Device and method for controlling growth state of carbon nano tubes based on decoupling heat treatment and application thereof

A technology of carbon nanotubes, growth state, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

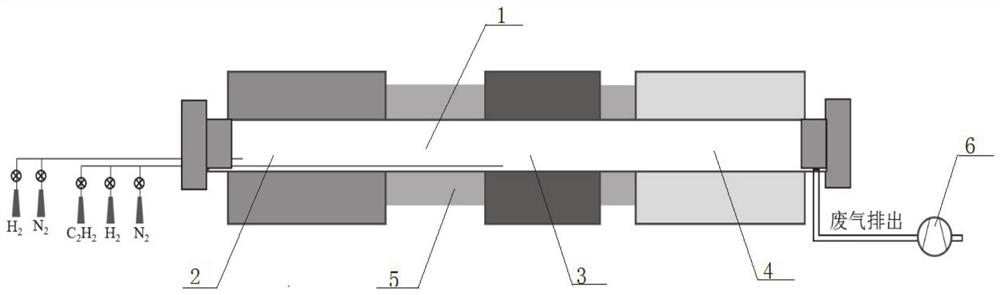

[0066] Step 1: Purging the experimental reactor with inert gas and maintaining an inert environment to eliminate the interference of the air environment on the experiment.

[0067] Step 2: After the carbon fiber is modified by electrochemical anodization, the carbon fiber is immersed in 0.05mol / L Co(NO 3 ) 2 Load the catalyst precursor in the ethanol solution for 10 minutes;

[0068] Step 3: Put the carbon fiber obtained in step 2 into the catalyst reduction unit of the reactor, under an inert gas atmosphere, use H 2 Reducing the catalyst precursor coating to metal nanoparticles, the reduction temperature is 400°C, and the reduction time is 15 minutes;

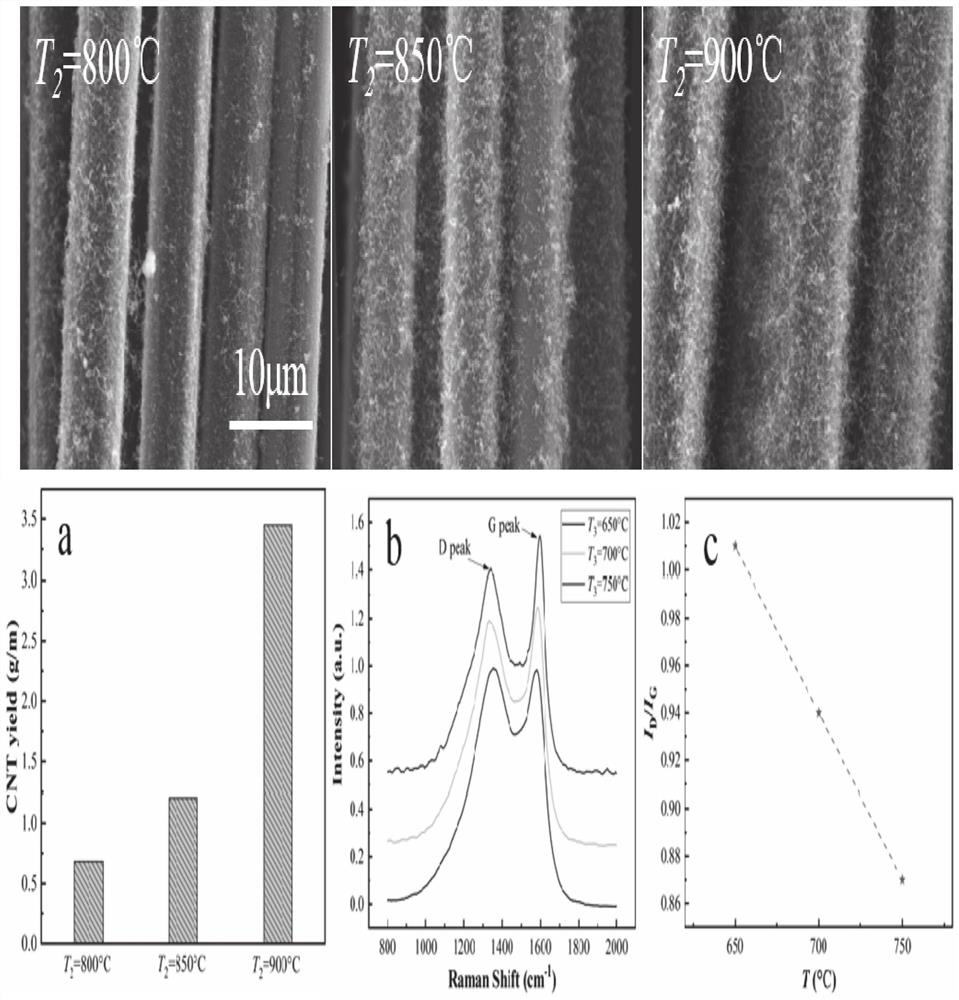

[0069] Step 4: Continue to extend the carbon fiber sample obtained in step 3 into the reactor, pass in the reaction gas, decompose in the carbon source decomposition unit at 800°C for 5 minutes, and then enter the carbon nanotube growth unit to synthesize carbon nanotubes at 650°C , and finally collect the samples.

[0070...

Embodiment 2

[0072] Step 1: Purging the experimental reactor with inert gas and maintaining an inert environment to eliminate the interference of the air environment on the experiment.

[0073] Step 2: After the carbon fiber is modified by electrochemical anodization, the carbon fiber is immersed in 0.05mol / L Co(NO 3 ) 2 Load the catalyst precursor in the ethanol solution for 10 minutes;

[0074] Step 3: Put the carbon fiber obtained in step 2 into the catalyst reduction unit of the reactor, under an inert gas atmosphere, use H 2 The catalyst precursor coating was reduced to metal nanoparticles, the reduction temperature was 450°C, and the reduction time was 15 minutes;

[0075] Step 4: Continue to extend the carbon fiber sample obtained in step 3 into the reactor, pass in the reaction gas, decompose in the carbon source decomposition unit at 800°C for 5 minutes, and then enter the carbon nanotube growth unit to synthesize carbon nanotubes at 650°C , and finally collect the samples.

...

Embodiment 3

[0078] Step 1: Purging the experimental reactor with inert gas and maintaining an inert environment to eliminate the interference of the air environment on the experiment.

[0079] Step 2: After the carbon fiber is modified by electrochemical anodization, the carbon fiber is immersed in 0.05mol / L Co(NO 3 ) 2 Load the catalyst precursor in the ethanol solution for 10 minutes;

[0080] Step 3: Put the carbon fiber obtained in step 2 into the catalyst reduction unit of the reactor, under an inert gas atmosphere, use H 2Reducing the catalyst precursor coating to metal nanoparticles, the reduction temperature is 500°C, and the reduction time is 15 minutes;

[0081] Step 4: Continue to extend the carbon fiber sample obtained in step 3 into the reactor, pass in the reaction gas, decompose in the carbon source decomposition unit at 800°C for 5 minutes, and then enter the carbon nanotube growth unit to synthesize carbon nanotubes at 650°C , and finally collect the samples.

[0082]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com