Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116 results about "Interfacial bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

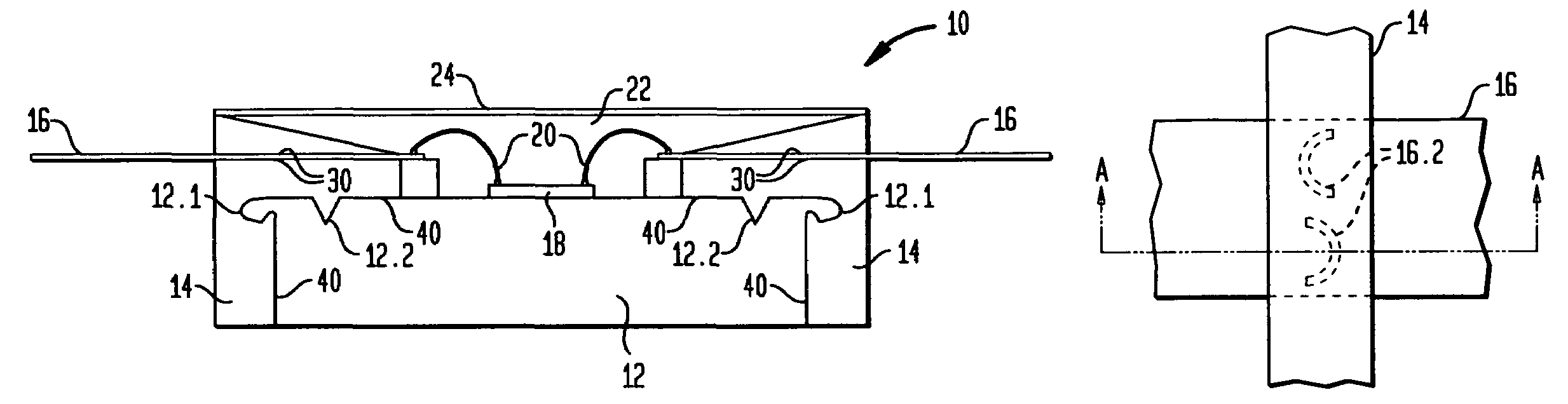

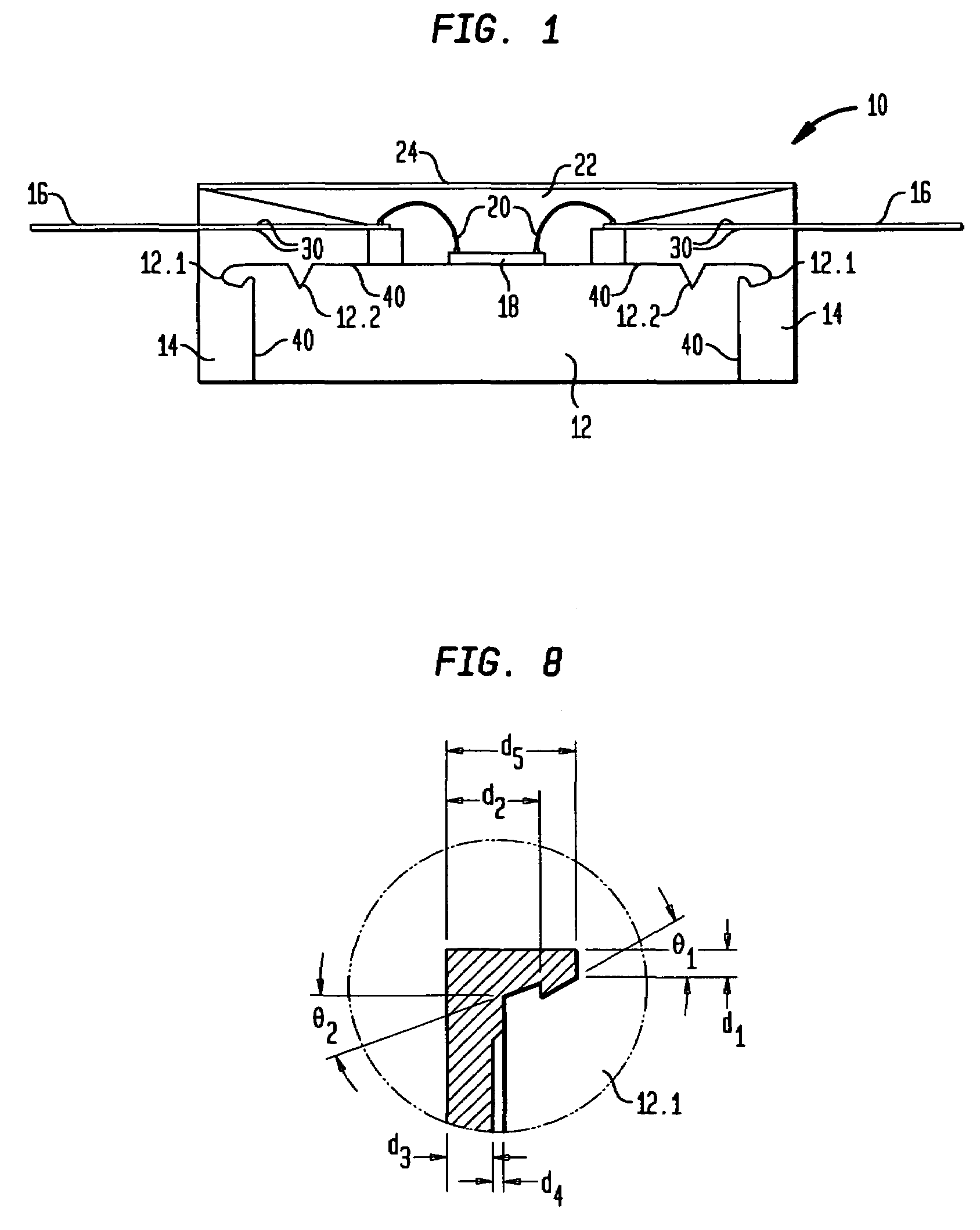

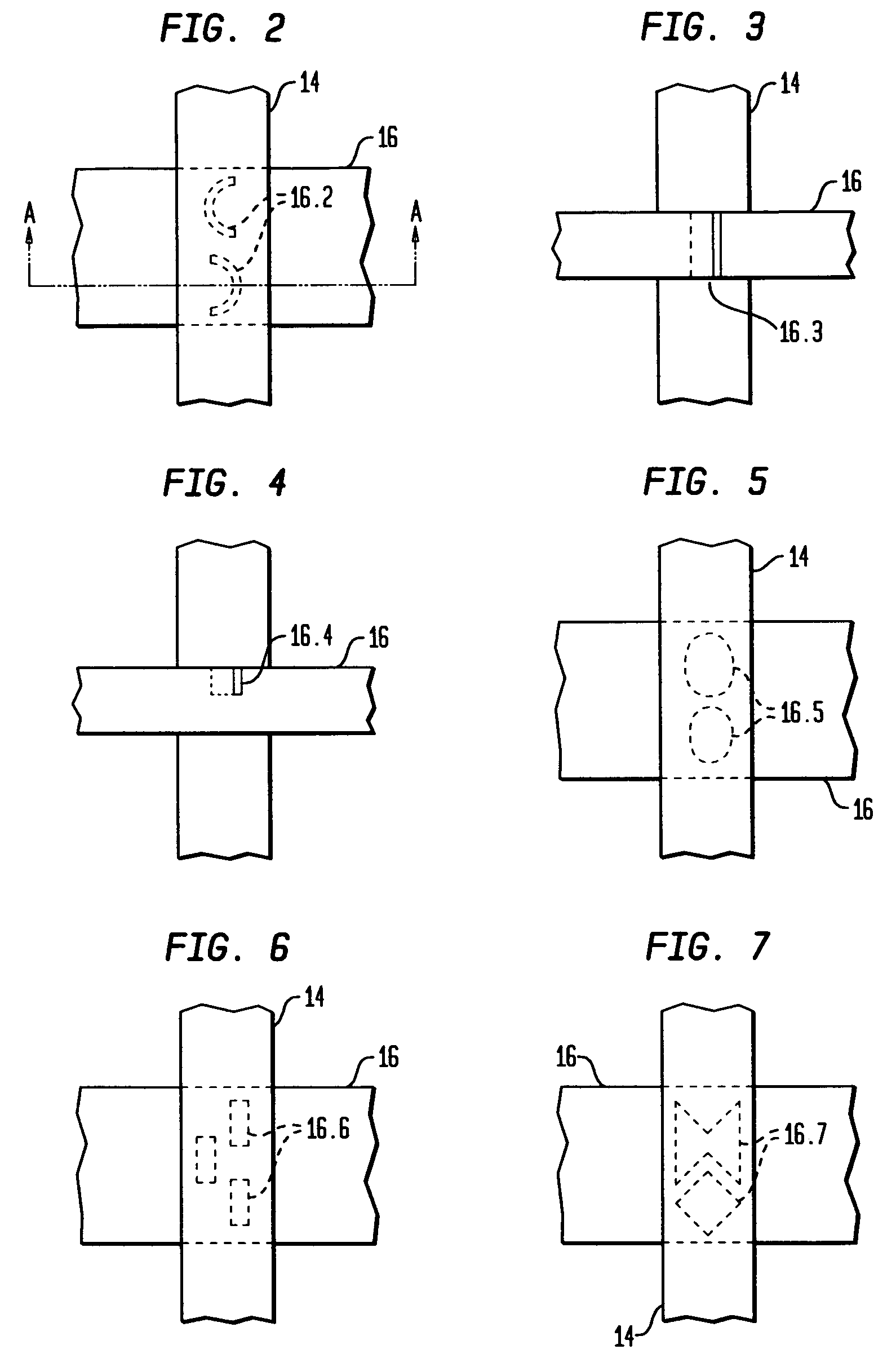

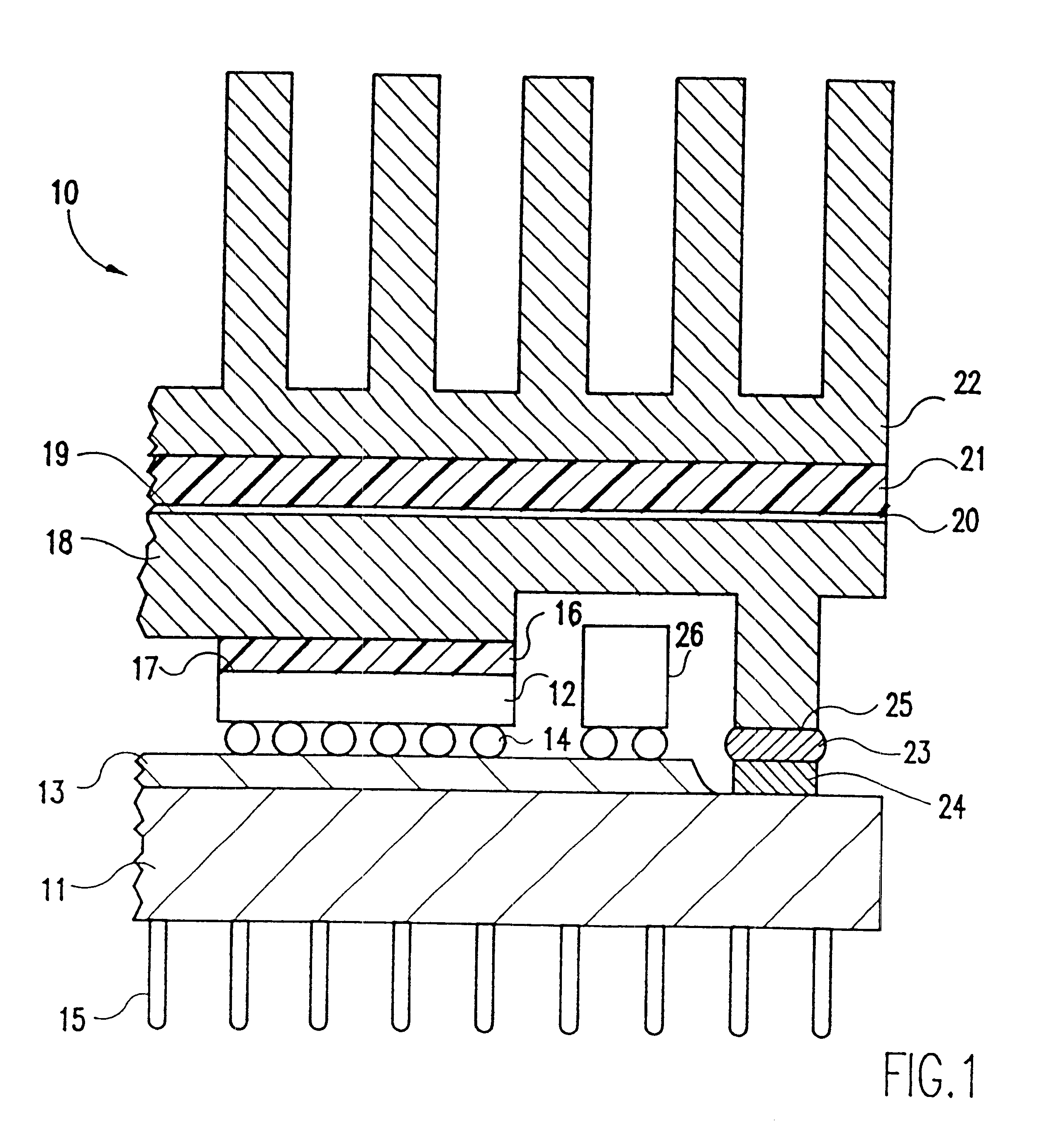

Semiconductor device package with reduced leakage

ActiveUS7224047B2Strong and low leakageReduce leakageSemiconductor/solid-state device detailsSolid-state devicesInterfacial bondSemiconductor package

Owner:BELL SEMICON LLC

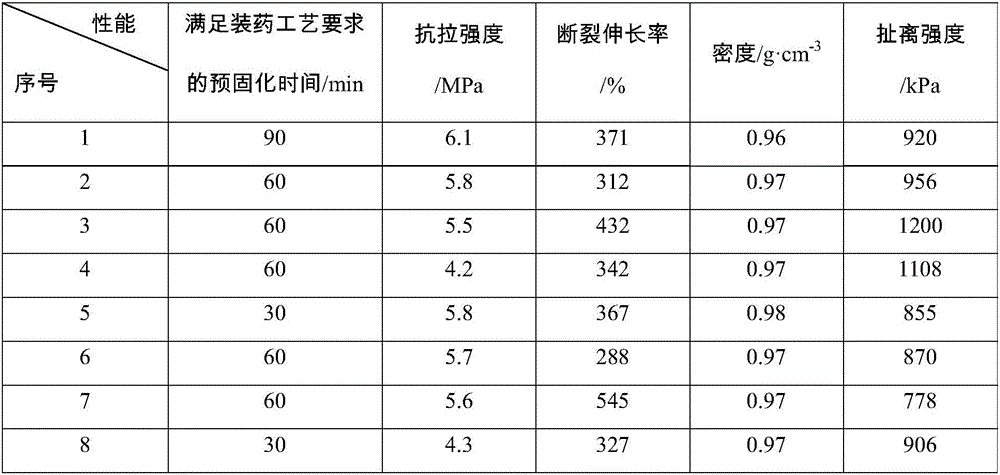

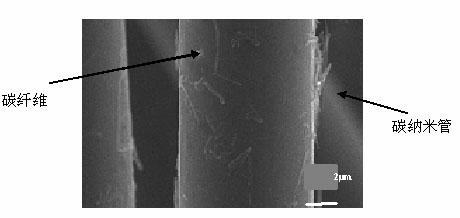

Carbon fiber emulsion sizing agent improved by carbon nano tube and preparation method of carbon fiber emulsion sizing agent

InactiveCN102212967APlay the role of stress transmissionIncreased interlaminar shear strengthCarbon fibresEmulsionCarbon fibers

The invention relates to a carbon fiber emulsion sizing agent improved by a carbon nano tube and a preparation method of the carbon fiber emulsion sizing agent. The carbon fiber emulsion sizing agent comprises a carbon fiber sizing agent, the carbon nano tube, a dispersing agent and a solvent. The preparation method comprises the following steps of: 1, preparing the carbon fiber sizing agent; and 2, adding the carbon fiber sizing agent into the solvent to prepare a sizing working solution, mixing the carbon nano tube and the sizing working solution, performing ultrasonic treatment for 1 to 4 hours at the power of 300 to 600w, adding the dispersing agent, and performing ultrasonic dispersion for 2 to 4 hours to obtain the carbon fiber emulsion sizing agent improved by the carbon nano tube. The carbon fiber emulsion sizing agent has favorable stability, the post processability of carbon fiber can be improved after being processed by the emulsion sizing agent, the interfacial bond strength between the carbon fiber and substrate resin can be enhanced, the shear strength among layers is enhanced, and the performance of a composite material is improved to a certain extent. Moreover, the preparation method is simple, low in cost and environment-friendly.

