Coproducing cement technological method of producing acid using phosphogypsum and sulfur

A process method and sulfuric acid-making technology, applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems of increasing production cost, large influence of acid-making equipment, low efficiency, etc., to reduce the possibility of pollution, improve production intensity, and improve the overall effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

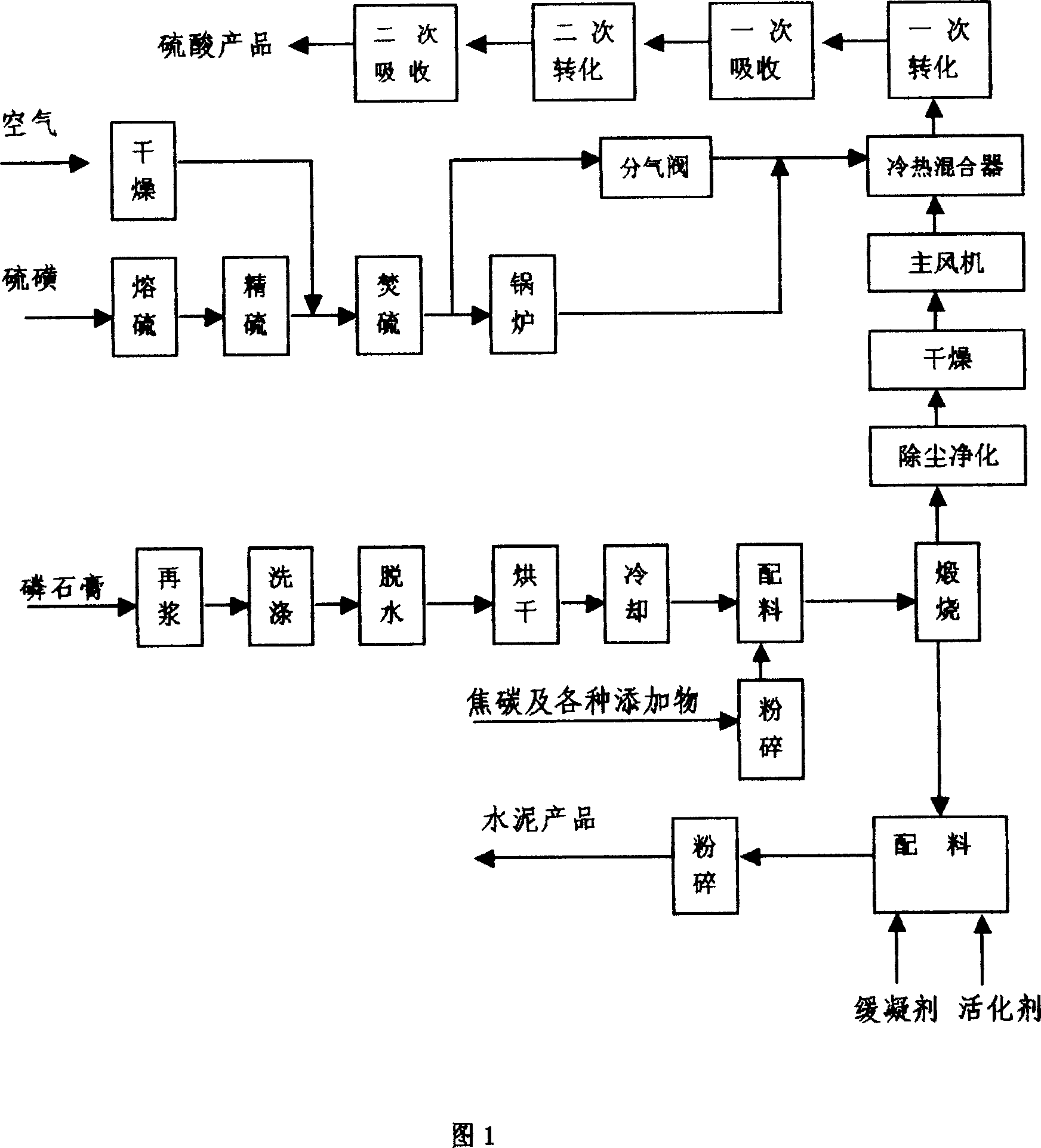

Image

Examples

Embodiment 1

[0048] After reslurry washing and purification, free P 2 o 5 The phosphogypsum is 0.65% and the F content is 0.21%. It is sent to the dehydrator to dehydrate and remove the washing water, and then enters the dryer for drying. After cooling, it enters the batching bin. Anthracite, silica and kaolin are ground by an air-swept ball mill to reach a particle size of -200 mesh sieve between 10 and 12%, and enter the batching bin through blasting to homogenize the prepared cement raw materials. The homogenized raw meal is put into the rotary kiln for calcination, and the decomposition section of the rotary kiln is controlled at 1280-1335°C through coal injection gun and air volume adjustment, and the carbon in the anthracite in the kiln reduces phosphogypsum to CaO and SO 2 , the CaO in the material is in the sintering section at 1430-1480 ° C, and the mineralization reaction occurs with the silica to survive the dicalcium silicate (C 2 S) and tricalcium silicate (C 3 S) The reac...

Embodiment 2

[0055] After reslurry washing and purification, free P 2 o 5 The phosphogypsum is 0.96% and the F content is 0.33%. It is sent to the dehydrator to dehydrate and remove the washing water, and then enters the dryer for drying. After cooling, it enters the batching bin. Anthracite, silica and kaolin are ground by an air-swept ball mill to reach a particle size of -200 mesh sieve between 10 and 12%, and enter the batching bin through blasting to homogenize the prepared cement raw materials. The homogenized raw meal is put into the rotary kiln for calcination, and the decomposition section of the rotary kiln is controlled at 1280-1335°C through coal injection gun and air volume adjustment, and the carbon in the anthracite in the kiln reduces phosphogypsum to CaO and SO 2 , the CaO in the material is in the sintering section at 1430-1480 ° C, and the mineralization reaction occurs with the silica to survive the dicalcium silicate (C 2 S) and tricalcium silicate (C 3 S) The reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com