Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1332results about How to "Resilient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

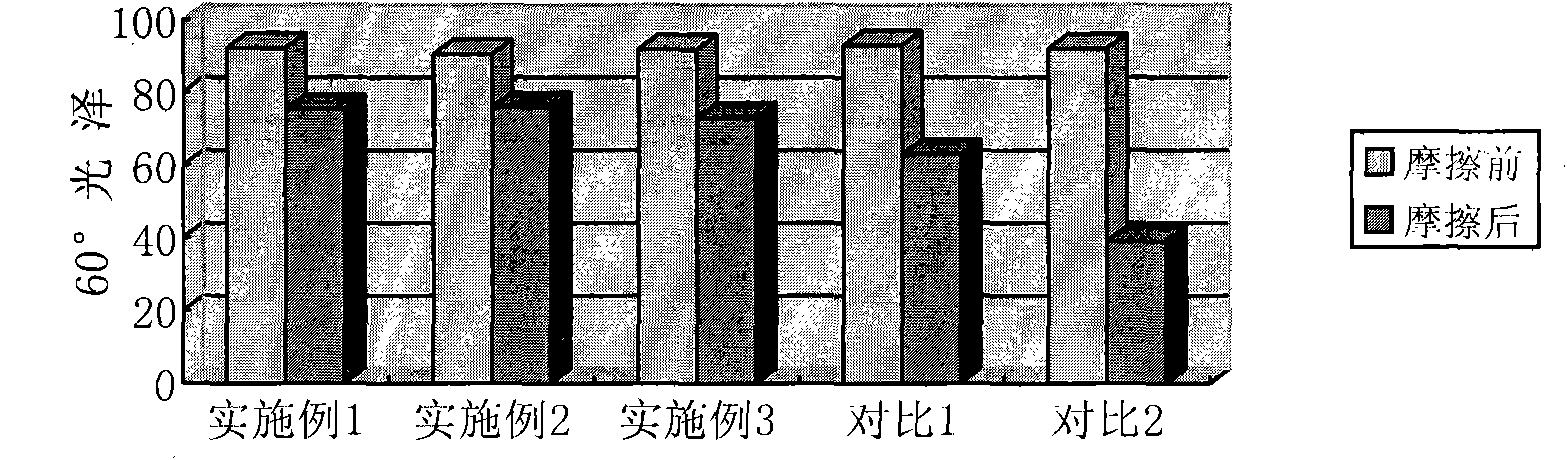

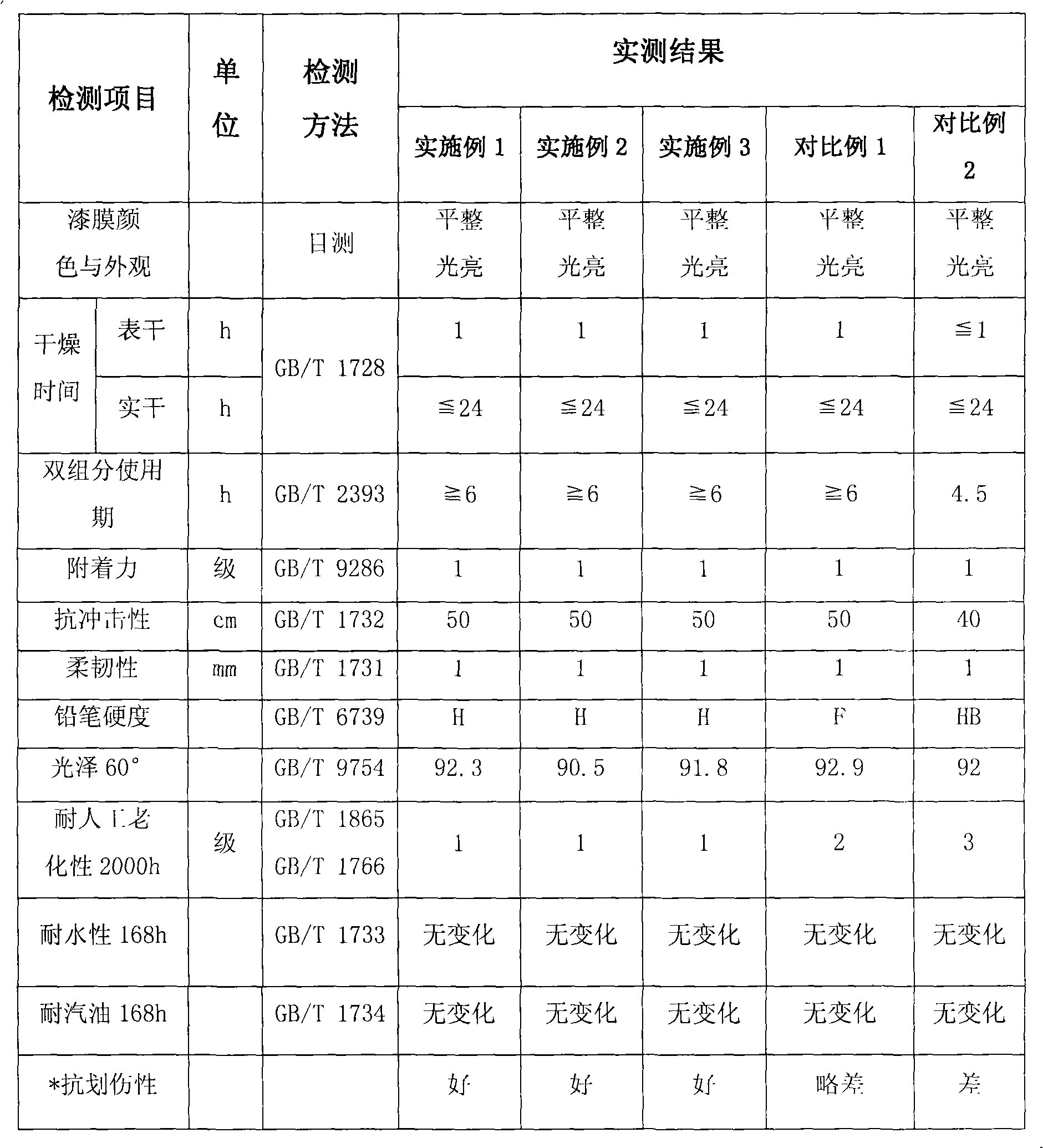

Wear-resisting scratch-resisting weather-proof polyurethane coating and preparation method thereof

ActiveCN101792639AImprove scratch resistanceGood weather resistancePolyurea/polyurethane coatingsPolyester coatingsScavengerAcrylic resin

The invention relates to a double-component polyurethane coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises hydroxyl-containing acrylic resin, fluorocarbon resin, polyester resin, non-nanoscale titanium white, nanometer titanium dioxide, nanometer silicon dioxide and various auxiliary agents; and the component B comprises polyisocyanate curing agent, solvent and moisture scavenger. The component A and the component B are mixed at the weight ratio of 4:1-5:1 to obtain the polyurethane coating. The coating has excellent wear resistance, scratch resistance and weather proofness, has favorable decoration, and is suitable for coating the surfaces of rapid trains, automobiles and the like which have higher requirements on decoration and physiochemical performance.

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

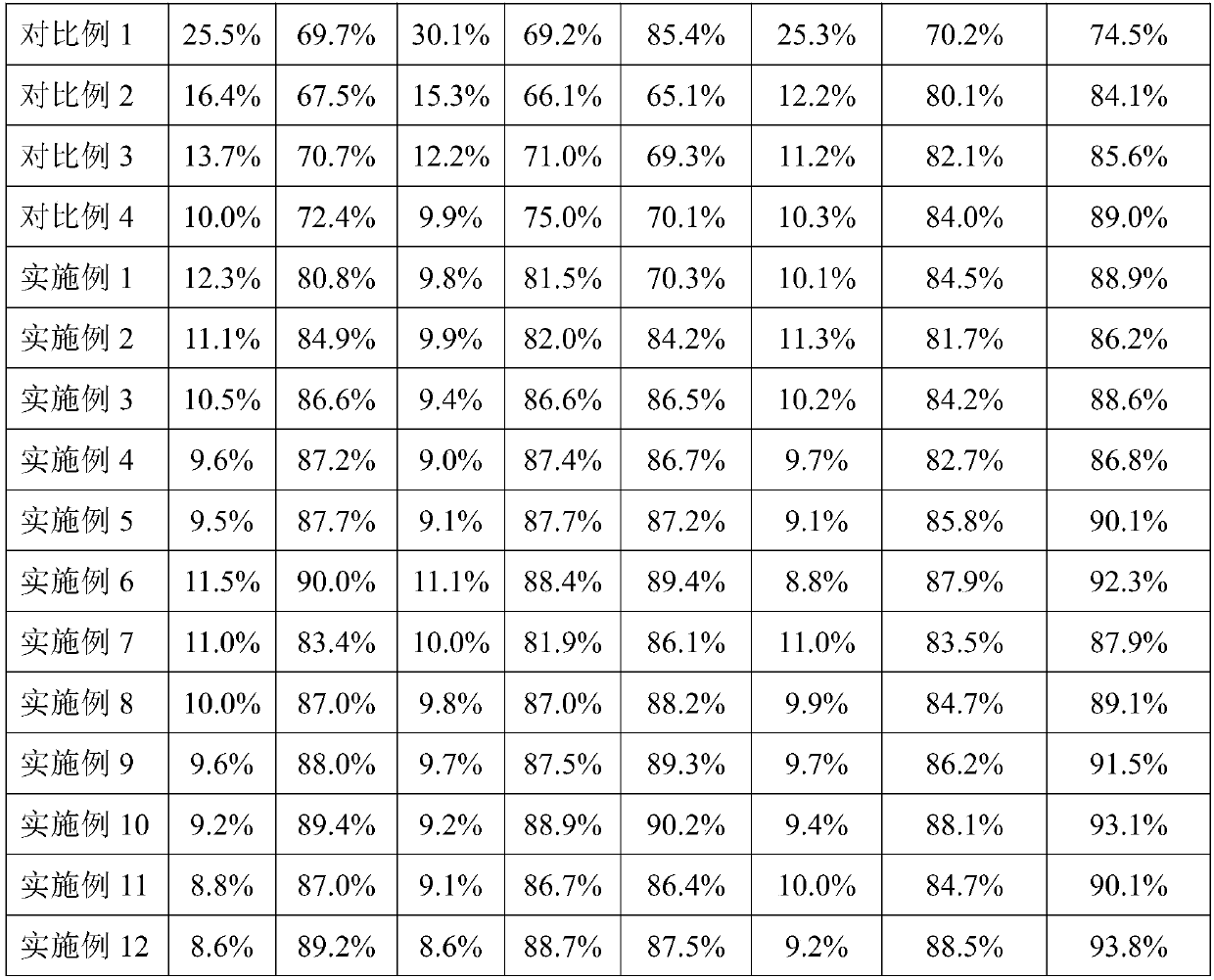

Lithium ion battery electrolyte and high-energy-density lithium ion battery using same

InactiveCN109659614AImproved High Temperature StoragePromote circulationSecondary cells servicing/maintenanceOrganic electrolytesHigh energyElectrical impedance

The invention provides a lithium ion battery electrolyte and a high-energy-density lithium ion battery using the same. The lithium ion battery electrolyte comprises a non-aqueous organic solvent, a lithium salt and additives. The additives comprise a negative electrode film-forming additive, a nitrile or ether nitrile compound, an acid anhydride compound and a lithium salt type additive. Accordingto the lithium ion battery electrolyte, 0.3-20wt% of the negative electrode film-forming additive such as vinylene carbonate and / or fluorocarbonate can form an excellent SEI film on a carbon-containing negative electrode, a silicon-containing negative electrode or a silicon carbon alloy negative electrode and the like, thereby stabilizing the negative electrode and ensuring excellent battery performance; 0.2-6.5wt% of the nitrile or ether nitrile compound, the acid anhydride compound and a combination of them can complex metal ions of a positive electrode or form a protective film on the surface of the positive electrode, thereby stabilizing the positive electrode and improving battery performance; and the 0.5-3 wt% of the lithium salt type additive in the lithium ion battery electrolytecan lower the impedance of the battery so as to improve the low temperature performance of the battery or improve the high temperature performance of the battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

