Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Uniform activation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesizing ultrafine calcium carbonate by utilizing carbide slag

ActiveCN102602973AImprove conversion rateUniform particle size distributionCalcium/strontium/barium carbonatesSolid waste disposalWater contentCis-Butenedioic Acid

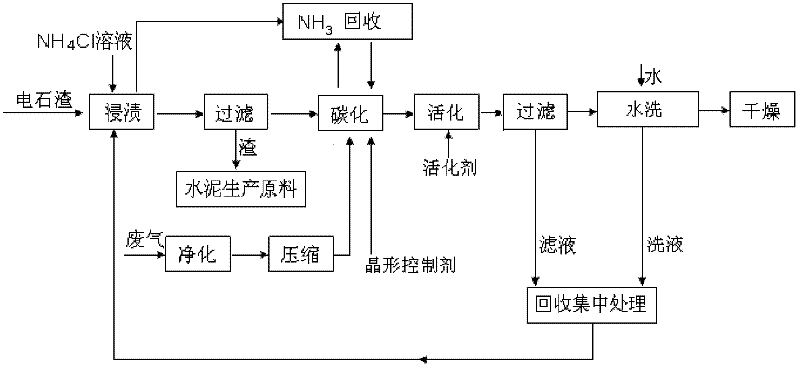

The invention relates to a method for synthesizing ultrafine calcium carbonate by utilizing carbide slag. The method comprises the following steps of: (1) dissolving carbide slag: uniformly mixing carbide slag with water in a ratio of (1:6)-(1:20) to ensure that the carbide slag is fully dissolved into a turbid liquid, wherein the water content of the carbide slag is 20-45%; (2) carrying out impregnation reaction: adding ammonium chloride into the turbid liquid of the carbide slag for uniformly mixing, wherein the mass ratio of carbide slag to ammonium chloride is (1:0.7)-(1:2.5), after the impregnation reaction is finished, filtering and removing the slag to obtain a clear calcium chloride solution; and (3) carrying out carbonization reaction: adding a crystal form control agent into a calcium chloride solution for fully dissolving, introducing CO2 into the solution to carry out carbonization reaction till the pH (potential of Hydrogen) value of the reaction solution is less than or equal to 7 to obtain ultrafine calcium carbonate slurry, wherein the crystal form control agent is one or more than two mixtures of sulfate, chloride, citrate, sodium dodecyl benzene sulfonate, pyrophosphate, oleic acid, ammonium citrate, N-methyl pyrrolidone and maleic acid.

Owner:SINOMA INT ENG +1

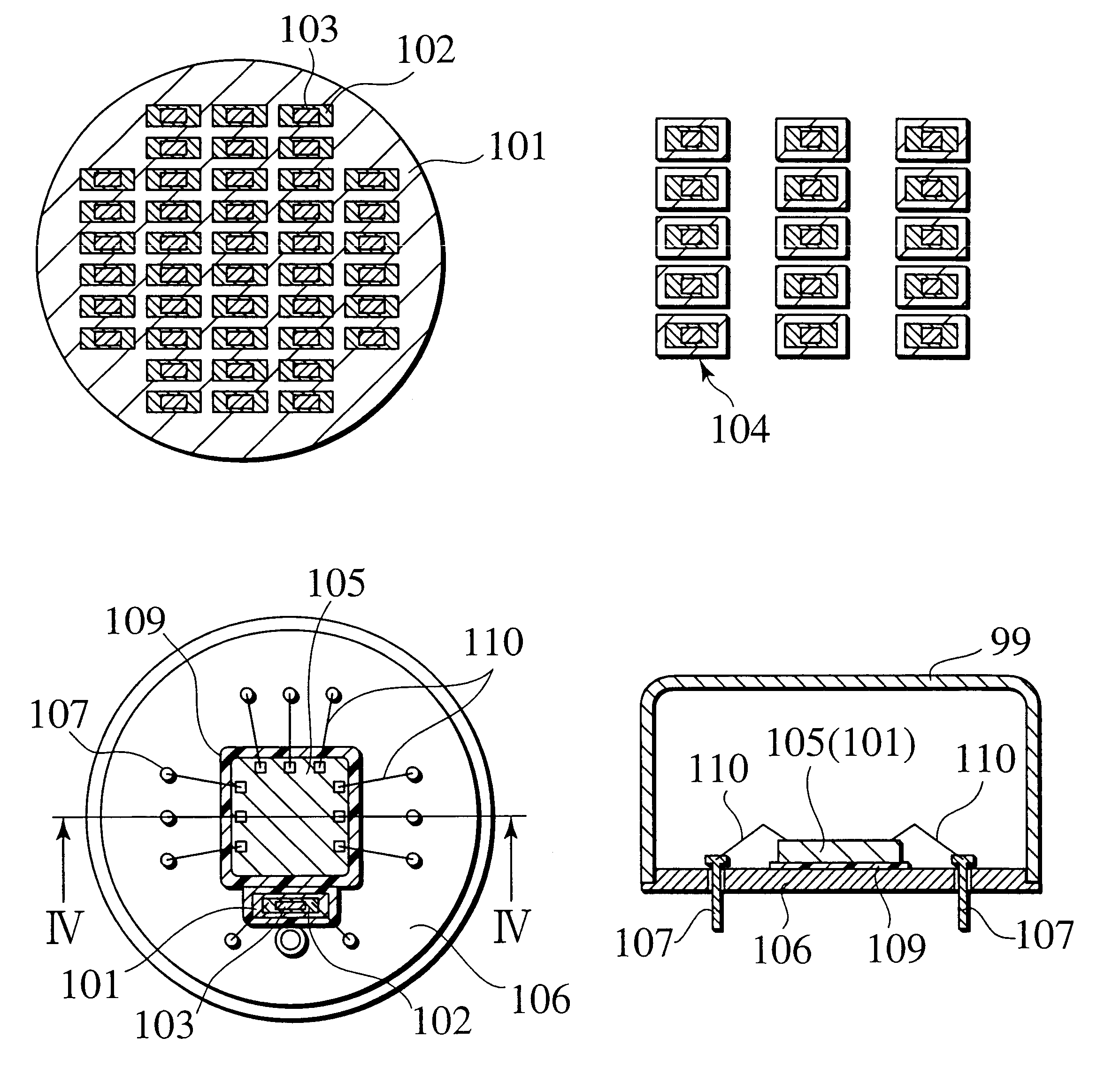

Disk-like gettering unit, integrated circuit, encapsulated semiconductor device, and method for manufacturing the same

InactiveUS20020037633A1Reduce in quantityUniform activationRadiation pyrometrySemiconductor/solid-state device detailsSiliconSemiconductor

