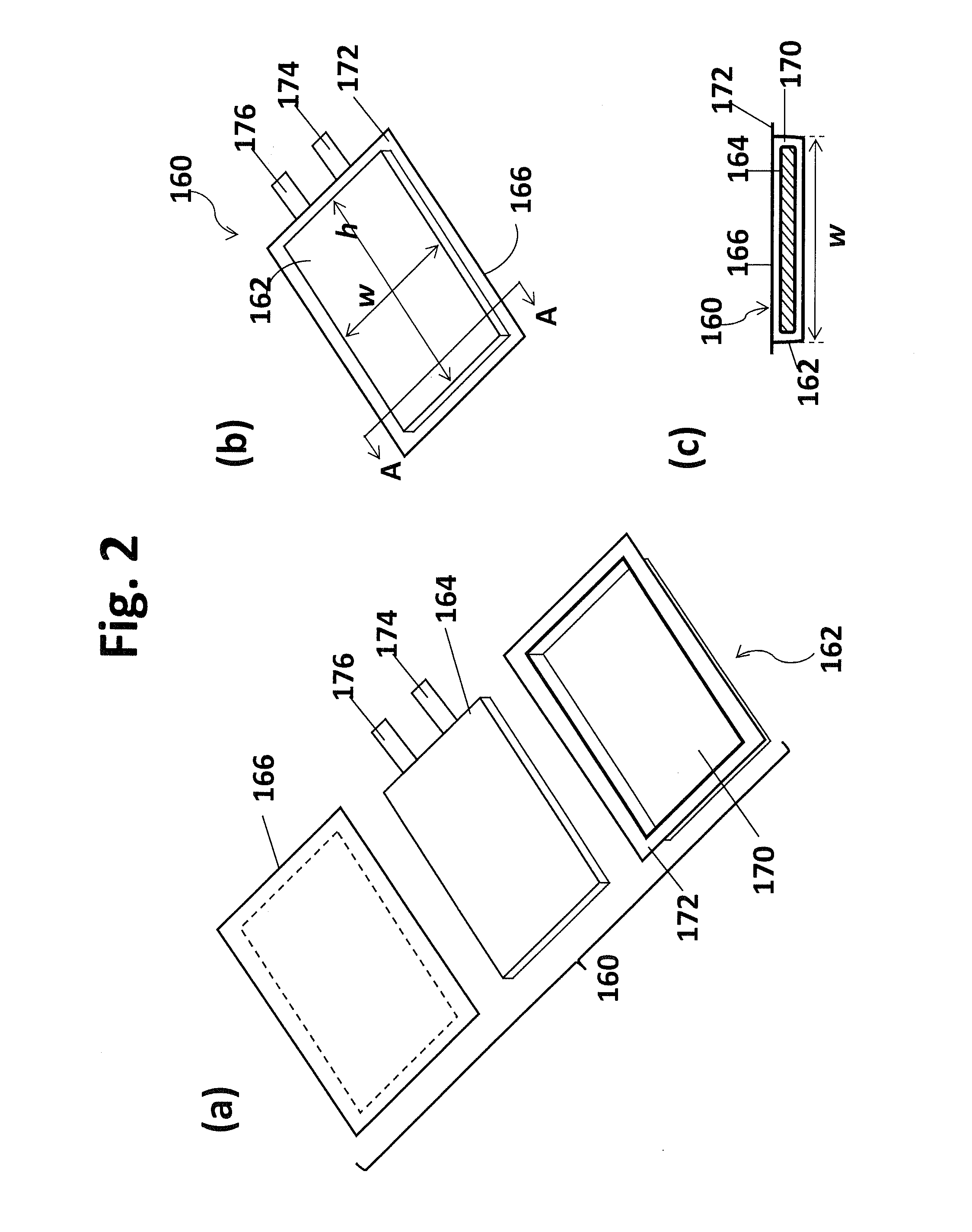

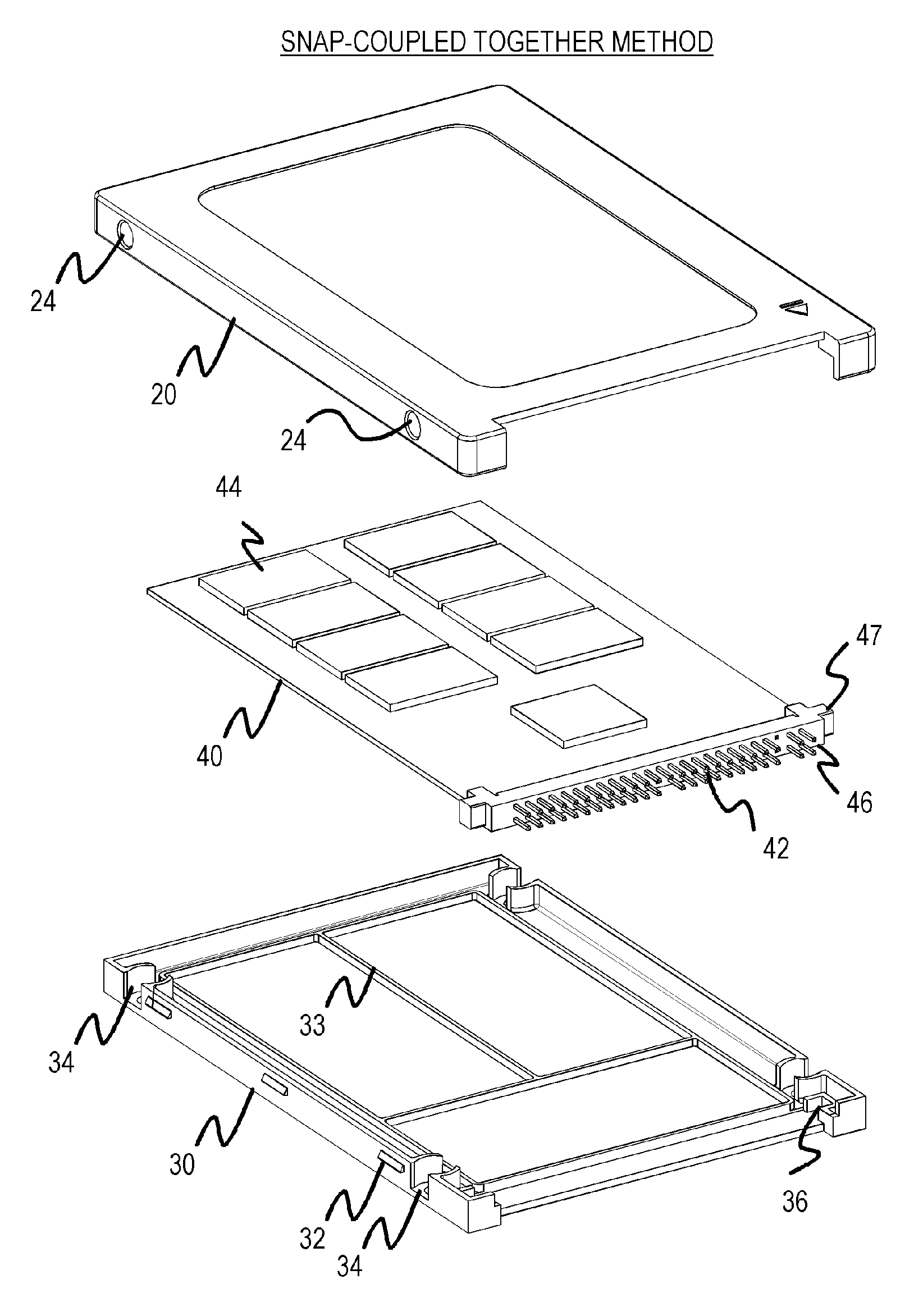

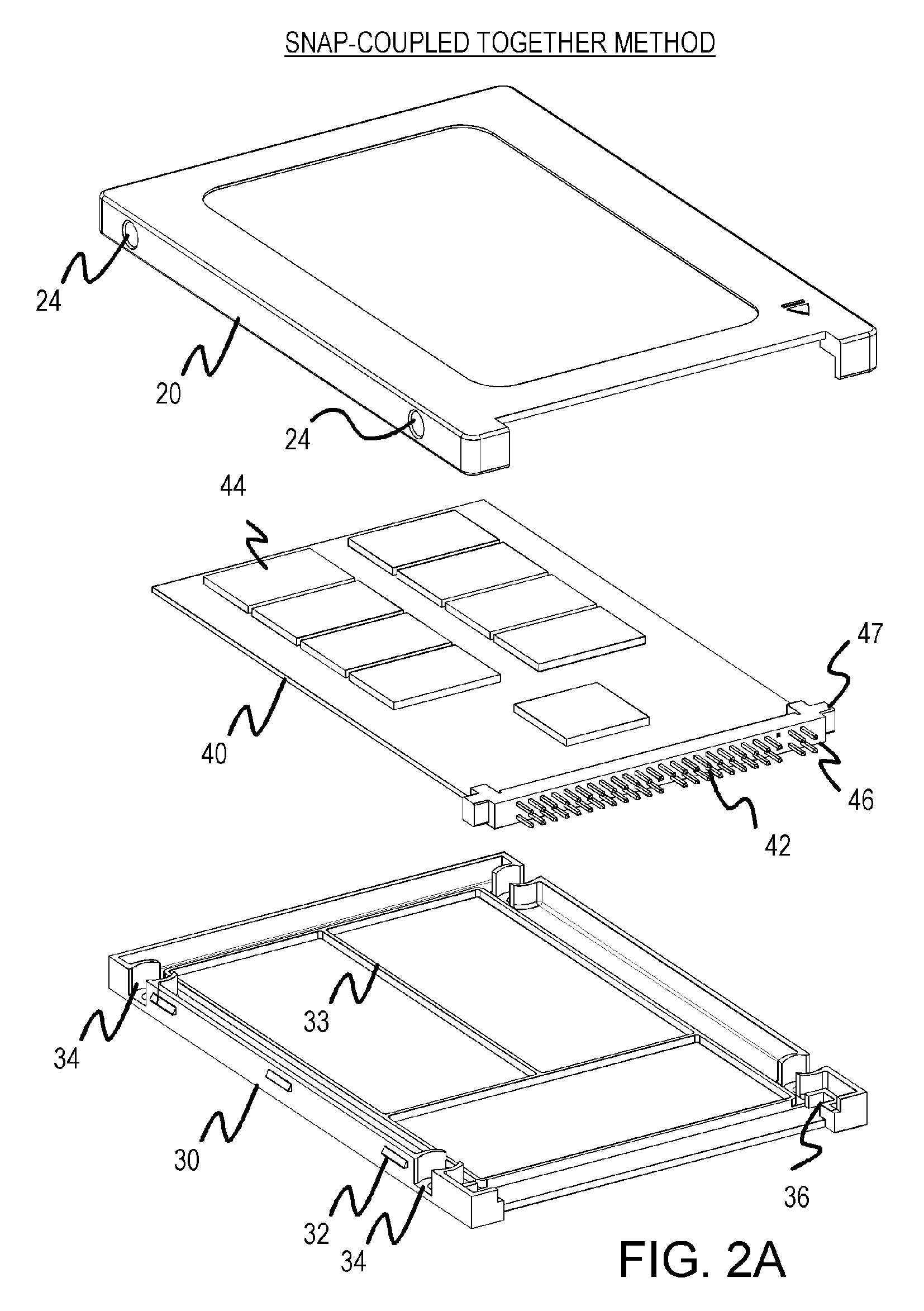

Thin flash-hard-drive with two-piece casing

InactiveUS7649742B2Couplings bases/casesPrinted circuits structural associationsHard disc driveEngineering

A flash-memory drive replaces a hard-disk drive using an integrated device electronics (IDE) interface. The flash drive has a printed-circuit board assembly (PCBA) with a circuit board with flash-memory chips and a controller chip. The controller chip includes an input / output interface circuit to an external computer over the IDE interface, and a processing unit to read blocks of data from the flash-memory chips. The PCBA is encased inside an upper case and a lower case, with an IDE connector that fits through and opening between the cases. The cases can be assembled with the PCBA by a snap-together, ultrasonic-press, screw-fastener, or thermal-bond adhesive method. Center lines formed on the inside of the cases fit between rows of flash-memory chips to improve case rigidity. The connector has two rows of pins that straddle the center line of the circuit board for a balanced design.