Owner:DONGHUA UNIV

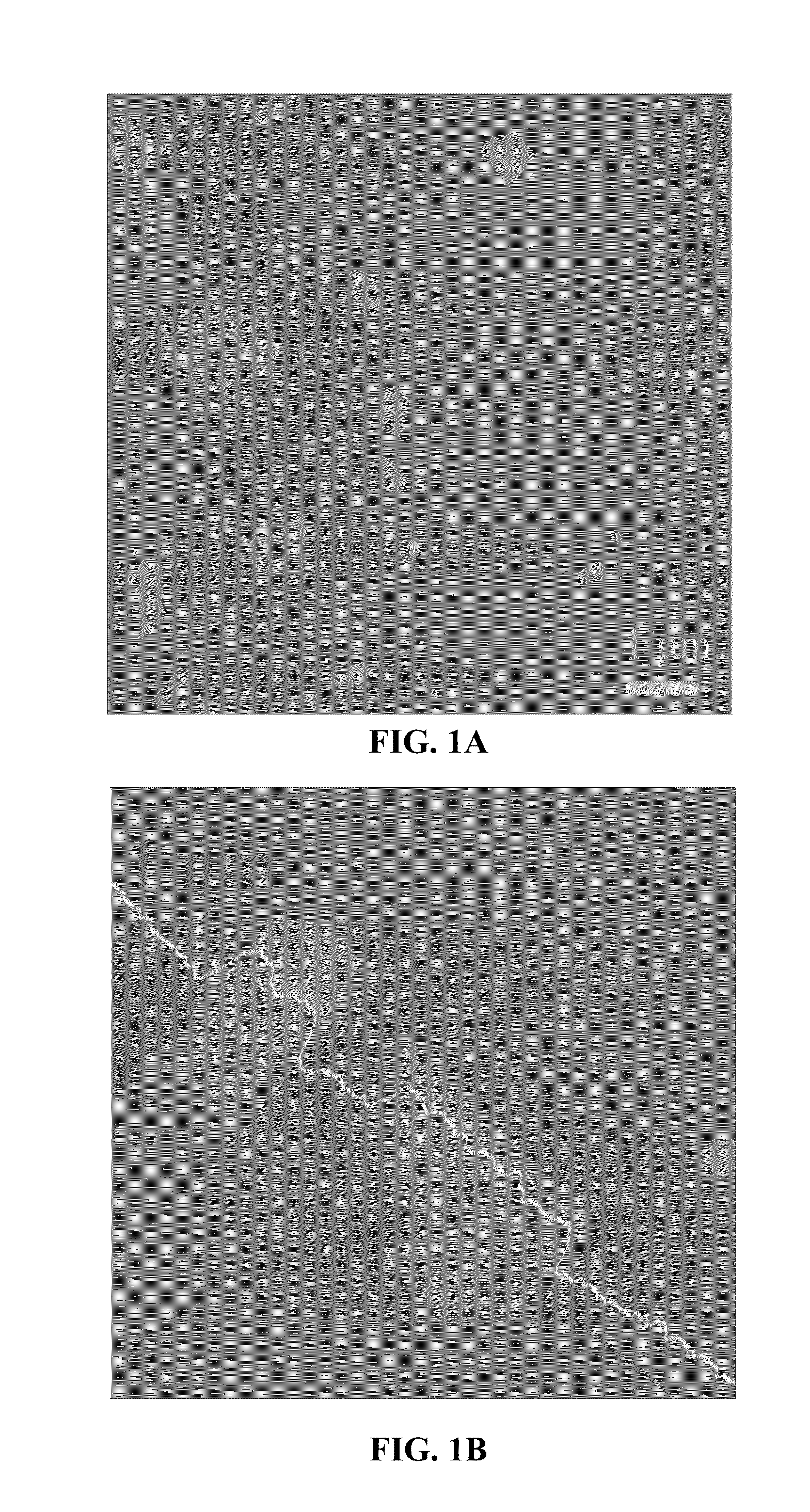

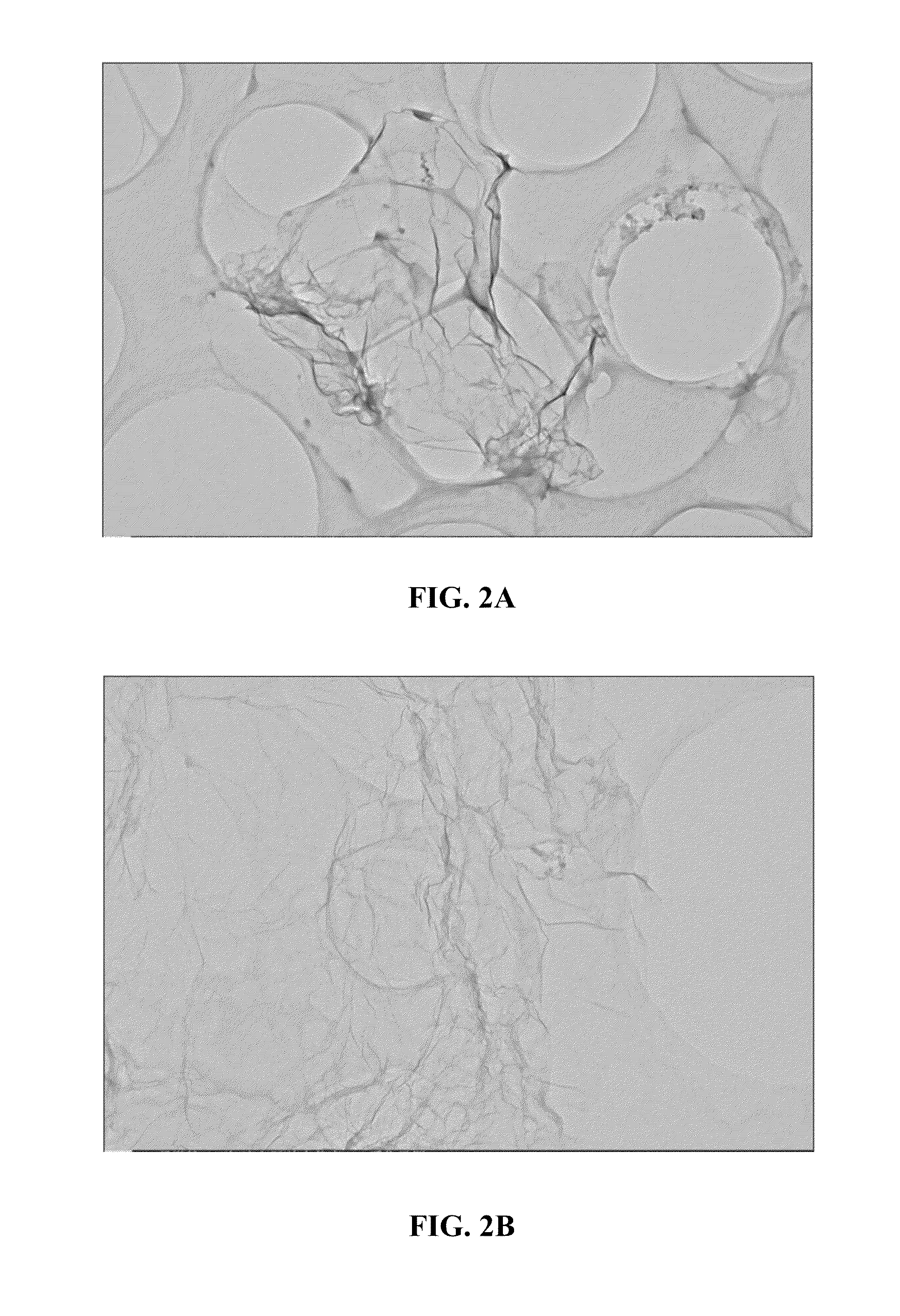

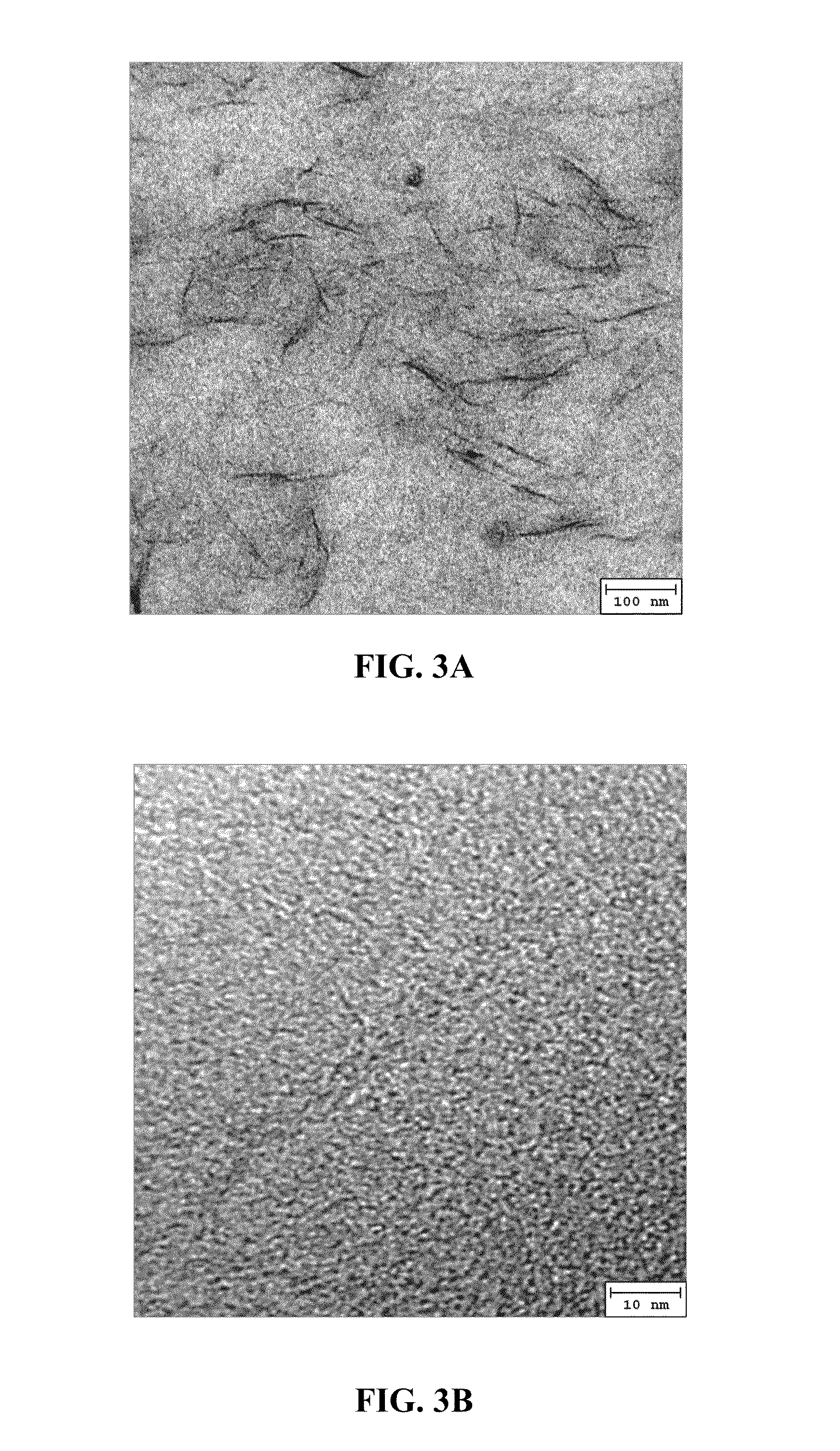

Process for preparing completely delaminated graphene oxide/rubber nanocomposite

A process for preparing a completely delaminated graphene oxide / rubber nanocomposite. The process combines emulsion compounding with flocculation or spray drying, retains the morphology of graphene oxide / rubber composite in a liquid state, and achieves highly dispersed and highly delaminated morphology dispersed on nano scale. Furthermore, a substance able to produce ionic bonding or chemical bonding with the surface functional groups of graphene oxide is added to graphene oxide / hydrosol, as a surfactant, thus the interfacial bonding between graphene oxide and the rubber is increased. The composite is subjected to subsequent compounding and vulcanization to prepare a vulcanizate with dynamic performance, such as a high tensile strength, stress at a definite elongation, tearing strength, etc.

Owner:BEIJING UNIV OF CHEM TECH

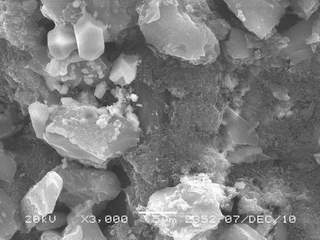

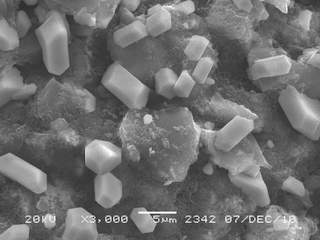

Lead-carbon composite material

ActiveCN102074702AProportionally largeEnhanced interface bindingCell electrodesCapacitanceCarbon composites

The invention relates to a lead-carbon composite material, which is prepared by depositing lead inside active carbon particles and among active carbon particles through an electrolytic deposition method. The lead is 5 to 65 mass percent of the lead-carbon composite material, and grows in a polyhedral particle shape from holes of the active carbon so as to achieve good interfacial bond of the lead and the carbon. The lead-carbon composite material has larger specific gravity, and is more easily mixed with anode active materials of a lead-acid storage battery, such as lead powder and the like uniformly. The lead-carbon composite material has the specific capacitance of 72 to 115F / g in sulfuric acid electrolyte with the density of 1.28g / m<3>, so the lead-carbon composite material can directly serve as an anode material of an ultrabattery, or serve as the anode active material of the ultrabattery to be applied to ultrabattery manufacture.

Owner:ZHUZHOU SMELTER GRP +1

Method using a thin adhesion promoting layer for bonding silicone elastomeric material to nickel and use thereof in making a heat sink assembly

InactiveUS6451155B1Improve bindingEffective combinationAdhesive processesSemiconductor/solid-state device detailsElastomerPolymer science

A heat sink assembly and method for attaching a multi-chip module cap to a polymeric heat sink adhesive by means of a thin adhesion-promoting metal film layer, which provides an interfacial bond between the cap and polymeric adhesive meeting package performance and reliability requirements. There is also a method of promoting adhesion between a silicon-containing polymeric adhesive and a metal surface using the thin adhesion-promoting metal film layer and the products thereof.