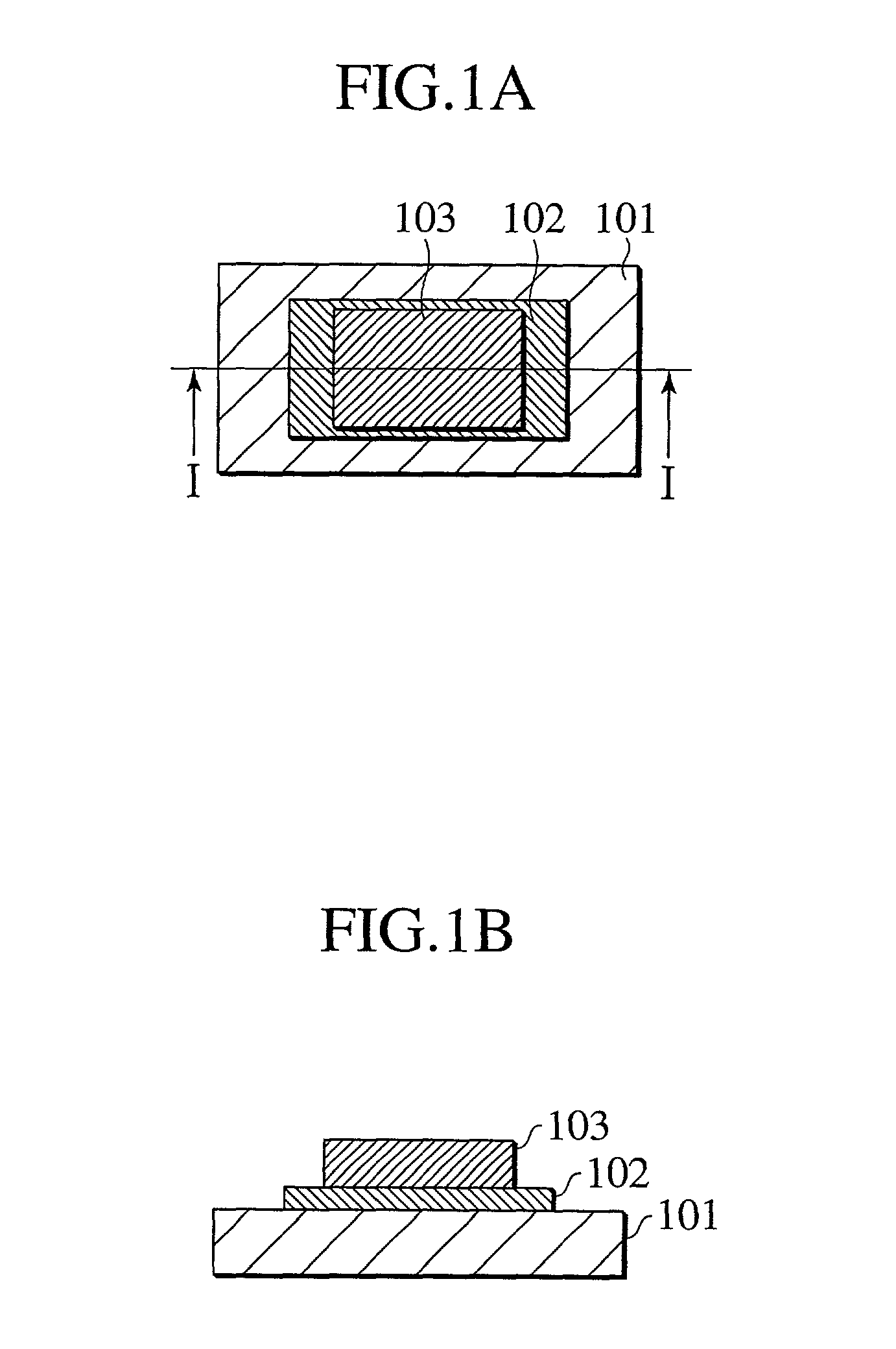

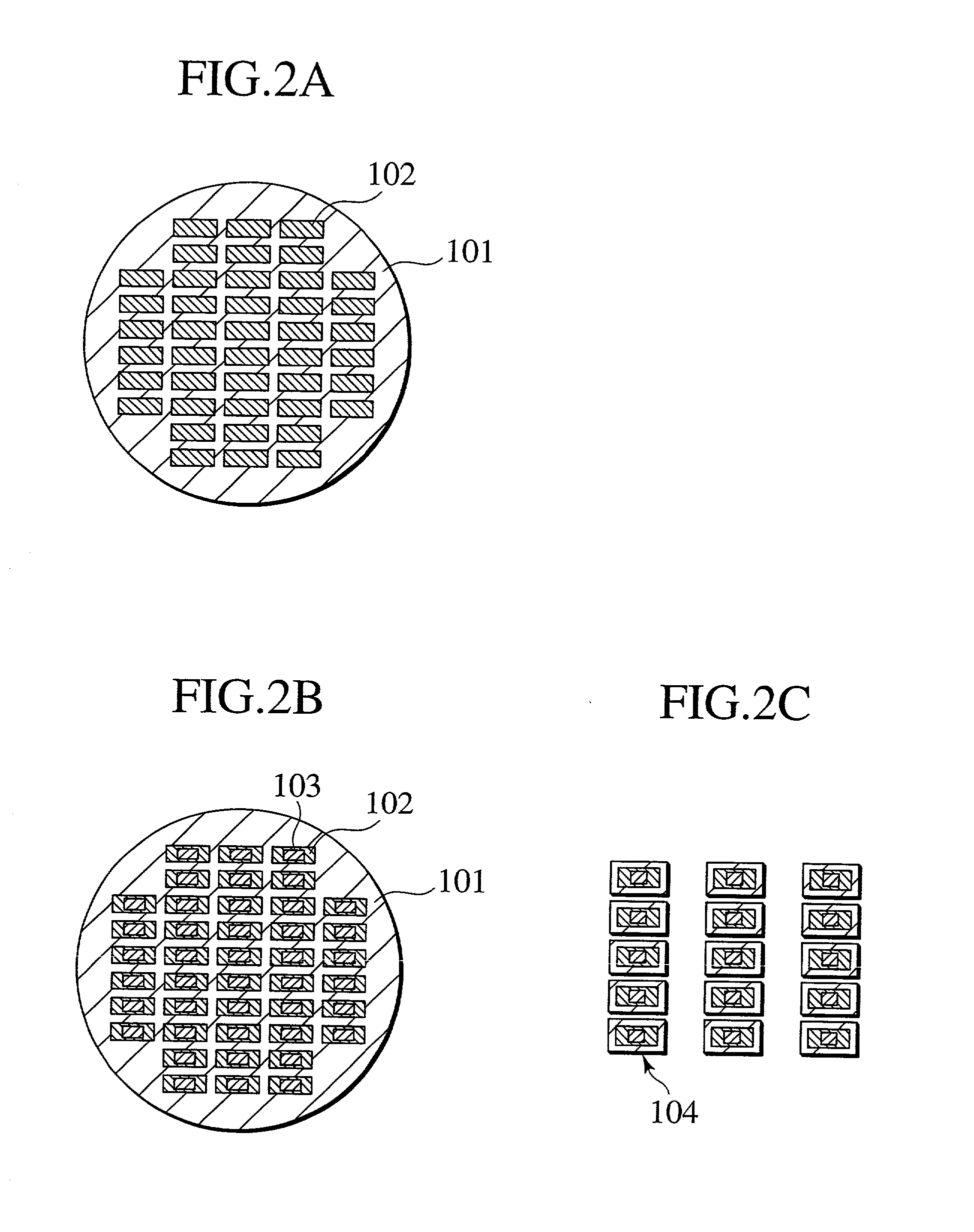

A gettering unit encompasses a silicon substrate, a thin film heater disposed on the silicon substrate, and a gettering layer disposed selectively on the thin film heater. Here, the thin film heater is made of metallic film such as platinum (Pt) or chromium (Cr) film. The area of the gettering layer is smaller than the area for the thin film heater so as to expose first and second end terminals of the thin film heater. The first and second end terminals of the thin film heater serves as the bonding pads in the assembling process.

Owner:NISSAN MOTOR CO LTD

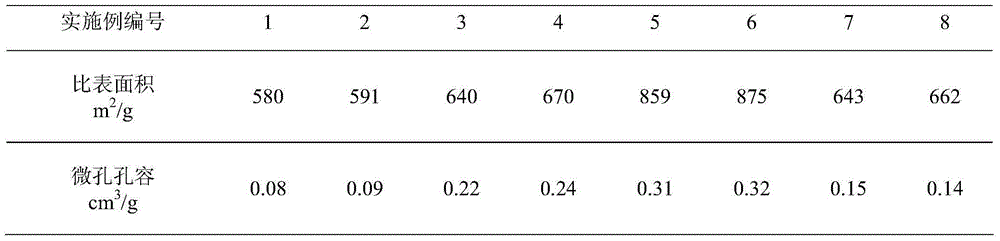

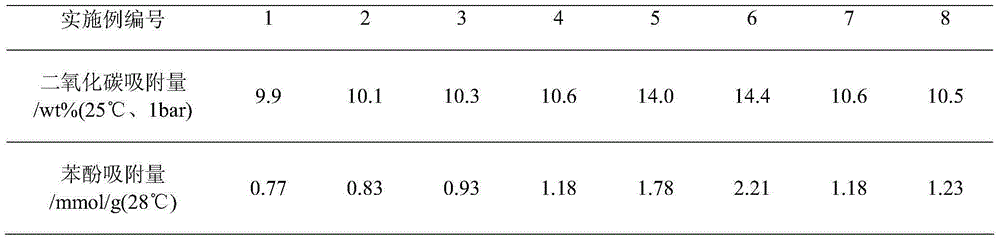

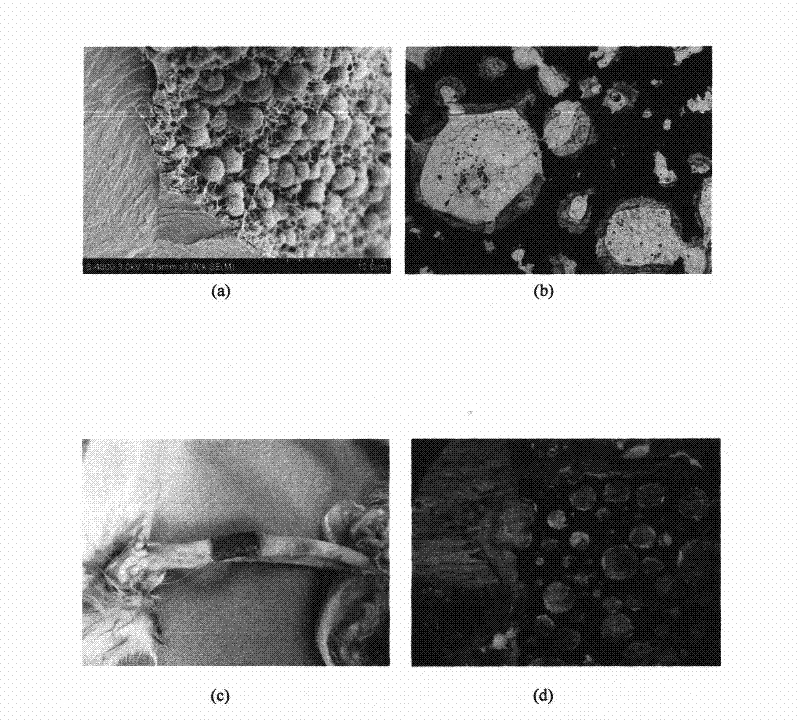

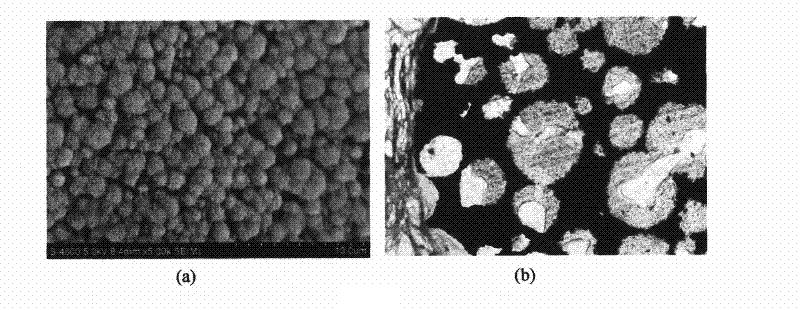

Preparation method for activated carbon material and application thereof

The invention provides a preparation method for an activated carbon material. The preparation method comprises the following steps: 1) taking an activator aqueous solution, adding ion exchange resin and stirring and mixing the mixture for ion exchange; 2) washing, filtering and drying the obtained mixture to obtain the required resin; 3) optional one step: a, carbonizing the obtained resin in an N2 atmosphere; b, after pre-oxidizing the obtained resin in air, carbonizing the resin in the N2 atmosphere; and 4) washing and drying the obtained carbon material to obtain the required activated carbon material. The invention further discloses an activated carbon material by adopting the method and application thereof. According to the activated carbon material and the application thereof provided by the invention, the activator can be uniformly dispersed and the carbon material is activated by alkali metal ions at a high temperature. The prepared activated carbon material has good application potential in adsorbing carbon dioxide and phenol.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Ceramic products possessing antisepsis and water mineralization and activation functions, and its preparation method and uses

InactiveCN1733648AGood antibacterialSustainable accessWater/sewage treatment by substance additionCalcium carbonateActivation function

Ceramic products possessing antisepsis and water mineralization and activation functions, and its preparation method and uses, wherein the ceramic product is prepared from the following ingredients (by weight ratio): montmorillonite 25-60 parts, diatomite 10-30 parts, aluminum oxide 5-20 parts, silicon oxide 3-15 parts, calcium carbonate 15-45 parts, multifunctional health ceramic material 5-20 parts, adhesive 9-15 parts through proportioning, disintegrating, mixing, blank making and sintering.

