Grammite raphioid fibre crystal-nano calcium carbonate micro-nano composite powder material and production method

A nano-calcium carbonate and composite powder technology, applied in the direction of polycrystalline material growth, crystal growth, fibrous fillers, etc., can solve the problems of insufficient bonding, loss of excellent performance of micro-nano composite powder materials, etc., and achieve good economic benefits. , The effect of surface energy and chemical activity improvement, specific surface area improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

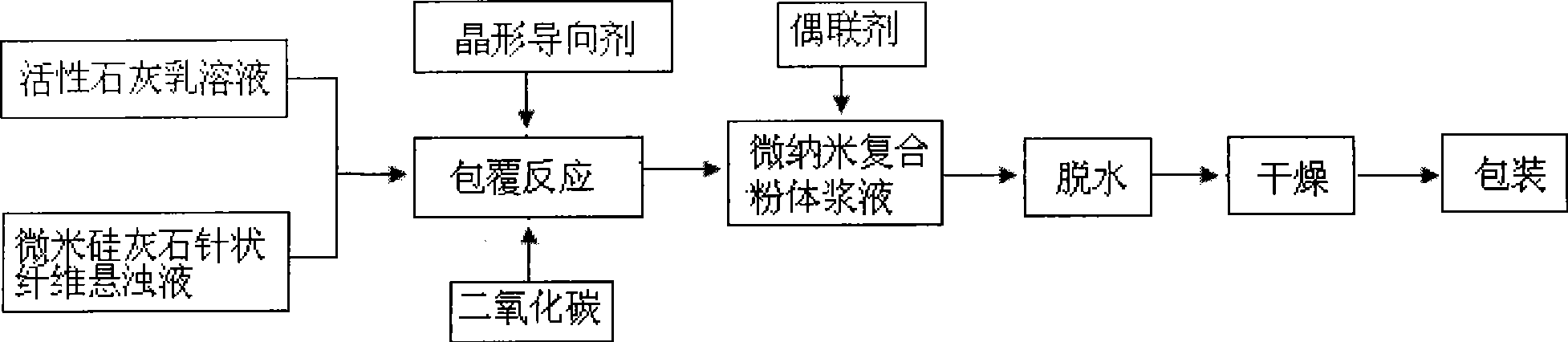

Method used

Image

Examples

Embodiment 1

[0032] A wollastonite needle-like fiber crystal-nanometer calcium carbonate micro-nano composite powder material, which is a micro-nano composite powder coated with nano-calcium carbonate crystals on the surface of micron wollastonite needle-like fiber crystals, micron wollastonite needles The average particle size of the fibrous crystals is 10 μm to 30 μm, the average particle size of the nano-calcium carbonate crystals is 40 nm to 100 nm, the crystal shape of the nano-calcium carbonate crystals is cubic, and the coating amount of the micro-nano composite powder is nano-carbonic acid Calcium crystals and micron wollastonite needle-like fiber crystals account for 3% of the mass, and the coating rate is ≥98%.

[0033] A wollastonite needle-like fiber crystal-nanometer calcium carbonate micro-nano composite powder material, its production steps are:

[0034] Step 1: Prepare micron wollastonite needle-like fiber crystals according to conventional physical methods, add 500mL of clea...

Embodiment 2

[0040] A wollastonite needle-like fiber crystal-nanometer calcium carbonate-coupling agent micro-nano composite powder material, which is that the nano-calcium carbonate crystal is first coated on the surface of the micron wollastonite needle-like fiber crystal, and then the surface of the nano-calcium carbonate crystal is covered Micro-nano triple composite powder coated with a layer of coupling agent. The average particle size of micron wollastonite needle-like fiber crystals is 10 μm to 30 μm, the average particle size of the nano-calcium carbonate crystals is 40-100 nm, the crystal shape of the nano-calcium carbonate crystals is spherical, and the nano-calcium carbonate crystals in the micro-nano composite powder The coating amount of the calcium crystal is 10% of the mass of the wollastonite needle fiber crystal, and the coating rate is ≥98%. The coupling agent is a titanate coupling agent, and its mass is about 1% of the wollastonite needle-like fiber.

[0041] A wollas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com