Owner:SUPER TALENT TECH CORP

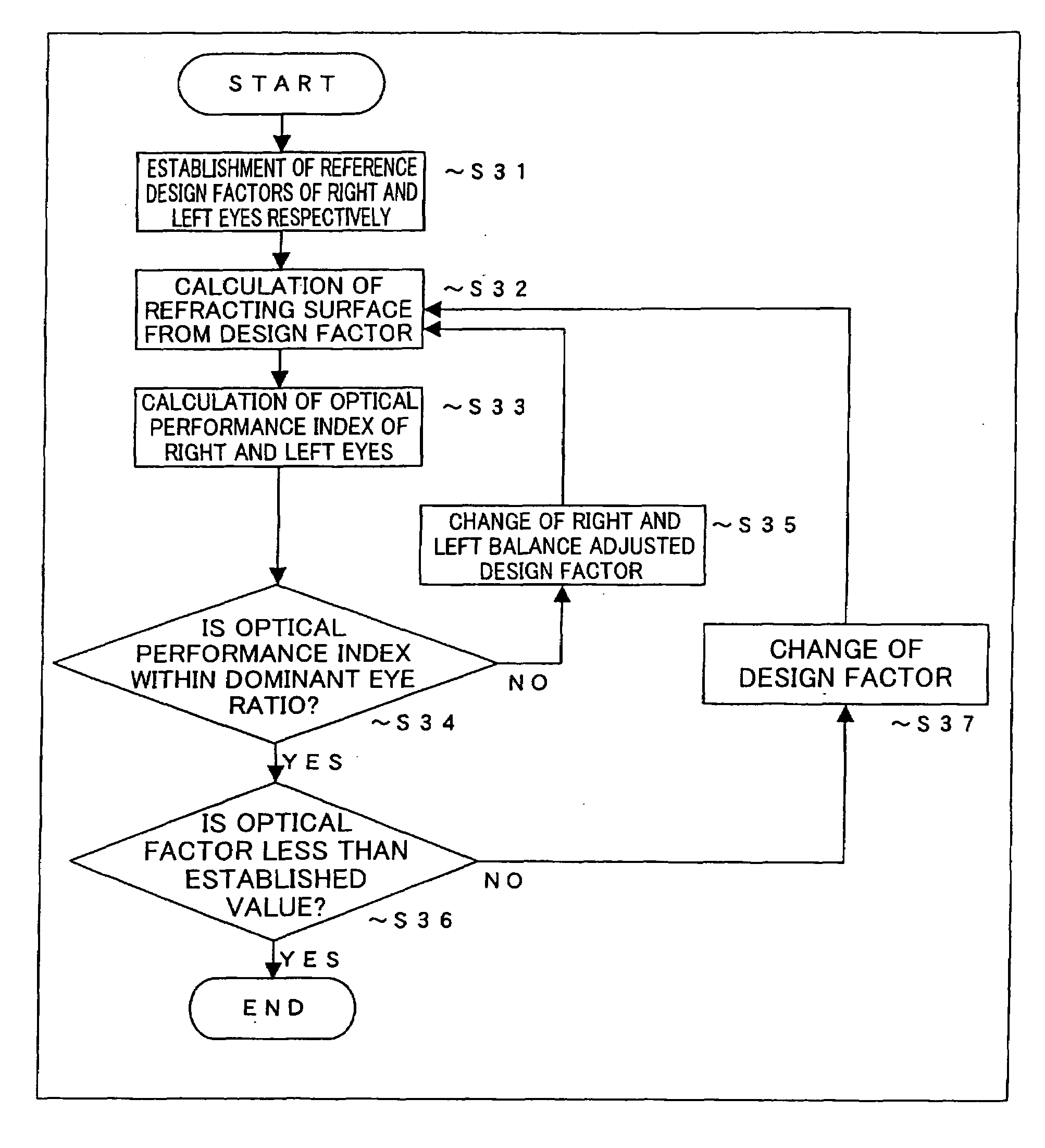

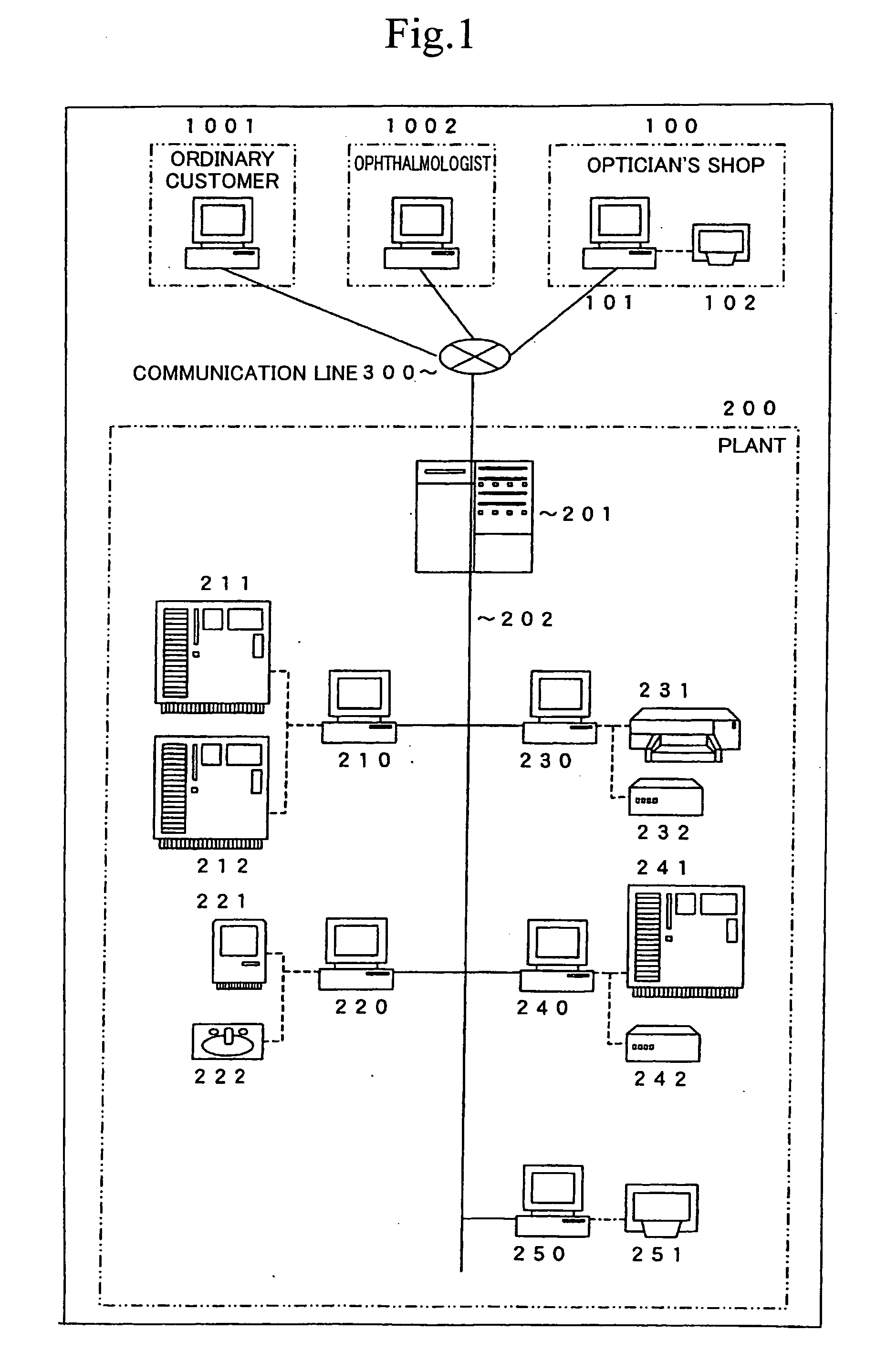

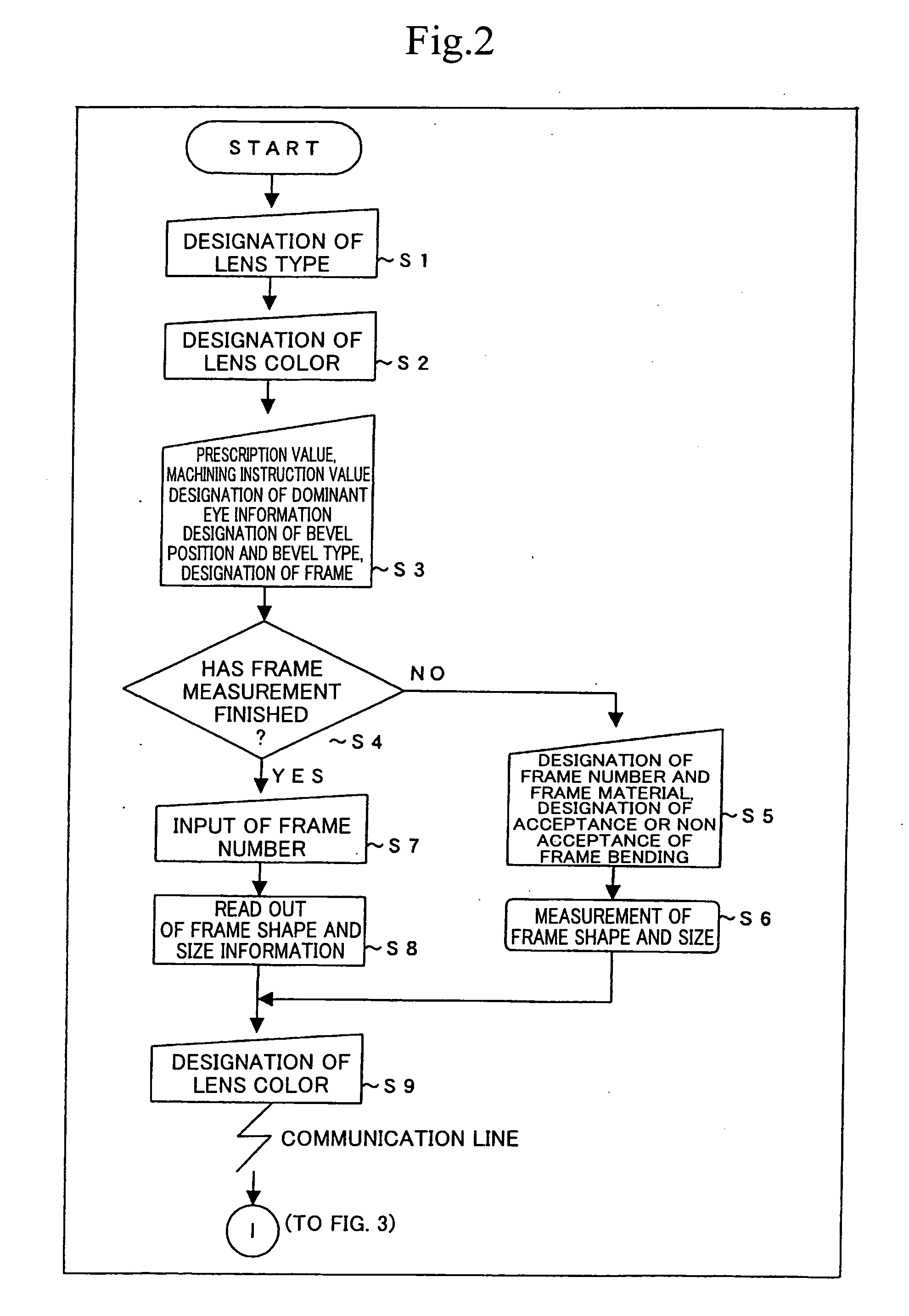

Manufacturing Method for Spectacle Lens and Spectacle Lens

ActiveUS20080273170A1Good lookingBinocular vision comfortableSpectales/gogglesPhysical therapies and activitiesEngineeringEye lens

To ensure optical performance within a permissible range, making outward appearance excellent, and making binocular vision comfortable. In cases where a difference of prescription including dioptric power between the right and left eyes is equal to or more than prescribed, when curvature of a first refracting surface and a second refracting surface of the right and left spectacle lenses is designed, binocular vision balanced design such as selection of at least either of a first or second refracting surface out of the right and left spectacle lenses, or an intermediate curvature of the first and second surfaces of the right and left spectacle lenses according to a dominant eye ratio so that a difference between curvature of the first refracting surfaces of right and left spectacle lenses is within a prescribed range after the right and left spectacle lenses fulfill prescription conditions containing dioptric power respectively, and optical performance of the right and left spectacle lenses are within their permissible ranges respectively.

Owner:HOYA CORP

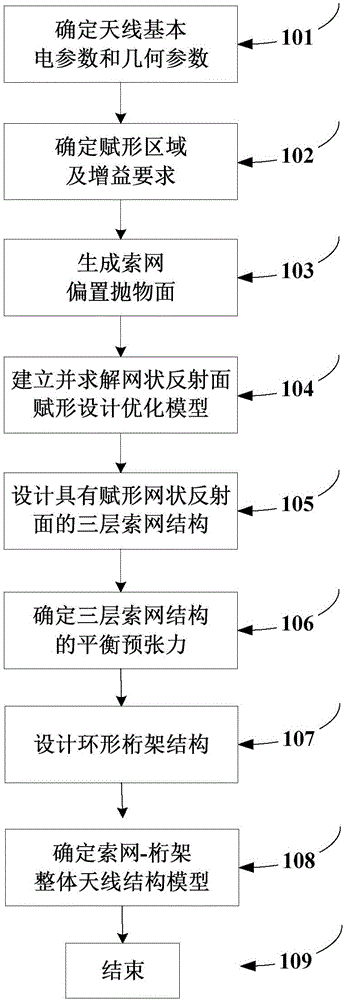

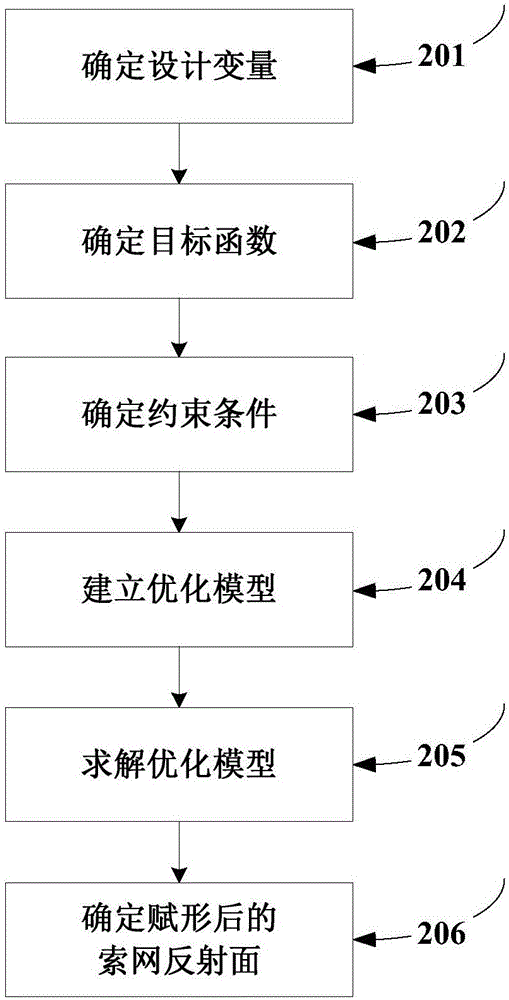

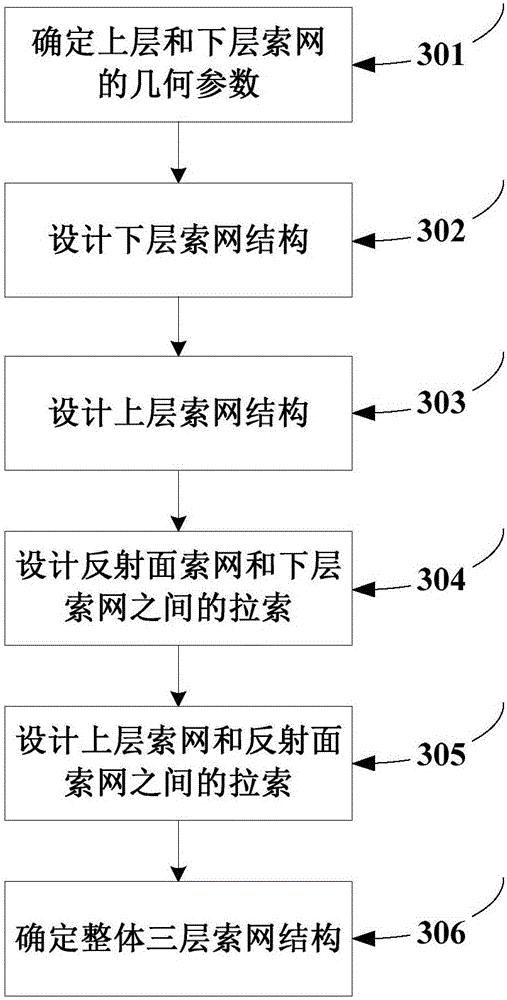

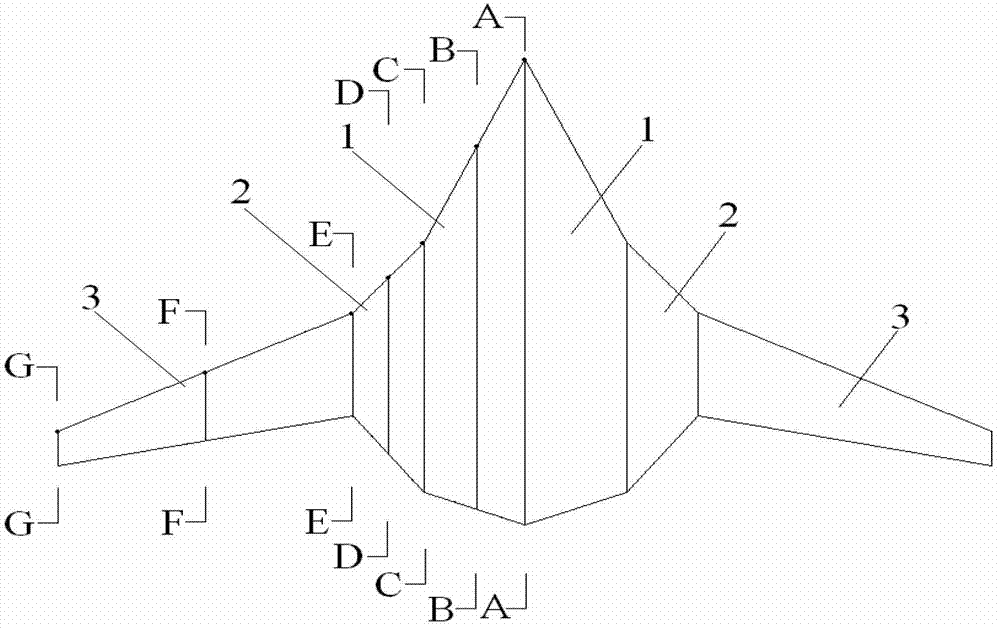

Method for designing novel mesh antenna structure with shaped pattern

ActiveCN106294970AStretchableSimple structureDesign optimisation/simulationSpecial data processing applicationsRealizabilityBalance design

The invention discloses a method for designing a novel mesh antenna structure with a shaped pattern. The method comprises the steps of conducting shape design on a reflective surface of an antenna cable net firstly; then designing the cable net structures of an upper layer and a lower layer according to the shaped meshed reflective surface, so that an overall three-layer cable net structure is obtained; conducting pretension balancing design on the three-layer cable net structure so as to guarantee the tensile property and realizability of the structure; designing a three-layer truss structure supporting the three-layer cable net finally, so that a cable net-truss overall antenna structure is obtained. By extending a two-layer cable net structure of a peripheral truss type extendable mesh antenna into the three-layer cable net structure, the mesh antenna structure with the shaped reflective surface is obtained, and the design process is simple; the designed shaped mesh antenna structure is tensile, easy to realize and high in engineering application value.

Owner:XIDIAN UNIV

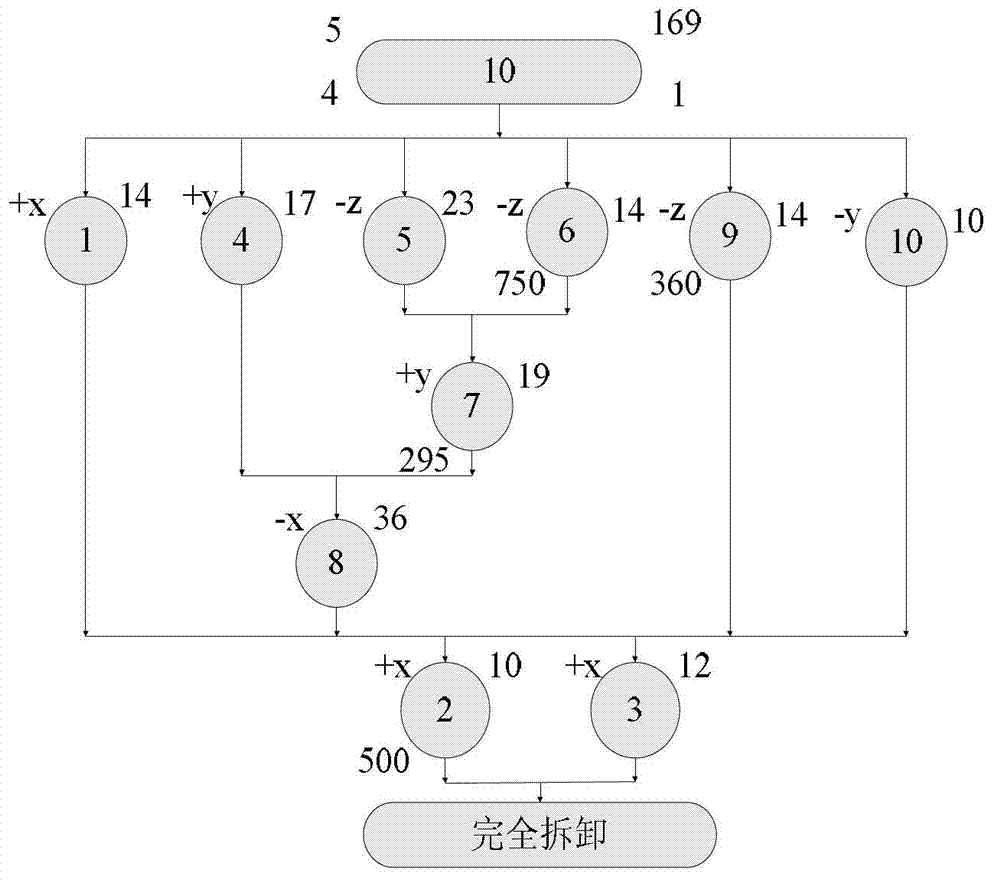

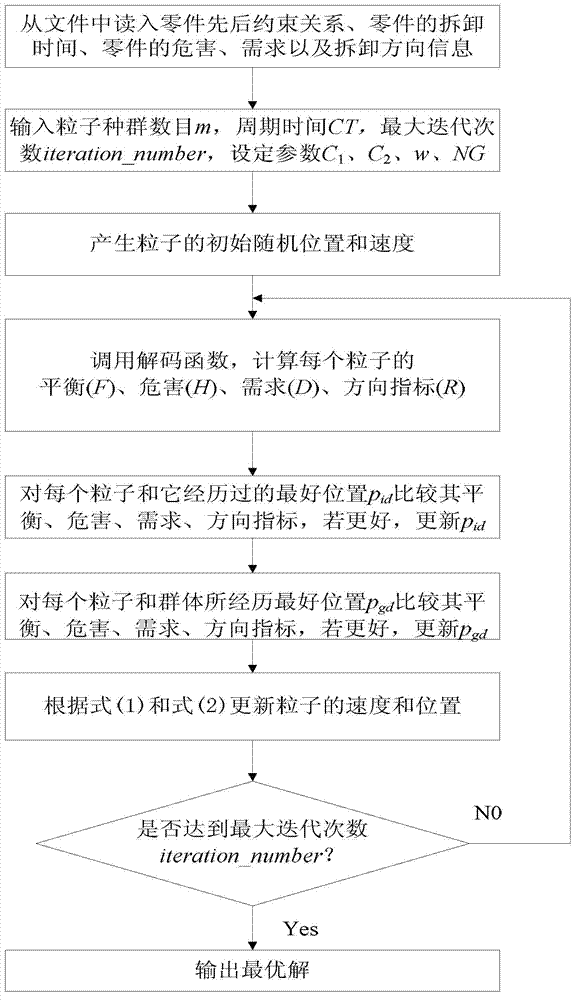

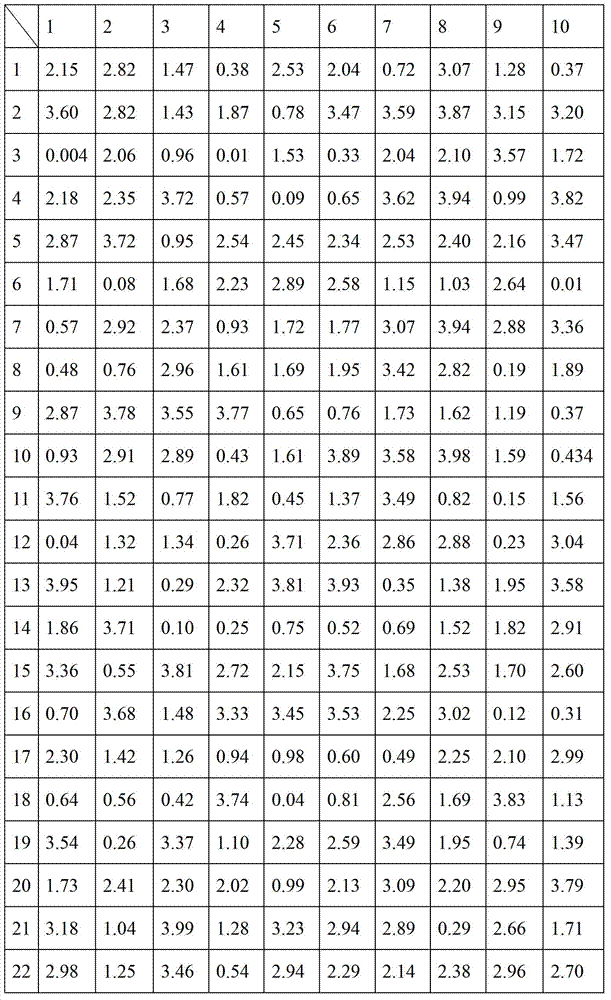

Balance control method of multi-objective disassembly line

InactiveCN102830621ASolve balance problemsSolve control problemsAdaptive controlIdle timeComputer-integrated manufacturing

The invention discloses a balance control method of a multi-objective disassembly line. The method is characterized by planning a complex disassembly line in a reasonable time, and proposing a relatively optimal solution. The solution comprises division of work stations, arrangement of tasks in the work stations and beats of the assembly line. According to the invention, under the premise of meeting precedence relations and beats constraints, five aspects of the assembly line are collaboratively considered: (1) minimizing number of work stations, that is, minimizing total idle time; (2) equalizing the idle time of each work station as much as possible, that is, balancing time of each work station; (3) removing harmful parts as soon as possible; (4) removing high demand parts as soon as possible; and (5) minimizing change of disassembly direction. The method is close to disassembly environment in actual production, and therefore, the balance design planning and reasonable control of the disassembly line are realized, thereby improving the efficiency of the disassembling line, and optimizing conditions of an actual production and manufacturing system. The method can be applied to modeling and analyzing software of a manufacturing system, management and control module of a computer integrated manufacturing system and actual control.

