Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Simplify the heat transfer process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

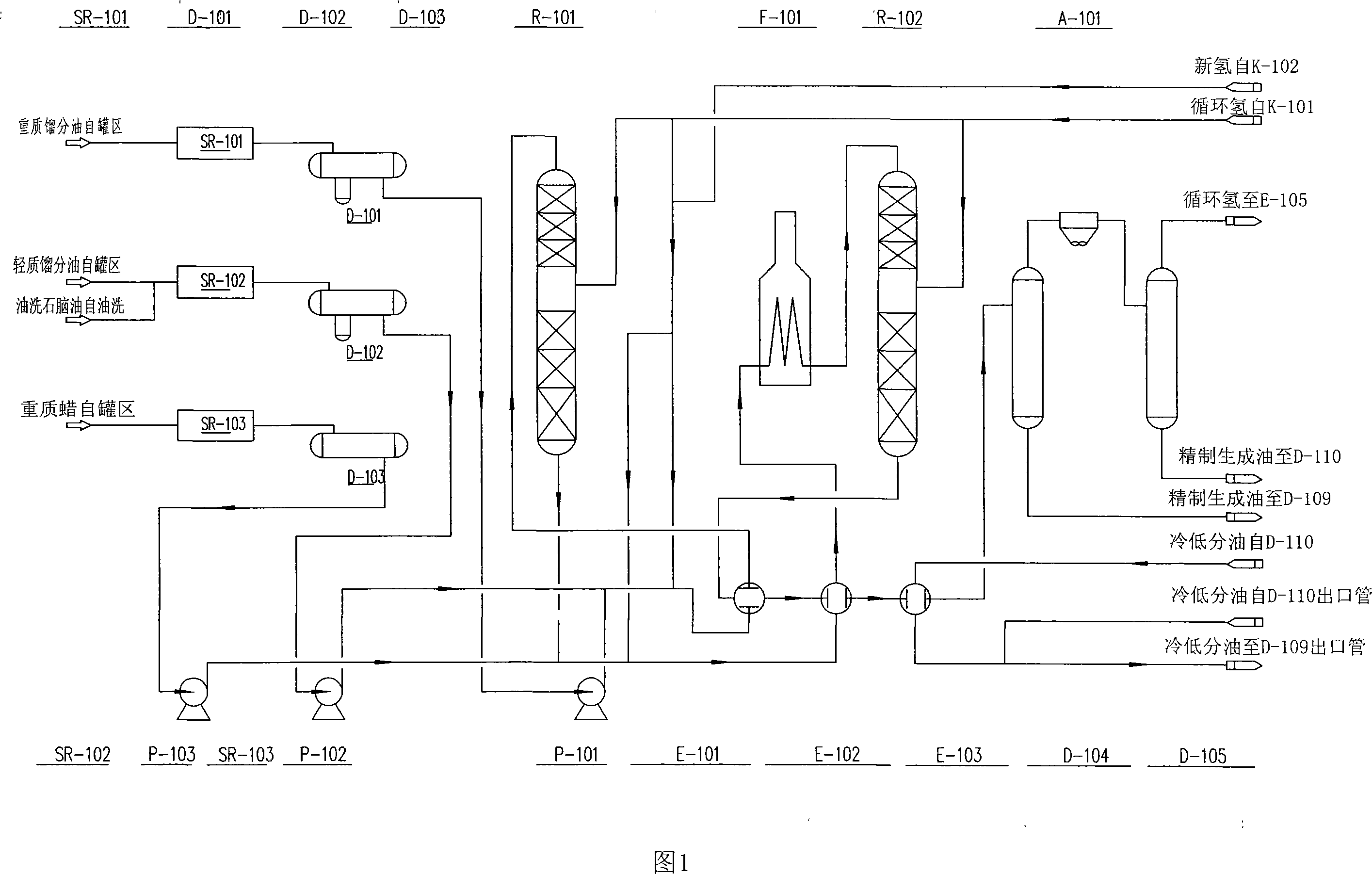

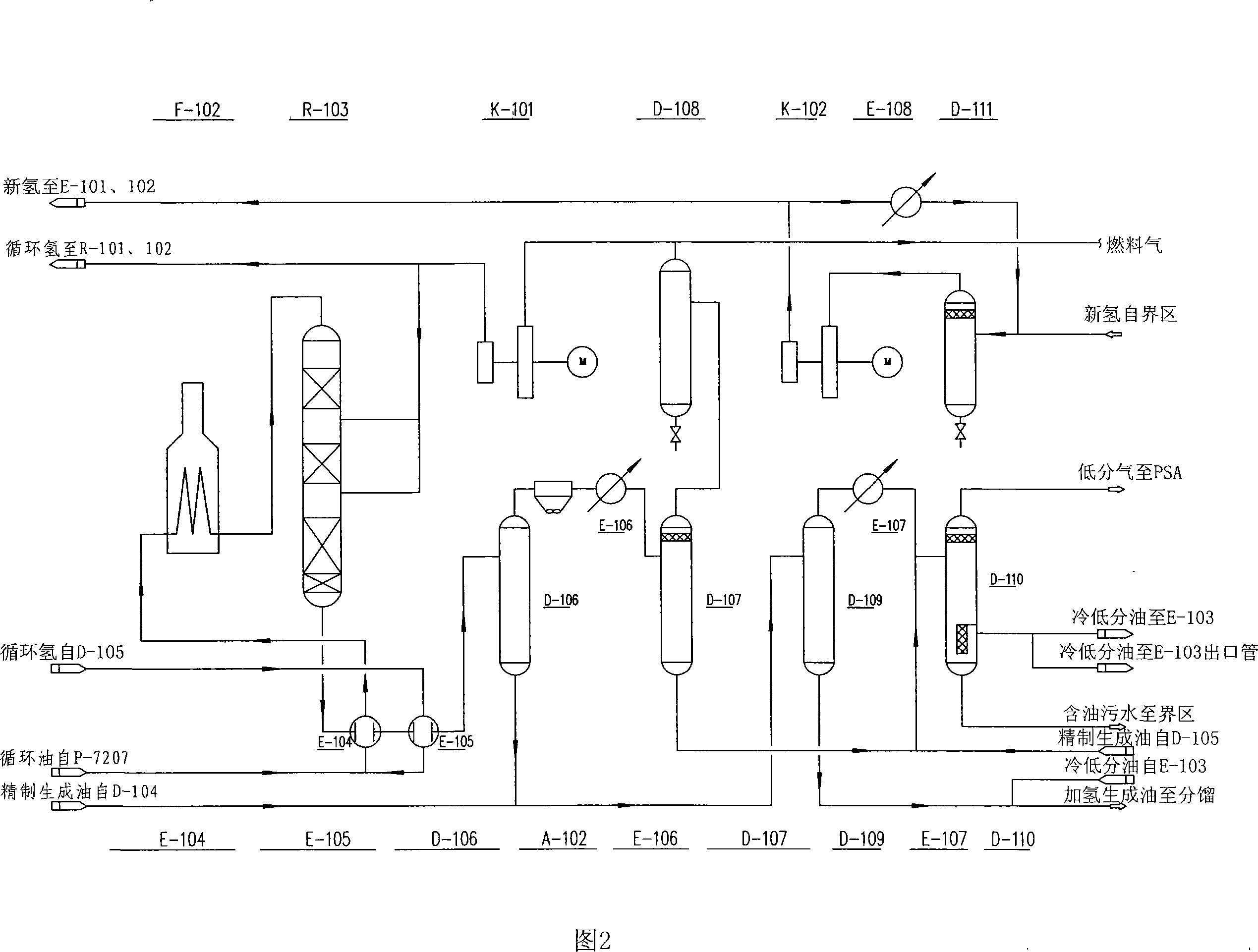

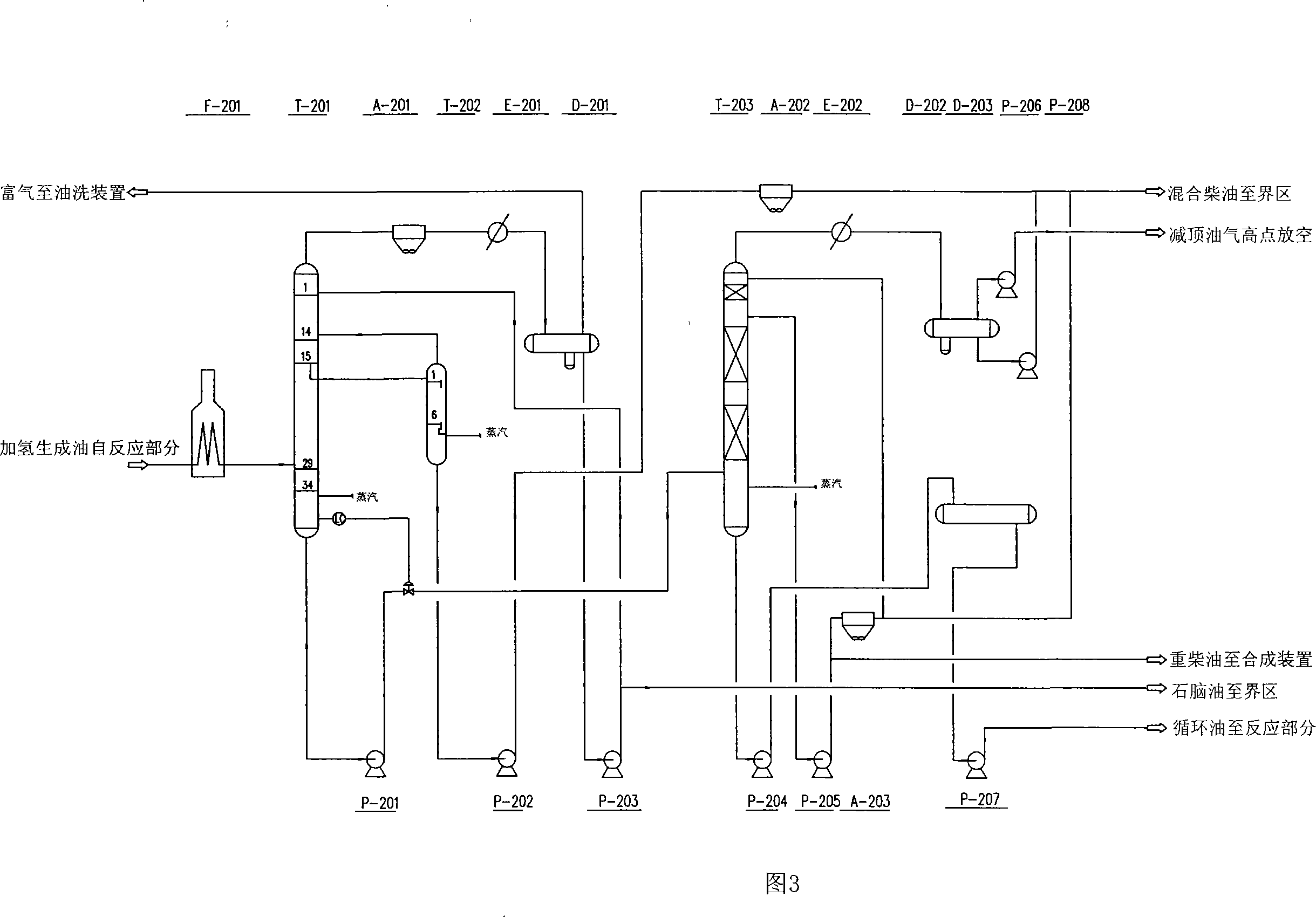

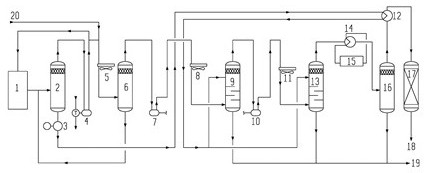

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

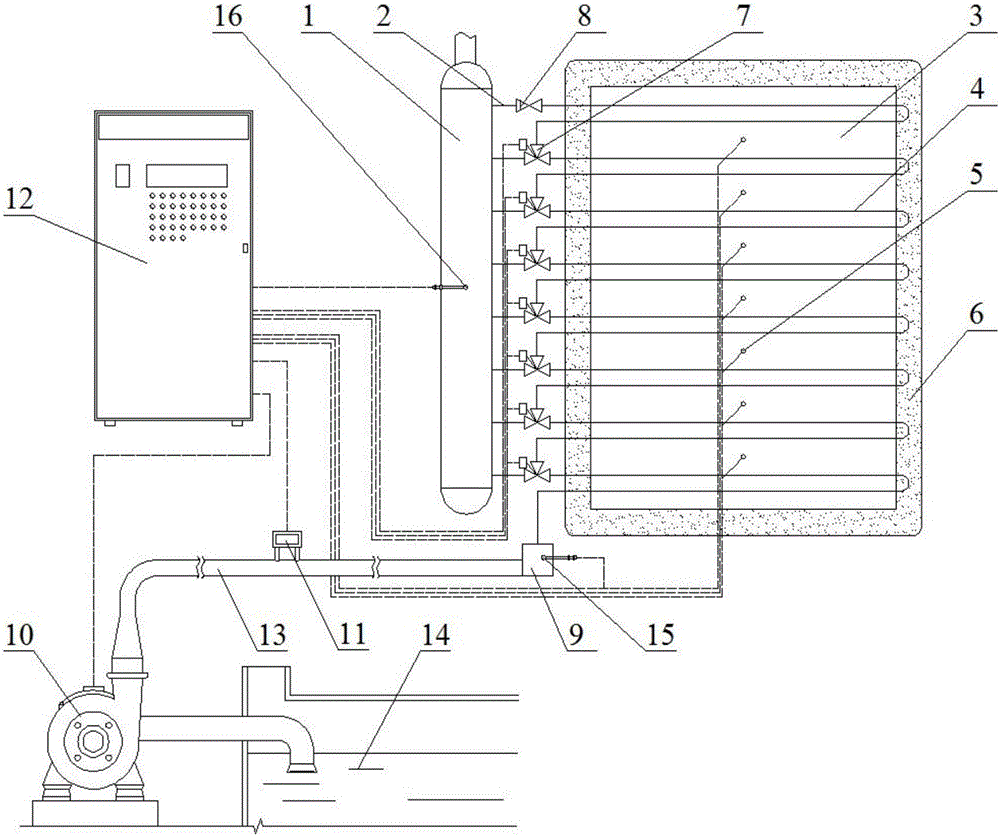

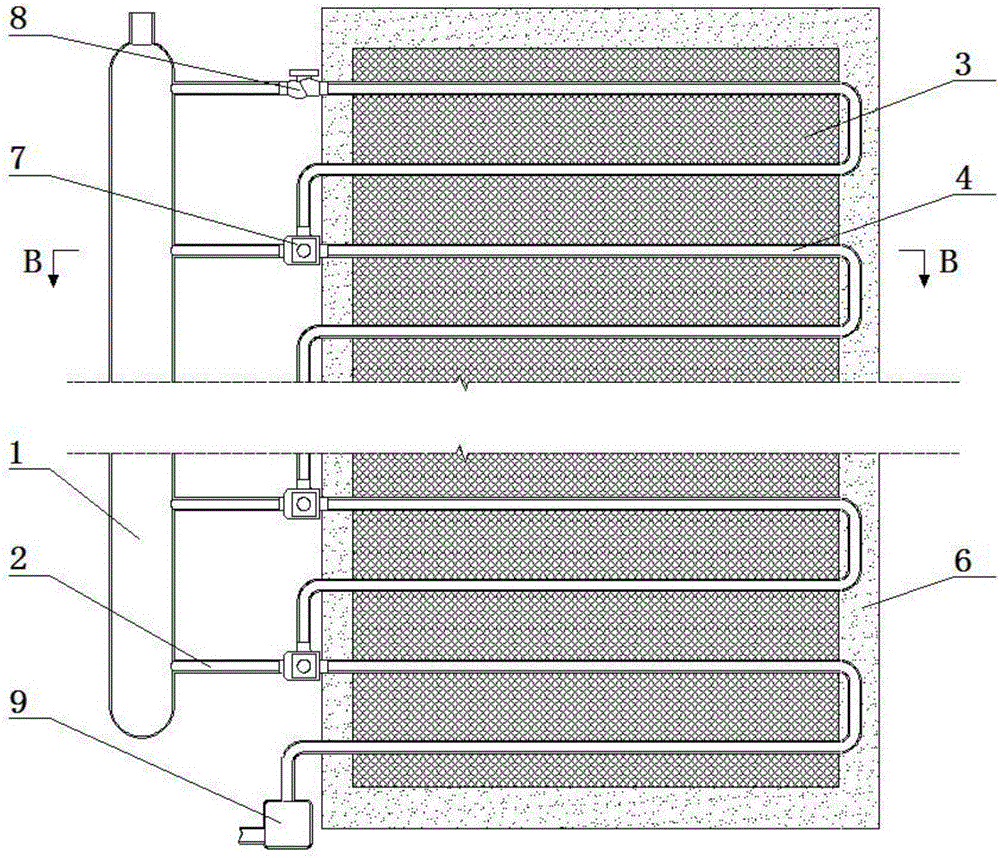

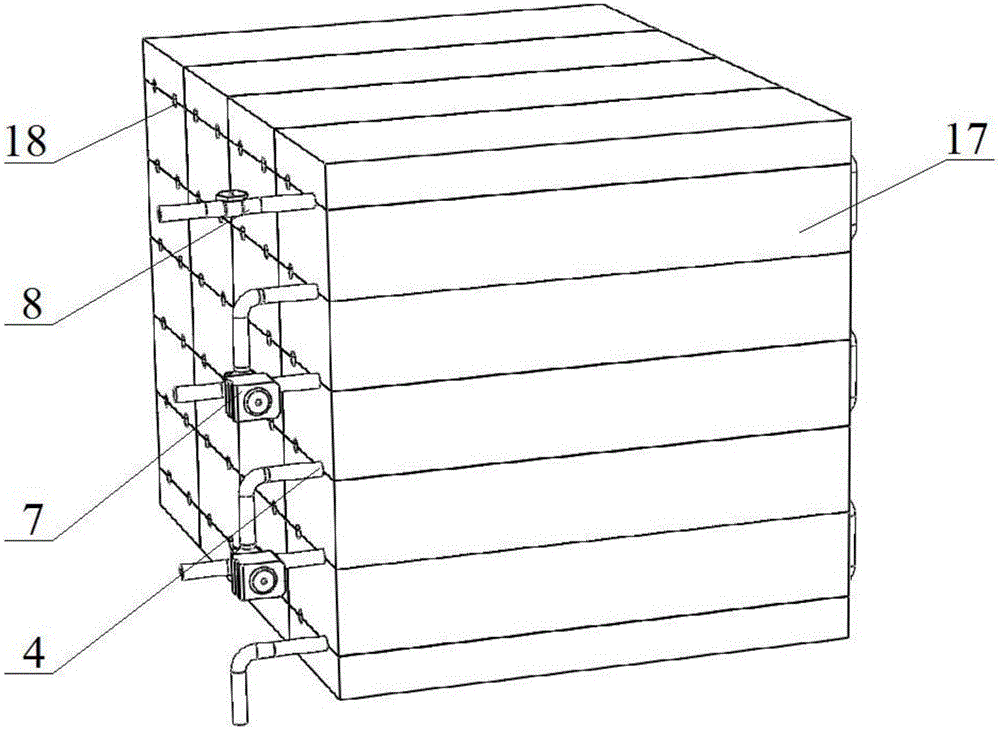

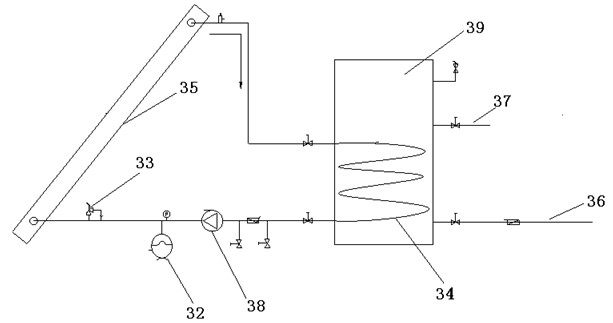

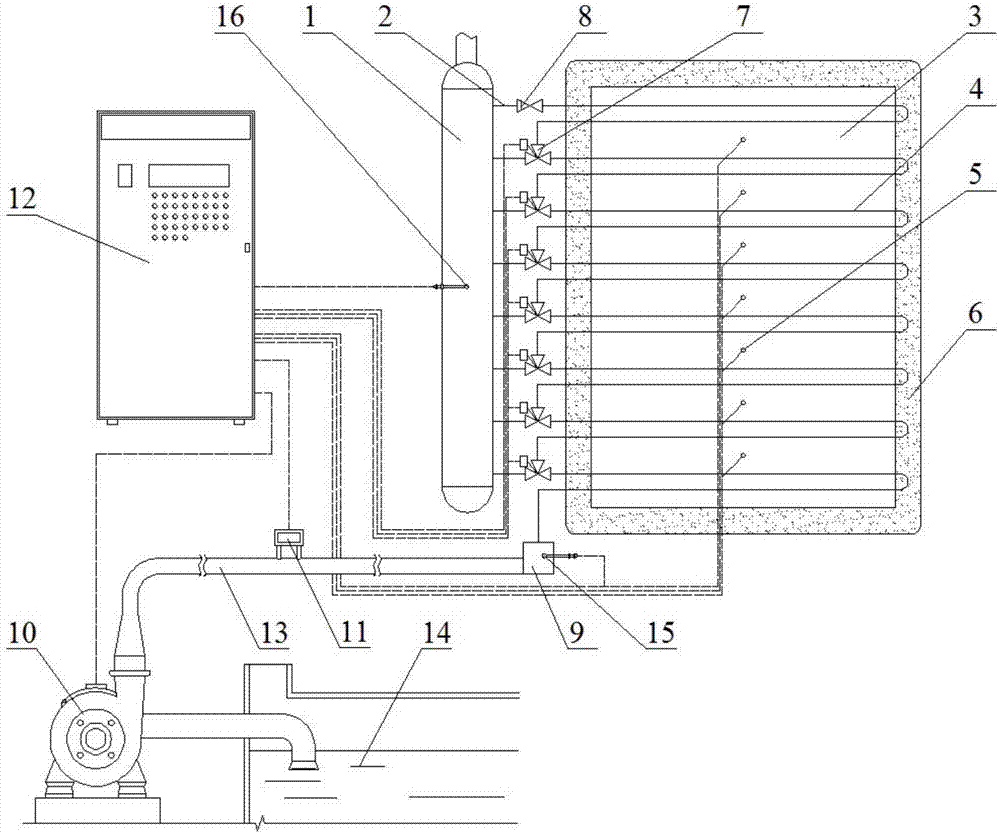

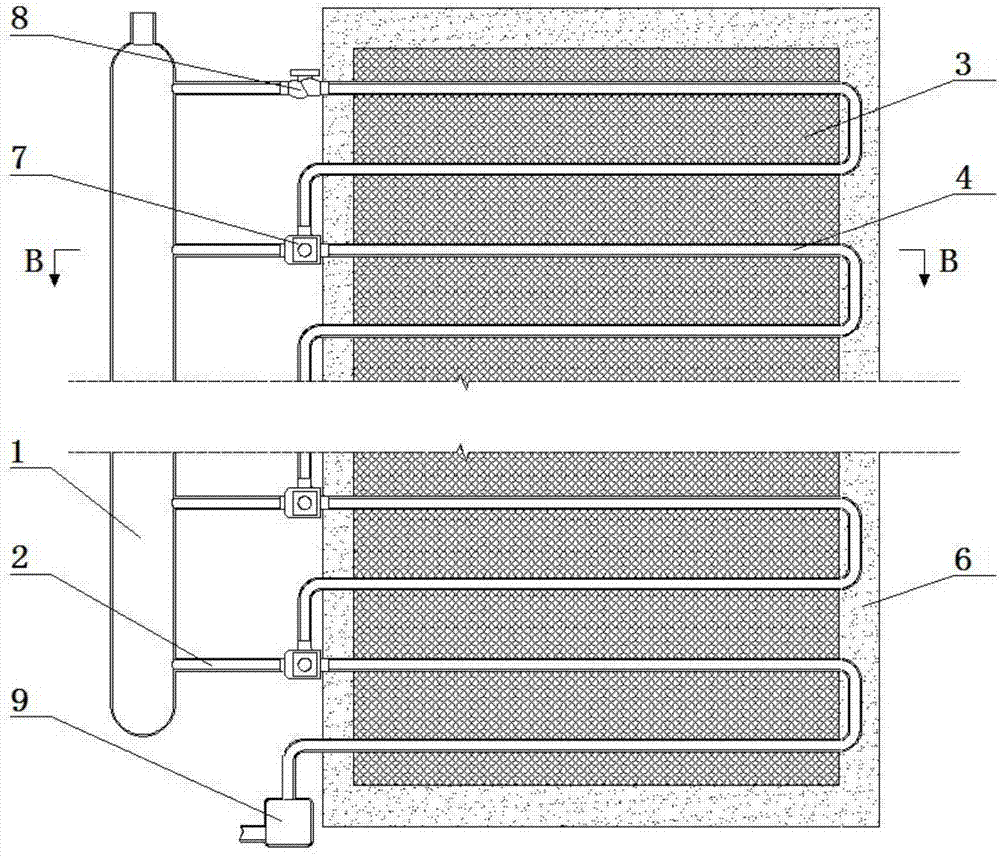

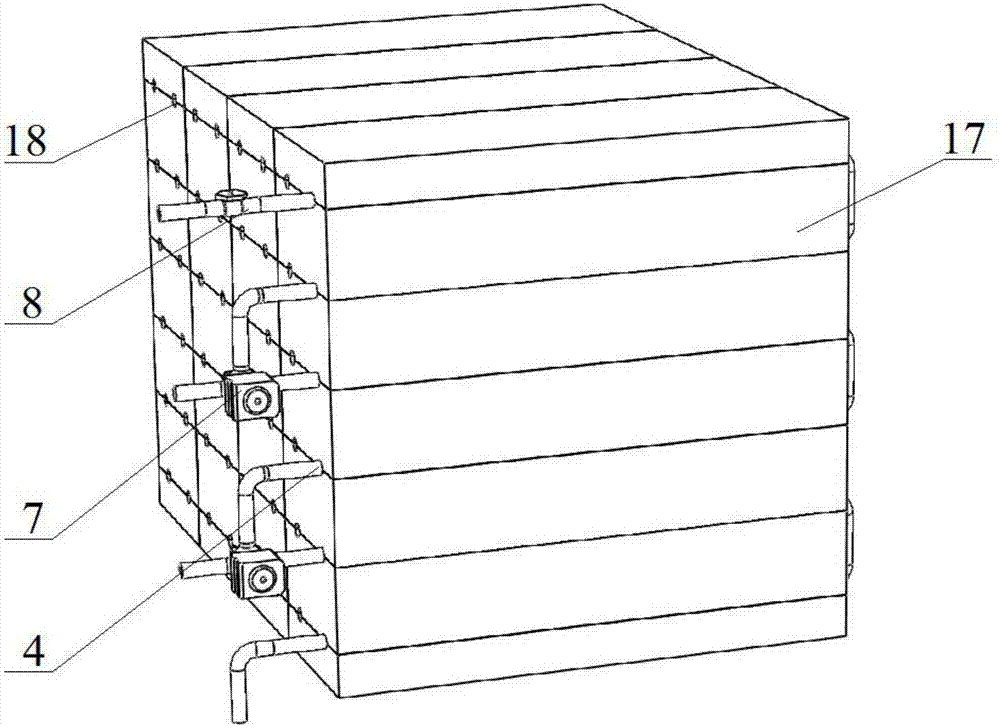

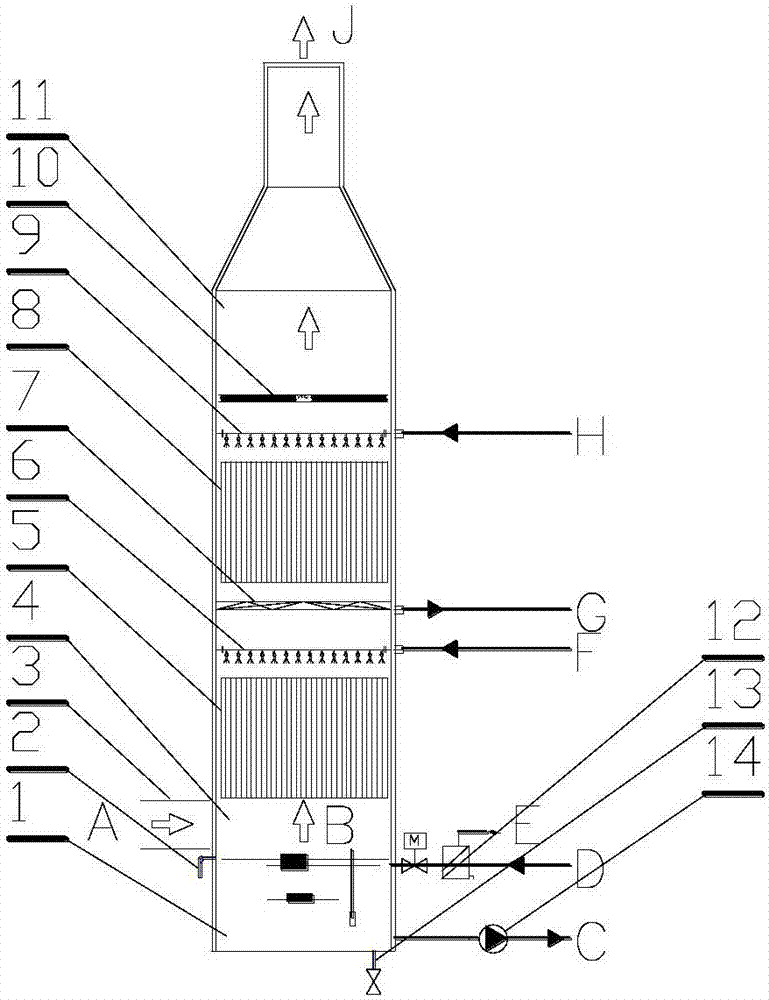

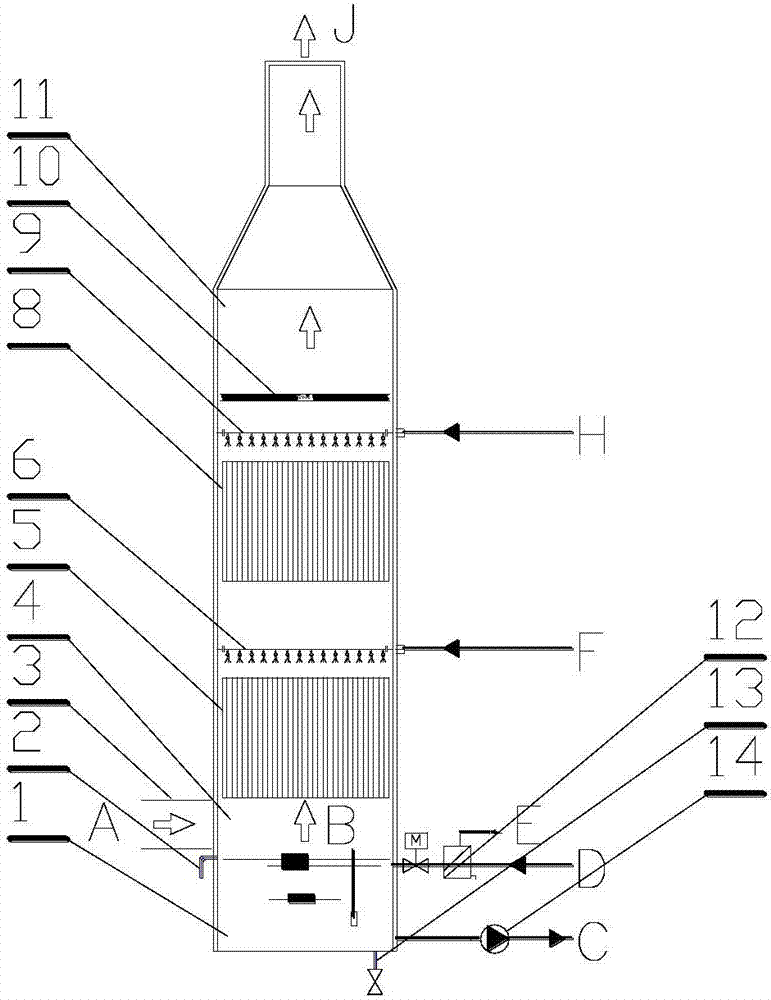

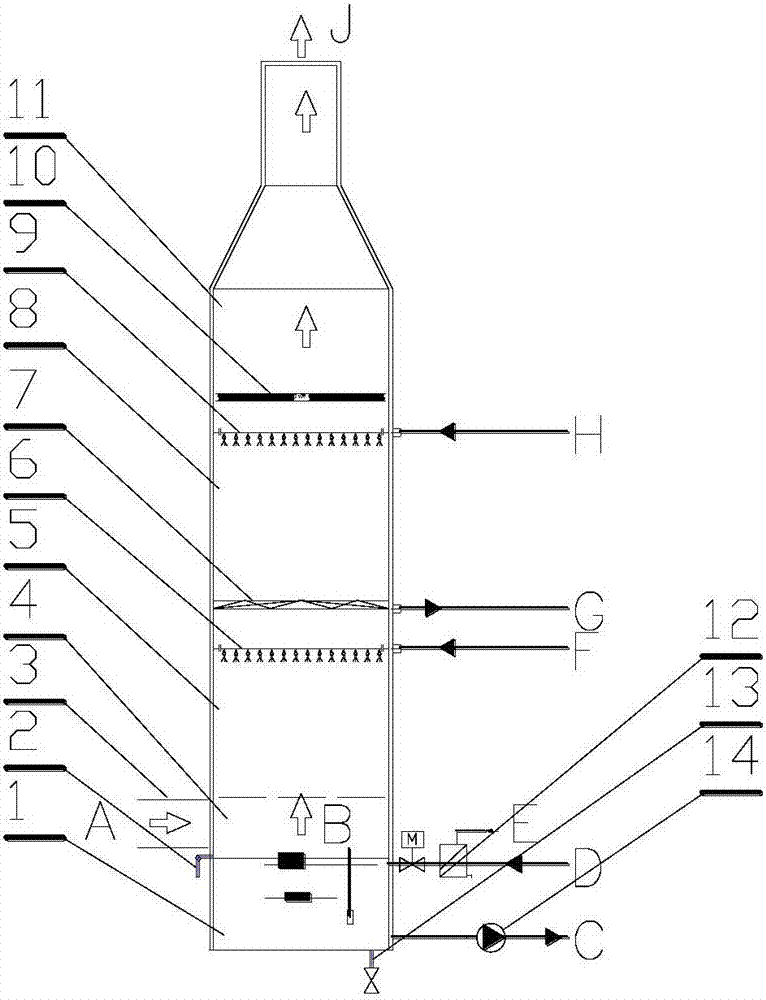

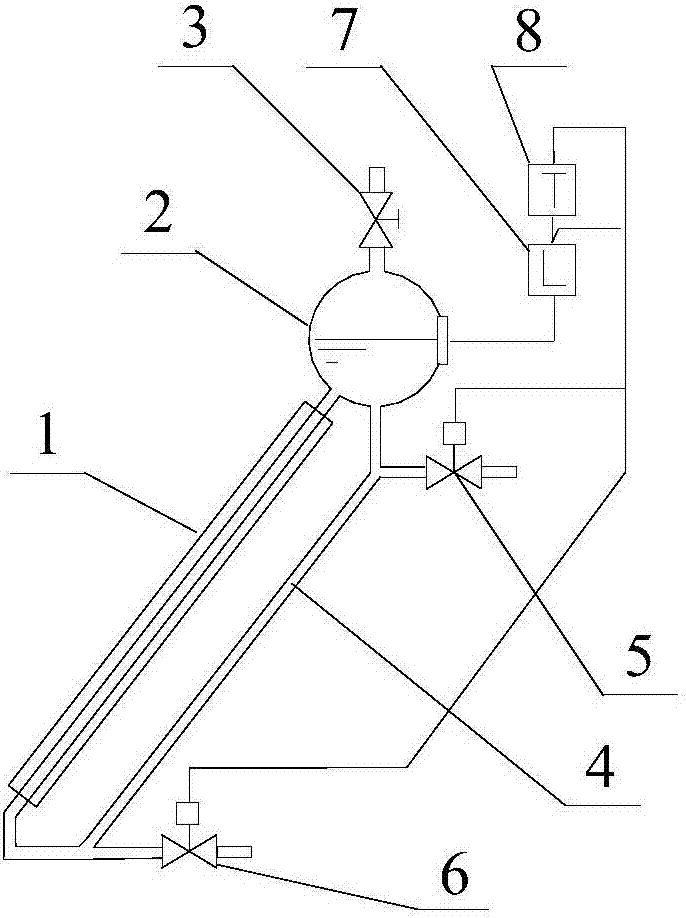

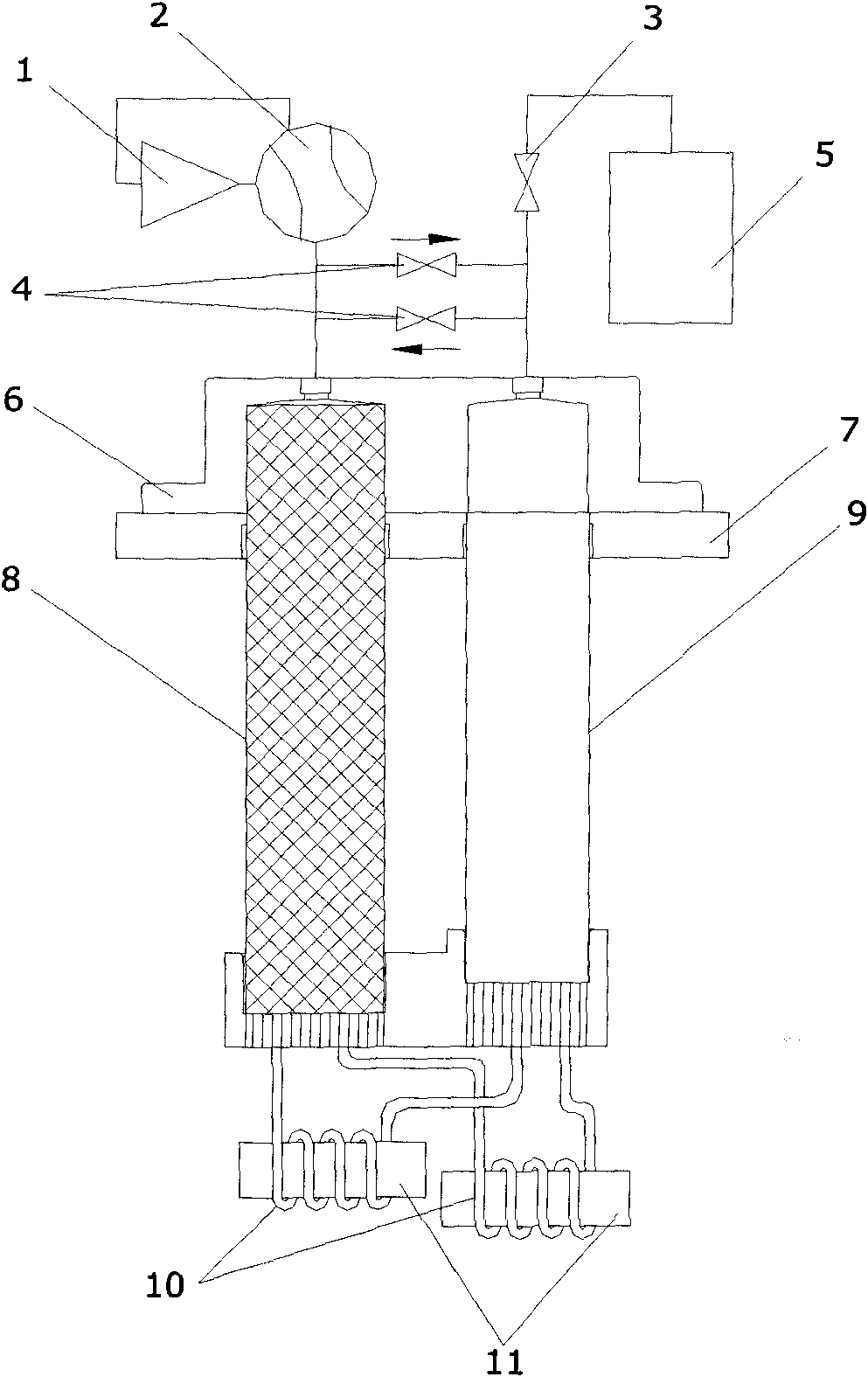

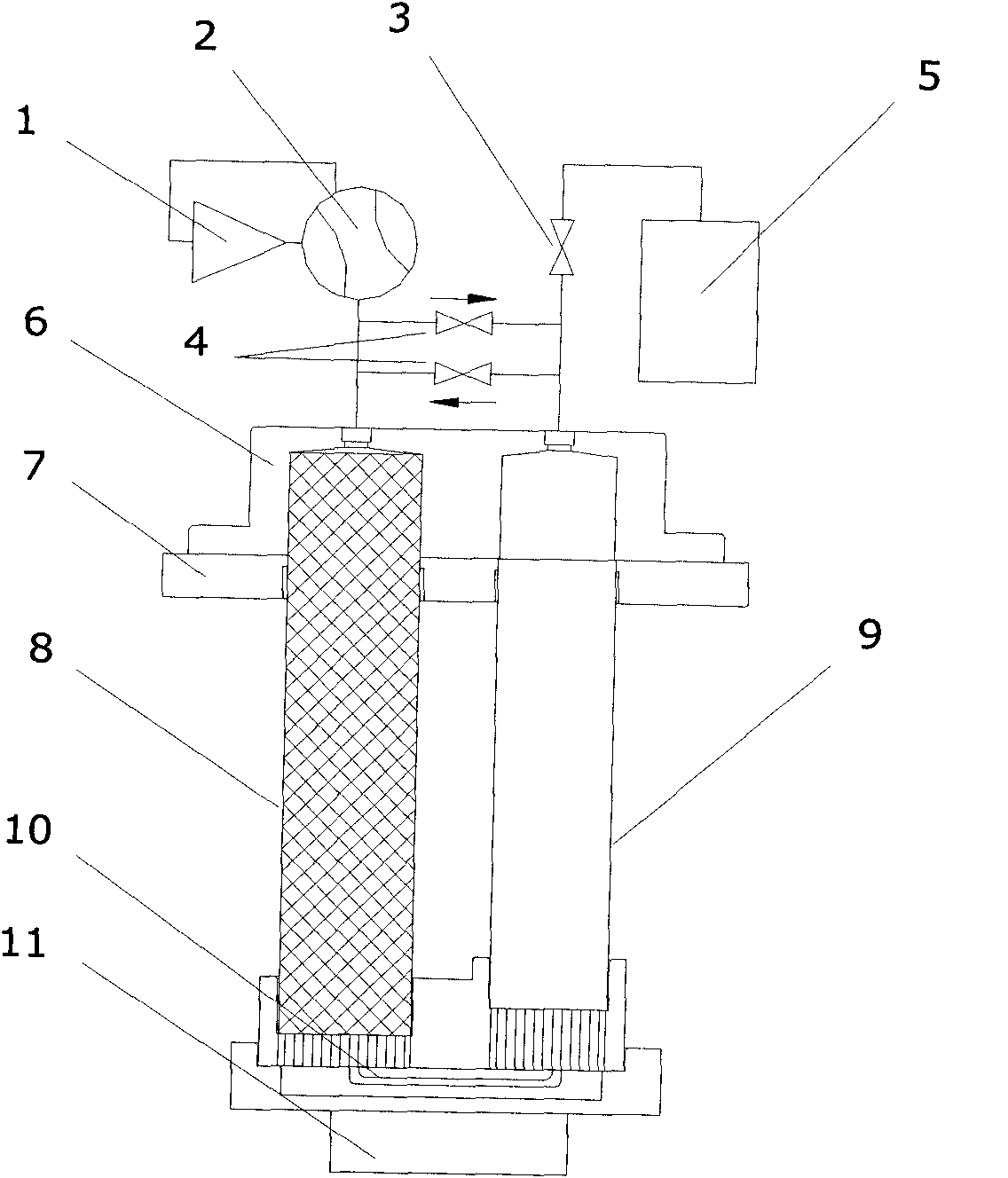

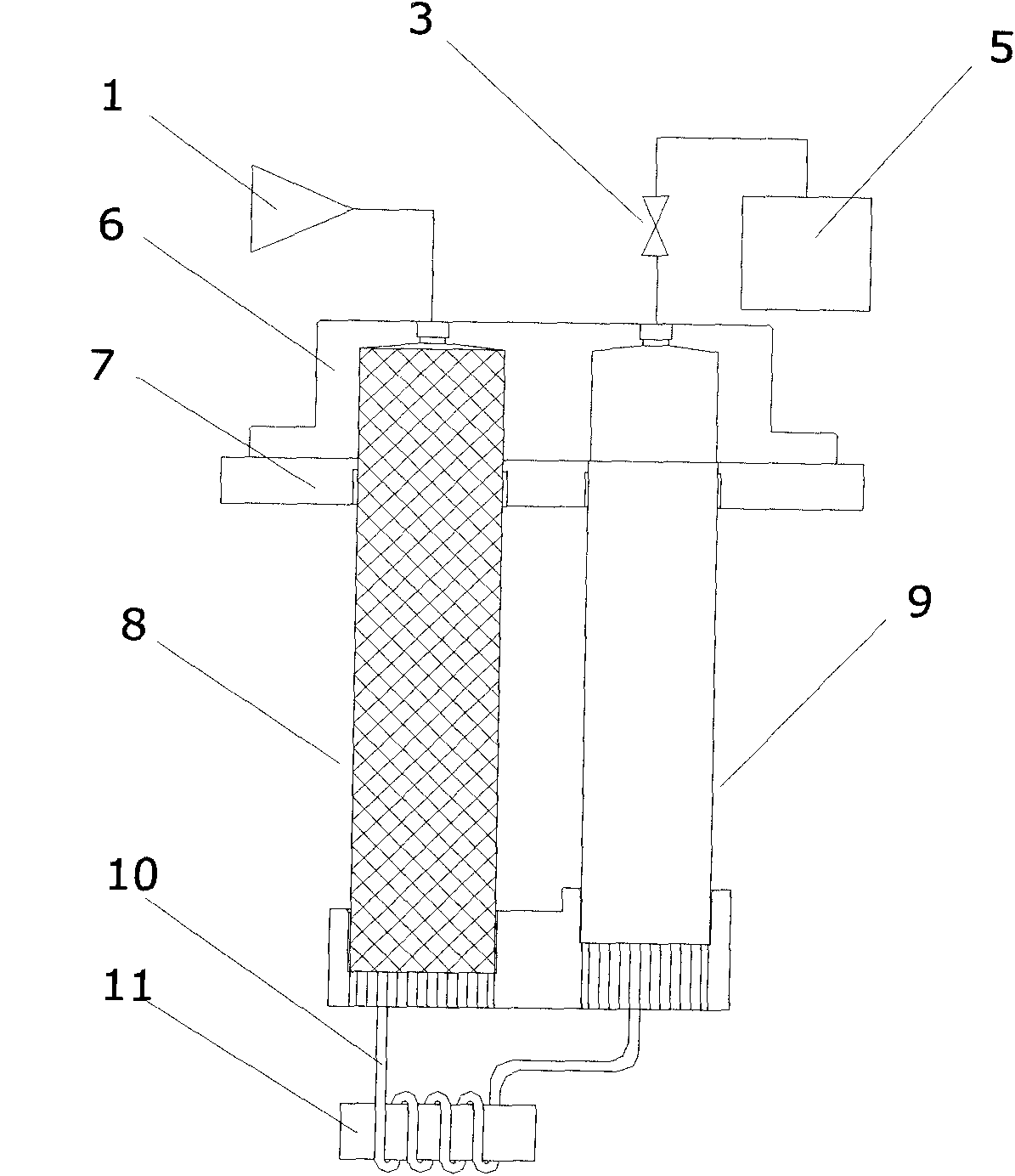

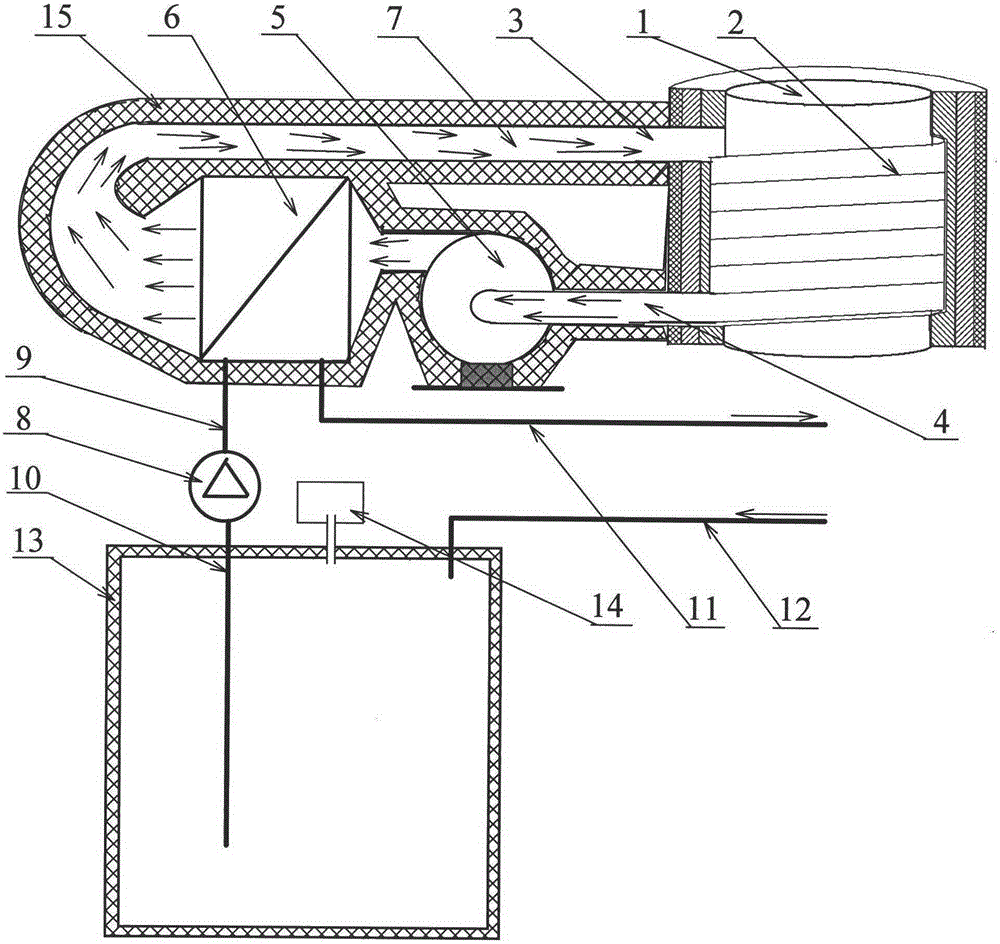

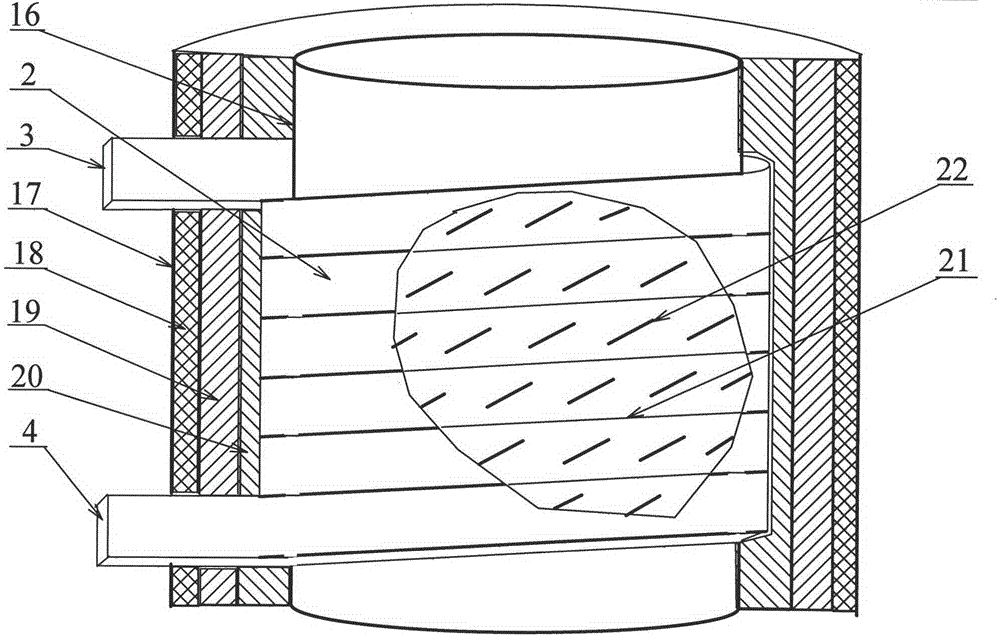

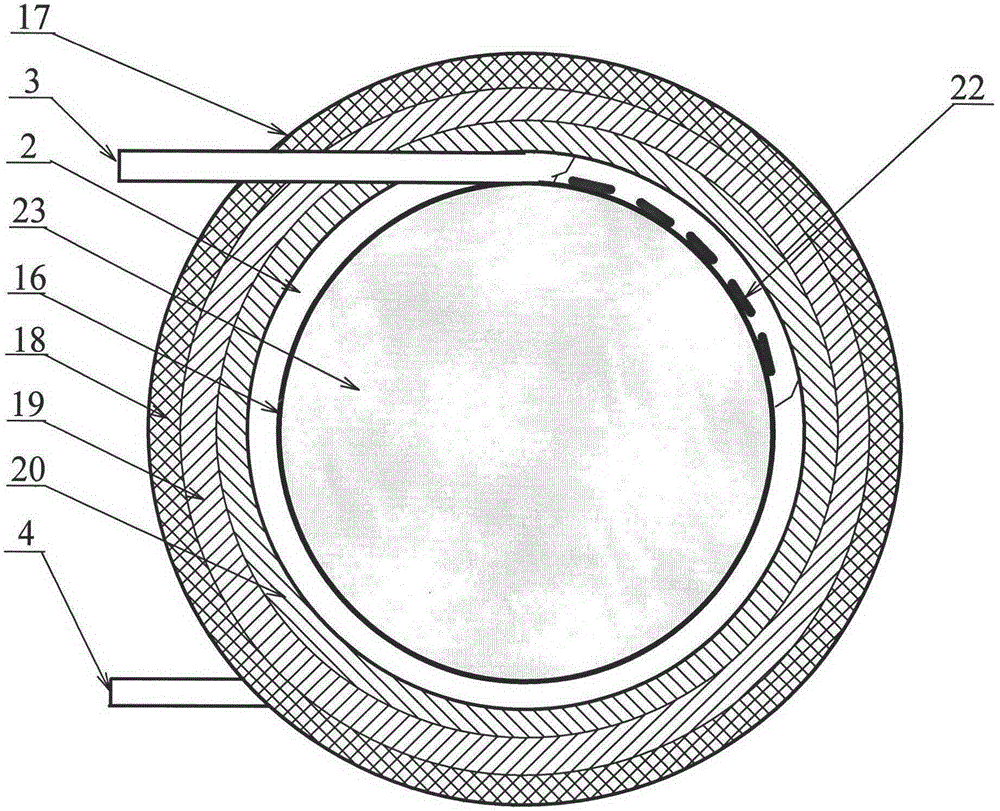

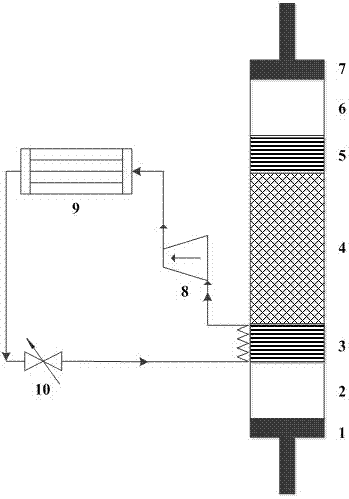

Sensible heat storage type direct steam generation system and method based on series-connection adjustment

ActiveCN105953202ASimplify the heat transfer processEasy to calculate and designSteam generation heating methodsHeat storage plantsEngineeringCheck valve

The invention discloses a sensible heat storage type direct steam generation system and method based on series-connection adjustment. The system comprises an outlet header, an outlet connection pipe, a heat storage body, a heat exchange pipe, a first temperature sensor, a sealed heat-preserving layer, a three-way valve, a check valve, an inlet header, a circulating water pump, a flowmeter, a control cabinet, a water supplementing connection pipe, a water storage pond, a second temperature sensor and a third temperature sensor. A