Blast furnace stemming

A technology for popping mud and blast furnace, applied in the field of blast furnace mud and preparation, can solve the problems of high temperature, unclean iron, running a large flow, etc., and achieve the effects of long storage time, cost saving and price reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

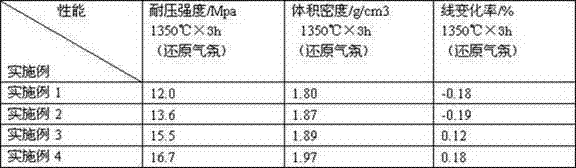

Examples

Embodiment 1

[0017] One for 1080m 3 The blast furnace clay is characterized in that the blast furnace clay is composed of the following components by weight: used waste clay: 10-20 parts; waste high-alumina bricks: 5-15 parts; raw coal gangue: 10-20 parts parts; coal gangue calcined ore: 10~25 parts; composite clay: 10~20 parts; regenerated graphite electrode powder: 10~35 parts; vanadium pentoxide: 8~18 parts, asphalt powder: 3~8 parts; Glydol n 2002: 1.0~1.7 parts; additional binder: 14.5 parts. Preparation method of gun mud: Put all the raw materials into the mixer and pre-mix for 10 minutes; then add 90% of the total amount of binder, and wet mill for 30 minutes; add the remaining 10% of binder, and then wet mill for 10 minutes ;Sliced by a mud slicer, then through a mud extruder, extruded into a shape, and bagged, which is the finished product; the extruded temperature is set at 75°C.

Embodiment 2

[0019] One for 2500m 3 The blast furnace clay is characterized in that the blast furnace clay is composed of the following components by weight: used waste clay: 10-20 parts; waste high-alumina bricks: 5-15 parts; raw coal gangue: 10-20 parts 20 parts; coal gangue calcined cooked ore: 10~25 parts; composite clay: 10~20 parts; regenerated graphite electrode powder: 10~35 parts; vanadium pentoxide: 8~18 parts, asphalt powder: 3~8 parts; Glydol n 2002: 1.0~1.7 parts; Added binder: 14 parts. Preparation method of gun mud: Put all the raw materials into the mixer and pre-mix for 10 minutes; then add 90% of the total amount of binder, and wet mill for 30 minutes; add the remaining 10% of binder, and then wet mill for 10 minutes ;Sliced by a mud slicer, then through a mud extruder, extruded into a shape, and bagged, which is the finished product; the extruded temperature is set at 72°C.

Embodiment 3

[0021] One for 3200m 3 The blast furnace clay is characterized in that the blast furnace clay is composed of the following components by weight: used waste clay: 10-20 parts; waste high-alumina bricks: 5-15 parts; raw coal gangue: 10-20 parts 20 parts; coal gangue calcined cooked ore: 10~25 parts; composite clay: 10~20 parts; regenerated graphite electrode powder: 10~35 parts; vanadium pentoxide: 8~18 parts, asphalt powder: 3~8 parts; Glydol n 2002: 1.0~1.7 parts; Added binder: 13 parts. Preparation method of gun mud: Put all the raw materials into the mixer and pre-mix for 10 minutes; then add 90% of the total amount of binder, and wet mill for 30 minutes; add the remaining 10% of binder, and then wet mill for 10 minutes ;Sliced by a mud slicer, then through a mud extruder, extruded into a shape, and bagged, which is the finished product; the extruded temperature is set at 78°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com