Owner:淄博博纳科技发展有限公司

Disk-like gettering unit, integrated circuit, encapsulated semiconductor device, and method for manufacturing the same

InactiveUS6590280B2Reduce in quantityUniform activationRadiation pyrometrySemiconductor/solid-state device detailsThin membraneSilicon

Owner:NISSAN MOTOR CO LTD

Preparation method of bone inducing porous titanium artificial bone

The invention relates to a preparation method of bone inducing porous titanium artificial bone. The method comprises the following steps: a porous titanium block is processed into a required shape and is washed; the surface is activated; the porous titanium block is put into acid solution which is prepared by sulfuric acid, hydrochloric acid and deionized water to be processed and then is put into alkali solution of sodium hydroxide; or put into acid solution which is prepared by hydrofluoric acid, nitric acid and deionized water to be processed and is then put into hydrogen peroxide solution; or put into acid solution which is prepared by hydrofluoric acid, nitric acid and deionized water to be processed and is then put into hydrogen peroxide solution which contains tantalum pentachloride; the method is characterized in that the surface of the porous titanium can be activated uniformly without pre-depositing a calcium phosphate layer, when being soaked in simulated body fluid at 36.5DEG C, bone-like apatite can be induced to deposit in 28 days; and bone inductivity can be given to the porous titanium artificial bone. The bone inducing porous titanium artificial bone is used for repairing, replacing or reinforcing bone tissue and can reinforce the regeneration of the bone tissue and the interfacial bond of the implant site; and the process is simple and the operation is convenient.

Owner:SICHUAN UNIV

Production method of cellulose acetate

The invention belongs to the field of polymer chemistry, and relates to a preparation method of cellulose acetate. The cellulose acetate obtained by the method has low turbidity and high viscosity. The method comprises the following steps of: A, activating 1 weight part of cellulose by using 8 to 20 weight parts of glacial acetic acid at the temperature of between 20 and 60 DEG C; B, adding 0.005 to 0.05 weight part of catalyst and 3 to 6 weight parts of acetic anhydride; C, adding 0.5 to 1.5 weight parts of high-concentration acetic acid solution at the temperature of between 10 and 25 DEG C, and reacting till the content of the acetic acid is 60.5 to 62.5 percent, wherein the high-concentration acetic acid solution is 80 mass percent acetic acid; D, adding 0.5 to 1.5 weight part of 5 to 15 weight percent aqueous solution of acetate, and reacting for 1 to 3 hours at the temperature of between 20 and 50 DEG C; and E, filtering, settling and granulating. The preparation method is simple and convenient in the production process and easy in operation; the reaction time is shortened; the prepared product has high substitution degree, namely the content of the acetic acid is more than or equal to 60.0 percent; the product has high viscosity, namely the falling ball viscosity is more than or equal to 70 seconds; and the cellulose acetate is particularly suitable for manufacturing polarizing films in optical elements.

Owner:LUZHOU NORTH CHEM IND

Method for synthesizing ultrafine calcium carbonate by utilizing carbide slag

ActiveCN102602973BImprove conversion rateImprove stabilityCalcium/strontium/barium carbonatesSolid waste disposalSlagCarbonization

Owner:SINOMA INT ENG +1

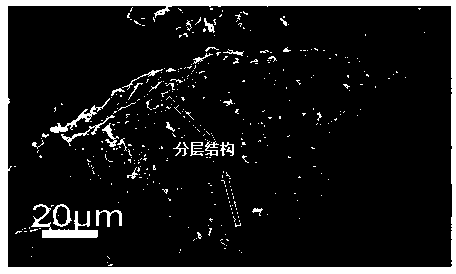

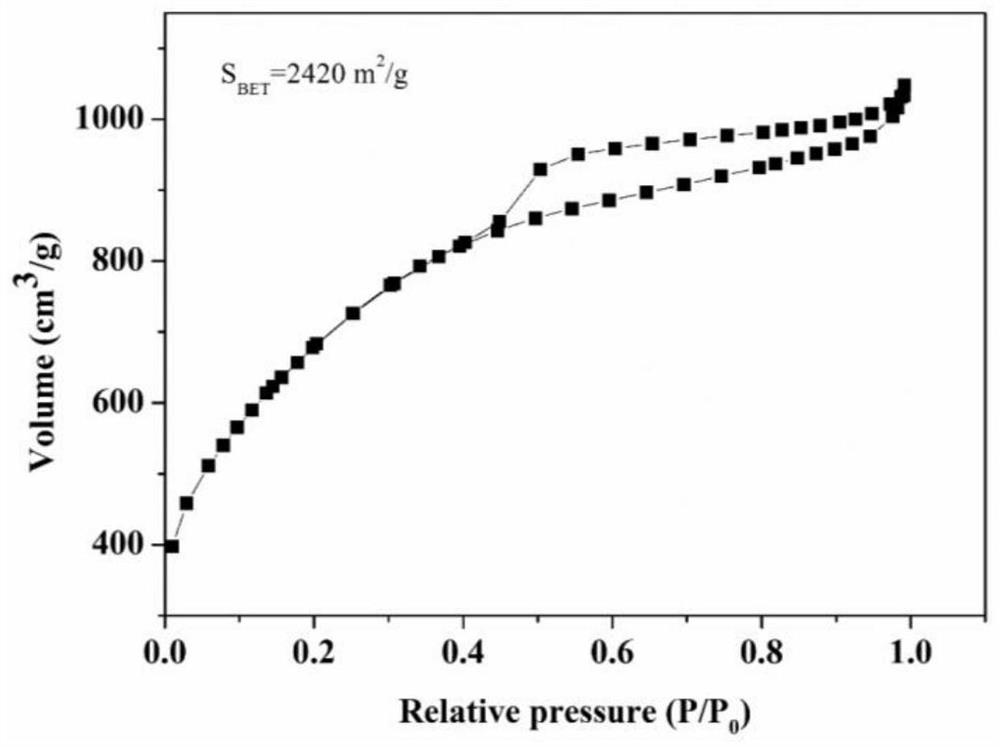

Preparation method of layered porous active carbon electrode material for supercapacitor

ActiveCN107680826AReduce manufacturing costEfficient resource utilizationHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMetallurgy

A preparation method of a layered porous active carbon electrode material for a supercapacitor relates to the technical field of a supercapacitor electrode material. The layered porous active carbon electrode material for the supercapacitor is obtained by the steps of mixing casing after being carbonized with KOH and deionized water under an ultrasonic condition, performing drying to obtain a mixture, activating the mixture in a nitrogen atmosphere and finally performing grinding. The casing is rich in source, can be reproduced and is environmental-friendly, the active carbon material preparedby a simple processing technology has a layered structure, developed specific area and reasonable aperture distribution and has relatively good capacitance performance in the supercapacitor when usedas the electrode material. The preparation process is simple and easy to operate and has important significance to reduction of the production cost of high-surface active carbon for the supercapacitor.

Owner:YANGZHOU UNIV

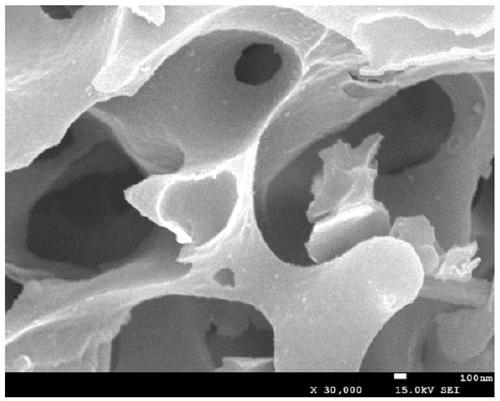

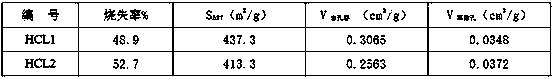

Tobacco matrix activated carbon and preparation method thereof

InactiveCN111137889ASimple componentsSimple processCarbon compoundsLow-density polyethyleneActivated carbon

The invention discloses tobacco matrix activated carbon and a preparation method thereof. The tobacco matrix activated carbon is obtained by mixing anhydrous K2CO3, tobacco waste powder and low-density polyethylene powder and performing high-temperature carbonization in a protective gas environment. The methylene blue adsorption capacity of the activated carbon is as high as 806 mg / g and is far higher than the standard methylene blue adsorption capacity of first-grade products. Low-density polyethylene plastic is added, so activation process is more sufficient, activation effect is uniform, and the prepared activated carbon has a more developed pore structure. Potassium carbonate is used as an activating agent, generated K<+> can break a carbon chain to form a complex salt, and the catalytic process of repeated ring opening, cracking and ring opening enriches the microstructure of the activated carbon. CO2 is also a good physical activating agent, so the pore volume and the pore-forming efficiency of the activated carbon can be increased.