pipeline series-connection method is adopted for the system, by means of the method that the heat exchange area is increased in the flowing direction, the problem that because the temperature of the heat storage body is lowered, the heat exchange coefficient and the heat exchange power are reduced is solved; and in the heat exchange process of the system, the flow in single pipelines is not changed, the heat exchange process is relatively simple, and design and calculation of the system are convenient. By means of implementation of the system, the running cost of a traditional electric boiler can be effectively lowered, after calculation, the cost generated by adopting the steam system is equivalent to that generated by adopting a natural gas system, and broad market application prospects are achieved.

Owner:ZHEJIANG UNIV

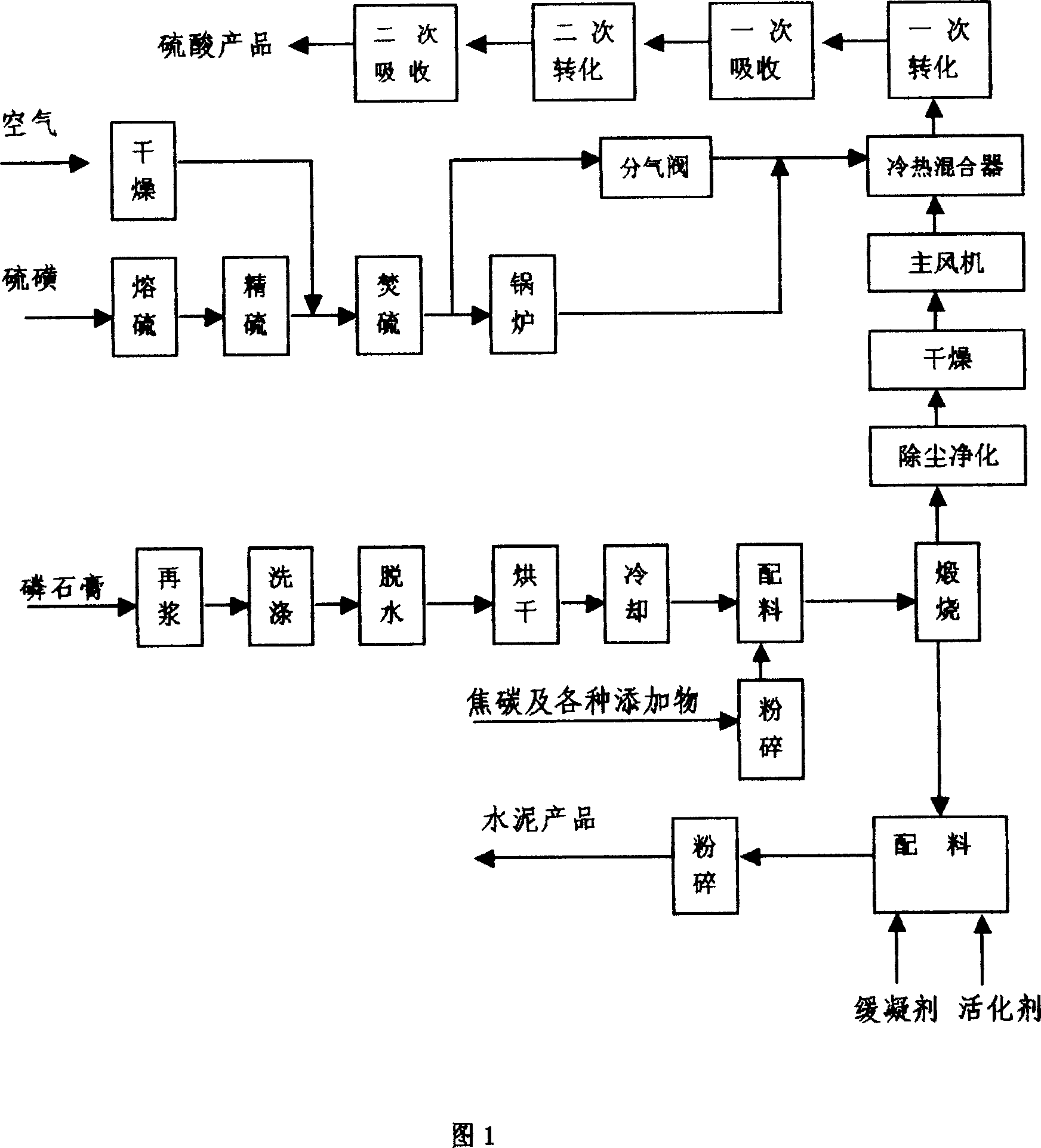

Coproducing cement technological method of producing acid using phosphogypsum and sulfur

ActiveCN1948131AIncrease production intensitySimplify the heat transfer processSulfur-trioxide/sulfuric-acidExhaust gasSlag

The present invention relates to a process capable of simultaneously preparing acid and producing cement by combining phosphogypsum with sulfur. It is characterized by utilizing waste slag phosphogypsum obtained by wet process phosphoric acid production to prepare acid and produce cement. In the concrete, the invented process includes the following steps: utilizing low-concentration SO2 gas discharged out from rotary kiln of phosphogypsum acid-making system and making said kiln gas undergo the processes of washing, cleaning and drying, then be mixed with high-concentration SO2 gas discharged from sulfur acid-making system to obtain the SO2 gas whose concentration is 8-9%; and adopting an advanced two-stage two-absorption acid-making process to prepare sulfuric acid; at the same time firing the phosphogypsum in the rotary kiln to obtain cement clinker, grinding and blending so as to obtain cement.

