Two-stage and multi-stage type-II absorption heat transformer

An absorption heat pump and new process technology, applied in the field of low-temperature waste heat utilization and energy-saving equipment, can solve the problems of increasing heat transfer links, increasing equipment complexity, and increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

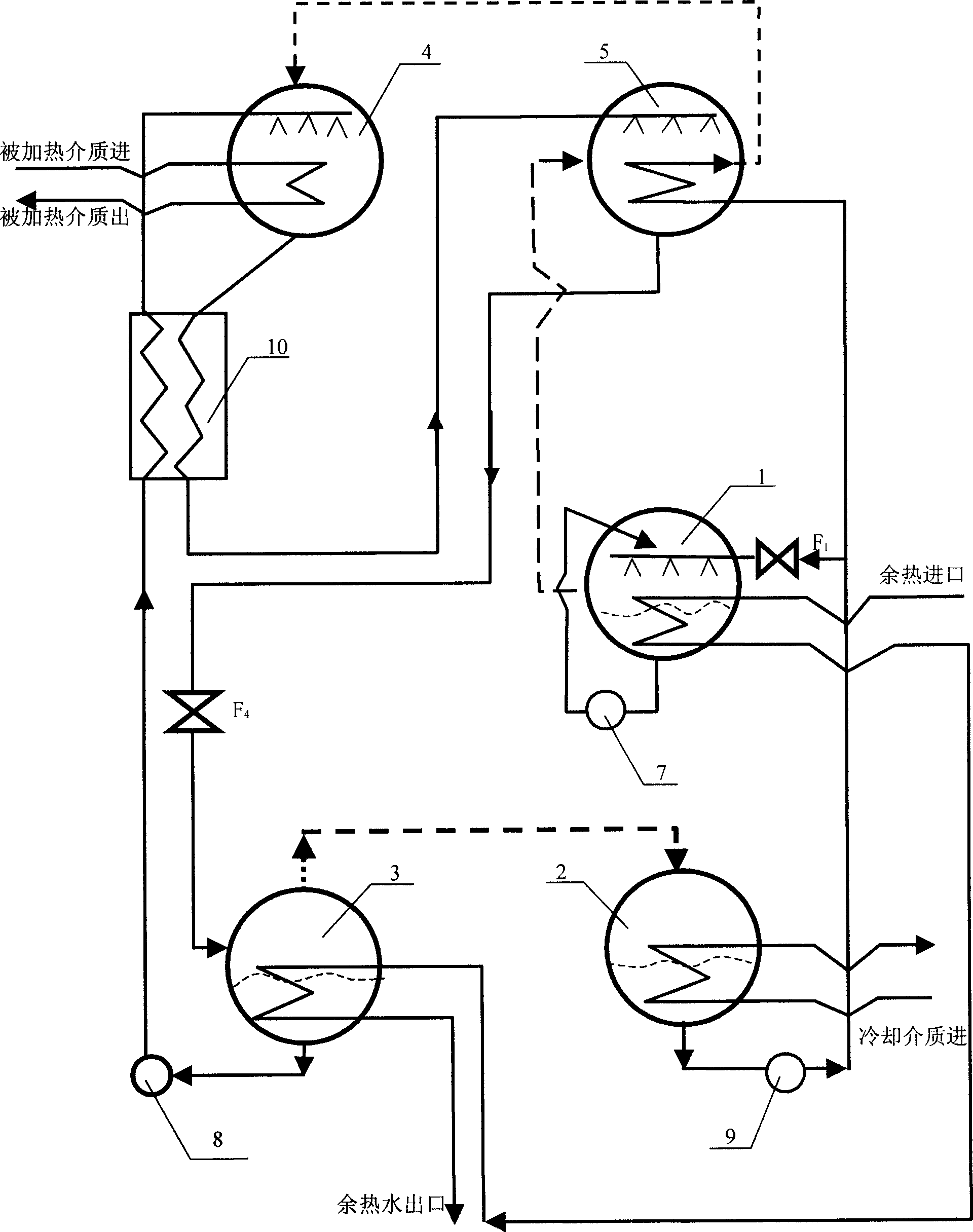

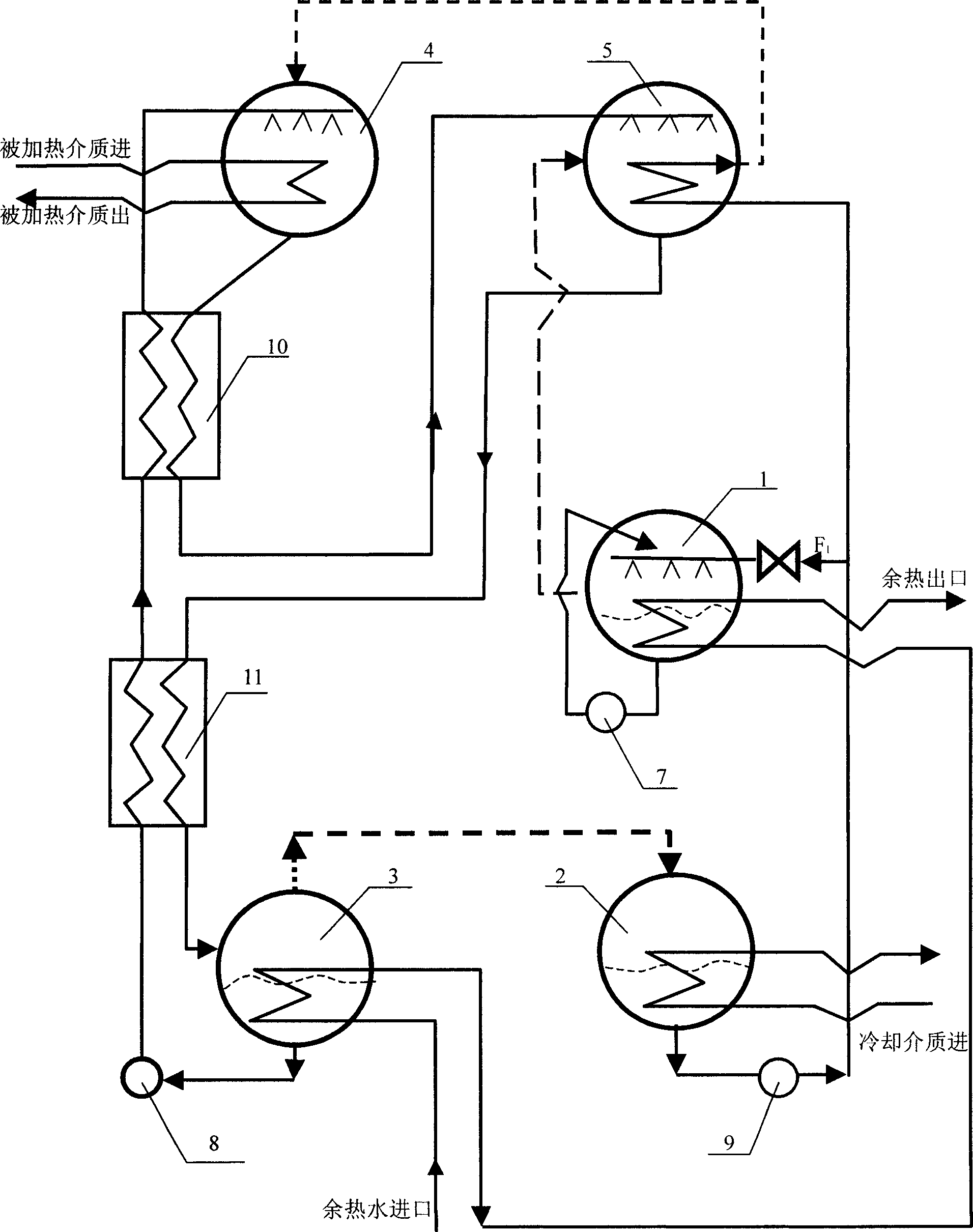

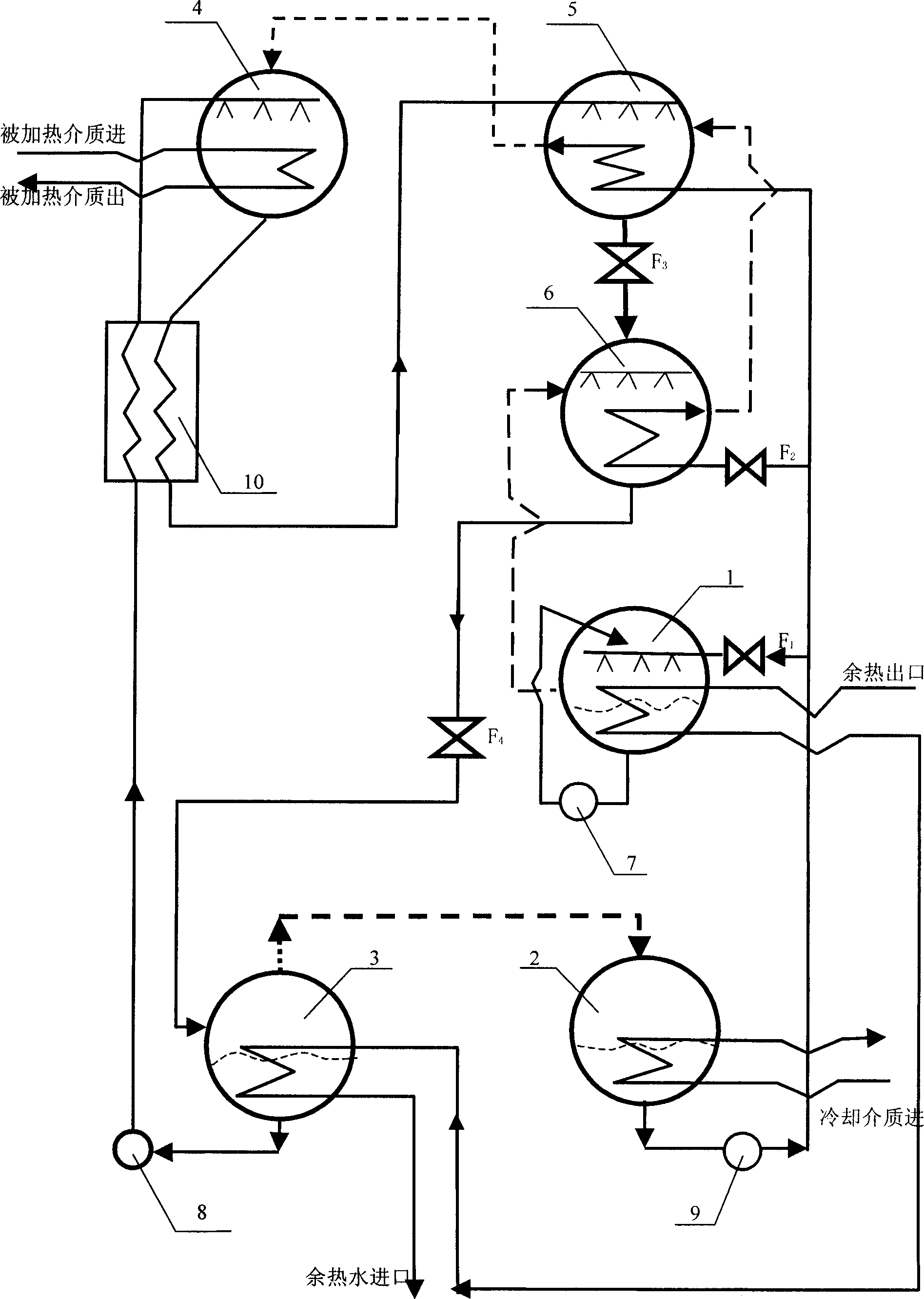

[0016] In the two-stage second type absorption heat pump, the purpose of the present invention is achieved like this, 1. structurally, this heat pump is mainly made up of evaporator 1, condenser 2, generator 3, absorber 4 and absorption-evaporator 5, There is no longer an intermediate absorber and its corresponding intermediate evaporator that rely on the intermediate circuit for heat exchange; ②The waste heat fluid either enters the evaporator 1 first, then enters the generator 3, or enters the generator 3 first, and then enters the evaporation The device 1 is the same as the traditional structure and process; ③The solution from the absorber 4 enters the absorption-evaporator 5, and inside it, the solution absorbs the refrigerant vapor from the evaporator, and this process is carried out outside the heat exchange tube bundle; The heated refrigerant m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com