High-cycle fatigue test method for blisk

An integral blisk and high-cycle fatigue technology, which is applied in the testing of machine/structural components, vibration testing, and testing of material strength by applying repetitive force/pulsation force, etc., can solve the difference between the boundary conditions of the blade test and the boundary conditions of the use environment Far, blisk damage, test data impact and other problems, to achieve the effect of shortening the test period, reducing the test cost, and reducing the error of the test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

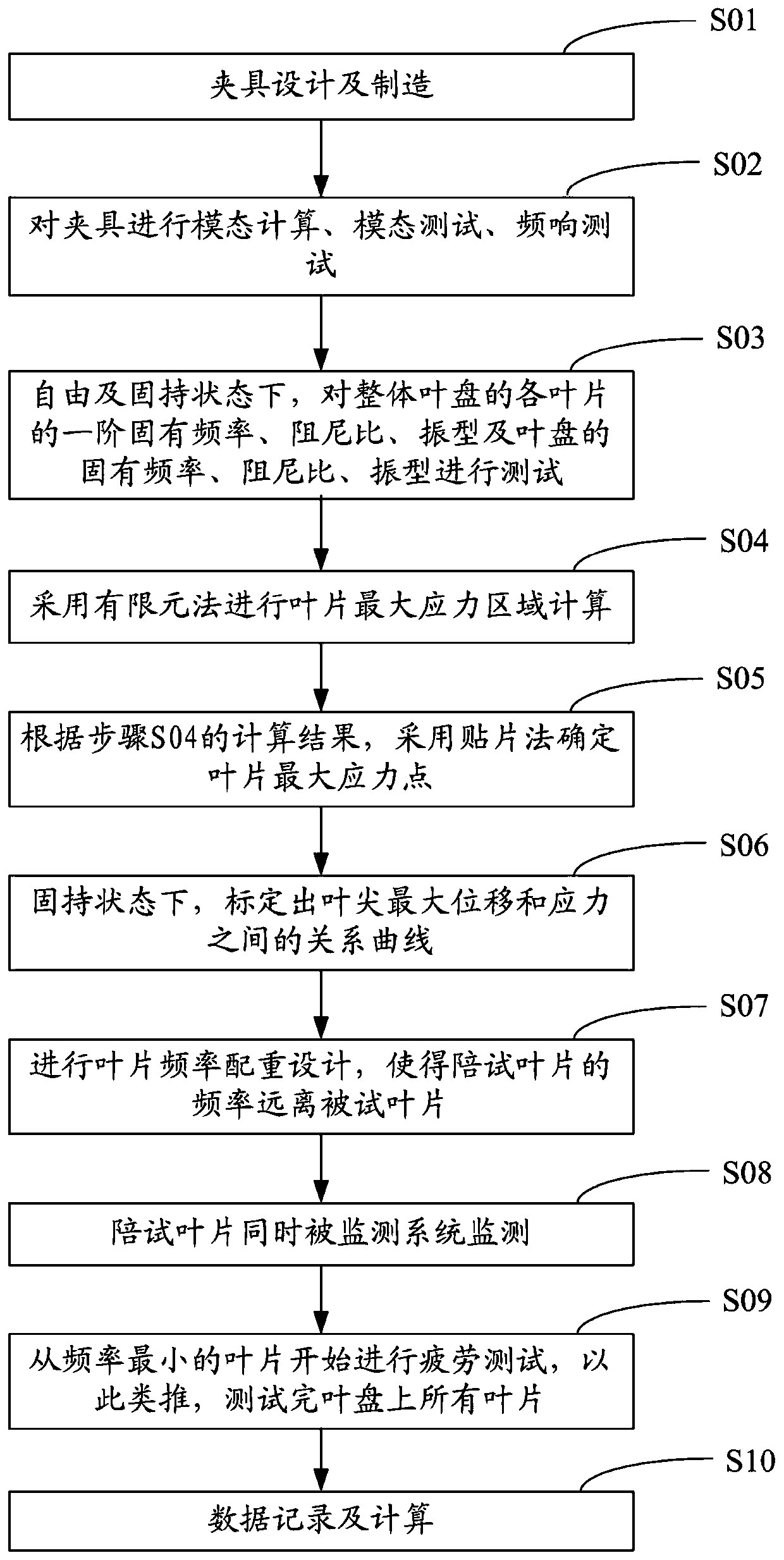

[0046] Such as figure 1 Shown, a kind of high cycle fatigue test method of blisk among the present invention, comprises the following steps:

[0047] Step S01, fixture design and manufacture.

[0048] Step S02, performing modal calculation, modal test, and frequency response test on the fixture.

[0049] The fixture is installed on the vibrating table, and the excitation force of 0.5g is used to scan the frequency from low frequency to high frequency. The first few resonance frequencies of the fixture appear in the frequency sweep results, such as figure 2 As shown, they are 1700Hz, 2000Hz, 2346Hz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com