Owner:GLOBALFOUNDRIES INC

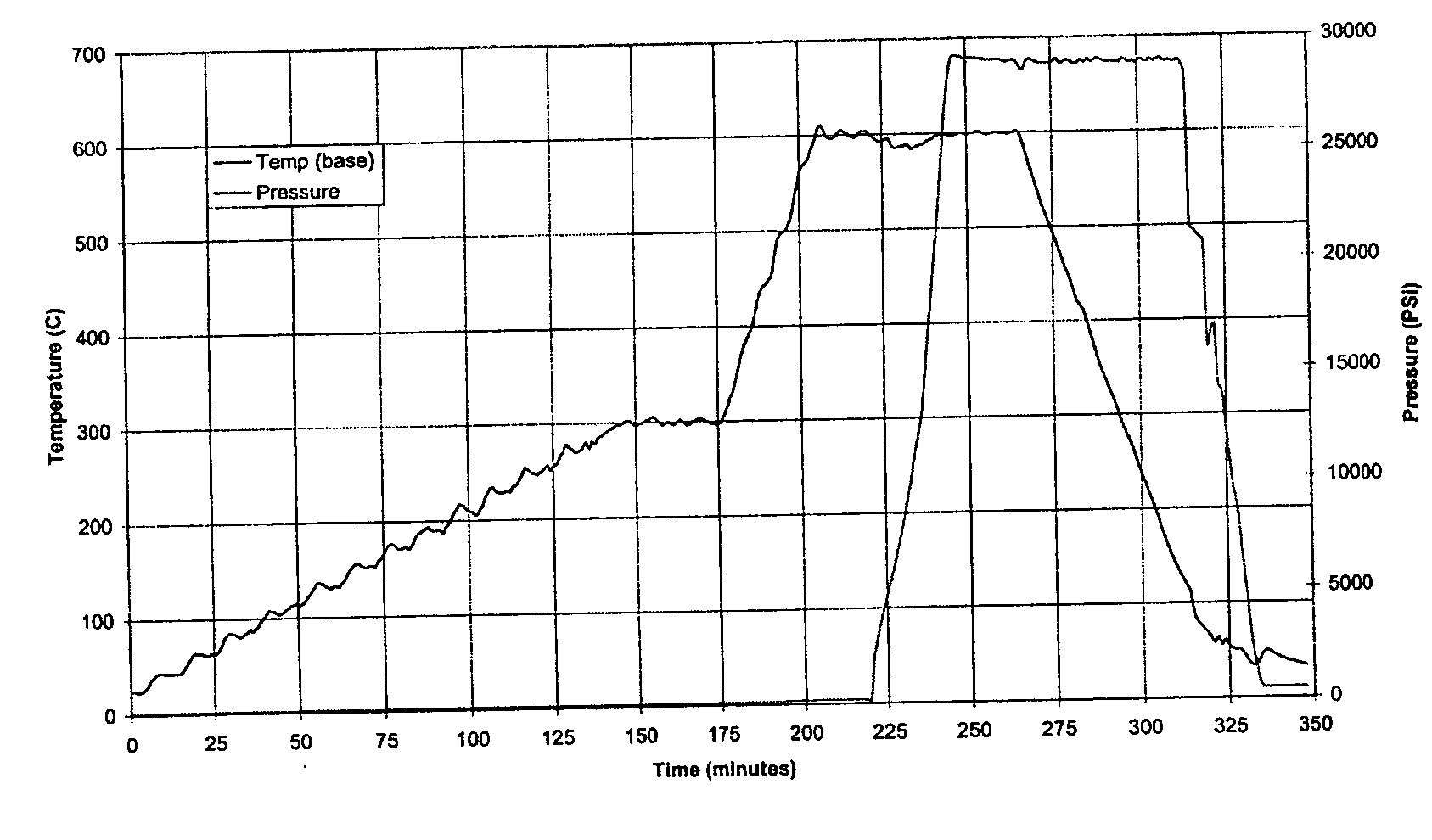

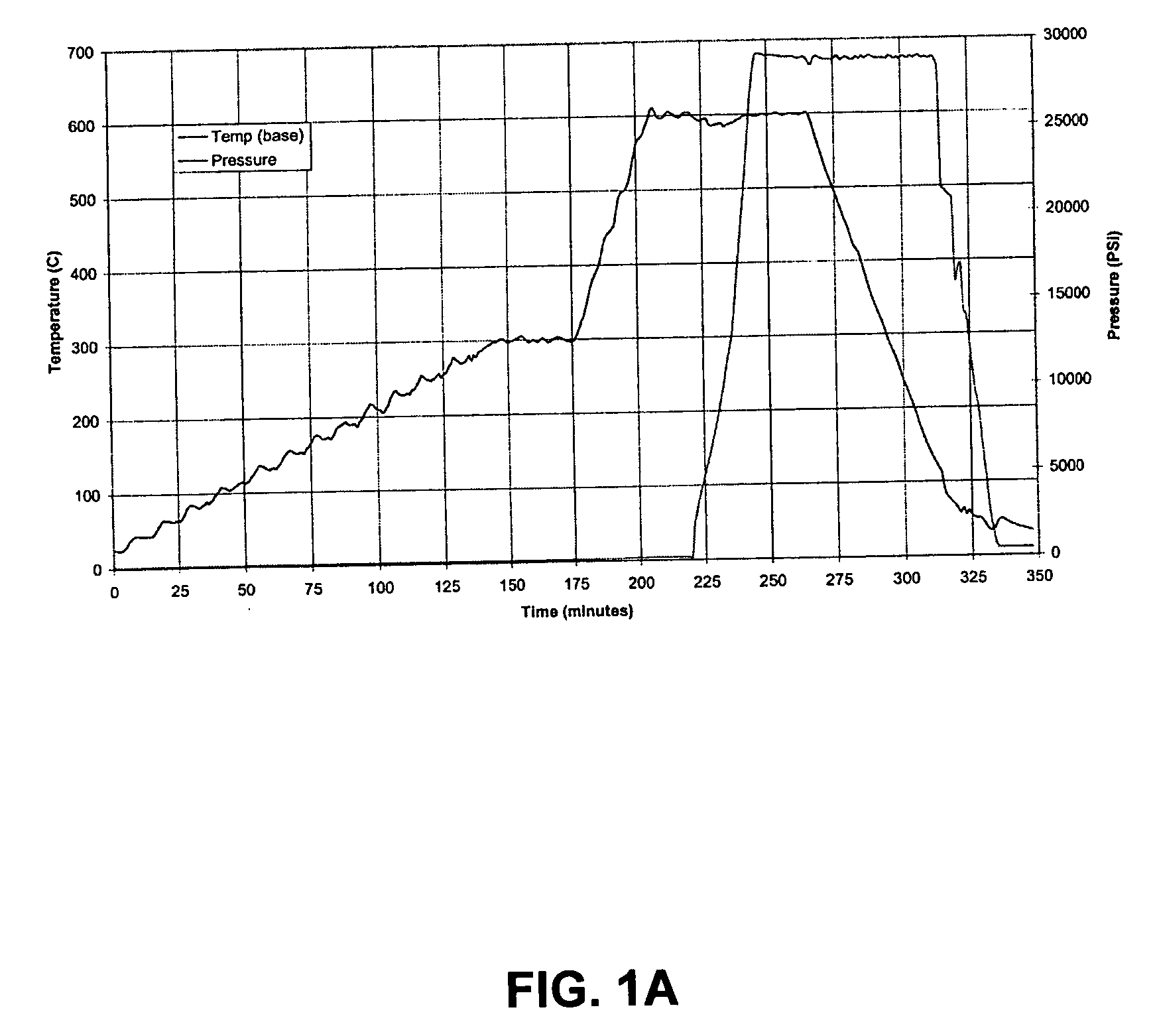

Recovery method of carbon-fiber reinforced resin-base composite material with pretreatment modes

ActiveCN103897213AImprove recycling efficiencyIncreased pore sizePlastic recyclingBulk chemical productionRecovery methodCarbon fibers

The invention discloses a recovery method of a carbon-fiber reinforced resin-base composite material with pretreatment modes, which is characterized by comprising the following steps: carrying out heat-moisture treatment, loop speed-up aging treatment or water-jet impact treatment on a carbon-fiber reinforced resin-base composite material, and carrying out supercritical reaction to obtain high-performance carbon fibers, thereby implementing recovery of the carbon-fiber reinforced resin-base composite material. The heat-moisture treatment and loop speed-up aging treatment in the method enable the interfacial structure of the material to generate new pores and cracks, so that the resin base generates the phenomena of swelling and plasticizing, the pore size in the resin base is increased, and a small amount of resin base is stripped from the carbon fibers; the water-jet impact treatment mode can lower the interfacial bonding property of the material and previously destroy the structure of the resin base; all the three modes can enhance the mass diffusion of the supercritical fluid in the resin base, accelerate the degradation of the resin base in the supercritical fluid environment and enhance the recovery efficiency of the carbon fibers.

Owner:HEFEI UNIV OF TECH

Method for testing interfacial bond behavior of road asphalt mixture

The invention discloses a method for testing interfacial bond behavior of a road asphalt mixture, filling the blank of a method for testing interfacial bond behavior of asphalt and aggregate in an asphalt mixture under the conditions of freezing and thawing cycle, temperature aging, pressure aging and ultraviolet radiation aging. According to the technical scheme, the method comprises the following steps: performing sample preparation on an asphalt mixture; performing water freezing and thawing, salt freezing and thawing, temperature aging, pressure aging, ultraviolet radiation aging and three-point bending test on a semicircular test piece; and testing strain fields such as interfacial bond degenerative process, interfacial crack conditions, crack development tendency and interfacial debonding between the asphalt and aggregate specific to the influence of different asphalt mixtures on different aging conditions and different freezing and thawing cycle conditions, and calculating to obtain interfacial bond behavior fracture energy and fracture toughness property. According to the method, materials and grading types of the asphalt mixtures can be selected under different conditions, so that a scientific basis is provided for quality inspection and engineering characteristic evaluation of asphalt pavement material products in cold, strong ultraviolet ray districts.

Owner:INNER MONGOLIA UNIV OF TECH

Polycarbonate composite material and preparation method thereof and method for manufacturing LED (Light Emitting Diode) lamp housing

ActiveCN102250462AImprove interfacial adhesionReduced solvent stress cracking resistancePoint-like light sourceGlobesEpoxyProcedure Agents

The invention discloses a polycarbonate (PC) composite material and a preparation method thereof and a method for manufacturing an LED (Light Emitting Diode) lamp housing. The composite material is prepared from the following components in percentage by weight: 84-98.59 percent of polycarbonate resin, 0.01-8 percent of light diffusant, 1-5 percent of silicone resin, 0.1-1 percent of processing agent, 0.1-1 percent of thermal stabilizer, 0.1-1 percent of light stabilizer and 0.1-1 percent of processing aid. In the invention, the light diffusant is processed by using epoxy resin, so that the interfacial bond of the light diffusant and polycarbonate is improved, and the solvent-stress-resistant cracking performance of the PC composite material is decreased. Ordered arrangement of polycarbonate molecules is increased and the internal stress is reduced under optimized injection mould temperature; and the minimum influence of a toughening component on the transparency of a final lamp housing product is guaranteed by adding the silicone resin with refractive index of 1.587 and toughening effect. The reduction in impact strength of the lamp housing product brought by higher mould temperature during injection molding can be compensated by adding the silicone resin. The light diffusion PC material with a balance among light transmittance, haze and diffusion angle is obtained by adding the light diffusant, so that an LED lamp emits non-dazzling, soft and pleasant light.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Liner material for improving interfacial bonding of HTPB propellant and preparation method thereof

The invention discloses a liner material for improving interfacial bonding of an HTPB propellant and a preparation method thereof. The liner material provided by the invention comprises two parts, namely an interpenetrating polymer network I and an interpenetrating polymer network II, wherein the interpenetrating polymer network I comprises a curing agent of isocyanate, a chain extender of dihydric alcohol or diamine, a cross-linking agent of a multiple active functional group compound and a plasticizer, and also comprises adhesives comprising hydroxyl-terminated polybutadiene, nitrine or polyether and other hydroxyl-terminated macromolecule dihydric alcohols. The interpenetrating polymer network II comprises an epoxy resin, polyacrylate, polyurethane, polysiloxane, a vinyl ester resin and other resins. According to the invention, a novel technology can be provided to adapt to a propellant liner, so that the interfacial bonding property between the liner and the propellant is improved.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

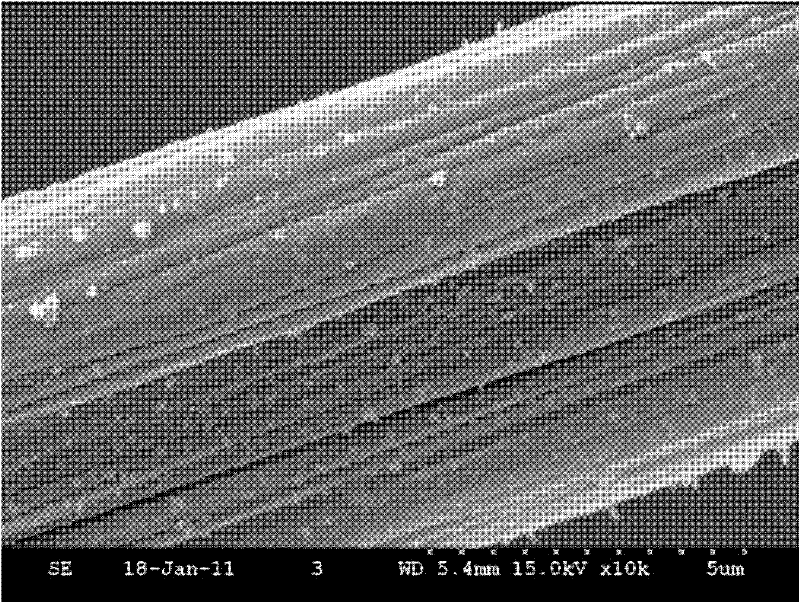

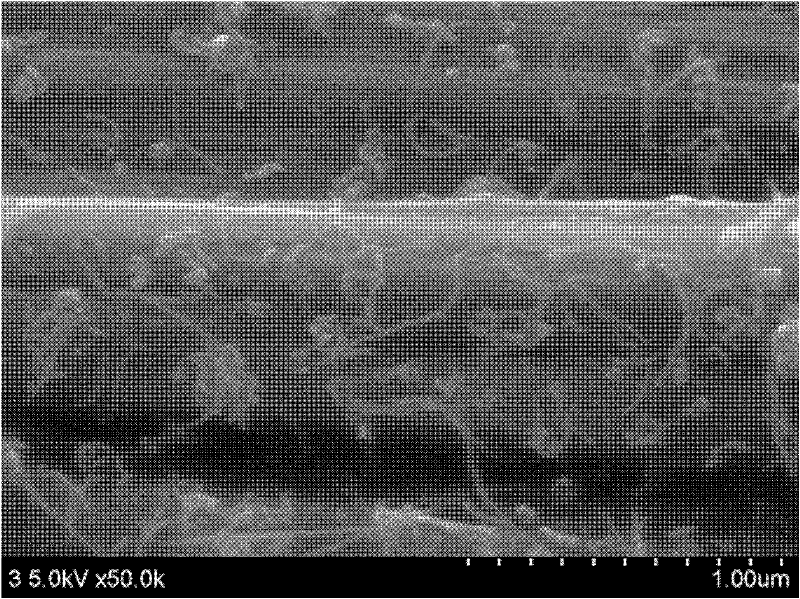

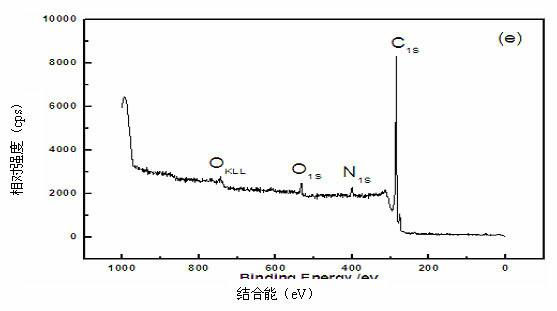

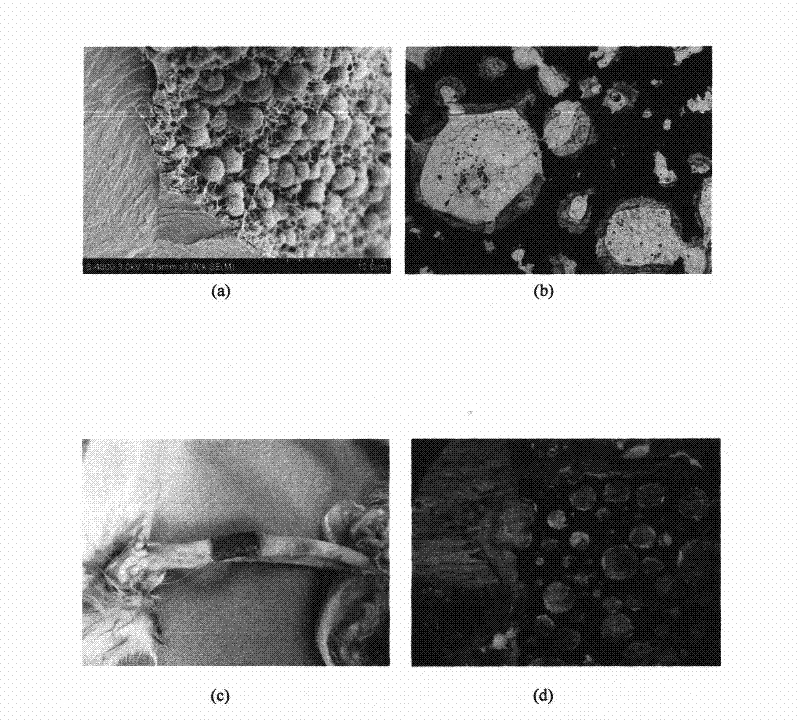

Method for preparing functional carbon fibers

InactiveCN102108634AImprove interface strengthIncreased interlaminar shear strengthCarbon fibresCarbon fibersResin matrix