Owner:SICHUAN BRANCH OF CHINA TOBACCO +1

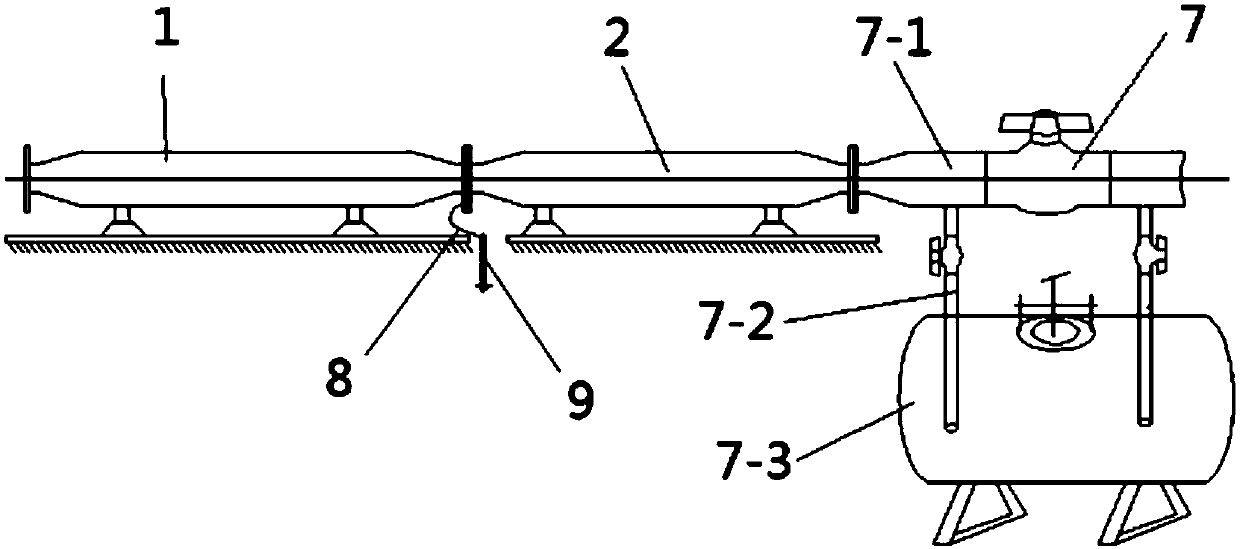

Method for producing desulfurization and denitrification hollow activated carbon

ActiveCN107840333AThe adsorption index is stableStacked weightGas treatmentCarbon compoundsActivated carbonGranularity

The invention discloses a method for producing desulfurization and denitrification hollow activated carbon. The method comprises the following steps: (1) grinding, namely grinding soft coal, coking coal, coke powder and asphalt in a weight ratio of (30-40):(20-30):(15-25):(10-15) in a grinding machine till 70% of the raw materials with granularity of 325 meshes can pass; (2) mixing, namely mixingthe grinded carbon powder, coal tar and water in a weight ratio of 80:(10-15):(10-15) at 35-50 DEG C; and (3) pelletizing, namely pelletizing the mixed material in a pelletizing machine, wherein the diameter of the pelletized material is 9.0-10.0mm, and the inner diameter of the pelletized material is 2-3mm. The method disclosed by the invention is reasonable in design, and compared with conventional desulfurization and denitrification activated carbon, the desulfurization and denitrification hollow activated carbon produced by using the method has the advantages of being activated both insideand outside, light in piling weight, large in adsorption contact area, and the like, and has very good market application values.

Owner:SHANXI XINHUA CHEM

A process of producing a cellulose carbamate fiber filament

InactiveCN106637460AImprove spinnabilitySolve the problem of not being able to adapt to industrial mass productionArtificial filaments from cellulose derivativesCelluloseFiber

The invention relates to a process of producing a cellulose carbamate fiber filament, and belongs to the technical field of cellulose carbamate fiber production. Through specific cellulose activation, cellulose carbamate preparation, cellulose carbamate solution preparation, and spinning steps, a complete cellulose carbamate fiber filament producing process having a high degree of completion is formed. A prepared spinning stock solution has good spinnability, a final product has good performance, the process is particularly suitable for industrial large-scale production, and the production cost, the production efficiency and product quality are all taken into account.

Owner:YIBIN GRACE GROUP CO LTD

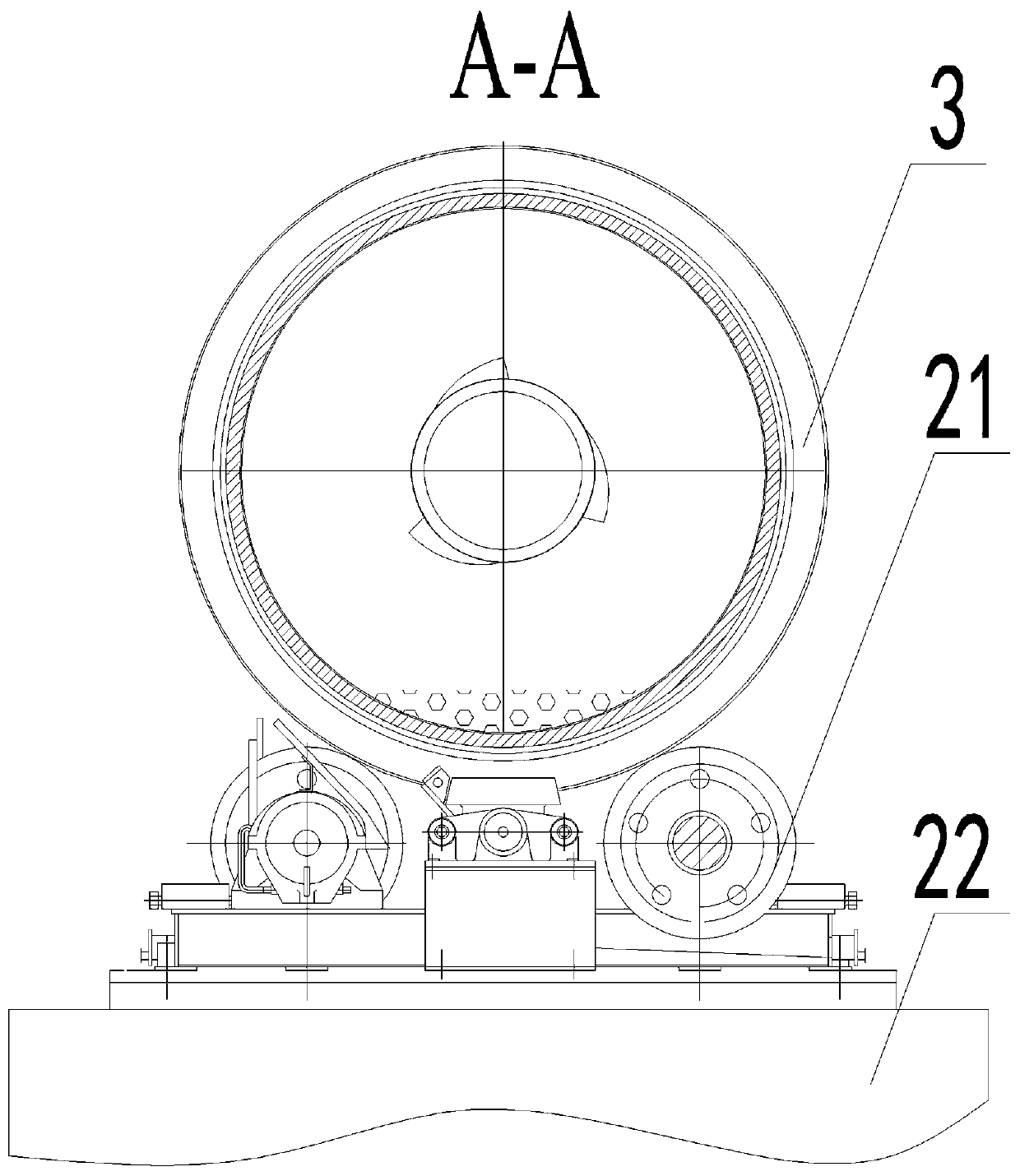

A method for preparing kaolin roasting activated rotary kiln

InactiveCN108088240BReduce pollutionReduce manufacturing costRotary drum furnacesFluidized bedEngineering

The invention relates to the technical fields of environment protection and resource cyclic and comprehensive utilization, in particular to a using method of a roasting activation rotary kiln for preparing kaolin. The method is characterized in that high aluminum balls roll continuously and rub with each other in the roasting activation rotary kiln along with rotation of the roasting activation rotary kiln, grinding of circulating fluidized bed coal fired boiler fly ash remaining at the bottom of the roasting activation rotary kiln is achieved, and thus qualified finished kaolin particles areproduced.

Owner:LINYI JINHAIHUI TECH

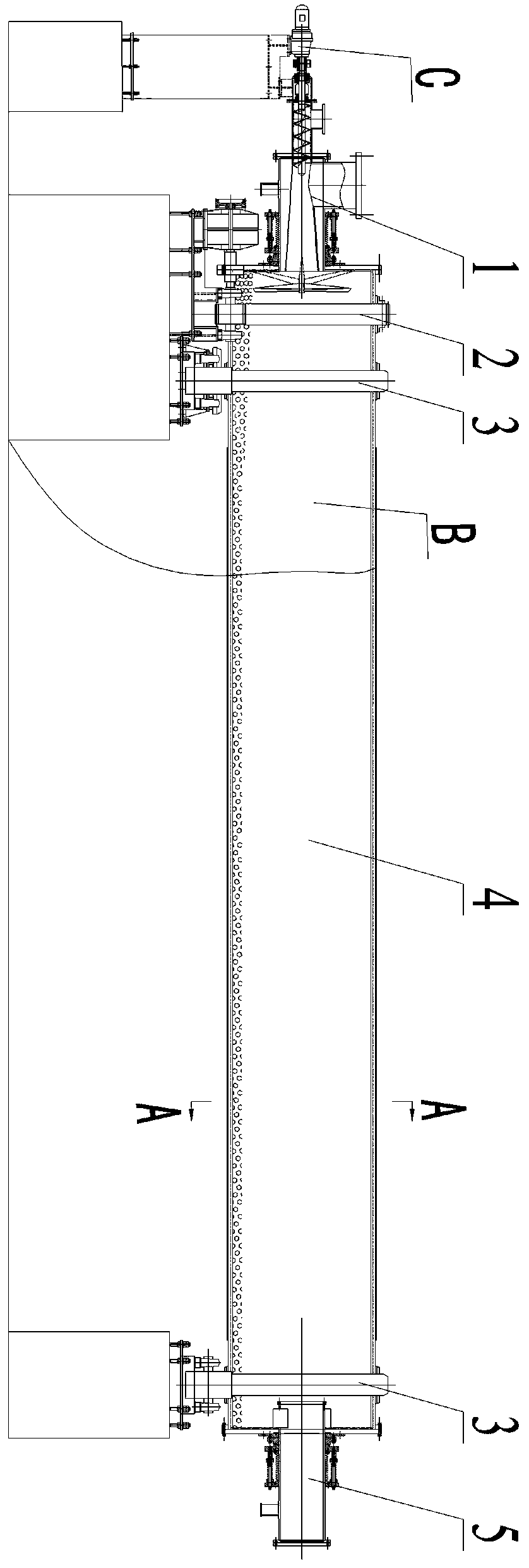

Production process of activated carbon

InactiveCN103058184AUniform activationHigh yieldCarbon compoundsChemical industryActivated carbonCombustion