Owner:SOUTHWEST JIAOTONG UNIV

Battery designs with high capacity anode materials and cathode materials

Improved high energy capacity designs for lithium ion batteries are described that take advantage of the properties of high specific capacity anode active compositions and high specific capacity cathode active compositions. In particular, specific electrode designs provide for achieving very high energy densities. Furthermore, the complex behavior of the active materials is used advantageously in a radical electrode balancing design that significantly reduced wasted electrode capacity in either electrode when cycling under realistic conditions of moderate to high discharge rates and / or over a reduced depth of discharge.

Owner:IONBLOX INC

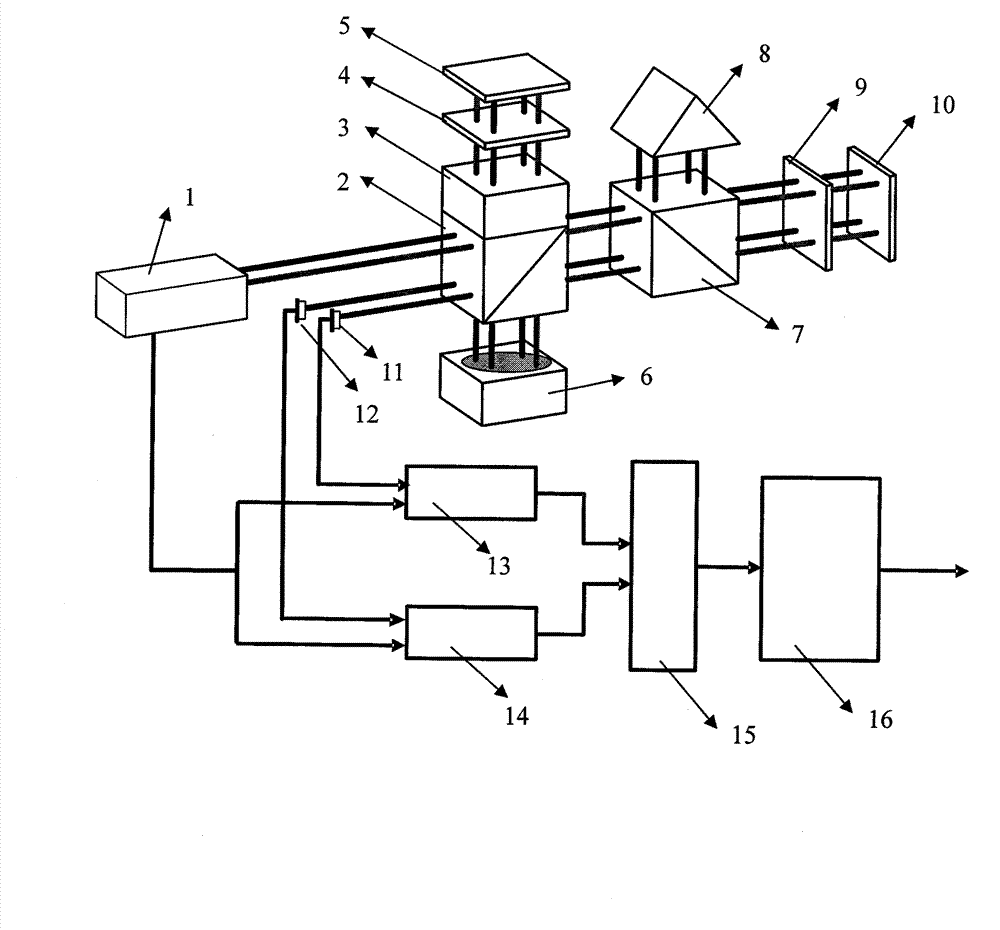

High-speed and high-resolution laser heterodyne interferometry method and high-speed and high-resolution laser heterodyne interferometry device

ActiveCN102853769AGood effectEliminate nonlinear errorsUsing optical meansOptical elementsLaser lightOptoelectronics

The invention discloses a high-speed and high-resolution laser heterodyne interferometry method and a high-speed and high-resolution laser heterodyne interferometry device, and belongs to the technical field of laser application. Reference light and measuring light which are separated from each other spatially are adopted, balance design for a measuring light path is carried out, and two interferometry signals with opposite Doppler frequency shifts are generated by the method, and are selectively used for interferometry according to the movement direction and the speed of a measured object. The high-speed and high-resolution laser heterodyne interferometry method and the high-speed and high-resolution laser heterodyne interferometry device have the advantages that influence of temperature change to measurement is reduced, frequency aliasing in an interferometer is eliminated, measurement precision of heterodyne interferometry is improved, and the problem of limitation on measuring speed due to frequency difference of laser light sources is solved.

Owner:HARBIN INST OF TECH

Battery cell engineering and design to reach high energy

Improved high energy capacity designs for lithium ion batteries are described that take advantage of the properties of high specific capacity anode active compositions and high specific capacity cathode active compositions. In particular, specific electrode designs provide for achieving very high energy densities. Furthermore, the complex behavior of the active materials is used advantageously in a radical electrode balancing design that significantly reduced wasted electrode capacity in either electrode when cycling under realistic conditions of moderate to high discharge rates and / or over a reduced depth of discharge.

Owner:ZENLABS ENERGY INC

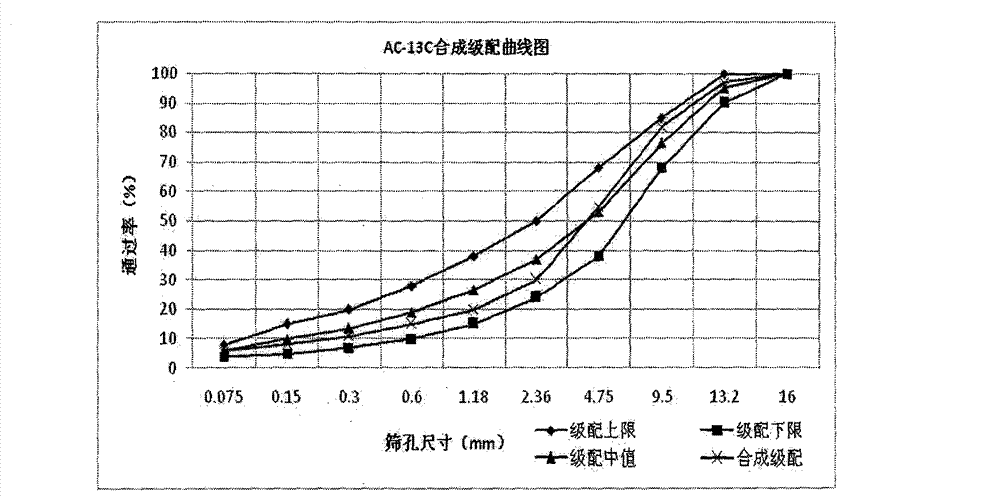

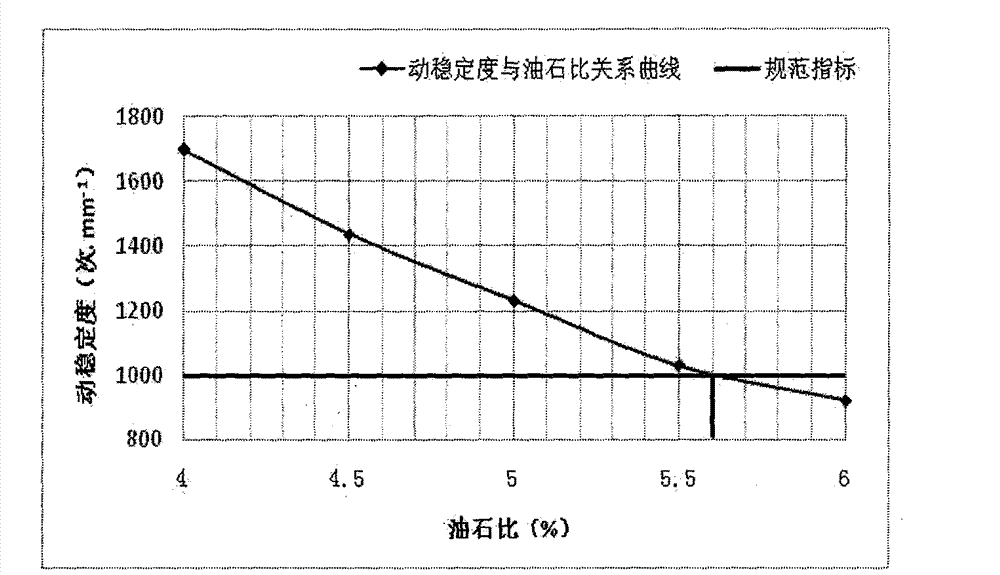

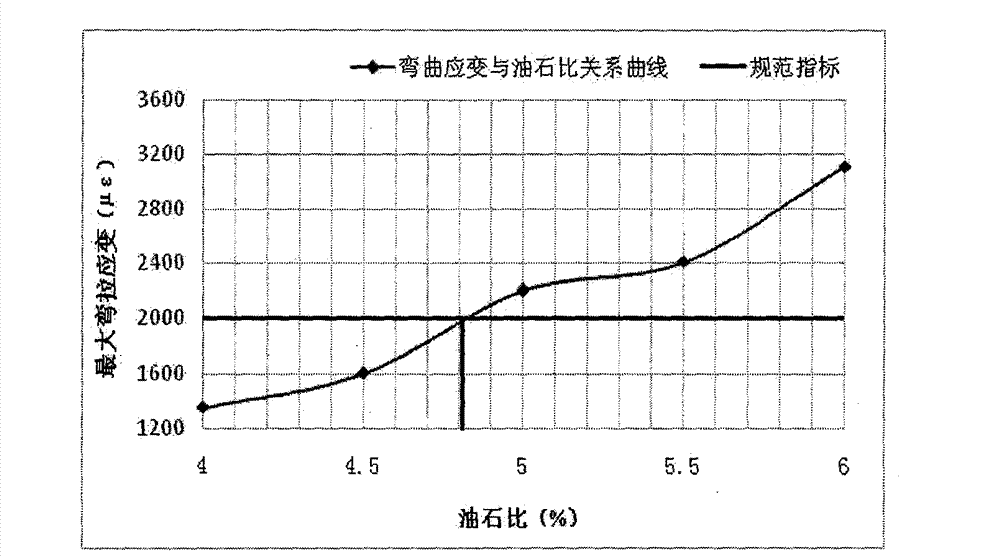

Method for determining optimal asphalt aggregate ratio of asphalt mixture based on pavement performance

ActiveCN103015292AResolve mutual restraintAchieving a Balanced DesignClimate change adaptationRoads maintainenceCrack resistanceAsphalt

The invention relates to a method for determining an optimal asphalt aggregate ratio of an asphalt mixture based on pavement performance. By the method, the optimal asphalt aggregate ratio of the mixture is determined based on the pavement performance of the mixture; determination of the optimal asphalt aggregate ratio of the asphalt mixture is well combined with the pavement performance of the asphalt mixture; the mutual dependence between the high temperature stability and the low temperature cracking resistance as well as the mutual dependence between the high temperature stability and the water stability in the pavement performance of the asphalt mixture are fully considered; and by the method for determining the optimal asphalt aggregate ratio of the asphalt mixture based on the pavement performance, balance design of the pavement performance of the asphalt mixture is realized. The method for determining the optimal asphalt aggregate ratio of the asphalt mixture based on the pavement performance can be applied to design of common asphalt mixtures and modified asphalt mixtures.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

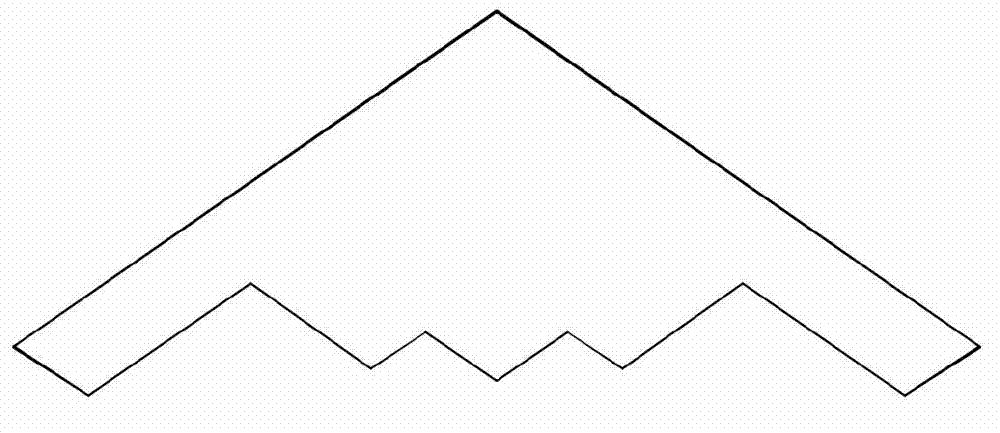

Aerobat aerodynamic configuration adopting mixing wing body

ActiveCN102730181AQuick transitionMinimize adverse effects on aerodynamic performanceWing shapesFuselagesFlight vehicleArea ratio

The invention relates to an aerobat aerodynamic configuration adopting a mixing wing body. According to an aerodynamic configuration on one side of a mixing wing body aerobat, a center aerobat body, a transition section and an outer wing section are respectively arranged along the expending direction of the aerobat body, the transition section is positioned between the center aerobat body and the outer wing section, and an area ratio of the center aerobat body to the transition section to the outer wing section is 1:0.350:0.554. With the technical scheme, the drag divergence Mach number Madd is 0.83, and the maximum lift-drag ratio kmax is 25, wherein the maximum lift-over-drag ratio of the mixing wing body layout is increased by 8.7% than the maximum lift-over-drag ratio of the wing body fusion layout, such that the mixing wing body layout provides higher aerodynamic efficiency and better lift-drag than the wing body fusion layout. With the present invention, the longitudinal moment static stability margin is 3%, and basically meets the self-balancing design requirement during cruise flight. Meanwhile, the aerodynamic configuration of the present invention has a large loading space.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