The invention belongs to the technical field of nanomaterials, and in particular relates to a method for preparing functional carbon fibers. The method comprises the following steps of: performing carboxylation functionalization on carbon nanotubes; introducing diamine or polyamine onto the carbon nanotubes to obtain amino-coated carbon nanotubes; reacting the amino-coated carbon nanotubes with carboxyl-coated carbon fibers, and controlling reaction time; and introducing diamine or polyamine onto the surfaces of the carbon fibers to obtain the amino functional carbon fibers of which the surfaces are grafted with the carbon nanotubes. The reaction steps are simple and controllable; the carbon fibers are toughened through the strength and toughness of the carbon nanotubes; the adhesive property between the carbon fibers and a resin matrix is improved; the interfacial bond strength of a composite material is improved; and defects that the interfacial rigidity is increased and the toughness is reduced after the carbon fibers are treated by the conventional carbon fiber treatment method are well overcome. The prepared carbon fibers of which the surfaces are grafted with the carbon nanotubes have wide application range.

Owner:TONGJI UNIV

Method for preparing B4C-Al neutron-absorbing plate for spent fuel storage and transportation

ActiveCN102110484AControl criticalOvercoming reactivityNuclear energy generationReactors manufactureFuel tankInterfacial bond

The invention discloses a method for preparing a B4C-Al neutron-absorbing plate for spent fuel storage and transportation, which is implemented by adopting a frame rolling technique through the following steps: firstly, uniformly mixing a certain amount of B4C powder and Al matrix powder; then, carrying out mould pressing on the obtained mixture so as to obtain a compact green core body, sintering the compact green core body in a vacuum furnace, putting the sintered core body into an aluminum alloy frame, and sealing the aluminum alloy frame; and finally, rolling to obtain a plate. The process for preparing the neutron-absorbing plate is simple, the B4C is uniformly distributed into an Al matrix, and the B4C and the Al matrix have a good interfacial bond. The neutron-absorbing plate prepared by using the method disclosed by the invention is suitable for being used as a neutron-absorbing material in spent fuel tanks and transportation containers, thereby controlling the critical safetyof the spent fuel.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

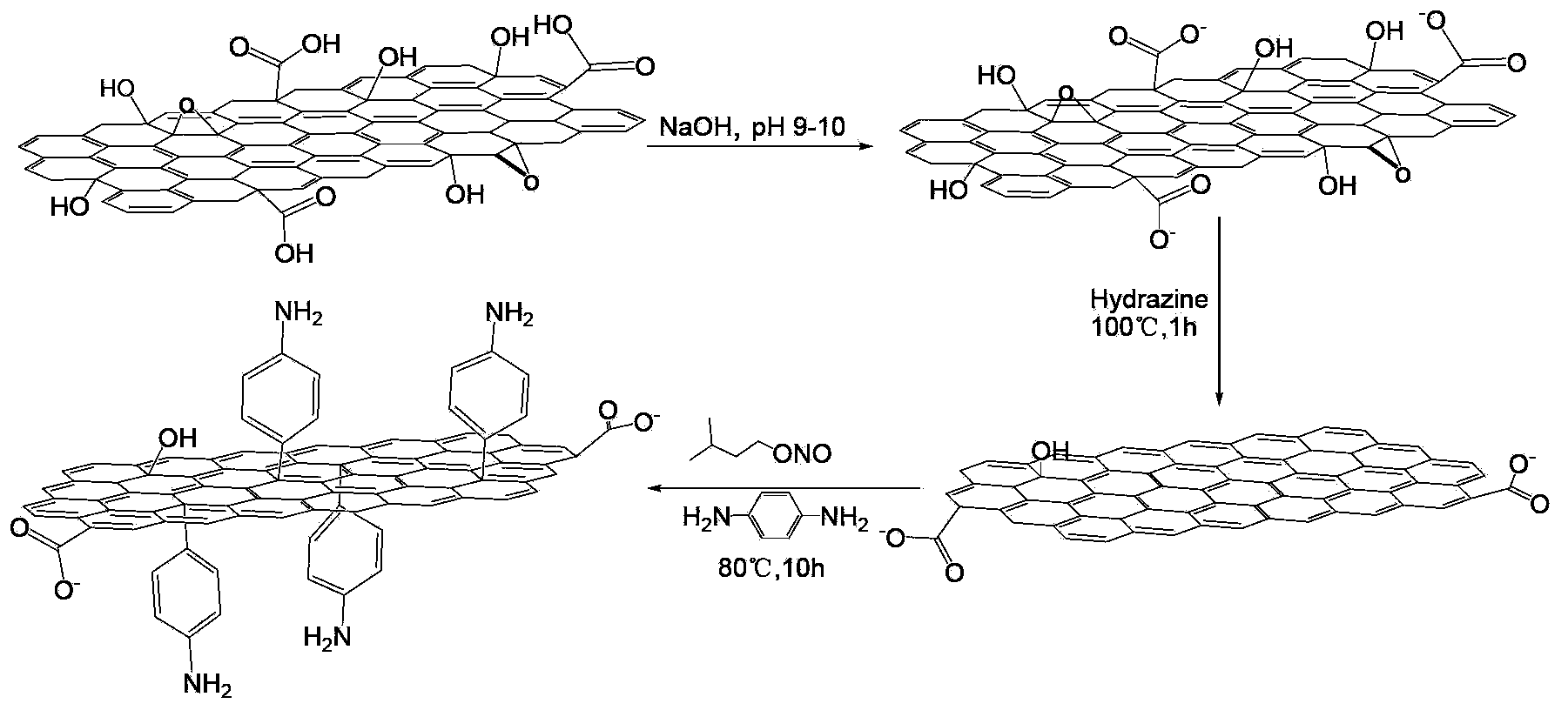

Modified graphene/bismaleimide resin composite material and preparation method thereof

The invention discloses a modified graphene / bismaleimide resin composite material and a preparation method thereof, and belongs to the technical field of the preparation of nanometer composite materials. The preparation method comprises the following steps: firstly preparing graphite oxide, then preparing modified graphene, and finally preparing a composite material according to 0.1-0.5wt% of modified graphene content in the composite material. The shock strength of the modified graphene / bismaleimide resin composite material disclosed by the invention is 19.557 to 26.171KJ / m<2>, and compared with the toughness of original bismaleimide resin, the toughness of the modified graphene / bismaleimide resin composite material is increased by 3.67% to 38.74%. The interfacial bonding property between the modified graphene and the bismaleimide resin is greatly improved, so that the toughness of the bismaleimide resin is improved, and the exertion of the property of the graphene is facilitated; compared with the toughness of the bismaleimide resin and a reduced graphene / bismaleimide resin composite material, the toughness of the modified graphene / bismaleimide resin composite material is greatly improved.

Owner:BEIHANG UNIV

Isostatic pressure assisted wafer bonding method

InactiveUS20060240640A1Semiconductor/solid-state device manufacturingNon-electric welding apparatusInterfacial bondWafer bonding

Owner:RGT UNIV OF CALIFORNIA

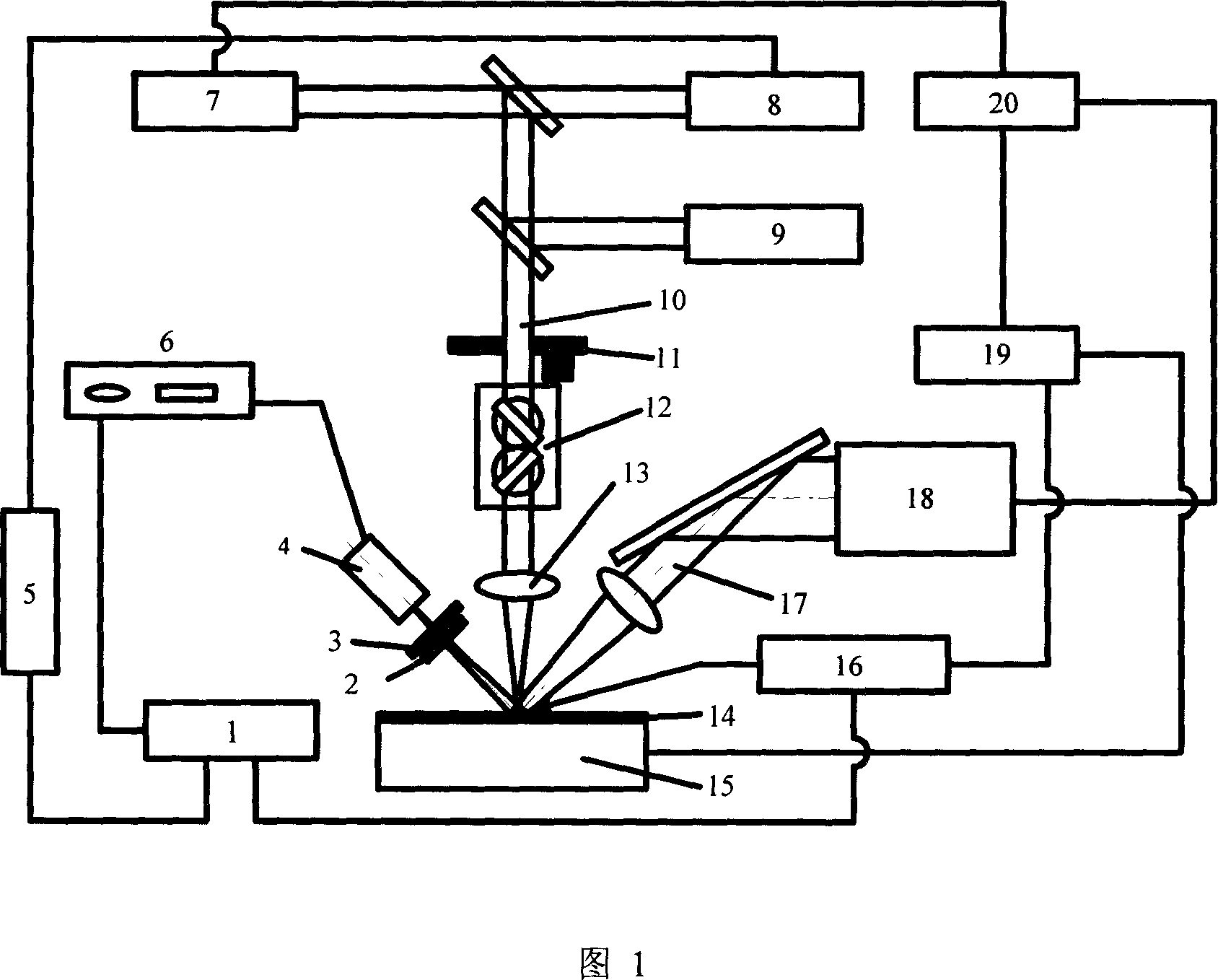

Coating interfacial bond strength detecting method and apparatus based on XRD

InactiveCN1975394AAccurately characterize binding strengthUsing mechanical meansMaterial analysis using radiation diffractionBond interfaceData treatment

The invention relates to the method and the device to detect the bond strength of the coat interface based on the XRD which belongs to the optical detection technology. The device includes the input path system composed of the YAG laser, the working table, the sample clipping system, the laser bean detecting signal analysis system and the data processing system composed by the computer and the X radial. The basic principle is that the hot effect of the laser acts on the coat surface to generate a hot coupling gradient temperature field, so the residue stress of the bond interface is changed which can express the interface bond strength. The temperature is achieved by controlling the laser power, the facular diameter and the acting time.

Owner:JIANGSU UNIV

Preparation method of bone inducing porous titanium artificial bone

The invention relates to a preparation method of bone inducing porous titanium artificial bone. The method comprises the following steps: a porous titanium block is processed into a required shape and is washed; the surface is activated; the porous titanium block is put into acid solution which is prepared by sulfuric acid, hydrochloric acid and deionized water to be processed and then is put into alkali solution of sodium hydroxide; or put into acid solution which is prepared by hydrofluoric acid, nitric acid and deionized water to be processed and is then put into hydrogen peroxide solution; or put into acid solution which is prepared by hydrofluoric acid, nitric acid and deionized water to be processed and is then put into hydrogen peroxide solution which contains tantalum pentachloride; the method is characterized in that the surface of the porous titanium can be activated uniformly without pre-depositing a calcium phosphate layer, when being soaked in simulated body fluid at 36.5DEG C, bone-like apatite can be induced to deposit in 28 days; and bone inductivity can be given to the porous titanium artificial bone. The bone inducing porous titanium artificial bone is used for repairing, replacing or reinforcing bone tissue and can reinforce the regeneration of the bone tissue and the interfacial bond of the implant site; and the process is simple and the operation is convenient.

Owner:SICHUAN UNIV

Preparation method of glass-fiber-reinforced epoxy resin composite material modified by circuit board recovered powder and nanoparticles

The invention belongs to the technical field of solid waste comprehensive utilization, and particularly relates to a preparation method of a glass-fiber-reinforced epoxy resin composite material modified by circuit board recovered powder and nanoparticles. The preparation method provided by the invention comprises the following steps of: modifying glass fibers with a coupling agent to obtain surface-activated glass fiber reinforcement; carrying out surface activating treatment on dry circuit board recovered powder and nanoparticles, and then mixing with epoxy resins to obtain an epoxy resin base body filled and modified by the circuit board recovered powder and nanoparticles; and finally compounding the coupling-agent-modified glass fiber reinforcement and the epoxy resin base body filled and modified by the circuit board recovered powder and nanoparticles to obtain the glass-fiber-reinforced epoxy resin composite material modified by circuit board recovered powder and nanoparticles. The preparation method utilizes the coupling-agent-treated glass fibers to improve the interfacial bonding properties between the glass fibers and the resin base body and to improve the interfacial bond strength of the composite material, utilizes the strength and toughness of the glass fibers to strengthen and toughen the resin base body, and utilizes the surface-activated recovered powder and nanoparticles to fill and modify the resin base body, thus improving the overall performance of the composite material and significantly improving the interfacial bond strength of the composite material and the mechanical properties of the glass fiber composite material, and can be widely applied in the fields of aerospace, automobile shipping, traffic transportation, mechatronics, etc.