The invention relates to a production process of activated carbon. The production process of activated carbon comprises the following steps: 1, feeding a dried carbonized material to a furnace body through a furnace end feeder of a rotary activating oven, setting the temperature in the furnace body at 800-1000 DEG C, and arranging thermocouple temperature sensing devices and air blowers in front three sections of the furnace body; 2, introducing water steam to the furnace body to be reacted with the carbonized material, controlling the reaction time within 3-10 hours, and recovering tail gases generated by reaction through a tail gas recovery device arranged at the tail of the furnace, and then, mainly introducing the mixed gases in form of CO and H2 to the boiler which generates the water steam for combustion of the boiler; and 3, feeding the activated carbon obtained by reaction from a discharge port at the tail of the furnace to a discharge cooler to be cooled, and smashing, verifying, packaging and putting in storage. According to the production process of activated carbon provided by the invention, the yield is high, the product quality is good, the labor intensity is low, the production efficiency is high, and the process is energy-saving and environmentally-friendly.

Owner:江金寿

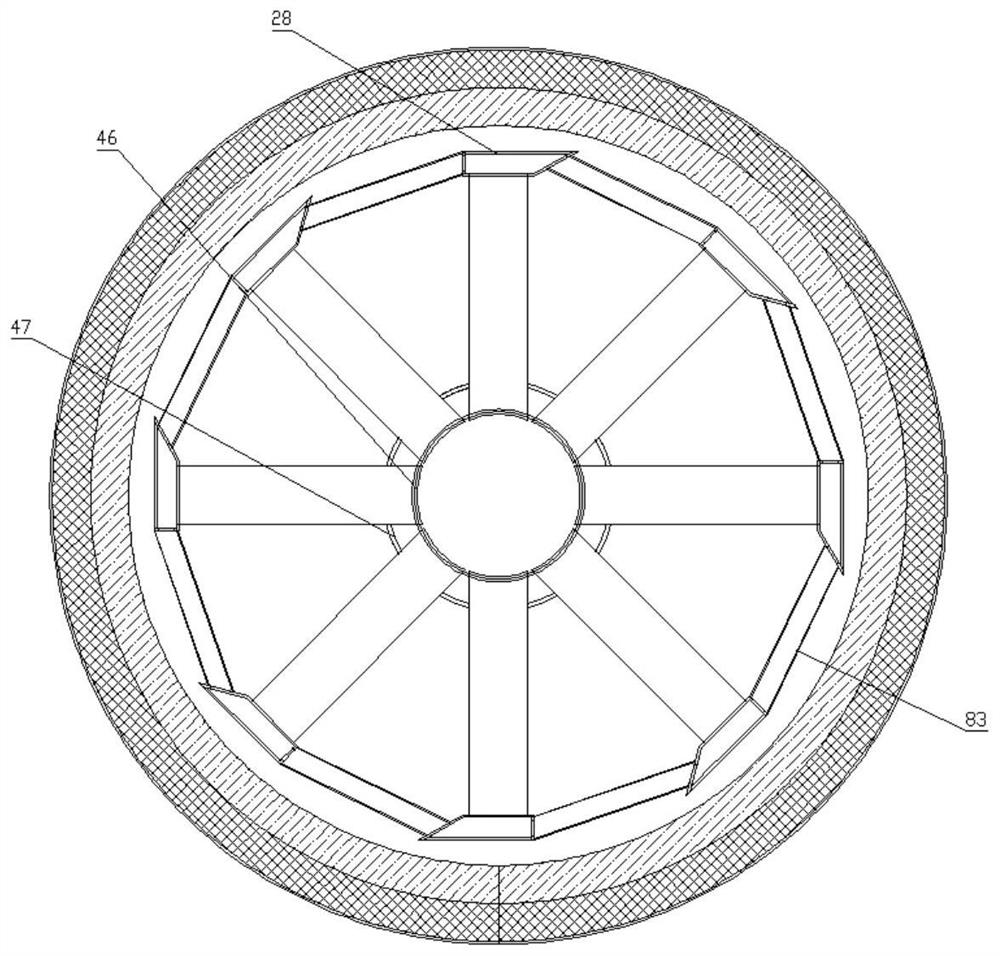

Uniform internal heating stirring type activation kiln

ActiveCN111689499AIncrease the cross-sectional areaReduce the cross-sectional areaCarbon compoundsActivated carbonThermodynamics

The invention discloses a uniform internal heating stirring type activation kiln, and belongs to the field of activated carbon. The uniform internal heating stirring type activation kiln comprises a kiln body, a feeding mechanism, a flow guide stirring mechanism, a water seal mechanism, a discharging mechanism and a hot blast stove, and the feeding mechanism is arranged on the side wall of the kiln body; the kiln main body mainly comprises a kiln upper cover and a kiln lower body, the kiln lower body mainly comprises a hot-blast stove body, a hot-blast stove shell and a lower body shell fixedly connected with the hot-blast stove shell, and the flow guide stirring mechanism is connected in the lower body shell; the kiln has a stirring effect and also has the effect of transporting activators; when the flow guide stirring paddles rotate to any place, the activators is conveyed to any place; the flow guide stirring paddles are uniformly distributed in the material layer; the activated material layer with the thickness of two meters is simultaneously stirred from inside to outside, is simultaneously heated and is in contact with the activators so that the activation is uniform, the specific surface area of the activated carbon is large, the activation time is shortened, and the single-machine productivity is high.

Owner:舒克孝

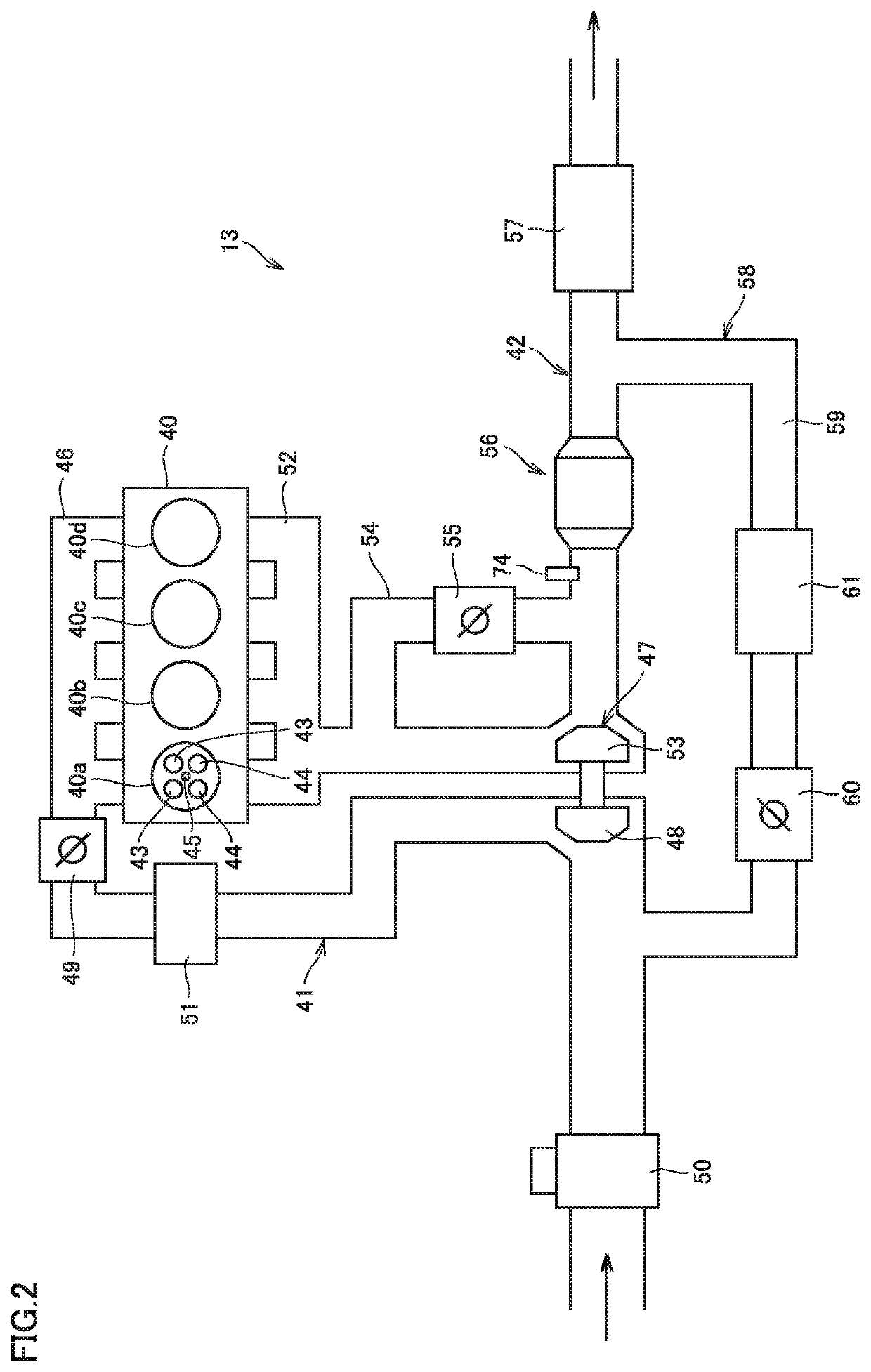

Hybrid vehicle

ActiveUS20200325839A1Shorten the time periodWarm-up control can be made efficientHybrid vehiclesElectrical controlPtru catalystExhaust fumes

When it is determined that control of warm-up of a catalyst is necessary at the time of start of an engine, an ECU starts warm-up control. Initially, the ECU performs first processing for a first set time period. In the first processing, the ECU sets the engine to an idle state and fully opens a waste gate valve. When the first set time period has elapsed since the first processing was started, the ECU performs second processing. In the second processing, the ECU sets the engine to a prescribed rotation speed and fully closes the waste gate valve. When a second set time period has elapsed since the second processing was started, the ECU quits the second processing and quits warm-up control.