Owner:GUIZHOU CHANHEN CHEM CO LTD

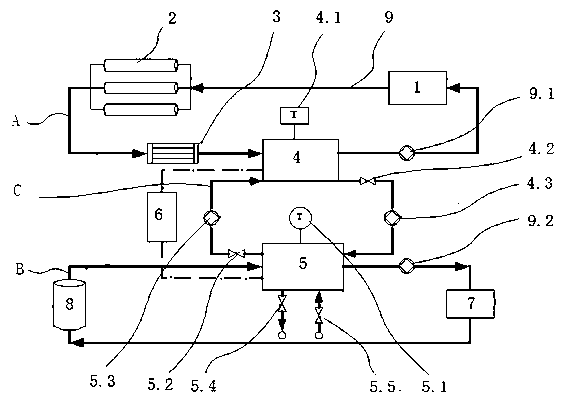

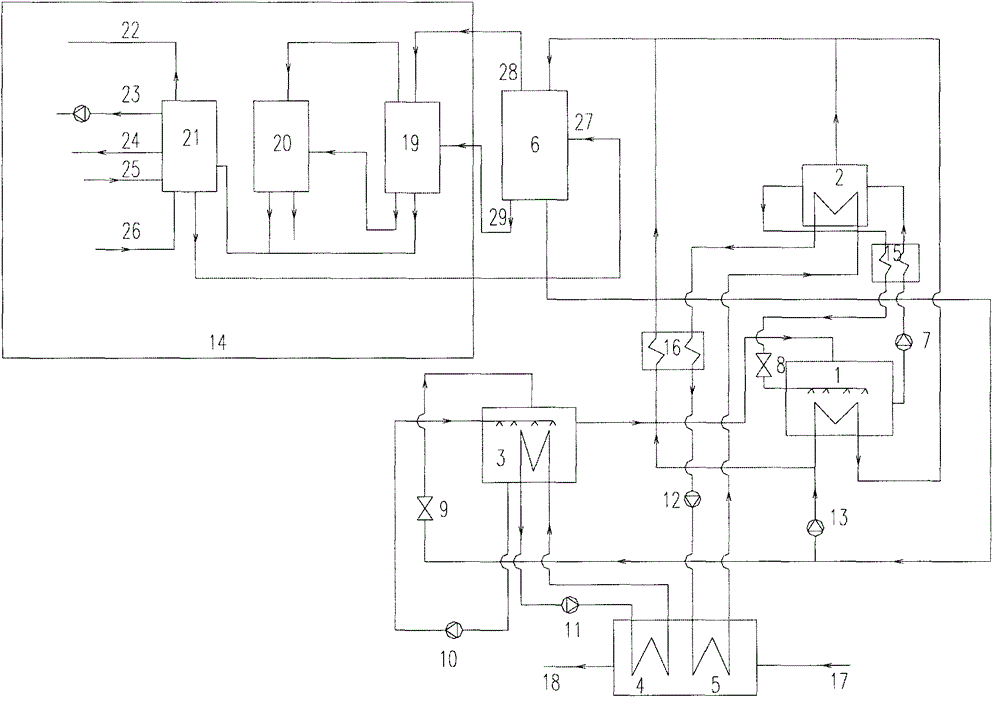

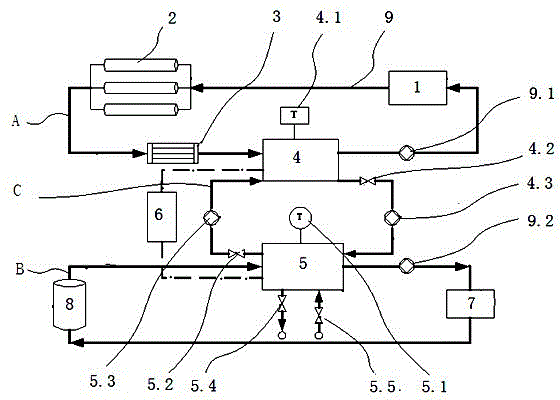

Fuel-cell power generation system

ActiveCN102800882AReduce hidden dangersFast deliveryFuel cell auxillariesSolid electrolyte fuel cellsWater cyclingPower generation system

The invention relates to a fuel-cell power generation system, and in particular relates to a high-power proton exchange membrane fuel-cell power generation system in an underwater isolated air environment. The fuel-cell power generation system comprises a proton exchange membrane fuel cell module, a hydrogen and oxygen storage device, a direct current (DC) / DC conversion unit, a monitoring unit, a heat exchanger, a water tank, a water pump, a valve and a circulating water pipe; a hot water circulating branch comprises a thermostatic hot water tank, a circulating hot water conveying water pump, a proton exchange membrane fuel cell module, a hydrogen storage device and a heat exchanger; a cold water circulating branch comprises a cold water tank, a circulating cold water conveying water pump, a DC / DC conversion unit and an oxygen storage device; a hot and cold water balancing branch comprises a thermostatic hot water tank, a hot water control valve, a balanced hot water conveying water pump, a cold water tank, a cold water control valve and a balanced cold water conveying water pump; one end of the monitoring unit is connected with the thermostatic hot water tank, and the other end of the monitoring unit is connected with the cold water tank. The fuel-cell power generation system has the advantages that the system does not depend on outside air, is safe and reliable, the heat exchange process inside the system is simple and direct, and the heat cycle efficiency is high.