Owner:TONGJI UNIV

Fiber-enhanced cement-based composite material

InactiveCN104909648AResilientImprove interfacial bond strengthSolid waste managementCarbon nanotubeVolcanic ash

The invention aims at providing a fiber-enhanced cement-based composite material. The material comprises the raw materials of, by weight, 120-160 parts of cement, 150-200 parts of a fine aggregate, 230-330 parts of a coarse aggregate, 26-40 parts of silica fume, 10-20 parts of volcanic ash, 23-35 parts of fly ash, 12-25 parts of carbon nanotube, 10-23 parts of polymer resin, 5-12 parts of a water reducing agent, 35-55 parts of water, and 5-20 parts of fiber. According to the invention, a water-binder ratio is controlled at below 0.23; materials with specific types, specific particle sizes and specific amounts are selected; and several excellent fiber materials and polymer resin are selected, such that the composite material is more compact. On a basis that the strength of the composite material meets application requirements, the material has certain toughness. The fracture energy can reach 20000-40000J / m<2>, and interfacial bond strength is high. The material can be subjected to natural curing or high-temperature steam curing, such that construction processes such as model casting, spraying and scrape coating can be satisfied.

Owner:JIUQING PAINT SHANGHAI

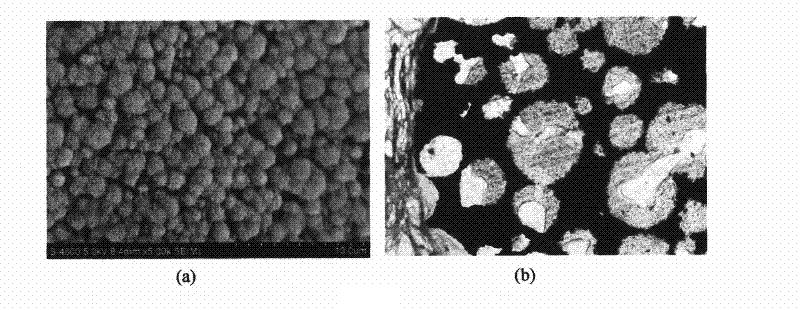

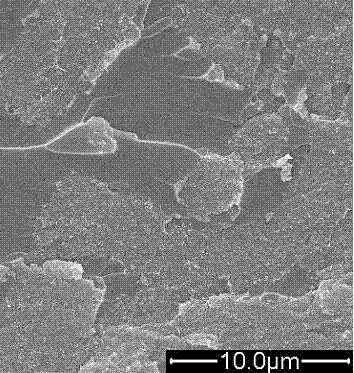

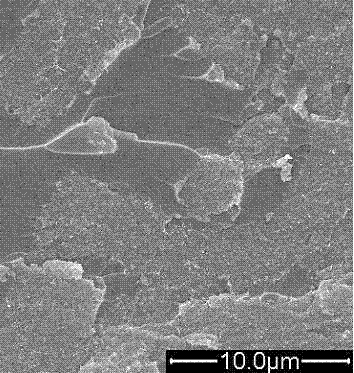

Bi-component interfacial bonding organosilicone connection paint matched with pollution release type anti-fouling paint

ActiveCN106336799AImprove adhesionNo foamingAntifouling/underwater paintsPaints with biocidesCavitationSolvent

The invention discloses bi-component interfacial bonding organosilicone connection paint matched with pollution release type anti-fouling paint. The bi-component interfacial bonding organosilicone connection paint is prepared from a first component and a second component according to the weight ratio of 10:1. The first component is prepared from organosilicone, pigments and filler, a solvent and a thixotropic agent. The second component is prepared from a high-toughness curing agent and a reaction promoter. The bi-component interfacial bonding organosilicone connection paint is prepared from the first component including, by weight, 35-55% of organosilicone, 20-40% of pigments and filler, 15-30% of solvent and 0-5% of thixotropic agent and the second component including, by weight, 10-20% of high-toughness curing agent and 0.01-0.03% of reaction promoter. According to the connection paint, the problem that pollution release type anti-fouling paint and anti-rusting paint are poor in adhesive force is solved, the adhesive strength to an anticorrosion coating reaches 2.2 MPa or above, the connection strength for an anti-fouling coating reaches 1.3 MPa or above, and 100% cohesive failure is shown; after being scoured by 50 sections of high-speed flow for 1,000 hours, the coatings are free of bubbling, disengaging and cavitation damage, and have good adhesive performance.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Preparation method of ZTA particle enhanced steel-based composite liner plate based on chemical activation treatment

ActiveCN106735100AHigh bonding strengthEnhanced interface bindingSuperimposed coating processBiological activationInterfacial bonding

The invention discloses a preparation method of a ZTA particle enhanced steel-based composite liner plate based on chemical activation treatment. The preparation method comprises the following steps: (1) carrying out high temperature salt-bath plating on ZTA particles, and obtaining uniform titanium plated layers on the surfaces of the ZTA particles; (2) forming nickel layers at the peripheries of the titanium plated layers; (3) sintering the plated ZTA particles, and mutually connecting the ZTA particles to form a porous prefabricated part; and (4) fixing the prefabricated part on the end surface or the working surface of a cast, pouring a steel base material metal solution through a casting-penetrating process, and carrying out cooling to obtain the ZTA particle enhanced steel-based composite liner plate. During the salt-bath titanium plating, titanium and the surfaces of the ZTA ceramic particles form metallurgical bonding, so that the interfacial bonding property between the titanium layers and the ZTA ceramic particles is enhanced. The ZTA ceramic particles subjected to the salt-bath titanium plating is then subjected to chemical nickel plating, and a titanium-nickel alloy can be generated at a titanium-nickel bonding part; and the titanium-nickel alloy layers achieve the effect of a flexible transitional layer between a metal base body and the ZTA particles, so that the bonding strength of the interface is greatly enhanced.

Owner:陕西明熙康普科技有限公司

Interface finishing agent improving rubber-cement stone substrate in rubber concrete

InactiveCN101182157ANo adverse effects on workabilityImprove interfacial bond strengthSolid waste managementPolymer scienceCarvacryl acetate

The invention relates to an interface treatment agent for improving the rubber-cement matrix in rubber concrete, which belongs to the technical field of concrete admixtures. At present, the interface treatment agents for improving the rubber particle-cement stone matrix mainly include: water washing, Na(OH) solution corrosion and carbon tetrachloride solution cleaning treatment, etc. But above-mentioned material use effect is unsatisfactory. The present invention is characterized in that it is prepared by uniformly mixing three materials: styrene-acrylic acid ester-silicon coupling agent copolymer, ethylene-vinyl acetate copolymer, and polyvinyl alcohol coupling agent (PVA). The weight percentages of each component are: styrene-acrylate-organic silicon coupling agent copolymer accounts for 40-70%, ethylene-vinyl acetate copolymer accounts for 20-40%, and PVA coupling agent accounts for 10-20%. . Compared with the rubber aggregate concrete without surface treatment, the interface agent of the present invention can effectively improve the interface bonding strength between the rubber particles and the cement stone matrix, thereby increasing the compressive strength of the rubber aggregate concrete by more than 6%. The workability of the concrete was not adversely affected.

Owner:BEIJING UNIV OF TECH

Preparation method for high-strength flame-retardant wood-plastic floor

The invention discloses a preparation method for a high-strength flame-retardant wood-plastic floor, and belongs to the technical field of preparation of floors. According to the method provided by the invention, sepiolite and a phosphoric acid solution are mixed and dispersed to obtain a flame-retardant functional mother liquor, a dimethyl sulfoxide solution of E-51 epoxy resin is added dropwiseinto an alkalizing solution of beta-cyclodextrin for a reaction to obtain nano fibers, polyethylene masterbatch particles are subjected to rubber mixing for melting, a wood and stone fiber sponge is mixed, the obtained material is injected into a hot pressing mold for hot pressing to obtain the high-strength flame-retardant wood-plastic floor, lignin is adsorbed on the fiber surface and in the pores to enhance interfacial bonding force of the lignin and sepiolite fibers, and therefore the compressive strength of the wood-plastic floor is improved; and the nano fiber sponge is prepared by soaking of resin in the flame-retardant functional mother liquor, sepiolite powder in the flame-retardant functional mother liquor is a magnesium-enriched silicate compound, the compound can form a magnesium hydroxide crystal and ammonium phosphate under the action of an ammonia gas and phosphoric acid, the integrity of a polyethylene matrix skeleton is maintained, oxygen supply during combustion is insufficient, combustion is quickly stopped, and therefore the better flame retardant effect on the wood-plastic floor is achieved.

Owner:常州鼎众冷暖设备工程有限公司

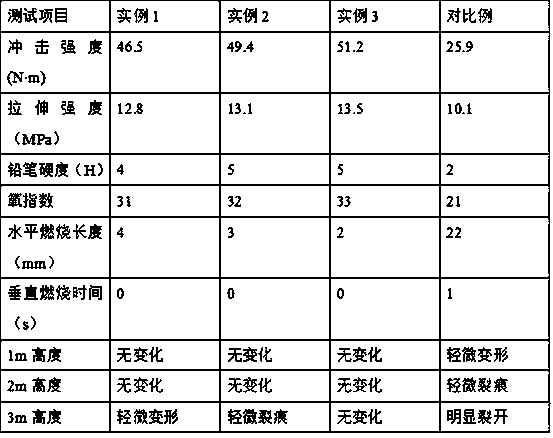

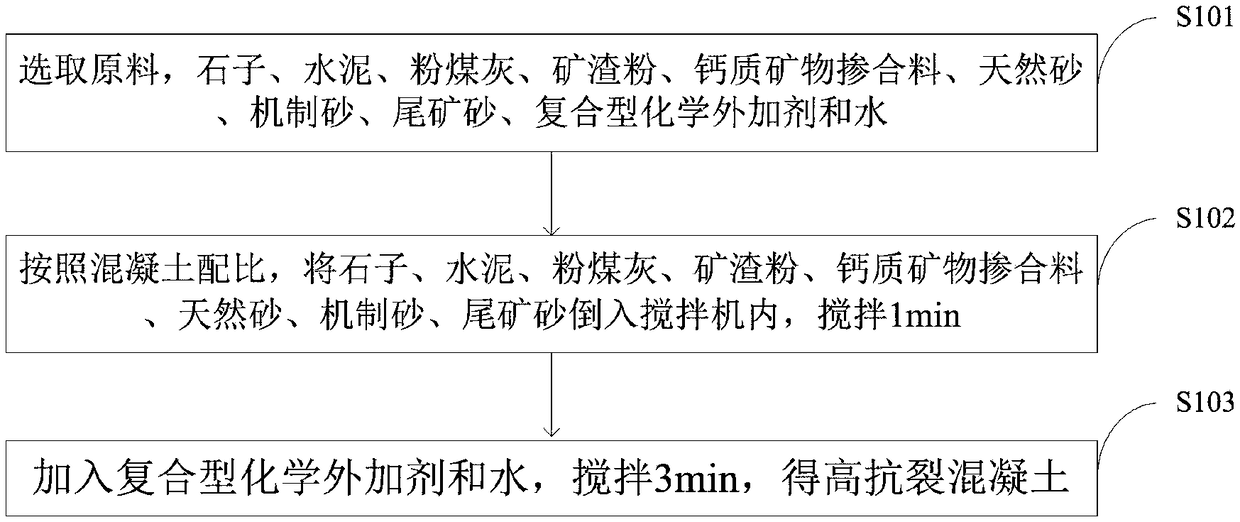

Low-cost alternative resource high-crack-resistance concrete and preparation method thereof

The invention belongs to the technical field of concrete, and discloses a low-cost alternative resource high-crack-resistance concrete and a preparation method thereof. In parts by weight, the components and the dosages of the high-crack-resistance concrete are 280 to 450 parts of cement, 20 to 60 parts of fly ash, 50 to 80 parts of slag powder, 10 to 30 parts of calcium mineral admixture, 0 to 200 parts of natural sand, 300 to 500 parts of machine-made sand, 200 to 400 parts of tailing sand, 800 to 1200 parts of stone, 4 to 8 parts of compound chemical additive and 90 to 270 parts of water. The invention solves the problem that natural river sand resource is scarce and the problem that pollution and energy consumption are high in the process of cement production, and greatly reduces the cost of concrete per cubic meter; since machine-made sand, tailing sand and calcium mineral admixture are adopted, the interfacial bond strength of the concrete can be improved, and the crack resistance of the concrete can be improved; and the problems of poor cohesiveness and easy bleeding and segregation existing in concrete are effectively solved.

Owner:CHINA BUILDING MATERIALS ACAD

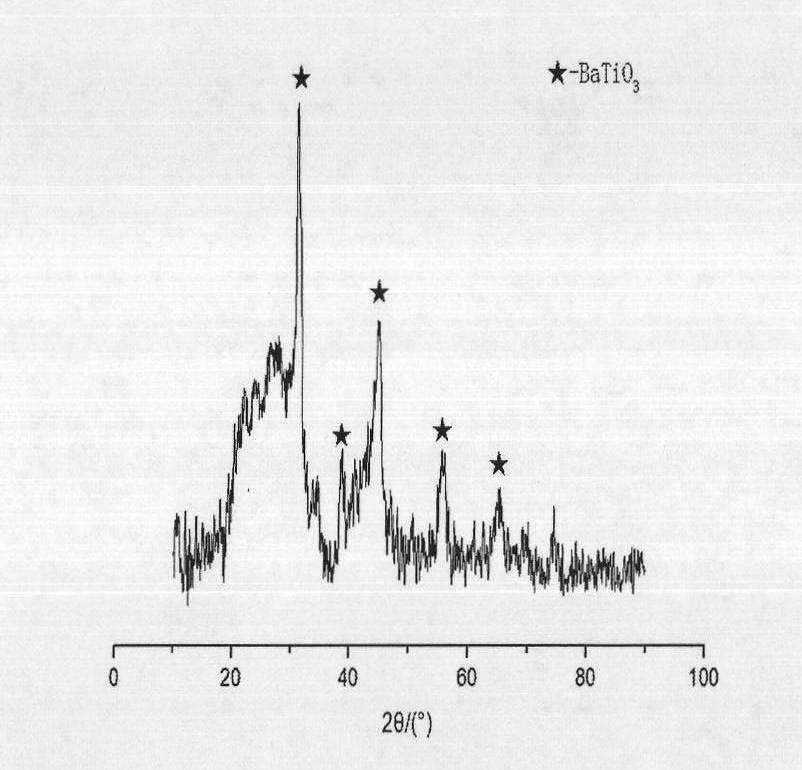

Nanocrystalline barium titanate-carbon composite powder and preparation method thereof

The invention relates to nanocrystalline barium titanate-carbon composite powder and a preparation method thereof. The invention adopts a technical scheme that: the preparation method comprises the following steps of: mixing analytically pure BaCO3 and titanium powder serving as raw materials in a molar ratio of 1:1, adding 0 to 10 percent of nickel powder, 0 to 10 percent of iron powder and 0 to10 percent of carbonyl nickel powder based on the total mass of the raw materials into the mixture, and uniformly mixing to obtain a mixed raw material; and filling the mixed raw material and steel balls in a mass ratio of 1:30-1:70 into a stainless steel ball milling jar, sealing, vacuumizing to -0.05MPa or charging one of high-purity argon, high-purity hydrogen and CO2 into the stainless steel ball milling jar after vacuumizing to -0.05MPa, and performing ball milling for 10 to 120 hours on a planet ball mill to obtain the nanocrystalline BaTiO3-C composite powder. The preparation method has the characteristics of simple process and easy industrialization. The prepared nanocrystalline barium titanate-carbon composite powder is uniformly dispersed and is good in interfacial bond strength. The crystalline particle size is nanoscale.

