Hinged column type double-pull-rod cantilever stacker

A double tie-rod and stacker technology, applied in the field of cantilever stackers, can solve the problems of large structural size, heavy weight, and high power of the running and slewing mechanisms of the whole machine, and achieve light weight of the whole machine, enhanced fatigue resistance, and The effect of reduction in turning and running power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

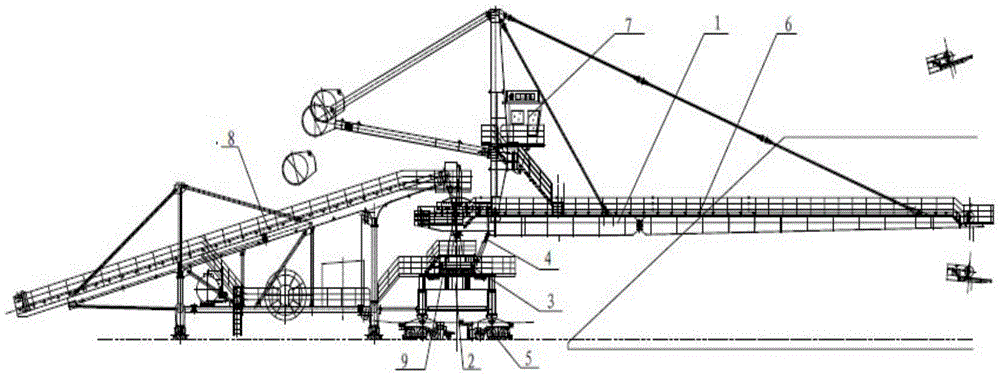

[0047] like Figure 1 to Figure 10 The hinged column type double-tie-rod cantilever stacker shown includes: upper steel structure 1, door seat frame 2, slewing device 3, pitching device 4, running device 5, belt conveyor system 6, driver's cab device 7, tail car device 8 and material transfer device 9;

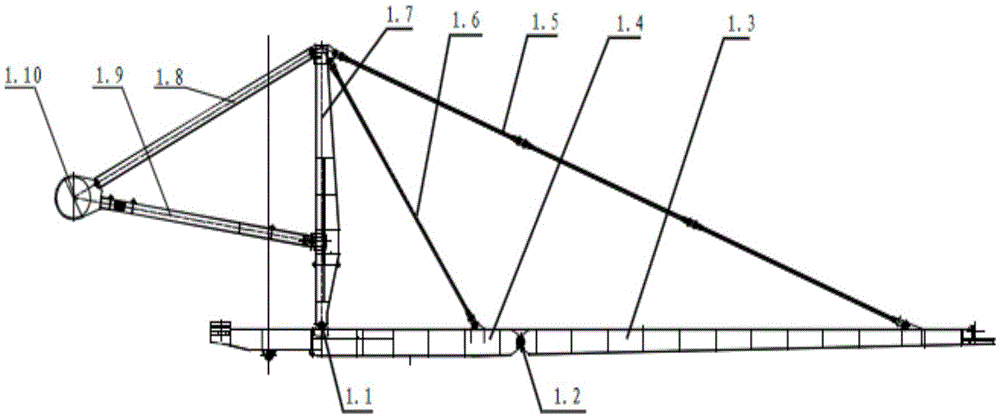

[0048] The upper steel structure 1 includes: column 1.7, counterweight tie rod 1.8, counterweight arm 1.9, counterweight 1.10, cantilever beam and cantilever tie rod;

[0049] The column 1.7 is vertically hinged to the front end of the cantilever beam through the hinge shaft I1.1;

[0050] One end of the cantilever tie rod is fixed on the cantilever beam, and the other end is fixed on the column 1.7, forming a cable-stayed structure composed of the column 1.7, the cantilever beam and the cantilever tie rod;

[0051] The counterweight 1.10 is supported and fixed on the side of the column 1.7 opposite to the extension direction of the cantilever beam through the counterweight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com