Owner:TOYOTA JIDOSHA KK

Continuous production process for enabling gold metal to be firmly attached to aromatic special fiber filaments

ActiveCN113529409AGuaranteed StrengthGuaranteed adhesionFibre typesUltrasonic/sonic fibre treatmentAviationPolymer science

The invention discloses a continuous production process for enabling gold metal to be firmly attached to aromatic special fiber filaments, belongs to the technical field of metallization of special fibers, and relates to a method for continuously and uninterruptedly producing gold-plated aromatic special fibers such as aramid fibers, PBO fibers and polyimide fibers for 24 hours. Firstly, the problems that high-strength fiber metallization cannot leave a laboratory, and stable long fibers with consistent parameters cannot be produced, for example, more than thousands of meters of long fibers cannot be produced at a time are solved; and meanwhile, due to the controllability of the production speed and various electroplating parameters, the technical problems that the fibers are the same in length, different in required conductivity and different in plating layer thickness are solved, and different specifications can be customized according to the special requirements of space flight and aviation.

Owner:铜陵蔚屹新材料有限公司

Preparation method of nitrogen-doped porous carbon material

ActiveCN114516635AOxygen-rich functional groupsAchieve contactCarbon compoundsHybrid capacitor electrodesPorous carbonActive agent

The invention belongs to the technical field of porous carbon materials, and particularly relates to a preparation method of a nitrogen-doped porous carbon material and application of the nitrogen-doped porous carbon material in a supercapacitor. The nitrogen-doped porous carbon material is prepared by taking weathered coal humic acid as a carbon material precursor, urea as a nitrogen source and a potassium metal compound as an active agent through high-temperature reaction, and when the nitrogen-doped porous carbon material is applied to an electrode material of a supercapacitor, the supercapacitor shows excellent electrochemical performance. The initial raw materials are humic acid and urea which widely exist in nature and are low in price and rich in source, and the method only relates to a small number of procedures such as activation and cleaning, so that large-scale industrial production is easy to realize.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

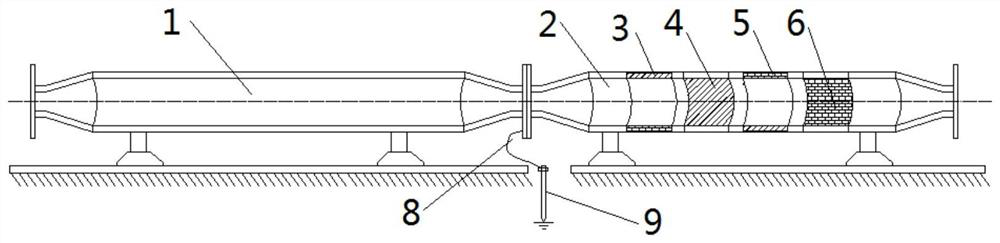

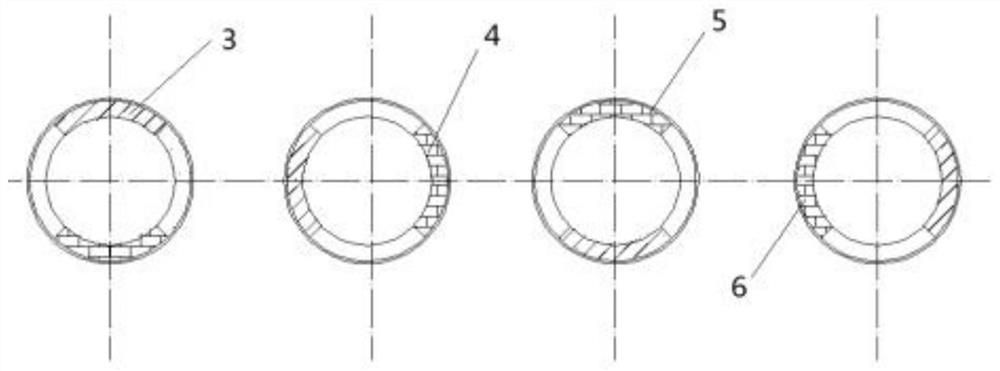

De-electronic magnetization combined activation apparatus for brackish water

ActiveCN108046387AImprove molecular activityImprove physical and chemical propertiesWater/sewage treatment by magnetic/electric fieldsPressurised distribution of liquid fertiliserBrackish waterMagnetization

The invention relates to de-electronic magnetization combined activation apparatus for brackish water. The apparatus comprises a de-electronic activation device arranged on an insulating plate, the de-electronic activation device is made of a metal material, and the de-electronic activation device is of a tubular shape with two ends open; the apparatus also comprises a tubular magnetization activation device with two ends open, one end of the magnetization activation device is in insulated connection with one end of the de-electronic activation device, the magnetization activation device communicates with the de-electronic activation device, and one end, connected with the magnetization activation device, of the de-electronic activation device is provided with a grounding device; and the inner cavity of the magnetization activation device is provided with a first magnet group, a second magnet group, a third magnet group and a fourth magnet group in the axial direction. The activation apparatus for the brackish water provided by the invention can effectively improve the physicochemical properties of the brackish water.

Owner:XIAN UNIV OF TECH

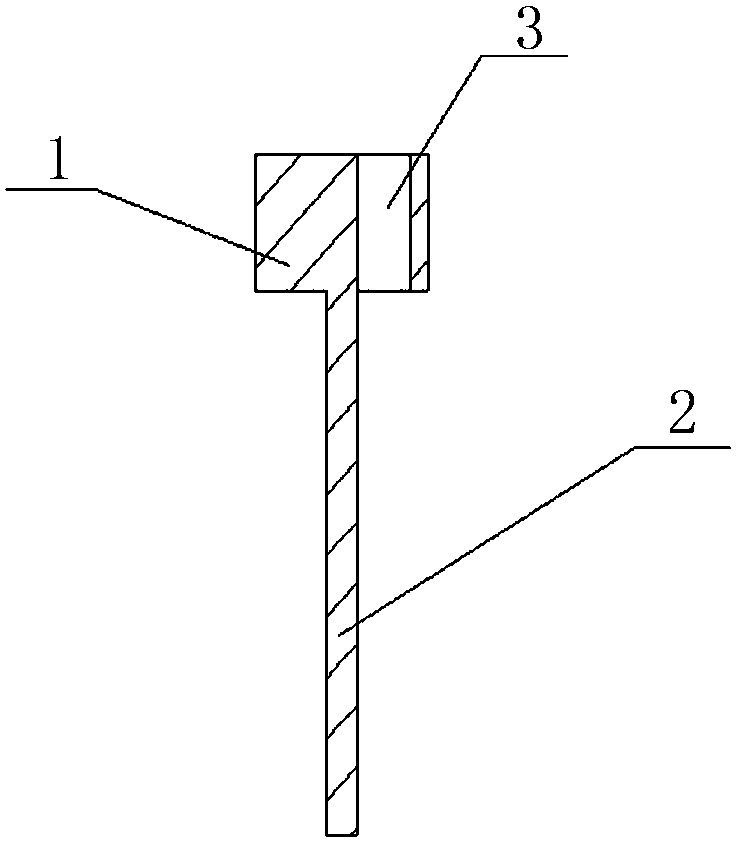

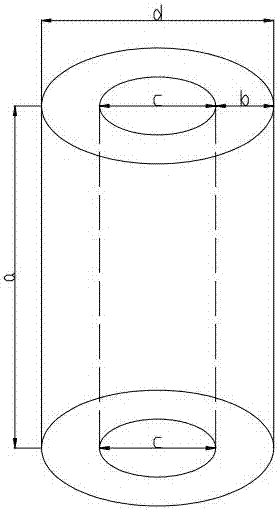

Activated carbon having hollow form

The invention relates to activated carbon having a hollow form, and a preparation method of activated carbon, belonging to the technical fields of coal chemical industry and environmental protection. The activated carbon having the hollow form mainly solves the problems that the existing columnar activated carbon is more in invalid holes, high in systemic resistance, not uniform in air flow distribution inside a bed layer, and the like. The activated carbon having the hollow form is mainly characterized in that the activated carbon is in a cylindrical regular granule shape provided with axial cylinder-shaped through holes; the activated carbon is prepared from the materials of 55-75% of anthracite, 28-40% of coal tar, 1-5% of a diluent and 1-10% of water; the preparation method of the activated carbon comprises the steps of grinding, preparing tar, preparing coal paste, firstly pressing into the columnar hollow form, then drying, carbonizing, activating, and the like. The activated carbon provided by the invention has the characteristics of being high in micropore structure ratio, low in bed layer resistance and uniform in air flow distribution; the preparation method is mainly used for preparing the columnar activated carbon.