Owner:WUHAN UNIV OF SCI & TECH

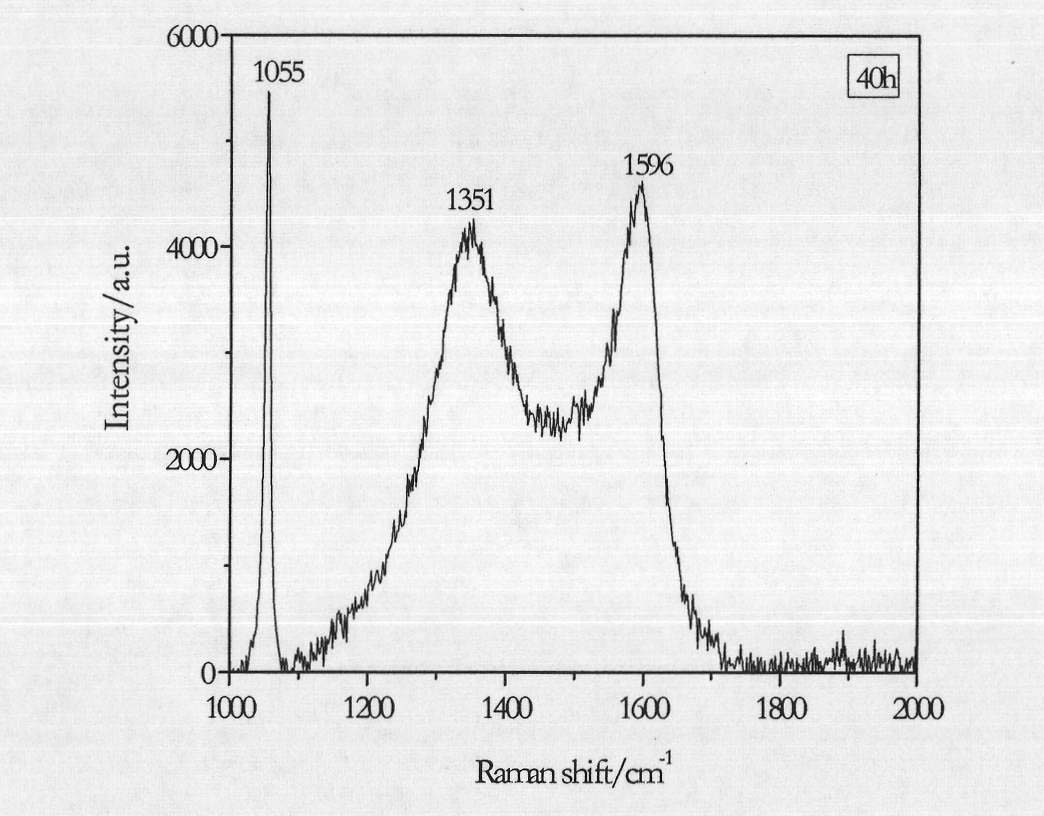

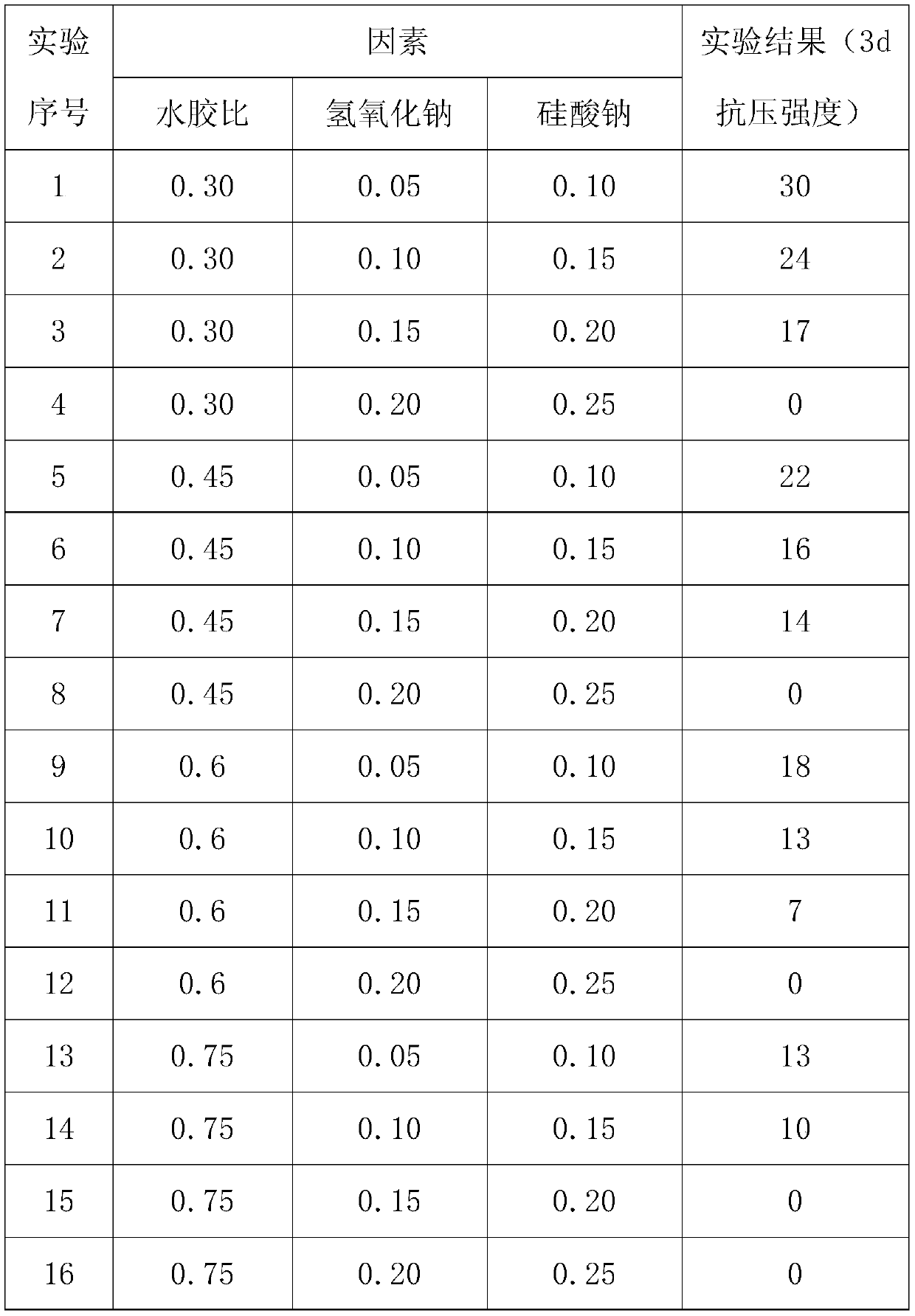

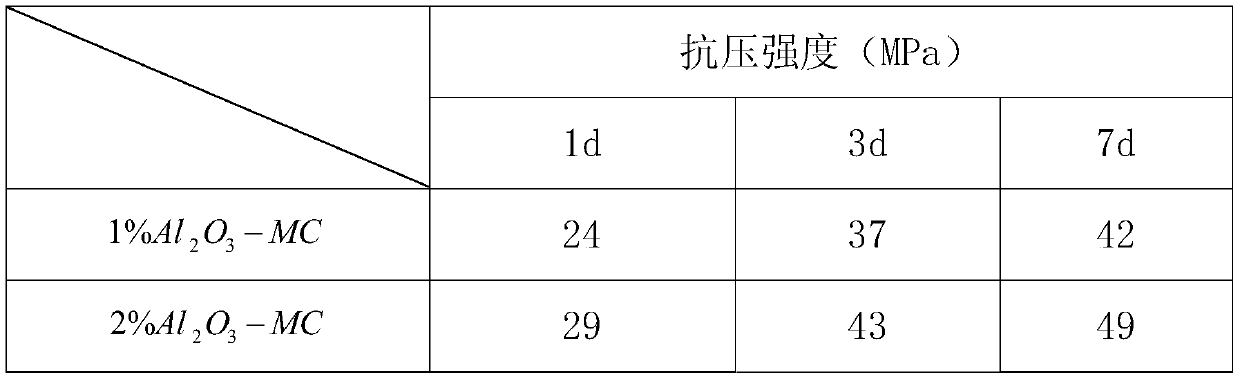

Nanometer Al2O3-Ca<2+>-based metakaolin geopolymer road repairing material

InactiveCN109809751AImprove heat resistanceGood freezing resistanceCement productionGeopolymerSodium silicate

The invention discloses a nanometer Al2O3-Ca<2+>-based metakaolin geopolymer road repairing material. A formula comprises nanometer Al2O3, Ca(OH)2, calcined kaolin, sodium silicate, sodium hydroxide and distilled water according to a mass ratio of 0.02 to 0.1 to 1 to 0.1 to 0.05 to 0.3. A metakaolin geopolymer has good interfacial bond property and excellent durability and heat resistance, can beused for well repairing cracks and pit slots on a road, and can improve the service life of the road repairing material. Tests show that by adding the Ca(OH)2 into the metakaolin geopolymer, the setting time of the road repairing material can be shortened, and by adding the Al2O3, the compressive strength of the road repairing material can be obviously increased. The 1d compressive strength of theroad repairing material can reach 31 MPa; the initial and final setting time of the road repairing material is respectively 60 min and 295 min; the mechanical property is excellent; and the road repairing material can replace cement as a new green building material to a certain extent, and has a good application prospect.

Owner:NORTHEAST FORESTRY UNIVERSITY

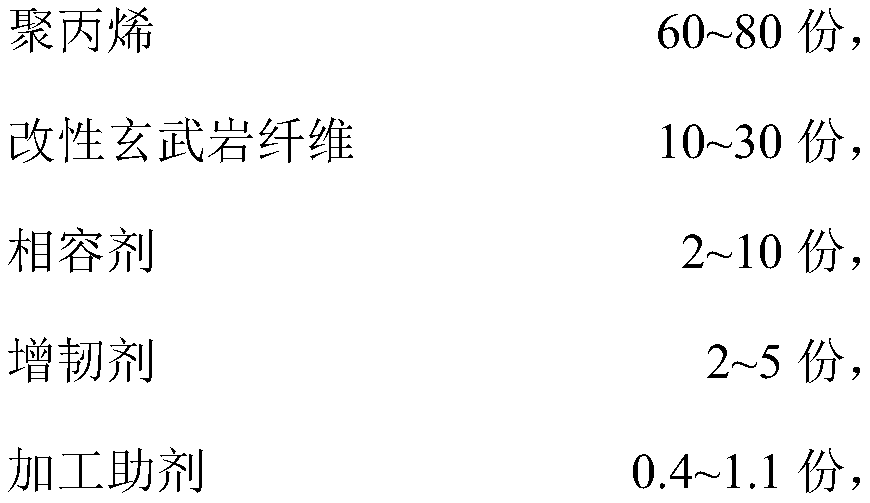

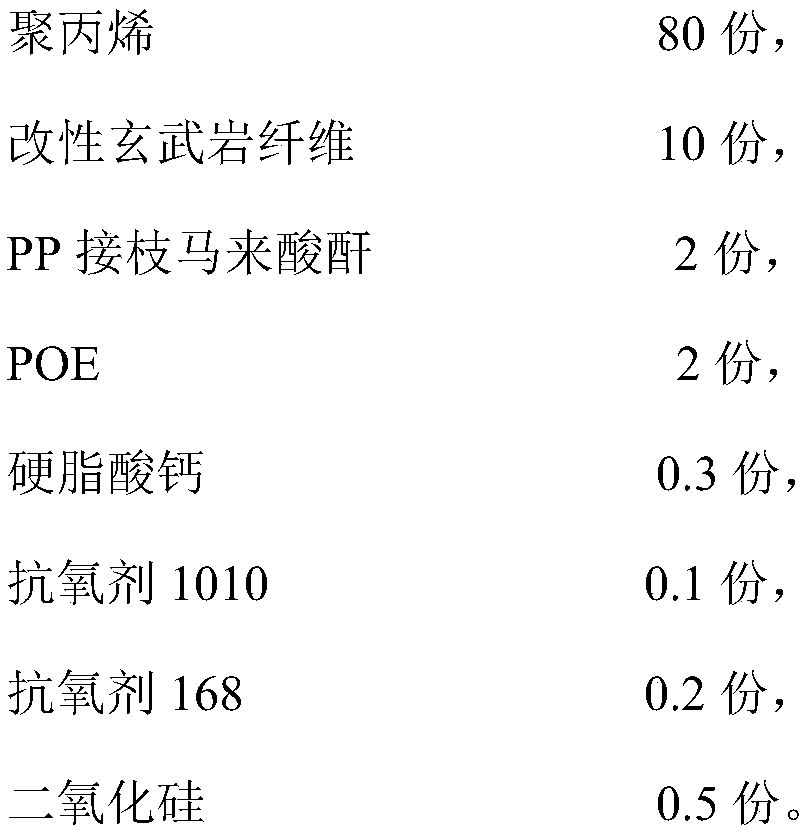

Polypropylene composite material and preparation method thereof

InactiveCN109337192AHigh mechanical strengthImprove the interface binding forcePolypropylene compositesInterfacial bond

The invention discloses a polypropylene composite material. The polypropylene composite material comprises modified basalt fiber, polypropylene, a compatibilizer, a toughening agent, a processing aidand silicon dioxide. Through modification of the surface of the basalt fiber, an interfacial bonding force between the basalt fiber and a polypropylene matrix is enhanced. The invention further discloses a preparation method of the polypropylene composite material. Through the combination of an extrusion technology and an LFT fiber infiltrating preparation technology, a long basalt fiber and polypropylene composite material with long fiber retention length is prepared; the polypropylene composite material prepared by the preparation method has the fiber length of 10-15mm, so that the preparedpolypropylene composite material has improved comprehensive properties such as stretching, bending and impact.

