Preparation method of carbon fiber reinforcement grafted by graphene oxide

A technology for acidifying carbon fiber and graphene, which is applied in the fields of carbon fiber, fiber processing, textiles and paper making, etc., can solve the problems of toxic process, harsh process conditions, difficult industrialized production, etc., to improve surface energy and wettability, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

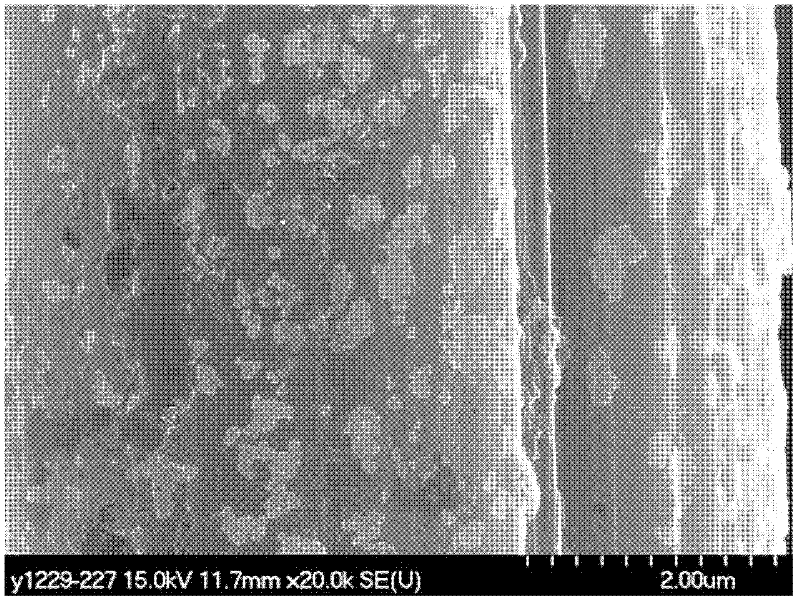

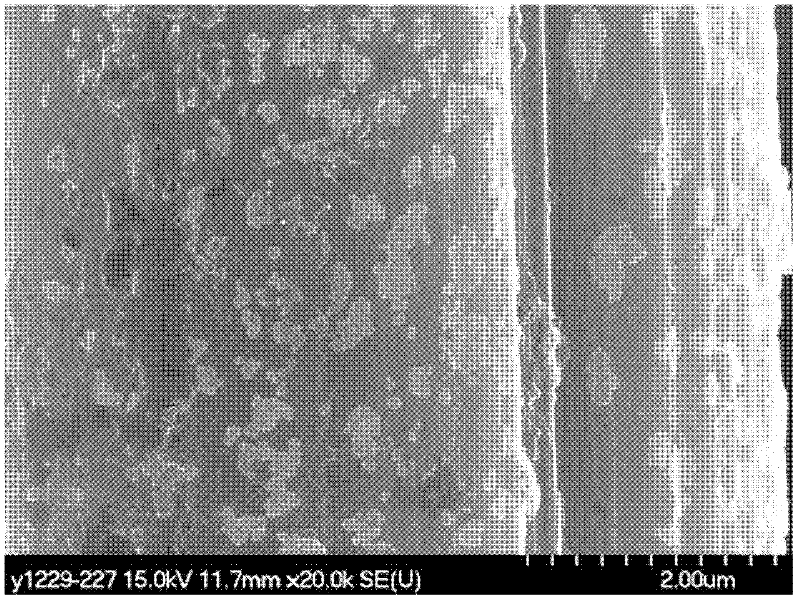

Image

Examples

specific Embodiment approach 1

[0012] Specific Embodiment 1: This embodiment is a preparation method of graphene oxide grafted carbon fiber reinforcement, which is achieved through the following steps: 1. Carbon fiber is subjected to acidification treatment to obtain acidified carbon fiber; 2. The acidified carbon fiber and mass percentage concentration Mix 1% polyamide-amine (PAMAM) methanol solution to obtain a mixed solution, then raise the temperature of the mixed solution to 20°C-50°C, and then react at a constant temperature for 4-12 hours, then take out the acidified carbon fiber and wash it with methanol for 2-5 wash with water for 2-5 times, and then vacuum-dry at 40-60°C to constant weight to obtain polyamide-amine-modified carbon fibers, wherein the mass ratio of acidified carbon fibers to polyamide-amine is 0.1-4:1; three 1. Add graphene oxide into the acetone solution, and ultrasonically treat it for 20-60 minutes to obtain a graphene oxide acetone suspension with a graphene oxide concentration ...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the carbon fiber is acidified by the following method in the step one: the ratio of carbon fiber and concentrated nitric acid is 1g: 350ml, the carbon fiber is added in the concentrated nitric acid, and then at 70 After reacting for 1 to 3 hours at a constant temperature of ℃ to 90 ℃, take out the carbon fiber, wash it until the pH of the washing liquid is about 7, and then dry it at 80 ℃ and -0.1MPa for 2 to 6 hours to obtain acidified carbon fiber. Other steps and parameters are the same as those in Embodiment 1.

[0017] In this embodiment, before the carbon fiber is acidified, the carbon fiber is subjected to conventional desizing treatment. The specific desizing treatment can be carried out as follows: put the carbon fiber into an analytically pure acetone solution, reflux at a constant temperature for 24-48 hours at 70-80°C, and perform desizing treatment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, the temperature of the mixed solution is raised to 25° C. to 40° C., and then reacted at constant temperature for 6 to 10 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com