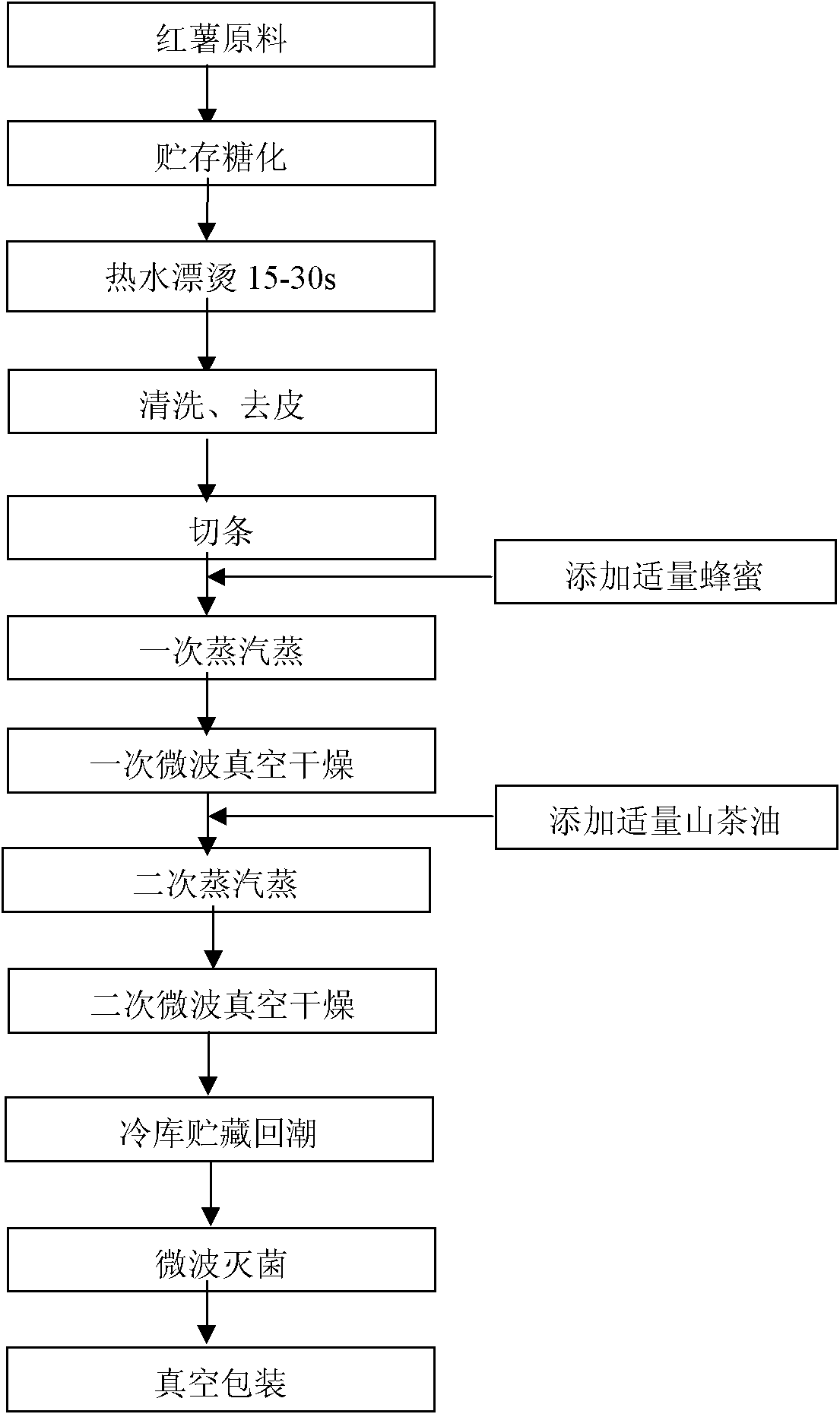

Method for processing instant dried sweet potato

The invention provides a method for processing an instant dried sweet potato, which comprises the following steps of: carrying out storage and saccharification pretreatment on a fresh sweet potato; cleaning the sweet potato, removing the peel of the fresh sweet potato and cutting the sweet potato into strips; blanching for 15-30 seconds; leaching; adding 1-3 percent by mass of honey; steaming for 30-45 minutes in steam; drying to the water content of 32-36 percent at 60-70 DEG C in microwave vacuum; adding 0.2-0.4 percent by mass of mountain naphthalene oil; steaming for 15-30 minutes in steam; drying to the water content of 14-18 percent at 50-60 DEG C in microwave vacuum; storing and dampening to the water content of 20-24 percent at 4-8 DEG C in a refrigeration house; and carrying out microwave sterilization at 30-40 DEG C for 3-6 minutes; and packaging in vacuum. By adopting the processing method of the invention, the produced instant dried sweet potato has flexible texture and certain toughness and can be chewed by all people regardless of age and sex; the product has uniform color, presents red gloss and has the potato flavor deserved by the variety, palatable sweetness, no any food additive, short vacuum microwave drying time and less loss of nutrition components; the product has the normal temperature quality guarantee period for 9 months and the refrigeration quality guarantee period for 12 months; the quality standard of the product meets the following condition: the total bacterial amount is not more than 1,000 CFU / g, the mould is not more than 50 CFU / G, the escherichia coli is not more than 30 MPN / 100g, and pathogenic bacteria are not detected; in addition, the energy consumed for producing the instant dried sweet potato is reduced by more than 30 percent compared with the energy consumed for producing the instant dried sweet potato by hot air drying.

Owner:ZHEJIANG UNIV OF TECH

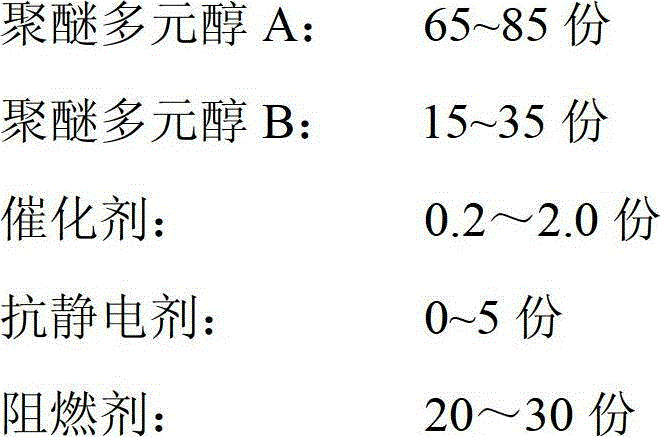

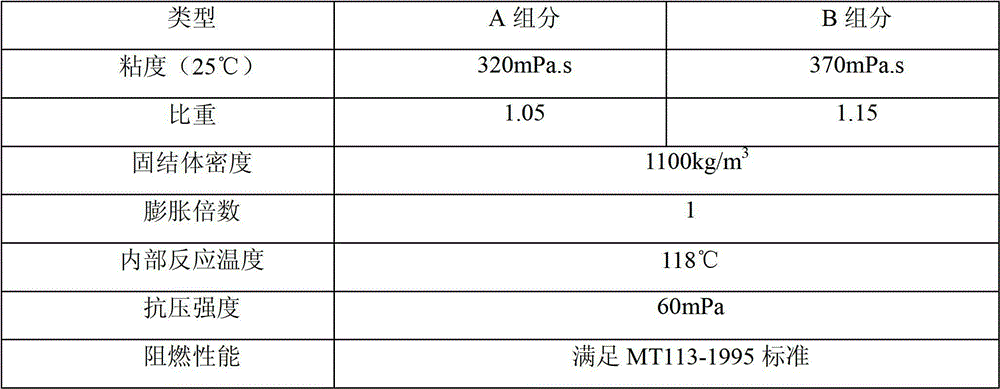

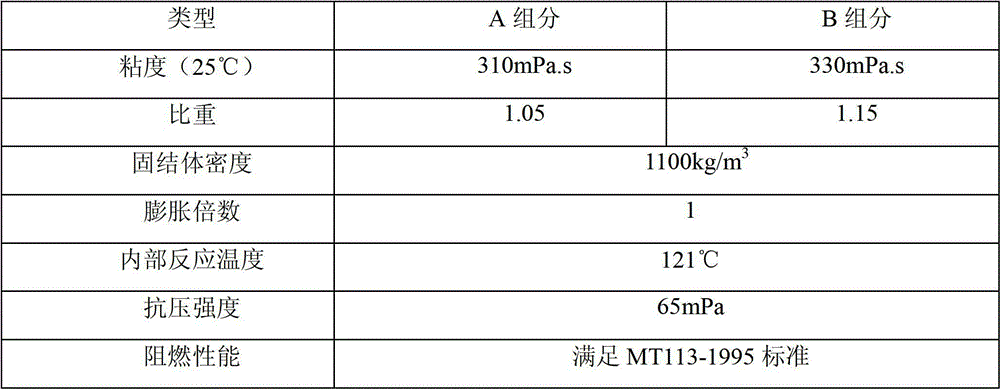

Low-temperature safety polyurethane injecting paste material for coal-rock mass reinforcement and preparation method thereof

The invention provides a low-temperature safety polyurethane injecting paste material for coal-rock mass reinforcement and a preparation method thereof, and belongs to the field of polyurethane compositions. The material consists of a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 100 parts of polyether polyol, 0.2 to 2.0 parts of catalyst, 0 to 5 parts of antistatic agent, and 20 to 30 parts of flame retardant; and the component B comprises the following raw materials in parts by weight: 70 to 90 parts of polyisocyanates, 5 to 20 parts of pre-polymer, and 5 to 10 parts of viscosity reducer. The preparation method comprises the following steps of: (1) preparation of the component A, namely mixing the raw materials of the component A for later use; and (2) preparation of the component B, namely mixing the raw materials of the component B, and performing nitrogen displacement for later use. The low-temperature safety polyurethane injecting paste material has the advantages of flame retardant and antistatic performances, high adhered strength, strong shearing resistance and high toughness. The preparation method is simple and practical, has low requirements on production equipment and staff, and is short in production cycle; and according to the whole process, three wastes are not produced, and the environment and health of workers are not influenced.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