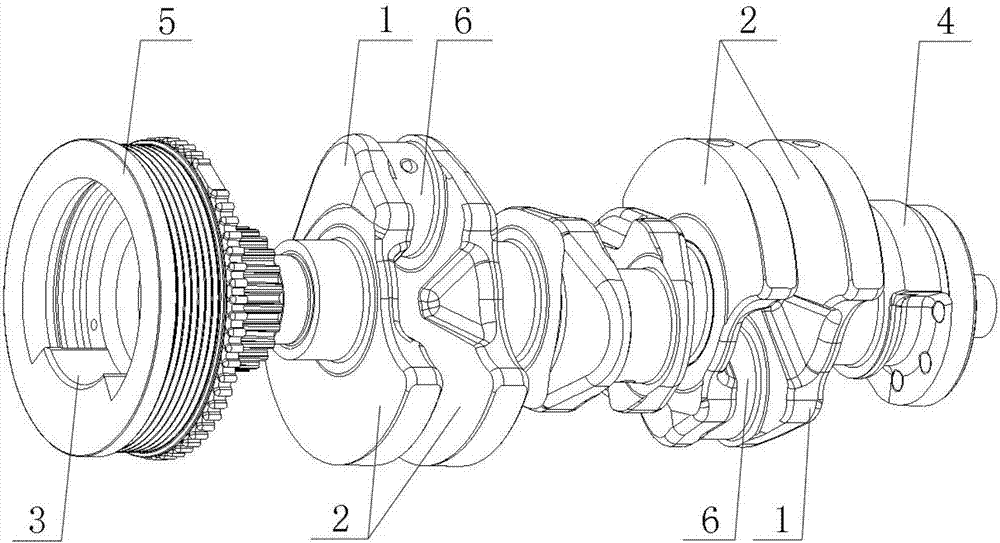

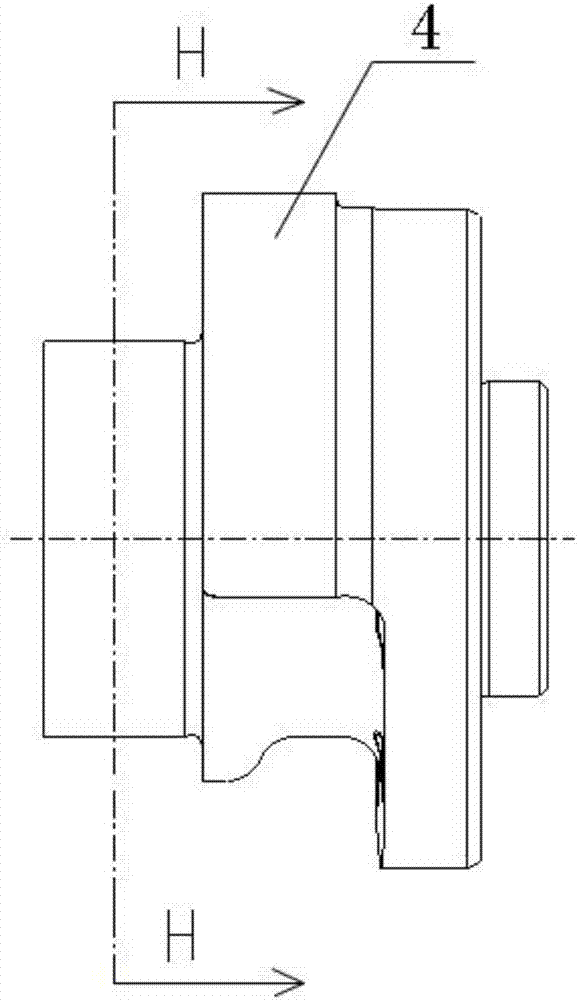

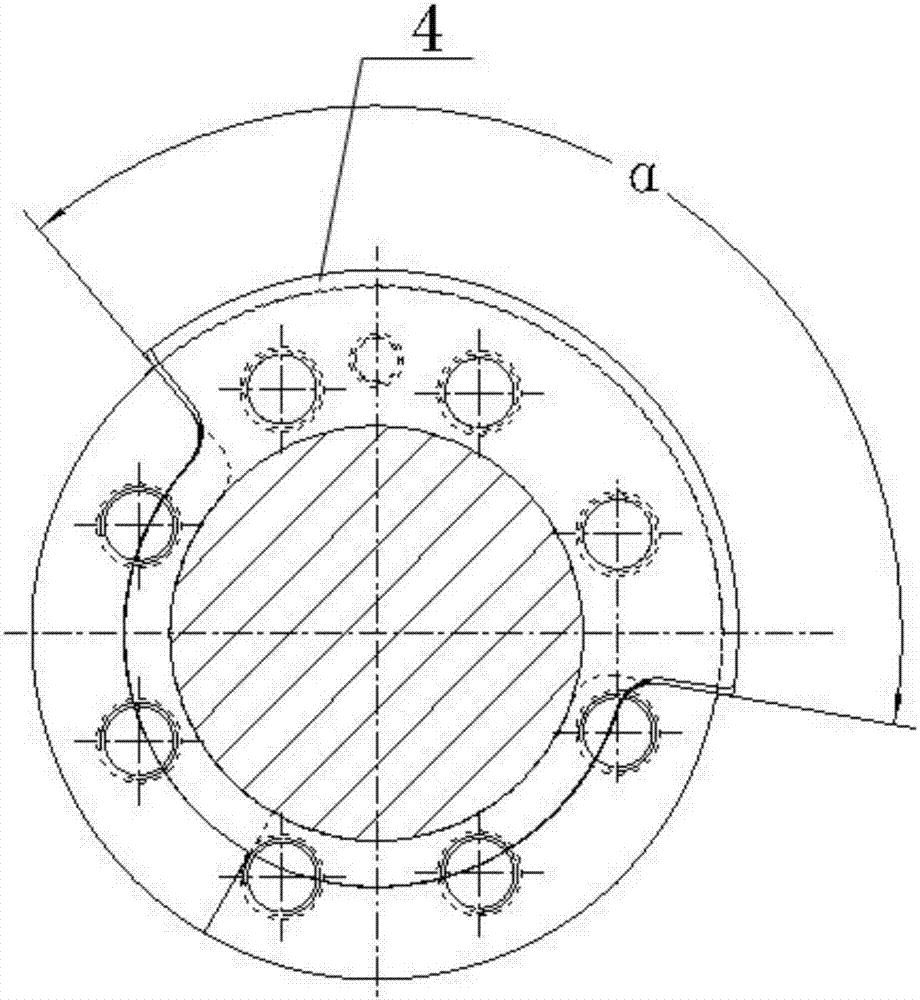

Vehicle, engine and crankshaft balance structure of engine

InactiveCN107237861AMeeting Basic Balance Water GoalsImprove universalityRotating vibration suppressionInertia force compensationEngineeringMoment of inertia

The invention discloses a crankshaft balance structure, which includes balance weights respectively arranged on several groups of crank arms with equal weight, and also includes a first counterweight arranged at the front end of the crankshaft and a second counterweight arranged at the rear end of the crankshaft. The mass of the first balance weight and the second balance weight are equal, the direction of the center of mass is opposite, and the direction of the center of mass of one of them is the same as the direction of the center of mass of the balance weight on the adjacent crank arm. In this way, the balance of the inertial force is maintained through the characteristics of the first counterweight and the second counterweight being equal in weight and reversed, and at the same time, one of them is in the same direction as the center of mass of the counterweight on the adjacent crank arm, so that the rotational inertia moment can be achieved Full balance and semi-balance of reciprocating inertia moment meet the basic balance design goal of the crankshaft system. Compared with the existing technology, there is no need to change the structure of the front and rear parts of the engine (such as the flywheel), which improves the universality and versatility . The invention also discloses an engine and a vehicle, the beneficial effects of which are as described above.

Owner:BEIQI FOTON MOTOR CO LTD

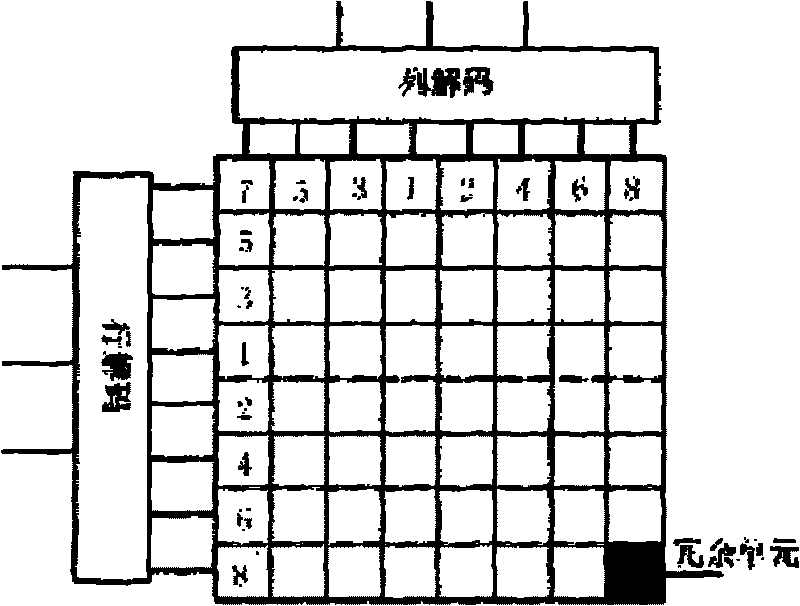

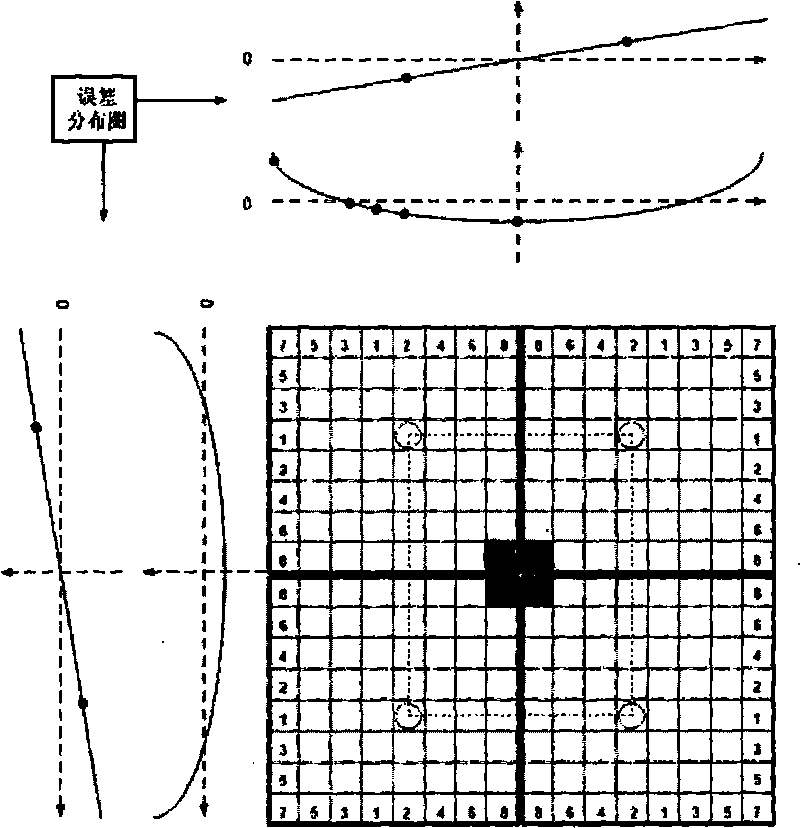

Unbalanced design method of high-position current source unit of current rudder-type digital-to-analog converter

ActiveCN101694843AHigh precisionSecond order error cancellationTransistorDigital-analogue convertorsDigital analog converterEngineering

The invention relates to an unbalanced design method of a high-position current source unit of a current rudder-type digital-to-analog converter, which can effectively reduce integral nonlinearity errors, thus improving the accuracy of the high-speed and high-accuracy current rudder-type digital-to-analog converter. The unbalanced design method comprises a high-position current source unit structure under the existing sequence of specific switches and is characterized in that the current intensity can be regulated by adjusting width-to-length ratio (W / L) of a row MOS tube at the outmost edge of two sides of each quadrant current source unit matrix, thus leading the current to be unequal with the current generated by other row current source units in the same quadrant, and using unbalanced current difference to counteract second-order errors brought by a system.

Owner:杭州思泰微电子有限公司

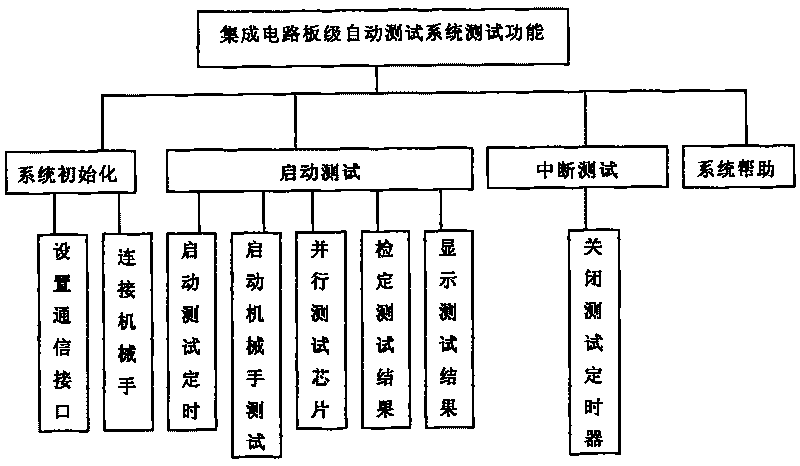

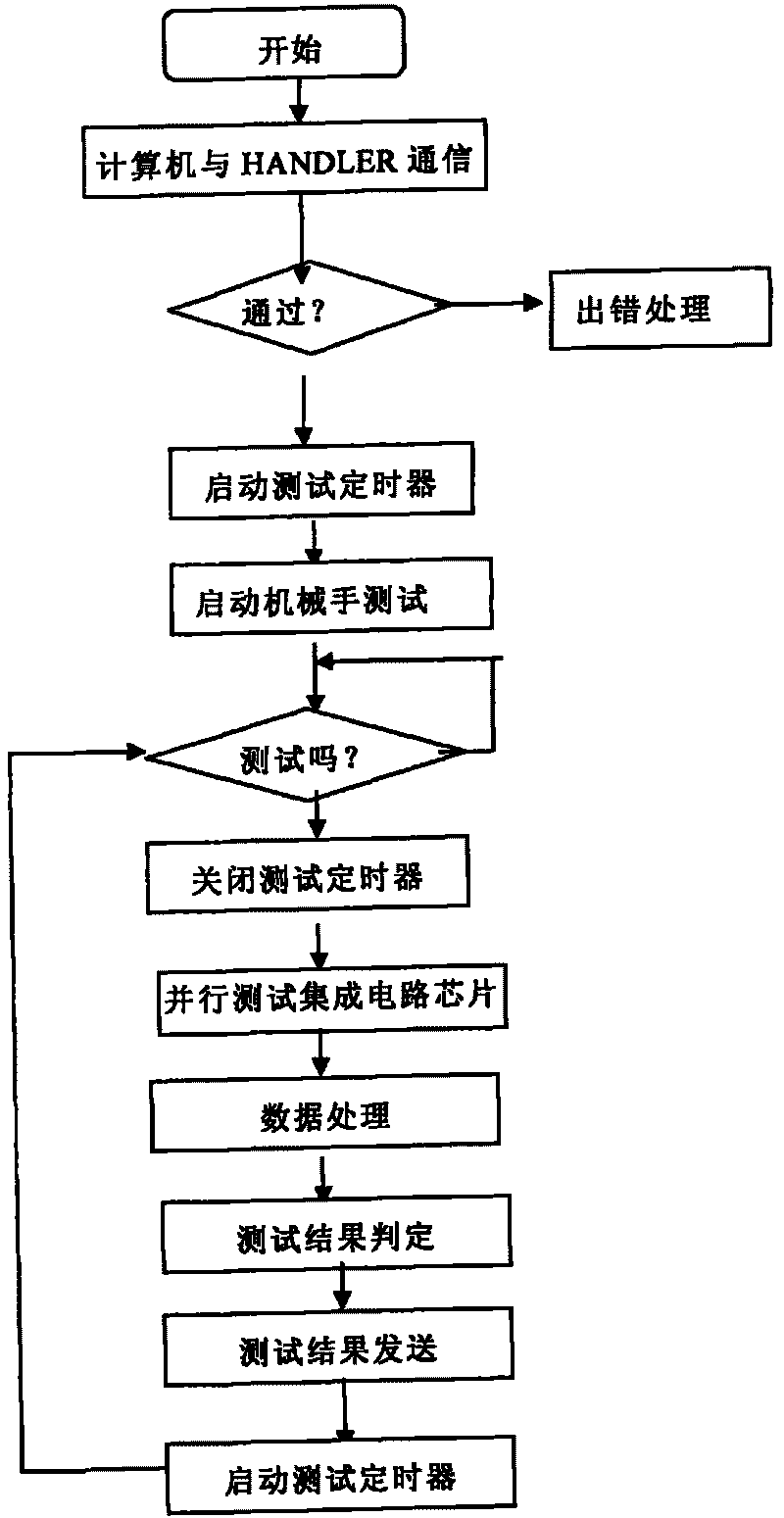

Automatic test system for integrated circuit board electrodes

InactiveCN101750578AEasy to useLow costElectronic circuit testingSortingBalance designIntegrated circuit

The invention discloses an automatic test system for integrated circuit board electrodes, which comprises a computer, a GPIB interface, a USB interface, an automatic separating machine and a test interface board, wherein the computer is connected with the GPIB interface and the USB interface, the GPIB interface is connected with the automatic separating machine, both the automatic separating machine and the USB interface are connected with the test interface board which is connected with tested devices. The automatic test system for integrated circuit board electrodes has the characteristics of convenient use, low cost, high automatic degree and the like, includes efficient parallel testing ability simultaneously, and shortens testing time by effectually balancing the resources for design and test, thereby offering a more effective test solution to users.

Owner:BEIJING CHIPADVANCED

Battery cell engineering and design to reach high energy

Improved high energy capacity designs for lithium ion batteries are described that take advantage of the properties of high specific capacity anode active compositions and high specific capacity cathode active compositions. In particular, specific electrode designs provide for achieving very high energy densities. Furthermore, the complex behavior of the active materials is used advantageously in a radical electrode balancing design that significantly reduced wasted electrode capacity in either electrode when cycling under realistic conditions of moderate to high discharge rates and / or over a reduced depth of discharge.

Owner:ZENLABS ENERGY INC

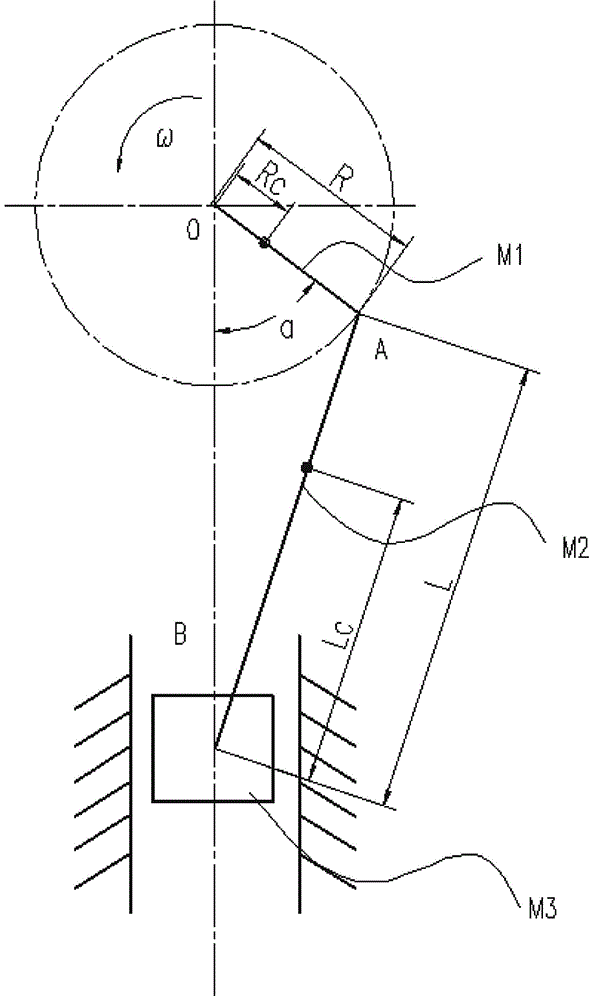

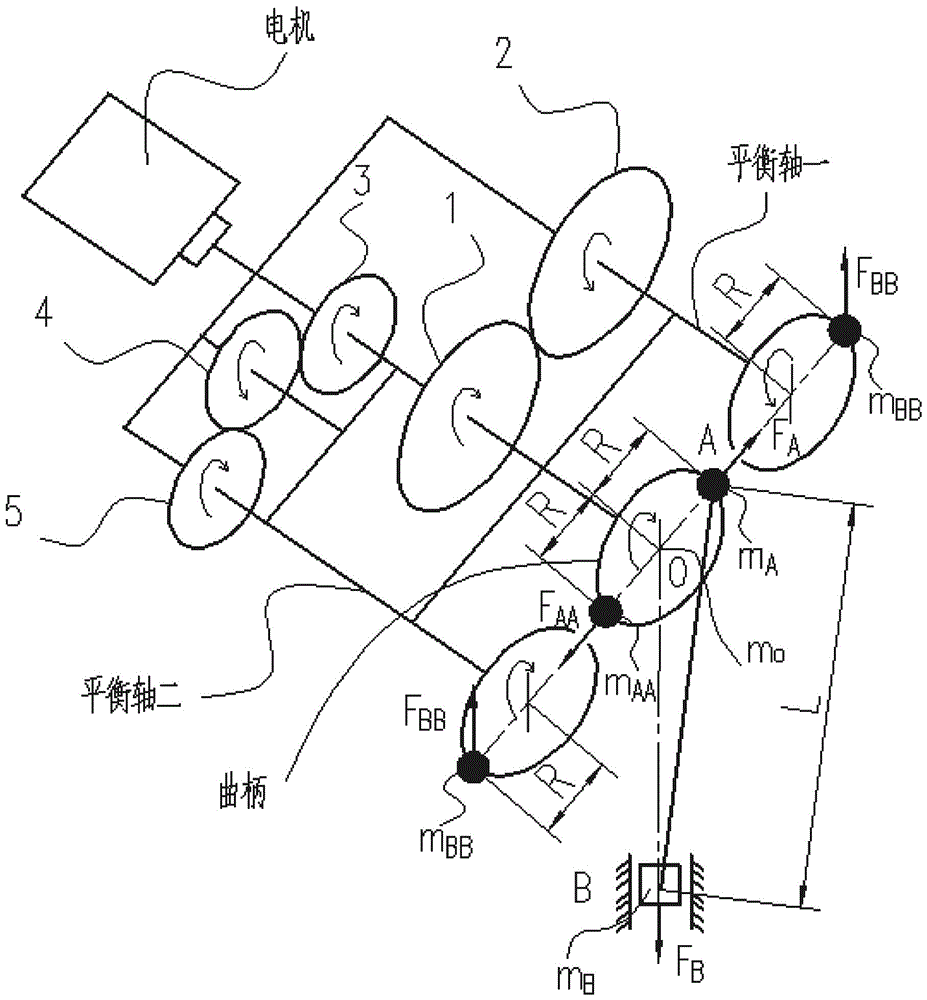

Automatic full-balance design method for high-speed gear shaping machine active movement inertia force

ActiveCN106763483AEfficient processProcess stabilityInertia force compensationGearingDynamic balanceEngineering

The invention discloses an automatic full-balance design method for high-speed gear shaping machine active movement inertia force. The automatic full-balance design method for the high-speed gear shaping machine active movement inertia force is characterized in that the full-balance design method for gear shaping machine active movement, namely crank connecting link sliding block mechanism inertia force is disclosed, a computational formula for balance block mass added onto a crankshaft when inertia force is in full-balance is elicited, the purpose of full-balance inertia force is achieved when the length of the crankshaft is adjusted at will, and a very good dynamic balance effect is achieved in the actual industrial application of a high-speed gear shaping machine.

