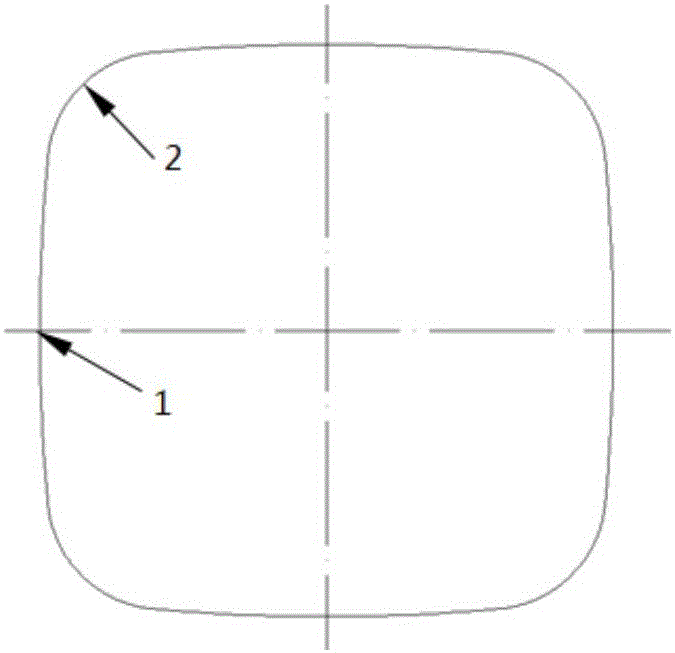

Engineering discrete variable based two-variable multi-circular arc special-shaped hole balance design method and model

A discrete variable, balanced design technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as the optimal radius size does not meet the processing standards, the contour of the special-shaped hole is too large, and it is difficult to obtain stable design points. , to achieve the effect of suppressing excessive dependence on the value boundary of variables, reducing the total amount of computation, and improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in combination with specific embodiments.

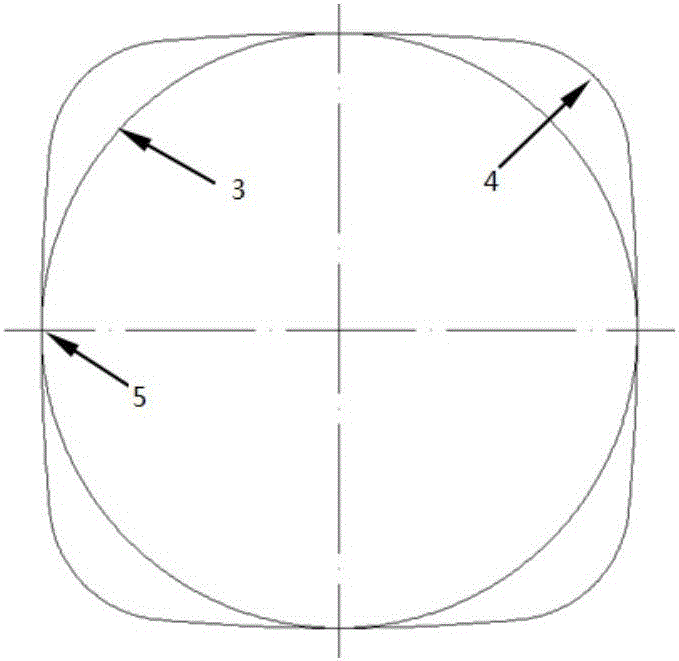

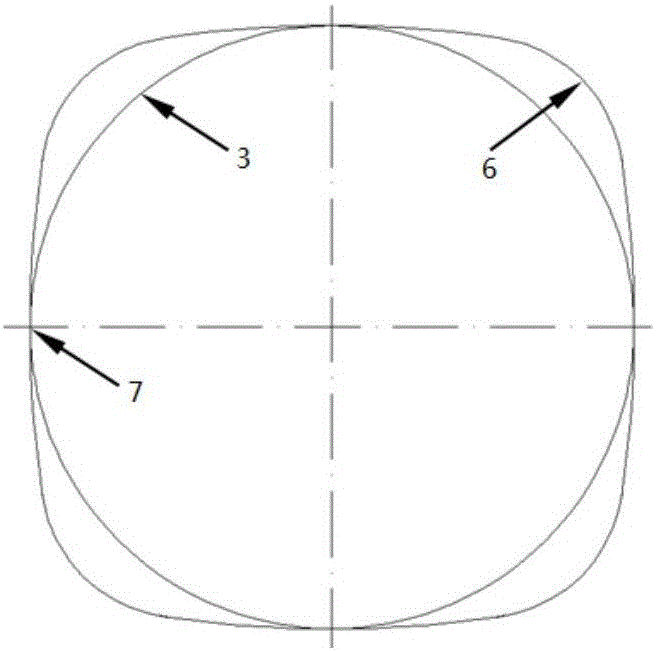

[0043] 1. Implementation method of discretization of design variables

[0044] 1) Discretization of the initial population: firstly, according to the arc radius standard series stipulated by the national standard, a standard candidate pool for each design variable is established to store the standard value of the arc radius; Variables are rounded. The principle is: the standard value of the arc radius series that is greater than the initial value and closest to it. It is guaranteed that each design variable sample is a discrete value randomly generated in the radius standard sequence pool.

[0045] The mathematical model of the custom conversion function is:

[0046] x t =min{X s |X s ≥X i}

[0047] Among them, X t Indicates the discrete design variable value after rounding, X s Indicates the standard value in the standard candidate pool, X i Represents a randoml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com