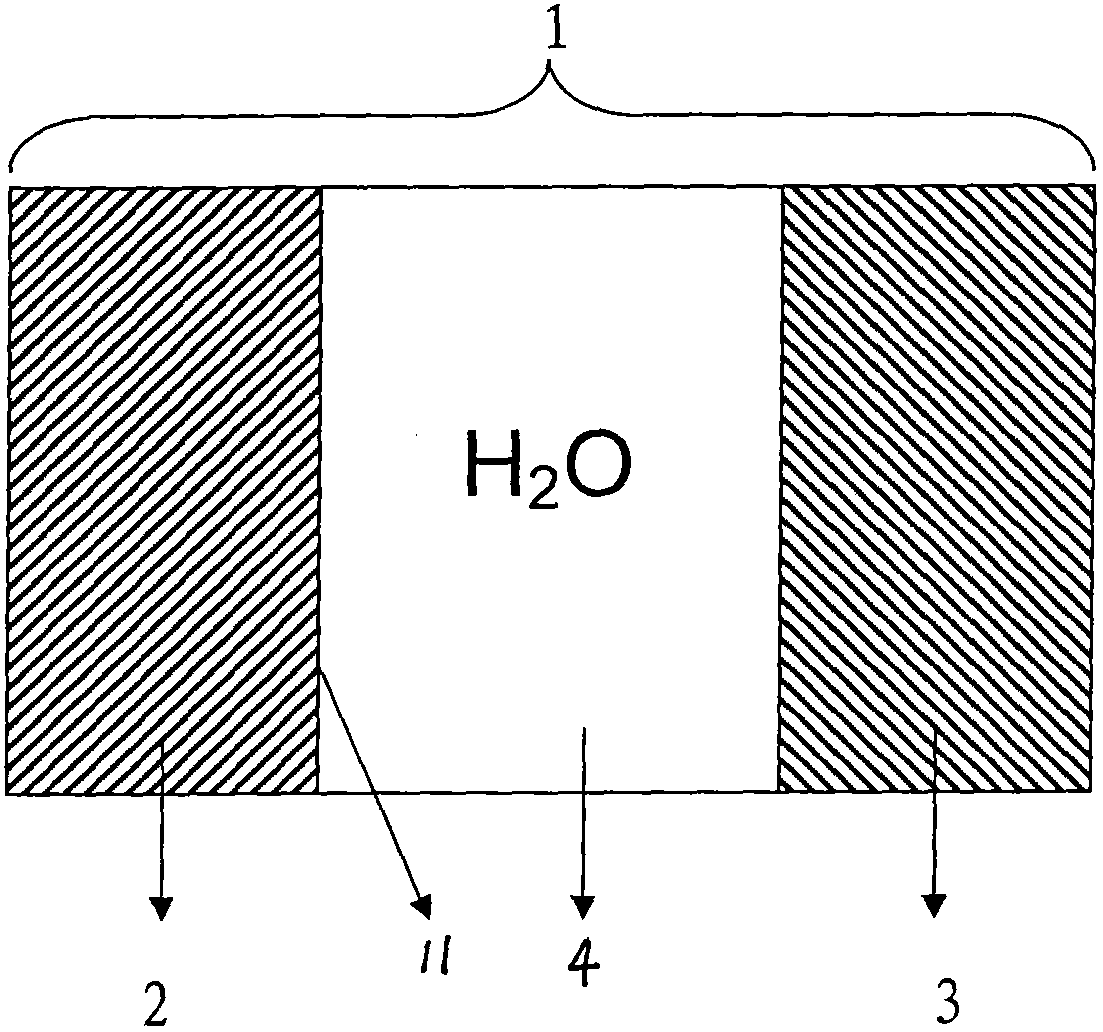

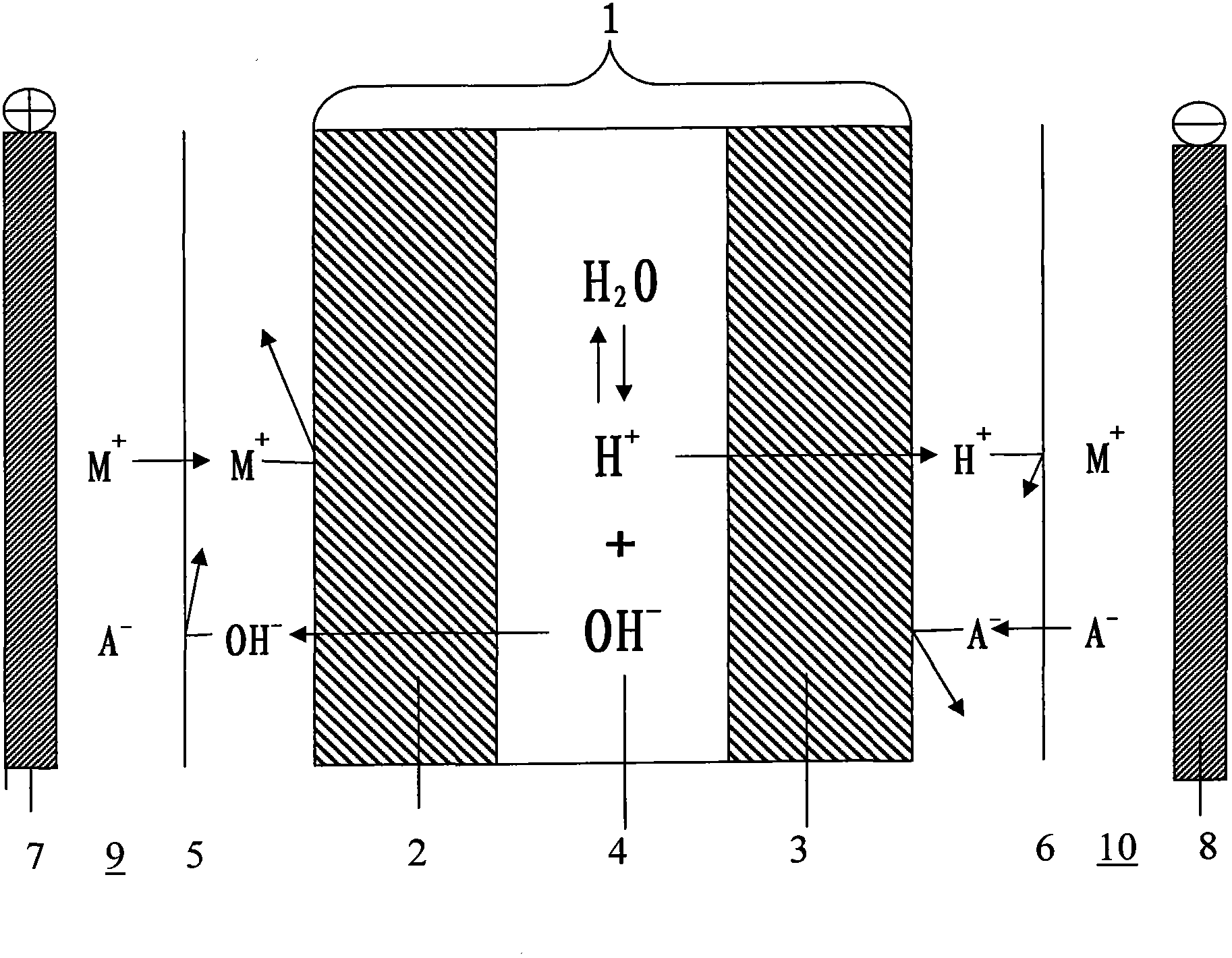

Method for manufacturing monolithic bipolar membrane

ActiveCN102061004AImpregnation temperature decreasesLower resistanceSemi-permeable membranesDecompositionDibenzoyl Peroxide

The invention relates to a method for manufacturing a monolithic bipolar membrane, which comprises the following steps of: immersing a substrate membrane in a solution containing styrene, divinybenzene and benzoyl peroxide, pressurizing the immersed membrane, wherein the substrate membrane is a thin alloy membrane formed by two-element blending of polyethylene and ethylene-octylene copolymer elastomer or by three-element blending of polyethylene, ethylene-octylene copolymer elastomer and polyisobutylene rubber; and pressurizing the membrane immersed in the solution and polymerizing under the condition of heating to obtain a base membrane; sulfonating one side face of the base membrane by heating in concentrated sulfuric acid; performing chloromethylation reaction of the membrane with one sulfonated side face in chloromethyl ether containing anhydrous stannic chloride so that the other side face of the membrane is chloromethyl; and immersing the membrane in a trimethylamine aqueous solution or a trimethylamine aqueous solution containing dimethylamine to carry out an aimination or quaterisation reaction to obtain the monolithic bipolar membrane. The method has the advantages that the immersing temperature is greatly reduced, the styrene and divinybenzene solution can be repeatedly used, and the electric resistance of the bipolar membrane is low. The bipolar membrane has a catalytic layer for accelerating water decomposition, the method is simple and convenient and is easy for large-scale industrialized production.

Owner:BEIJING TINGRUN MEMBRANE TECH DEV

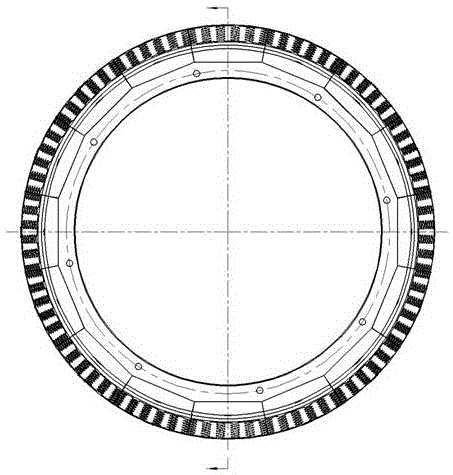

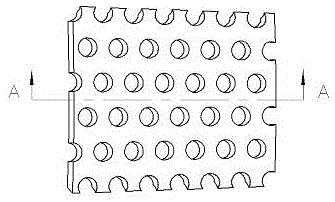

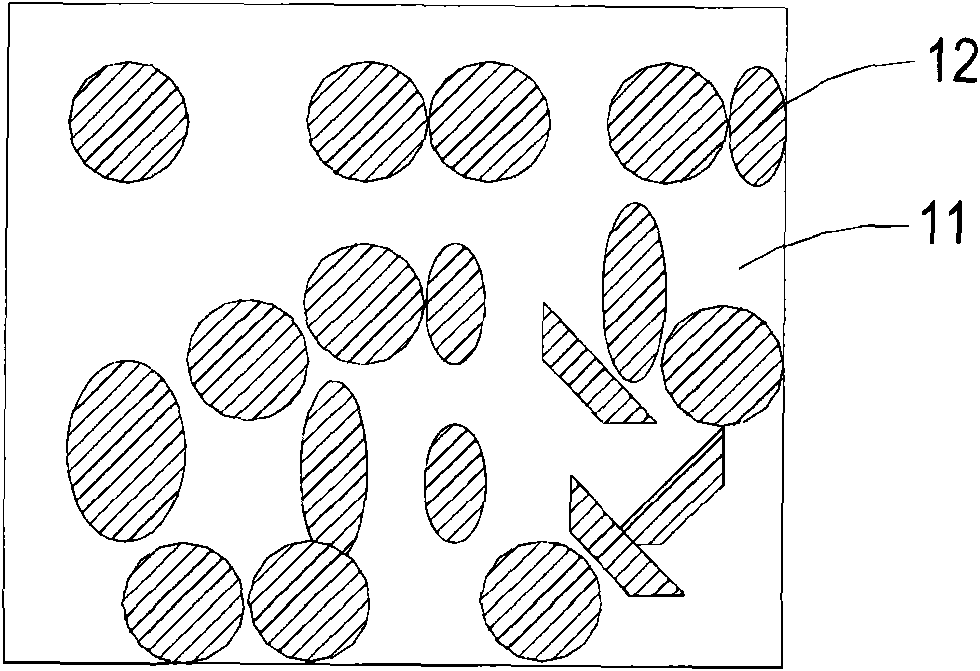

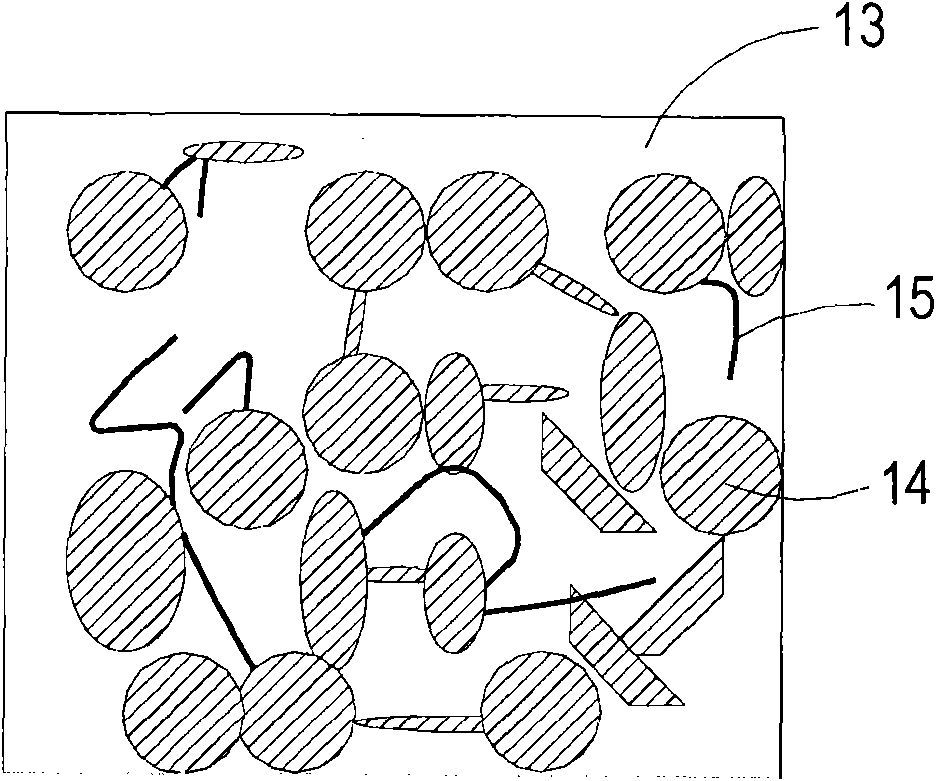

Manufacturing method of detachable ceramic alloy composite grinding roller

The invention discloses a manufacturing method of a detachable ceramic alloy composite grinding roller. The manufacturing method comprises the following steps: firstly, uniformly mixing ceramic particles and low-melting-point alloy powder by binders so as to obtain a mixture; stuffing the mixture in a mold cavity, and forming the mixture into a biscuit; putting the biscuit together with a mold into a drying cabinet, and drying and sintering the biscuit to obtain a ceramic precast part; and taking out the sintered ceramic precast part, fixing the taken ceramic precast part on the surface of a roller skin liner casting mold cavity, casting abrasion-proof alloying metal liquid to obtain a roller skin liner of which the surface presents metallurgical bond by the ceramic precast part and an abrasion-proof alloy material, and finally fixing the roller skin liner on the surface of a roller core. According to the manufacturing method of the detachable ceramic alloy composite grinding roller disclosed by the invention, the roller skin liner is small in size and light in weight, the casting quality and the heat treatment technology are easy to control, and the qualified rate of finished products is high; the surface of the roller skin liner is composited by the high abrasion-proof ceramic precast part and an abrasion-proof alloy, so that the surface of the roller skin liner has double abrasion-proof properties and the toughness of the metal materials; the end surface of the roller skin liner is fixed by bolts, so that the roller skin liner can be detached on the site, and a new roller skin liner is replaced.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

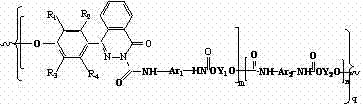

Flame-retardant heat-resistance polyurethane resin and preparation method of aqueous emulsion of polyurethane resin

ActiveCN103242504AOvercome mechanical propertiesImprove heat resistancePolyureas/polyurethane adhesivesInksPolyesterPolymer science

The invention belongs to the field of high molecular materials and in particular relates to flame-retardant heat-resistance polyurethane resin. The resin structure contains a residue structure obtained after reaction of heterocyclic polyol A, flame-retardant polyol and polyisocyanate, and the resin is obtained by adding heterocyclic polyol B as a crosslinking agent at the post phase of polyurethane synthesis. The flame-retardant heat-resistance polyurethane resin and an aqueous emulsion thereof are prepared by carrying out a reaction on heterocyclic polyol, polyester or polyester polyol, flame-retardant polyol, polyisocyanate and the like. As the heterocyclic structure is introduced in a polyurethane molecule chain, except for the characteristics of the common polyurethane paint coating, the flame-retardant heat-resistant polyurethane resin further has excellent heat resistance, corrosion resistance and high mechanical strength and mechanism performance and is high-grade flame-retardant polyurethane aqueous resin. The defects of the existing polyurethane coating in terms of heat resistance and mechanical property are overcome; and the prepared flame-retardant heat-resistance polyurethane resin has the advantages of intrinsic flame retardance, high heat resistance, large hardness, excellent mechanical property and high cost performance, is convenient to use and can be dried at low temperature.

Owner:DALIAN UNIV OF TECH

Preparation and application method of water-based ceramic anticorrosive paint

The invention relates to a surface coating technique, and aims to provide a preparation and coating method of a water-based ceramic anticorrosive paint. The method comprises the following steps: (1) component A precuring: regulating the pH value of a water-based silica sol by using a catalyst, adding deionized water and composite organosilane, and stirring to react to obtain the component A; (2) component B precuring: mixing a water-based silica sol, a pigment, a filler and assistants, and grinding to obtain the component B; and (3) mixing before use: mixing the component B with the precured component A, and oscillating, stirring or rolling to implement compounding and curing, thereby obtaining the water-based ceramic anticorrosive paint. The water-based ceramic paint has low content of VOCs (volatile organic compounds), and the content of VOCs of the final paint can be less than 100 g / L through the control of the alkoxy silane consumption; the prepared coating is environment-friendly and energy-saving, has the advantages of high hardness and favorable temperature resistance, and has certain toughness; the coated film can not easily crack; and the hardness can be enhanced by 1-2H, and the shock resistance is enhanced to 20-30cm.Kg.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

Medicine granule, preparation method thereof, and preparation containing same

InactiveCN101548953AHigh drug contentRounded surfaceOrganic active ingredientsPill deliveryChemistryBiomedical engineering

The invention discloses a medicine granule containing the following components by mass percent: 75 to 95 of medicine, 2 to 22 of thinner for pelletization, 0.06t to 0.5 of glidant, and 1.5 to 3.5 of adhesive. The invention also discloses a preparation method thereof and a preparation containing same. The medicine granule has high medicine content, round surface, higher rigidity and smaller grain diameter, can be directly used for tabletting, has less weight increment if being coated and can achieve a better taste masking effect. The method for preparing the medicine granule can simultaneously realize pelletization and coating technologies in a tangent spraying fluidized bed, has simple production steps and high efficiency, and can be applied to mass production.