Owner:宜昌长机科技有限责任公司

Variable displacement swash plate compressor

InactiveCN102011721AAppropriate amount of flexibilityReduce machining accuracyPositive displacement pump componentsMulti-stage pumpsReciprocating motionKinematic pair

The invention relates to a variable displacement swash plate compressor. A swash plate driving mechanisms with a flexible driving balance design is provided, has proper flexibility during work, overcomes unbalanced force and moment acting on the swash plate, improves vibration, noise, kinematic pair blockage and excessive wear caused by the unbalanced force and moment, and reduces machining and assembly precision of related workpieces; a piston with a spiral linear oil groove is provided and stores oil, and through the reciprocation of the piston and the acceleration change of the piston, lubricating oil flows reasonably between the kinematic pair and is uniformly distributed on the cylindrical surface of the piston and the peripheral surface of the cylinder to improve the sealing and lubricating properties between the piston and the peripheral surface of the cylinder, improve the performance of the compressor and prolong the service life of the piston; and a cylinder cover capable of being formed at one time through die casting and having simple process is provided, and suction and discharge channels adopt a single-section or multi-section expansion chamber-type cavity consisting of alternate contraction sections and expansion sections to improve the vibration and air flow noise caused by suction and discharge pulsation.

Owner:ZHEJIANG LONGDIAN AUTOMOTIVE PARTS MFG

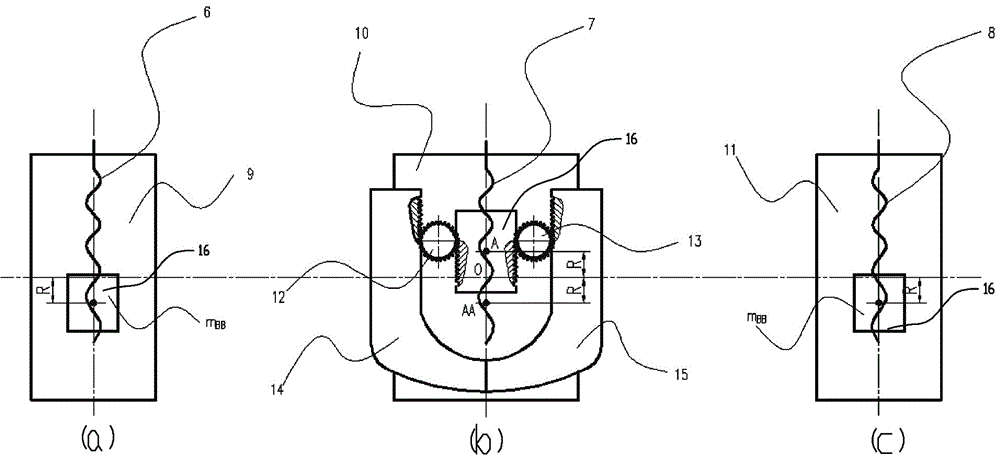

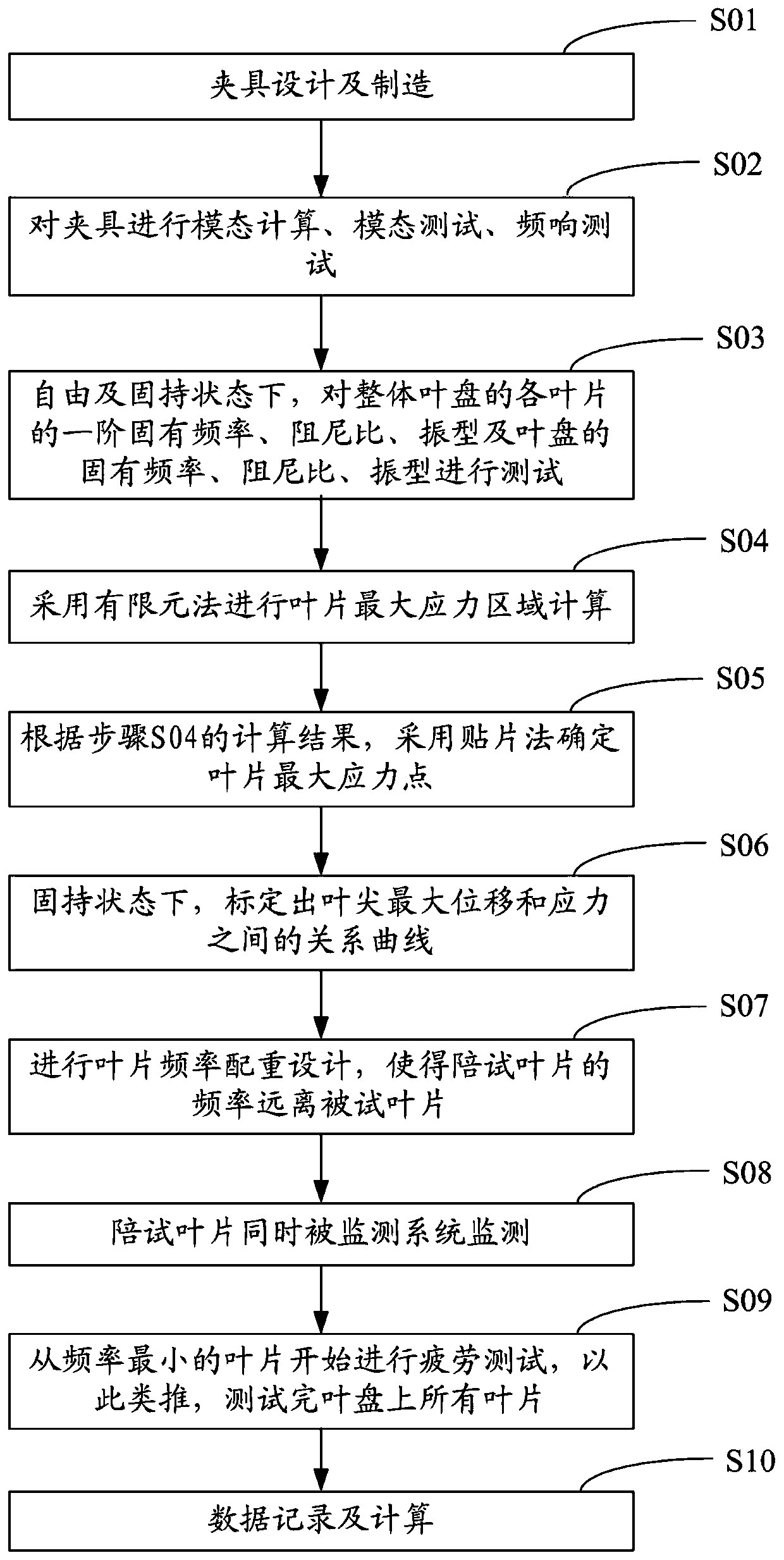

High-cycle fatigue test method for blisk

ActiveCN110146243AReduce test data errorReduce test costsMaterial strength using repeated/pulsating forcesVibration testingModal testingDamping ratio

The invention discloses a high-cycle fatigue test method for a blisk. The method comprises the following steps that: a clamp is designed and manufactured; modal calculation, modal testing and frequency response testing are performed on the clamp, and the first-order inherent frequency, damping ratio and vibration mode of the blisk are tested under free and holding states; a blade maximum stress area is calculated through a finite element method; a blade maximum stress point is determined through a strain gage bonding method; the relation curve of blade tip maximum displacement and stress is calibrated; blade frequency weight balancing design is carried out; test accompanying blades are monitored simultaneously by a monitoring system; and a fatigue test is started from a blade with the smallest frequency. Compared with a traditional blade cutting fatigue test method, the test method of the invention has the advantages that: the testing boundary condition of the blades of the blisk is closer to an actual using condition; the blisk is not damaged; test data errors caused by blade cutting surfaces are reduced; a test period is shortened; and test costs are reduced.

Owner:陕西陕航环境试验有限公司

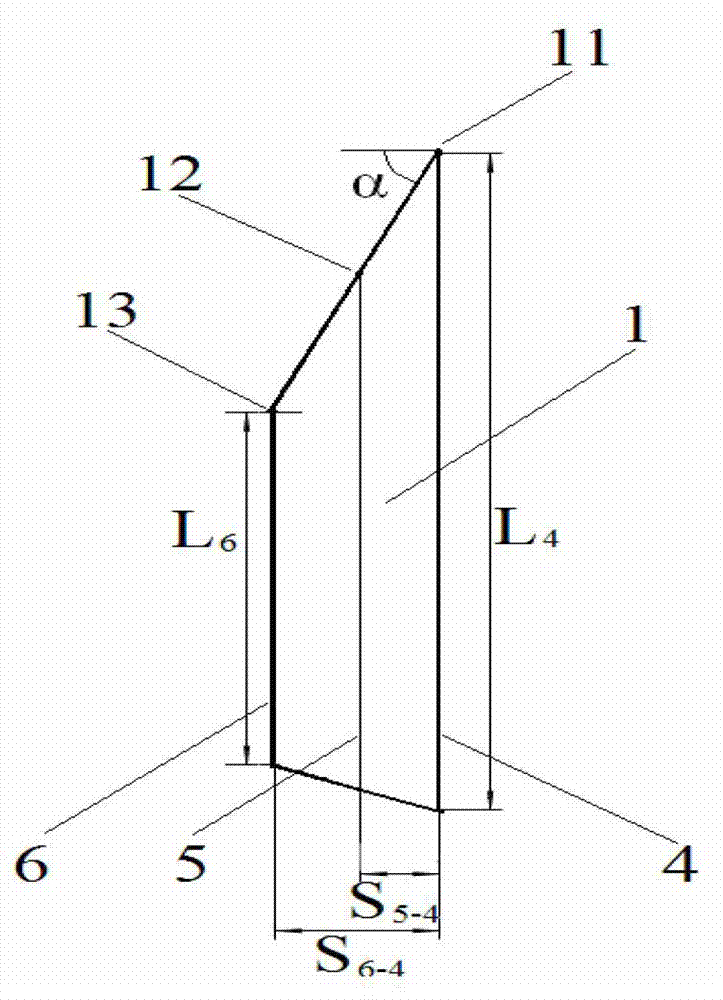

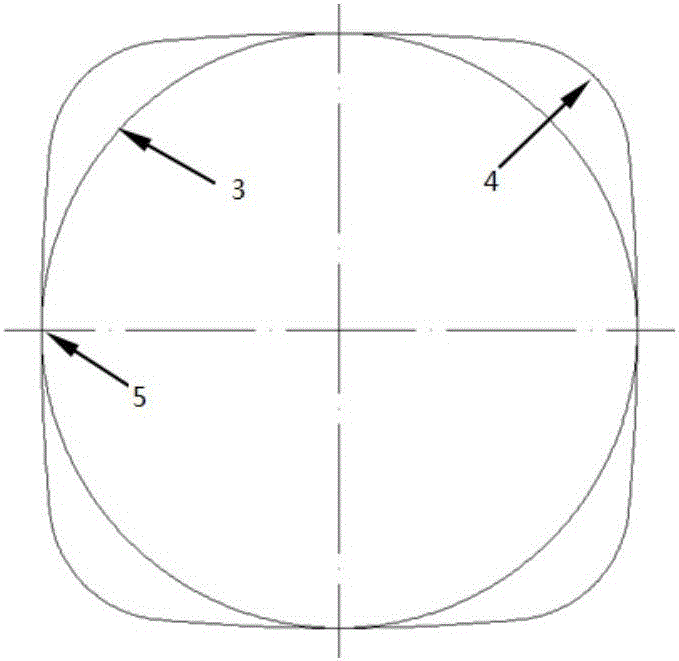

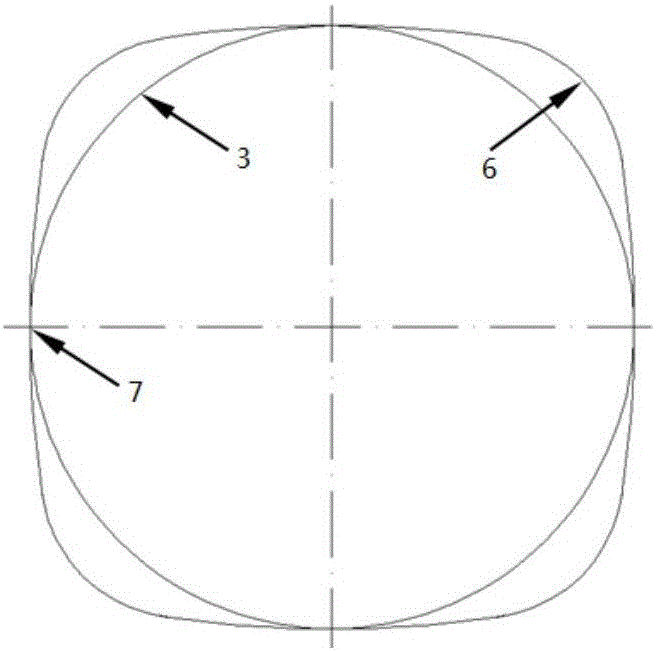

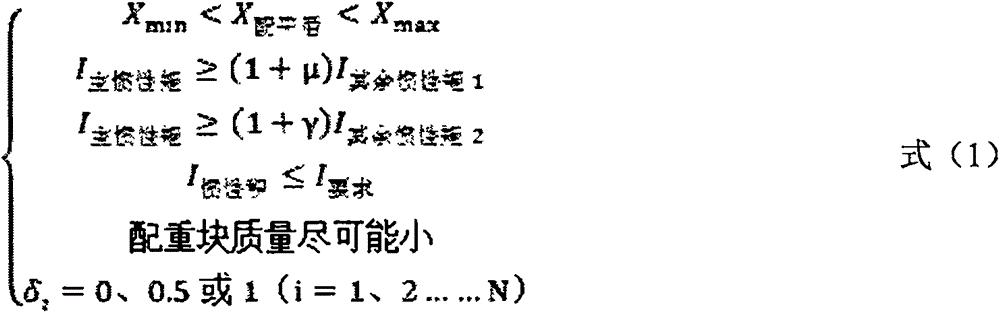

Engineering discrete variable based two-variable multi-circular arc special-shaped hole balance design method and model

ActiveCN105046000AQuality improvementSmall scaleSpecial data processing applicationsCircular discAviation

The present invention discloses an engineering discrete variable based two-variable multi-circular arc special-shaped hole balance design method and model. The method comprises: firstly, establishing a standard alternative pool for each design variable according to arc radius standard series defined by international standards, to store arc radius standard values; secondly, performing rounding on original continuous variables by using a self-defined conversion function; thirdly, performing control on design space of discrete variable combination by using a boundary verification module, and performing deletion on cross-boundary parameters; and finally, performing optimization iteration, and before optimization, performing sequential numbering on discrete design points by size. In the optimization iteration, when a new design point is selected, a new design point number is selected through number calculation, and then a new design point is determined according to a mapping relationship between the numbers of the discrete design points and actual design points. According to the method, the two-variable special-shaped hole profile design radius meets an industrial manufacturing standard, and the design of a connecting unit of a high-pressure turbine plate of an aircraft engine meets an equal-strength principle, thereby improving design efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