Owner:ORINKO NEW MATERIAL CO LTD

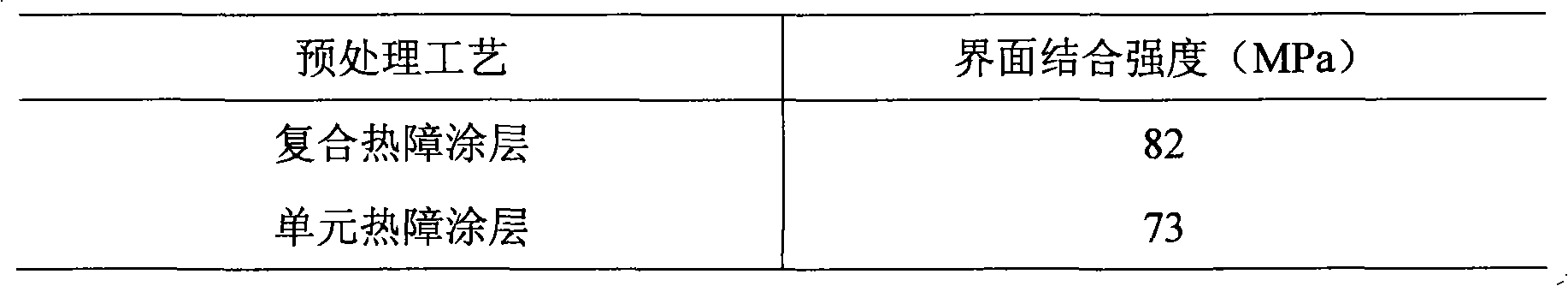

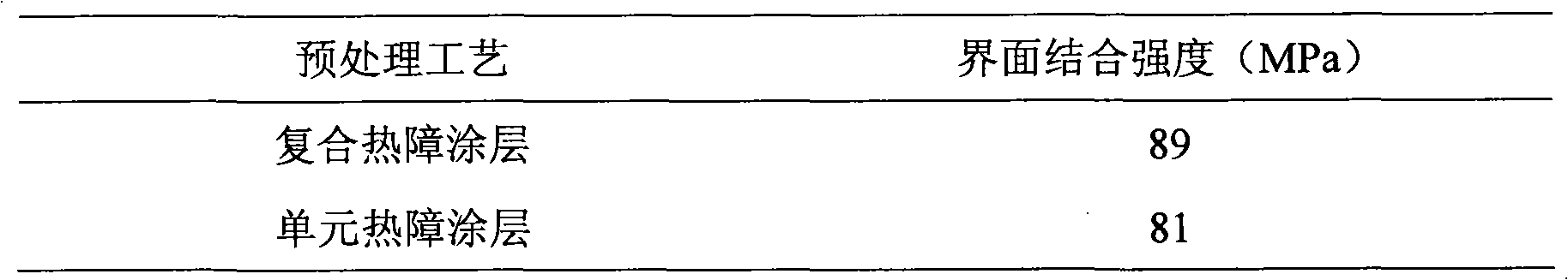

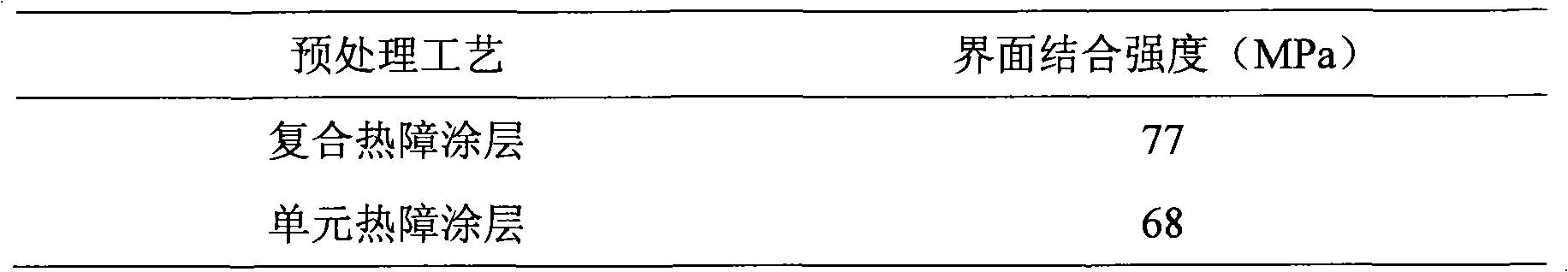

Method for preparing thermal expansion matching composite thermal barrier coating

InactiveCN101831602AImprove performanceExtended service lifeMolten spray coatingInterfacial bondAlloy

The invention discloses a method for preparing a thermal expansion matching composite thermal barrier coating, and relates to the field of surface coatings. The composite thermal barrier coating consists of a thermal barrier coating material Zr1-x-yHfxREyO2-y / 2 and a negative thermal expansion material Zr1-yREyW2-zMozO8-y / 2, wherein x is more than or equal to 0.01 and less than or equal to 1; y is more than or equal to 0.01 and less than or equal to 0.05; z is more than or equal to 0.3 and less than or equal to 1; and RE is one or more of La, Ce, Pr, Nd, Pm, SM, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc and Y. The method comprises the following steps of: 1) cutting a matrix alloy into a certain size; 2) according to the thermal expansion matching principle, matching thermal barrier coating nanopowder with negative thermal expansion material micropowder; 3) performing micro / nano composition reconstruction on two kinds of prepared powder; 4) performing laser radiation on reconstructed composite particles; and 5) filling the composite particles in a powder feeder, and preparing the thermal barrier coating through vacuum plasma spraying. The thermal barrier coating prepared has small interfacial stress, high bond strength, and good mechanical property. The method has simple process, is suitable for large-scale massive production, and can prepare the composite thermal barrier coating with firm interfacial bond.

