A static molten salt hot air heat exchange system

A hot air heat exchange and molten salt technology, which is applied in heating systems, indirect heat exchangers, heat exchanger types, etc., can solve the problem of difficult control of heating and heat exchange processes, many high-temperature molten salt conversion processes, and heat exchange structure Complicated problems, to achieve the effect of convenient control of heat exchange effect, small investment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

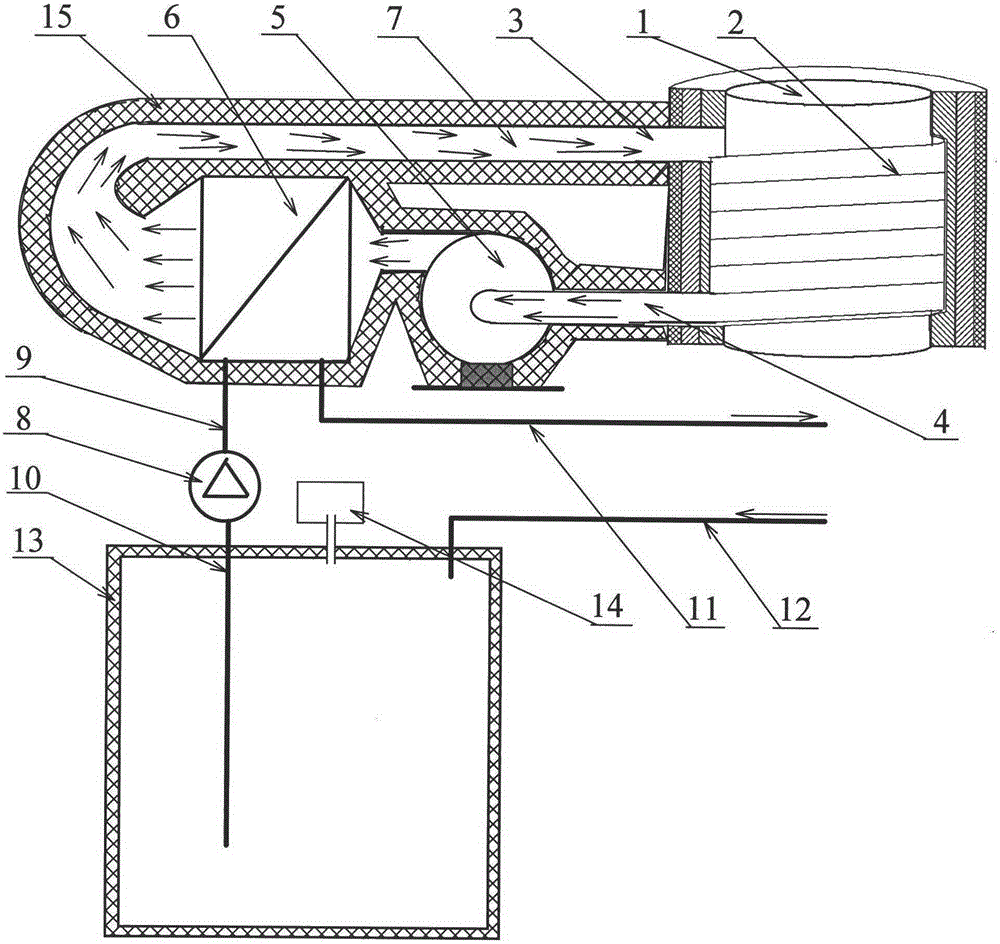

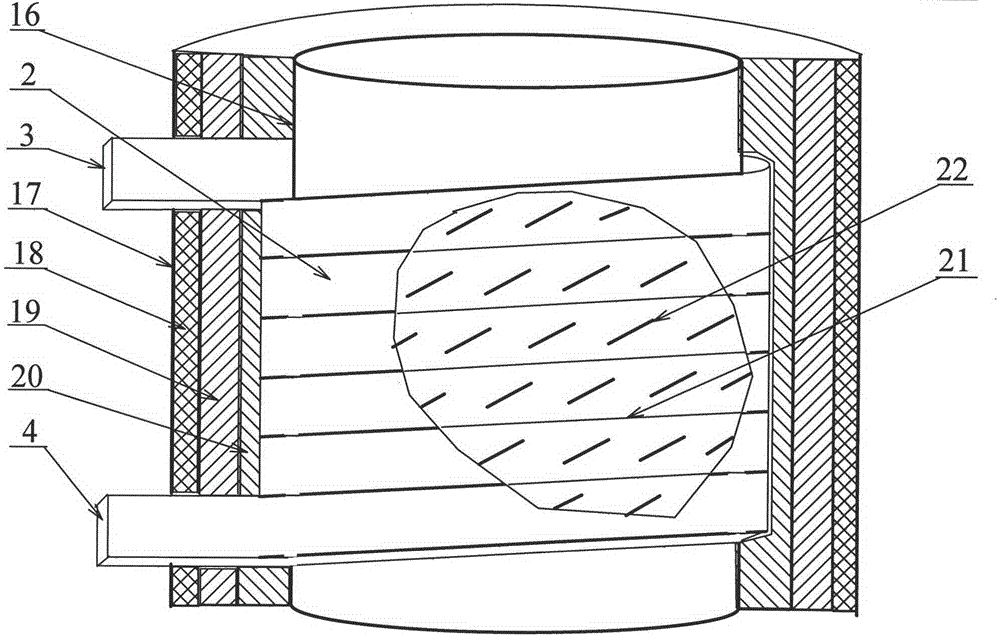

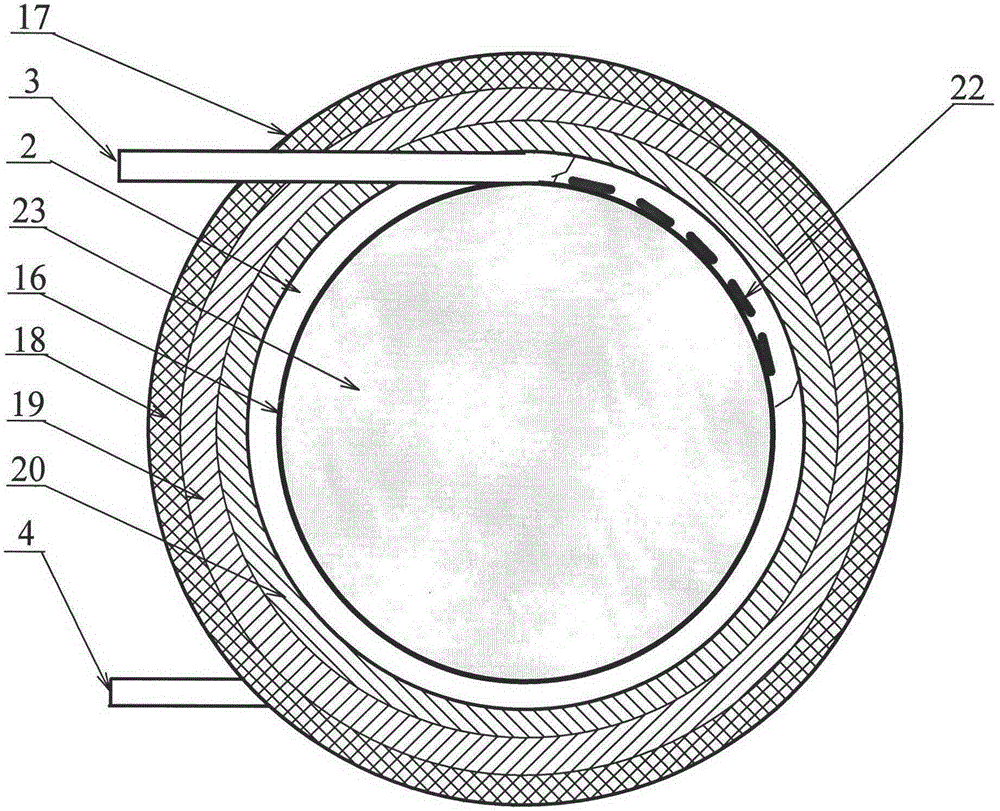

[0012] The present invention includes in the drawings: molten salt tank (1), spiral air pipe (2), air inlet (3), air outlet (4), fan (5), hot air / water heat exchanger (6), return air Between pipe (7), water supply pump (8), heat exchanger inlet pipe (9), water pump inlet pipe (10), heat exchanger outlet pipe (11), heating return pipe (12), and heating water tank (13) The molten salt tank (1) consists of molten salt tank body (16), spiral air duct (2), molten salt tank shell (17), molten salt tank outer insulation layer (18), molten salt tank The middle insulation layer (19) of the tank and the inner insulation layer (20) of the molten salt tank are composed. The molten salt tank body (16) is made of high-temperature-resistant and corrosion-resistant austenitic stainless steel, and is welded on the outer wall of the molten salt tank body (16). Make the spiral air duct (2), the interior of the spiral air duct (2) is separated by the air duct partition plate (21) to become a spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com