Owner:湖北长海新能源科技有限公司

Boiler smoke discharging condensed water heat-carrying circulation based three incorporated tower heat exchange method and device

PendingCN107559861AAchieve whitening effectReduce consumptionLighting and heating apparatusCombustion technology mitigationSpray towerCondensed water

The invention discloses a boiler smoke discharging condensed water heat-carrying circulation based three incorporated tower heat exchange method and device and belongs to the technical field of exhaust air heat recovery and boiler heating. By adopting a spray tower heat exchange structure with three incorporated towers, the device is divided into an air heating and humidification region, a smoke high-temperature heat exchange region and a smoke low-temperature heat exchange region from bottom to top. Smoke enters the high-temperature heat exchange region from the middle part of the tower, performs heat exchange with high-temperature waste heat circulation water, then rises to the low-temperature heat exchange region and is exhausted from the tower top after performing heat exchange with low-temperature waste heat circulation water; the low-temperature waste heat circulation water is sprayed from a low-temperature spraying device for heat exchange, is supplied to an air heating and humidification section for spraying heat exchange after passing through a water-air separator and heats inlet air of a boiler or directly descends to the high-temperature heat exchange region; and the high-temperature waste heat circulation water is sent into the high-temperature heat exchange region from a high-temperature spraying device for heat exchange and is supplied outside and heats heating net water after gathering in a pool at the tower bottom. A set of system can realize a main heat exchange process required for smoke recovery and heating, so that the system flow is greatly improved, the equipment amount and the occupying space are reduced, and investment and energy consumption are lowered.

Owner:TSINGHUA UNIV +1

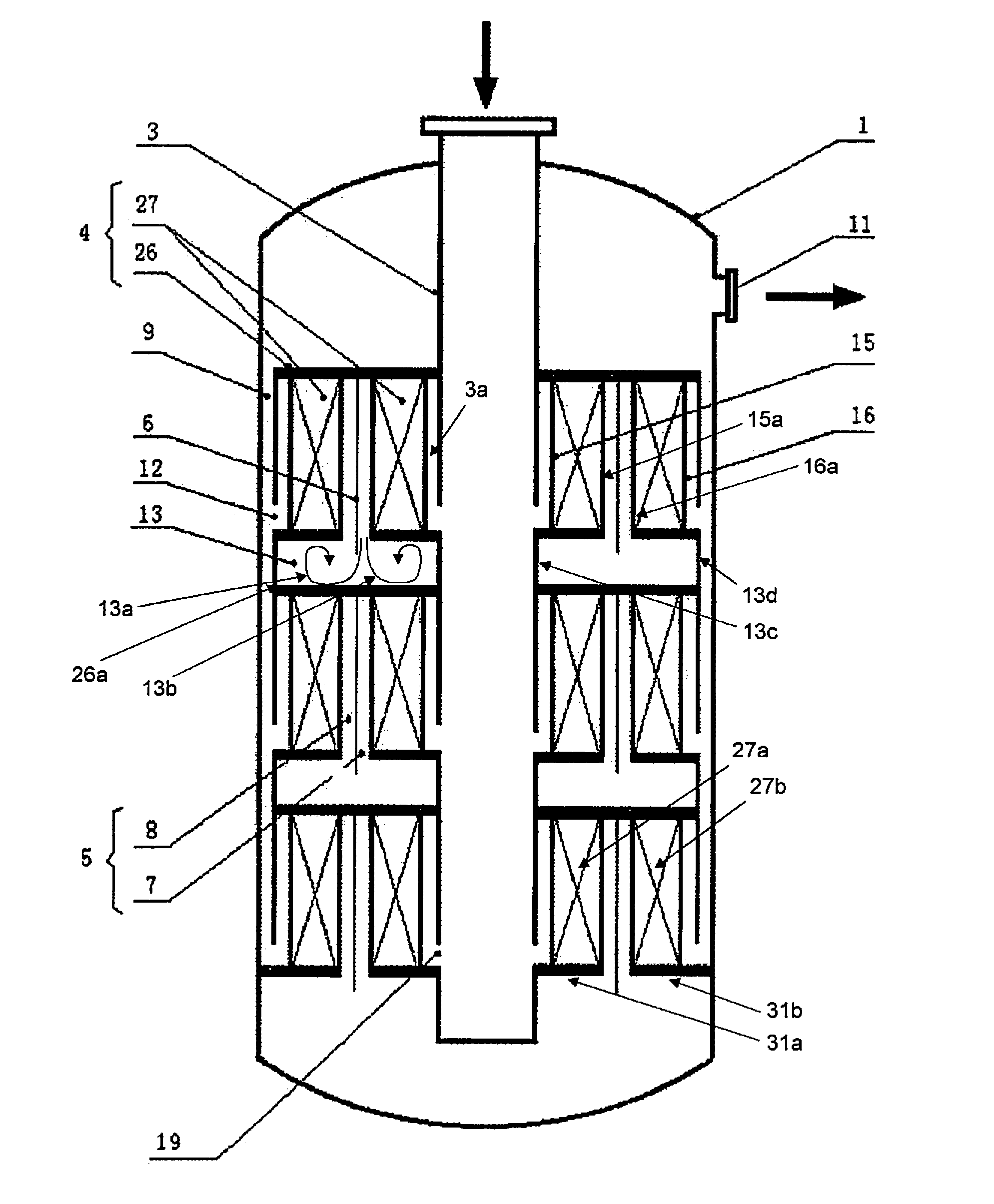

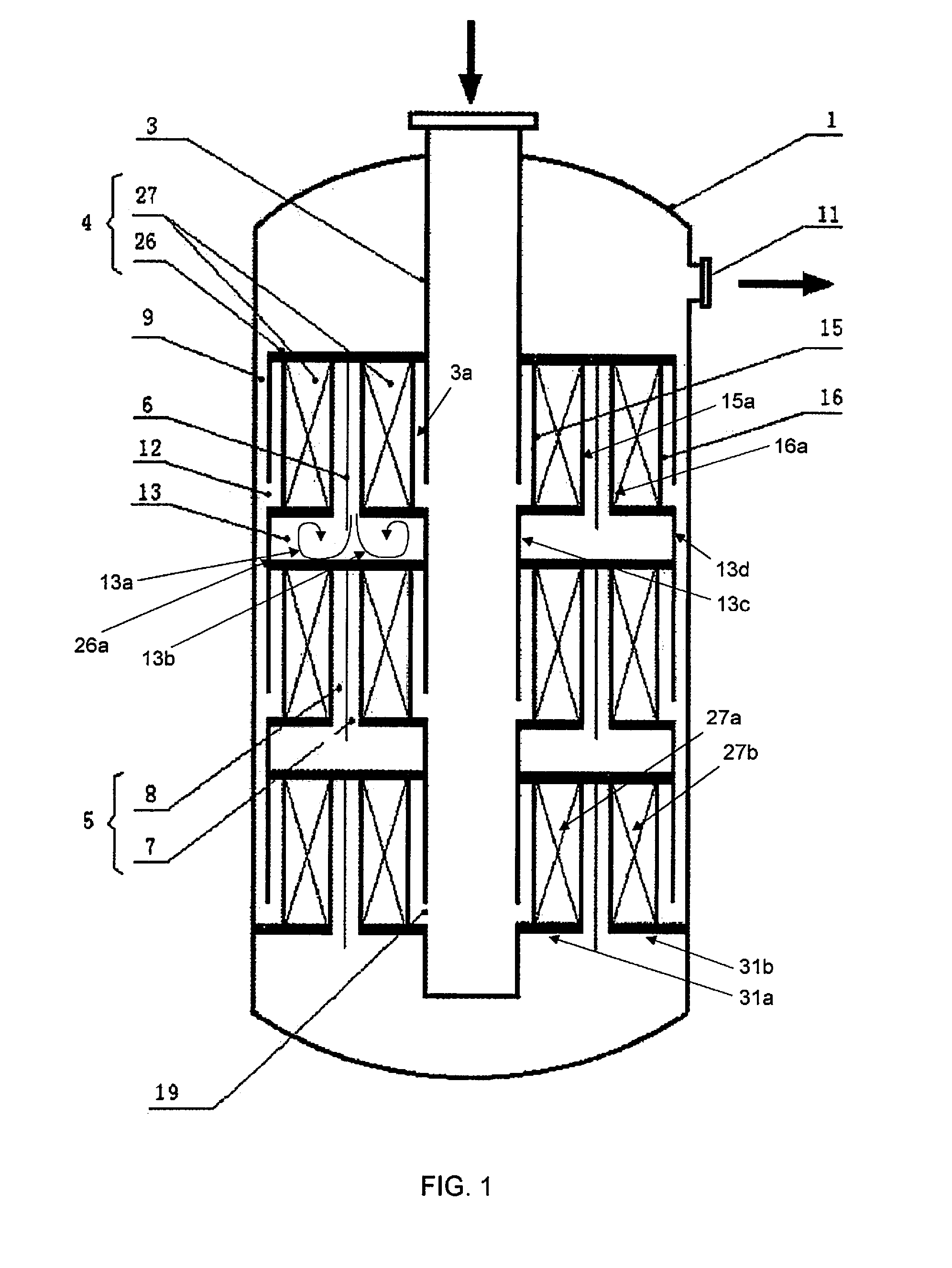

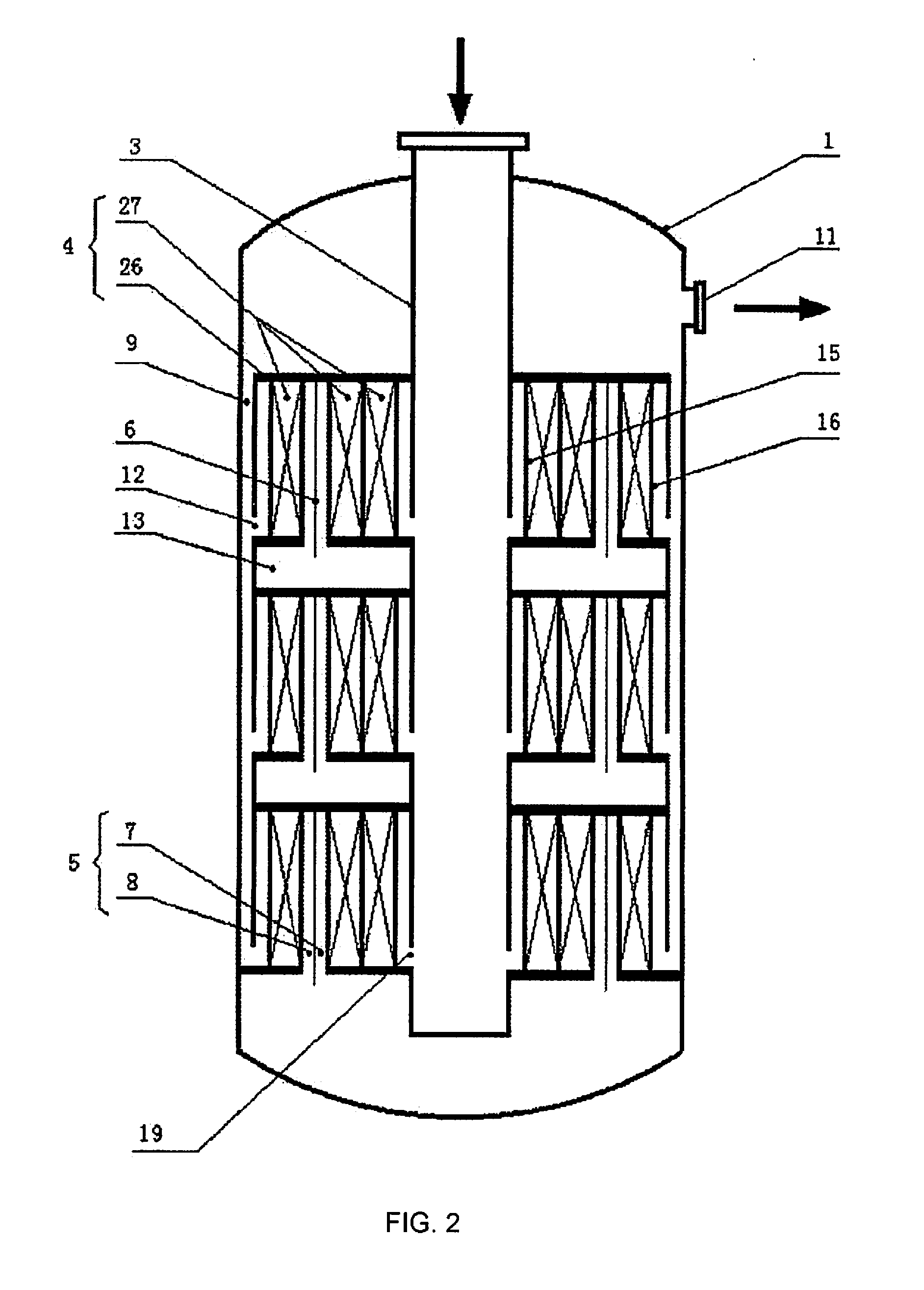

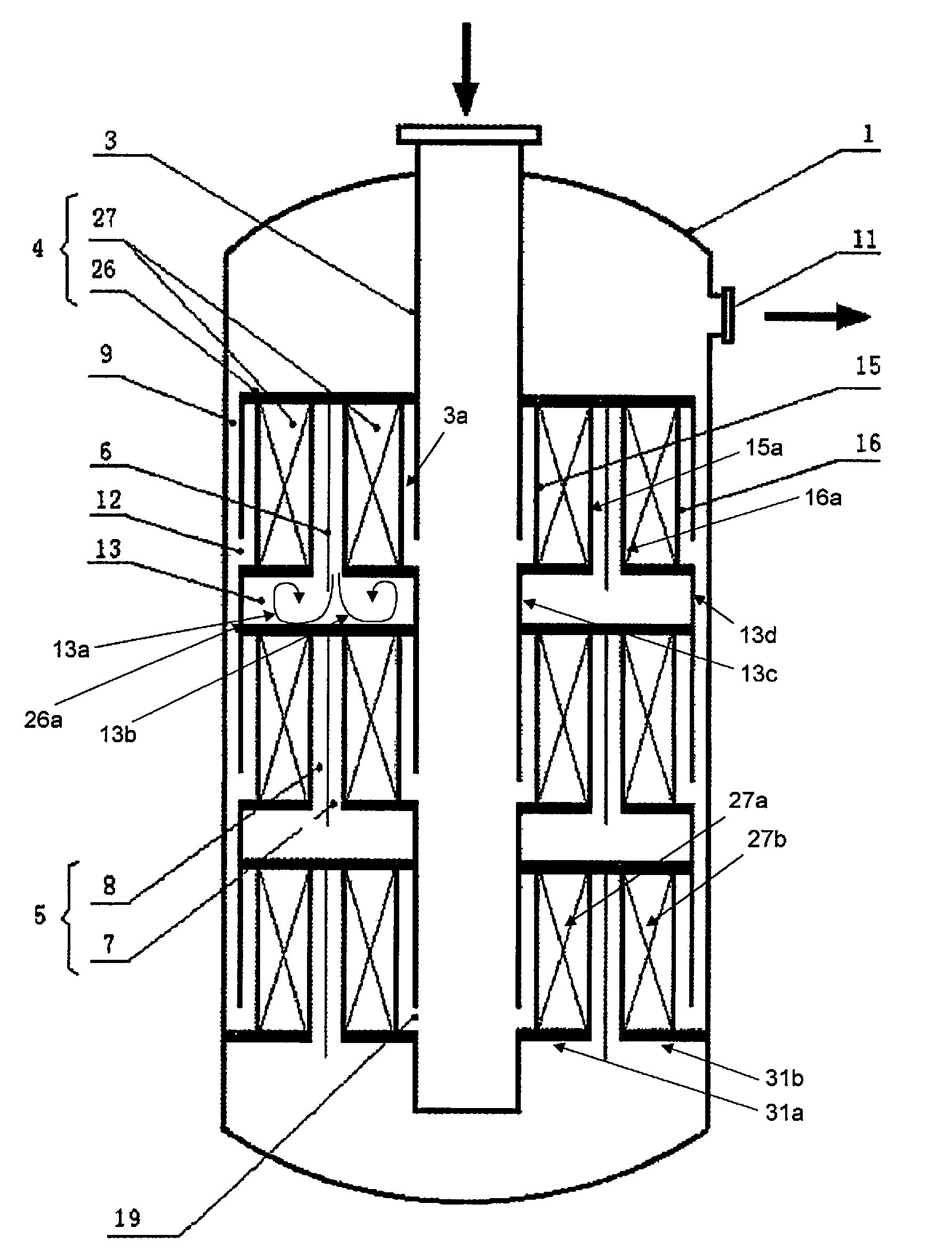

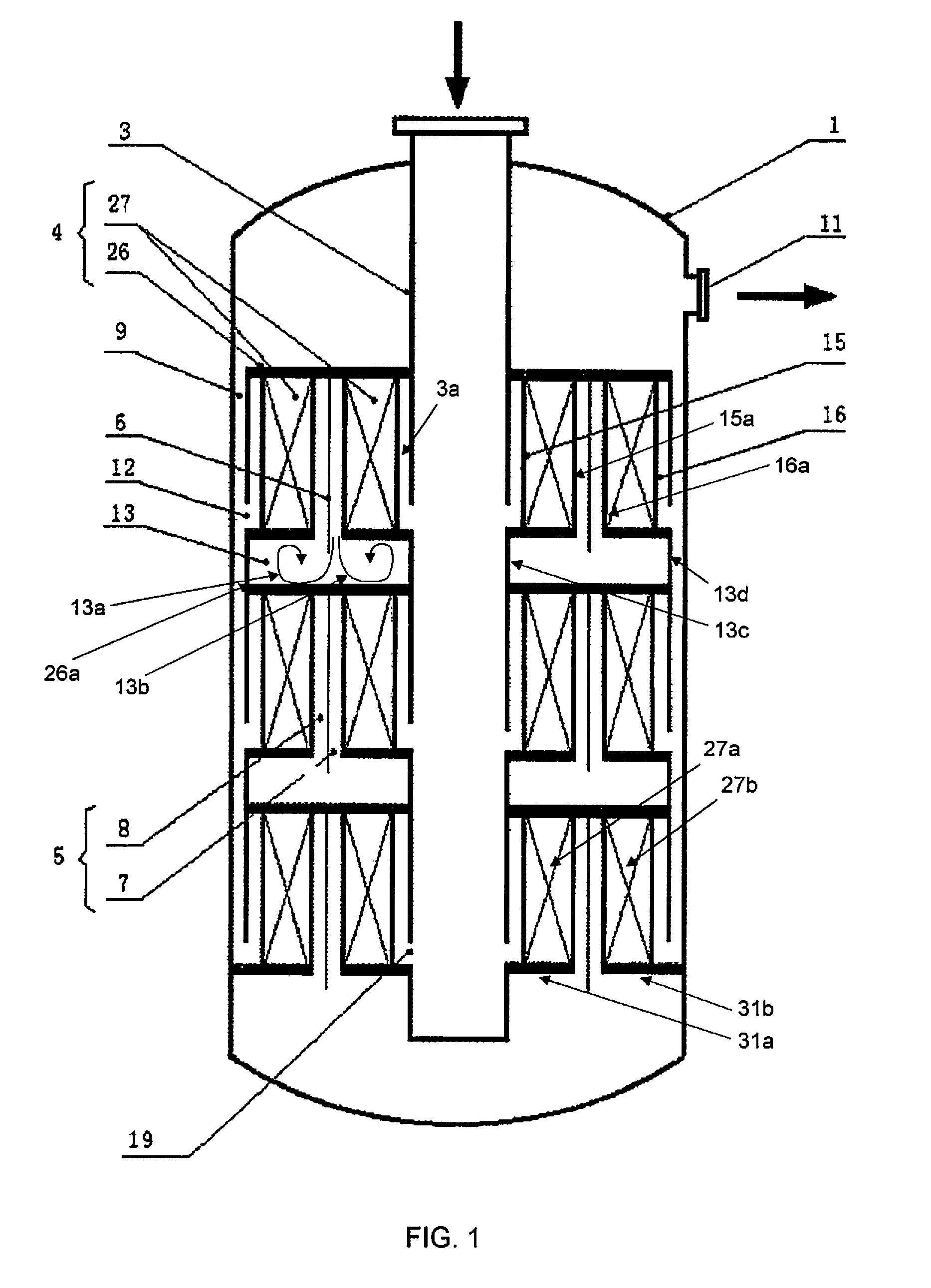

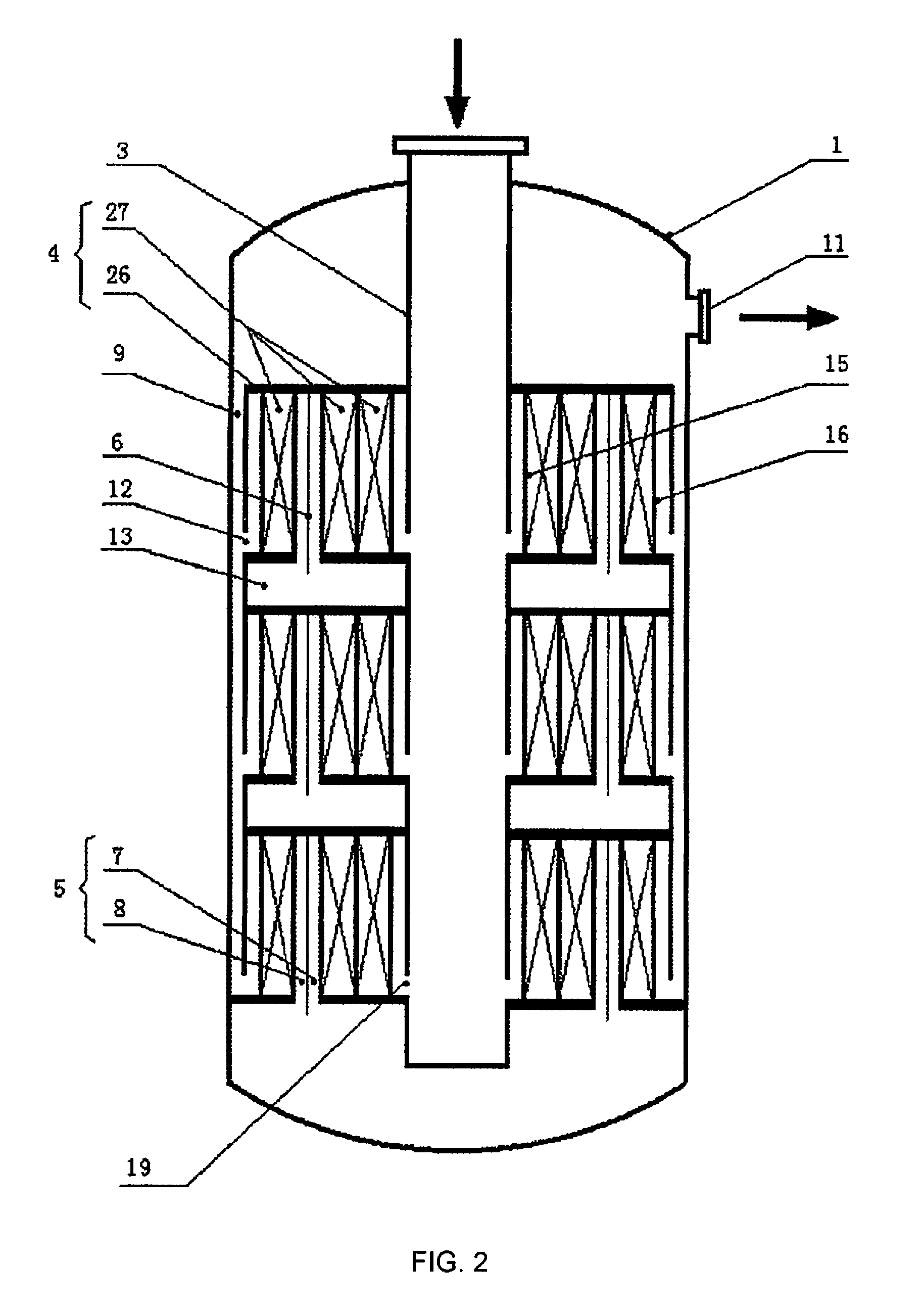

Radial-parallel catalytic reactor

InactiveUS20150343406A1Improve scalabilityStable jobExhaust apparatusSilencing apparatusProcess engineeringFeeding tube

The present invention comprises an axial radial catalytic reactor with a shell (as gas tight seal to maintain process gas flows within it) and a feed tube (passing from a source of process gas flow through the shell and into it do deliver feed gas to one or more levels of two annularly sequential catalyst beds), where one end of the feed tube is used as an inlet for feeding reaction mass. In one embodiment of the invention, an interior end of the feed tube is sealed.

