Coal mining and filling integrated method for coal mine

A coal mining method and technology for coal mines, applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems of less than 40% recovery rate in mining areas, overlying surrounding rock and surface deformation, and mine safety threats, etc. Saving material consumption, significant economic and social benefits, low direct and comprehensive costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] An integrated coal mining method for coal mining and filling includes the following steps:

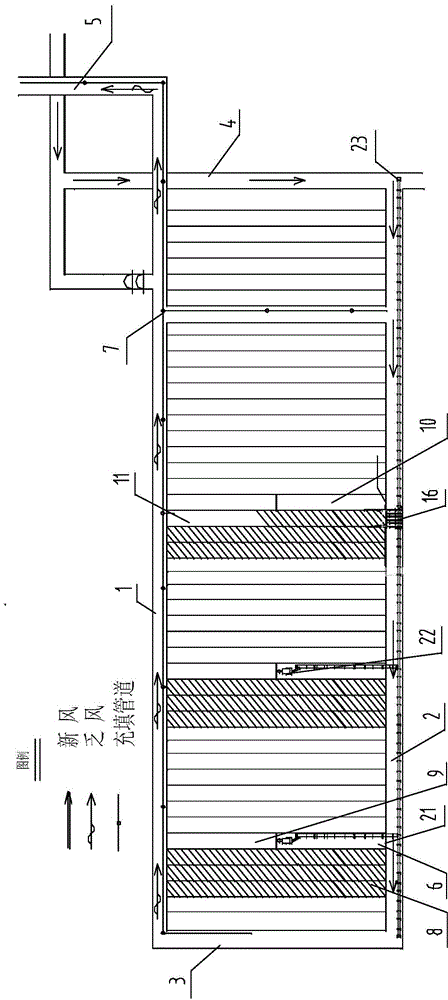

[0065] 1) In the mining area, develop the return air and fill the pipeline lane 1, the transportation and intake air lane 2 and the boundary air lane 3; the three roadways are connected, and there is centralized transportation on the opposite side of the boundary wind lane 3 The beltway 4 and the centralized transportation beltway 4 are connected with the return air and filling pipeline lane 1 and the transportation and air intake lane 2 in the area. The area enclosed by the four roadways is the working face of the mining area where the coal mining operation is carried out. Through the centralized transportation belt 4, fresh air enters the area return air and fills the pipeline lane 1 and the area boundary air lane 3, and the exhaust air is transported from the area and the air inlet lane 2 to the main return air lane 5 for coal mining operations. The area has formed a normal prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com