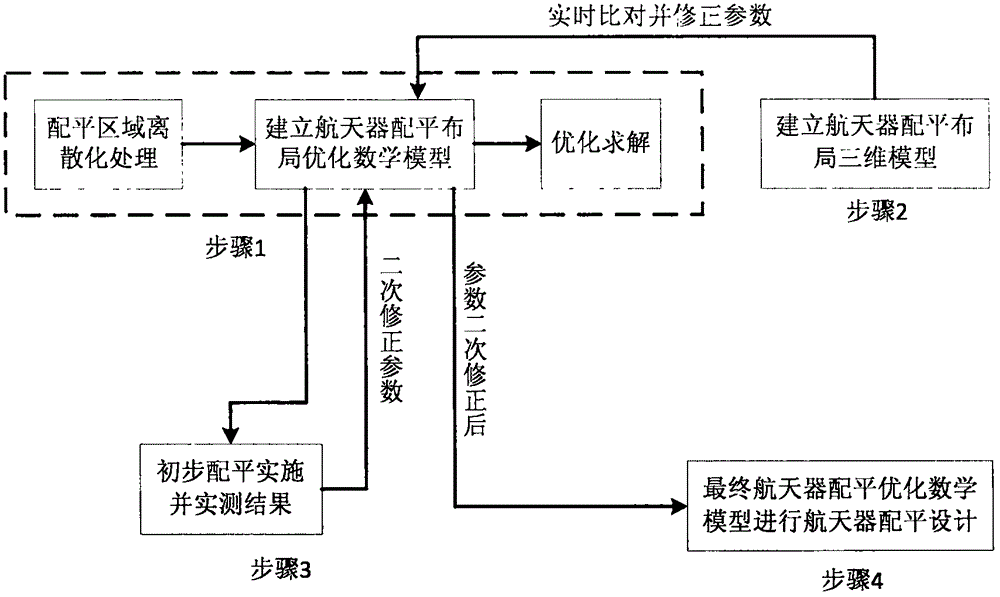

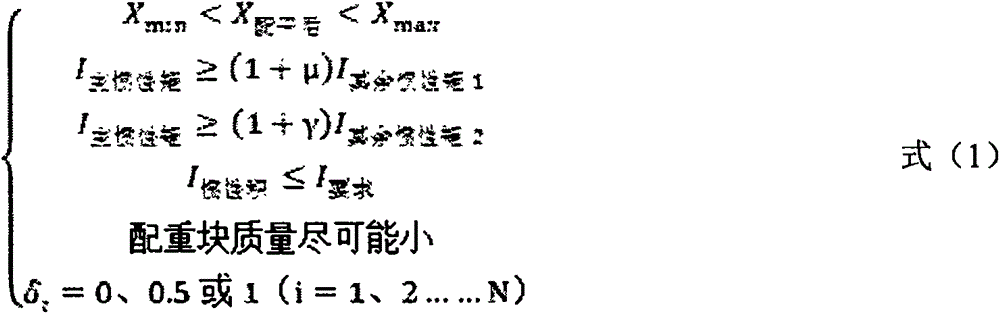

Spacecraft quality characteristic balancing method

InactiveCN106503322AImproved mass characteristic trim solution speedGeometric CADSpecial data processing applicationsMathematical modelMulti platform

The invention provides a spacecraft quality characteristic balancing method. The method comprises the following steps that discretization treatment is performed on a balancing region, a spacecraft balancing layout optimization mathematical model is built, and an optimization algorithm is used for performing preliminary design of a balancing scheme; a spacecraft cabin balancing layout three-dimensional model is constructed, computed results of two balancing design schemes of the optimization mathematical model and the three-dimensional model are compared in real time, a multi-software multi-platform calibrates and corrects parameters of the optimization mathematical model in real time; on the basis of the quality characteristic obtained before balancing of the aircraft, the corrected optimization mathematical model is used for performing preliminary balancing design work on the spacecraft, then, balancing is performed, and actual measurement of the quality characteristic is performed; according to the actual measurement value, some parameters of the optimization mathematical model are secondarily corrected; the optimization mathematical model obtained after secondary parameter correction is used for performing the quality characteristic balancing design work on the spacecraft. The method can rapidly provide optimized balancing weight selection and installation schemes and meet the requirement for the high-precision quality characteristic of the spacecraft.

Owner:BEIJING SPACE TECH RES & TEST CENT

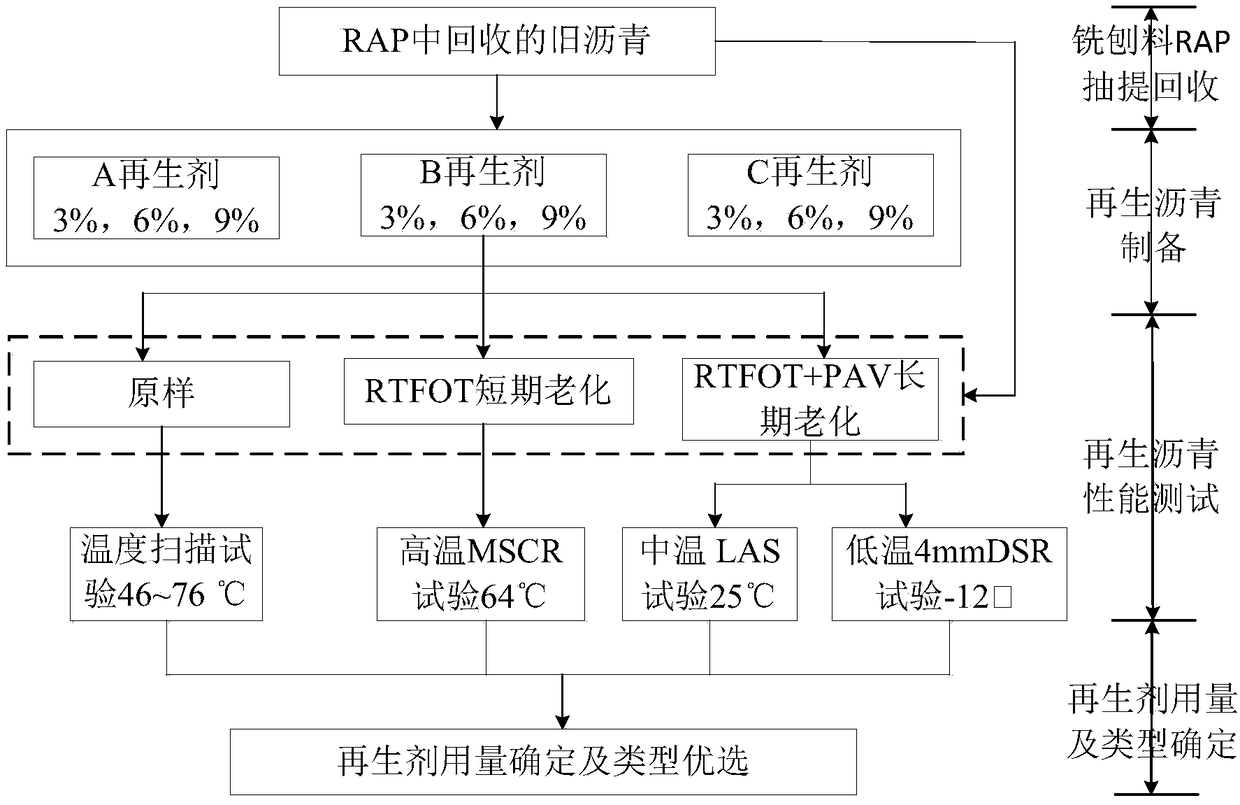

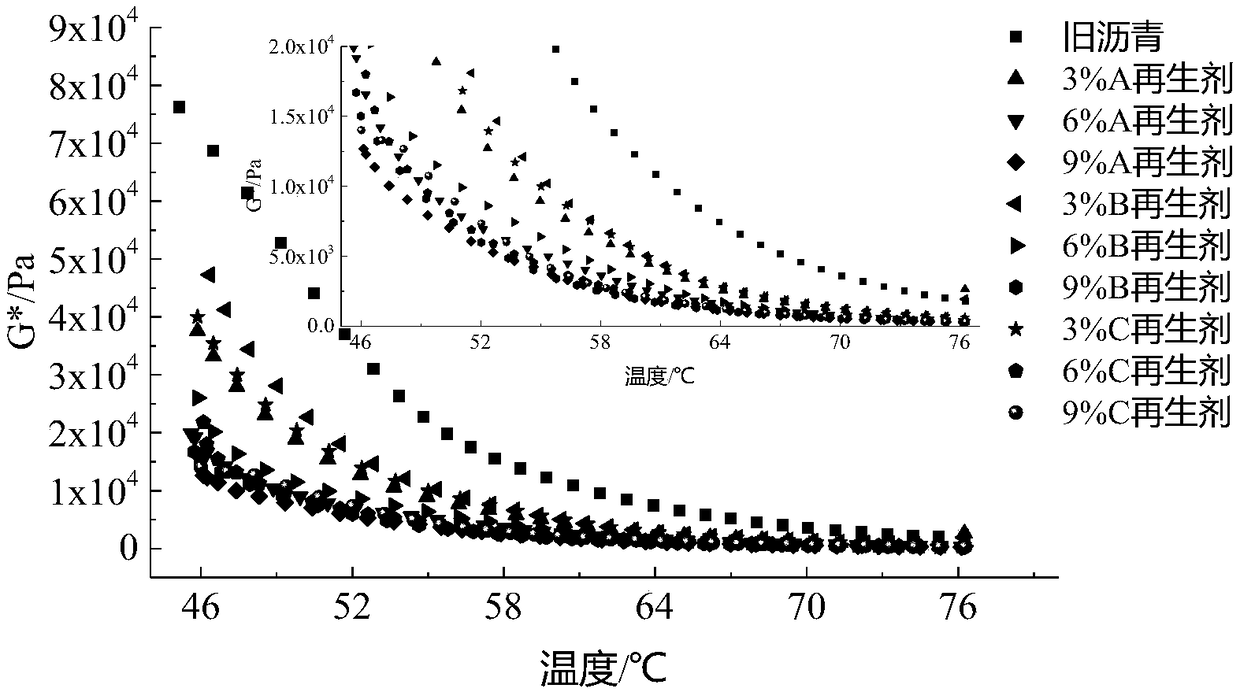

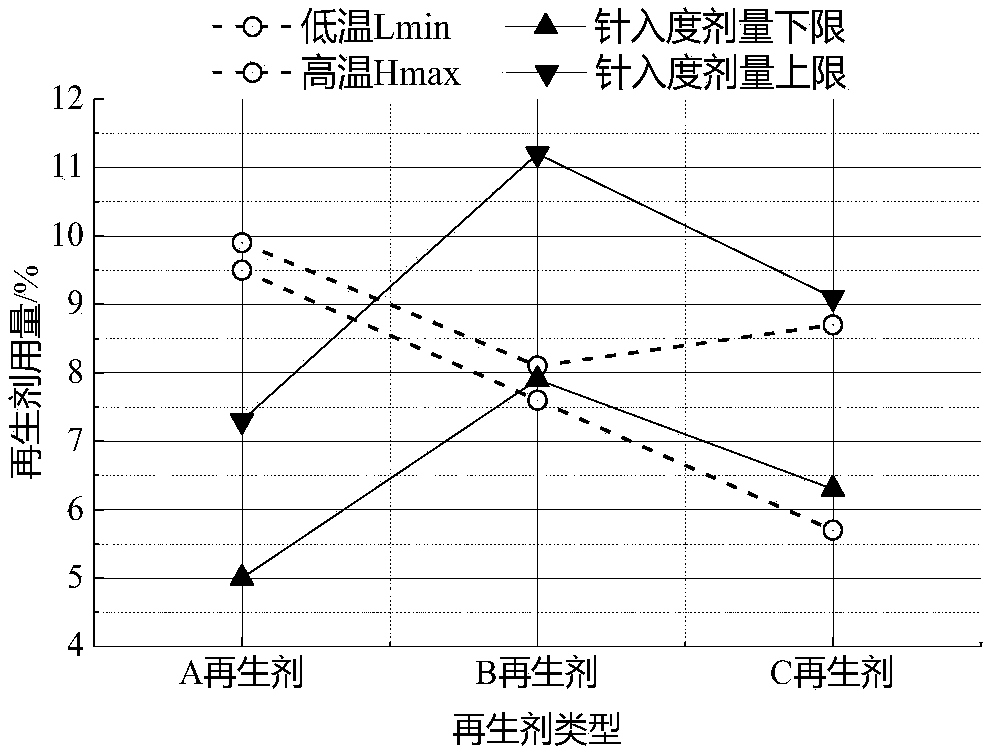

Asphalt regenerant consumption determining method based on rheological performance balance design

InactiveCN109142694AImprove permeabilityImprove diffusivityMaterial testing goodsShear modulusRelaxation modulus

The invention discloses an asphalt regenerant consumption determining method based on rheological performance balance design. The method includes steps: 1), recycling used asphalt from a milling and planing material RAP; 2), preparing regenerated asphalt samples for different regenerant consumptions; 3), testing composite shear modulus G*, high-temperature unrecoverable creep compliance Jnr-3.2, fatigue failure life Nf, low-temperature relaxation modulus G (t) and relaxation rate mr (t); 4), determining optimal regenerant consumption and type. Through the above mode, optimal regenerant consumption and type can be determined during used asphalt regeneration by starting from rheological performance reflecting regenerated asphalt material nature to enable pavement performance of a regeneratedasphalt mixture to meet requirements.

Owner:CHANGAN UNIV

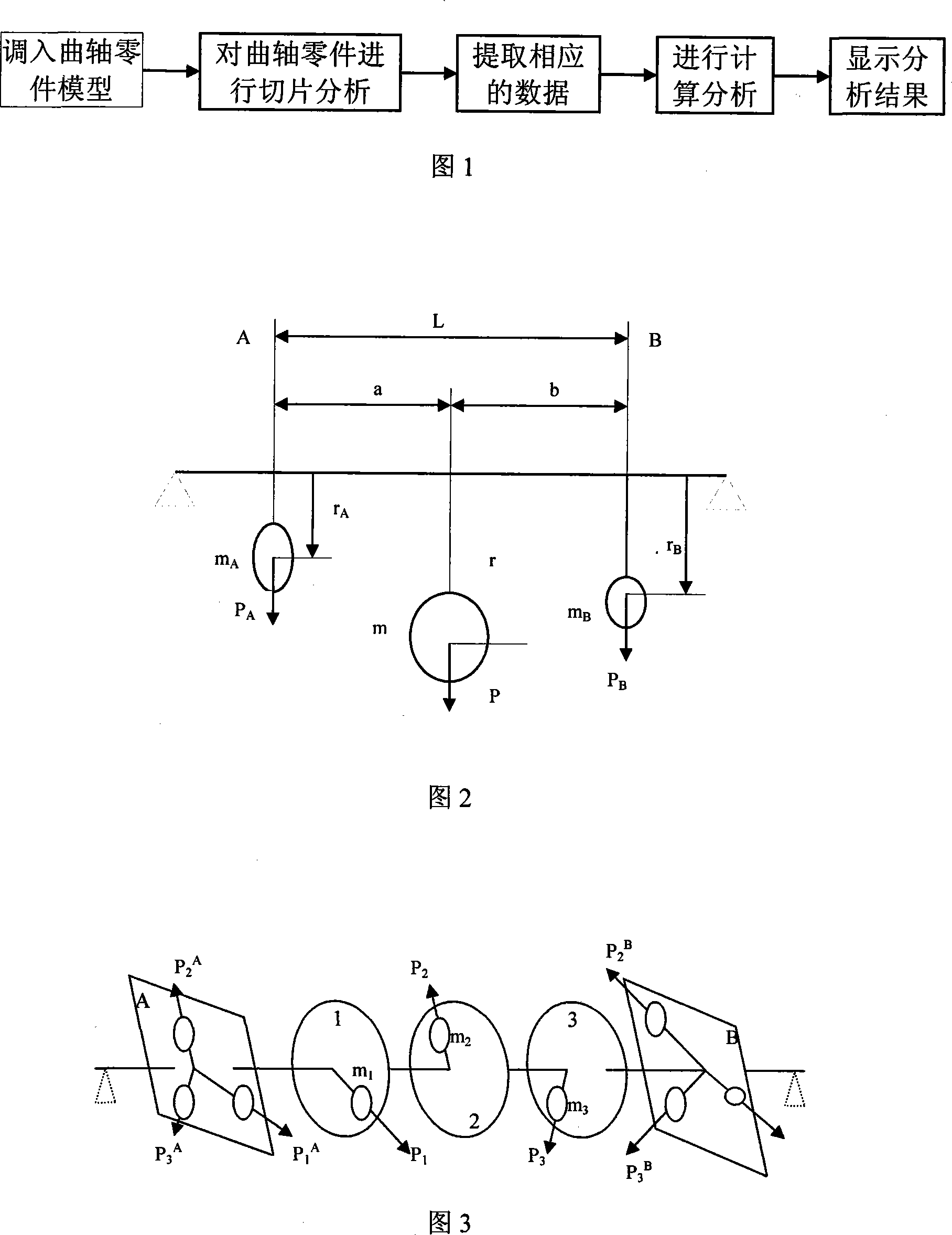

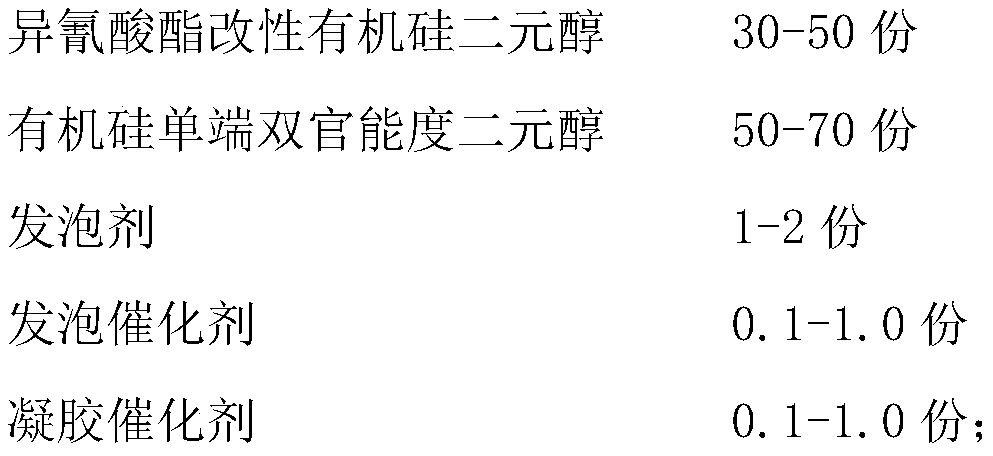

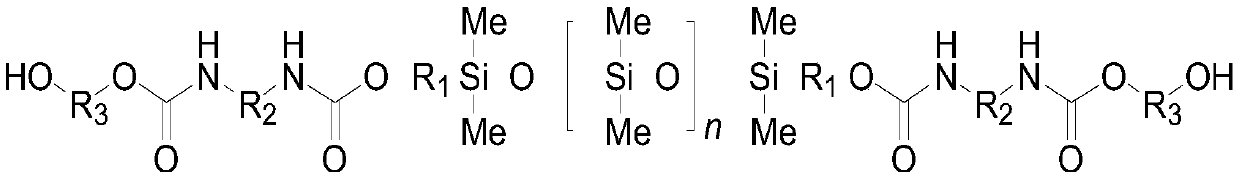

Crankshaft dynamic balance design method

InactiveCN101110093AEasy to modifyAvoid test workSpecial data processing applicationsDynamic balanceComputer science

