Multifunctional field partial discharge test system

A test system and field bureau technology, applied in the direction of testing dielectric strength, etc., can solve the problems of inability to carry out partial discharge test work normally, increase the workload of field test personnel, and affect the reliability of partial discharge test data, so as to avoid sudden Situation and test interruptions, improved work efficiency, and the effect of sensitive detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

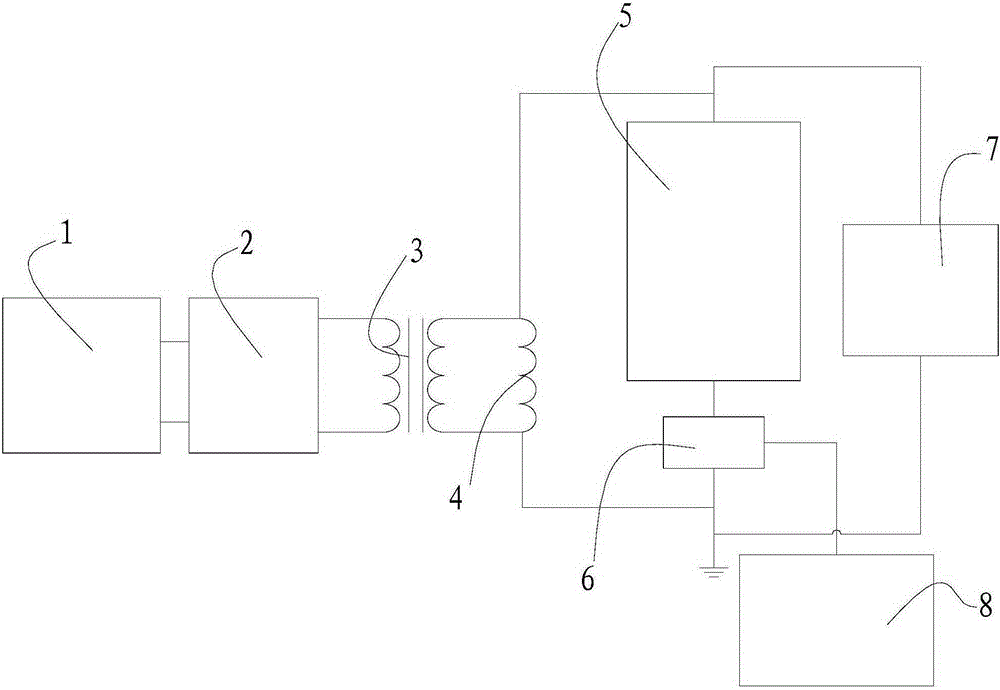

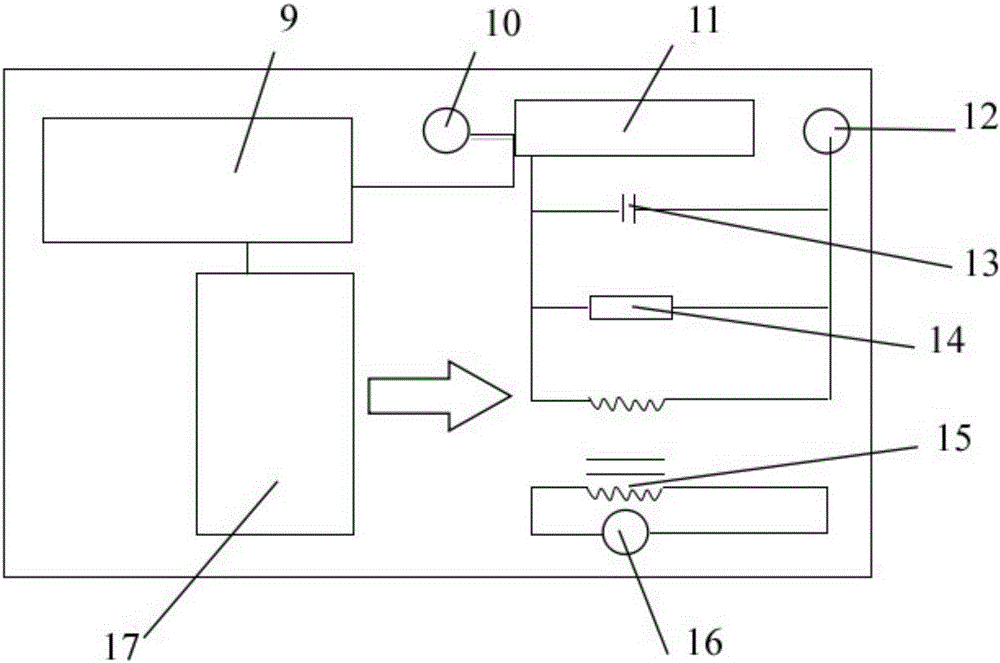

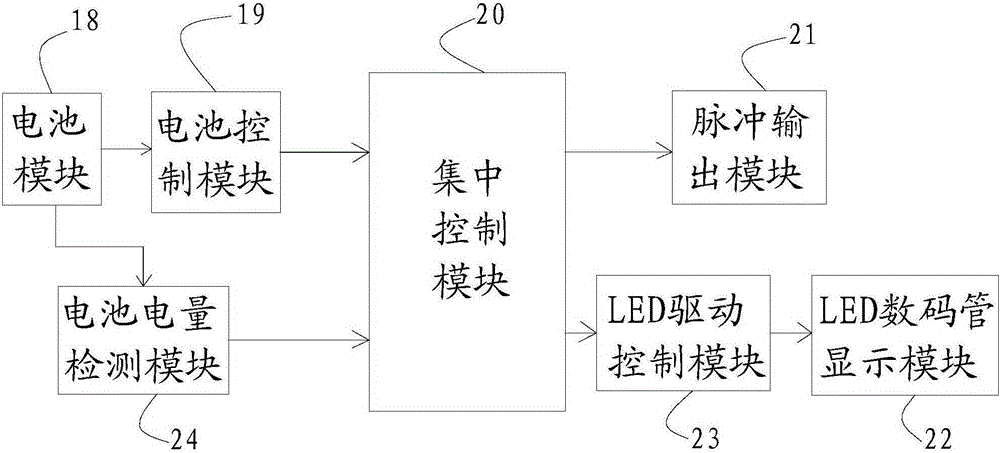

[0024] Such as Figure 1-2As shown, a multifunctional on-site partial discharge test system includes a voltage regulation controller 1, a variable frequency power supply 2, an excitation transformer 3, a reactor 4, a test object 5, a detection impedance 6, a pulse generator 7 and an electric pulse bureau. Amplifier 8, the input end of the voltage regulating controller 1 is connected to the power frequency voltage, the output end of the voltage regulating controller 1 is connected to the input end of the variable frequency power supply 2, the output end of the variable frequency power supply 2 is connected to the input end of the excitation transformer 3, and the excitation The output terminal of the transformer 3 is connected in parallel with the reactor 4, the reactor 4, the tested product 5, and the detection impedance 6 are connected in series to form a detection circuit, the end connected to the detection impedance 6 and the reactor 4 is grounded, and the pulse generator 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com