Owner:CHENGDU GUOHUA ENVIRONMENTAL TECH

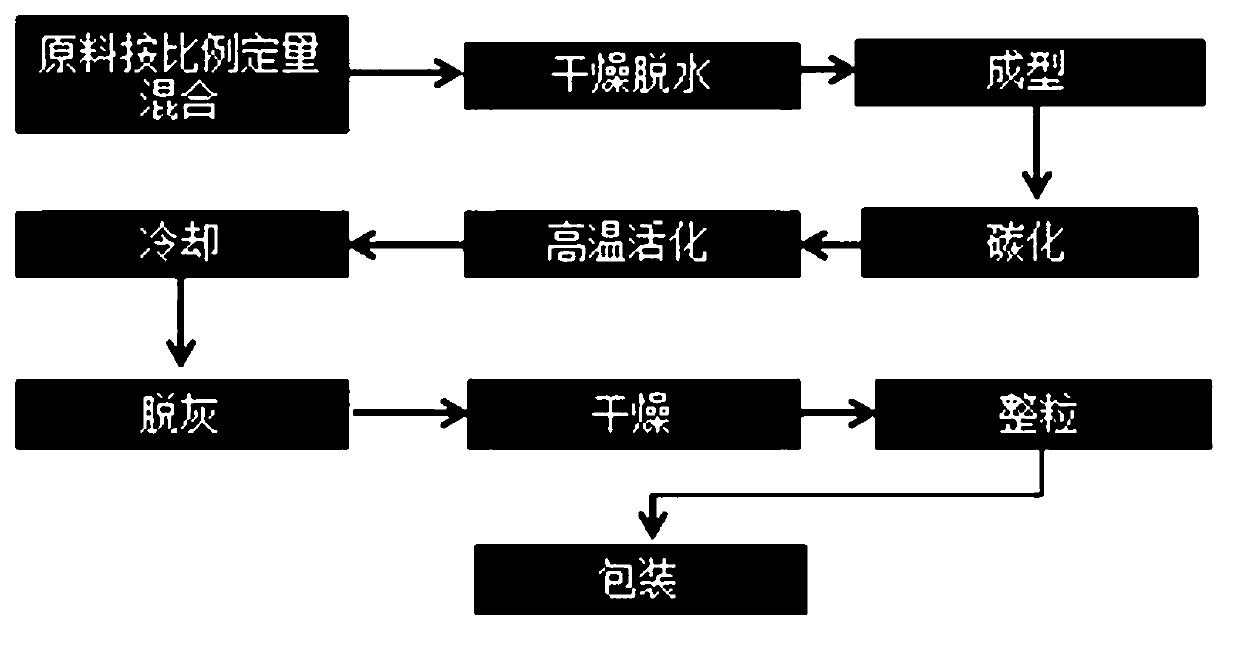

Production process for preparing activated carbon from sludge

InactiveCN110655076AImprove pyrolysis effectUniform activationCarbon compoundsTunnel kilnActivated carbon

The invention discloses a production process for preparing activated carbon from sludge. The production process comprises the following steps: 1, preparation of raw materials: mixing municipal sludge,a carburant and a surface strength additive, drying and dehydrating the mixed materials, then carrying out granulating, and sending a granulated material into a pyrolysis carbonization device for processing; 2, pyrolysis carbonization: adopting an internally-heating rotary kiln or an internally-heating tunnel kiln type pyrolysis carbonization furnace, and carrying out pyrolysis carbonization at atemperature of 500-700 DEG C for 30-45 min; and 3, activation: adopting a physical activation mode, and carrying out activation at 750-900 DEG C for 2-3 h with carbon dioxide and water vapor as activation media. According to the invention, biological sludge is used as a main raw material to prepare the biological sludge-based activated carbon, so the three purposes of reduction, harmless treatment and recycling of the sludge can be realized; and the biological sludge-based activated carbon can be used as a novel environment-friendly material for environmental protection treatment, so the problem of sludge treatment in China at present is effectively solved.

Owner:SHANXI XINHUA CHEM

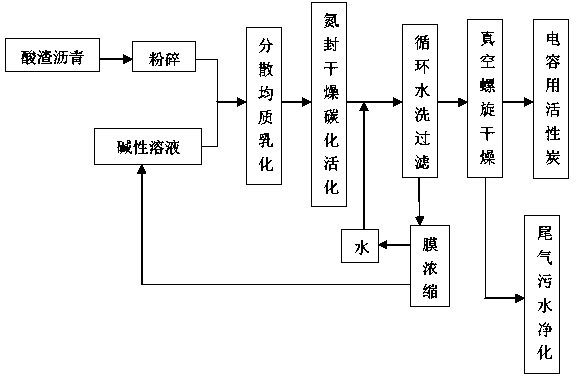

Method for preparing super capacitor active carbon by utilizing acid sludge pitch

ActiveCN109205618AReduce pollutionTo achieve the purpose of recyclingCarbon compoundsHybrid capacitor electrodesCapacitanceSludge

The invention provides a method for preparing super capacitor active carbon by utilizing acid sludge pitch. The method comprises the following steps that acid sludge pitch is smashed to obtain acid sludge pitch powder; the acid sludge pitch powder is placed in a basic solution to be mixed, the mixture is subjected to dispersion, homogenizing and emulsifying, and emulsion of the acid sludge pitch and the basic solution is obtained; the emulsion is placed into an activating oven to be dried and dehydrated, and then carbonized and activated at the high temperature and under protection of nitrogen; the activated product is washed till to be neutral, and then subjected to vacuum rotation drying, and the super capacitor active carbon is obtained. The acid sludge pitch being taken as the raw material is cheap and easy to get, and can be reused, and thus the pollution of the acid sludge pitch to the environment can be reduced. The acid sludge pitch has the rich acidic functional groups, and has the good polarity, the acid sludge pitch particles can be in contact with the basic solution in the nano size in the homogeneous emulsion, the mass transferring resistance is overcome, and thus theactivation process can be operated evenly.

Owner:佛山市光烨环保科技有限公司

Production method of cellulose acetate

The invention belongs to the field of polymer chemistry, and relates to a preparation method of cellulose acetate. The cellulose acetate obtained by the method has low turbidity and high viscosity. The method comprises the following steps of: A, activating 1 weight part of cellulose by using 8 to 20 weight parts of glacial acetic acid at the temperature of between 20 and 60 DEG C; B, adding 0.005to 0.05 weight part of catalyst and 3 to 6 weight parts of acetic anhydride; C, adding 0.5 to 1.5 weight parts of high-concentration acetic acid solution at the temperature of between 10 and 25 DEG C, and reacting till the content of the acetic acid is 60.5 to 62.5 percent, wherein the high-concentration acetic acid solution is 80 mass percent acetic acid; D, adding 0.5 to 1.5 weight part of 5 to15 weight percent aqueous solution of acetate, and reacting for 1 to 3 hours at the temperature of between 20 and 50 DEG C; and E, filtering, settling and granulating. The preparation method is simple and convenient in the production process and easy in operation; the reaction time is shortened; the prepared product has high substitution degree, namely the content of the acetic acid is more than or equal to 60.0 percent; the product has high viscosity, namely the falling ball viscosity is more than or equal to 70 seconds; and the cellulose acetate is particularly suitable for manufacturing polarizing films in optical elements.

Owner:LUZHOU NORTH CHEM IND

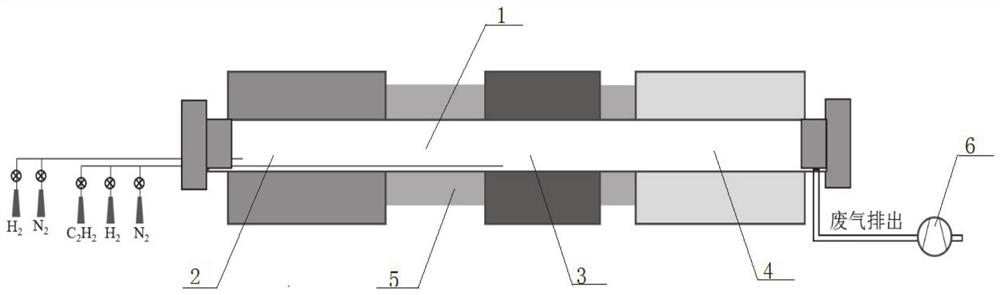

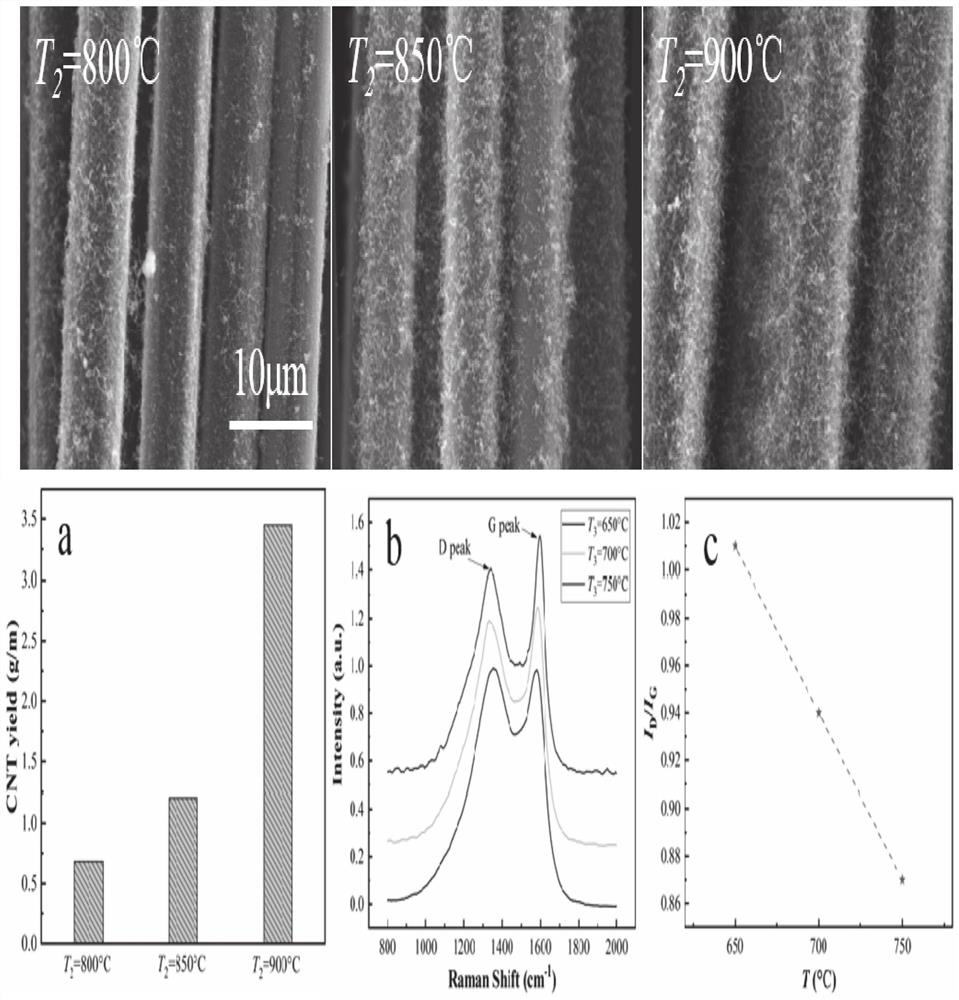

Device and method for controlling growth state of carbon nano tubes based on decoupling heat treatment and application thereof