Owner:ZHANG HUAIHAI +1

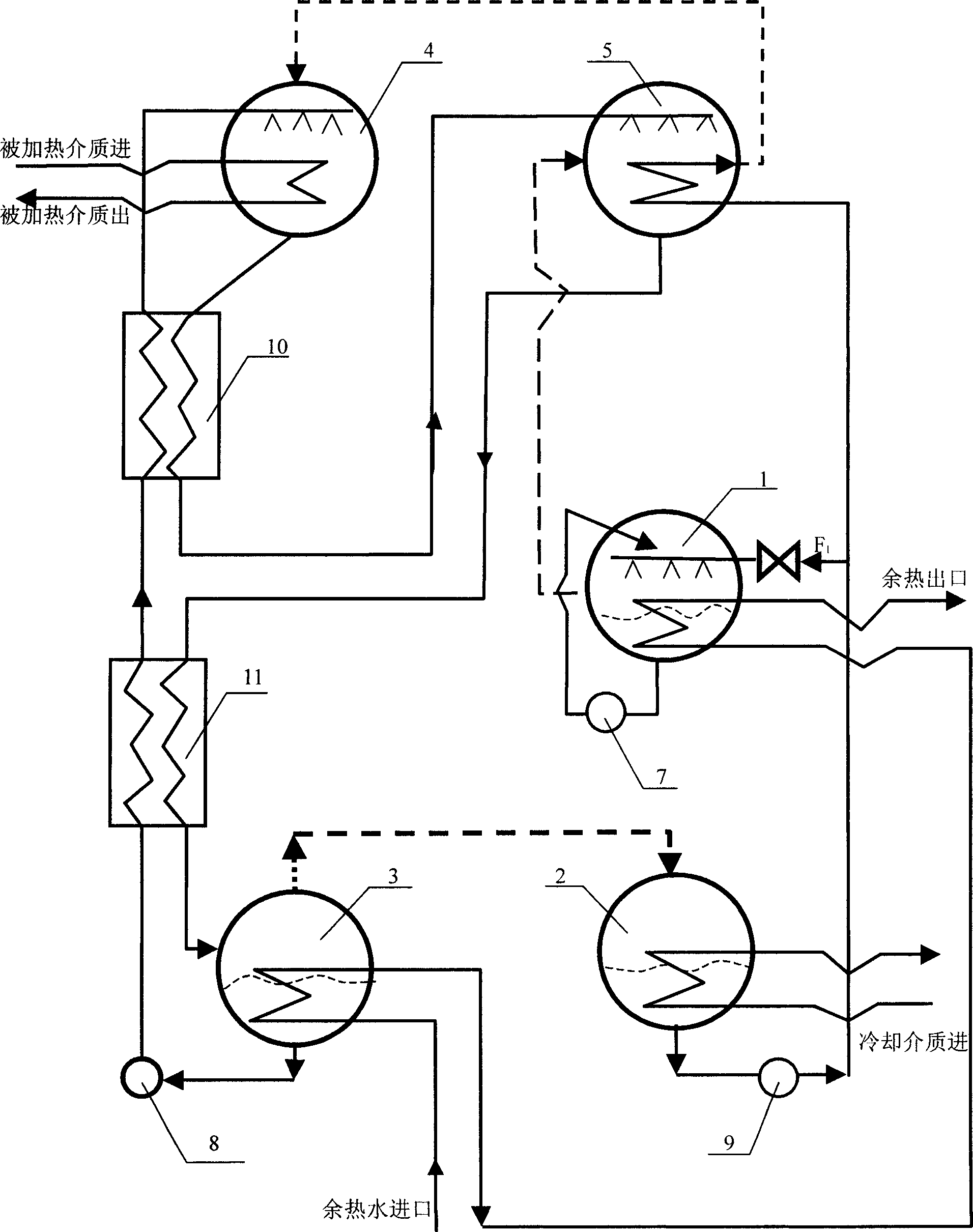

Two-stage and multi-stage type-II absorption heat transformer

The invention relates to a two-stage and multistage adsorption heat pump, belonging to the waste heat utilization technique. Wherein, it combines the middle absorbers with the middle vaporizer, to form adsorption-vaporization device; inside the adsorption-vaporization device, solution absorbs the steam of coolant from the vaporizer or superior (low-pressure) adsorption-vaporization device that processed outside the heat exchange tube; and the heated coolant from the coolant hydraulic pump flows the tube, the heat generated by using solution to absorb the steam of coolant is directly used to heat and gasify the coolant. Compared with present structure, the invention reduces the number of middle absorber and vaporizer, to make the number of adsorption-vaporization device lower 1 than the stage number, based on four basic elements that vaporizer, condenser, generator and absorber. The invention simplifies the process, improve the thermal parameter, and improve the temperature.

Owner:李华玉

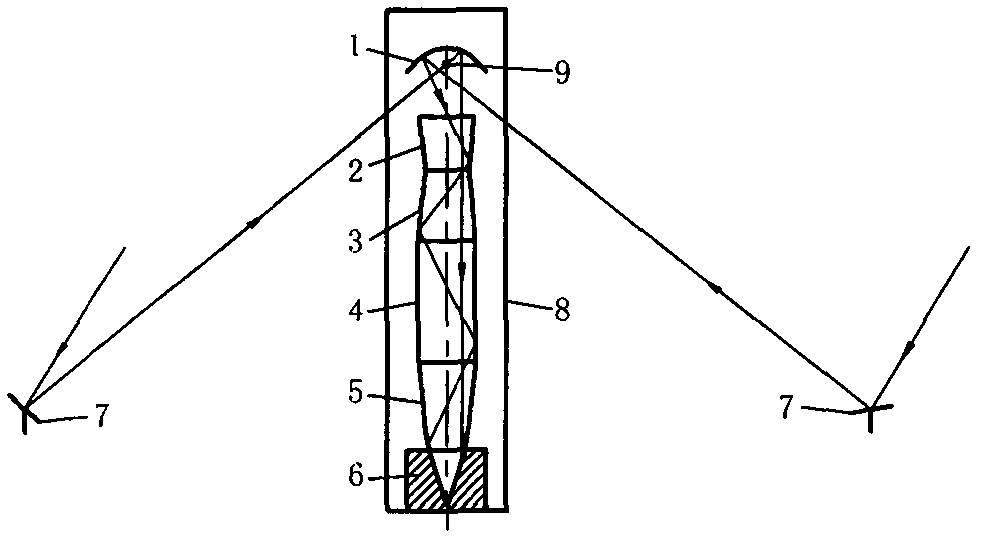

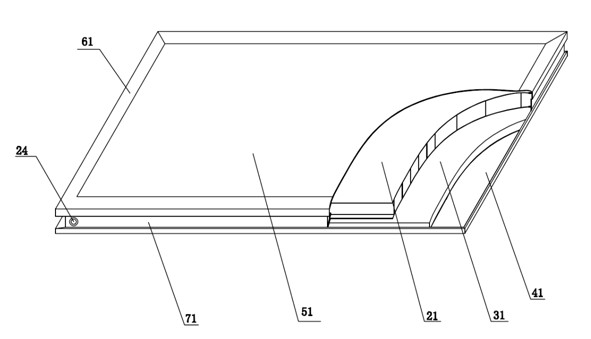

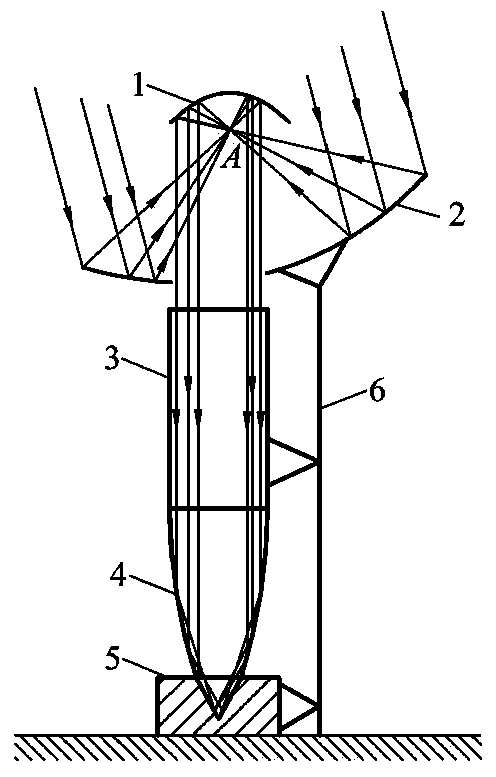

Solar heat collecting device

InactiveCN102563908AReduce loadReduce power consumptionSolar heating energySolar heat devicesHeliostatEngineering

The invention discloses a reflecting-tower-bottom type solar focusing high-temperature heat collecting device, which consists of a plurality of heliostats, a reflecting tower, a rotary parabolic mirror, a conical mirror, an inverted compound parabolic mirror, a cylindrical mirror, a compound parabolic mirror and a sunlight receiver, wherein the rotary parabolic mirror, the conical mirror, the inverted compound parabolic mirror, the cylindrical mirror, the compound parabolic mirror and the sunlight receiver are arranged on a reflecting tower in sequence from top to bottom. The sunlight is focused and reflected to the tower top of the reflecting tower by the plurality of heliostats, and then is reflected again on the sunlight receiver of the tower bottom from the tower top by the rotary parabolic mirror, the conical mirror, the inverted compound parabolic mirror, the cylindrical mirror and the compound parabolic mirror so as to realize heat collection, heat storage and heat exchange at the tower bottom. The reflecting-tower-bottom type solar focusing high-temperature heat collecting device has the advantages that the load of a tower body, the power consumption and the heat loss can be reduced, the process can be simplified, and high-temperature heat storage can be convenient. The reflecting-tower-bottom type solar focusing high-temperature heat collecting device is applicable to occasions such as solar thermal power generation and high-temperature heating.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

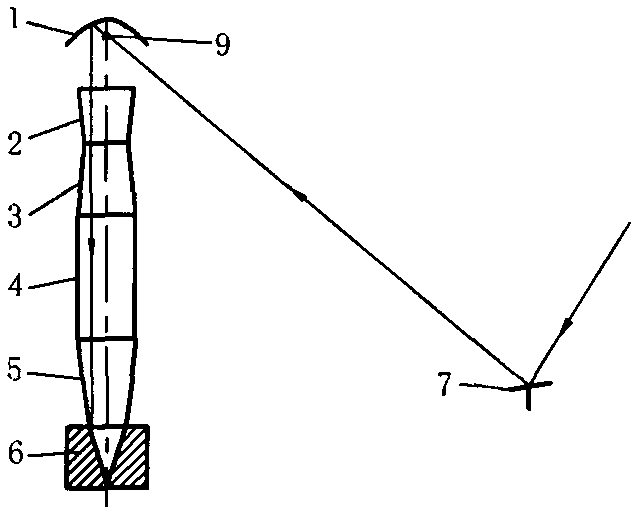

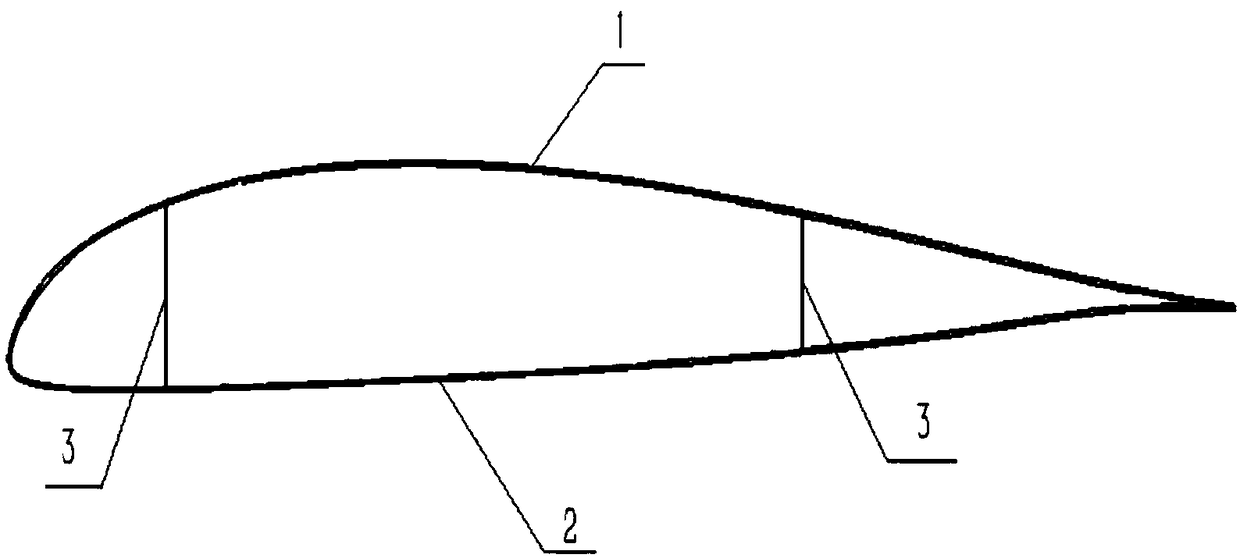

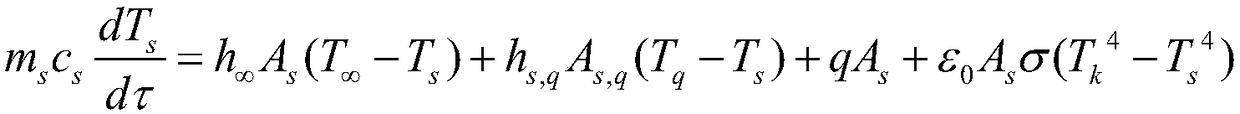

An aircraft fuel tank thermal calculation modeling method and a calculation model thereof

ActiveCN109145372AHeat calculation is fastThermal calculations are reliableSustainable transportationDesign optimisation/simulationExchange modelFuel tank

The invention relates to the technical field of aircraft fuel thermal management, in particular to an aircraft fuel tank thermal calculation modeling method and a calculation model thereof. A method for modeling the thermal calculation of an aircraft fuel tank comprises the follow steps: 1, abstracting the structure of the aircraft fuel tank as the recapitulative heat transfer boundary 2, making reasonable assumptions about the internal and external heat transfer conditions of the heat exchange boundary; 3, establishing a heat exchange model of that heat exchange boundary according to a reasonable assumption. The heat transfer models of the upper panel, the lower panel and the side panels of the aircraft fuel tank established by this method can be conveniently used for the heat calculationof the aircraft fuel tank, so that they can be incorporated into the heat calculation process of the fuel oil.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

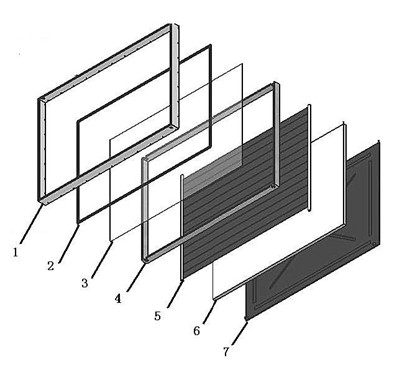

Flat Integral Solar Water Heater

InactiveCN102278827ACost-effectiveSimplify the heat transfer processSolar heating energySolar heat devicesThermodynamicsSolar water heating system

The invention discloses a flat integral solar water heater. The water heater comprises a flat plate box covered with a cover plate. There is a bottom plate under the box, and a frame around the periphery. There is an insulation layer between the box, the bottom plate, and the frame. The first threaded pipe mouth is a water inlet, the threaded pipe mouth arranged along the diagonal position of the water inlet is a hot water outlet, and the other two threaded pipe mouths are respectively provided with a temperature measuring probe and an electric heating pipe. The invention integrates several functions of heat absorption, heat conversion and hot water storage; it simplifies the heat exchange process, reduces system materials, and greatly improves the cost performance of the solar water heating system. A solid foundation has been laid.

Owner:吴俊田

Tower bottom reflecting type solar focusing heat-collecting device

InactiveCN102914064AReduce loadReduce heat lossSolar heating energySolar heat devicesHeliostatEngineering

Disclosed is a tower bottom reflecting type solar focusing heat-collecting device. The device consists of heliostats, a rotary paraboloidal mirror, tapered mirrors, a cylindrical mirror, a compound paraboloidal mirror, a sunlight receiver and a heat storage heat exchanger, wherein the rotary paraboloidal mirror, the tapered mirror, the cylindrical mirror, the tapered mirror, the compound paraboloidal mirror, the sunlight receiver and the heat storage heat exchanger are arranged sequentially from tower top to tower bottom, a plurality of heliostats are used for focusing and reflecting sunlight to the tower top, the rotary paraboloidal mirror, the tapered mirrors, the cylindrical mirror and the compound paraboloidal mirror are used for re-reflecting the sunlight to the sunlight receiver at the tower bottom from the tower top, the sunlight receiver is located in the heat storage heat exchanger, the heat storage and external heat exchanging are achieved on the heat storage heat exchanger, the focusing heat collection, heat storage and external heat exchanging are conducted at the bottom of the tower, the tower bottom load is reduced, the power consumption is reduced, the heat loss is reduced, the process is simplified, the high-temperature heat storage is facilitated, and the device is suitable to solar generating and high-temperature heating application occasions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

