A kind of blast furnace clay mixture

A technology of mixing material and tap mud, which is applied in the field of refractory plastics for blast furnace ironmaking, can solve the problems of unclean iron, tap hole reaming, affecting the service life and output growth of blast furnaces, etc., and achieves the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

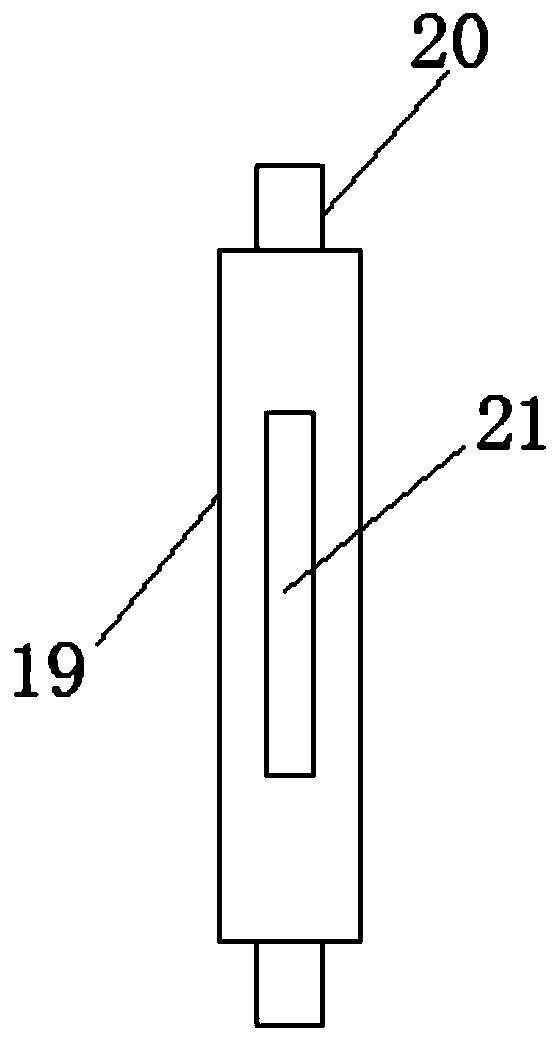

Image

Examples

Embodiment Construction

[0018] The invention provides a mixture of blast furnace clay. The blast furnace clay is composed of the following components by weight: aluminum chromium spinel: 15-25 parts; yttrium mullite: 5-10 parts; coal gangue Mine: 15-20 parts; coal gangue calcined cooked ore: 15-20 parts; composite clay: 5-15 parts; modified magnesium-iron-aluminum spinel powder; carbon resistance powder: 10-30 parts; vanadium pentoxide : 10-15 parts, asphalt powder: 5-8 parts; nanocellulose 1-2 parts; additional binder: 12-14 parts, thickener: 5-15 parts.

[0019] The above-mentioned external binder is modified low-benzopyrene tar.

[0020] The above-mentioned thickener is a mixture of vanadite and copper oxide in a weight ratio of 1:1.

[0021] The above-mentioned modified magnesium-iron-aluminum pre-synthesized spinel fine powder is 220 mesh, and its chemical composition is 10% of magnesium oxide, 35% of iron oxide, 53% of aluminum oxide and 2% of zirconium oxide.

[0022] The composite clay ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com