Owner:SHANGHAI INST OF PHARMA IND +1

Lignose and process for modifying phenolic resin with derivates thereof

The invention discloses a lignin and a method for modifying a phenolic resin which is a ramification thereof. The method that the polymerization is performed for a plurality of times and the extent of polymerization is deepened gradually is adopted to improve the uniform stability, the inoxidability, the toughness and the intensity of the product, effectively recycle the wasted resources, lower the cost and make the industrialization easier. The invention is realized by the technical proposal which is as follows: the phenolic resin low polymer is prepared firstly; the lignin or a ramification thereof is added to polymerize in order to obtain a preformed polymer secondly; finally, phenol and formaldehyde are added to polymerize in order to obtain the high polymer. A molding material prepared by the phenolic resin can be widely applied to the manufacture of a low-voltage apparatus, an insulating structure and a product for daily life.

Owner:JILIN UNIV

Preparation method for improving gel hardness of fish balls

The invention relates to a preparation method for improving the gel hardness of fish balls, which is characterized by comprising the following steps of: separating fish meat by using a meat separator, removing fish bones and black films, putting fish fillets into 5 to 8 percent salt solution and soaking for 20 to 40 minutes with continuous stirring; putting the fish meat from which fishy smell is removed into clear water in an amount which is 4 to 6 times that of fish meat, slowly stirring for 8 to 10 minutes, repeatedly washing by using circulating water, dissolving 2 to 4 percent of salt in water, adding into minced fillets, milling for 2 to 4 minutes, adding 0.1 to 0.6 percent of transglutaminase (TGase), milling for 6 to 10 minutes, adding seasonings into the minced fillets, and milling for 1 to 4 minutes; adding 3 to 6 percent of wheat gluten into the minced fillets, and milling for 2 to 5 minutes; putting the minced fillets into a 0 DEG C refrigerator for 1 to 3 hours, forming by using a ball making machine, and ensuring that the weight of each ball is 7 to 15g; and heating the fish balls to the temperature of between 37 and 45 DEG C, keeping for 15 to 25 minutes, putting into a 70 to 85 DEG C water bath for 20 to 30 minutes, fishing out, quickly cooling, quickly freezing, and packaging. The fish balls prepared by the method have smooth and mellow appearance, smooth mouthfeel, high elasticity and rich nutrition.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

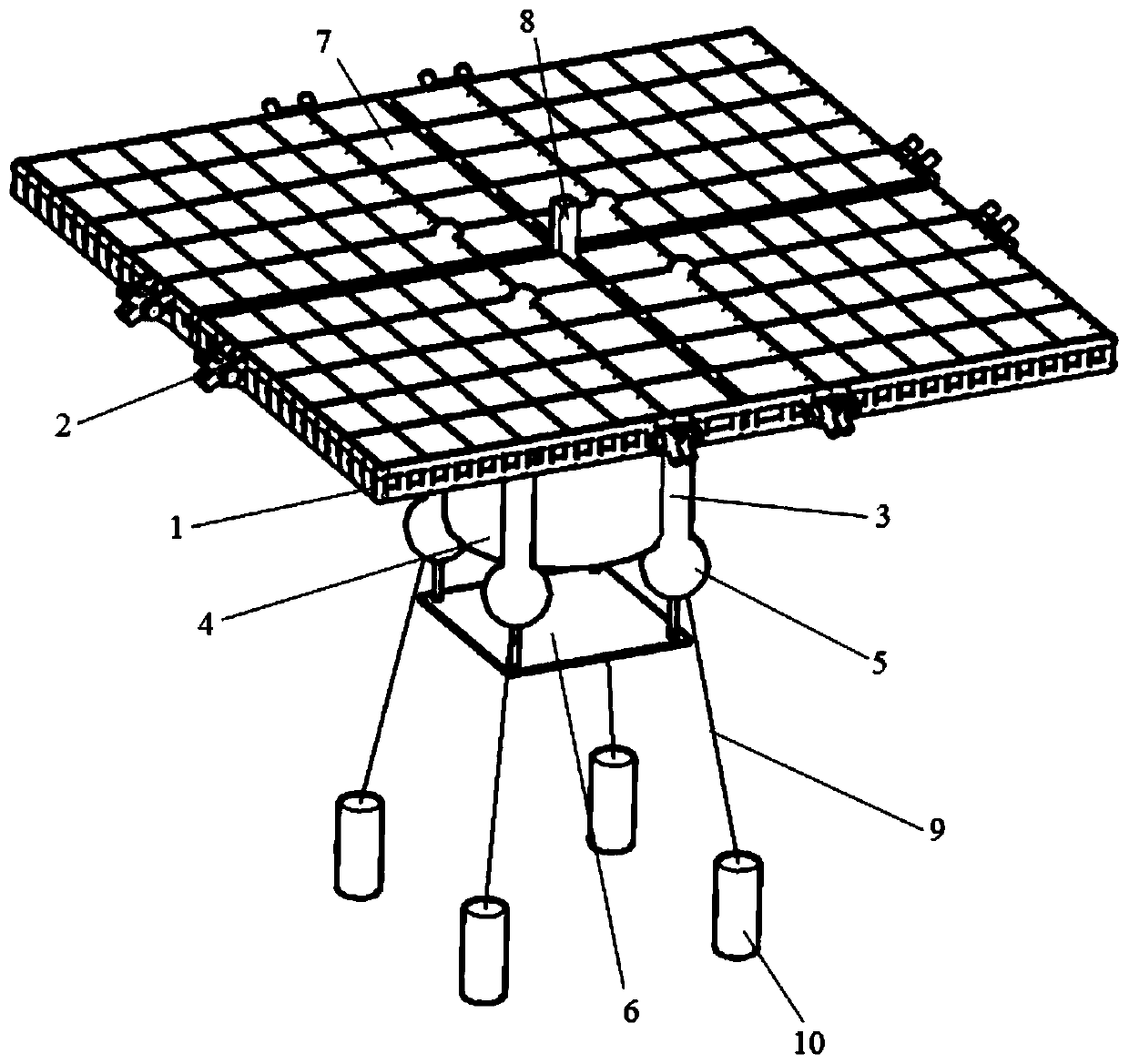

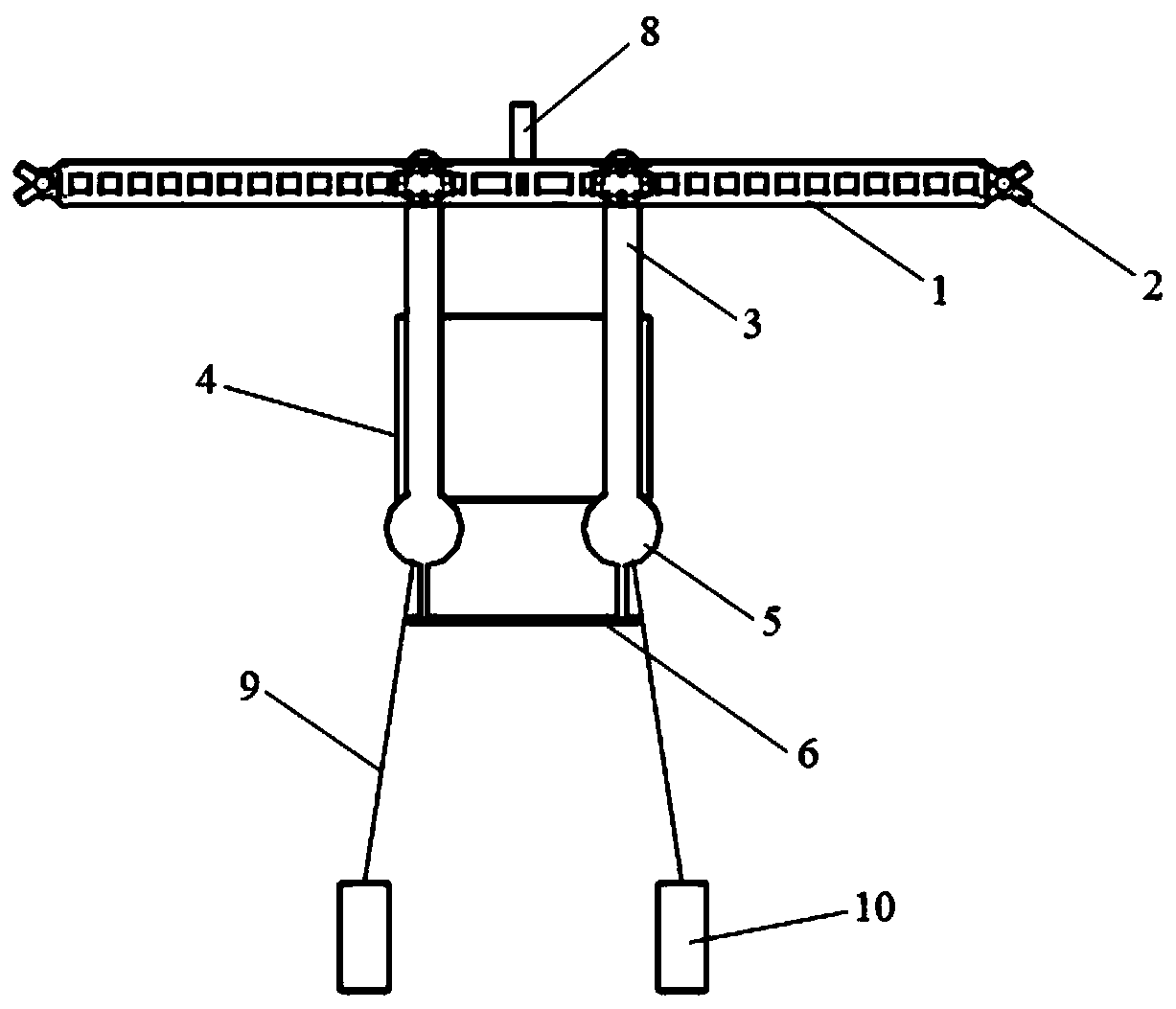

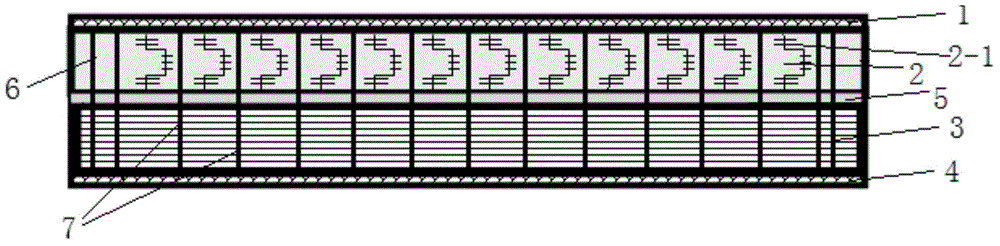

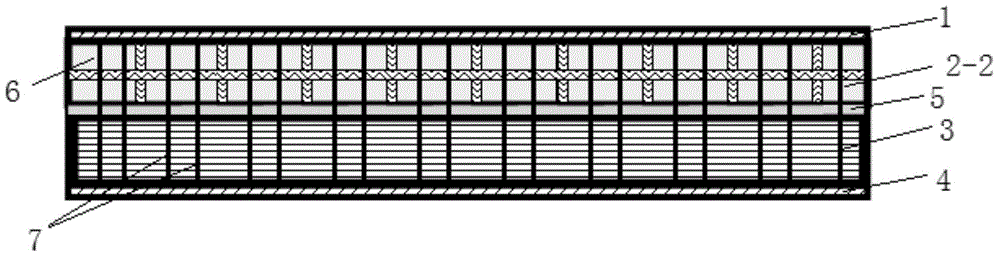

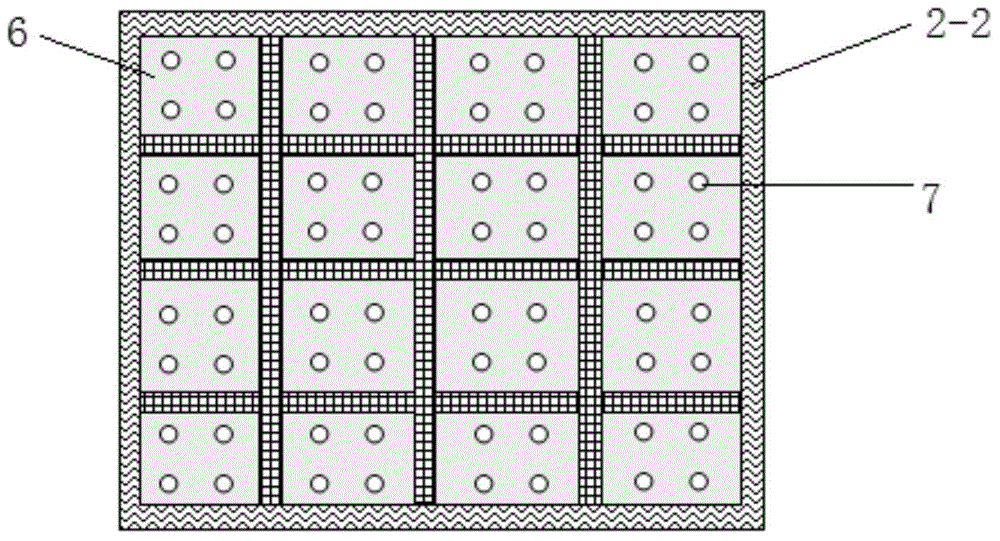

Wind and wave resisting floating type offshore photovoltaic power generation platform

PendingCN110450916AReduce huge bending momentsImprove integrityPhotovoltaic supportsSolar heating energySeabedEconomic feasibility

The invention discloses a wind and wave resisting floating type offshore photovoltaic power generation platform. A platform truss, a photovoltaic plate assembly, weight balls, support columns, a floater, a heaving plate, pile foundations and mooring cables are included. The photovoltaic plate assembly is flatly laid on the platform truss. The weight balls are arranged below the platform truss. Thesupport columns are connected with the platform truss and the weight balls. The floater is fixed between the support columns, and buoyancy provided by the floater can be transmitted to the photovoltaic power generation platform. The heaving plate is connected to the lower portions of the weight balls. The pile foundations are fixed in a seabed and used for mooring the offshore photovoltaic powergeneration platform. One ends of the mooring cables are moored to the support columns, and the other ends of the mooring cables are moored to the pile foundations. By means of the wind and wave resisting floating type offshore photovoltaic power generation platform, the capability of resisting wind, waves and flow loads through a supporting structure is guaranteed, economic feasibility and construction convenience are achieved, and accordingly application of the photovoltaic power generation platform to the field of ocean open water area is assisted.