InactiveCN111960405AGuaranteed efficient growthIncrease temperatureCarbon compoundsPtru catalystCarbon source

The invention provides a device and method for controlling the growth state of carbon nano tubes based on decoupling heat treatment and application thereof, and belongs to the technical field of carbon nano tube preparation. By designing a multi-zone rapid thermal CVD reactor, the catalyst formation temperature (T1), the carbon source decomposition temperature (T2) and the carbon nano tube nucleation and growth temperature (T3) are completely decoupled. Based on the decoupling technology, each of the three temperatures (T1, T2 and T3) possibly influencing the growth of a carbon nano tube can be independently researched, so that the decoupling technology has a good practical application value.

Owner:SHANDONG UNIV

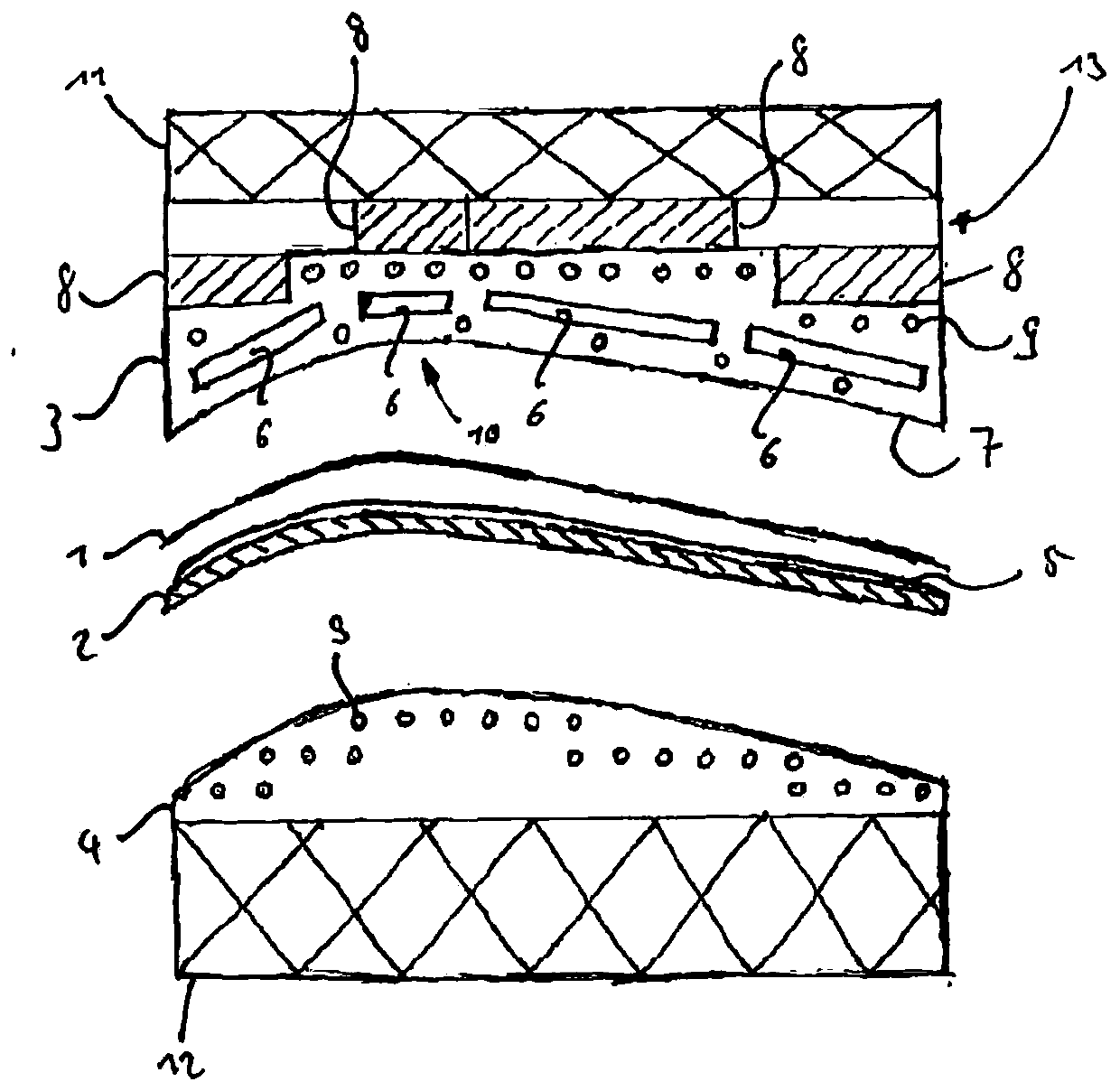

Method and device for applying a decorative layer

ActiveCN107053812BPrevent disengagementEasy to break awayLaminationLamination apparatusInterior spaceMaterials science

The present invention relates to a method and apparatus for coating a decorative layer (1) on a decorative part (2), and the decorative part is particularly used for the internal space of a vehicle. The method at least includes the steps of embedding the decorative part (2) between the two mold halves (3, 4); positioning the decorative layer (1) on the decorative part (2); fixing the decorative part (2) and the decorative layer (1) between the first mold half (3) and the second mold half (4); and exposing the insert (6) capable of induction heating of the first mold half (3) to the dynamic magnetic field to heat the mold halves.

Owner:LISA DRAXLMAIER GMBH

A method for preparing activated carbon for supercapacitors by using acid residue pitch

ActiveCN109205618BReduce pollutionUniform activationCarbon compoundsHybrid capacitor electrodesActivated carbonMass transfer resistance

The invention provides a method for preparing super capacitor active carbon by utilizing acid sludge pitch. The method comprises the following steps that acid sludge pitch is smashed to obtain acid sludge pitch powder; the acid sludge pitch powder is placed in a basic solution to be mixed, the mixture is subjected to dispersion, homogenizing and emulsifying, and emulsion of the acid sludge pitch and the basic solution is obtained; the emulsion is placed into an activating oven to be dried and dehydrated, and then carbonized and activated at the high temperature and under protection of nitrogen; the activated product is washed till to be neutral, and then subjected to vacuum rotation drying, and the super capacitor active carbon is obtained. The acid sludge pitch being taken as the raw material is cheap and easy to get, and can be reused, and thus the pollution of the acid sludge pitch to the environment can be reduced. The acid sludge pitch has the rich acidic functional groups, and has the good polarity, the acid sludge pitch particles can be in contact with the basic solution in the nano size in the homogeneous emulsion, the mass transferring resistance is overcome, and thus theactivation process can be operated evenly.

Owner:佛山市光烨环保科技有限公司

Ceramic products possessing antisepsis and water mineralization and activation functions, and its preparation method and uses

InactiveCN100390098CSustainable accessSustainably obtain highly effective antibacterialWater/sewage treatment by substance additionActivation functionMontmorillonite

Ceramic products possessing antisepsis and water mineralization and activation functions, and its preparation method and uses, wherein the ceramic product is prepared from the following ingredients (by weight ratio): montmorillonite 25-60 parts, diatomite 10-30 parts, aluminum oxide 5-20 parts, silicon oxide 3-15 parts, calcium carbonate 15-45 parts, multifunctional health ceramic material 5-20 parts, adhesive 9-15 parts through proportioning, disintegrating, mixing, blank making and sintering.

Owner:淄博博纳科技发展有限公司

A kind of solar heat storage material with kaolin as supporting matrix and its preparation method

ActiveCN103897667BPrevent leakageGood thermal cycle performanceHeat-exchange elementsMicrowaveParaffin oils

Owner:CENT SOUTH UNIV

Hybrid vehicle

ActiveUS11359565B2Avoid small quantitiesUniform activationHybrid vehiclesElectrical controlPtru catalystExhaust fumes

When it is determined that control of warm-up of a catalyst is necessary at the time of start of an engine, an ECU starts warm-up control. Initially, the ECU performs first processing for a first set time period. In the first processing, the ECU sets the engine to an idle state and fully opens a waste gate valve. When the first set time period has elapsed since the first processing was started, the ECU performs second processing. In the second processing, the ECU sets the engine to a prescribed rotation speed and fully closes the waste gate valve. When a second set time period has elapsed since the second processing was started, the ECU quits the second processing and quits warm-up control.

Owner:TOYOTA JIDOSHA KK

A de-electron magnetization combined brackish water activation device

ActiveCN108046387BImprove molecular activityImprove physical and chemical propertiesWater/sewage treatment by magnetic/electric fieldsPressurised distribution of liquid fertiliserBrackish waterCondensed matter physics

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com