Nanocrystalline barium titanate-carbon composite powder and preparation method thereof

A carbon composite powder, crystalline barium titanate technology, applied in the field of nanocrystalline barium titanate-carbon composite powder and its preparation, can solve the problems of uneven carbon dispersion, excessively large barium titanate grains, etc. Good combination, fine distribution, easy to industrialize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

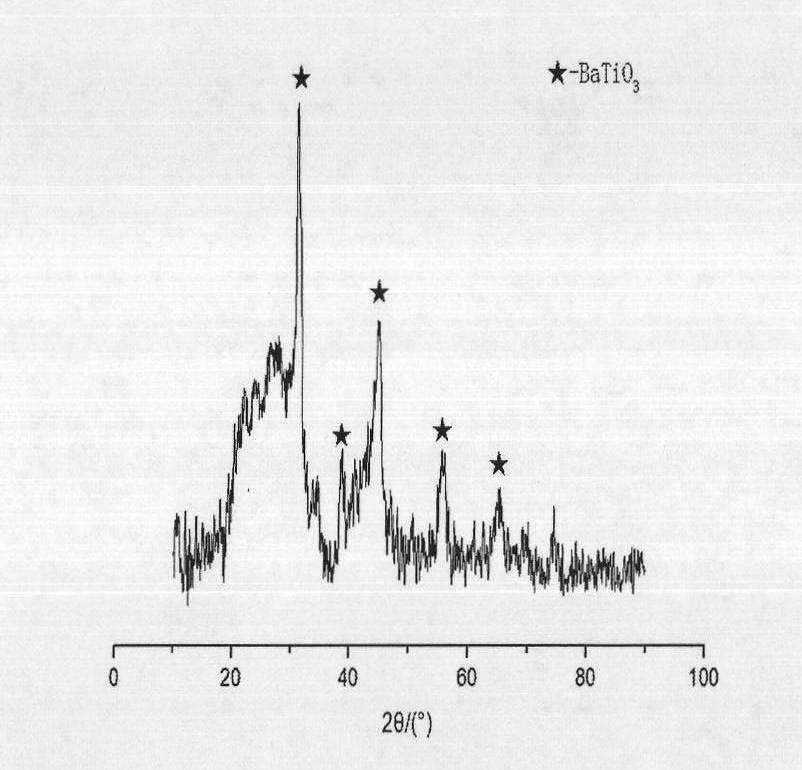

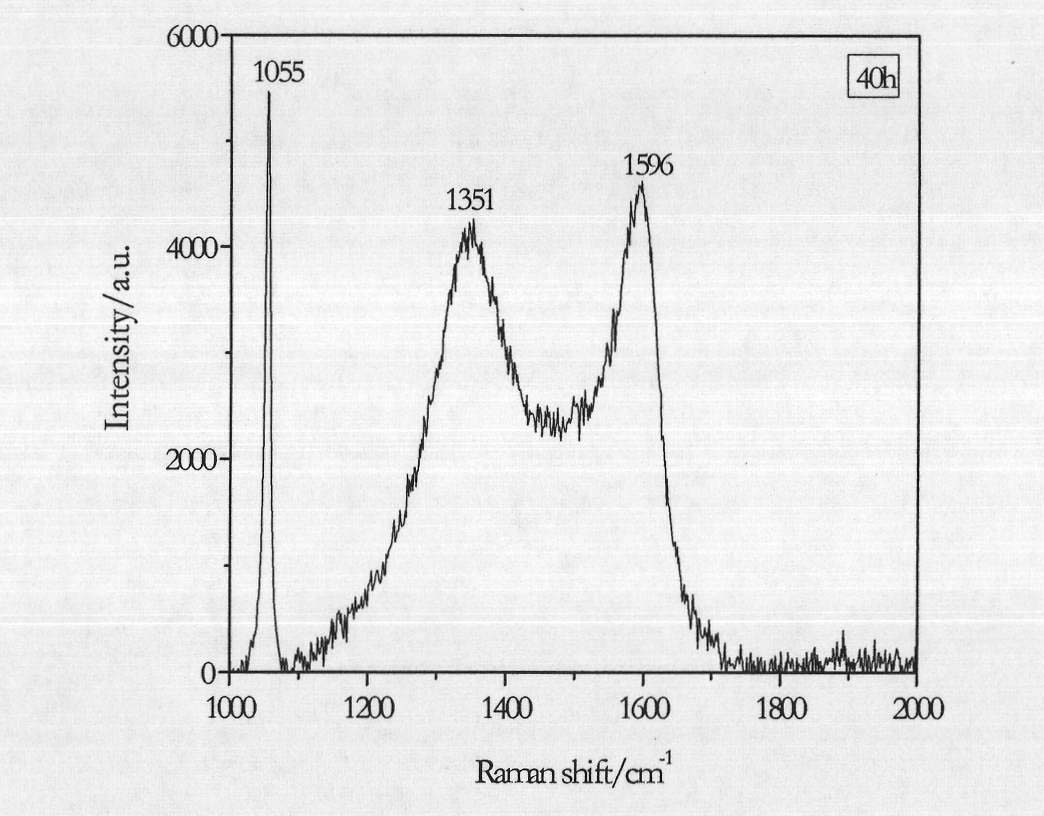

[0020] A nanocrystalline barium titanate-carbon composite powder and a preparation method thereof. Analytical pure BaCO 3 and metal titanium powder as raw materials, and mix them at a molar ratio of 1:1; then put the above mixed raw materials and steel balls into a stainless steel ball mill tank according to the mass ratio of the mixed raw materials and steel balls at a mass ratio of 1:50 to 1:70, and seal them. Vacuum to -0.05MPa, and then place it on a planetary ball mill for 80-120 hours to obtain nanocrystalline BaTiO 3 -C composite powder.

Embodiment 2

[0022] A nanocrystalline barium titanate-carbon composite powder and a preparation method thereof. Analytical pure BaCO 3 and metal titanium powder as raw materials, mixed with a molar ratio of 1:1, plus 0.1-3% of the total mass of the above-mentioned raw materials of metal nickel powder, mixed evenly, called mixed raw materials.

[0023] Then put the mixed raw materials and steel balls into a stainless steel ball mill tank according to the mass ratio of mixed raw materials and steel balls of 1:30 to 1:50, seal it, vacuumize it to -0.05MPa, and fill it with CO 2 gas, and then placed on a planetary ball mill for 60-100 hours to obtain nanocrystalline BaTiO 3 -C composite powder.

Embodiment 3

[0025] A nanocrystalline barium titanate-carbon composite powder and a preparation method thereof. Analytical pure BaCO 3 and metal titanium powder as raw materials, mixed with a molar ratio of 1:1, plus 0.1-3% of the total mass of the above-mentioned raw materials of metal iron powder, mixed evenly, called mixed raw materials. All the other are with embodiment 2. Nanocrystalline BaTiO 3 -C composite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com