Owner:TIANJIN UNIV

Processing process of automobile engine crank shaft

The invention provides a processing process of an automobile engine crank shaft. The process comprises the following processing steps of (1) blank forging; (2) coarse tuning: coarse turning of a main shaft neck and a connecting rod neck is carried out; (3) coarse drilling: coarse drilling of a main oil hole is carried out; (4) annealing heat treatment; (5) semi-finish turning: semi-finish turning is carried out on the main shaft neck and the connecting rod neck; (6) tempering; (7) fine turning: fine turning is carried out on the main shaft neck and the connecting neck; (8) coarse and fine grinding: coarse and fine grinding is carried out on the main shaft neck and the connecting rod neck; (9) hole drilling: coarse drilling, expanding and reaming of balance block installing holes and inclined oil holes are carried out; (10) compounding reinforcing; (11) rolling processing: each processed hole is subjected to rolling pressing processing; (12): the main shaft neck and the connecting rod neck are subjected to polishing processing; (13) anti-rust processing; (14) inspection and packaging. The process solves three problems of low rigidity intensity, poor wear resistance and good lubrication performance in the existing automobile engine crank shaft production process, so that the finally produced crank shaft has the sufficient rigidity and intensity, good impact load bearing capability and good abrasion resistance and lubrication performance.

Owner:ANHUI JINQINGLONG MACHINERY

Process for manufacturing multi-layer solid wood composite floor

InactiveCN101704263AQuality improvementRigorous workmanshipDomestic articlesFlooringSolid woodLacquer

The invention relates to a process for manufacturing a composite floor, in particular to a process for manufacturing a multi-layer solid wood composite floor. The process comprises twelve procedures of selecting a log, rotatably cutting and drying the log, sorting a solid wood core board, hot pressing and gluing the core board, fixing thickness and polishing a base material, sorting and preserving the base material, selecting solid wood skin, molding a floor blank, preserving the floor blank, cutting and slotting the floor, painting and drying for molding. The invention has strict process, good quality of the produced floor, smooth and flexible paint surface, no cracking, long service life and easy processing.

Owner:周广龙

Engineered extracellular matrix preparation method

ActiveCN1800372AWith strengthRepair deep skin defectsAnimal cellsProsthesisFiberCell-Extracellular Matrix

The invention relates to a method for preparing for organization project cell epimatrix, which adopts animal stromatin and desmocyte as raw material. It comprises: preparing for the culture liquid, extracting the stromatin, preparing for the cell-stromatin culture material, preparing for the cell epimatrix, dispelling the cell by freezing, and sterilization sanitizing packaging material and so on.

Owner:SHAANXI BOYU REGENERATIVE MEDICINE CO LTD

Ceramic composite material bullet-proof chest board and preparation method thereof

ActiveCN104949581AImprove structural impact resistanceGuaranteed bonding strengthSynthetic resin layered productsCeramic layered productsCeramic compositeMetallurgy

The invention discloses a ceramic composite material bullet-proof chest board and a preparation method thereof. The ceramic composite material bullet-proof chest board is composed of a carbon fiber composite surface rigid layer, a ceramic composite material sheet combination layer, a bullet-proof fiber composite material body layer and a back elastic surface carbon fiber composite back-convex-proof layer. The ceramic composite material sheet combination layer is made of special fiber reinforced ceramic matrix materials and is of a needling insertion type combined structure or a three-dimensional crazing-prevention framework structure; a composite cementing and micropore riveting combined technology is adopted between the ceramic composite material layer and the bullet-proof body layer; finally, the ceramic composite material sheet combination layer and the bullet-proof fiber composite material body layer are wrapped in a rigid structure composed of the carbon fiber composite surface rigid layer and the back-convex-proof layer to form a whole. The ceramic composite material bullet-proof chest board has various advantages of being light, low in back convex, stable in high and low temperature structure, long in service life and the like. Meanwhile, the problem that a seam bullet-proof characteristic in a traditional splicing structure of ceramic sheets is poor is effectively avoided, and the ceramic composite material bullet-proof chest board has the overall characteristics of multiple bullet-proof materials.