The invention discloses a design method for dynamic balance of crankshaft, which is characterized in that: conduct slicing analysis on a model of crankshaft model, that is, segment the model of crankshaft component for limited times to a plurality of slices and then extract corresponding data of the crankshaft component model; compare the data with the preset data to judge whether the dynamic balance of the crankshaft component model is within the scope of production requirements. This method, with convenient operation, accurate and fast calculation and analysis, is able to conduct the analysis on the dynamic balance of the modeled crankshaft component and reflect in time the status of component dynamic balance, so that the design personnel are able to modify the crankshaft design in time to reach the required dynamic balance and completely prevent the testing of finished products via a dynamic balance machine. Therefore, compared with conventional method, this method not only enhances the calculation precision but also saves much investment and materials.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

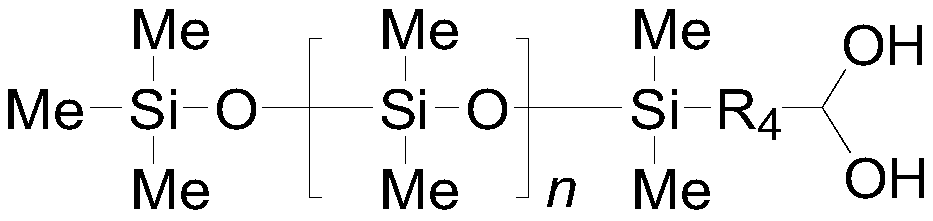

Solvent-free polyurethane intermediate layer resin of super-soft synthetic leather and preparation method of solvent-free polyurethane intermediate layer resin

The invention provides solvent-free polyurethane intermediate layer resin of super-soft synthetic leather and a preparation method of the solvent-free polyurethane intermediate layer resin. The solvent-free polyurethane intermediate layer resin is prepared from a component A and a component B which are in the proportion of 100:25-100:105, wherein the component A is prepared from cyanate modified organosilicone diol, organosilicon single-end double-function diol, a foaming agent, a foaming catalyst and a gel catalyst, and the component B is prepared from isocyanate, organosilicon polyether dioland organosilicon diamine. The balance design of super softness and good mechanical properties of the resin is achieved by reducing the degree of phase separation between the soft segment and the hard segment in the molecular structure and combining with the excellent mechanical properties of organic silicon, and the softness of the material is remarkably improved.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

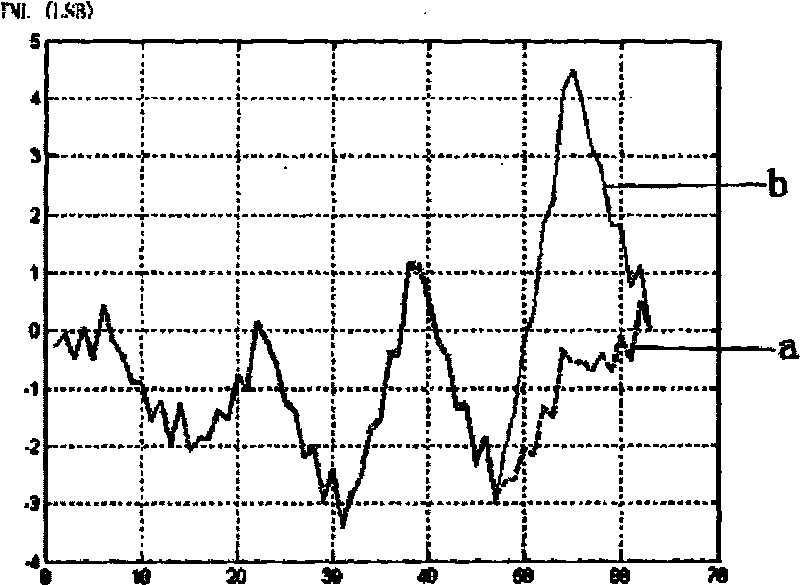

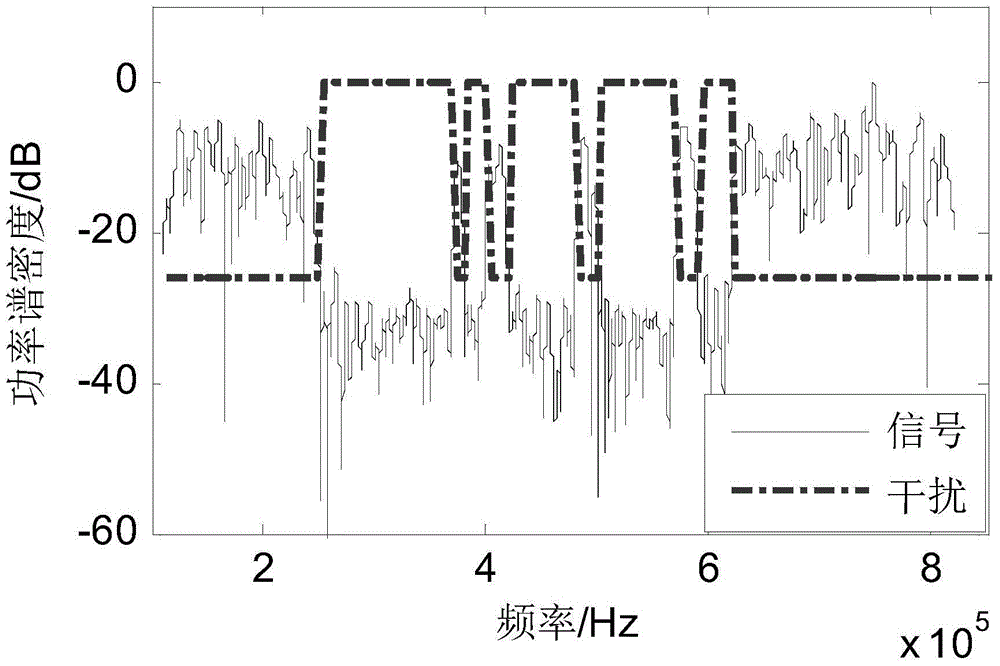

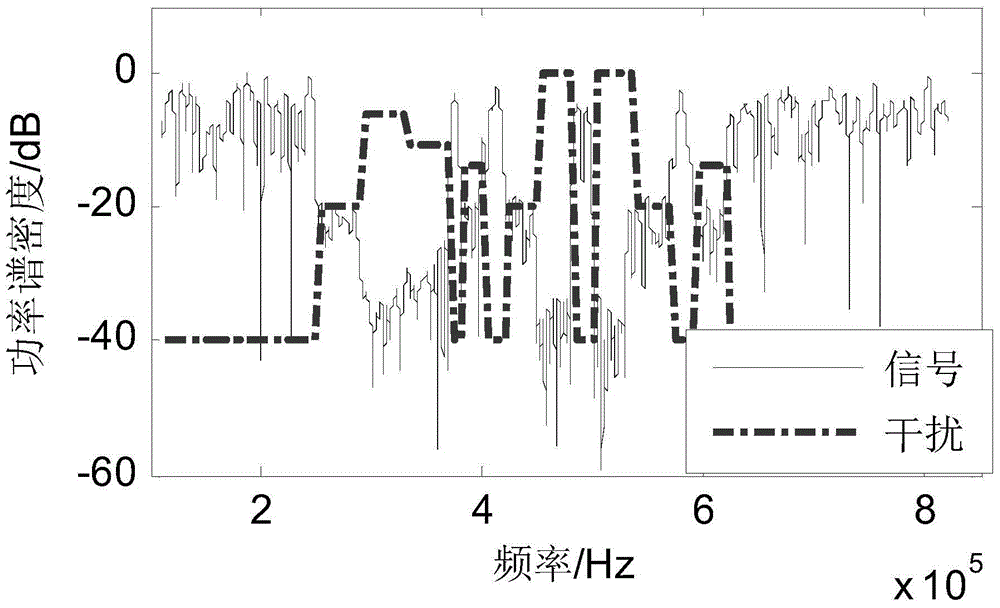

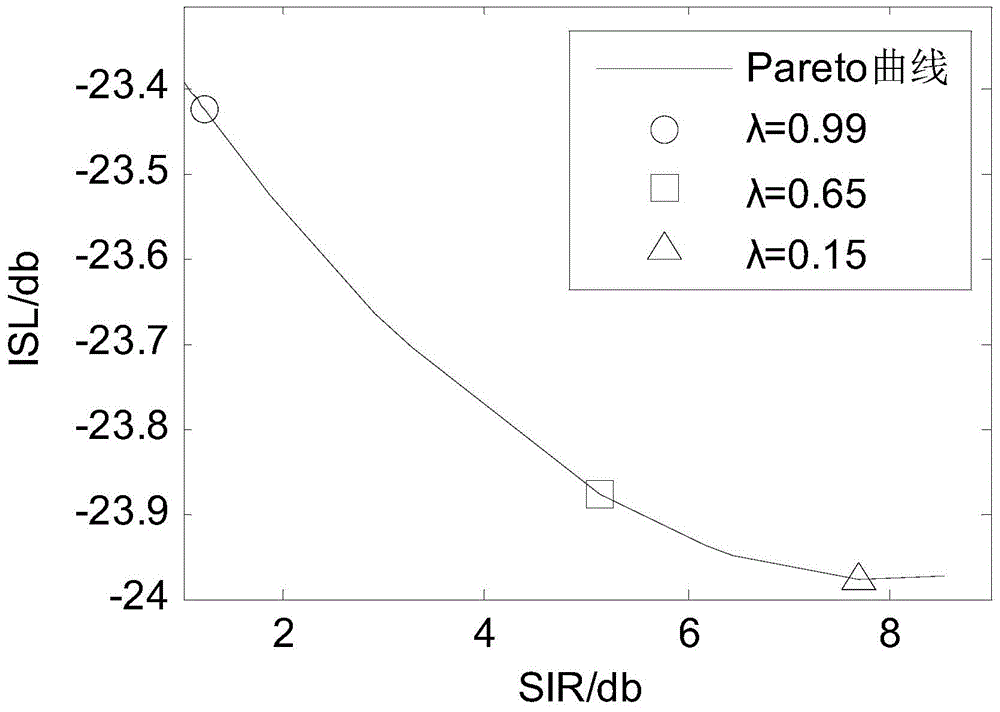

Method for designing continuous phase-modulation signal of non-continuous spectrum

ActiveCN105137422AImprove real-time performanceImprove signal to interference ratioRadio wave reradiation/reflectionHorizontal axisEngineering

The invention relates to a method for designing a signal, specifically to a method for designing a continuous phase-modulation signal of a non-continuous spectrum, and aims to solve the problem in an existing waveform design method that details of each frequency point of each pass band and stop band are not considered, so sufficient matching with changeable interference environment cannot be realized in signal design and the problem that balance design of a proportion of a signal to interference ratio to a sidelobe index is not flexible enough in a design process. The method firstly directs at a signal design general objective function P<Total>=[lambda]x<H>kx+(1-lambda)(2N-x<H>b-b<H>x), then utilizes a gradient iteration method to obtain a waveform optimal solution; then weight lambda is traversed from 1 to 0, a series of values of the signal to interference ratio and the sidelobe are obtained, one of the indexes are used as a horizontal axis, the other index is used as a longitudinal axis, and a curve that is obtained is a Pareto optimal curve; and the Pareto optimal curve is used as a tool for assisting selection an optimal balance between objective functions in multi-objective optimization to design the continuous phase-modulation signal of the non-continuous spectrum. The method provided by the invention is suitable for design of the continuous phase-modulation signal of the non-continuous spectrum.

Owner:HARBIN INST OF TECH

Differential common collector amplifying circuit

InactiveCN101232273AStrong interference abilityHigh input resistanceAmplifier modifications to reduce non-linear distortionPower amplifiersCommon collectorLow input

The invention relates to a difference common collector amplifying circuit which is a device of an amplifying signal current for decreasing the distortion factor of a power amplification circuit. At present, a well-known current amplifying circuit of a station amplifier generally adopts an OCL circuit, in which the utility ratio of a power supply is higher, the direct coupling is realized, the circuit is simple and the power is big, but the performance of common-mode interference resistance of the circuit is reduced because non-equilibrium design is adopted, and the distortion is larger. Based on a traditional monotube common collector amplifying circuit, the difference common collector amplifying circuit introduces a difference structure, and a fully symmetrical and balanceable circuit structure is used for resisting the common-mode interference. The invention can be mainly used in the fields of low-frequency signal current amplification, aural signal current amplification, amplifier impedance match, an amplifier high input impedance input circuit, an amplifier low input impedance output circuit, single end-balanced signal transformation, etc.