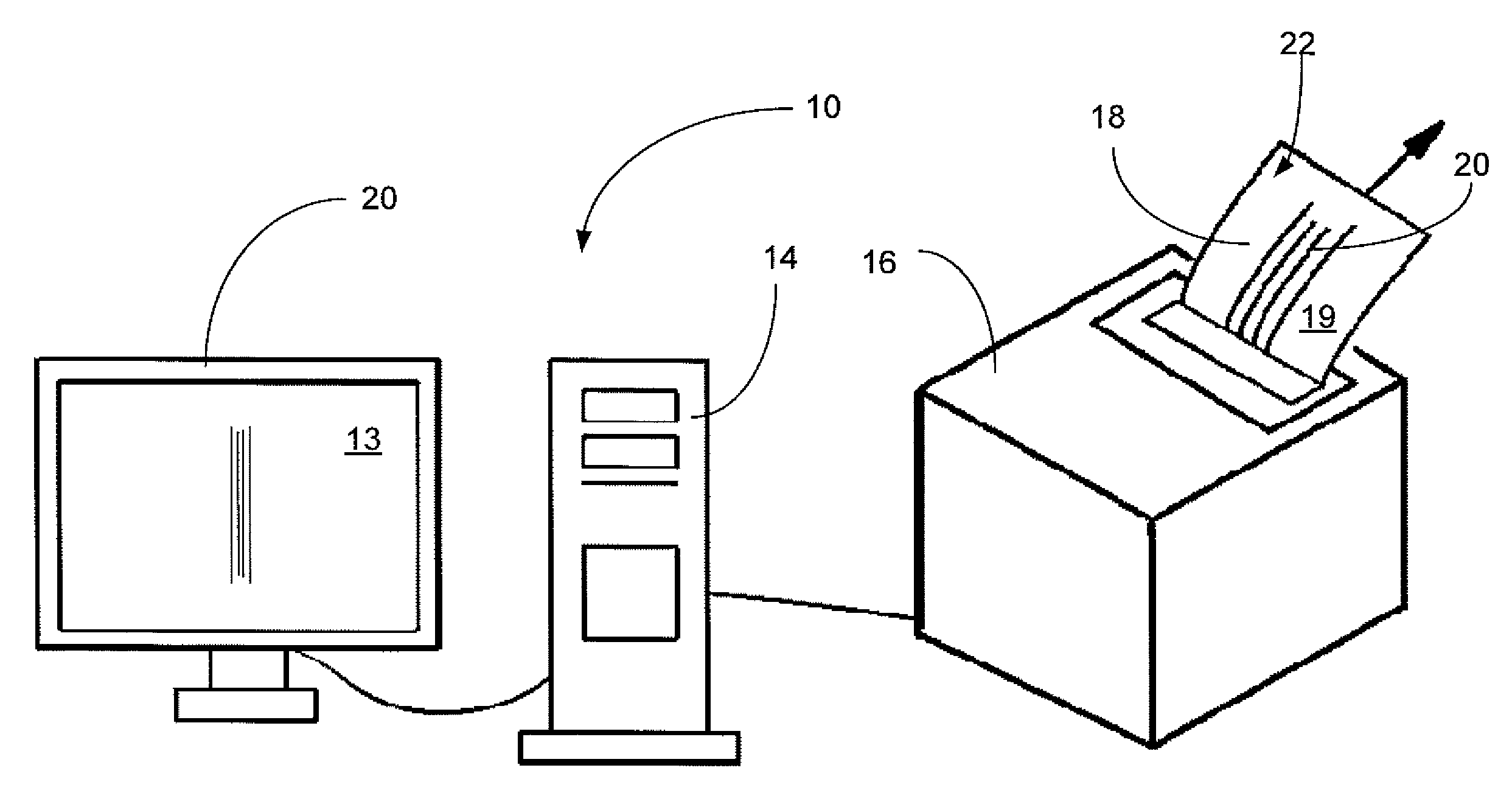

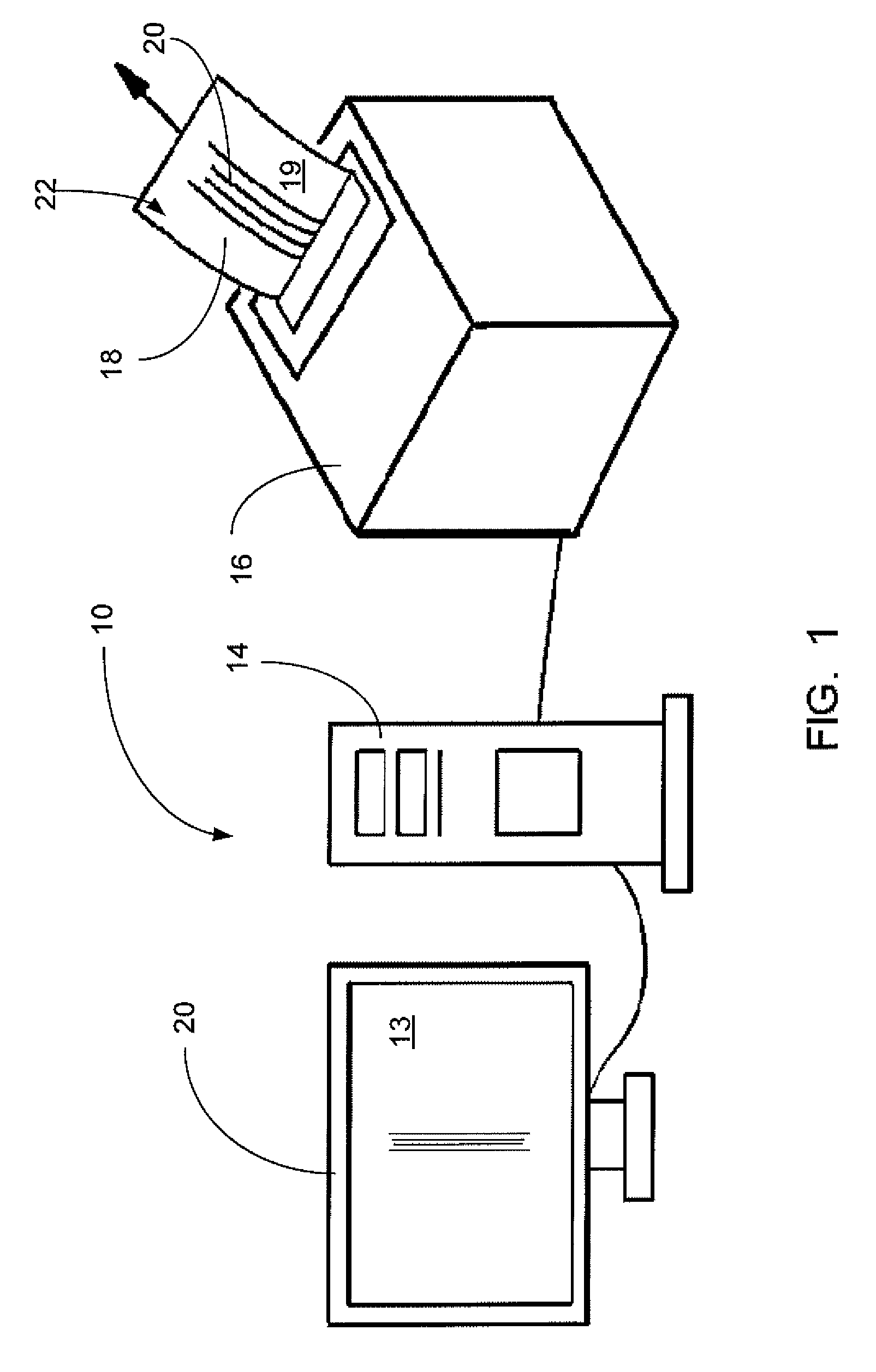

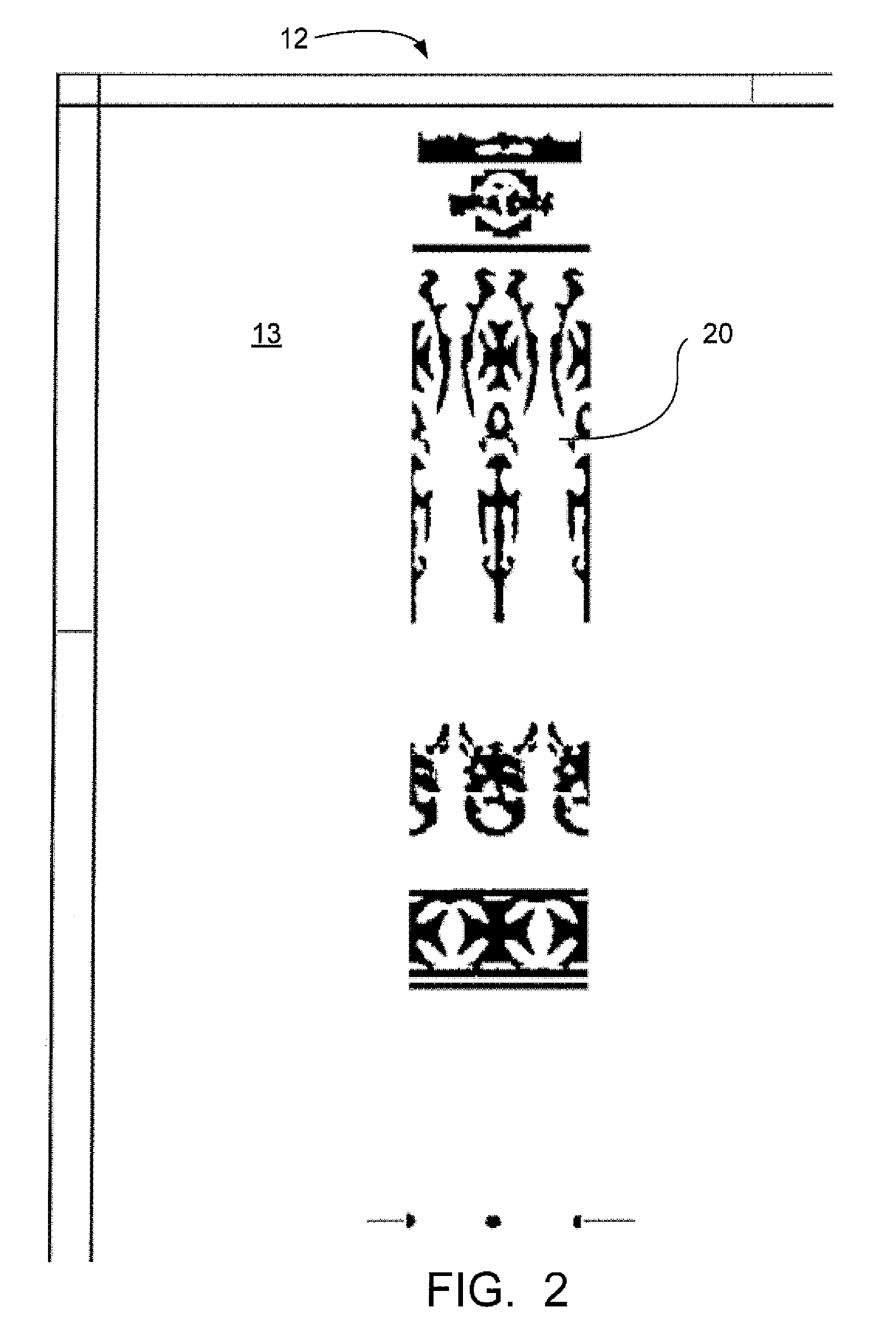

Process for producing and applying a laser heat transfer capable of printing on flat, cylindrical, curved, and irregularly shaped objects

ActiveUS7495162B1Cost effectiveLow costPercussion musical instrumentsElectrographic process apparatusOptoelectronicsPaper sheet

The process, which includes the concept of first producing a unique type of heat transfer formed of laser toner particles as well as the subsequent application of the heat transfer to a drumstick or decorated item, would include the steps of obtaining a sheet, roll, belt, etc. of suitable carrier material which has been treated or coated with a release agent (i.e. silicone coated paper); loading carrier material into a laser printer which has had the fusing stage removed or otherwise altered to facilitate the formation of laser toner images on the carrier material; using the laser printer to print a laser toner powder form of the desired image onto the carrier material via computer instruction; obtaining item to be printed and loading it into the heat transfer application machine; loading or feeding heat transfer as described into heat transfer application machine; transferring and fusing laser toner powder image to item to be printed with the heat transfer application machine (which applies heat and pressure in a controlled fashion to the unprinted side of the heat transfer such that the laser toner powders are pressed against the item to be printed); and removing printed item and used carrier material from application machine, with the heat transfer itself exhibiting characteristics which distinguish it as unique and particularly well suited to various applications.

Owner:POKALLUS KEVIN

Tail flue gas waste heat utilizing system of utility boiler based on hot blast recycling

InactiveCN106402838AReduce the temperatureImprove power generation efficiencyLiquid degasificationCombustion technology mitigationAir preheaterHigh pressure

The invention relates to a tail flue gas waste heat utilizing system of an utility boiler based on hot blast recycling. The tail flue gas waste heat utilizing system comprises a boiler water supply regenerative heating device and a boiler tail flue gas waste heat utilizing device, wherein the boiler water supply regenerative heating device is provided with a low-pressure heating unit, a high-pressure heating unit, a deoxygenizing unit and a water supply pump, which sequentially communicate; low-pressure extraction steam generated after work application of steam generated by the boiler is used by the low-pressure heating unit as a heat exchanging heat source; and high-pressure extraction steam generated after work application of steam is used by the high-pressure heating unit as a heat exchanging heat source. According to the tail flue gas waste heat utilizing system disclosed by the invention, a circulating hot wind is utilized as a heat-transfer medium, so that the temperature level and the heat-into-power conversion efficiency of the flue gas waste heat recycled by the water supply regenerative system are improved, the purpose that the electricity supply efficiency of an electricity generating system is substantially improved is realized, the investment and the operation control difficulty of a waste heat recovery system are reduced, the problems of the corrosion, the ash deposition and the abrasion of the waste heat recovery system are solved, the cold end low temperature corrosion of an air preheater is avoided, besides, newly building a bypass flue is not needed, the system is compact in technological process, and the construction of the engineering is facilitated.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

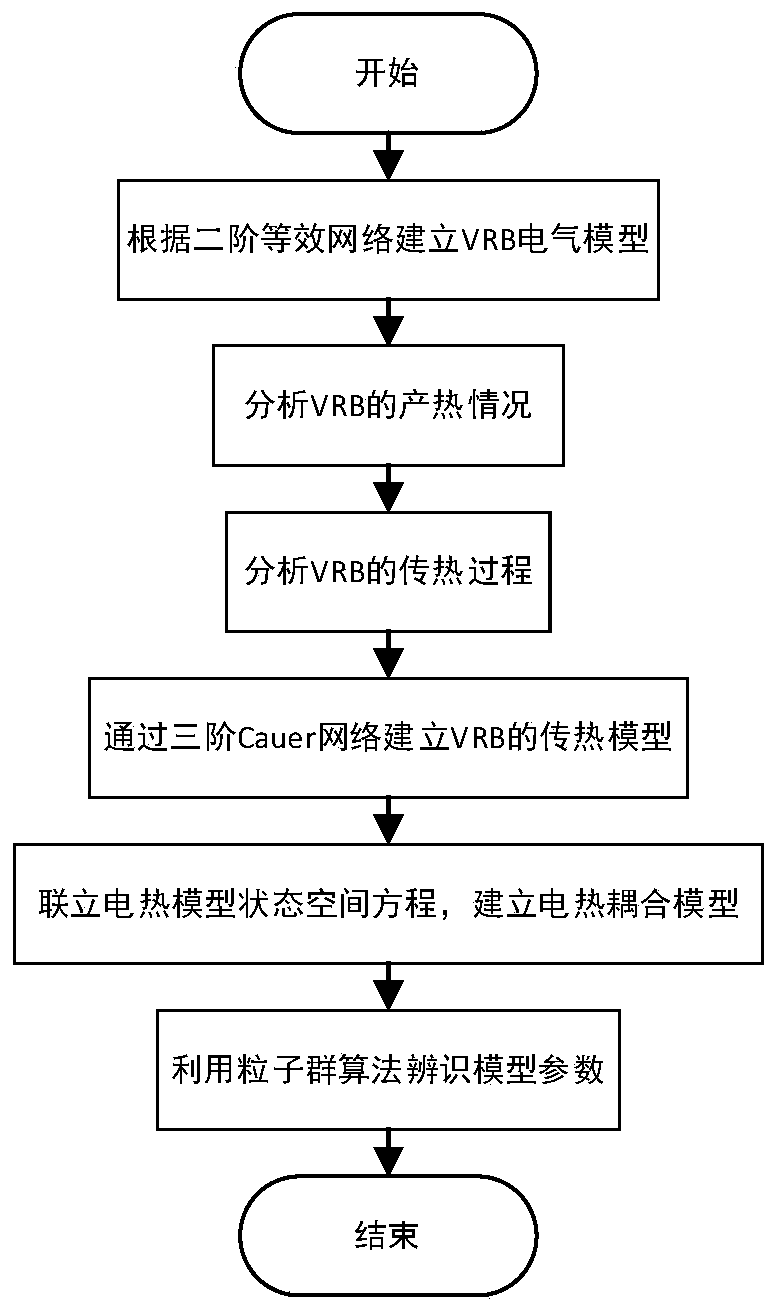

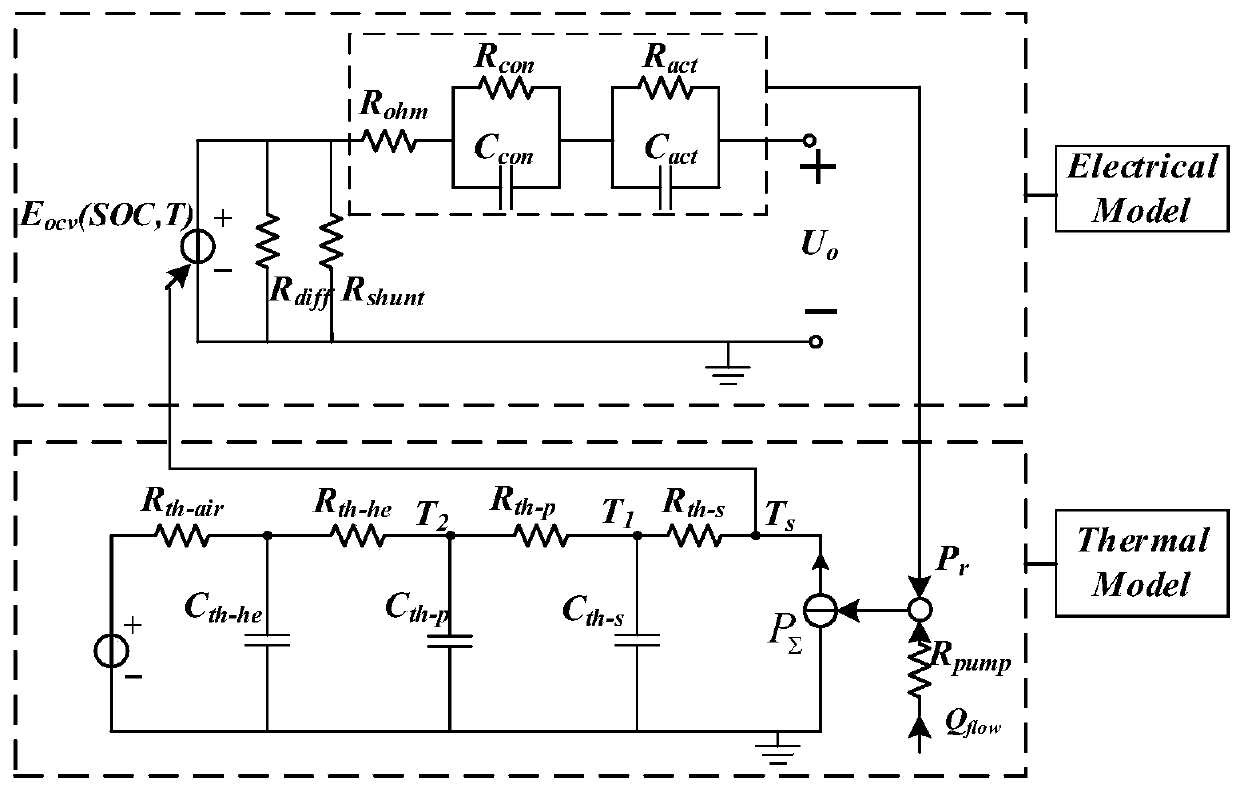

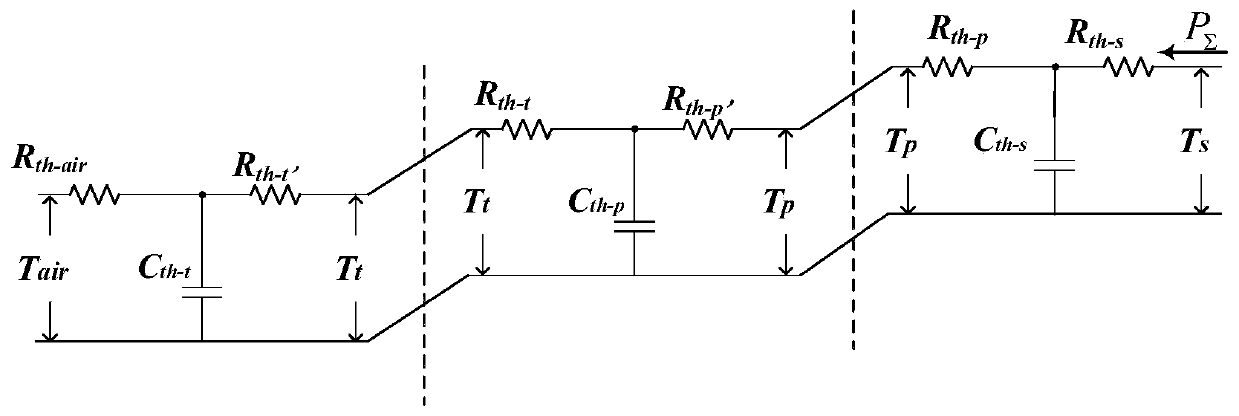

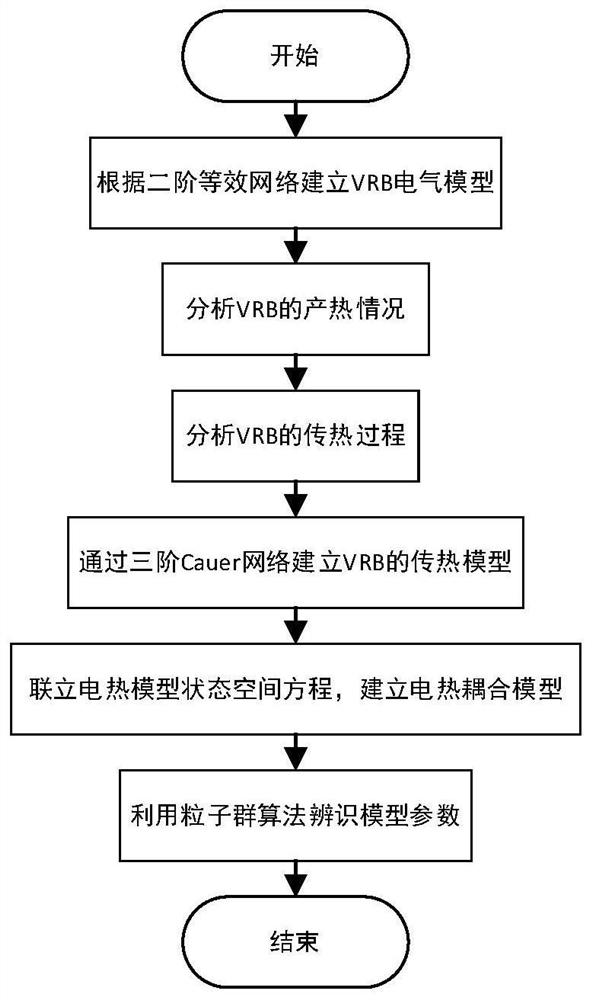

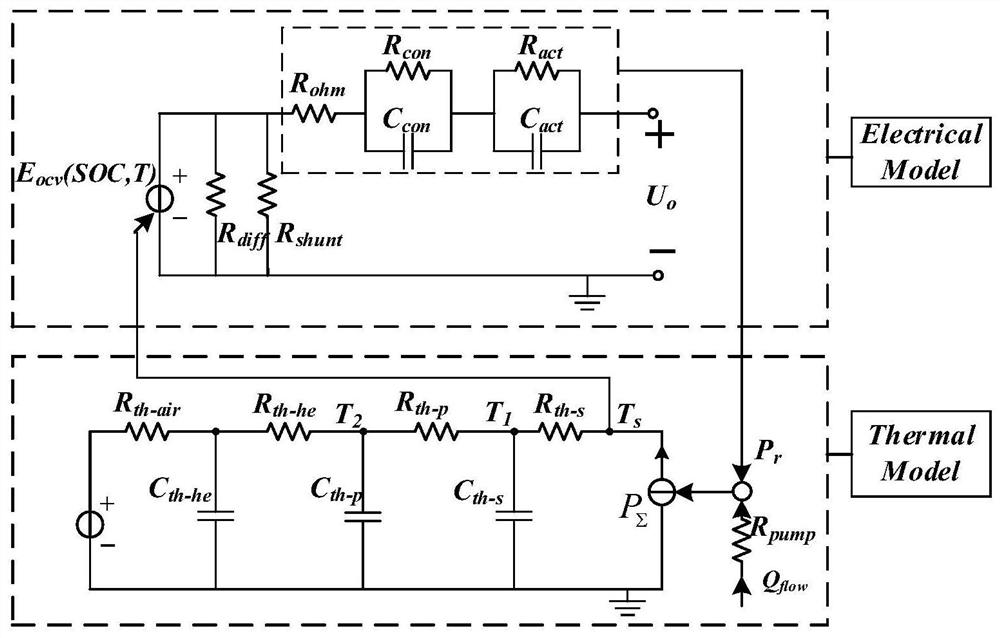

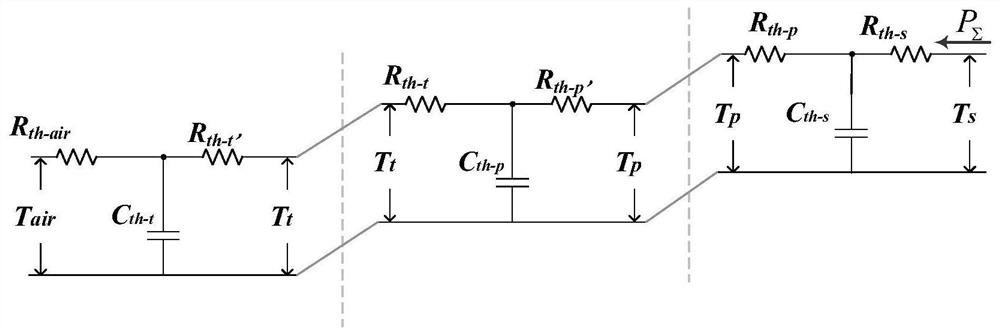

All-vanadium redox flow battery energy storage system equivalent method based on electric-thermal coupling

ActiveCN110276120ASafe and stable operationAccurate predictionDesign optimisation/simulationSpecial data processing applicationsTerminal voltageElectrical battery

The invention discloses an all-vanadium redox flow battery energy storage system equivalence method based on electric-thermal coupling. The method comprises: 1, performing modeling on electrical characteristics of a VRB according to a second-order resistance-capacitance network; 2, performing parameter identification by using a particle swarm algorithm; 3, analyzing the heat production condition of each module in the operation of the battery; 4, analyzing the heat transfer process of the VRB system; 5, based on an electric-thermal ratio fitting principle, a heat transfer path being equivalent; and 6, combining all the states obtained in the step 2 and the step 5 to obtain a complete state space equation of the VRB energy storage system electric heating coupling model. According to the method, the electrical characteristics and the heat generation characteristics of the VRB energy storage system during operation and the coupling relation between the electrical characteristics and the heat generation characteristics are comprehensively considered, the charge state, the terminal voltage and the temperature states of all parts of the battery can be accurately predicted, and safe and stable operation of the VRB is effectively guaranteed.