Owner:山东宽原新材料科技有限公司

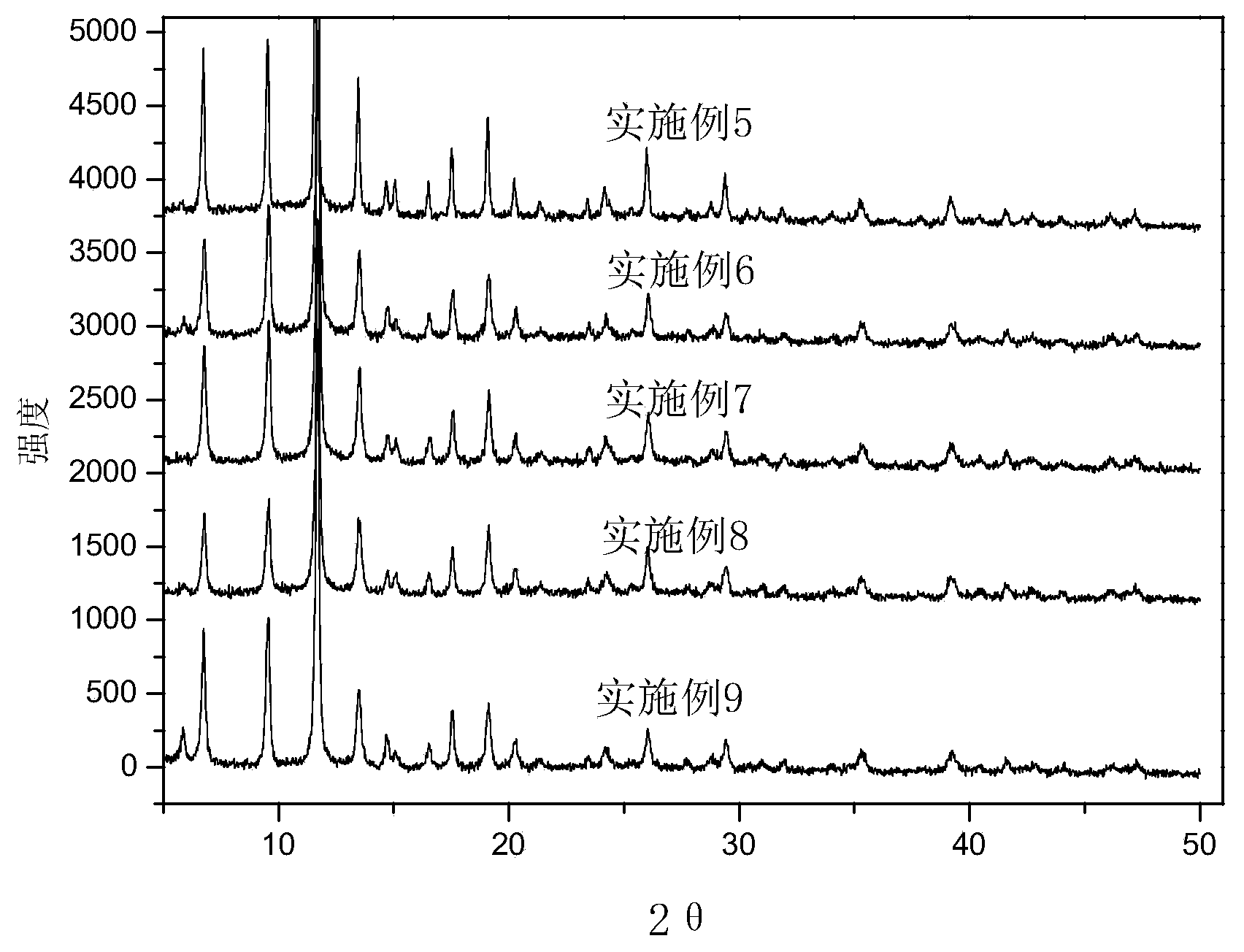

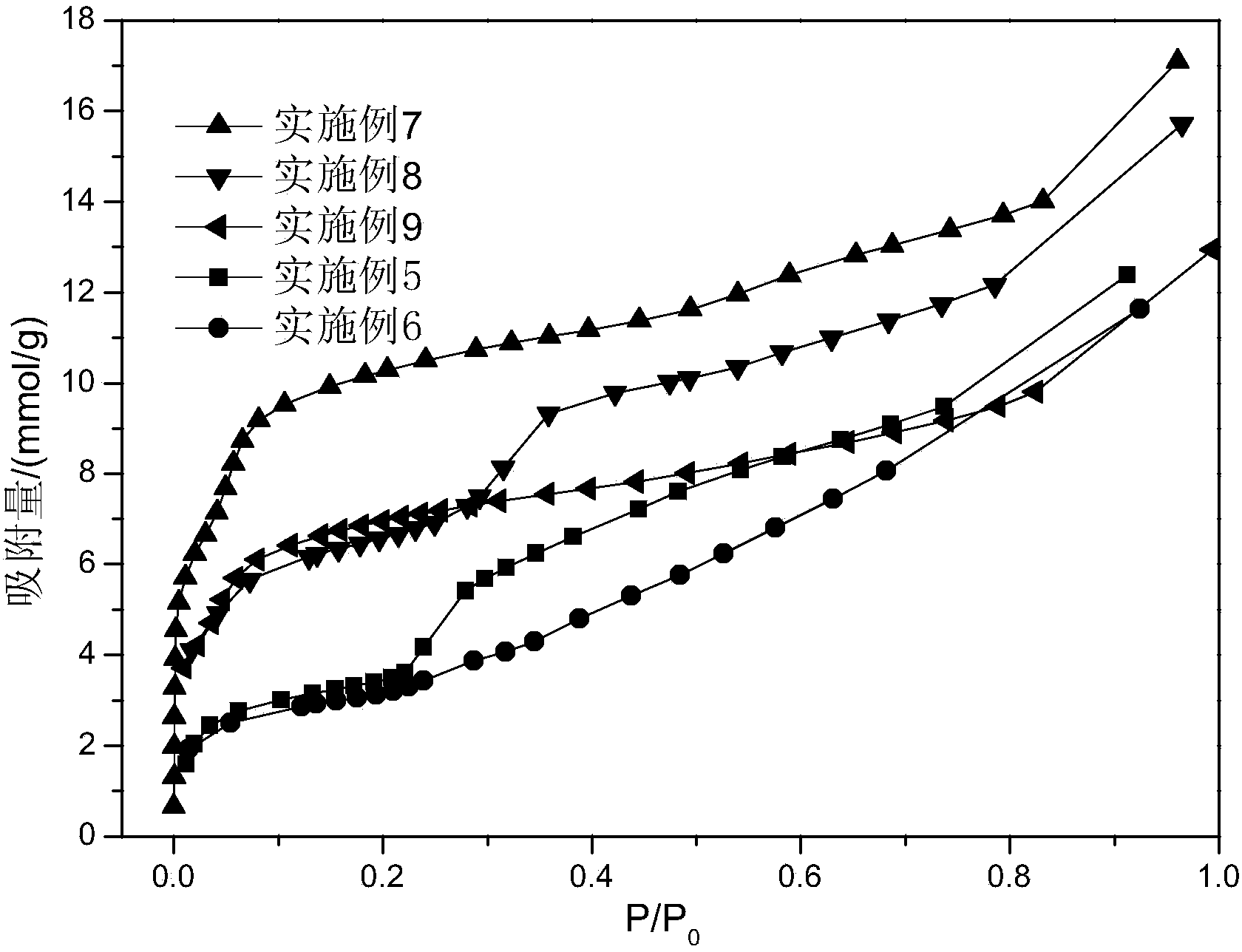

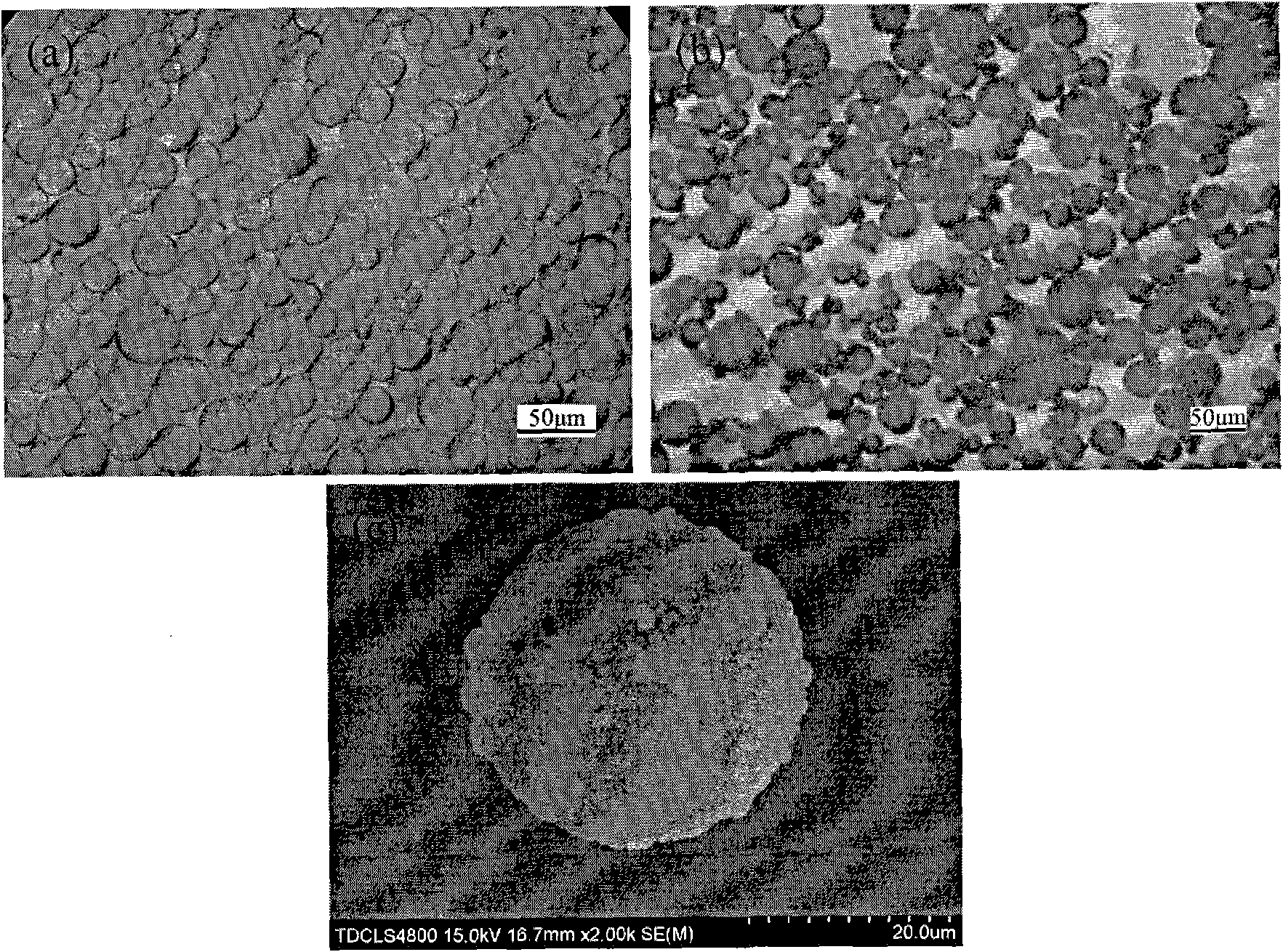

Spherical forming Cu base metal organic skeleton-graphene oxide composite material and preparation method of spherical forming Cu base metal organic skeleton-graphene oxide composite material

ActiveCN104226256AShort reaction timeNo solvent requiredOther chemical processesAlkali metal oxides/hydroxidesMetal-organic frameworkOxide composite

The invention belongs to the technical field of metal organic skeleton material forming and discloses a preparation method of the spherical forming Cu base metal organic skeleton-graphene oxide composite material. The method comprises the following specific steps: proportionally mixing water, methyl hydroxypropyl cellulose and silicate resin with Cu base organic skeleton-graphene oxide composite porous material powder which is synthesized by using a mechanical ball milling method so as to obtain a mixture, adding the mixture into a pelletizer, pelleting, and drying, so as to obtain the spherical forming Cu base metal organic skeleton-graphene oxide composite material. The spherical forming Cu base metal organic skeleton-graphene oxide composite material prepared by using the preparation method has the advantages of relatively large surface area, open pore structure and the like and has the special appearance, volume, mechanical strength, toughness and water resistance which are necessary for an actual industrial application.

Owner:SOUTH CHINA UNIV OF TECH

Environment-friendly braking friction material and preparation method thereof

The invention provides an environment-friendly braking friction material containing natural plant fiber, natural mineral fiber, natural mineral powder and cardanol-based benzoxazine modified phenolic resin and a preparation method thereof. The natural plant fiber is one or a plurality of flax, ramie, jute, hemp and sisal processed by a chemical method (alkali and acid) and a physical method (high-pressure steam), the natural mineral fiber comprises needle-like limestone and basalt fiber, and the natural mineral powder comprises zircon, barite, vermiculite and graphite. The invention also provides a preparation method of the natural mineral powder and cardanol-based benzoxazine pellet and a preparation method of cardanol-based benzoxazine in-situ toughening phenolic resin.

Owner:BEIJING UNIV OF CHEM TECH

Flame retardant polystyrene foamed hard wood-imitating material and preparation method thereof

The invention discloses a flame retardant polystyrene foamed hard wood-imitating material and a preparation method thereof. The hard wood-imitating material comprises, by weight, 50-70 parts of recovered polystyrene, 55-75 parts of high impact polystyrene, 35-45 parts of flame retardant masterbatch for a core layer, 30-40 parts of special flame retardant masterbatch for a surface layer, 0.5-0.9 parts of a foaming agent, 1-4 parts of a flexibilizer, 0.1-0.5 parts of a plasticizer, and 0.5-0.9 parts of a coloring agent. The flame retardant polystyrene foamed hard wood-imitating material of the present invention has high intensity flame retardation, is a hard foamed wood-imitating material with certain toughness and low density, and simultaneously has the advantages of fireproofing, waterproofing, oil resistance, insect prevention, mildew resistance, weatherproofing, light weight and the like.

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

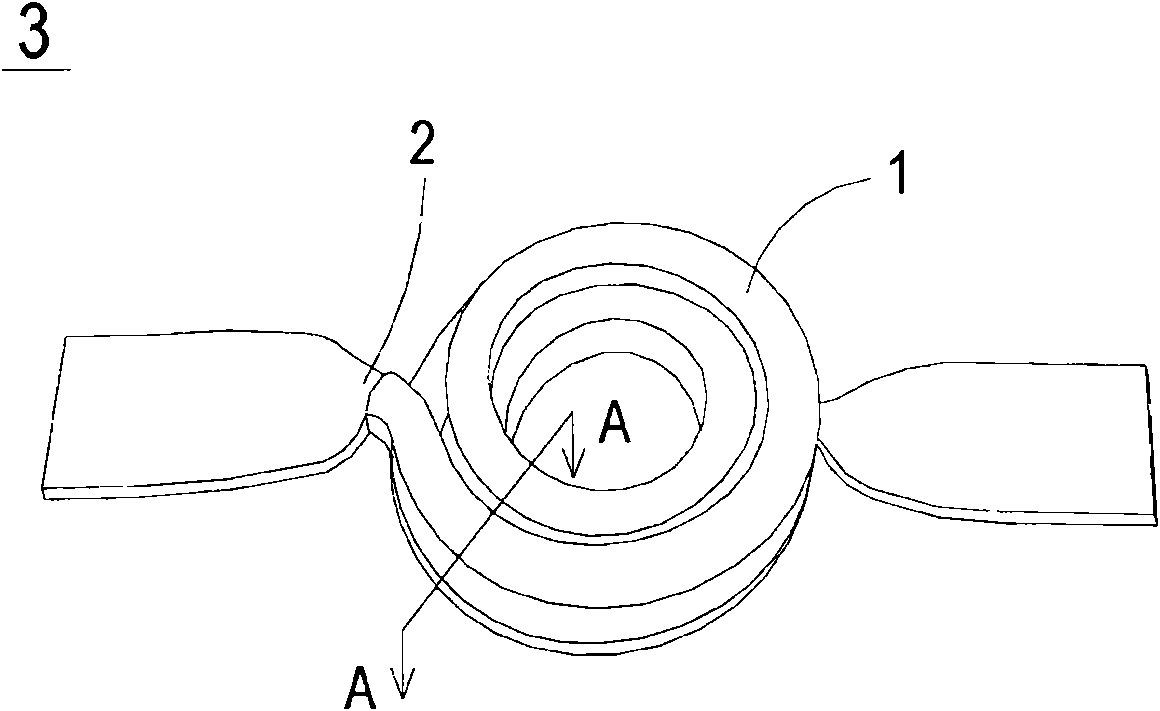

High-temperature insulation composite, insulated conductor and magnetic element

ActiveCN101857724AResilientImprove space utilizationElectrically conductive connectionsTransformers/inductances coils/windings/connectionsUltimate tensile strengthMaterials science

The invention relates to a high-temperature insulation composite, an insulated conductor and a magnetic element. The high-temperature insulation composite comprises an organic material and inorganic bond materials, wherein the weight percent content of the inorganic bond materials is between 10% and 90%; and the high-temperature insulation composite still has strength and insulating property after being subject to the process of high temperature above 400 DEG C, can be used for manufacturing the novel integrated magnetic element with high performance; and an insulated coil coated with the high-temperature insulation coating can be directly embedded in magnetic materials requiring high temperature annealing / sintering, thereby greatly improving the production efficiency of the magnetic element and being suitable for large-scale bulk production, improving the space use ratio of the magnetic element, reducing the manufacturing cost of the magnetic element, and improving the power density and performance of relative electronic products.