Owner:黄骐

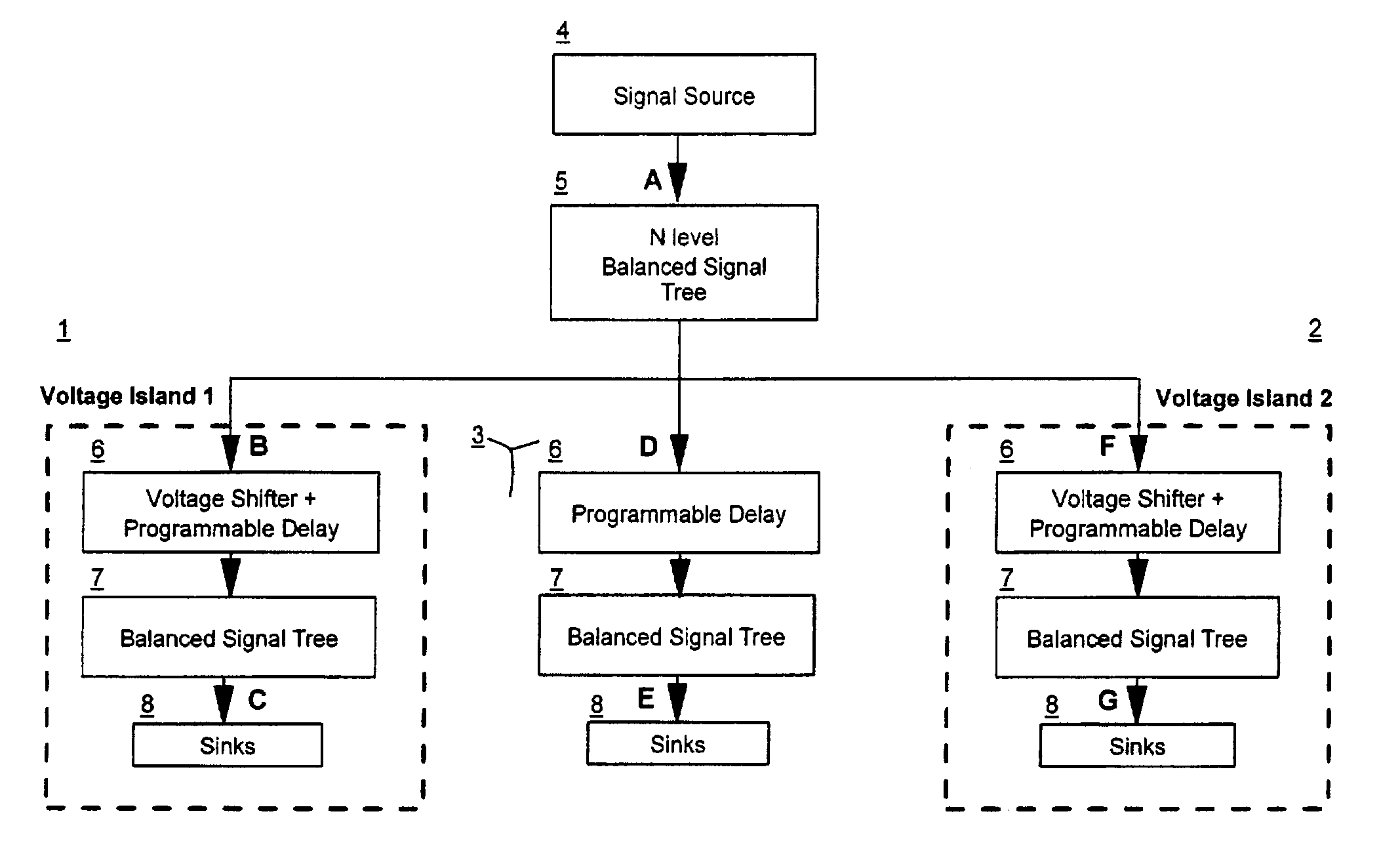

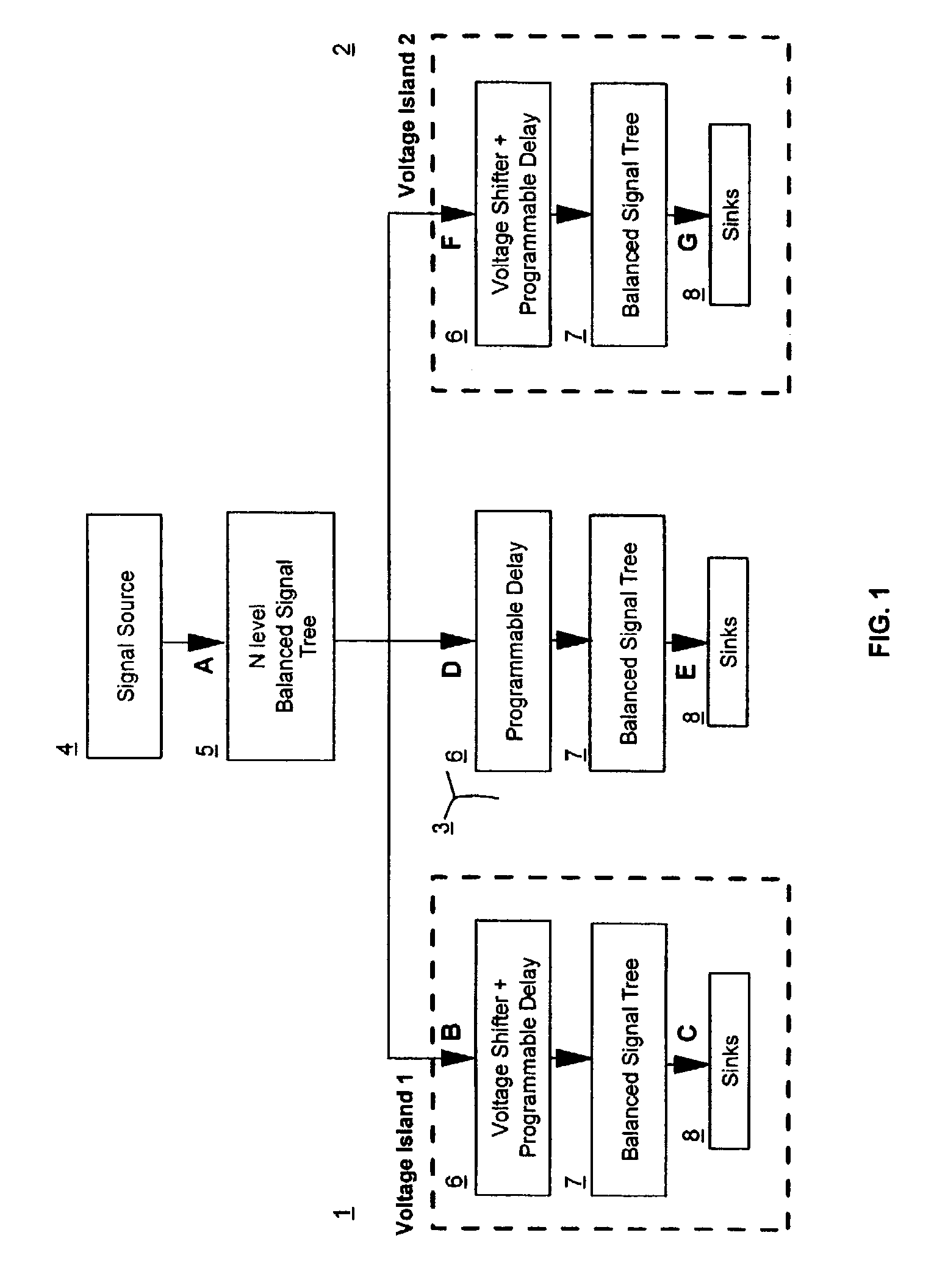

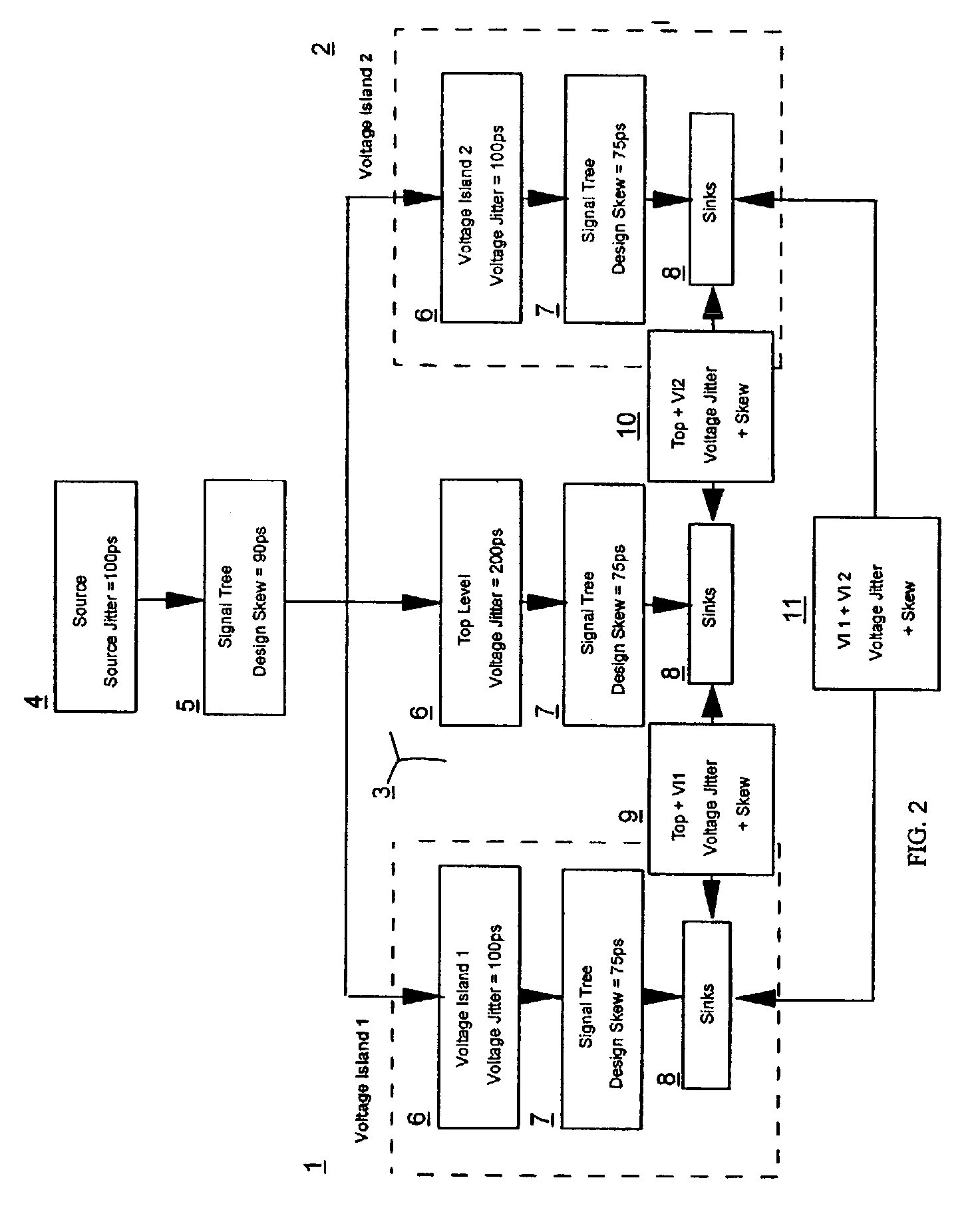

Signal balancing between voltage domains

InactiveUS6986116B2Solid-state devicesSemiconductor/solid-state device manufacturingVoltage generatorEngineering

A method for balancing signals across an IC design having multiple voltage domains. The method uses a voltage tress to balance the signals at the top level above the voltage domains. Then using worst case and best case signal latencies determines the average latency in each voltage domain. Then balancing signals at the other levels of the design by incrementing the latencies in each domain until a target level based on the slowest average latency is reached.

Owner:MARVELL ASIA PTE LTD

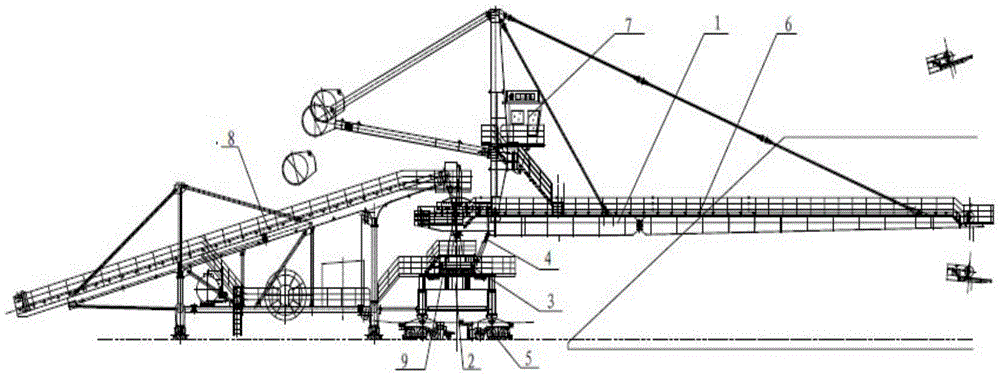

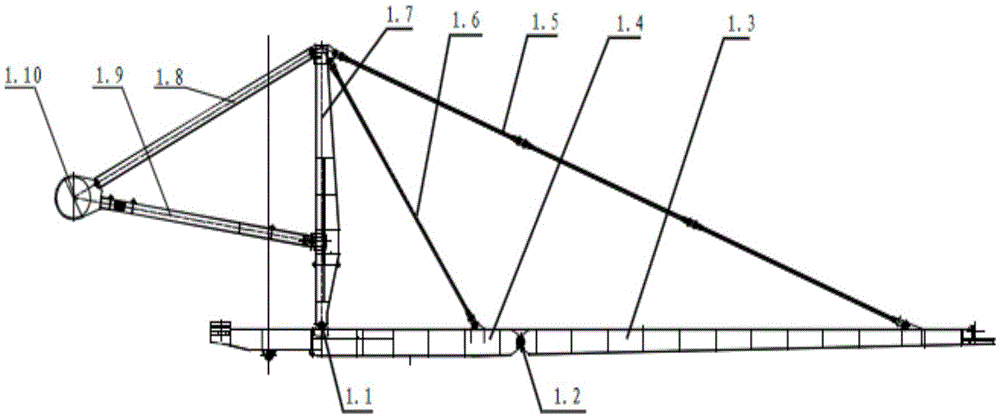

Hinged column type double-pull-rod cantilever stacker

InactiveCN105417196AReduce weightReduce the weight of the counterweightLoading/unloadingCantilevered beamSupporting system

The invention discloses a hinged column type double-pull-rod cantilever stacker. The hinged column type double-pull-rod cantilever stacker comprises an upper steel structure, a portal base frame, a rotation device, a pitching device, a traveling device, a belt conveyor system, a cab device, a tail-car device and a material transferring device. The upper steel structure comprises a vertical column, a balance weight pull rod, a balance weight arm, a balance weight, a cantilever beam and cantilever pull rods, wherein the vertical column is vertically hinged to the front end of the cantilever beam through a hinged shaft I; one ends of the cantilever pull rods are fixed to the cantilever beam, the other ends of the cantilever pull rods are fixed to the vertical column, and a cable-stayed structure composed of the vertical column, the cantilever beam and the cantilever pull rods is formed; the balance weight is supported and fixed to the lateral face, opposite to the extending direction of the cantilever beam, of the vertical column through the balance weight pull rod and the balance weight arm, and the balance weight pull rod, the balance weight arm and the vertical column jointly form a triangular supporting system. By the adoption of the technical scheme, the bottom of the vertical column has no bending moment through the hinged arrangement of the vertical column and the balance design of a balance weight mechanism and a cantilever beam fixing mechanism, and the safety of the whole steel structure is improved at the same time.

Owner:大连华锐重工冶金设备制造有限公司 +1

Computer belt cutting machine

InactiveCN105364955ASimple structureReduce functionMetal working apparatusWebs handlingCamKnife blades

The invention discloses a computer belt cutting machine. The machine is particularly used for feeding method improving. According to the requirement of the angle of a cutting material, the inclination position of a feeding device is adjusted to carry out inclination cutting. Through the improvement of balance design of a cutter rest and a cutter rest eccentric cam, an upper blade and a lower blade can be made wider, and the purpose is wider.

Owner:PUTIAN JIANQIANG SEWING EQUIP CO LTD

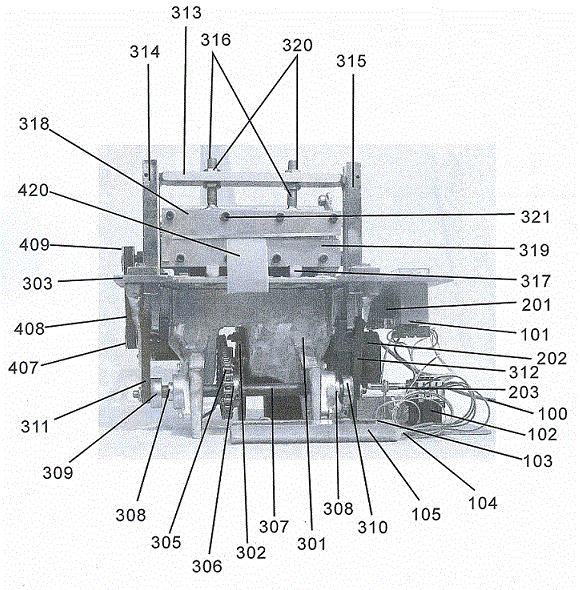

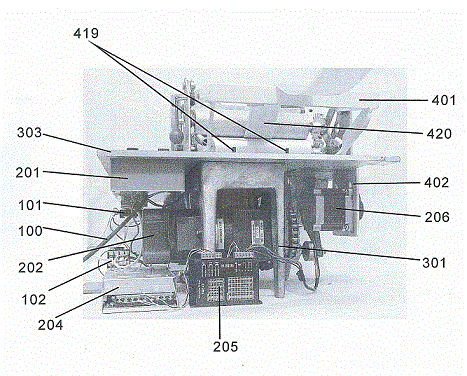

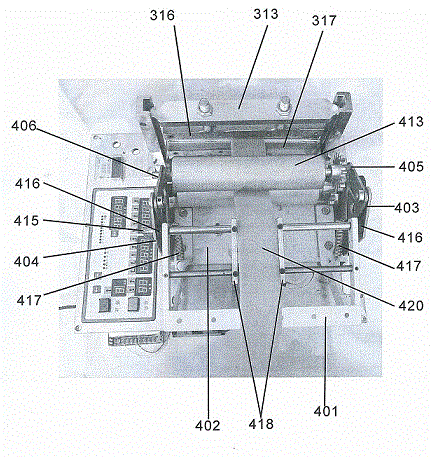

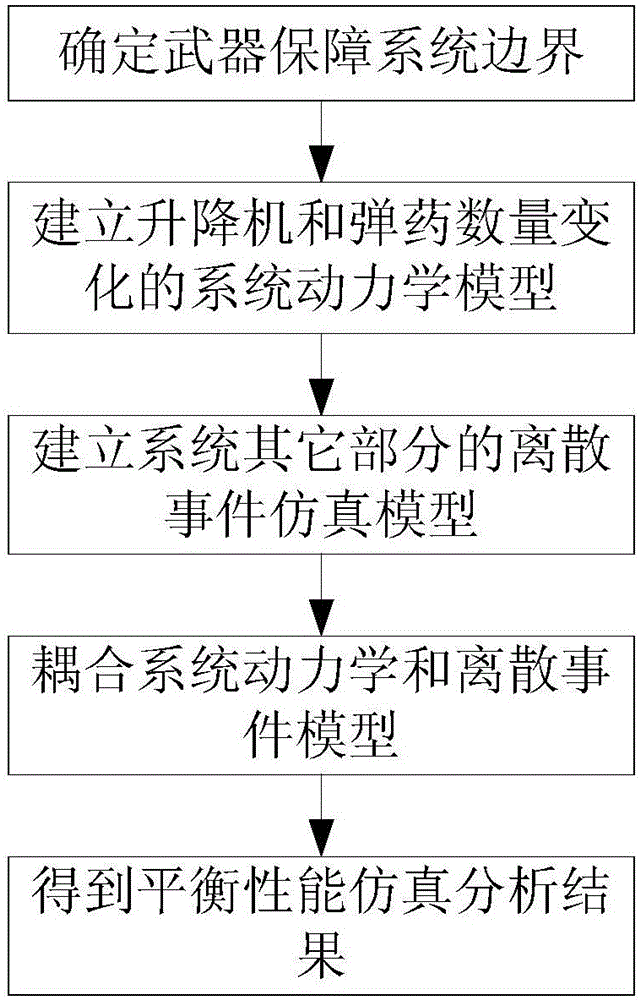

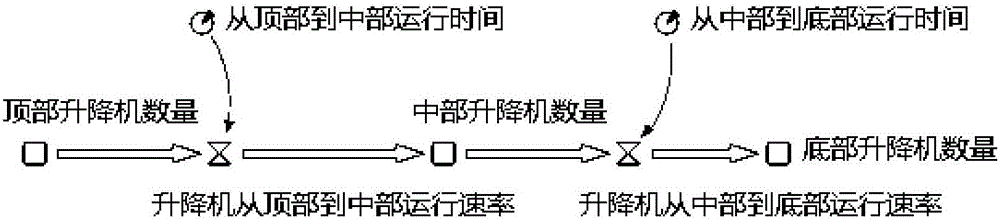

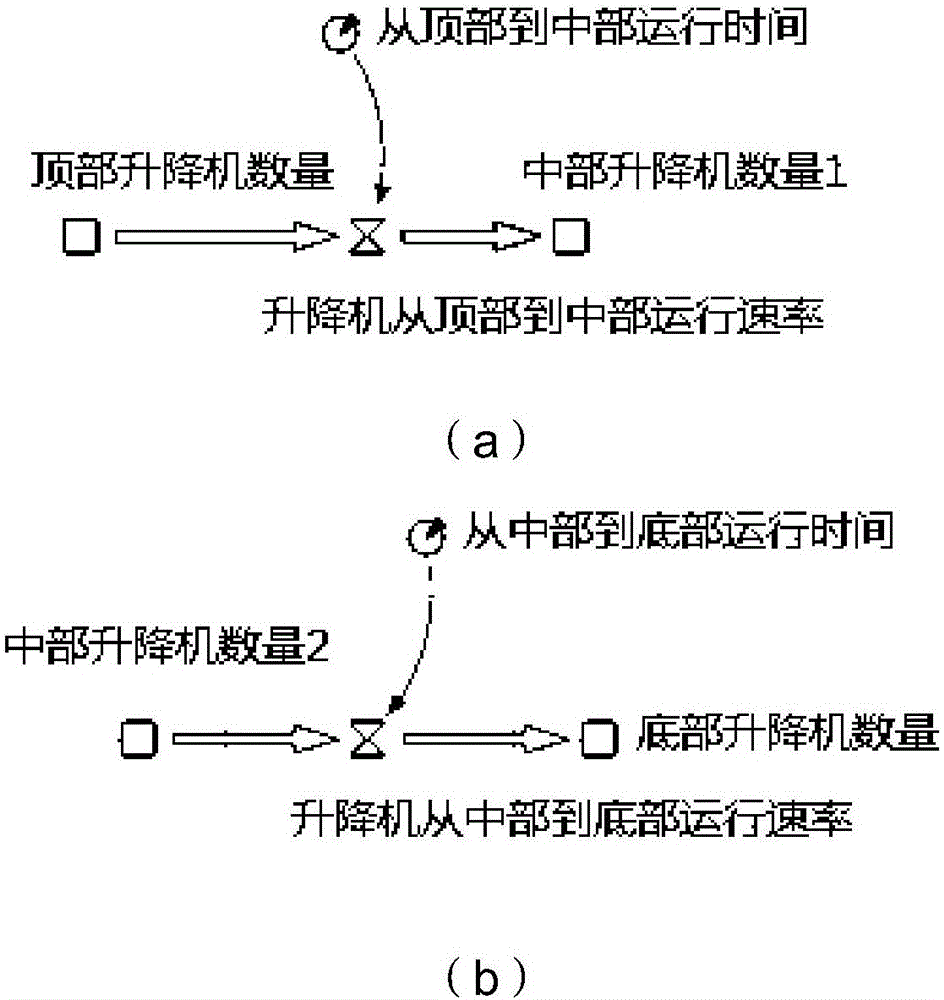

System-dynamics-based balance design method for weapon support system

ActiveCN105824999AImprove transport efficiencyMeet consumptionSpecial data processing applicationsResource utilizationEvent model

A system-dynamics-based balance design method for a weapon support system comprises the following steps: firstly, determining the boundary of the weapon support system, and making clear that system dynamics is used for modeling of a lift and the change of ammunition quantity and discrete event simulation is used for modeling of other parts in the system; then building a system dynamics model of the lift and the change of ammunition quantity, and building a discrete event simulation model of other parts of the system; coupling the system dynamics model and the discrete event model to obtain an integral model of the weapon support system; finally, performing simulation analysis based on the obtained integral model to obtain a balance performance simulation result and to identify probable unbalance points in the weapon support system. The system-dynamics-based balance design method can analyze transport of ammunition and assembly resource utilization ratio in the system, find out bottleneck and unbalanced links in the process and improve the resource utilization efficiency of the system.

Owner:CSSC SYST ENG RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com