Owner:JIANGSU UNIV

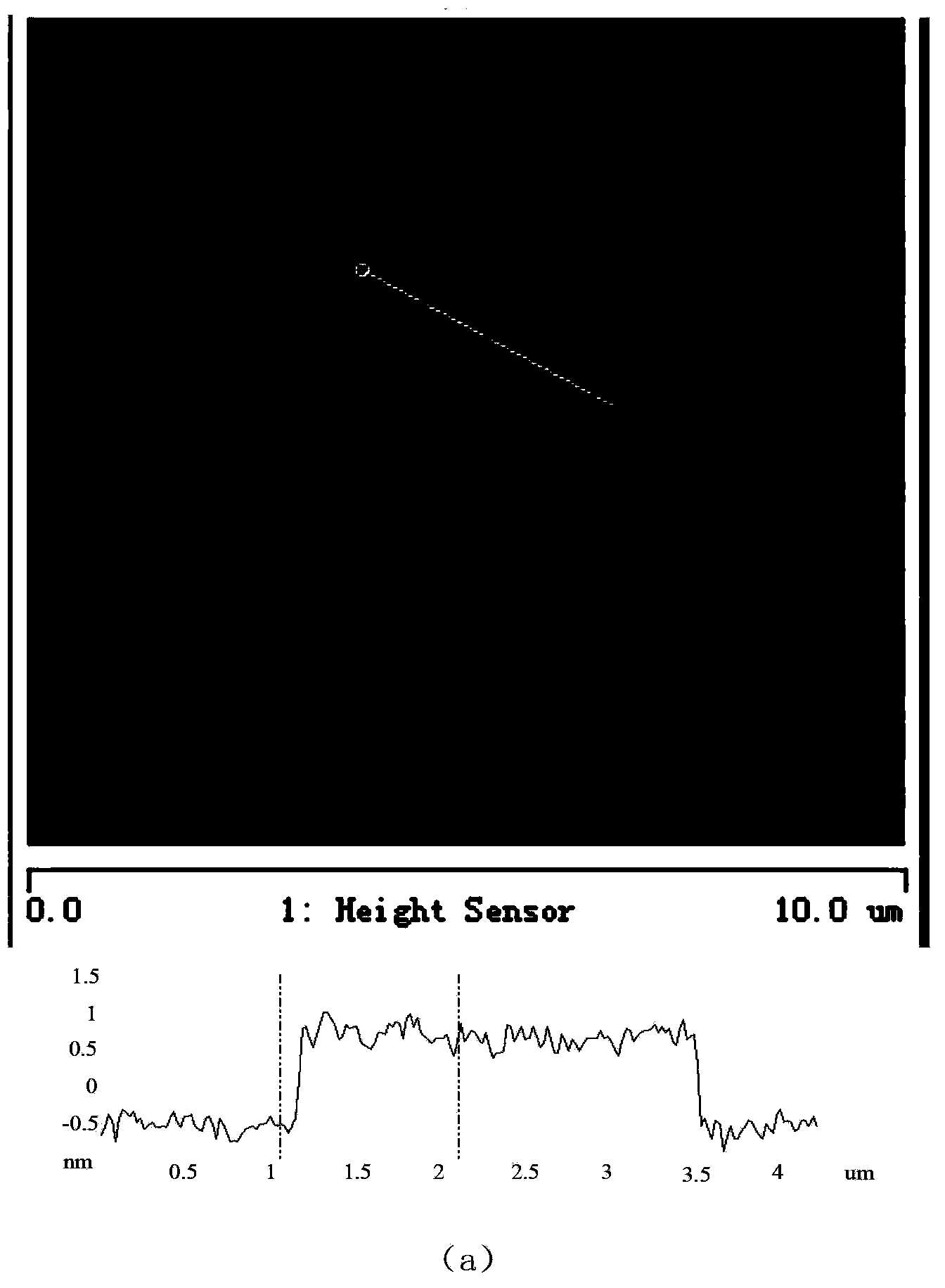

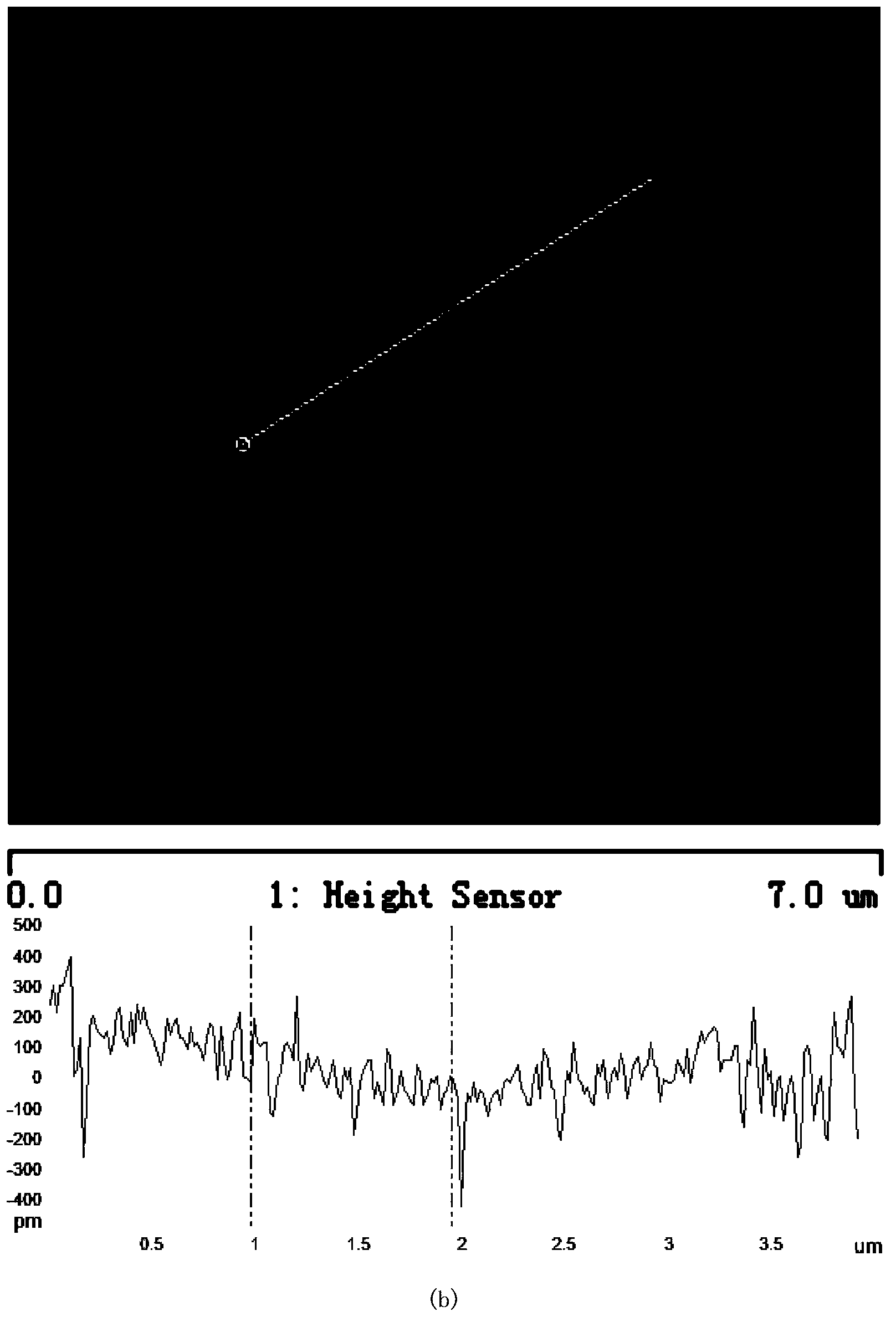

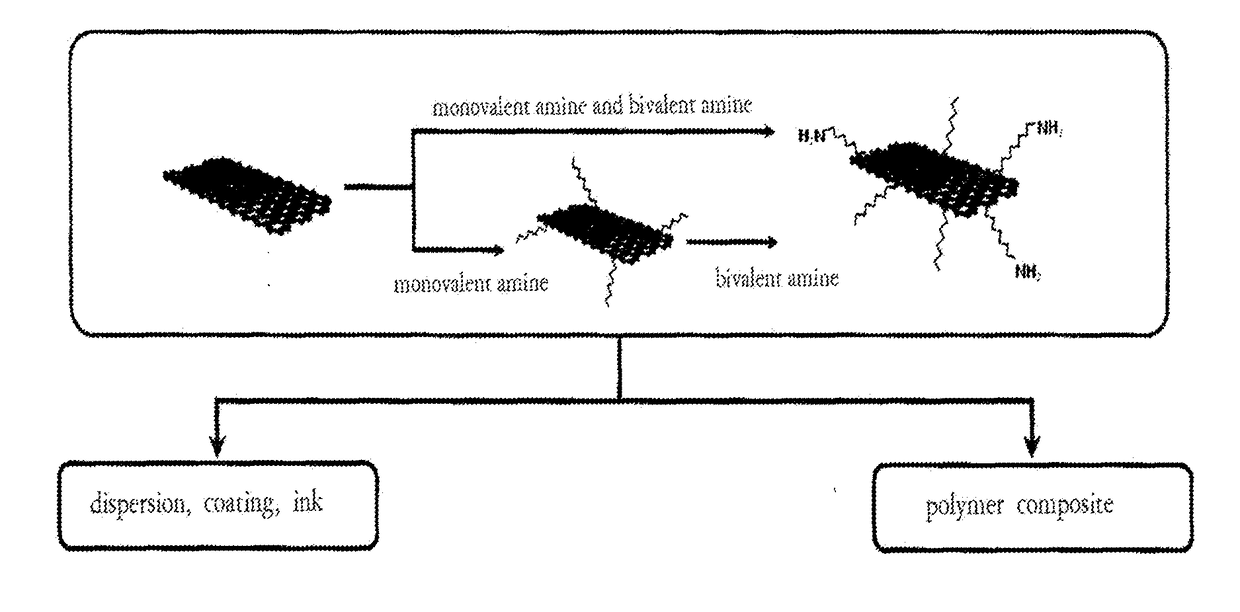

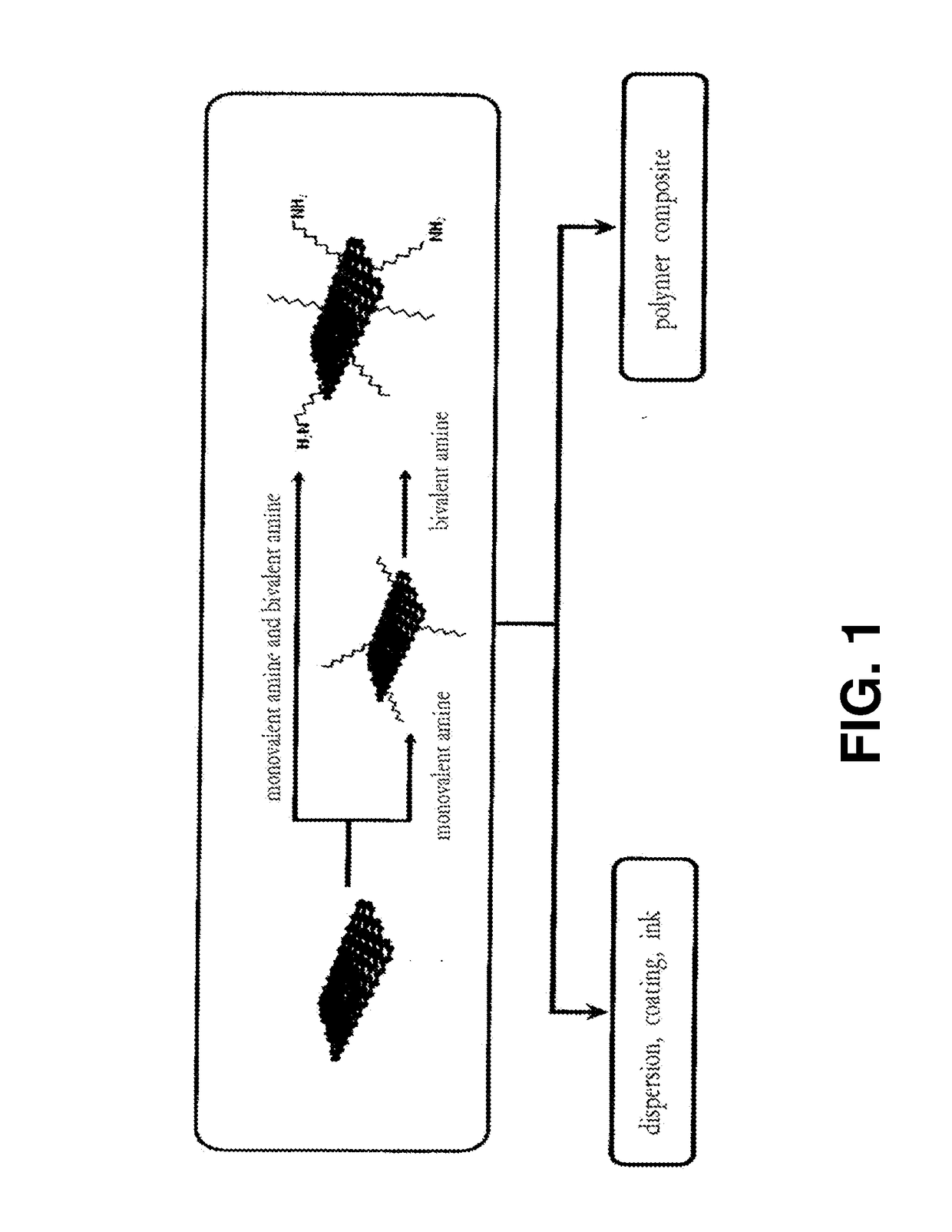

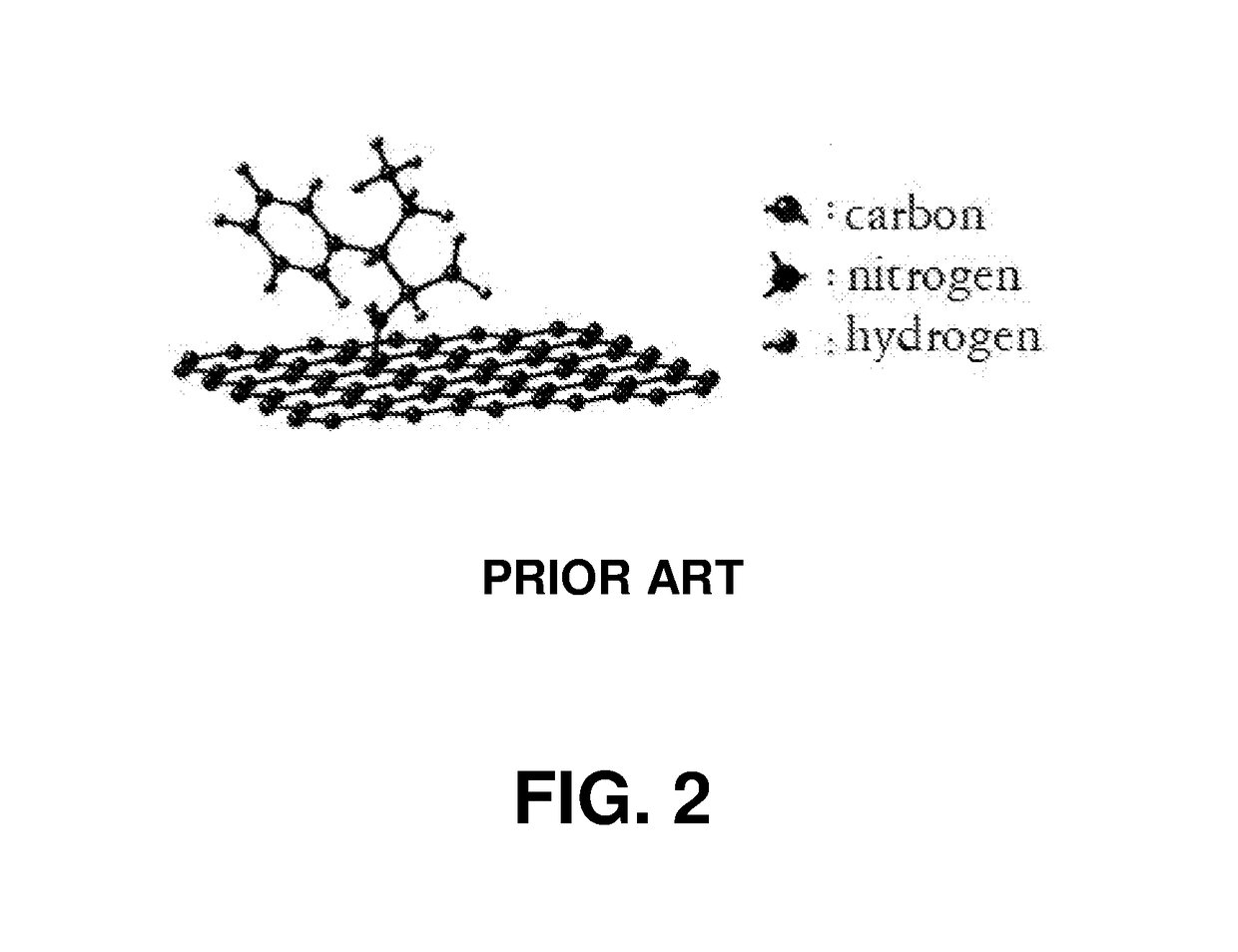

Functionalized graphene comprising two or more types of amines, and preparation method therefor

ActiveUS20180079647A1Excellent kneading performanceGood kneadabilityOrganic chemistryGrapheneInterfacial bondCvd graphene

Disclosed is a functionalized graphene containing two or more amines having excellent electrical, thermal and mechanical properties by allowing good interfacial bonding force and uniform dispersion with a thermoplastic polymer, and a method for preparing the functional graphene. The functionalized graphene comprises a carbon material selected from the group consisting of graphene, reduced graphene, graphene oxide, and mixture thereof; and a monovalent amine group and a bivalent or higher amine group which are bonded to the carbon material.

Owner:DONGJIN SEMICHEM CO LTD

Preparation method of ZTA particle enhanced steel-based composite grinding roller based on chemical activation treatment

ActiveCN106735101AHigh bonding strengthEnhanced interface bindingSuperimposed coating processInterfacial bondNickel alloy

The invention discloses a preparation method of a ZTA particle enhanced steel-based composite grinding roller based on chemical activation treatment. The preparation method comprises the following steps: (1) carrying out high temperature salt-bath plating on ZTA particles, and obtaining uniform titanium plated layers on the surfaces of the ZTA particles; (2) forming nickel layers at the peripheries of the titanium plated layers; (3) sintering the plated ZTA particles, and mutually connecting the ZTA particles to form a porous prefabricated part; and (4) fixing the prefabricated part on the end surface or the working surface of a cast, pouring a steel base material metal solution through a casting-penetrating process, and carrying out cooling to obtain the ZTA particle enhanced steel-based composite grinding roller. During the salt-bath titanium plating, titanium and the surfaces of the ZTA ceramic particles form metallurgical bonding, so that the interfacial bonding property between the titanium layers and the ZTA ceramic particles is enhanced. The ZTA ceramic particles subjected to the salt-bath titanium plating is then subjected to chemical nickel plating, and a titanium-nickel alloy can be generated at a titanium-nickel bonding part; and the titanium-nickel alloy layers achieve the effect of a flexible transitional layer between a metal base body and the ZTA particles, so that the bonding strength of the interface is greatly enhanced.

Owner:XI AN JIAOTONG UNIV

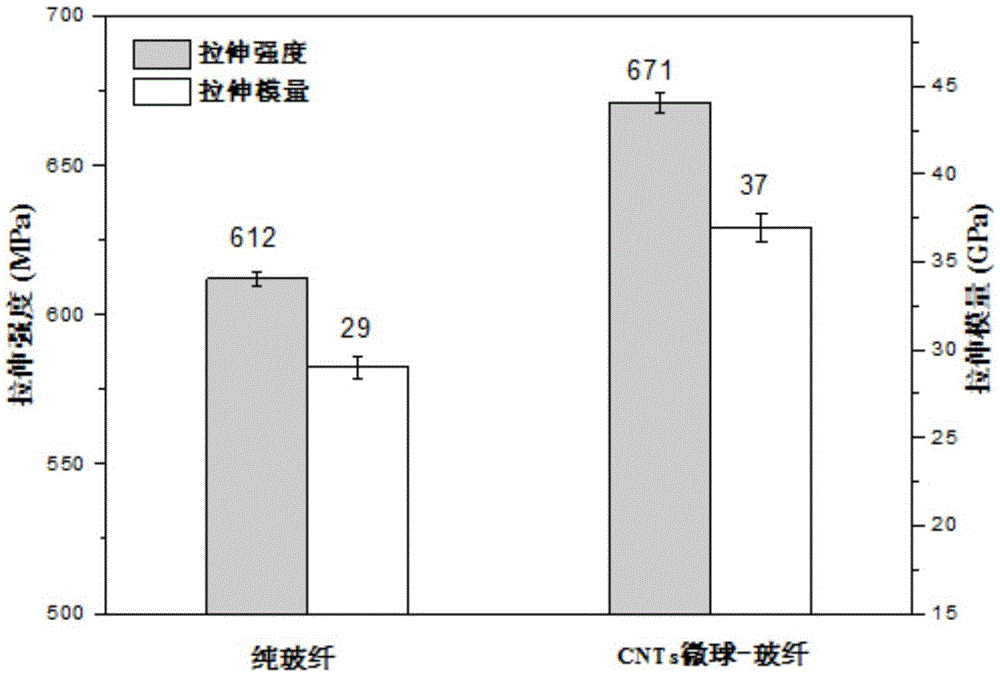

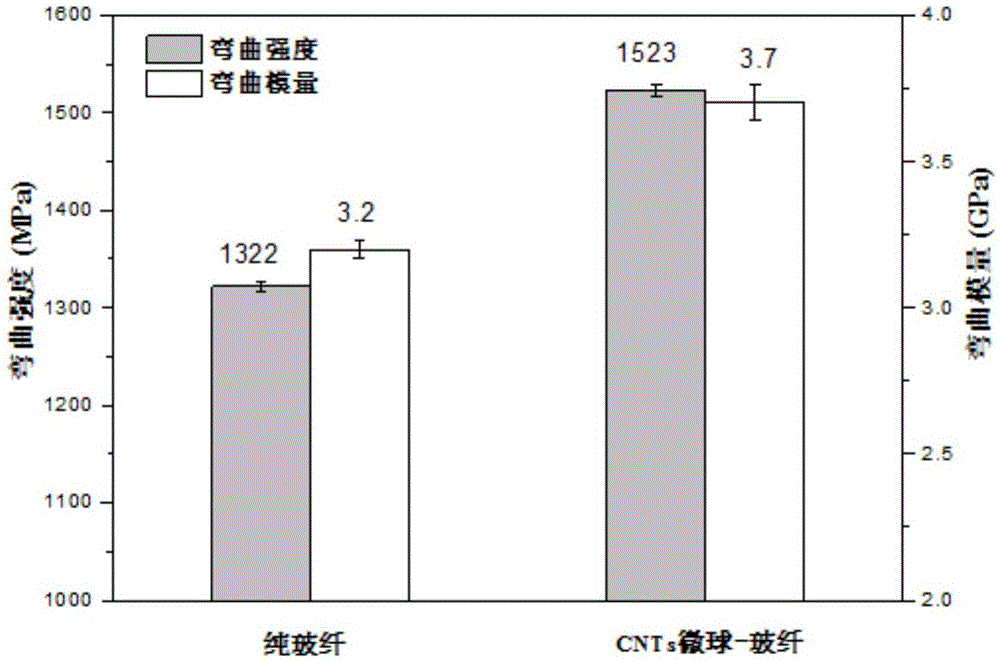

Carbon nano-tube microsphere/glass fiber synergistically-reinforced epoxy composite material preparation method

ActiveCN105153639ASolve the problem of agglomerationImprove interface strengthGlass fiberMaterials preparation

The present invention discloses a carbon nano-tube microsphere / glass fiber synergistically-reinforced epoxy composite material preparation method, which comprises: completely dissolving a solid epoxy resin in an organic solvent, adding carbon nano-tubes, a surfactant and a latent curing agent, and carrying out mixing stirring and uniform ultrasonic dispersing to obtain a carbon nano-tube and epoxy resin mixing solution; transferring the mixing solution to a liquid separation container with an orifice or micro-pore on the bottom portion, and slowly dropping into a below collection container filled with deionized water and a dispersing agent; after the solution completely drops, collecting the microspheres, repeatedly washing, and drying for spare; and uniformly paving the microspheres between glass fiber fabrics, pre-heating to melt the microspheres, pouring an epoxy resin glue liquid by using a resin transfer molding process, and carrying out high-temperature curing to obtain the material. According to the present invention, the problem that the carbon nano-tubes are filtered and agglomerate in the resin transfer molding process can be effectively solved, the interfacial bond strength of the composite material can be improved, and the stable performance of the composite material can be achieved.

Owner:HOHAI UNIV +1

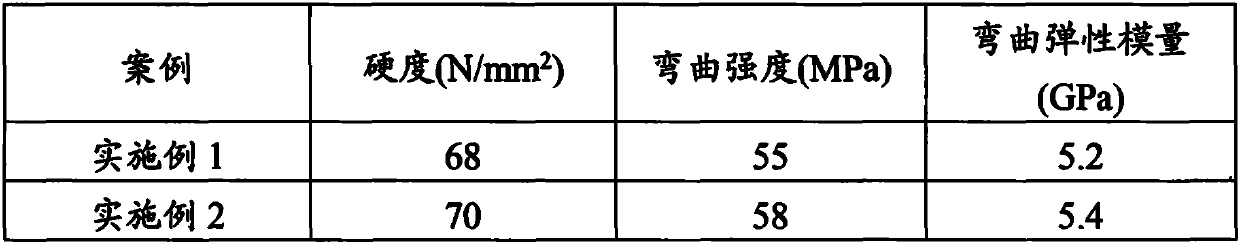

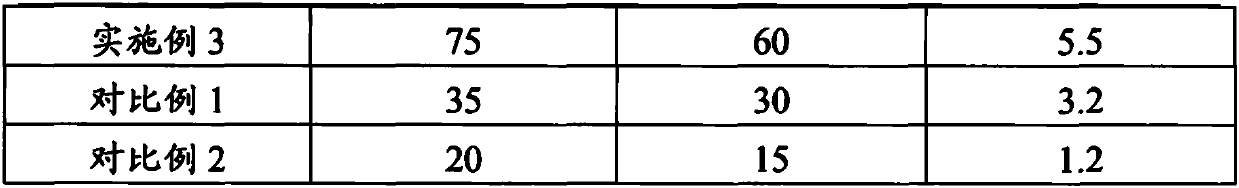

Co-extrusion wood-plastic composite material and preparation method thereof

InactiveCN110216959AImprove mechanical propertiesGood mechanical propertiesDomestic upholsterySynthetic resin layered productsSurface layerFlexural modulus

The invention belongs to the technical field of wood-plastic composite materials, and particularly relates to a co-extrusion wood-plastic composite material and a preparation method thereof. A coupling agent is adopted as a middle layer for bonding a core layer and a surface layer, the interfacial bonding force of the surface layer and the core layer is enhanced, and long fiber-reinforced resin isadded to the middle layer, so that the mechanical properties of the wood-plastic composite material is improved significantly. The wood-plastic composite material has a hardness of 75 N / mm<2> , the bending strength reaches 60 MPa, and the flexural modulus can reach 5.5 GPa.

Owner:六盘水康博木塑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com