Owner:WUHAN UNIV OF TECH +1

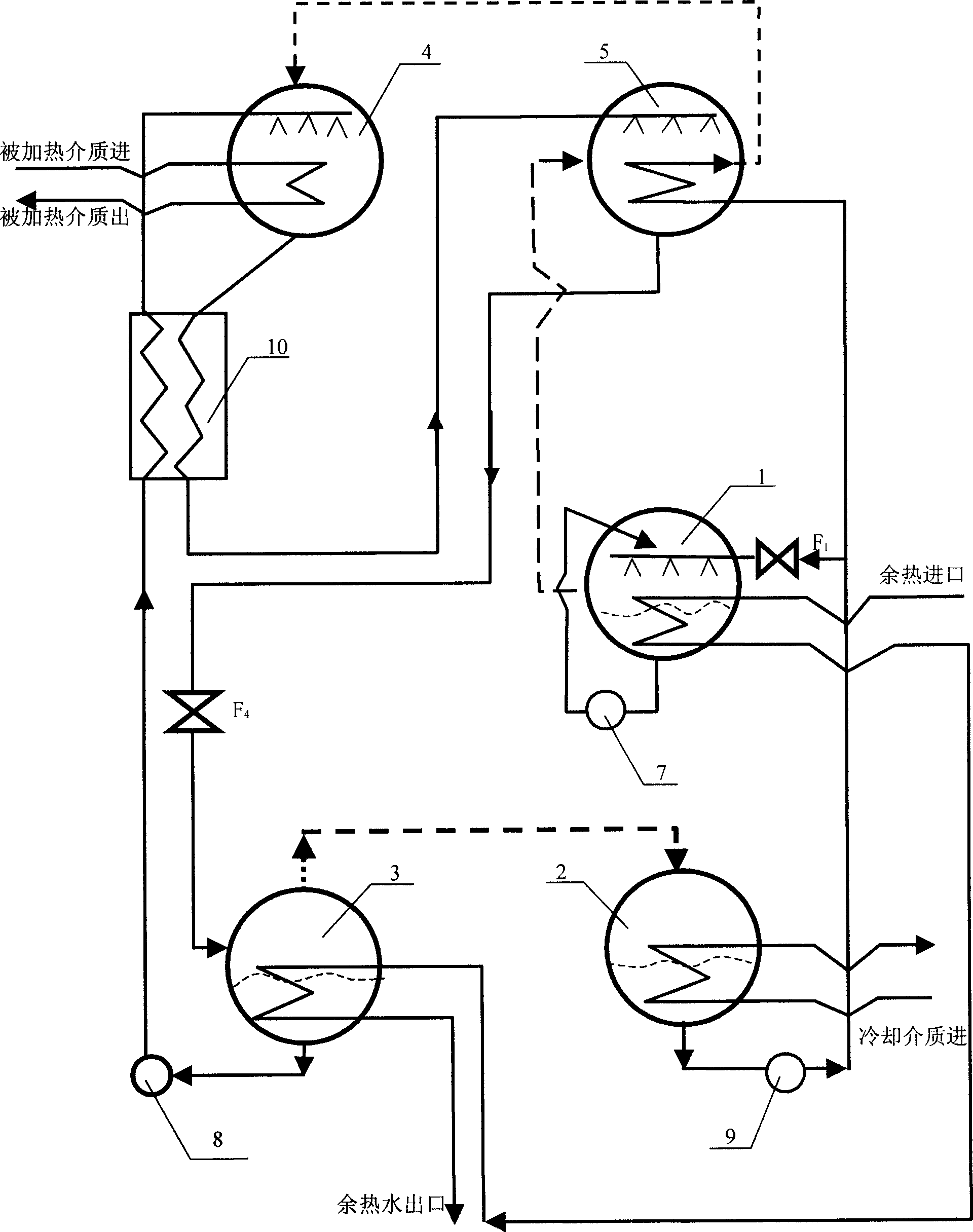

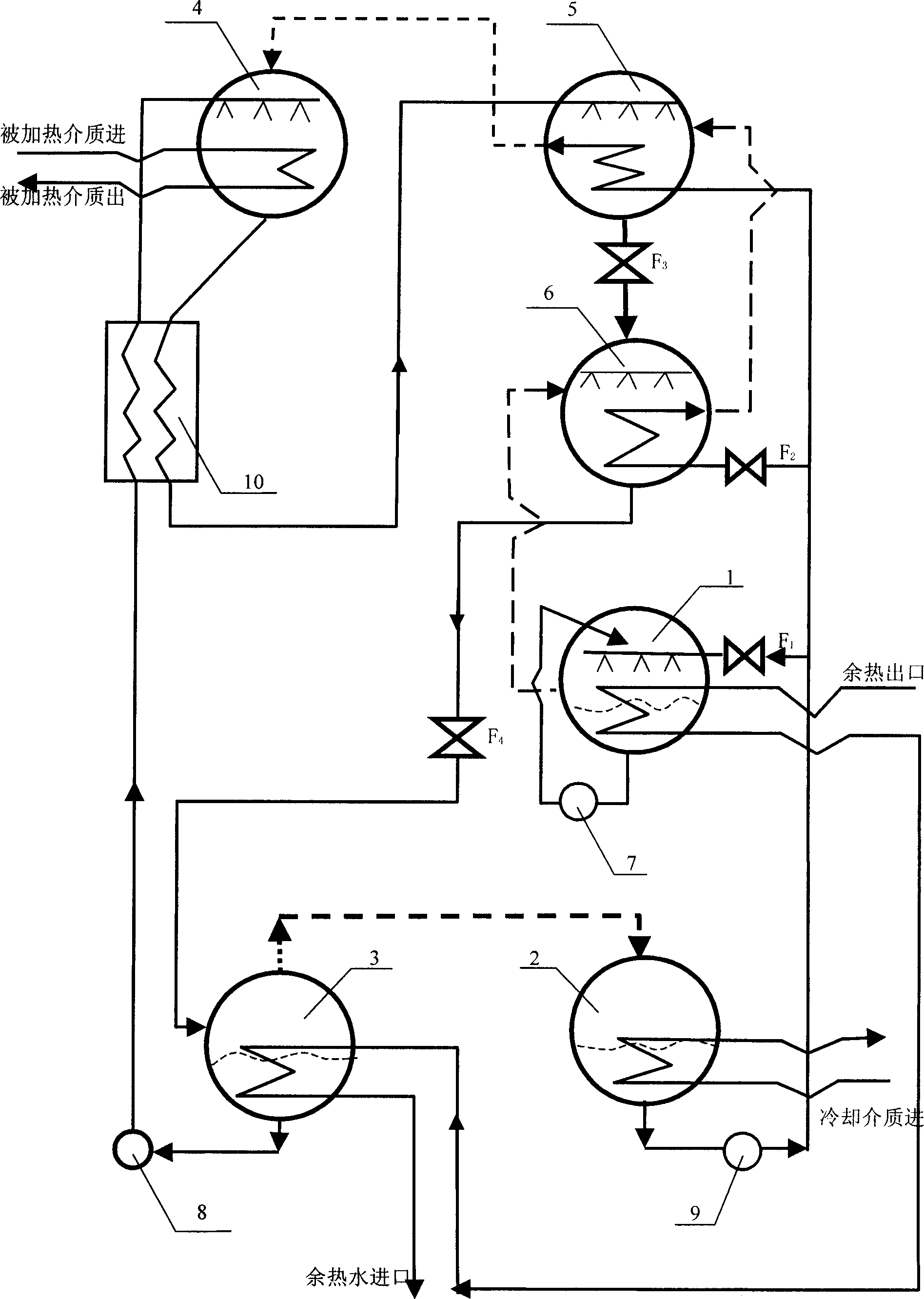

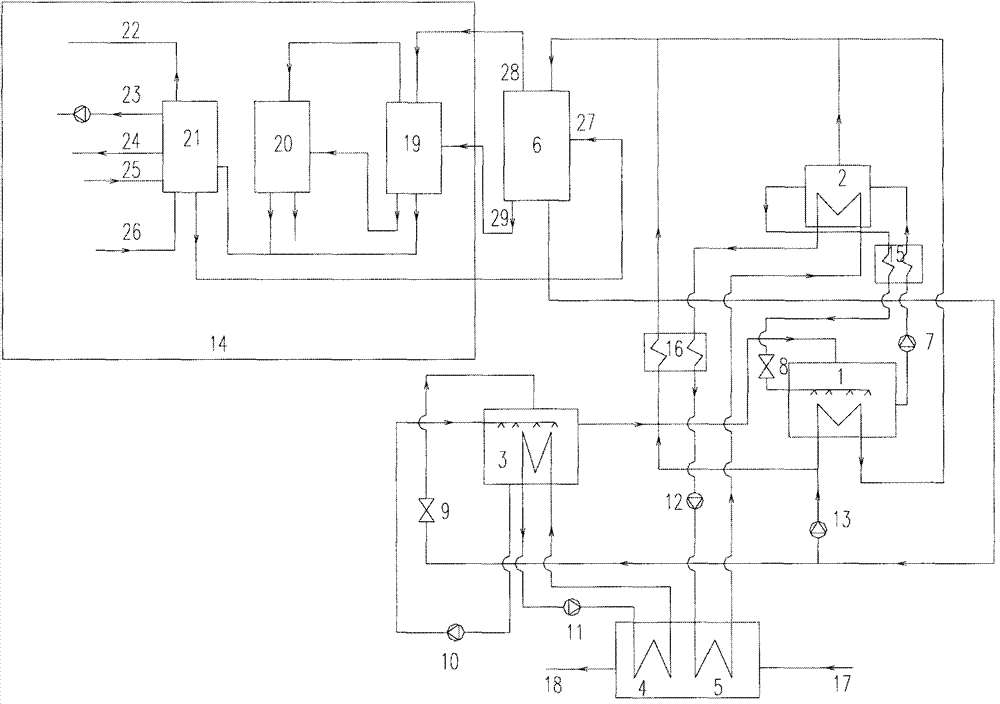

Method of combination of flue gas low-temperature waste heat utilization and salt-containing waste water treatment

ActiveCN104973641AReduce lossesSave heat medium water linkWater/sewage treatmentIncreasing energy efficiencyFlue gasEvaporation

The invention relates to the field of petrochemical engineering and provides a method of combination of flue gas low-temperature waste heat utilization and salt-containing waste water treatment. The method is characterized by including the steps of: 1) completing an absorbent solution circulation; 2) completing a refrigerant circulation; 3) completing a high-temperature flue gas heat exchange circulation; 4) completing a low-temperature flue gas heat exchange circulation; and 5) closely combining absorption heat exchange with low-temperature multiple-effect evaporation, so that the two processes of the absorption heat exchange and the low-temperature multiple-effect evaporation can be completed. By means of integration of a condenser in absorption heat exchange and a first-effect evaporator in the low-temperature multiple-effect evaporation, the low-temperature waste heat utilization and the salt-containing waste water treatment are combined, so that a heat medium water step is canceled. The method is reduced in heat exchange temperature difference and system loss, is increased in device economy and achieves the double objects of saving energy and reducing emission in a manner of treating wastes with wastes.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

A Sensible Heat Storage Direct Steam Generation System and Method Based on Series Regulation

ActiveCN105953202BSimplify the heat transfer processSimple designSteam generation heating methodsHeat storage plantsWater storageEngineering

The invention discloses a sensible heat storage type direct steam generation system and method based on series-connection adjustment. The system comprises an outlet header, an outlet connection pipe, a heat storage body, a heat exchange pipe, a first temperature sensor, a sealed heat-preserving layer, a three-way valve, a check valve, an inlet header, a circulating water pump, a flowmeter, a control cabinet, a water supplementing connection pipe, a water storage pond, a second temperature sensor and a third temperature sensor. A pipeline series-connection method is adopted for the system, by means of the method that the heat exchange area is increased in the flowing direction, the problem that because the temperature of the heat storage body is lowered, the heat exchange coefficient and the heat exchange power are reduced is solved; and in the heat exchange process of the system, the flow in single pipelines is not changed, the heat exchange process is relatively simple, and design and calculation of the system are convenient. By means of implementation of the system, the running cost of a traditional electric boiler can be effectively lowered, after calculation, the cost generated by adopting the steam system is equivalent to that generated by adopting a natural gas system, and broad market application prospects are achieved.

Owner:ZHEJIANG UNIV

Two-stage cascade high-humidity smoke condensing and spraying heat exchange method and device

The invention discloses a two-stage cascade high-humidity smoke condensing and spraying heat exchange method and device, and belongs to the technical field of exhaust air heat recovery and boiler heat supply. An integrated two-stage spraying tower type heat exchange structure is adopted, waste heat of a high-temperature section and waste heat of a low-temperature section of high-humidity smoke are extracted correspondingly for different heating process water, wherein smoke enters a tower from the lower portion of the tower and flows upwards, sequentially passes through a high-temperature heat exchange section and a low-temperature heat exchange section for direct contact filler or air tower heat exchange and discharged from the tower top; low-temperature process circulation water is sent into the low-temperature heat exchange section through a second-stage spraying device for heat exchange, and is output through a water air separator or continues moving downwards after the temperature of the water is increased; and high-temperature process circulation water is sent into the high-temperature heat exchange section through a first-stage spraying device and is output after being collected in a tower bottom pond. Series-parallel-connection combined cascade countercurrent heat exchange is formed between system smoke and two paths of process water with different parameters, lots of smoke waste heat is recovered by the high-temperature section, and process water flows in high flow; and smoke is cooled and dehumidified greatly by the low-temperature section, and process water flows with large temperature difference.

Owner:TSINGHUA UNIV +1

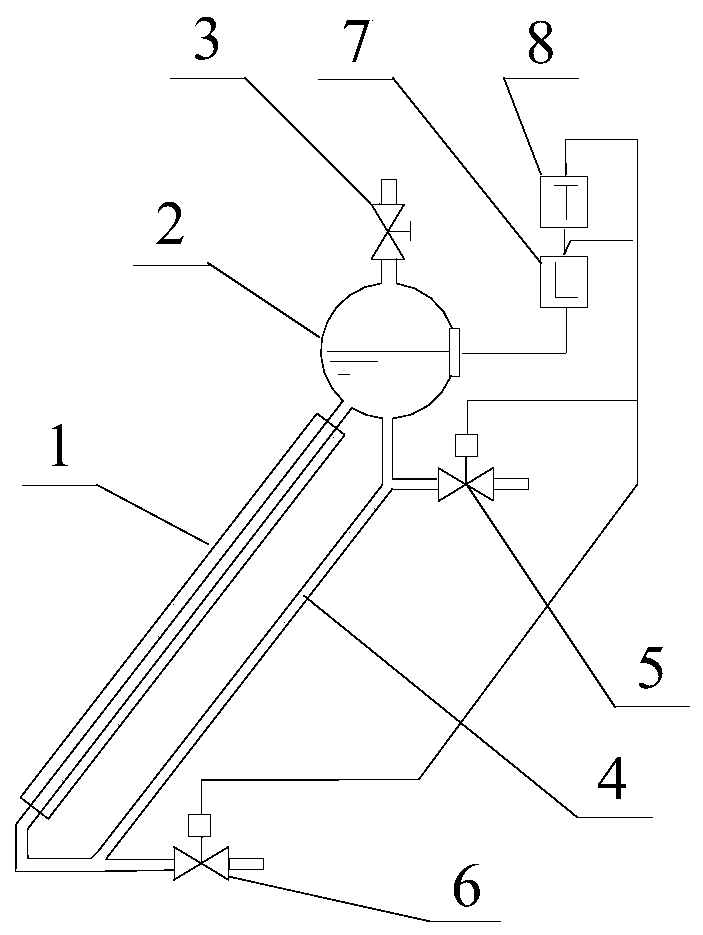

Hygroscopic solution regeneration system

ActiveCN107137944AAchieve recyclingReduce intermediate linksEvaporators with forced circulationEvaporator regulation/controlExhaust valveClosed loop

The invention discloses a hygroscopic solution regeneration system. The system comprises an evacuated collector pipe, a solution tank, a return pipe, an inlet valve, an outlet valve and an exhaust steam valve. During use, the exhaust steam valve and the inlet valve are switched on, and a hygroscopic solution enters the system from the inlet valve; the hygroscopic solution entering the evacuated collector pipe is heated by the evacuated collector pipe firstly, then due to the effect of the density difference between the hygroscopic solution in the evacuated collector pipe and the unheated hygroscopic solution exists, the hygroscopic solution flows in a closed loop formed by the evacuated collector pipe, the solution tank and the return pipe, and heating of the hygroscopic solution in the system is completed. Meanwhile, steam generated during heating of the hygroscopic solution is exhausted from the exhaust valve, regeneration of the hygroscopic solution is completed finally, and the regenerated hygroscopic solution flows out of the outlet valve to be recycled. By the design of the hygroscopic solution regeneration system, the hygroscopic solution is directly heated by the evacuated collector pipe, and the intermediate link of a heat exchanger is omitted, so that the heat transfer process is simplified, heat transfer efficiency is improved, and problems in the field at the present stage are solved.

Owner:GUANGDONG UNIV OF TECH

Radial-parallel catalytic reactor

InactiveUS9504979B2Improve scalabilityStable jobChemical/physical/physico-chemical stationary reactorsProcess engineeringFeeding tube

The present invention comprises an axial radial catalytic reactor with a shell (as gas tight seal to maintain process gas flows within it) and a feed tube (passing from a source of process gas flow through the shell and into it do deliver feed gas to one or more levels of two annularly sequential catalyst beds), where one end of the feed tube is used as an inlet for feeding reaction mass. In one embodiment of the invention, an interior end of the feed tube is sealed.

Owner:ZHANG HUAIHAI +1

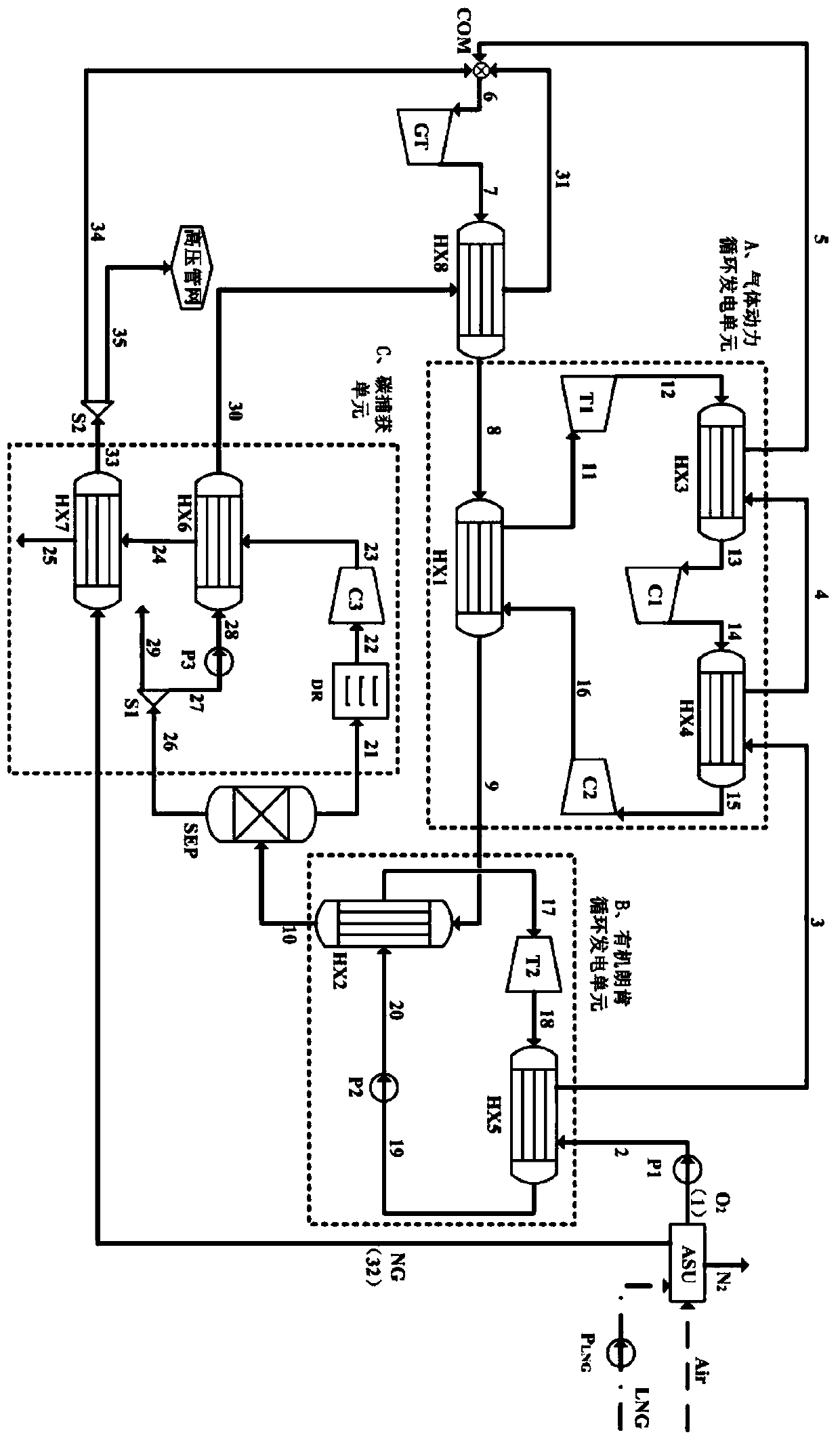

A Power Generation System Utilizing Latent Heat of Vaporization of Exhaust Smoke from Natural Gas Power Plant

ActiveCN108331625BSolve the problem of general waste of latent heat of vaporizationImprove power generation efficiencySolidificationLiquefactionHigh energyPower cycle

The invention discloses a power generation system utilizing the latent heat of vaporization of exhaust smoke from a natural gas power plant. The system proposes a compound combined cycle power generation unit for an oxygen-enriched combustion natural gas power plant. The flue gas after oxygen-enriched combustion passes through a gas turbine GT, The gas power cycle power generation unit A and the organic Rankine cycle power generation unit B can fully recover the latent heat of vaporization in the flue gas, reduce the exhaust gas temperature below normal temperature, and then separate the CO in the flue gas 2 and water to achieve carbon capture C. In the present invention, the gas power cycle is used to avoid the phase change of the heat exchange medium and improve the heat exchange effect; the organic Rankine cycle is used to fully recover the latent heat of vaporization in the flue gas, which greatly improves the power generation efficiency of the system; the present invention can effectively solve the problem of low temperature flue gas The latent heat of vaporization of middle water vapor is generally wasted, the energy consumption of carbon capture is high, and the cold energy of LNG is seriously wasted. At the same time, the power generation efficiency of the system is improved, and an energy-saving, environmentally friendly, and efficient integrated power generation system is truly realized.

