Method for producing gamma-aminobutyric acid with high yield

A technology of amino acid and glutamic acid, which is applied in the field of bioengineering, can solve the complicated problems of separation and purification of GABA, meet the needs of industrialization, wide pH stability range, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Acquisition of Bacillus megaterium glutamic acid decarboxylase gene

[0032] (1) Bacillus megaterium strains were inoculated in LB medium, cultured at 37°C for 12 hours to collect the bacterial cells, and genomic DNA was extracted using a bacterial genome extraction kit.

[0033] (2) Using primers gaD1 (5'GGGTTTCATATGATGCCTCAATGGCATCCGCATCG 3', the sequence is shown in SEQ ID NO:5) and gaD2 (5'CCGCTCGAGTTAATGATGAAATCCATTGTCGTAT 3', the sequence is shown in SEQ ID NO:6) to clone glutamic acid from genomic DNA gaD gene of decarboxylase;

[0034] (3) Connect the gene to the PMD19simple cloning vector for sequencing to obtain a gene sequence such as SEQ ID NO:1, and a corresponding amino acid sequence such as SEQ ID NO:3;

[0035] (4) Digest the target gene and expression vector pET24a at 37°C for 2 hours with restriction endonucleases Nde I and XhoI;

[0036] (5) Ligate the target gene and plasmid pET24a after digestion and gel recovery with T4 ligase at 16°C ...

Embodiment 2

[0038] Example 2: Protein engineering of Bacillus megaterium glutamate decarboxylase

[0039] (1) Using Modeller software to carry out homology modeling on glutamic acid decarboxylase GAD (JMB 342, 119-130 (2004)), the key amino acids F67, V68, M88, and I89 of the Loop structure of the catalytic active center of GAD were mutated to Alanine; after the mutation, construct a recombinant strain according to the method in Example 1, collect the thalline after shaking the flask for fermentation, and perform enzyme activity detection. The results are shown in Table 1. The 67th phenylalanine F and the 68th valine When the acid V was mutated into alanine A, the enzyme activity of GAD increased by 26.8% and 49.0%, respectively, indicating that the 67th and 68th positions were the key sites affecting the enzyme activity, so two sites were selected for combined mutation.

[0040] Table 1 Determination of enzyme activity of different mutants

[0041]

[0042] (2) Combining mutations of...

Embodiment 3

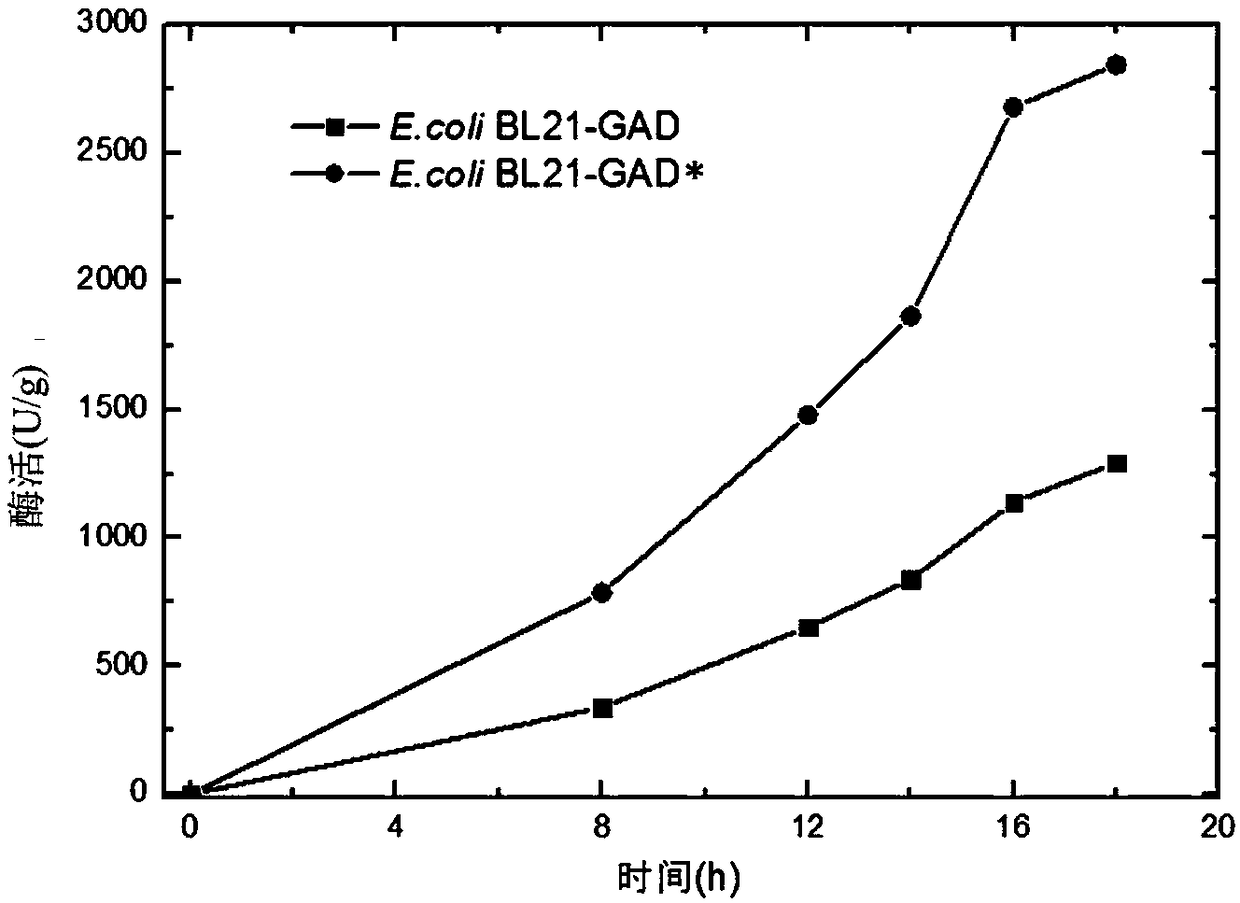

[0043] Embodiment 3: recombinant bacterial strain fermentation produces glutamic acid decarboxylase

[0044] (1) Seed medium formula: LB medium, yeast powder 5g / L, tryptone 10g / L, NaCl 10g / L.

[0045] Fermentation medium formula: glycerol 5g / L, yeast powder 20g / L, tryptone 15g / L, K 2 HPO 4 12H 2 O 3.0g / L, KH 2 PO 4 18.0g / L.

[0046] The composition of the feed medium is: glycerol 500g / L, MgSO 4 ·7H 2 O 30g / L.

[0047] (2) Recombinant strains E.coli BL21-GAD and E.coli BL21-GAD* were inoculated in the fermentation medium according to the inoculum size of 5%, the air volume was 0.8-1.5vvm, the temperature was 37°C, and the agitation was 600rpm to cultivate until the OD600 was 3.0-4.0 , lower the temperature to 25°C, add 5g / L lactose to induce the expression of glutamic acid decarboxylase, when the OD600 reaches 11.0-13.0, the dissolved oxygen suddenly rises, and the rate of 4-5mL / h per liter of fermentation broth starts to be supplemented Feed the medium, and finish the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com