NDT test result accuracy improving method and apparatus thereof

A technology of test results and accuracy, applied in the direction of using one-time impact force to test material strength, investigation stage/state change, etc., can solve problems such as tissue coarsening range, misjudgment of steel performance, tissue growth of test piece, etc., to achieve The effect of reducing test data error and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

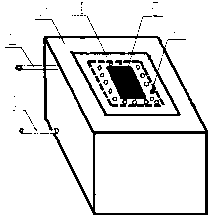

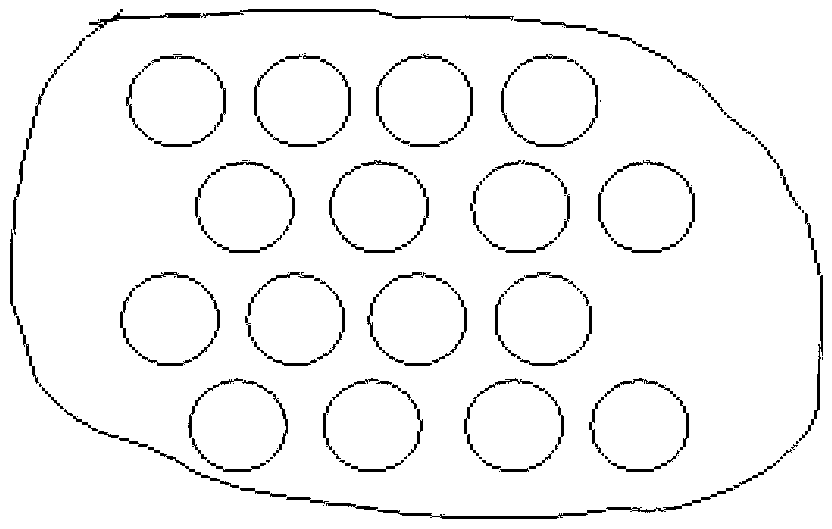

[0027] A device to improve the accuracy of NDT test results, such as figure 1 and figure 2 As shown, it includes a cooling box 3 that can pass into the circulating cooling liquid and a specimen tank 4 placed inside the cooling box 3. On the surface of the same side of the cooling box 3, a cooling liquid outlet 2 and a cooling liquid outlet 2 for the cooling liquid to enter and exit are respectively provided. The height of the liquid inlet 1 and the cooling liquid outlet 2 is higher than that of the cooling liquid inlet 1, and the height of the cooling liquid outlet 2 is flush with the upper surface of the cooling box 3. The side wall and the bottom surface of the test piece groove 4 are provided with several A circular through-hole 6 that is evenly distributed to allow cooling liquid to flow through is provided with several (two in this embodiment) ribs 7 that protrude toward the inside of the tank body on the bottom surface of the test piece tank 4 .

[0028] In this embod...

Embodiment 2

[0035] The methods and devices used to improve the accuracy of NDT test results are as follows:

[0036] 1. Make the E690 marine engineering steel that needs to be measured into a test specimen 5.

[0037] 2. Connect the coolant inlet 1 and coolant outlet 2 of the cooling box 3 to circulating liquid nitrogen. After the liquid nitrogen can circulate and pass through the cooling box 3 stably, the test piece 5 is placed in the test piece groove 4, so that the test piece 5 Fully contact with liquid nitrogen, and weld the crack source weld bead required for the test on the test piece 3, and reduce the temperature of the test piece 5 during surfacing welding by liquid nitrogen.

[0038] 4. The crack source is processed on the weld bead of specimen 5, the cooling rate of the heat affected zone is 50~100°C / s, the structure of the heat affected zone is martensite + lath bainite, and the width of the heat affected zone is 0.5mm (Without using the cooling equipment, the cooling rate of ...

Embodiment 3

[0041] The methods and devices used to improve the accuracy of NDT test results are as follows:

[0042] 1. The 9% Ni low temperature steel to be measured is made into test specimen 5.

[0043]2. Connect the cooling liquid inlet 1 and the cooling liquid outlet 2 of the cooling box 3 to the circulating cooling water. After the cooling water can circulate and pass through the cooling box 3 stably, the test piece 5 is placed in the test piece groove 4, so that the test piece 5 Fully contact with the cooling water, and weld the crack source weld bead required for the test on the test piece 3, reduce the temperature of the test piece 5 during surfacing welding through the cooling water, and the cooling rate of the heat-affected zone is 30~60℃ / s, The structure of the heat-affected zone is martensite + bainite, and the width of the heat-affected zone is 0.6mm (without using the cooling equipment, the cooling rate of the heat-affected zone is 0~45°C / s, and the structure of the heat-af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com