Owner:DELTA ELECTRONICS INC

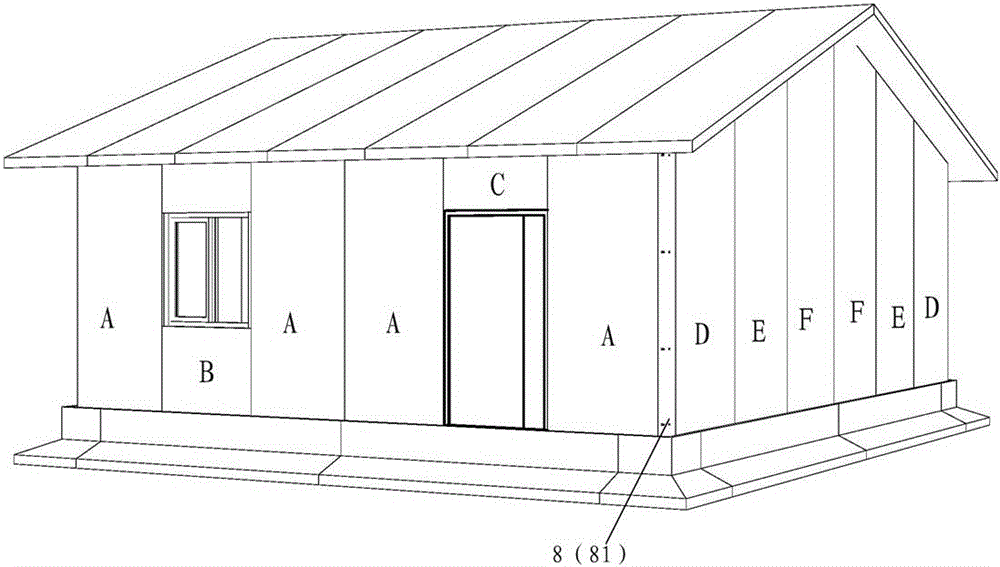

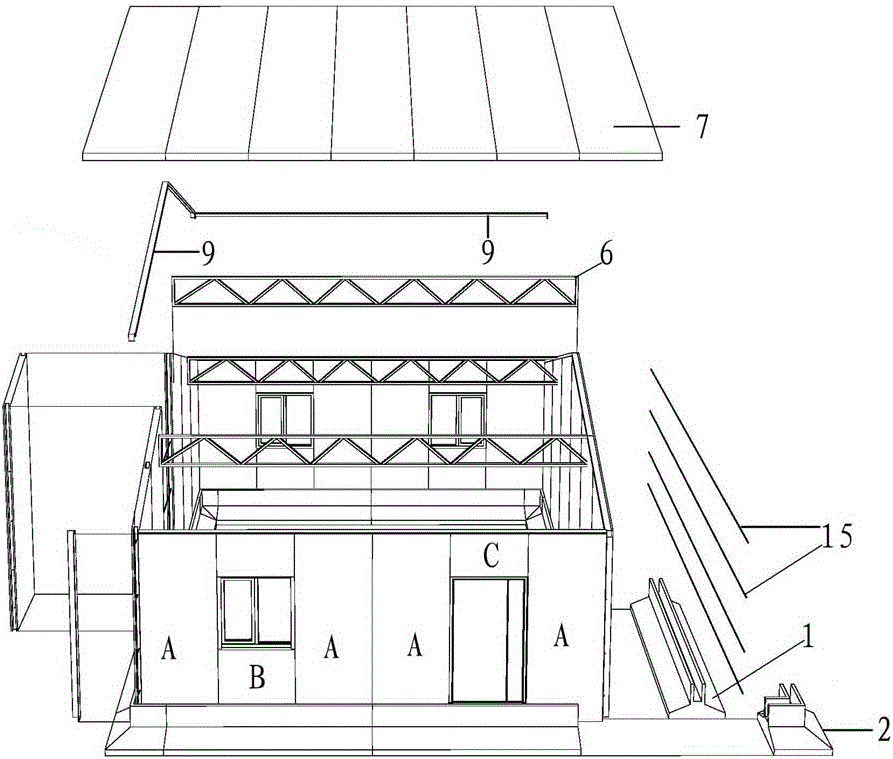

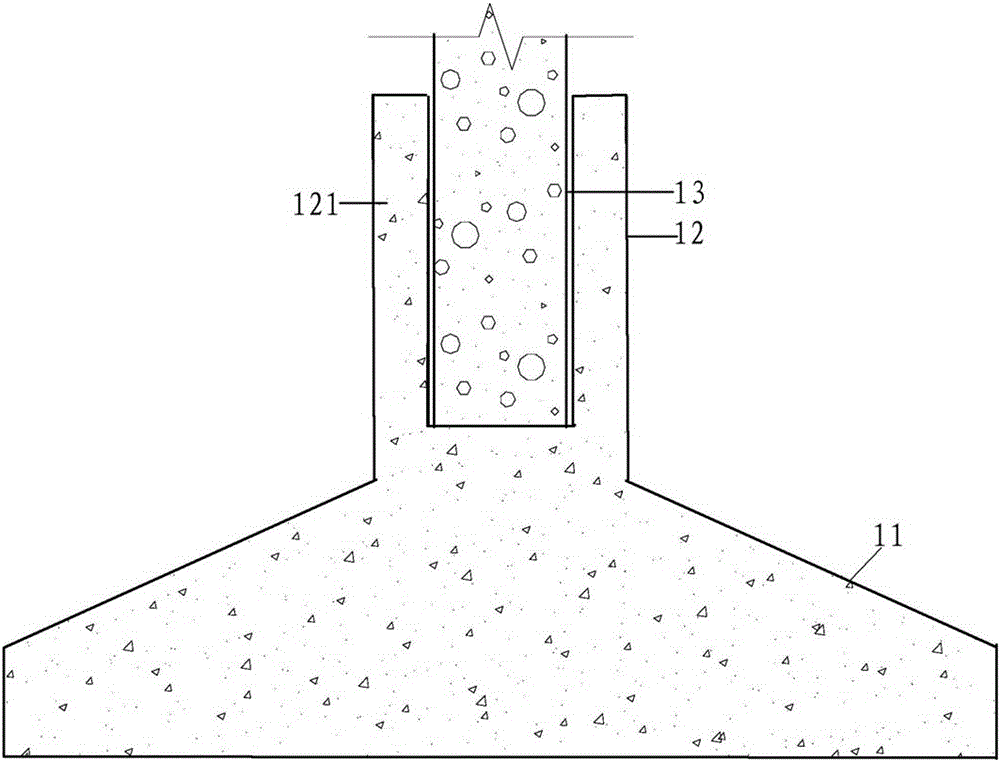

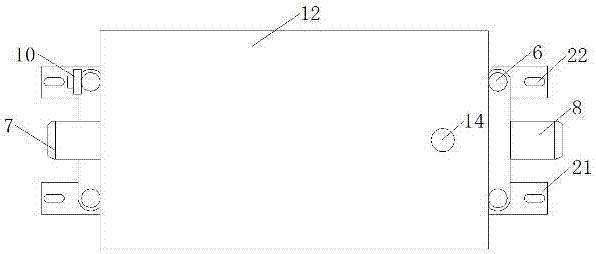

Plugging type combined house

ActiveCN105696706AAnti-seismicWith insulationBuilding constructionsDwelling buildingEngineeringStructural engineering

Owner:ZHONGQINGDA TECH HLDG CO LTD +1

Soluble mold core and preparation method thereof

The invention provides a soluble mold core and a preparation method thereof. The soluble mold core comprises the main ingredients, such as polyethylene glycol binder, filling and plasticizer, wherein the mass ratio of the polyethylene glycol binder to the filling is 60:40 to 40:60, the mass ratio of paraffin to polyethylene in the plasticizer is 20:80 to 5:95, and the plasticizer is 1 to 5 percent of the total mass of the polyethylene glycol binder and the filling. The soluble mold core has a certain strength and toughness, can ensure the smooth molding of a paraffin mold, can be easier to lose in an aqueous medium under the condition of undamaging the performance and the shape of the paraffin mold and can satisfy the requirements for manufacturing high-quality castings.

Owner:江苏嘉宸合金科技有限公司

Method for manufacturing monolithic bipolar membrane

ActiveCN102061004BIncrease elasticityImprove flexibilitySemi-permeable membranesElastomerBenzoyl peroxide

The invention relates to a method for manufacturing a monolithic bipolar membrane, which comprises the following steps of: immersing a substrate membrane in a solution containing styrene, divinybenzene and benzoyl peroxide, pressurizing the immersed membrane, wherein the substrate membrane is a thin alloy membrane formed by two-element blending of polyethylene and ethylene-octylene copolymer elastomer or by three-element blending of polyethylene, ethylene-octylene copolymer elastomer and polyisobutylene rubber; and pressurizing the membrane immersed in the solution and polymerizing under the condition of heating to obtain a base membrane; sulfonating one side face of the base membrane by heating in concentrated sulfuric acid; performing chloromethylation reaction of the membrane with one sulfonated side face in chloromethyl ether containing anhydrous stannic chloride so that the other side face of the membrane is chloromethyl; and immersing the membrane in a trimethylamine aqueous solution or a trimethylamine aqueous solution containing dimethylamine to carry out an aimination or quaterisation reaction to obtain the monolithic bipolar membrane. The method has the advantages that the immersing temperature is greatly reduced, the styrene and divinybenzene solution can be repeatedly used, and the electric resistance of the bipolar membrane is low. The bipolar membrane has a catalytic layer for accelerating water decomposition, the method is simple and convenient and is easy for large-scale industrialized production.

Owner:福建省延润膜环保科技有限公司

Coarse grain noodles

ActiveCN103766752AHigh biological potencyReasonable ratioYeast food ingredientsFood ingredient functionsMillet flourDietary fibres

The invention relates to coarse grain noodles which comprise the following raw materials in parts by weight: 80-100 parts of flour, 2-5 parts of corn powder, 1-3 parts of peanut powder, 1-3 parts of millet powder, 5-8 parts of mashed pumpkin, 0.5-2 parts of yeast powder and 0.3-0.8 part of guar gum. The invention also relates to a preparation method of coarse grain noodles. In the invention, the raw materials of the coarse grain noodles are fermented, and the overall nutritional value of the coarse grain noodles is increased; as functional noodles, the coarse grain noodles provided by the invention are rich in dietary fibers easy to digest and absorb as well as other nutrient substances.

Owner:ANHUI YANZHIFANG FOOD

Flame resisting wave-absorbing material and method for making same

InactiveCN1909115AImproved high power performanceResilientScreening apparatusConductive coatingEngineering

The related preparation method for a new flame-resisting wave-absorbing material used on full / semi-anechoic chamber comprises: with non-woven fabrics as basal body, painting flame-retardant coat on both inner and outer surfaces of the fabric, drying; then painting conductive coat on former coat, drying; impressing and forming, and folding into the unit body. This invention improves product performance greatly.

Owner:NANJING BOPING ELECTRONICS TECH CO LTD

Preparation method of edible jerky and calfskin, pigskin and fish skin biting chew for pet

ActiveCN102630827AImprove freshnessReduce fishy smellAnimal feeding stuffWorking-up animal fodderRaw meatBiting

The invention relates to the field of pet food, and in particular relates to a preparation method of edible jerky and calfskin, pigskin and fish skin biting chew for a pet. According to the preparation method disclosed by the invention, poultry, livestock meat or bright flesh of fish or fresh skin of animals such as pig, calf and fish is taken as raw material, the raw material is minced and chopped, moulded and frozen and then split, or the raw material is directly split and then frozen, or the raw material is split into the required shape and then frozen, subsequently microwave vacuum dryingis carried out, and sterilizing and packaging are carried out, and thus the edible jerky or calfskin, pigskin and fish skin biting chew for the pet is obtained. The edible jerky or calfskin, pigskin and fish skin biting chew finished product can show primary colour of raw meat, has a strong meat flavour and maintains nutrition of a meat product while a food calling function is realized. The edible jerky or calfskin, pigskin and fish skin biting chew can be taken as a meat snack for the pet and also can be taken as a nutritional supplement for an old-aged dog or little dog after being rewatered and torn up.

Owner:JIANGSU YIHE PET PROD CO LTD

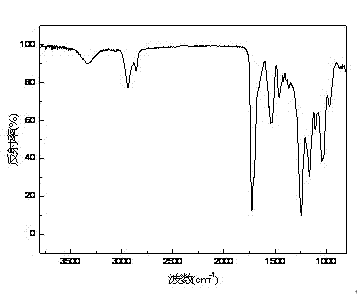

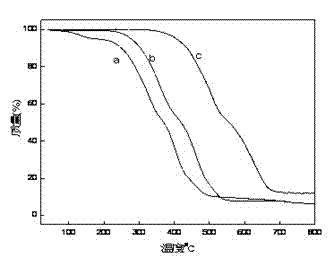

Hemicellulose/chitosan based compound membrane with high flexibility and mechanical strength and preparation method thereof

The invention discloses a method for preparing a hemicellulose / chitosan based compound membrane with high flexibility and mechanical strength. The method comprises the following steps: (1) dissolvingchitosan in an acetic acid solution, heating and stirring to prepare a chitosan solution; (2) dissolving hemicellulose in an acetic acid solution, heating and stirring to prepare a hemicellulose solution; (3) mixing the hemicellulose solution and the chitosan solution, and adding a cellulose nano-fiber solution; (4) adding plasticizer into the mixed solution, stirring the mixed solution at room temperature, centrifuging to remove insoluble impurities, performing ultrasonic degassing, and standing to obtain a compound membrane-forming solution; and (5) putting the membrane-forming solution in aculture dish, drying in a vacuum drying tank to form a membrane. The hemicellulose / chitosan based compound membrane has relatively high flexibility, relatively high tensile strength and relatively good oxygen resistance, is antibacterial and antioxidative, and has a relatively good application prospect in food package, oxidation resistance and other aspects.

