Flame-retardant heat-resistance polyurethane resin and preparation method of aqueous emulsion of polyurethane resin

A technology of polyurethane resin and water emulsion, applied in the direction of polyurea/polyurethane coating, polyurea/polyurethane adhesive, adhesive type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

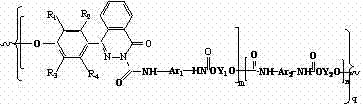

[0044] Add polyether polyol, FRC-6, a small amount of dibutyltin dilaurate and dimethylol propionic acid into a reactor with mechanical stirring and reflux condensation, stir and dissolve, add TDI, and 2 React at 40° C. for 1 h under protection, and add heterocyclic polyol B to obtain a prepolymer. Then drop to room temperature and add methyl ethyl ketone, add appropriate amount of triethylamine to neutralize. Add water to fully emulsify, remove methyl ethyl ketone by rotary evaporation, and obtain a flame-retardant heterocyclic polyurethane emulsion with a solid content of 30%, lay a film, and cure at 60°C. The limiting oxygen index LOI is 28.

[0045] Prepare the aqueous emulsion and carry out the following tests:

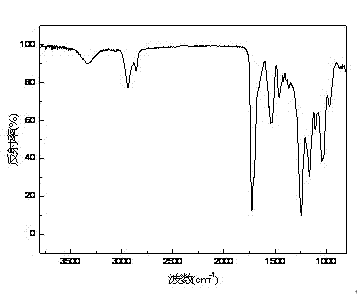

[0046] Infrared spectrum test: FTIR-430 Spectrometer produced by Japan JASCO Company was used to test the infrared spectrum of polyurethane foam plastics by film reflection or potassium bromide tablet method.

[0047] The limiting oxygen index is tested acco...

Embodiment 2

[0053] Add polyether polyol, Fyrol-6, a small amount of dibutyltin dilaurate, dimethylol propionic acid and a small amount of N,N-dimethylacetamide into a reactor with mechanical stirring and reflux condensation, stir and dissolve, add TDI, in N 2 React at 60°C for 4 hours under protection, and add heterocyclic polyol B to obtain a prepolymer. Then drop to room temperature and add acetone, and add appropriate amount of triethylamine to neutralize. Add water to fully emulsify, remove acetone by rotary evaporation, and obtain a flame-retardant heterocyclic polyurethane emulsion with a solid content of 35%, lay a film, and cure at 70°C. The limiting oxygen index LOI is 28.

Embodiment 3

[0055] Add heterocyclic polyol A, MDI and a small amount of N-methylpyrrolidone into a reactor with mechanical stirring and reflux condensation, stir and heat to dissolve, rise to 60°C for 1 hour. Add polyester polyol, FRC-6, a small amount of dibutyltin dilaurate and dimethylolpropionic acid and stir to dissolve. 2 React at 70°C for 4 hours under protection to obtain a prepolymer. Then drop to room temperature and add acetone, and add appropriate amount of triethylamine to neutralize. Add water to fully emulsify, remove acetone by rotary evaporation, and obtain a flame-retardant heterocyclic polyurethane emulsion with a solid content of 40%, lay a film, and cure at 80°C. The limiting oxygen index LOI is 28.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com