A method of combining low-temperature waste heat utilization of flue gas with treatment of saline wastewater

A combination of salty wastewater and technology, applied in the field of petrochemical industry, can solve the problems of high energy consumption, high fuel consumption and air pollution of evaporators, and achieve the effects of improving thermal efficiency, reducing emissions, reducing heat exchange temperature difference and system loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with specific implementation examples, however, these examples are not intended to limit the scope of the present invention in any way.

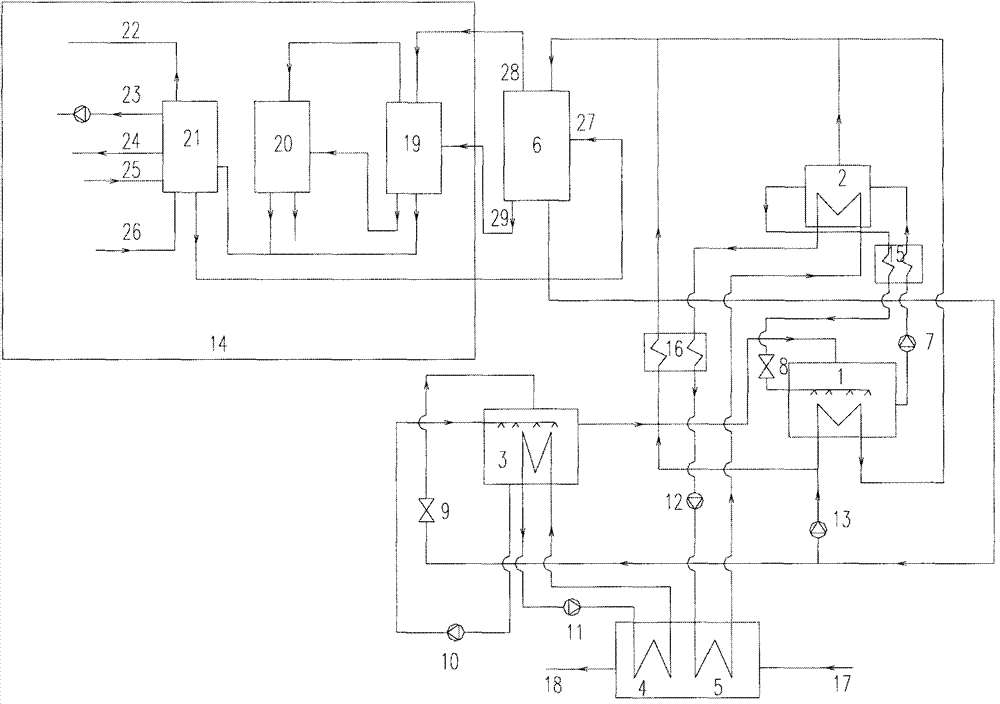

[0029] The technical solution of the present invention is to adopt the method of deep combination of absorption heat exchange and low-temperature multi-effect evaporation, the condenser of absorption heat exchange and the first effect evaporator of low-temperature multi-effect evaporation are combined into one, so that the heat exchange process can be obtained Simplification reduces the heat exchange temperature difference and improves the heat utilization rate of the whole device. The flow of the device is shown in the attached figure, the device mainly consists of absorber 1; generator 2; evaporator 3; flue gas low temperature heat exchanger 4; flue gas high temperature heat exchanger 5; low temperature multi-effect evaporation condenser 6; solution pump 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com