Owner:BEIJING FORESTRY UNIVERSITY

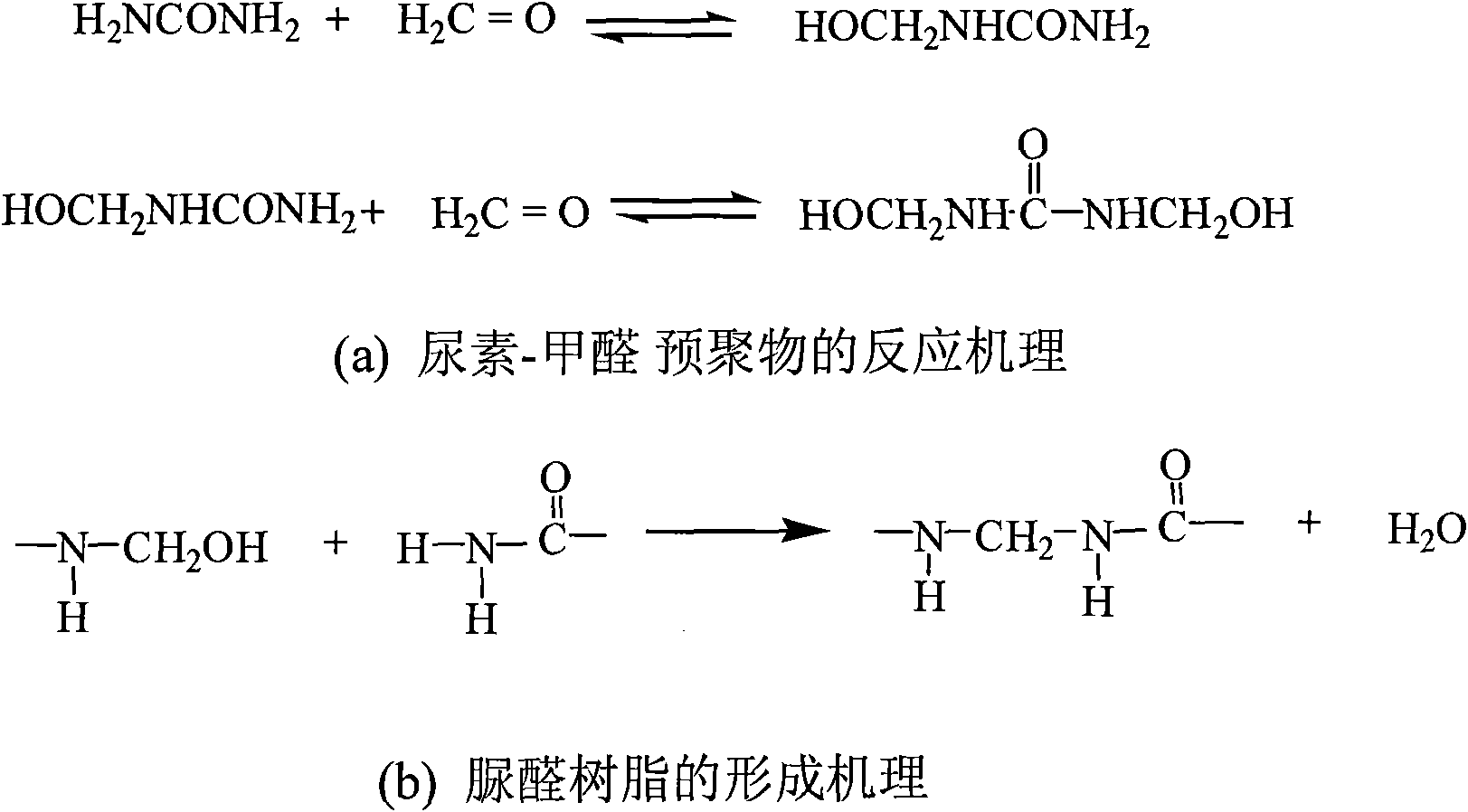

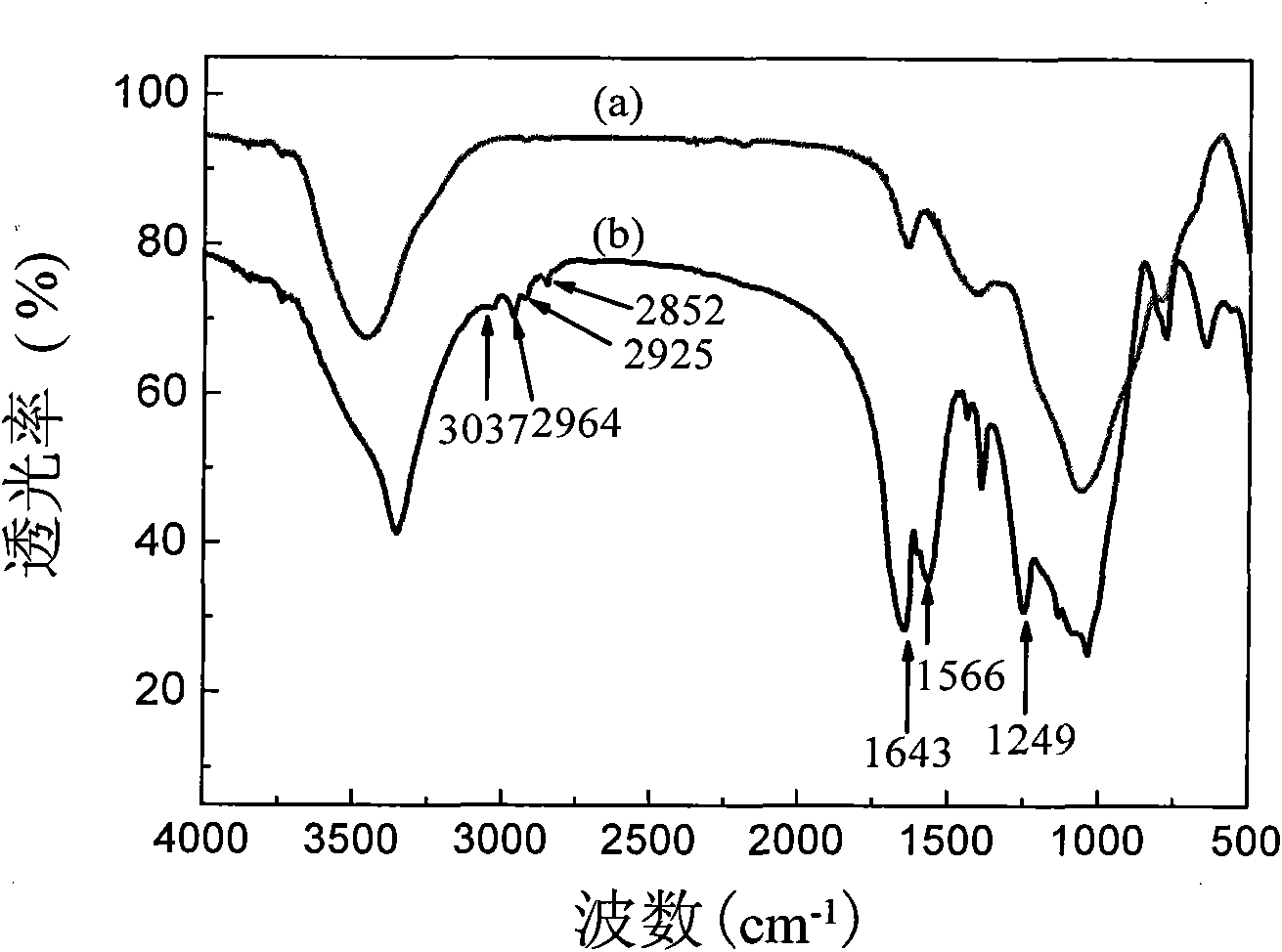

Method for in situ polymerization of surface modified hollow micro glass bead from urea-formaldehyde resin

InactiveCN102311530AImprove wear resistanceMeasure the impact strengthPigment treatment with macromolecular organic compoundsPolymer scienceIn situ polymerization

The invention relates to a new method for in situ polymerization of a surface modified hollow micro glass beads from urea-formaldehyde resin. The raw materials comprise the following components in part by weight: 30 parts of urea, 30-60 parts of formaldehyde, 2-5 parts of tween dispersant, 75-105 parts of hollow micro glass beads and 400 parts of distilled water. The method has a simple process; a product has a core-shell structure, wherein the core is the hollow micro glass beads and the shell is the urea-formaldehyde resin; the hollow micro glass beads modified by the method are added into a polypropylene / ethylene-octene copolymer base materials (PP / POE); and compared with a composite material of the hollow micro glass beads which are not subjected to surface modification and the hollow micro glass beads which are subjected to KH-550 silane coupling agent surface modification, the method has the advantages of obviously improving the interface compatibility of the hollow micro glass beads and the base materials and obviously improving the mechanical property of the composite materials. The hollow micro glass beads modified by the method can be widely applied to the fields of high-grade building materials, plastic, rubber, paints, electrical insulation materials, heat insulation, sound insulation, automobiles, aerospace, military special high-molecular composite materials and the like; meanwhile, the method provides a new idea for the surface modification of other inorganic particles.

Owner:TIANJIN CHENGJIAN UNIV

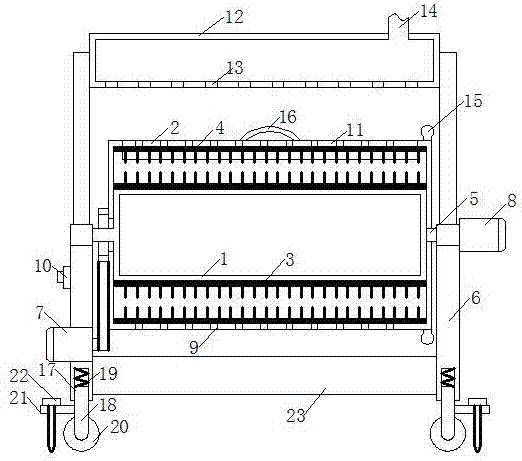

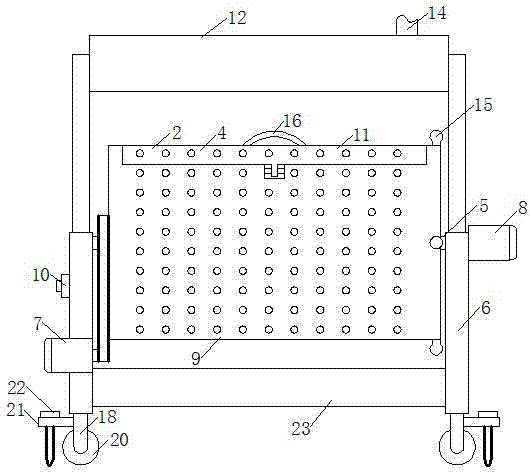

Concentric type double-layer tuber vegetable cleaning device

InactiveCN107019233AResilientAvoid secondary pollutionClimate change adaptationFood treatmentEngineeringPlant Tubers

The invention discloses a concentric type double-layer tuber vegetable cleaning device. The device comprises an inner cylinder and a water tank, wherein a second motor is fixed on a support frame; drain holes are uniformly formed in an outer cylinder; a switch is mounted on the support frame and electrically connected with a first motor and the second motor; a feed port is formed in the upper end of the outer cylinder; a charging door is hinged onto the feed port. According to the concentric type double-layer tuber vegetable cleaning device, the outer cylinder is arranged on the outer side of the inner cylinder, the inner cylinder and the outer cylinder rotate in opposite directions, so that an inner brush and an outer brush move in the opposite directions, tuber vegetables are driven to rotate while upper and lower surfaces of the tuber vegetables are cleaned, and all surfaces can be cleaned more thoroughly; the inner brush and the outer brush have toughness and can deeply clean sunk parts of the tuber vegetables, the cleaning is more thorough, water is sprayed from the water tank, accordingly, more water is saved, and the tuber vegetables are cleaner and avoids secondary pollution.

Owner:合肥齐飞信息技术有限公司

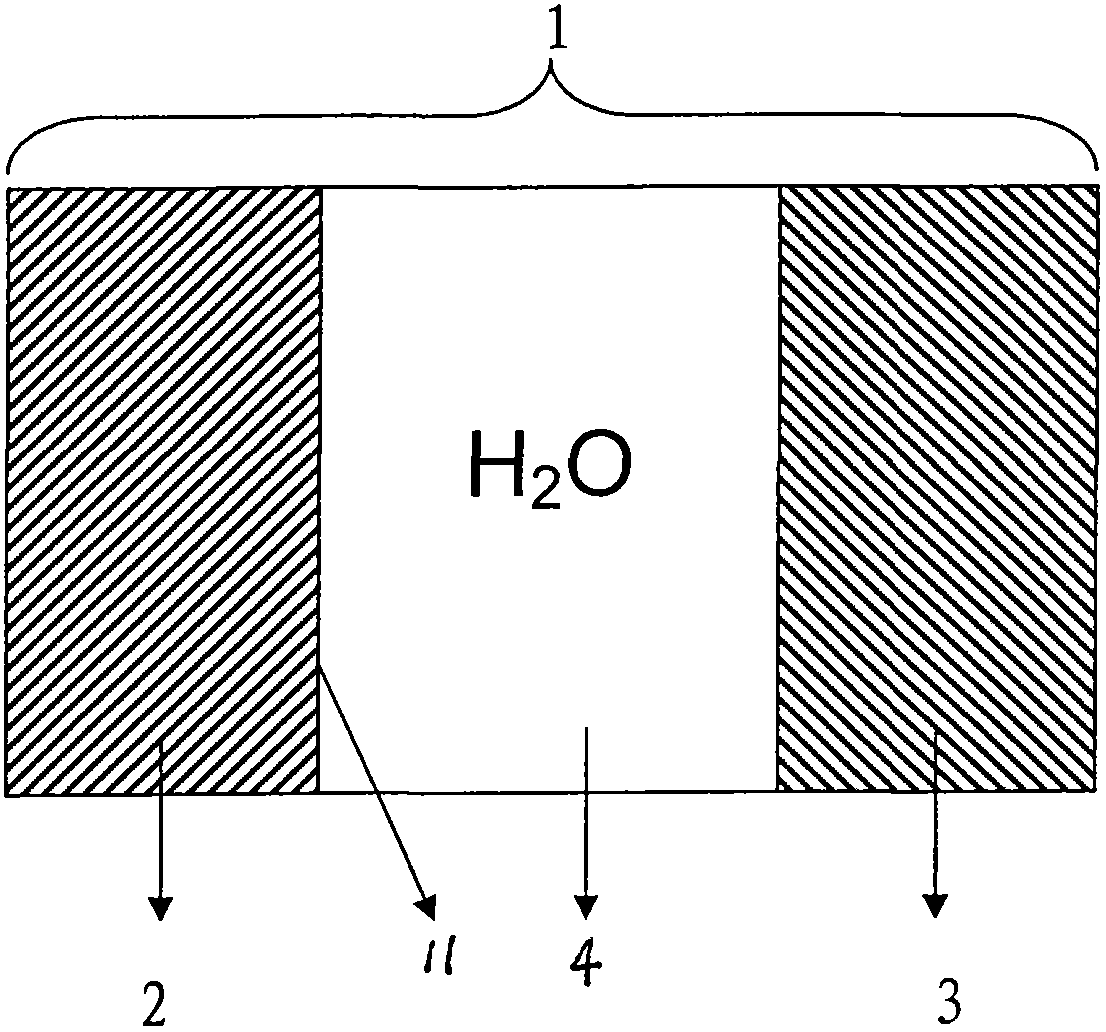

Method for preparing homogeneous-phase cation-exchange membrane

ActiveCN102134327AImprove mechanical propertiesImpregnation temperature decreasesSemi-permeable membranesCation exchanger materialsSheet resistanceChemistry

The invention relates to a method for preparing a homogeneous-phase cation-exchange membrane. In the method, a binary blending alloy film of polyethylene and the copolymer elastomer of ethylene and octylene, or the ternary blending alloy film of polyethylene, copolymer elastomer of ethylene and octylene and isobutylene rubber is taken as a basilar membrane. The method comprises the following steps: dipping the basilar membrane into the solution containing styrene, divinyl benzene and peroxide benzoyl; pressurizing an impregnated film and heating and polymerizing to obtain the basilar membrane; and sulfonating the basilar membrane in concentrated sulfuric acid to obtain the cation-exchange membrane. The cation-exchange membrane has the advantages that: the alloy membrane has elasticity and flexibility, greatly enhanced mechanical property and toughness; the impregnated temperature is reduced greatly; and the polyethylene and ethylene solution can be recycled, the prepared cation-exchange membrane has high capacity which can be 2.5 milliequivalent / g dry film, the sheet resistance is about 1cm<2>, and the dichloroethane is not needed for pre-swelling the basilar membrane during the sulfonation.

Owner:福建省延润膜环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com