Owner:HUAZHONG UNIV OF SCI & TECH

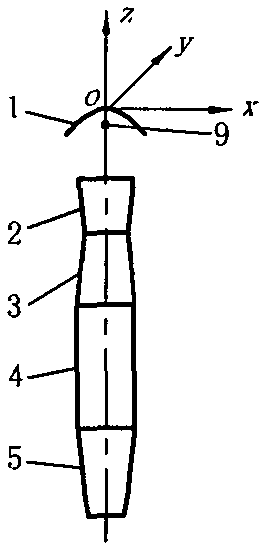

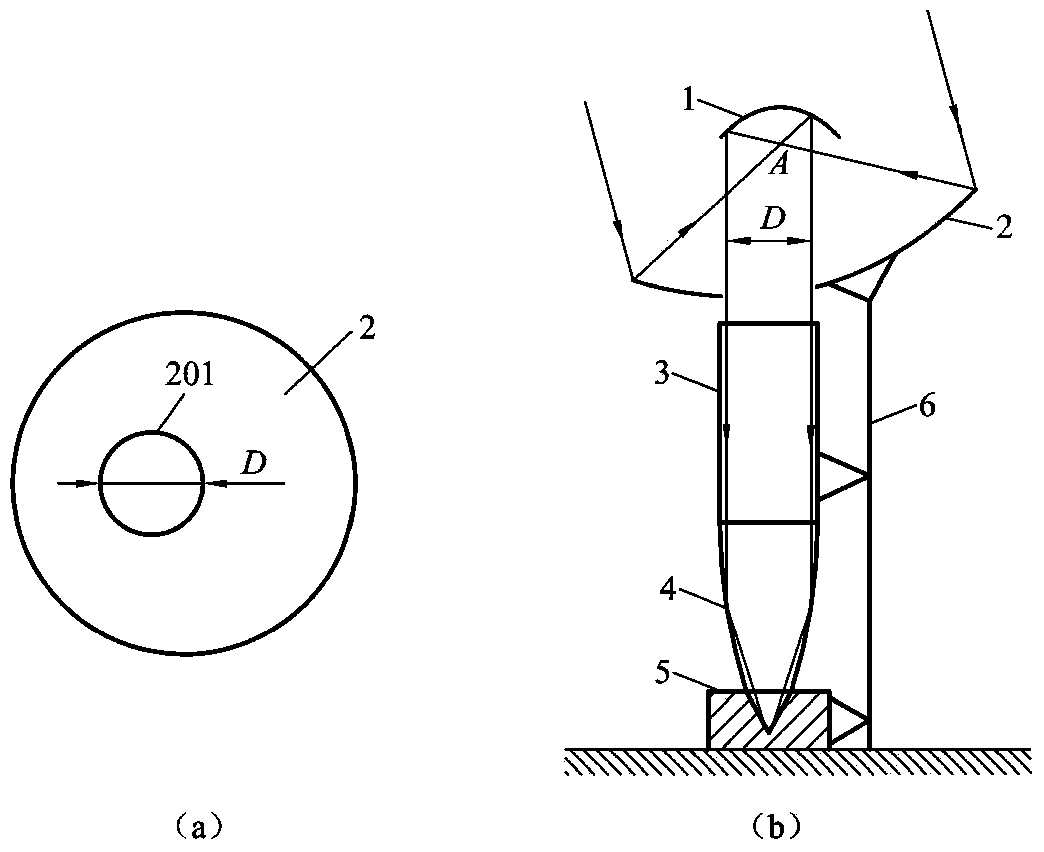

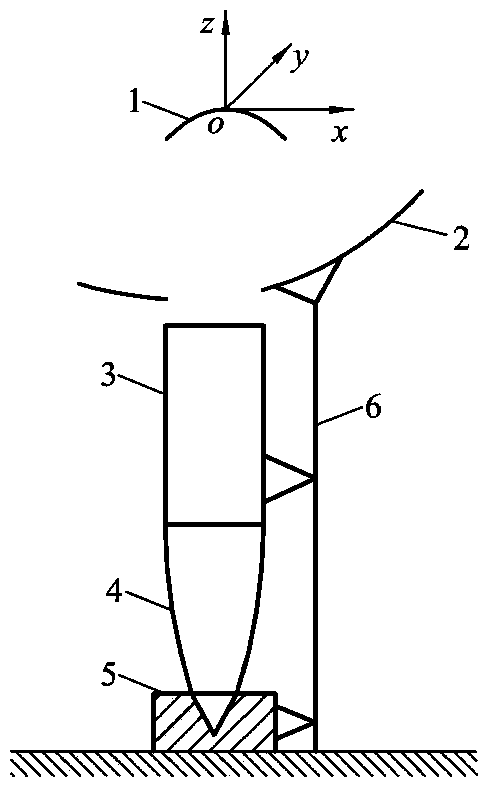

A Downward Reflecting Solar Concentrating Heat Collector

InactiveCN105423573BReduce power consumptionReduce heat lossSolar heating energyMoving/orienting solar heat collectorsHeliostatTransmittance

The present invention proposes a downwardly reflecting solar energy focusing heat collection device, comprising: a rotating parabolic mirror (1), a rotating parabolic heliostat with a transmission hole (2), a cylindrical mirror (3), and a compound parabolic mirror (4) , sunlight receiver (5) and support frame (6); the rotating parabolic mirror (1) is inverted and placed on the rotating parabolic heliostat (2) with a transmission hole, the cylindrical mirror (3), the compound paraboloid The mirror (4) and the sunlight receiver (5) are placed directly below the transmission hole (201) of the rotating parabolic heliostat (2) with the transmission hole; The heliostat (2) is reflected on the inverted rotating parabolic mirror (1), and then reflected downwards by it into a parallel beam passing through the transmission hole (201) to the compound parabolic mirror (4) directly below it, and finally reflected On the solar heat collector (5), realize the downward focusing reflection of sunlight.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Object-oriented cooling device based on pulse tube refrigerator

InactiveCN101818981AImprove cooling efficiencyImprove transmission efficiencyLighting and heating apparatusRefrigeration devicesInlet valveRotary valve

The invention discloses an object-oriented cooling device based on a pulse tube refrigerator, comprising a compressor, a rotary valve, an orifice valve, a two-way intake valve, an air reservoir, a close over, a flange, a heat regenerator, a pulse tube, a cold finger connection coiler and a device to be cooled, wherein the compressor is connected with the rotary valve which is respectively connected with the hot end of the heat regenerator and one end of the two-way intake valve, the air reservoir is respectively connected with the hot end of the pulse tube and the other end of the two-way intake valve through the orifice valve, and the cold end of the pulse tube and the cold end of the heat regenerator are connected through one or more copper tubes which are respectively coiled or welded on one or more devices to be cooled. The cold finger connection coiler of a refrigerator is directly coiled or welded on the devices to be cooled, thereby the invention enlarges the heat exchange area between the refrigerator cold finger and the devices to be cooled, reduces heat transfer temperature difference and obviously enhances the cooling performance; and the refrigerator can be used for directly cooling a plurality of devices to be cooled simultaneously, thereby enhancing the cooling efficiency of the refrigerator and greatly expanding the application range of the cryogenic refrigerator.

Owner:ZHEJIANG UNIV

A method of combining low-temperature waste heat utilization of flue gas with treatment of saline wastewater

ActiveCN104973641BSimplify the heat transfer processReduce heat transfer temperature differenceWater/sewage treatmentEnergy based wastewater treatmentFlue gasEvaporation

The invention relates to the field of petrochemical engineering and provides a method of combination of flue gas low-temperature waste heat utilization and salt-containing waste water treatment. The method is characterized by including the steps of: 1) completing an absorbent solution circulation; 2) completing a refrigerant circulation; 3) completing a high-temperature flue gas heat exchange circulation; 4) completing a low-temperature flue gas heat exchange circulation; and 5) closely combining absorption heat exchange with low-temperature multiple-effect evaporation, so that the two processes of the absorption heat exchange and the low-temperature multiple-effect evaporation can be completed. By means of integration of a condenser in absorption heat exchange and a first-effect evaporator in the low-temperature multiple-effect evaporation, the low-temperature waste heat utilization and the salt-containing waste water treatment are combined, so that a heat medium water step is canceled. The method is reduced in heat exchange temperature difference and system loss, is increased in device economy and achieves the double objects of saving energy and reducing emission in a manner of treating wastes with wastes.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Method and a system for separating hydrogen obtained by reforming

ActiveCN113913220AGood re-contact purification effectIncreased reformed hydrogen purityHydrogen separationGaseous fuelsHydrogen purityProcess engineering

The invention discloses a method and a system for separating hydrogen obtained by reforming, which are used for improving the purity of the hydrogen obtained by reforming, improving the liquid yield and further reducing the energy consumption of a device. The system mainly comprises a reaction product separator, a reforming hydrogen supercharger inlet liquid separation tank, a first-section recontact tower, a second-section recontact tower, a reforming hydrogen liquid separation tank and a reforming hydrogen dechlorination tank, wherein a top outlet of the reaction product separator is connected with a reforming recycle hydrogen compressor; an outlet of the reforming recycle hydrogen compressor is connected with the reforming hydrogen supercharger inlet liquid separation tank; an outlet in the bottom of the reaction product separator is respectively connected with the upper part of the first-section recontact tower and the upper part of the second-section recontact tower through a reforming hydrogen heat exchanger; and an outlet in the top of the reforming hydrogen supercharger inlet liquid separation tank is connected with the lower part of the first-section recontact tower through a reforming hydrogen supercharger first section and a first-section recontact air cooler in sequence; a top outlet of the first-section recontact tower is connected with the lower part of the second-section recontact tower through a reforming hydrogen supercharger second section and a second-section re-contact air cooler in sequence; a top outlet of the second-section recontact tower is connected with the reforming hydrogen liquid separation tank, and a top outlet of the reforming hydrogen liquid separation tank is connected with the reforming hydrogen dechlorination tank through the reforming hydrogen heat exchanger.

Owner:CHINA PETROLEUM & CHEM CORP +2

An equivalent method for an all-vanadium redox flow battery energy storage system based on electrothermal coupling

ActiveCN110276120BSafe and stable operationAccurate predictionDesign optimisation/simulationSpecial data processing applicationsCapacitanceElectrical battery

The invention discloses an equivalent method of an all-vanadium redox flow battery energy storage system based on electrothermal coupling, comprising steps: 1. Modeling the electrical characteristics of VRB according to the second-order resistance-capacitance network; 2. Using particle swarm algorithm to calculate parameters Identification; 3. Analyze the heat production of each module during battery operation; 4. Analyze the heat transfer process of the VRB system; 5. Equivalent the heat transfer path based on the electrothermal analogy principle; 6. Combine steps 2 and 5 The obtained states are combined to obtain the state space equation of the complete electrothermal coupling model of the VRB energy storage system. The invention comprehensively considers the electrical characteristics and heat generation characteristics of the VRB energy storage system during operation and the coupling relationship between the two, and can accurately predict the state of charge, terminal voltage and temperature state of each part of the battery, effectively ensuring the VRB energy storage system. safe and stable operation.

Owner:WUHAN UNIV OF TECH +1

Fuel-cell power generation system

ActiveCN102800882BReduce hidden dangersFast deliveryFuel cell auxillariesSolid electrolyte fuel cellsWater circulationPower generation system

The invention relates to a fuel cell power generation system, especially a high-power proton exchange membrane fuel cell power generation system in an underwater isolated air environment, which includes a proton exchange membrane fuel cell module, hydrogen and oxygen storage devices, a DC / DC conversion unit, and a monitoring unit. Units, heat exchangers, water tanks, water pumps, valves, and circulating water pipes; hot water circulation branches include constant temperature hot water tanks, circulating hot water delivery pumps, proton exchange membrane fuel cell modules, hydrogen storage devices, heat exchangers; cold water circulation Branch includes cold water tank, circulating cold water pump, DC / DC conversion unit, oxygen storage device; hot and cold water balance branch includes constant temperature hot water tank, hot water control valve, balanced hot water pump, cold water tank, cold water control The valve balances the cold water delivery pump; one end of the monitoring unit is connected to the constant temperature hot water tank, and the other end is connected to the cold water tank. The invention has the advantages of being independent of external air, safe and reliable, simple and direct heat exchange process inside the system, and high heat cycle efficiency.

Owner:湖北长海新能源科技有限公司

A static molten salt hot air heat exchange system

InactiveCN104266522BIncrease heat release areaImprove heat transfer efficiencyHeat storage plantsSpace heating and ventilation detailsMolten saltControllability

Disclosed is a static molten salt hot air heat exchanging system. The static molten salt hot air heat exchanging system comprises a high-volume molten salt tank with good heat preservation performance, so that liquid molten salt does not need to flow and is heated inside the molten salt tank through electric heating tubes; the outer wall of the molten salt tank is directly welded with a spiral hot air passage, the outer wall of the molten salt tank inside the hot air passage is welded with rib plates, so that the heat radiating area can be enlarged; high-temperature hot air passes through a hot air / water heat exchanger, so that the heat exchanging efficiency can be improved, the heat exchanging process can be simplified, and the heat exchanging effects are easy to control. Due to the fact of being simple in structure, compared with other molten salt heat exchanging modes, the static molten salt hot air heat exchanging system has the advantages of being simple in heat exchanging process, high in heat exchanging efficiency and controllability, free from potential risks, short in construction cycle, low in investment, easy to implement and the like.

Owner:山东省汶上重力机械厂

Refrigerator and method for direct coupling of Stirling cycle and vapor compression refrigeration cycle

ActiveCN104913541BReduce power consumptionSimplify the heat transfer processRefrigeration machinesDirect couplingEngineering

The invention discloses a Stirling cycle and steam compression refrigeration cycle directly-coupled refrigerating machine and method. The refrigerating machine comprises a Stirling refrigerating machine body and a steam compression refrigerating machine body. The Stirling refrigerating machine body comprises a compression piston, a compression cavity, a condensation evaporator, a heat regenerator, a cold-end heat exchanger, an expansion chamber and a push piston. The steam compression refrigerating machine body comprises a compressor, a condenser, a throttling valve and a condensation evaporator. Cold fluid in the condensation evaporators is a working medium for the steam compression refrigeration cycle, hot fluid is a working medium for the Stirling cycle, and the cold fluid and the hot fluid exchange heat through the wall of the heat exchanger. The working medium for the steam compression refrigeration cycle is used for directly cooling the working medium for the Stirling cycle, compared with a refrigerating medium cooling method, the average temperature of the working medium in the condensation evaporators can be greatly reduced, and the performance of the Stirling cycle is improved. The heat exchange process is simplified, auxiliary power consumption equipment of the condensation evaporators is reduced, and the refrigerating efficiency of the whole system is improved.

Owner:ZHEJIANG UNIV

A hygroscopic solution regeneration system

ActiveCN107137944BAchieve recyclingReduce intermediate linksEvaporators with forced circulationEvaporator regulation/controlExhaust valveInlet valve

The invention discloses a hygroscopic solution regeneration system. The system comprises an evacuated collector pipe, a solution tank, a return pipe, an inlet valve, an outlet valve and an exhaust steam valve. During use, the exhaust steam valve and the inlet valve are switched on, and a hygroscopic solution enters the system from the inlet valve; the hygroscopic solution entering the evacuated collector pipe is heated by the evacuated collector pipe firstly, then due to the effect of the density difference between the hygroscopic solution in the evacuated collector pipe and the unheated hygroscopic solution exists, the hygroscopic solution flows in a closed loop formed by the evacuated collector pipe, the solution tank and the return pipe, and heating of the hygroscopic solution in the system is completed. Meanwhile, steam generated during heating of the hygroscopic solution is exhausted from the exhaust valve, regeneration of the hygroscopic solution is completed finally, and the regenerated hygroscopic solution flows out of the outlet valve to be recycled. By the design of the hygroscopic solution regeneration system, the hygroscopic solution is directly heated by the evacuated collector pipe, and the intermediate link of a heat exchanger is omitted, so that the heat transfer process is simplified, heat transfer efficiency is improved, and problems in the field at the present stage are solved.

Owner:GUANGDONG UNIV OF TECH

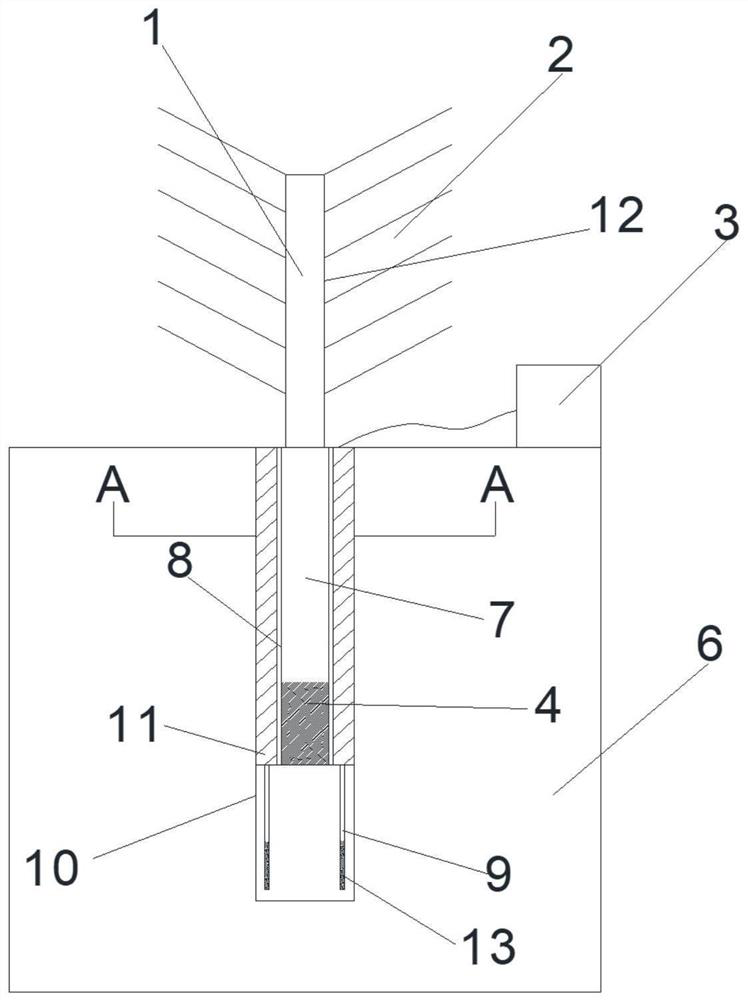

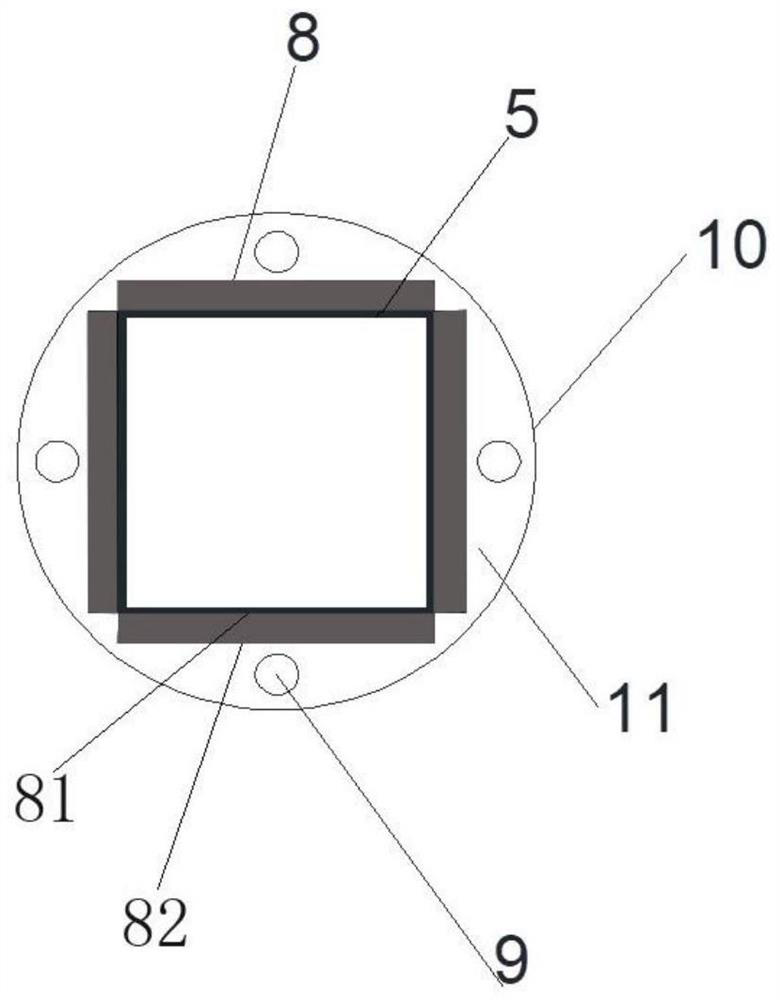

A capsule type heat energy extraction device and method for coal field fire area

ActiveCN109861587BImprove cooling efficiencyImprove utilization efficiencyGenerators/motorsEngineeringThermoelectric conversion

The invention discloses a capsule-type heat energy extraction device and method in a coal field fire area, which belongs to the technical field of thermoelectric conversion equipment, and solves the problems of low heat energy utilization rate, low thermoelectric conversion efficiency, large engineering quantity, and difficult recovery and repetition in the prior art. use etc. The device of the present invention comprises a thermoelectric power generation device, a heat transfer device and a cooling device; the thermoelectric power generation device forms a hollow columnar structure, the cold end (81) is inside the columnar structure, and the hot end (82) is outside the columnar structure; the heat transfer device is used to increase heat end (82), the heat transfer device includes a high thermal conductivity capsule (11) and a medium temperature heat pipe (9); the cooling device is used to reduce the temperature of the cold end (81), and the cooling device includes a high thermal conductivity capsule heat pipe (5) and cooling fins (2). The device and method of the invention are suitable for heat energy extraction in coal field fire areas.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com