Low-cost alternative resource high-crack-resistance concrete and preparation method thereof

A high-crack-resistant concrete technology, applied in the field of concrete, can solve problems such as high energy consumption, high pollution, and poor activity, and achieve the effects of improving interface bonding strength, improving work performance, and solving poor cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

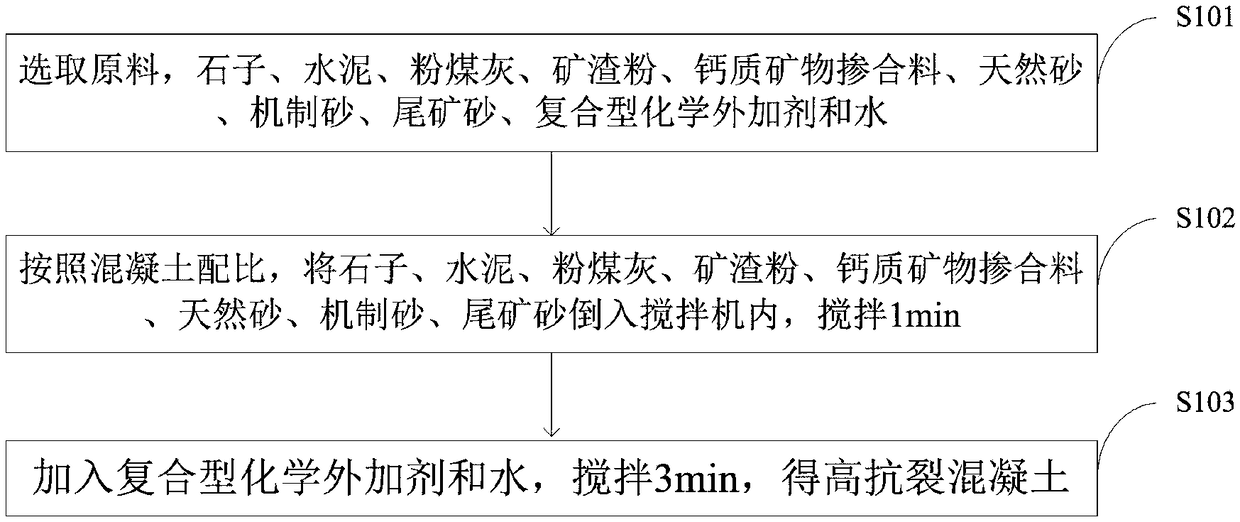

Method used

Image

Examples

Embodiment 1

[0060] The low-cost alternative resource high crack-resistant concrete provided by the present invention has the following components and dosages by weight: 280 parts of cement, 20 parts of fly ash, 50 parts of slag powder, 10 parts of calcareous mineral admixture, and 300 parts of machine-made sand 200 parts of tailings sand, 800 parts of gravel, 90 parts of compound chemical admixture 4 and water.

Embodiment 2

[0062] The low-cost alternative resource high-crack-resistant concrete provided by the present invention has the following components and dosages by weight: 2450 parts of cement, 60 parts of fly ash, 80 parts of slag powder, 30 parts of calcareous mineral admixture, and 200 parts of natural sand 500 parts of machine-made sand, 400 parts of tailings sand, 1200 parts of gravel, 8 parts of compound chemical admixture and 270 parts of water.

Embodiment 3

[0064] The low-cost alternative resource high-crack-resistant concrete provided by the present invention has the following components and dosages by weight: 380 parts of cement, 40 parts of fly ash, 70 parts of slag powder, 20 parts of calcareous mineral admixture, and 100 parts of natural sand 400 parts of machine-made sand, 300 parts of tailings sand, 1000 parts of gravel, 6 parts of compound chemical admixture and 180 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com