Preparation method of bone inducing porous titanium artificial bone

An osteoinductive, porous titanium technology, applied in the field of biomedical materials, can solve problems such as speeding up the bone healing process, and achieve the effects of speeding up the bone healing process, convenient operation, and overcoming brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

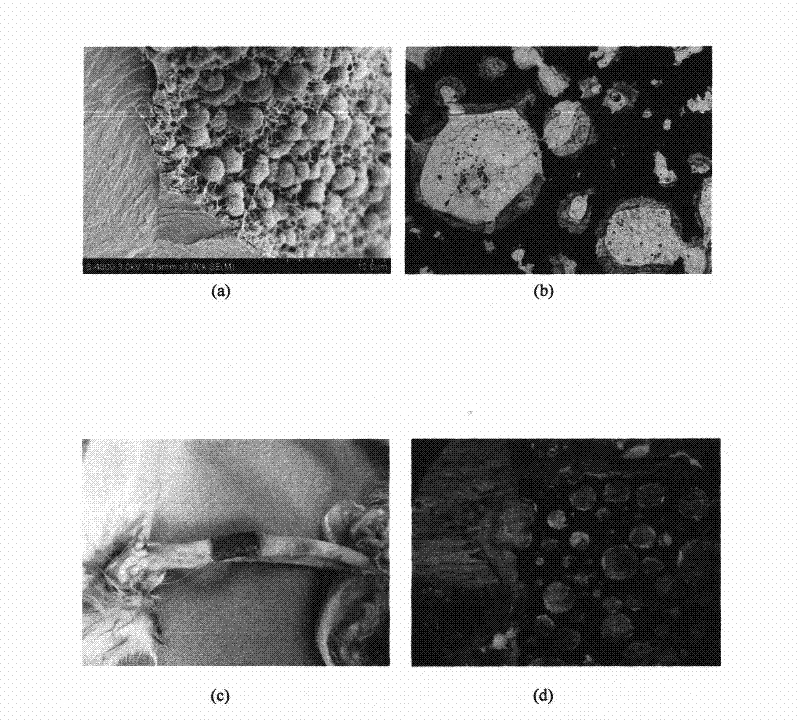

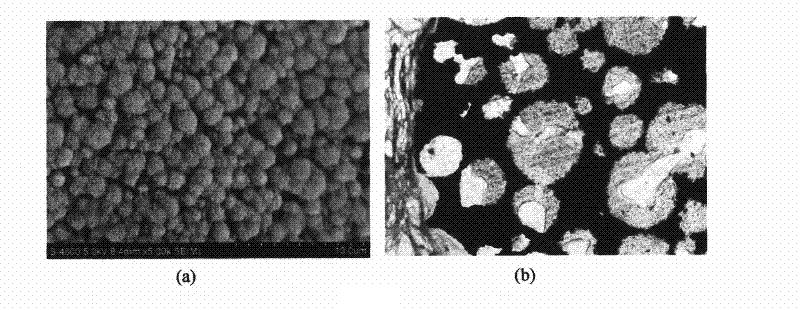

[0034] The porous titanium block prepared by the slurry foaming method is machined into a sample with a length of 4 mm, a width of 5 mm, and a height of 12 mm. The pore size is mainly distributed in the range of 100-700 μm, and the average large pore size is 270 μm. The pore wall is rough and has The micropores of 2-70 microns are distributed on the walls of the macropores. The samples were ultrasonically cleaned with petroleum ether, acetone, absolute ethanol and deionized water for 20 minutes respectively, rinsed with deionized water, and then dried at room temperature to obtain the porous titanium artificial bone. Put the cleaned porous titanium artificial bone into an acid solution made of 98wt% sulfuric acid, 38wt% hydrochloric acid and deionized water with a volume ratio of 1:1:2, and place it in an oven at 70°C for 1 hour; take it out and use Rinse it with deionized water, then put it into 6M / L sodium hydroxide solution, keep it at 70°C for 5 hours, then rinse it gently...

Embodiment 2

[0037] The porous titanium block prepared by the slurry foaming method is machined into a sample with a diameter of 4 mm and a height of 10 mm. The pore size is mainly distributed in the range of 100-700 μm, and the average large pore size is 320 μm. The pore wall is rough, with 2- Micropores of 70 microns are distributed on the walls of large pores. The samples were ultrasonically cleaned with petroleum ether, acetone, absolute ethanol and deionized water for 20 minutes respectively, rinsed with deionized water, and then dried at room temperature to obtain the porous titanium artificial bone. Put the cleaned porous titanium artificial bone into the acid solution made of 55wt% hydrofluoric acid, 65wt% nitric acid and deionized water with a volume ratio of 1:10:89, treat it at room temperature for 90 seconds, take it out and place it in the Ultrasonic cleaning in deionized water for 15 minutes, then rinsed with deionized water and dried at room temperature; then placed in 30wt%...

Embodiment 3

[0039] The porous titanium alloy block prepared by the slurry foaming method is machined into a cube sample with a side length of 5mm. The pore size is mainly distributed in the range of 100-700μm, the average macropore size is 450μm, and the pore wall is rough. There are 2 -80 micron micropores are distributed on the walls of the macropores. The samples were ultrasonically cleaned with petroleum ether, acetone, absolute ethanol and deionized water for 20 minutes respectively, rinsed with deionized water, and then dried at room temperature to obtain the porous titanium artificial bone. Put the cleaned porous titanium artificial bone into the acid solution made of 55wt% hydrofluoric acid, 65wt% nitric acid and deionized water with a volume ratio of 1:10:89, treat it at room temperature for 90 seconds, take it out and place it in the Ultrasonic cleaning in deionized water for 15 minutes, then rinsed with deionized water and dried at room temperature; then placed in 30wt% hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com