Balance control method of multi-objective disassembly line

A control method and multi-objective technology, applied in the field of flexible production line design and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

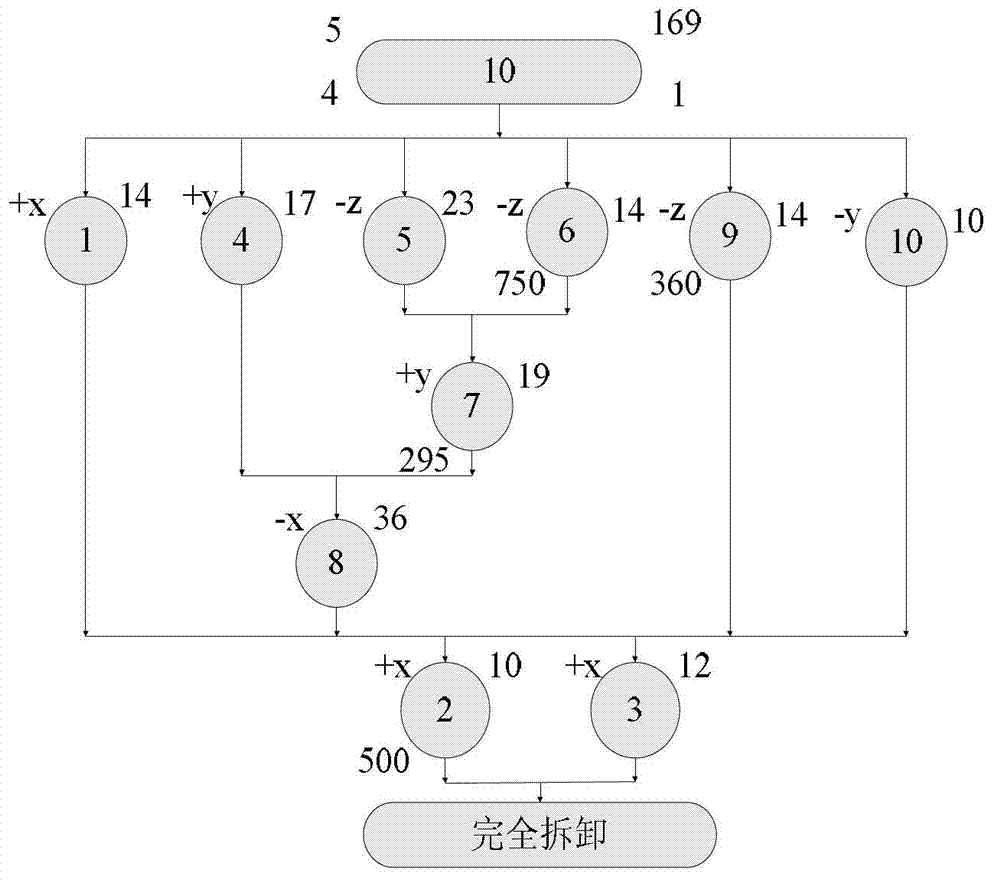

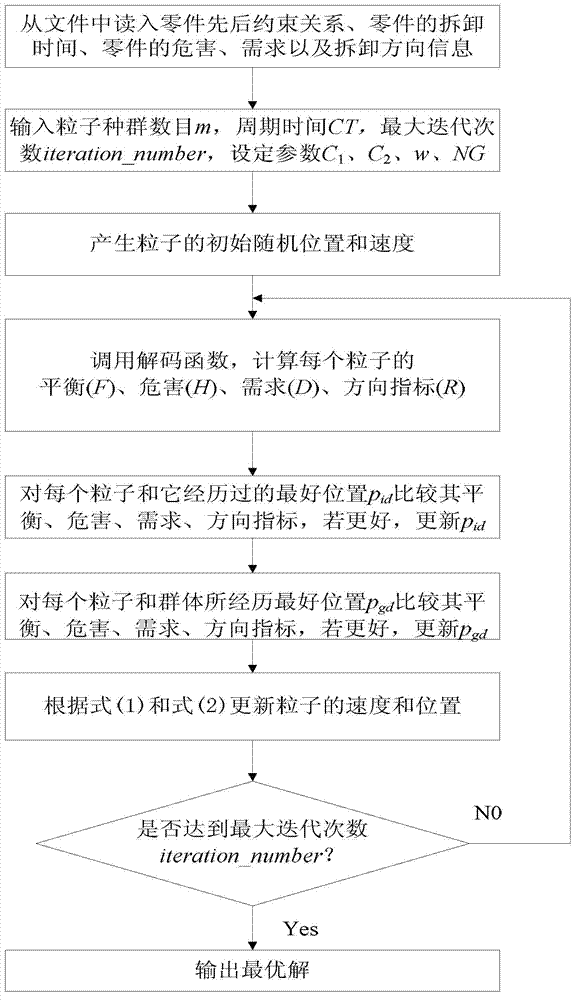

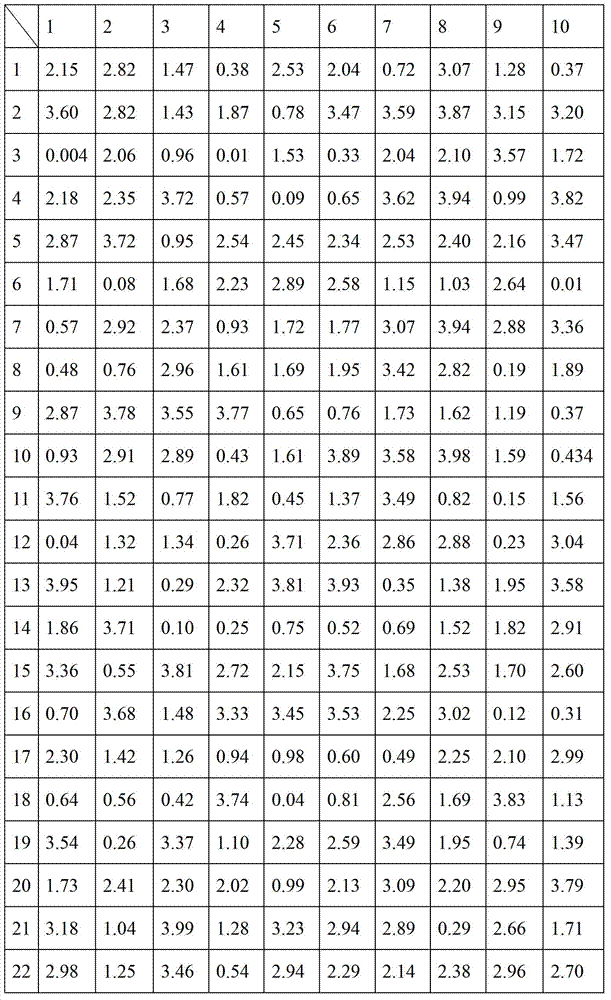

[0074] The invention adopts MATLAB to realize the proposed novel algorithm as an executable program. A test problem is verified. There are 10 tasks in this problem. The task sequence constraint relationship is as follows: figure 1 As shown, the number inside the circle indicates the task number, the upper left corner outside the circle indicates the disassembly direction of the part, the lower left corner indicates the demand for the part, the upper right corner indicates the disassembly time of the part, and the lower right corner indicates the hazard attribute of the part. Set the number of particles to 30, the takt time to 40, the maximum number of iterations to 30, and set the parameter w of the algorithm max =0.9, w min =0.4, C 1 =2,C 2 =2, NG=20, when the program solves the calculation example, it first reads the part sequence constraint relationship of the tested problem, the part disassembly time, hazard, demand and disassembly direction information from the noteboo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com